Polymer Dielectric-Based Emerging Devices: Advancements in Memory, Field-Effect Transistor, and Nanogenerator Technologies

Abstract

:1. Introduction

2. Polymer Dielectric-Based Electronics

2.1. Memory Devices

2.2. Field-Effect Transistors (FETs)

2.3. Triboelectric Nanogenerators (TENGs)

3. Recent Advances in Electronic Devices

3.1. Memory Devices

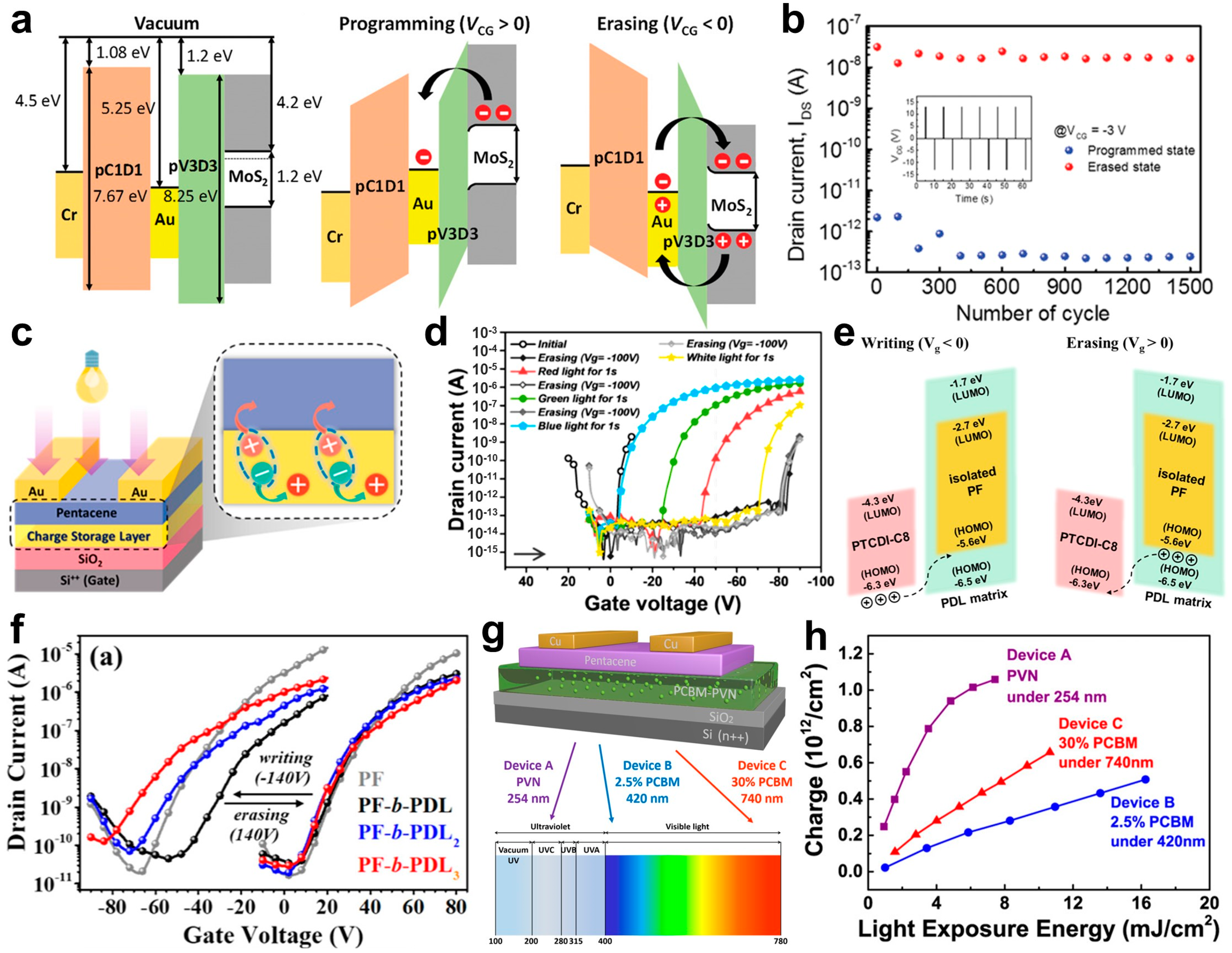

3.1.1. Polymer Dielectric-Based Memory Devices

3.1.2. Application of Polymer Dielectric Materials for Conductive Filament Memristors

3.1.3. Application of Polymer Dielectric Materials for Charge Trap Memory Transistors

3.2. Field-Effect Transistors (FETs)

3.2.1. Overview of Polymer Dielectric Materials for FET Devices

3.2.2. Polymer-Based Dielectric Materials for FET Devices

| Dielectric Material | Semiconductor | Operating Voltage (V) | Current on/off Ratio | Mobility (cm2·V−1·s−1) | Subthreshold Swing (mV·dec−1.) | Applied Strain (%) | [Ref.] |

|---|---|---|---|---|---|---|---|

| Polyurea | DNTT | 3 | >105 | 1.39 | 370 | 2 | [97] |

| P(CEA-co-BDDVE) | C8-BTBT | 5 | >106 | 3.39 | 87.4 | 2.5 | [5] |

| CTBN-C6 | P3HT NWs/PDMS | 50 | >104 | 0.0031 | N/A | 34 | [101] |

| pentacene | 50 | >106 | 0.12 | N/A | N/A | ||

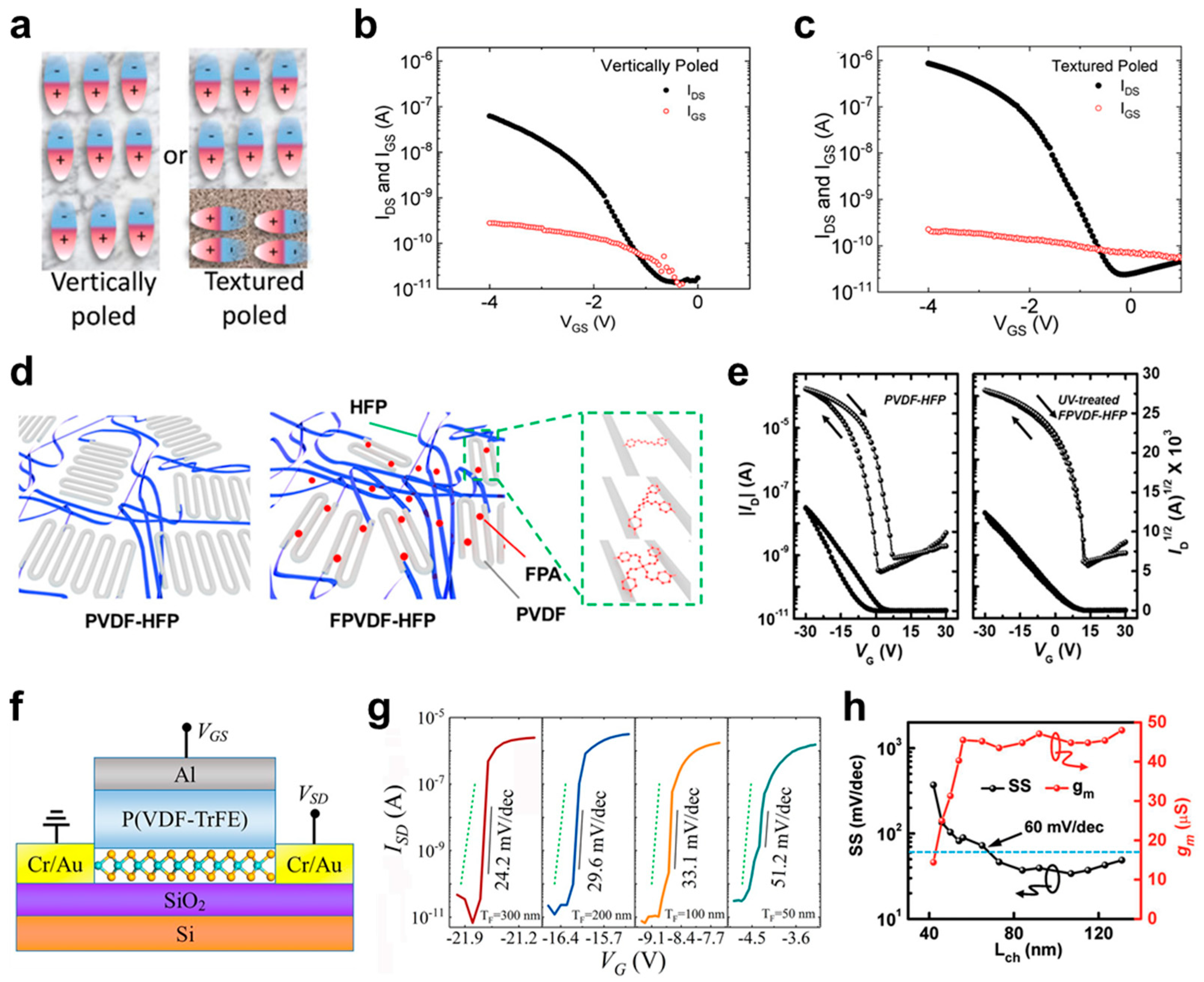

| PVDF-TrFE (vertically poled) | TIPS-pentacene | 4 | >104 | 0.08 | 200 | N/A | [160] |

| PVDF-TrFE (textured poled) | TIPS-pentacene | 4 | >105 | 1 | 350 | N/A | |

| 4FCOC 1 | C10-DNTT | 30 | >107 | 1.30 | N/A | N/A | [161] |

| PTCDI-C13 2 | 30 | >106 | 0.13 | N/A | N/A | ||

| PVDF-TrFE | 2D MoS2 | 40 | >105 | N/A | 24.2 | N/A | [162] |

| HfO2/PVDF-TrFE | 2D MoS2 | 2.5 | >105 | N/A | 42.5 | N/A | [163] |

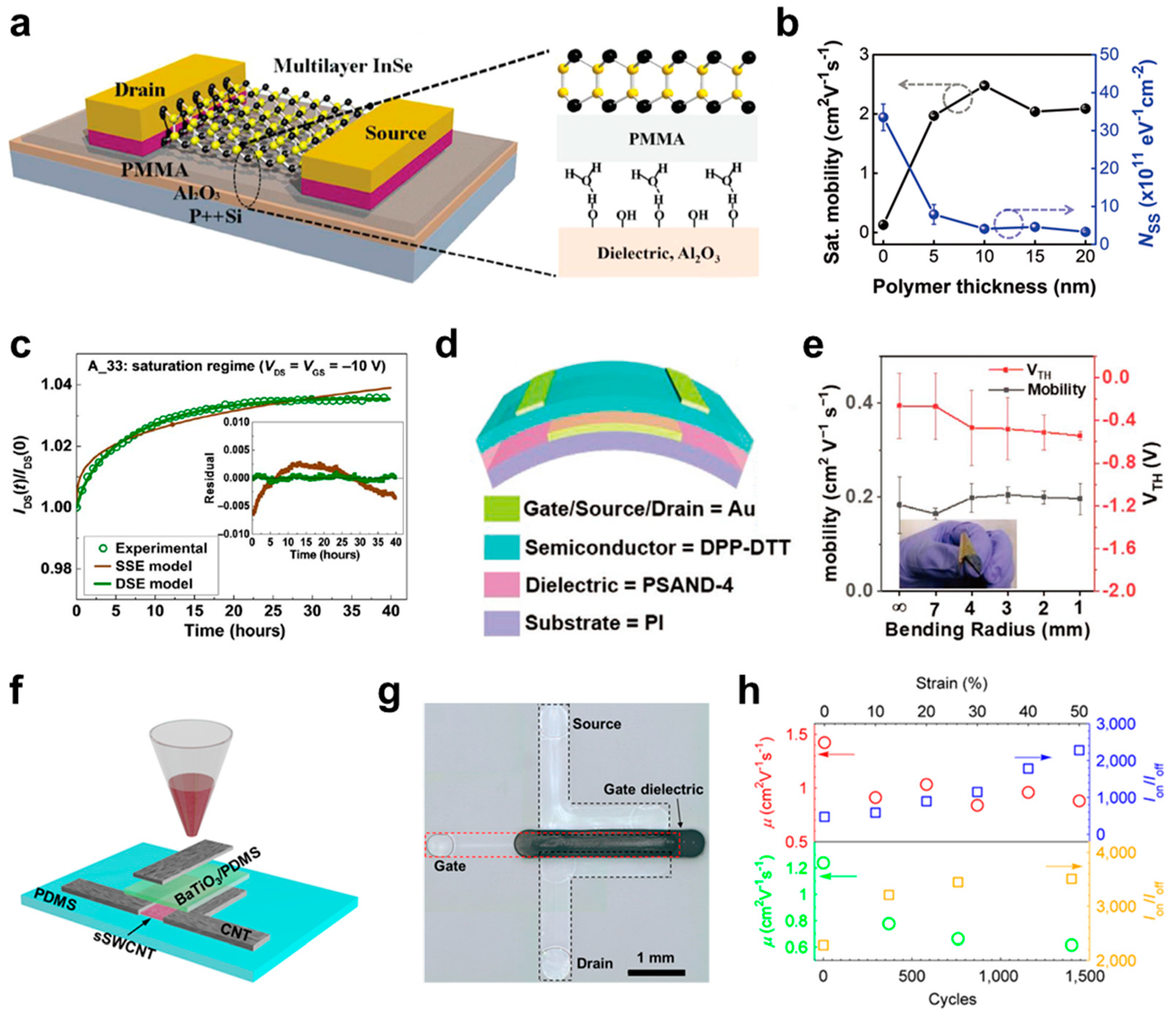

| PMMA/Al2O3 | 2D InSe | 8 | >107 | 1055 | 300 | N/A | [107] |

| P(CEA-co-DEGDVE)/Al2O3 | C8-BTBT | 3 | >106 | 2.48 | 68.4 | 1.2 | [164] |

| CYTOP/HfO2-Al2O3 | TIPS-pentacene/PTAA | 10 | >105 | 0.8 | 700 | N/A | [165] |

| diF-TES-ADT 3/PTAA | 10 | >105 | 1.4 | 320 | N/A | ||

| PSAND-4 | pentacene | 3 | >103 | 0.40 | N/A | N/A | [106] |

| F16CuPC 4 | 2 | >101 | 0.020 | N/A | N/A | ||

| DPP-DTT | 3 | >103 | 0.17 | N/A | 1.2 | ||

| PDIF-CN2 5 | 2 | >102 | 0.18 | N/A | N/A | ||

| BaTiO3/PDMS | Carbon nanotube | 30 | >102 | 4 | N/A | 50 | [166] |

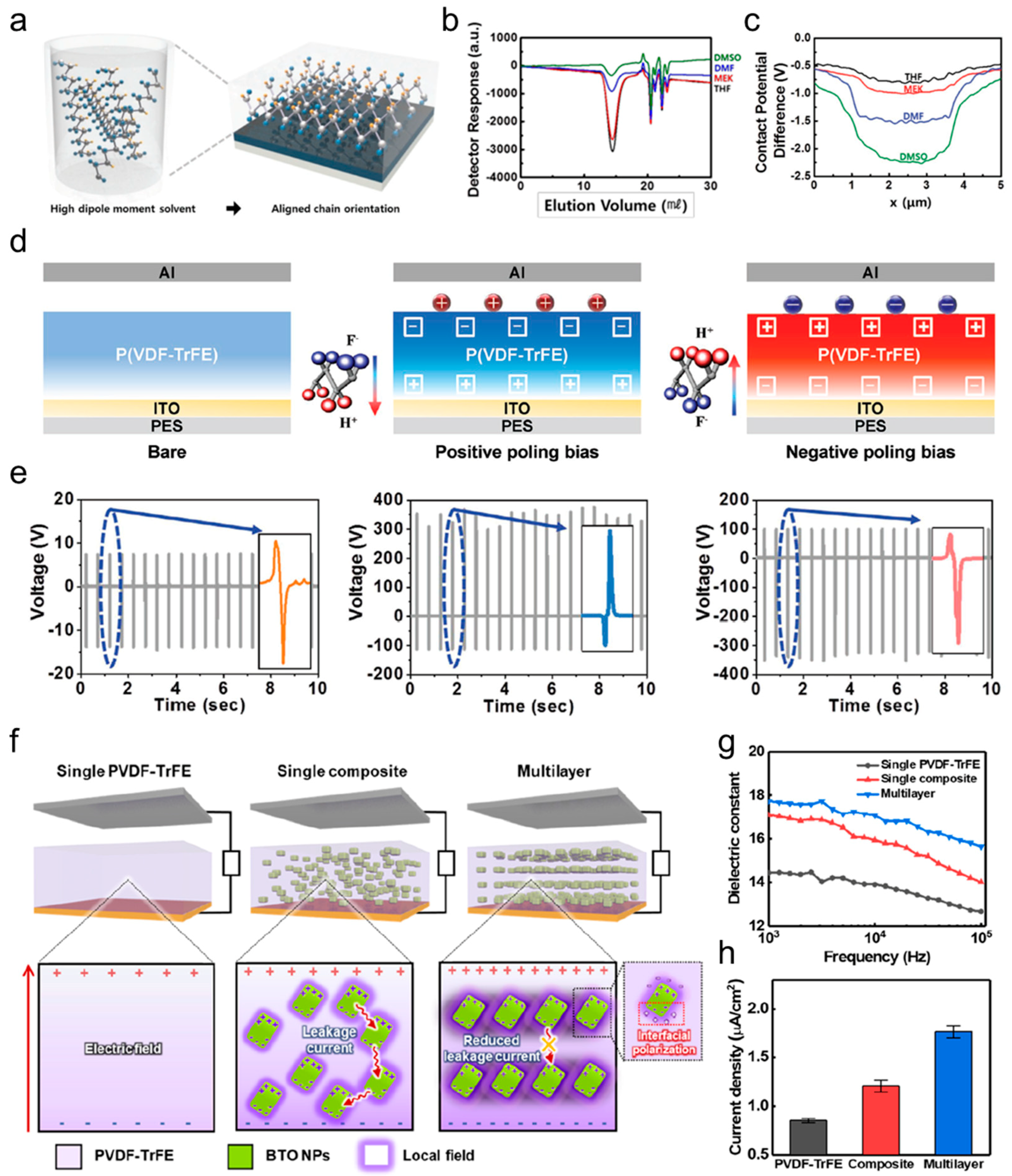

3.2.3. Ferroelectric Polymers for FET Devices

3.2.4. Polymer–Inorganic Hybrid Dielectric Materials for FET Devices

3.3. Triboelectric Nanogenerators (TENGs)

3.3.1. Overview of Polymer Dielectric Materials for TENGs

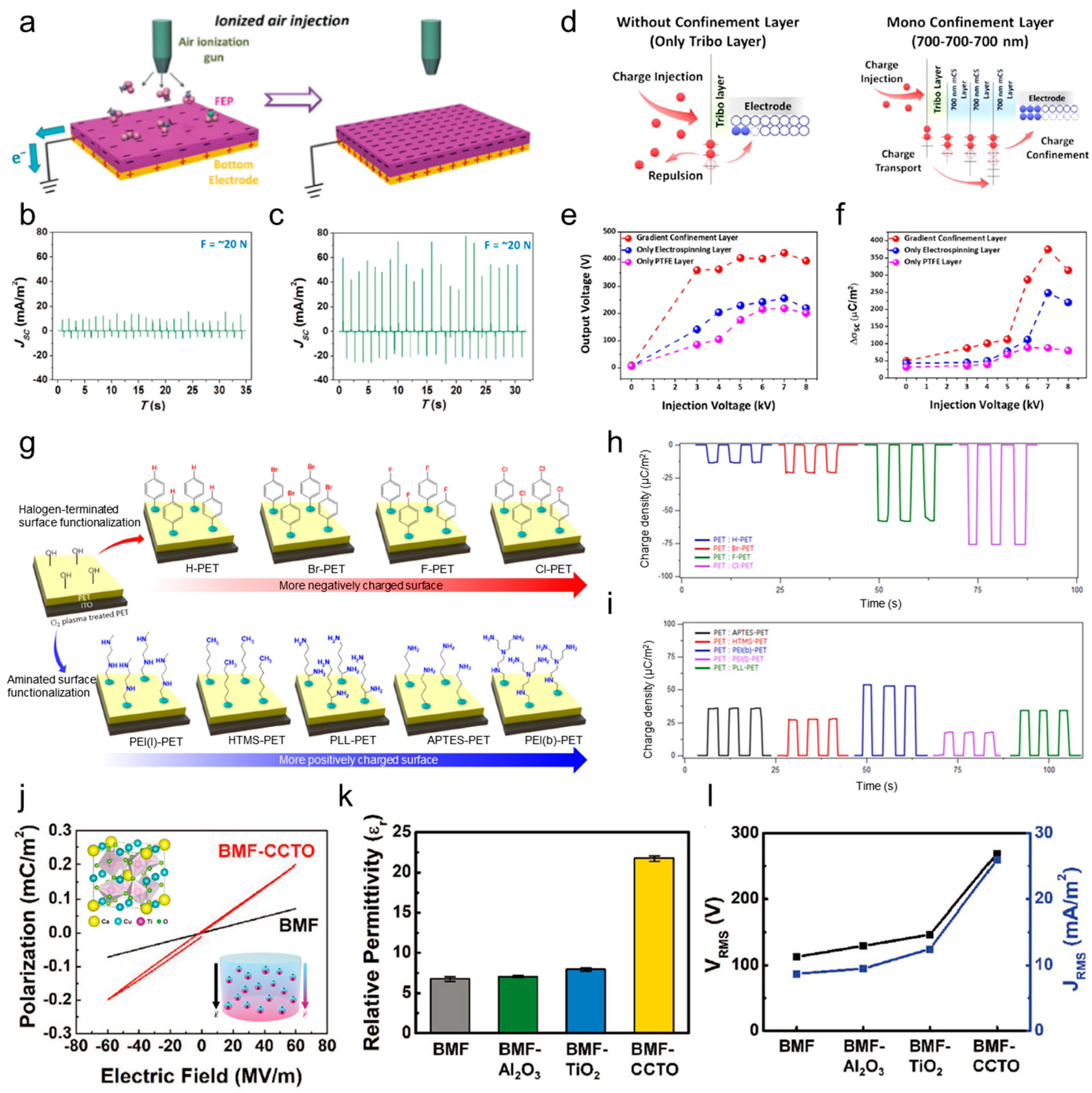

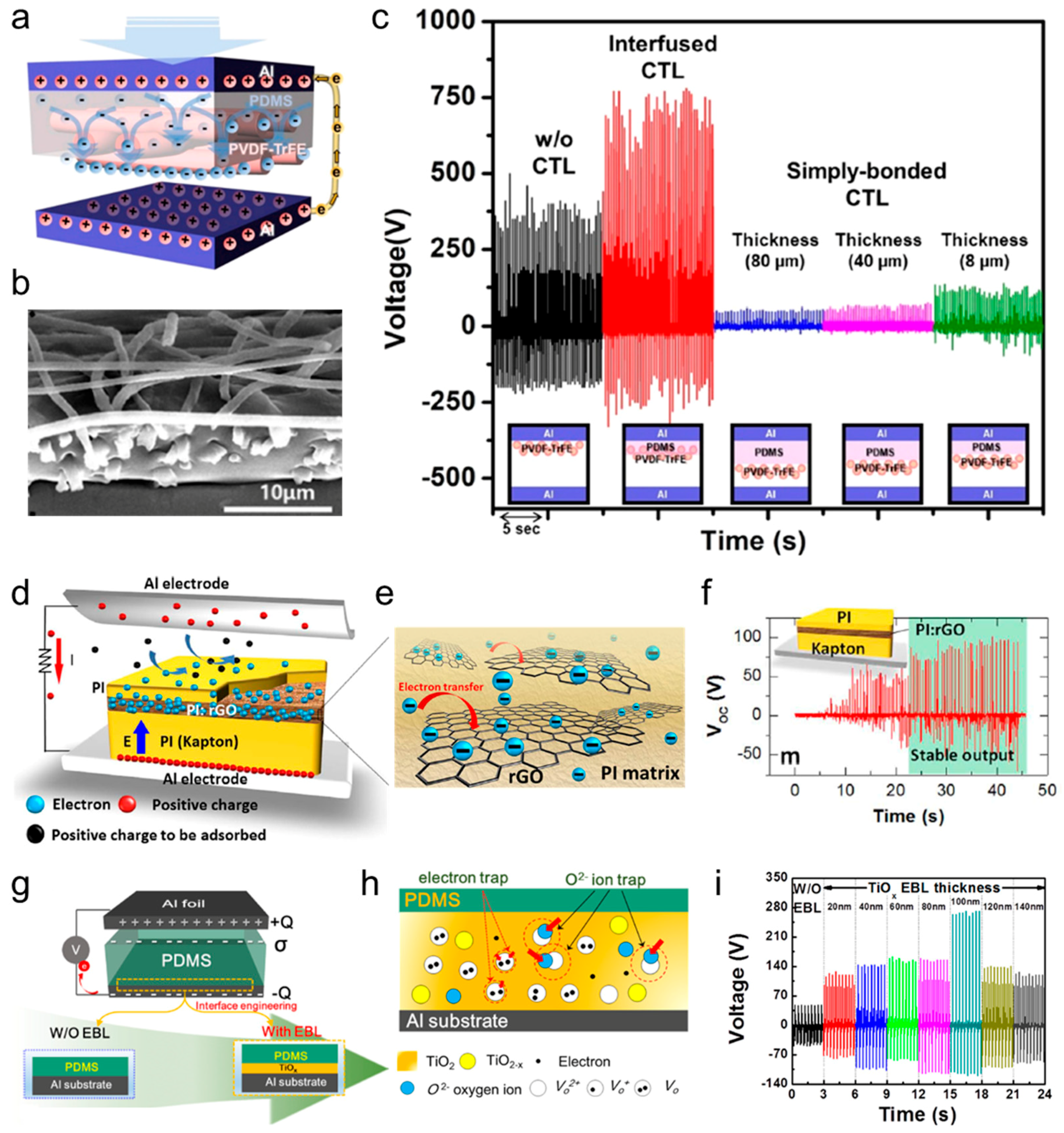

3.3.2. Polymer-Based Dielectric Materials and Strategies for Enhancing TENG Devices

3.3.3. Ferroelectric Polymers for TENG Devices

3.3.4. Polymer–Inorganic Hybrid Dielectric Materials for TENG Devices

| Dielectric Material | Working Mode | Surface Charge Density | Output Voltage | Output Current | Output Power | Applied Force, Pressure | [Ref.] |

|---|---|---|---|---|---|---|---|

| FEP | Single electrode | ~200 μC·m−2 | ~1000 VPP | ~78 mA/m2 (IPP) | 315 W/m2 | 20 N | [243] |

| mCSs 1 | Single electrode | ~75 μC·m−2 | ~600 VPP | 12.8 μA (IPP) | 5.83 mW | 80 N | [223] |

| PEI(b)-PET 2 | Double electrode | 52 μC m−2 | ~520 VPP | 110 mA/m2 (IPP) | 55 W/m2 | 0.15 MPa | [244] |

| BMF-CCTO 3 | Free-standing | N/A | 268 VRMS | 25.8 mA/m2 (IRMS) | 25.8 W/m2 | N/A | [60] |

| PVDF-TrFE (DMSO) | Double electrode | N/A | ~340 VPP | ~220 μA (IPP) | N/A | 1 kgf | [247] |

| PVDF-TrFE (poled) | Double electrode | 20.86 nC·m−2 | ~400 Vamp | N/A | N/A | 1 kgf | [252] |

| PVDF-TrFE/BTO | Double electrode | N/A | ~44 Vamp | 1.77 μA/cm2 (Iamp) | 29.4 μW/cm2 | 98 kPa | [250] |

| PVDF-TrFE/PDMS | Double electrode | N/A | ~40 VPP | ~350 μA (IPP) | 125.5 mW/cm2 | N/A | [260] |

| PI/rGO 4 | Double electrode | N/A | 190 Vamp | ~70 μA (Iamp) | 6.3 W/m2 | N/A | [261] |

| PDMS/TiO2 | Double electrode | 30 μC·m−2 | 272 Vamp | ~9.1 μA (Iamp) | N/A | 5 N | [257] |

4. Challenges

4.1. Challenges in the Area of Dielectric Polymers for Future Memory Technologies

- (1)

- Electrical Property Improvement: Polymers have shown high dielectric constants and reliable insulating properties, but their electrical characteristics are often not as advanced as those of inorganic materials. Enhancing the dielectric constant and minimizing the leakage current paths, even at extremely thin thicknesses, requires molecular-level material and structural design. For example, incorporating polar functional groups that respond effectively to electric fields can improve the dielectric constant [262,263]. In addition, forming a denser polymer matrix can help reduce the leakage currents [97].

- (2)

- Process Optimization: Polymer dielectric films are primarily fabricated through solution-based processing methods, which offer simplicity and potential for large-scale production [96,264]. On the other hand, these methods can introduce residual solvents or additives that adversely affect electrical properties [80]. Exploring alternative processing techniques, such as chemical vapor deposition (CVD), can help achieve high-purity polymer films and homogeneous mixing, improving the overall performance of memory devices [51,55,85,86,95].

4.2. Challenges in the Area of Dielectric Polymers for Future FETs

- (1)

- The electrical properties should be further improved. Although a high dielectric constant and reliable insulating properties have been secured in some polymers, polymer dielectric materials are still considered inferior to inorganic counterparts in their electrical characteristics. Overcoming these limitations and developing polymer dielectric layers with high capacitance will need molecular-level material and structural design [5,36]. For example, increasing the dielectric constant by allowing polar functional groups to respond to the applied electric field may be necessary [114,117,121,126], and ferroelectric polymer can be a representative example of this design [171,182,188]. In addition, it is essential to densify the polymer matrix to minimize the leakage current path even at extremely thin thicknesses [115,124,127,128].

- (2)

- Appropriate material design and process optimization are necessary. Polymer dielectric films are mostly fabricated through solution-based processing methods, which are advantageous in terms of process simplicity and potential printability [47,118,166]. On the other hand, solution processes can affect the electrical properties of polymer dielectric layers due to residual solvents or additives. Research has been performed on polymer dielectric materials based on chemical vapor deposition processes such as parylene [31,32,265]. Nevertheless, these processes require vacuum equipment and cost. Furthermore, reliable and uniform processability on a large scale should also be ensured to expand the practical application potential for polymer dielectric materials [9,50,164].

4.3. Challenges in the Area of Dielectric Polymers for Future TENGs

- (1)

- Efficiency and output performance: Although some polymer dielectrics show promising triboelectric properties, achieving higher efficiency and output performance remains challenging. Enhancing the dielectric constant and surface charge density through material innovation and surface engineering is critical to improving the efficiency of TENGs. For example, integrating high-dielectric nanoparticles, such as BaTiO3 or TiO2, into the polymer matrix can significantly boost the output performance. In addition, producing nanocomposite structures that incorporate conductive fillers like Au nanoparticles can further enhance charge transport and storage capabilities, increasing the overall energy conversion efficiency of TENGs [266].

- (2)

- Durability and wear resistance: TENGs are subject to repeated mechanical contact and friction, which can degrade polymer materials over time. Developing polymers with high mechanical durability and wear resistance is essential for ensuring long-term reliability and consistent performance [267]. Innovations can enhance durability, such as crosslinking polymer chains to produce a more robust network or adding wear-resistant additives. For example, incorporating silicone-based elastomers or other flexible yet tough materials can reduce surface wear and maintain the integrity of the triboelectric layers. Furthermore, applying protective coatings that resist abrasion and environmental degradation can help preserve the functional properties of the polymer dielectric materials in TENGs.

- (3)

- Environmental stability: TENGs often operate under various environmental conditions, such as humidity, temperature fluctuations, and UV exposure. Ensuring that polymer dielectrics maintain their performance under these conditions requires the development of environmentally robust materials. Polymers with inherent environmental stability, such as fluorinated polymers or those that can be chemically modified to resist harsh conditions, will be crucial for the reliable operation of TENGs in diverse settings. For example, surface modification with hydrophobic coatings can prevent moisture absorption [268], while UV stabilizers protect the material from photodegradation. In addition, selecting polymers that have a broad operational temperature range can ensure consistent performance in both high- and low-temperature environments.

5. Conclusions and Outlook

5.1. Interconnected Functionalities

- (1)

- Memory devices and FETs: Polymer dielectric materials can be used to develop flexible, low-power memory devices that integrate seamlessly with FETs. The high dielectric constants and reliable insulating properties of polymers enable the development of memory–transistor hybrid systems that combine data storage with logic functions, such as logic-in-memory systems. This integration can result in compact, high-performance devices capable of performing complex computations while retaining data, all within a flexible form factor.

- (2)

- TENGs and FETs: TENGs can be self-powered sources for FET-based electronic circuits and sensors. By converting mechanical energy from movements or environmental vibrations into electrical energy, TENGs can provide a sustainable power supply for FETs, eliminating the need for external batteries. This integration is beneficial for wearable sensors and remote monitoring devices where replacing or recharging batteries is impractical.

5.2. Specific Integration Strategies in Artificial Intelligence of Things (AIoT) Devices

Author Contributions

Funding

Conflicts of Interest

References

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Zhang, G.; Li, H.U.; Iagodkine, E.; Haque, A.; Chen, L.-Q.; Jackson, T.N. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef]

- Seong, H.; Pak, K.; Joo, M.; Choi, J.; Im, S.G. Vapor-phase deposited ultrathin polymer gate dielectrics for high-performance organic thin film transistors. Adv. Electron. Mater. 2016, 2, 1500209. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Pi, M.; Ran, R. High-strength, highly conductive and woven organic hydrogel fibers for flexible electronics. J. Chem. Eng. 2022, 428, 131172. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, C.; Jiao, H.; Zhang, M. Polyvinyl alcohol/SiO2 hybrid dielectric for transparent flexible/stretchable all-carbon-nanotube thin-film-transistor integration. Adv. Electron. Mater. 2020, 6, 1901133. [Google Scholar] [CrossRef]

- Choi, J.; Kang, J.; Lee, C.; Jeong, K.; Im, S.G. Heavily crosslinked, high-k ultrathin polymer dielectrics for flexible, low-power organic thin-film transistors (OTFTs). Adv. Electron. Mater. 2020, 6, 2000314. [Google Scholar] [CrossRef]

- Hung, C.C.; Wu, H.C.; Chiu, Y.C.; Tung, S.H.; Chen, W.C. Crosslinkable high dielectric constant polymer dielectrics for low voltage organic field-effect transistor memory devices. J. Polym. Sci. Part A Polym. Chem. 2016, 54, 3224–3236. [Google Scholar] [CrossRef]

- Wang, S.; Yang, C.; Li, X.; Jia, H.; Liu, S.; Liu, X.; Minari, T.; Sun, Q. Polymer-based dielectrics with high permittivity and low dielectric loss for flexible electronics. J. Mater. Chem. C 2022, 10, 6196–6221. [Google Scholar] [CrossRef]

- Zheng, X.; Pu, Z.; Hu, L.; Tian, Y.; Xia, J.; Cheng, J.; Zhong, J. Synthesis and properties of high performance polysulfone resin with low dielectric constant and dielectric loss. J. Mater. Sci. Mater. Electron. 2019, 30, 18168–18176. [Google Scholar] [CrossRef]

- Kim, W.; Kwon, J.; Takeda, Y.; Sekine, T.; Tokito, S.; Jung, S. Flexible and printed organic nonvolatile memory transistor with bilayer polymer dielectrics. Adv. Mater. Technol. 2021, 6, 2100141. [Google Scholar] [CrossRef]

- Wang, K.; Liu, J.; El-Khouly, M.E.; Cui, X.; Che, Q.; Zhang, B.; Chen, Y. Water-soluble polythiophene-conjugated polyelectrolyte-based memristors for transient electronics. ACS Appl. Mater. Interfaces 2022, 14, 36987–36997. [Google Scholar] [CrossRef]

- Woo, M.H.; Jang, B.C.; Choi, J.; Lee, K.J.; Shin, G.H.; Seong, H.; Im, S.G.; Choi, S.Y. Low-power nonvolatile charge storage memory based on MoS2 and an ultrathin polymer tunneling dielectric. Adv. Funct. Mater. 2017, 27, 1703545. [Google Scholar] [CrossRef]

- Han, Y.; Lee, S.; Kim, M.; Shin, W.; Lee, H.k.; Koo, R.H.; Lee, S.T.; Kim, C.H.; Yoo, H. Charge Transport Advancement in Anti-Ambipolar Transistors: Spatially Separating Layer Sandwiched between N-Type Metal Oxides and P-Type Small Molecules. Adv. Funct. Mater. 2024, 34, 2316217. [Google Scholar] [CrossRef]

- Lee, S.-H.; Xu, Y.; Khim, D.; Park, W.-T.; Kim, D.-Y.; Noh, Y.-Y. Effect of polymer gate dielectrics on charge transport in carbon nanotube network transistors: Low-k insulator for favorable active interface. ACS Appl. Mater. Interfaces 2016, 8, 32421–32431. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.; Kim, C.-H.; Yoo, H. Dual-Gate Operation and Configurable Logic From Solution Pattern-Based Zinc Tin Oxide Thin-Film Transistors. IEEE Trans. Electron. Devices 2024, 71, 3020–3025. [Google Scholar] [CrossRef]

- Walser, M.; Kalb, W.; Mathis, T.; Brenner, T.; Batlogg, B. Stable complementary inverters with organic field-effect transistors on Cytop fluoropolymer gate dielectric. Appl. Phys. Lett. 2009, 94, 053303. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Hinchet, R.; Seung, W.; Kim, S.W. Recent progress on flexible triboelectric nanogenerators for selfpowered electronics. ChemSusChem 2015, 8, 2327–2344. [Google Scholar] [CrossRef] [PubMed]

- An, J.; Wang, Z.M.; Jiang, T.; Liang, X.; Wang, Z.L. Whirling-folded triboelectric nanogenerator with high average power for water wave energy harvesting. Adv. Funct. Mater. 2019, 29, 1904867. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Z.; Guo, X.; Su, H.; Sun, K.; Yang, D.; Xiao, W.; Wang, Q.; He, D. Controlled growth of fine multifilaments in polymer-based memristive devices via the conduction control. ACS Appl. Mater. Interfaces 2020, 12, 34370–34377. [Google Scholar] [CrossRef]

- Chou, Y.-H.; Chang, H.-C.; Liu, C.-L.; Chen, W.-C. Polymeric charge storage electrets for non-volatile organic field effect transistor memory devices. Polym. Chem. 2015, 6, 341–352. [Google Scholar] [CrossRef]

- Hsu, L.-C.; Isono, T.; Lin, Y.-C.; Kobayashi, S.; Chiang, Y.-C.; Jiang, D.-H.; Hung, C.-C.; Ercan, E.; Yang, W.-C.; Hsieh, H.-C. Stretchable OFET memories: Tuning the morphology and the charge-trapping ability of conjugated block copolymers through soft segment branching. ACS Appl. Mater. Interfaces 2021, 13, 2932–2943. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-X.; Gao, X.; Lv, J.-J.; Zhong, Y.-N.; Xu, C.; Xu, J.-L.; Wang, S.-D. Filter-free selective light monitoring by organic field-effect transistor memories with a tunable blend charge-trapping layer. ACS Appl. Mater. Interfaces 2019, 11, 40366–40371. [Google Scholar] [CrossRef] [PubMed]

- Kwon, H.j.; Ye, H.; Shim, K.; Girma, H.G.; Tang, X.; Lim, B.; Kim, Y.; Lee, J.; Park, C.E.; Jung, S.H. Newly synthesized nonvacuum processed high-k polymeric dielectrics with carboxyl functionality for highly stable operating printed transistor applications. Adv. Funct. Mater. 2021, 31, 2007304. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, Z.; Chen, S.-C.; Dai, S.; Huang, J.; Zheng, Q. Binary polymer composite dielectrics for flexible low-voltage organic field-effect transistors. Org. Electron. 2018, 53, 205–212. [Google Scholar] [CrossRef]

- Rahmanudin, A.; Tate, D.J.; Marcial-Hernandez, R.; Bull, N.; Garlapati, S.K.; Zamhuri, A.; Khan, R.U.; Faraji, S.; Gollu, S.R.; Persaud, K.C. Robust high-capacitance polymer gate dielectrics for stable low-voltage organic field-effect transistor sensors. Adv. Electron. Mater. 2020, 6, 1901127. [Google Scholar] [CrossRef]

- Davies, D. Charge generation on dielectric surfaces. J. Phys. D Appl. Phys. 1969, 2, 1533. [Google Scholar] [CrossRef]

- Seung, W.; Yoon, H.J.; Kim, T.Y.; Ryu, H.; Kim, J.; Lee, J.H.; Lee, J.H.; Kim, S.; Park, Y.K.; Park, Y.J. Boosting power-generating performance of triboelectric nanogenerators via artificial control of ferroelectric polarization and dielectric properties. Adv. Energy Mater. 2017, 7, 1600988. [Google Scholar] [CrossRef]

- Wan, Q.; Chen, Q.; Freithaler, M.A.; Velagala, S.R.; Liu, Y.; To, A.C.; Mahajan, A.; Mukkamala, R.; Xiong, F. Toward Real-Time Blood Pressure Monitoring via High-Fidelity Iontronic Tonometric Sensors with High Sensitivity and Large Dynamic Ranges. Adv. Healthc. Mater. 2023, 12, 2202461. [Google Scholar] [CrossRef]

- Song, J.; Liu, H.; Zhao, Z.; Lin, P.; Yan, F. Flexible organic transistors for biosensing: Devices and applications. Adv. Mater. 2024, 36, 2300034. [Google Scholar] [CrossRef]

- Chen, X.; Han, X.; Shen, Q.D. PVDF-based ferroelectric polymers in modern flexible electronics. Adv. Electron. Mater. 2017, 3, 1600460. [Google Scholar] [CrossRef]

- Kwon, J.; Takeda, Y.; Shiwaku, R.; Tokito, S.; Cho, K.; Jung, S. Three-dimensional monolithic integration in flexible printed organic transistors. Nat. Commun. 2019, 10, 54. [Google Scholar] [CrossRef]

- Stucchi, E.; Dell’Erba, G.; Colpani, P.; Kim, Y.H.; Caironi, M. Low-voltage, printed, all-polymer integrated circuits employing a low-leakage and high-yield polymer dielectric. Adv. Electron. Mater. 2018, 4, 1800340. [Google Scholar] [CrossRef]

- Wu, X.; Wang, S.; Huang, W.; Dong, Y.; Wang, Z.; Huang, W. Wearable in-sensor reservoir computing using optoelectronic polymers with through-space charge-transport characteristics for multi-task learning. Nat. Commun. 2023, 14, 468. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Hu, H.; Wang, M.; Xu, J.; Wang, S. Stretchable transistors and functional circuits for human-integrated electronics. Nat. Electron. 2021, 4, 17–29. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, Y.; Zhong, D.; Zhang, Z.; Choudhury, S.; Lai, J.-C.; Gong, H.; Niu, S.; Yan, X.; Zheng, Y. Neuromorphic sensorimotor loop embodied by monolithically integrated, low-voltage, soft e-skin. Science 2023, 380, 735–742. [Google Scholar] [CrossRef]

- Wang, B.; Huang, W.; Chi, L.; Al-Hashimi, M.; Marks, T.J.; Facchetti, A. High-k gate dielectrics for emerging flexible and stretchable electronics. Chem. Rev. 2018, 118, 5690–5754. [Google Scholar] [CrossRef]

- Kang, J.; Yoon, J.; Lee, B.; Jung, H.; Kim, J.; Nam, W.; Jeong, K.; Choi, J.; Son, D.; Im, S.G. Ultrathin, solvent-resistant dielectric for monolithic fabrication of low-power, intrinsically stretchable active-matrix electronic skin. Device 2024, 2, 100426. [Google Scholar] [CrossRef]

- Xiong, Y.; Luo, L.; Yang, J.; Han, J.; Liu, Y.; Jiao, H.; Wu, S.; Cheng, L.; Feng, Z.; Sun, J.; et al. Scalable spinning, winding, and knitting graphene textile TENG for energy harvesting and human motion recognition. Nano Energy 2023, 107, 108137. [Google Scholar] [CrossRef]

- Cheng, P.; Dai, S.; Liu, Y.; Li, Y.; Hayashi, H.; Papani, R.; Su, Q.; Li, N.; Dai, Y.; Liu, W.; et al. An intrinsically stretchable power-source system for bioelectronics. Device 2024, 2, 100216. [Google Scholar] [CrossRef]

- Hu, S.; Chang, S.; Xiao, G.; Lu, J.; Gao, J.; Zhang, Y.; Tao, Y. A Stretchable Multimode Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Sensing. Adv. Mater. Technol. 2021, 7, 2100870. [Google Scholar] [CrossRef]

- Anju, V.; Narayanankutty, S.K. High dielectric constant polymer nanocomposite for embedded capacitor applications. Mater. Sci. Eng. B 2019, 249, 114418. [Google Scholar] [CrossRef]

- Thakur, Y.; Zhang, T.; Iacob, C.; Yang, T.; Bernholc, J.; Chen, L.; Runt, J.; Zhang, Q. Enhancement of the dielectric response in polymer nanocomposites with low dielectric constant fillers. Nanoscale 2017, 9, 10992–10997. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, X.; Zhang, B.; Zhang, T.; Lu, W.; Chen, Z.; Liu, Z.; Kim, S.H.; Donovan, B.; Warzoha, R.J. High-temperature polymers with record-high breakdown strength enabled by rationally designed chain-packing behavior in blends. Matter 2021, 4, 2448–2459. [Google Scholar] [CrossRef]

- Kang, S.; Kim, S.; Yoo, H. Light-Assisted/Light-Driven Memory Behaviors with Small Molecule-Fluoropolymer-Small Molecule-Stacked Floating-Gate Heterostructures. ACS Photonics 2023, 10, 1310–1319. [Google Scholar] [CrossRef]

- Ren, H.; Cui, N.; Tang, Q.; Tong, Y.; Zhao, X.; Liu, Y. High-performance, ultrathin, ultraflexible organic thin-film transistor array via solution process. Small 2018, 14, 1801020. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Hu, Z.; Liu, H.; Lan, L.; Peng, J.; Wang, J.; Cao, Y. Flexible all-organic, all-solution processed thin film transistor array with ultrashort channel. Sci. Rep. 2016, 6, 29055. [Google Scholar] [CrossRef] [PubMed]

- Chung, S.; Jang, M.; Ji, S.B.; Im, H.; Seong, N.; Ha, J.; Kwon, S.K.; Kim, Y.H.; Yang, H.; Hong, Y. Flexible High-Performance All-Inkjet-Printed Inverters: Organo-Compatible and Stable Interface Engineering. Adv. Mater. 2013, 25, 4773–4777. [Google Scholar] [CrossRef]

- Conti, S.; Lai, S.; Cosseddu, P.; Bonfiglio, A. An Inkjet-Printed, Ultralow Voltage, Flexible Organic Field Effect Transistor. Adv. Mater. Technol. 2017, 2, 1600212. [Google Scholar] [CrossRef]

- Kim, I.; Ju, B.; Zhou, Y.; Li, B.M.; Jur, J.S. Microstructures in all-inkjet-printed textile capacitors with bilayer interfaces of polymer dielectrics and metal–organic decomposition silver electrodes. ACS Appl. Mater. Interfaces 2021, 13, 24081–24094. [Google Scholar] [CrossRef]

- Yang, S.C.; Choi, J.; Jang, B.C.; Hong, W.; Shim, G.W.; Yang, S.Y.; Im, S.G.; Choi, S.Y. Large-scale, low-power nonvolatile memory based on few-layer MoS2 and ultrathin polymer dielectrics. Adv. Electron. Mater. 2019, 5, 1800688. [Google Scholar] [CrossRef]

- Kim, N.; Oh, J.; Kim, S.; Cha, J.H.; Choi, J.; Im, S.G.; Choi, S.Y.; Jang, B.C. Realistic Chest X-Ray Image Synthesis via Generative Network with Stochastic Memristor Array for Machine Learning-Based Medical Diagnosis. Adv. Funct. Mater. 2024, 34, 2305136. [Google Scholar] [CrossRef]

- Han, J.S.; Le, Q.V.; Choi, J.; Hong, K.; Moon, C.W.; Kim, T.L.; Kim, H.; Kim, S.Y.; Jang, H.W. Air-stable cesium lead iodide perovskite for ultra-low operating voltage resistive switching. Adv. Funct. Mater. 2018, 28, 1705783. [Google Scholar] [CrossRef]

- Zhang, Z.C.; Li, Y.; Li, J.; Chen, X.D.; Yao, B.W.; Yu, M.X.; Lu, T.B.; Zhang, J. An ultrafast nonvolatile memory with low operation voltage for high-speed and low-power applications. Adv. Funct. Mater. 2021, 31, 2102571. [Google Scholar] [CrossRef]

- Hung, C.C.; Chiu, Y.C.; Wu, H.C.; Lu, C.; Bouilhac, C.; Otsuka, I.; Halila, S.; Borsali, R.; Tung, S.H.; Chen, W.C. Conception of stretchable resistive memory devices based on nanostructure-controlled carbohydrate-block-polyisoprene block copolymers. Adv. Funct. Mater. 2017, 27, 1606161. [Google Scholar] [CrossRef]

- Lee, S.; Seong, H.; Im, S.G.; Moon, H.; Yoo, S. Organic flash memory on various flexible substrates for foldable and disposable electronics. Nat. Commun. 2017, 8, 725. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Yoo, H. Combination of Polymer Gate Dielectric and Two-Dimensional Semiconductor for Emerging Field-Effect Transistors. Polymers 2023, 15, 1395. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Wang, Z.; Chen, X.; Li, L.; Li, J.; Ji, D.; Li, L.; Hu, W. Low-voltage polymer-dielectric-based organic field-effect transistors and applications. Nano Sel. 2022, 3, 20–38. [Google Scholar] [CrossRef]

- Kim, S.; Seo, J.; Choi, J.; Yoo, H. Vertically integrated electronics: New opportunities from emerging materials and devices. Nanomicro Lett. 2022, 14, 201. [Google Scholar] [CrossRef]

- Yu, H.; Chen, Y.; Wei, H.; Gong, J.; Xu, W. High-k polymeric gate insulators for organic field-effect transistors. Nanotechnology 2019, 30, 202002. [Google Scholar] [CrossRef]

- Kim, J.; Ryu, H.; Lee, J.H.; Khan, U.; Kwak, S.S.; Yoon, H.J.; Kim, S.W. High permittivity CaCu3Ti4O12 particle-induced internal polarization amplification for high performance triboelectric nanogenerators. Adv. Energy Mater. 2020, 10, 1903524. [Google Scholar] [CrossRef]

- Zhou, Y.S.; Wang, S.; Yang, Y.; Zhu, G.; Niu, S.; Lin, Z.-H.; Liu, Y.; Wang, Z.L. Manipulating nanoscale contact electrification by an applied electric field. Nano Lett. 2014, 14, 1567–1572. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Lin, M.; Wang, Z.; Zhao, X.; Cai, Y.; Liu, Q.; Fang, Y.; Yang, Y.; He, M.; Huang, R. Low power parylene-based memristors with a graphene barrier layer for flexible electronics applications. Adv. Electron. Mater. 2019, 5, 1800852. [Google Scholar] [CrossRef]

- Jang, B.C.; Kim, S.; Yang, S.Y.; Park, J.; Cha, J.-H.; Oh, J.; Choi, J.; Im, S.G.; Dravid, V.P.; Choi, S.-Y. Polymer analog memristive synapse with atomic-scale conductive filament for flexible neuromorphic computing system. Nano Lett. 2019, 19, 839–849. [Google Scholar] [CrossRef]

- Baeg, K.-J.; Noh, Y.-Y.; Kim, D.-Y. Charge transfer and trapping properties in polymer gate dielectrics for non-volatile organic field-effect transistor memory applications. Solid State Electron. 2009, 53, 1165–1168. [Google Scholar] [CrossRef]

- Feng, Y.; Gao, X.; Zhong, Y.-N.; Wu, J.-L.; Xu, J.-L.; Wang, S.-D. Solution-processed polymer thin-film memristors with an electrochromic feature and frequency-dependent synaptic plasticity. Adv. Intell. Syst. 2019, 1, 1900022. [Google Scholar] [CrossRef]

- Forrest, S.R. The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature 2004, 428, 911–918. [Google Scholar] [CrossRef]

- Park, H.L.; Kim, M.H.; Lee, S.H. Introduction of interfacial load polymeric layer to organic flexible memristor for regulating conductive filament growth. Adv. Electron. Mater. 2020, 6, 2000582. [Google Scholar] [CrossRef]

- Scott, J.C.; Bozano, L.D. Nonvolatile memory elements based on organic materials. Adv. Mater. 2007, 19, 1452–1463. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Y.; Wang, X.; Sim, K.; Liu, J.; Chen, J.; Feng, X.; Xu, H.; Yu, C. Moisture-triggered physically transient electronics. Sci. Adv. 2017, 3, e1701222. [Google Scholar] [CrossRef]

- Fu, K.K.; Wang, Z.; Dai, J.; Carter, M.; Hu, L. Transient electronics: Materials and devices. Chem. Mater. 2016, 28, 3527–3539. [Google Scholar] [CrossRef]

- Oh, S.; Kim, H.; Kim, S.E.; Kim, M.-H.; Park, H.-L.; Lee, S.-H. Biodegradable and flexible polymer-based memristor possessing optimized synaptic plasticity for eco-friendly wearable neural networks with high energy efficiency. Adv. Intell. Syst. 2023, 5, 2200272. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, H.L.; Keum, C.M.; Lee, I.H.; Kim, M.H.; Lee, S.D. Organic flexible memristor with reduced operating voltage and high stability by interfacial control of conductive filament growth. Phys. Status Solidi-Rapid Res. Lett. 2019, 13, 1900044. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. Biodegradable single-polymer composites from polyvinyl alcohol. Colloid Polym. Sci. 2012, 290, 359–370. [Google Scholar] [CrossRef]

- Ahmed, H.; Hashim, A. Geometry optimization, optical and electronic characteristics of novel PVA/PEO/SiC structure for electronics applications. Silicon 2021, 13, 2639–2644. [Google Scholar] [CrossRef]

- Fortunato, E.; Correia, N.; Barquinha, P.; Pereira, L.; Gonçalves, G.; Martins, R. High-performance flexible hybrid field-effect transistors based on cellulose fiber paper. IEEE Electron Device Lett. 2008, 29, 988–990. [Google Scholar] [CrossRef]

- Yang, D.; Yang, H.; Guo, X.; Zhang, H.; Jiao, C.; Xiao, W.; Guo, P.; Wang, Q.; He, D. Robust polyethylenimine electrolyte for high performance and thermally stable atomic switch memristors. Adv. Funct. Mater. 2020, 30, 2004514. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, C.; Liu, G.; Zhu, X.; Chen, X.; Pan, L.; Tan, H.; Xue, W.; Ji, Z.; Wang, J. Thermally-stable resistive switching with a large ON/OFF ratio achieved in poly (triphenylamine). Chem. Commun. 2014, 50, 11856–11858. [Google Scholar] [CrossRef]

- Krishnan, K.; Aono, M.; Tsuruoka, T. Thermally stable resistive switching of a polyvinyl alcohol-based atomic switch. J. Mater. Chem. C 2018, 6, 6460–6464. [Google Scholar] [CrossRef]

- Li, J.; Qian, Y.; Li, W.; Yu, S.; Ke, Y.; Qian, H.; Lin, Y.H.; Hou, C.H.; Shyue, J.J.; Zhou, J. Polymeric Memristor Based Artificial Synapses with Ultra-Wide Operating Temperature. Adv. Mater. 2023, 35, 2209728. [Google Scholar] [CrossRef]

- Moon, H.; Seong, H.; Shin, W.C.; Park, W.-T.; Kim, M.; Lee, S.; Bong, J.H.; Noh, Y.-Y.; Cho, B.J.; Yoo, S. Synthesis of ultrathin polymer insulating layers by initiated chemical vapour deposition for low-power soft electronics. Nat. Mater. 2015, 14, 628–635. [Google Scholar] [CrossRef]

- Gohil, J.; Bhattacharya, A.; Ray, P. Studies on the crosslinking of poly (vinyl alcohol). J. Polym. Res. 2006, 13, 161–169. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, X.; Wang, T.; Shi, X.; Liu, Y.; Zuo, Y.; Xu, L.; Wang, M.; Hu, X.; Yang, X. Robust DNA-Bridged Memristor for Textile Chips. Angew. Chem. Int. Ed. 2020, 59, 12762–12768. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wu, C.; Lv, Y.; Zhang, Y.; Liu, W. High-performance flexible polymer memristor based on stable filamentary switching. Nano Lett. 2022, 22, 7246–7253. [Google Scholar] [CrossRef]

- Che, Q.; Wang, X.; El-Khouly, M.E.; Li, G.; Liu, J.; Zhang, B.; Chen, Y. Improving the Long-Term Stability of BPQD-Based Memory Device via Modification with Polyvinylpyrrolidone-Grafted Polydopamine. Adv. Electron. Mater. 2022, 8, 2101057. [Google Scholar] [CrossRef]

- Jang, B.C.; Seong, H.; Kim, S.K.; Kim, J.Y.; Koo, B.J.; Choi, J.; Yang, S.Y.; Im, S.G.; Choi, S.-Y. Flexible nonvolatile polymer memory array on plastic substrate via initiated chemical vapor deposition. ACS Appl. Mater. Interfaces 2016, 8, 12951–12958. [Google Scholar] [CrossRef]

- Bae, H.; Jang, B.C.; Park, H.; Jung, S.-H.; Lee, H.M.; Park, J.-Y.; Jeon, S.-B.; Son, G.; Tcho, I.-W.; Yu, K. Functional circuitry on commercial fabric via textile-compatible nanoscale film coating process for fibertronics. Nano Lett. 2017, 17, 6443–6452. [Google Scholar] [CrossRef]

- Lee, S.; Kim, S.; Yoo, H. Contribution of polymers to electronic memory devices and applications. Polymers 2021, 13, 3774. [Google Scholar] [CrossRef]

- Chen, M.-N.; Chang, S.-W.; Prakoso, S.P.; Li, Y.-T.; Chen, K.-L.; Chiu, Y.-C. Unveiling the photoinduced recovery mystery in conjugated polymer-based transistor memory. ACS Appl. Mater. Interfaces 2021, 13, 44656–44662. [Google Scholar] [CrossRef] [PubMed]

- Shih, C.-C.; Chiang, Y.-C.; Hsieh, H.-C.; Lin, Y.-C.; Chen, W.-C. Multilevel photonic transistor memory devices using conjugated/insulated polymer blend electrets. ACS Appl. Mater. Interfaces 2019, 11, 42429–42437. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Yu, T.; Wan, Z.; Wang, Y.; Li, Z.; Yin, J.; Gao, X.; Xia, Y.; Liu, Z. High-Performance Pentacene-Based Field-Effect Transistor Memory Using the Electrets of Polymer Blends. Adv. Electron. Mater. 2022, 8, 2101342. [Google Scholar] [CrossRef]

- Lin, C.F.; Lin, Y.C.; Yang, W.C.; Hsu, L.C.; Ercan, E.; Hung, C.C.; Yu, Y.Y.; Chen, W.C. Multiband Photoresponding Field-Effect Transistor Memory Using Conjugated Block Copolymers with Pendent Isoindigo Coils as a Polymer Electret. Adv. Electron. Mater. 2021, 7, 2100655. [Google Scholar] [CrossRef]

- Chi, H.-Y.; Hsu, H.-W.; Tung, S.-H.; Liu, C.-L. Nonvolatile organic field-effect transistors memory devices using supramolecular block copolymer/functional small molecule nanocomposite electret. ACS Appl. Mater. Interfaces 2015, 7, 5663–5673. [Google Scholar] [CrossRef]

- Shu, S.; Xu, T.; Su, J. A flexible floating-gate based organic field-effect transistor non-volatile memory based on F8BT/PMMA integrated floating-gate/tunneling layer. Phys. Scr. 2023, 98, 045402. [Google Scholar] [CrossRef]

- He, W.; Xu, W.; He, H.; Jing, X.; Liu, C.; Feng, J.; Luo, C.; Fan, Z.; Wu, S.; Gao, J. From Unipolar, WORM-Type to Ambipolar, Bistable Organic Electret Memory Device by Controlling Minority Lateral Transport. Adv. Electron. Mater. 2020, 6, 1901320. [Google Scholar] [CrossRef]

- Pak, K.; Choi, J.; Lee, C.; Im, S.G. Low-power, flexible nonvolatile organic transistor memory based on an ultrathin bilayer dielectric stack. Adv. Electron. Mater. 2019, 5, 1800799. [Google Scholar] [CrossRef]

- Li, Z.; An, L.; Khuje, S.; Tan, J.; Hu, Y. Solution-shearing of dielectric polymer with high thermal conductivity and electric insulation. Sci. Adv. 2021, 7, eabi7410. [Google Scholar] [CrossRef]

- Yoo, S.; Kim, D.-G.; Ha, T.; Chan Won, J.; Jang, K.-S.; Kim, Y.H. Solution-processable, thin, and high-κ dielectric polyurea gate insulator with strong hydrogen bonding for low-voltage organic thin-film transistors. ACS Appl. Mater. Interfaces 2018, 10, 32462–32470. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Choi, M.-J.; Jang, H.W. Ferroelectric field effect transistors: Progress and perspective. APL Mater. 2021, 9, 021102. [Google Scholar] [CrossRef]

- Chen, R.S.; Lu, Y. Negative capacitance field effect transistors based on van der Waals 2D materials. Small 2023, 2304445. [Google Scholar] [CrossRef]

- Nketia-Yawson, B.; Noh, Y.Y. Recent progress on high-capacitance polymer gate dielectrics for flexible low-voltage transistors. Adv. Funct. Mater. 2018, 28, 1802201. [Google Scholar] [CrossRef]

- Kang, B.; Song, E.; Lee, S.B.; Chae, B.-G.; Ahn, H.; Cho, K. Stretchable polymer gate dielectric with segmented elastomeric network for organic soft electronics. Chem. Mater. 2018, 30, 6353–6360. [Google Scholar] [CrossRef]

- Koo, J.H.; Kang, J.; Lee, S.; Song, J.-K.; Choi, J.; Yoon, J.; Park, H.J.; Sunwoo, S.-H.; Kim, D.C.; Nam, W. A vacuum-deposited polymer dielectric for wafer-scale stretchable electronics. Nat. Electron. 2023, 6, 137–145. [Google Scholar] [CrossRef]

- Yoo, H.; Heo, K.; Ansari, M.H.R.; Cho, S. Recent advances in electrical doping of 2D semiconductor materials: Methods, analyses, and applications. Nanomaterials 2021, 11, 832. [Google Scholar] [CrossRef]

- Park, H.; Choi, J.; Shim, J.; Lee, S.M.; On, S.; Yun, H.J.; Kim, S.; Im, S.G.; Yoo, H. Functional polymeric passivation-led improvement of bias stress with long-term durability of edge-rich nanoporous MoS2 thin-film transistors. npj 2D Mater. Appl. 2022, 6, 21. [Google Scholar] [CrossRef]

- Jeong, J.W.; Hwang, H.S.; Choi, D.; Ma, B.C.; Jung, J.; Chang, M. Hybrid polymer/metal oxide thin films for high performance, flexible transistors. Micromachines 2020, 11, 264. [Google Scholar] [CrossRef]

- Chen, Y.; Zhuang, X.; Goldfine, E.A.; Dravid, V.P.; Bedzyk, M.J.; Huang, W.; Facchetti, A.; Marks, T.J. Printable organic-inorganic nanoscale multilayer gate dielectrics for thin-film transistors enabled by a polymeric organic interlayer. Adv. Funct. Mater. 2020, 30, 2005069. [Google Scholar] [CrossRef]

- Feng, W.; Zheng, W.; Cao, W.; Hu, P. Back gated multilayer InSe transistors with enhanced carrier mobilities via the suppression of carrier scattering from a dielectric interface. Adv. Mater. 2014, 26, 6587–6593. [Google Scholar] [CrossRef]

- Kwon, H.j.; Ye, H.; Baek, Y.; Hong, J.; Wang, R.; Choi, Y.; Lee, I.; Park, C.E.; Nam, S.; Kim, J. Printable ultra-flexible fluorinated organic–inorganic nanohybrid sol–gel derived gate dielectrics for highly stable organic thin-film transistors and other practical applications. Adv. Funct. Mater. 2021, 31, 2009539. [Google Scholar] [CrossRef]

- Kim, M.J.; Jeong, J.; Lee, T.I.; Kim, J.; Tak, Y.; Park, H.; Im, S.G.; Cho, B.J. Large-Area, Conformal, and Uniform Synthesis of Hybrid Polymeric Film via Initiated Chemical Vapor Deposition. Macromol. Mater. Eng. 2021, 306, 2000608. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Shi, Z.; Mei, J.; Wang, X.; Yan, D.; Cui, Z. Novel high-k polymers as dielectric layers for organic thin-film transistors. Polym. Chem. 2015, 6, 6651–6658. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Zhang, C.; Zhang, Y.; Cui, Z.; Yan, D.; Shi, Z. Organic thin-film transistors with novel high-k polymers as dielectric layers. Polym. Chem. 2015, 6, 3685–3693. [Google Scholar] [CrossRef]

- Ye, H.; Ryu, K.Y.; Kwon, H.-j.; Lee, H.; Wang, R.; Hong, J.; Choi, H.H.; Nam, S.Y.; Lee, J.; Kong, H. Amorphous Fluorinated Acrylate Polymer Dielectrics for Flexible Transistors and Logic Gates with High Operational Stability. ACS Appl. Mater. Interfaces 2023, 15, 32610–32620. [Google Scholar] [CrossRef]

- Zou, J.; Li, S.; Wang, H.; Wang, W.; Shi, Z.; Jiang, Y.; Cui, Z.; Yan, D. High-k polymer materials containing cyclic carbonate as gate dielectrics for application in low-voltage operating organic thin-film transistors. J. Mater. Chem. C 2019, 7, 15357–15363. [Google Scholar] [CrossRef]

- Choe, Y.-S.; Yi, M.H.; Kim, J.-H.; Ryu, G.-S.; Noh, Y.-Y.; Kim, Y.H.; Jang, K.-S. Crosslinked polymer-mixture gate insulator for high-performance organic thin-film transistors. Org. Electron. 2016, 36, 171–176. [Google Scholar] [CrossRef]

- Choi, J.; Joo, M.; Seong, H.; Pak, K.; Park, H.; Park, C.W.; Im, S.G. Flexible, low-power thin-film transistors made of vapor-phase synthesized high-k, ultrathin polymer gate dielectrics. ACS Appl. Mater. Interfaces 2017, 9, 20808–20817. [Google Scholar] [CrossRef]

- Choi, J.; Seong, H.; Pak, K.; Im, S.G. Vapor-phase deposition of the fluorinated copolymer gate insulator for the p-type organic thin-film transistor. J. Inf. Disp. 2016, 17, 43–49. [Google Scholar] [CrossRef]

- Choi, J.; Yoon, J.; Kim, M.J.; Pak, K.; Lee, C.; Lee, H.; Jeong, K.; Ihm, K.; Yoo, S.; Cho, B.J. Spontaneous generation of a molecular thin hydrophobic skin layer on a sub-20 nm, high-k polymer dielectric for extremely stable organic thin-film transistor operation. ACS Appl. Mater. Interfaces 2019, 11, 29113–29123. [Google Scholar] [CrossRef]

- Feng, L.; Jiang, C.; Ma, H.; Guo, X.; Nathan, A. All ink-jet printed low-voltage organic field-effect transistors on flexible substrate. Org. Electron. 2016, 38, 186–192. [Google Scholar] [CrossRef]

- Hallani, R.K.; Moser, M.; Bristow, H.; Jenart, M.V.; Faber, H.; Neophytou, M.; Yarali, E.; Paterson, A.F.; Anthopoulos, T.D.; McCulloch, I. Low-temperature cross-linking benzocyclobutene based polymer dielectric for organic thin film transistors on plastic substrates. J. Org. Chem. 2019, 85, 277–283. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Kim, J.W.; Lee, E.K.; Park, J.-I.; Lee, B.-L.; Kwon, Y.-N.; Byun, S.; Jung, M.-S.; Kim, J.-J. Cross-linked poly (hydroxy imide) gate-insulating materials for low-temperature processing of organic thin-film transistors. J. Mater. Chem. C 2018, 6, 13359–13366. [Google Scholar] [CrossRef]

- Kwon, J.S.; Park, H.W.; Kim, D.H.; Kwark, Y.-J. Solvent-free processable and photo-patternable hybrid gate dielectric for flexible top-gate organic field-effect transistors. ACS Appl. Mater. Interfaces 2017, 9, 5366–5374. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.K.; Kim, J.Y.; Chung, J.W.; Lee, B.-L.; Kang, Y. Photo-crosslinkable polymer gate dielectrics for hysteresis-free organic field-effect transistors with high solvent resistance. RSC Adv. 2014, 4, 293–300. [Google Scholar] [CrossRef]

- Li, S.; Feng, L.; Zhao, J.; Guo, X.; Zhang, Q. Low temperature cross-linked, high performance polymer gate dielectrics for solution-processed organic field-effect transistors. Polym. Chem. 2015, 6, 5884–5890. [Google Scholar] [CrossRef]

- Sun, W.; Zhao, J.; Chen, S.; Guo, X.; Zhang, Q. Thermally cross-linked polyvinyl alcohol as gate dielectrics for solution processing organic field-effect transistors. Synth. Met. 2019, 250, 73–78. [Google Scholar] [CrossRef]

- Yang, H.; Kim, M.-J.; Kang, B.-G.; Lee, B.H. Organic Field-Effect Transistors with Bottlebrush Polymer Gate Dielectrics Thermally Cross-Linked in Less Than 1 min. Chem. Mater. 2021, 33, 6356–6364. [Google Scholar] [CrossRef]

- Ye, H.; Kwon, H.j.; Shin, S.C.; Lee, H.y.; Park, Y.H.; Tang, X.; Wang, R.; Lee, K.; Hong, J.; Li, Z. The hidden potential of polysilsesquioxane for high-k: Analysis of the origin of its dielectric nature and practical low-voltage-operating applications beyond the unit device. Adv. Funct. Mater. 2022, 32, 2104030. [Google Scholar] [CrossRef]

- Jung, S.; Albariqi, M.; Gruntz, G.; Al-Hathal, T.; Peinado, A.; Garcia-Caurel, E.; Nicolas, Y.; Toupance, T.; Bonnassieux, Y.; Horowitz, G. A TIPS-TPDO-tetraCN-based n-type organic field-effect transistor with a cross-linked PMMA polymer gate dielectric. ACS Appl. Mater. Interfaces 2016, 8, 14701–14708. [Google Scholar] [CrossRef]

- Noh, Y.-Y.; Sirringhaus, H. Ultra-thin polymer gate dielectrics for top-gate polymer field-effect transistors. Org. Electron. 2009, 10, 174–180. [Google Scholar] [CrossRef]

- Oh, J.Y.; Rondeau-Gagné, S.; Chiu, Y.-C.; Chortos, A.; Lissel, F.; Wang, G.-J.N.; Schroeder, B.C.; Kurosawa, T.; Lopez, J.; Katsumata, T. Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nature 2016, 539, 411–415. [Google Scholar] [CrossRef]

- Wang, S.; Xu, J.; Wang, W.; Wang, G.-J.N.; Rastak, R.; Molina-Lopez, F.; Chung, J.W.; Niu, S.; Feig, V.R.; Lopez, J. Skin electronics from scalable fabrication of an intrinsically stretchable transistor array. Nature 2018, 555, 83–88. [Google Scholar] [CrossRef]

- Wang, W.; Wang, S.; Rastak, R.; Ochiai, Y.; Niu, S.; Jiang, Y.; Arunachala, P.K.; Zheng, Y.; Xu, J.; Matsuhisa, N. Strain-insensitive intrinsically stretchable transistors and circuits. Nat. Electron. 2021, 4, 143–150. [Google Scholar] [CrossRef]

- Xu, J.; Wang, S.; Wang, G.-J.N.; Zhu, C.; Luo, S.; Jin, L.; Gu, X.; Chen, S.; Feig, V.R.; To, J.W. Highly stretchable polymer semiconductor films through the nanoconfinement effect. Science 2017, 355, 59–64. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Wu, H.-C.; Zhu, C.; Ehrlich, A.; Shaw, L.; Nikolka, M.; Wang, S.; Molina-Lopez, F.; Gu, X.; Luo, S. Multi-scale ordering in highly stretchable polymer semiconducting films. Nat. Mater. 2019, 18, 594–601. [Google Scholar] [CrossRef]

- Ho, J.-C.; Lin, Y.-C.; Chen, C.-K.; Hsu, L.-C.; Chen, W.-C. Hydrogel-based sustainable and stretchable field-effect transistors. Org. Electron. 2022, 100, 106358. [Google Scholar] [CrossRef]

- Hur, J.S.; Kim, J.O.; Kim, H.A.; Jeong, J.K. Stretchable polymer gate dielectric by ultraviolet-assisted hafnium oxide doping at low temperature for high-performance indium gallium tin oxide transistors. ACS Appl. Mater. Interfaces 2019, 11, 21675–21685. [Google Scholar] [CrossRef]

- Kim, J.O.; Hur, J.S.; Kim, D.; Lee, B.; Jung, J.M.; Kim, H.A.; Chung, U.J.; Nam, S.H.; Hong, Y.; Park, K.S. Network structure modification-enabled hybrid polymer dielectric film with zirconia for the stretchable transistor applications. Adv. Funct. Mater. 2020, 30, 1906647. [Google Scholar] [CrossRef]

- Lu, C.; Lee, W.-Y.; Shih, C.-C.; Wen, M.-Y.; Chen, W.-C. Stretchable polymer dielectrics for low-voltage-driven field-effect transistors. ACS Appl. Mater. Interfaces 2017, 9, 25522–25532. [Google Scholar] [CrossRef]

- Rao, Y.-L.; Chortos, A.; Pfattner, R.; Lissel, F.; Chiu, Y.-C.; Feig, V.; Xu, J.; Kurosawa, T.; Gu, X.; Wang, C. Stretchable self-healing polymeric dielectrics cross-linked through metal–ligand coordination. J. Am. Chem. Soc. 2016, 138, 6020–6027. [Google Scholar] [CrossRef]

- Zheng, Y.-Q.; Liu, Y.; Zhong, D.; Nikzad, S.; Liu, S.; Yu, Z.; Liu, D.; Wu, H.-C.; Zhu, C.; Li, J. Monolithic optical microlithography of high-density elastic circuits. Science 2021, 373, 88–94. [Google Scholar] [CrossRef]

- Choi, S.; Jo, J.-W.; Kim, J.; Song, S.; Kim, J.; Park, S.K.; Kim, Y.-H. Static and dynamic water motion-induced instability in oxide thin-film transistors and its suppression by using low-k fluoropolymer passivation. ACS Appl. Mater. Interfaces 2017, 9, 26161–26168. [Google Scholar] [CrossRef]

- Jia, J.; Jang, S.K.; Lai, S.; Xu, J.; Choi, Y.J.; Park, J.-H.; Lee, S. Plasma-treated thickness-controlled two-dimensional black phosphorus and its electronic transport properties. ACS Nano 2015, 9, 8729–8736. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Hong, S.; Yoo, H. Interfacial doping effects in fluoropolymer-tungsten diselenide composites providing high-performance P-type transistors. Polymers 2021, 13, 1087. [Google Scholar] [CrossRef]

- Nair, S.; Kathiresan, M.; Mukundan, T.; Natarajan, V. Passivation of organic field effect transistor with photopatterned Parylene to improve environmental stability. Microelectron. Eng. 2016, 163, 36–42. [Google Scholar] [CrossRef]

- Oh, J.G.; Pak, K.; Kim, C.S.; Bong, J.H.; Hwang, W.S.; Im, S.G.; Cho, B.J. A high-performance top-gated graphene field-effect transistor with excellent flexibility enabled by an iCVD copolymer gate dielectric. Small 2018, 14, 1703035. [Google Scholar] [CrossRef]

- Pak, K.; Seong, H.; Choi, J.; Hwang, W.S.; Im, S.G. Synthesis of ultrathin, homogeneous copolymer dielectrics to control the threshold voltage of organic thin-film transistors. Adv. Funct. Mater. 2016, 26, 6574–6582. [Google Scholar] [CrossRef]

- Seong, H.; Choi, J.; Jang, B.C.; Kim, M.; Yoo, S.; Choi, S.Y.; Im, S.G. A low-voltage organic complementary inverter with high operation stability and flexibility using an ultrathin iCVD polymer dielectric and a hybrid encapsulation layer. Adv. Electron. Mater. 2016, 2, 1500385. [Google Scholar] [CrossRef]

- Shin, E.-S.; Park, W.-T.; Kwon, Y.-W.; Xu, Y.; Noh, Y.-Y. Spontaneous doping at the polymer–polymer interface for high-performance organic transistors. ACS Appl. Mater. Interfaces 2019, 11, 12709–12716. [Google Scholar] [CrossRef] [PubMed]

- Tak, Y.J.; Keene, S.T.; Kang, B.H.; Kim, W.-G.; Kim, S.J.; Salleo, A.; Kim, H.J. Multifunctional, room-temperature processable, heterogeneous organic passivation layer for oxide semiconductor thin-film transistors. ACS Appl. Mater. Interfaces 2019, 12, 2615–2624. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, W.; Sangwan, V.K.; Wang, B.; Zeng, L.; Wang, G.; Huang, Y.; Lu, Z.; Bedzyk, M.J.; Hersam, M.C. Polymer doping enables a two-dimensional electron gas for high-performance homojunction oxide thin-film transistors. Adv. Mater. 2019, 31, 1805082. [Google Scholar] [CrossRef]

- Hong, S.; Yoo, G.; Kim, D.H.; Song, W.G.; Le, O.K.; Hong, Y.K.; Takahashi, K.; Omkaram, I.; Son, D.N.; Kim, S. The doping mechanism and electrical performance of polyethylenimine-doped MoS2 transistor. Phys. Status Solidi C 2017, 14, 1600262. [Google Scholar] [CrossRef]

- Huang, W.; Guo, P.; Zeng, L.; Li, R.; Wang, B.; Wang, G.; Zhang, X.; Chang, R.P.; Yu, J.; Bedzyk, M.J. Metal composition and polyethylenimine doping capacity effects on semiconducting metal oxide–polymer blend charge transport. J. Am. Chem. Soc. 2018, 140, 5457–5473. [Google Scholar] [CrossRef]

- Huang, W.; Zeng, L.; Yu, X.; Guo, P.; Wang, B.; Ma, Q.; Chang, R.P.; Yu, J.; Bedzyk, M.J.; Marks, T.J. Metal oxide transistors via polyethylenimine doping of the channel layer: Interplay of doping, microstructure, and charge transport. Adv. Funct. Mater. 2016, 26, 6179–6187. [Google Scholar] [CrossRef]

- Seo, Y.-M.; Jang, W.; Gu, T.; Whang, D. Highly efficient n-type doping of graphene by vacuum annealed amine-rich macromolecules. Materials 2020, 13, 2166. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Liu, Z.; Yin, Z.; Zheng, Q. Sandwich structured dielectrics for air-stable and flexible low-voltage organic transistors in ultrasensitive pressure sensing. Mater. Chem. Front. 2020, 4, 1459–1470. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, Z.; Jiang, Y.; Zheng, Q. Dielectric interface passivation of polyelectrolyte-gated organic field-effect transistors for ultrasensitive low-voltage pressure sensors in wearable applications. Mater. Today Electron. 2022, 1, 100001. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, Z.; Li, J.; Wang, Z. Transparent polymer nanoheterostructure films for flexible low-power organic transistors with high mobility, decent photostability, and ultralong-term air stability. Mater. Today Phys. 2023, 37, 101206. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, Z.; Wang, J.; Zheng, Q. Polyelectrolyte dielectrics for flexible low-voltage organic thin-film transistors in highly sensitive pressure sensing. Adv. Funct. Mater. 2019, 29, 1806092. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, Y.; Yin, Z. Low-power soft transistors triggering revolutionary electronics. Innovation 2024, 5, 100616. [Google Scholar] [CrossRef]

- Yin, Z.; Yin, M.J.; Liu, Z.; Zhang, Y.; Zhang, A.P.; Zheng, Q. Solution-processed bilayer dielectrics for flexible low-voltage organic field-effect transistors in pressure-sensing applications. Adv. Sci. 2018, 5, 1701041. [Google Scholar] [CrossRef] [PubMed]

- Laudari, A.; Pickett, A.; Shahedipour-Sandvik, F.; Hogan, K.; Anthony, J.E.; He, X.; Guha, S. Textured Poling of the Ferroelectric Dielectric Layer for Improved Organic Field-Effect Transistors. Adv. Mater. Interfaces 2019, 6, 1801787. [Google Scholar] [CrossRef]

- Kwon, H.-j.; Tang, X.; Shin, S.; Hong, J.; Jeong, W.; Jo, Y.; An, T.K.; Lee, J.; Kim, S.H. Facile photo-cross-linking system for polymeric gate dielectric materials toward solution-processed organic field-effect transistors: Role of a cross-linker in various polymer types. ACS Appl. Mater. Interfaces 2020, 12, 30600–30615. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Chen, Y.; Wu, G.; Li, D.; Tu, L.; Sun, S.; Shen, H.; Lin, T.; Xiao, Y.; Tang, M. Two-dimensional negative capacitance transistor with polyvinylidene fluoride-based ferroelectric polymer gating. npj 2D Mater. Appl. 2017, 1, 38. [Google Scholar] [CrossRef]

- Liu, X.; Liang, R.; Gao, G.; Pan, C.; Jiang, C.; Xu, Q.; Luo, J.; Zou, X.; Yang, Z.; Liao, L. MoS2 Negative-Capacitance Field-Effect Transistors with Subthreshold Swing below the Physics Limit. Adv. Mater. 2018, 30, 1800932. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Lee, C.; Kang, J.; Lee, C.; Lee, S.M.; Oh, J.; Choi, S.Y.; Im, S.G. A sub-20 nm organic/inorganic hybrid dielectric for ultralow-power organic thin-film transistor (OTFT) with enhanced operational stability. Small 2022, 18, 2203165. [Google Scholar] [CrossRef]

- Jia, X.; Fuentes-Hernandez, C.; Wang, C.-Y.; Park, Y.; Kippelen, B. Stable organic thin-film transistors. Sci. Adv. 2018, 4, eaao1705. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, S.; Miao, J.; Yu, Z.; Wang, C. Fully printed stretchable thin-film transistors and integrated logic circuits. ACS Nano 2016, 10, 11459–11468. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Wang, P.; Huang, H.; Wu, G.; Tian, B.; Hong, Z.; Wang, Y.; Sun, S.; Shen, H. Optoelectronic properties of few-layer MoS2 FET gated by ferroelectric relaxor polymer. ACS Appl. Mater. Interfaces 2016, 8, 32083–32088. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, T.; Hori, N.; Nakajima, T.; Kawae, T. Electrical characteristics of MoS2 field-effect transistor with ferroelectric vinylidene fluoride-trifluoroethylene copolymer gate structure. Appl. Phys. Lett. 2016, 108, 132903. [Google Scholar] [CrossRef]

- Li, D.; Wang, X.; Chen, Y.; Zhu, S.; Gong, F.; Wu, G.; Meng, C.; Liu, L.; Wang, L.; Lin, T. The ambipolar evolution of a high-performance WSe2 transistor assisted by a ferroelectric polymer. Nanotechnology 2018, 29, 105202. [Google Scholar] [CrossRef]

- Tian, B.; Liu, L.; Yan, M.; Wang, J.; Zhao, Q.; Zhong, N.; Xiang, P.; Sun, L.; Peng, H.; Shen, H. A robust artificial synapse based on organic ferroelectric polymer. Adv. Electron. Mater. 2019, 5, 1800600. [Google Scholar] [CrossRef]

- Wang, X.; Wang, P.; Wang, J.; Hu, W.; Zhou, X.; Guo, N.; Huang, H.; Sun, S.; Shen, H.; Lin, T. Ultrasensitive and broadband MoS2 photodetector driven by ferroelectrics. Adv. Mater. 2015, 27, 6575–6581. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Kizu, T.; Song, L.; Zhang, Y.; Jiang, S.; Qian, J.; Wang, Q.; Shi, Y.; Zheng, Y.; Nabatame, T. High-performance non-volatile field-effect transistor memories using an amorphous oxide semiconductor and ferroelectric polymer. J. Mater. Chem. C 2016, 4, 7917–7923. [Google Scholar] [CrossRef]

- Wen, J.; Yan, C.; Sun, Z. The application of a high-κ polymer dielectric in graphene transistors. Adv. Electron. Mater. 2020, 6, 2000031. [Google Scholar] [CrossRef]

- Chu, F.J.; Chen, Y.C.; Shih, L.C.; Mao, S.C.; Chen, J.S. Reconfigurable Physical Reservoir Enabled by Polarization of Ferroelectric Polymer P (VDF–TrFE) and Interface Charge-Trapping/Detrapping in Dual-Gate IGZO Transistor. Adv. Funct. Mater. 2024, 34, 2310951. [Google Scholar] [CrossRef]

- Jiao, H.; Wang, X.; Wu, S.; Chen, Y.; Chu, J.; Wang, J. Ferroelectric field effect transistors for electronics and optoelectronics. Appl. Phys. Rev. 2023, 10, 011310. [Google Scholar] [CrossRef]

- Li, L.; Liu, X.; Guo, J.; Ji, H.; Zhang, F.; Lou, Z.; Qin, L.; Hu, Y.; Hou, Y.; Teng, F. Low-operating-voltage two-dimensional tin perovskite field-effect transistors with multilayer gate dielectrics based on a fluorinated copolymer. J. Phys. Chem. Lett. 2023, 14, 2223–2233. [Google Scholar] [CrossRef]

- Luo, Z.D.; Yang, M.M.; Liu, Y.; Alexe, M. Emerging opportunities for 2D semiconductor/ferroelectric transistor-structure devices. Adv. Mater. 2021, 33, 2005620. [Google Scholar] [CrossRef]

- Niu, X.; Tian, B.; Zhu, Q.; Dkhil, B.; Duan, C. Ferroelectric polymers for neuromorphic computing. Appl. Phys. Rev. 2022, 9, 021309. [Google Scholar] [CrossRef]

- Yang, D.; Moon, Y.; Han, N.; Lee, M.; Beak, J.; Lee, S.-H.; Kim, D.-Y. Solution-processable low-voltage carbon nanotube field-effect transistors with high-k relaxor ferroelectric polymer gate insulator. Nanotechnology 2024, 35, 295202. [Google Scholar] [CrossRef]

- Faraji, S.; Hashimoto, T.; Turner, M.L.; Majewski, L.A. Solution-processed nanocomposite dielectrics for low voltage operated OFETs. Org. Electron. 2015, 17, 178–183. [Google Scholar] [CrossRef]

- Li, J.; Yan, F. Solution-processable low-voltage and flexible floating-gate memories based on an n-type polymer semiconductor and high-k polymer gate dielectrics. ACS Appl. Mater. Interfaces 2014, 6, 12815–12820. [Google Scholar] [CrossRef] [PubMed]

- Perinot, A.; Scuratti, F.; Scaccabarozzi, A.D.; Tran, K.; Salazar-Rios, J.M.; Loi, M.A.; Salvatore, G.; Fabiano, S.; Caironi, M. Solution-Processed Polymer Dielectric Interlayer for Low-Voltage, Unipolar n-Type Organic Field-Effect Transistors. ACS Appl. Mater. Interfaces 2023, 15, 56095–56105. [Google Scholar] [CrossRef] [PubMed]

- Ramos, B.; Lopes, M.; Buso, D.; Ternisien, M. Performance enhancement in N-channel organic field-effect transistors using ferroelectric material as a gate dielectric. IEEE Trans. Nanotechnol. 2017, 16, 773–777. [Google Scholar] [CrossRef]

- Tang, W.; Zhao, J.; Huang, Y.; Ding, L.; Li, Q.; Li, J.; You, P.; Yan, F.; Guo, X. Bias stress stability improvement in solution-processed low-voltage organic field-effect transistors using relaxor ferroelectric polymer gate dielectric. IEEE Electron. Device Lett. 2017, 38, 748–751. [Google Scholar] [CrossRef]

- Thuau, D.; Kallitsis, K.; Ha, S.; Bargain, F.; Soulestin, T.; Pecastaings, G.; Tencé-Girault, S.; Domingues Dos Santos, F.; Hadziioannou, G. High and temperature-independent dielectric constant dielectrics from PVDF-based terpolymer and copolymer blends. Adv. Electron. Mater. 2020, 6, 1901250. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Z.; Yang, L.; Qiao, Y.; Chang, D.; Yan, Y.; Wu, Z.; Hu, Z.; Zhang, J.; Lu, X. Constrain Effect of Charge Traps in Organic Field-Effect Transistors with Ferroelectric Polymer as a Dielectric Interfacial Layer. ACS Appl. Mater. Interfaces 2022, 14, 3095–3102. [Google Scholar] [CrossRef]

- Xu, M.; Xiang, L.; Xu, T.; Wang, W.; Xie, W.; Zhou, D. Low-voltage operating flexible ferroelectric organic field-effect transistor nonvolatile memory with a vertical phase separation P (VDF-TrFE-CTFE)/PS dielectric. Appl. Phys. Lett. 2017, 111, 183302. [Google Scholar] [CrossRef]

- Adhikari, J.M.; Gadinski, M.R.; Li, Q.; Sun, K.G.; Reyes-Martinez, M.A.; Iagodkine, E.; Briseno, A.L.; Jackson, T.N.; Wang, Q.; Gomez, E.D. Controlling Chain Conformations of High-k Fluoropolymer Dielectrics to Enhance Charge Mobilities in Rubrene Single-Crystal Field-Effect Transistors. Adv. Mater. 2016, 28, 10095–10102. [Google Scholar] [CrossRef]

- Shin, E.Y.; Cho, H.J.; Jung, S.; Yang, C.; Noh, Y.Y. A high-k fluorinated P (VDF-TrFE)-g-PMMA gate dielectric for high-performance flexible field-effect transistors. Adv. Funct. Mater. 2018, 28, 1704780. [Google Scholar] [CrossRef]

- Shin, Y.J.; Kang, S.J.; Jung, H.J.; Park, Y.J.; Bae, I.; Choi, D.H.; Park, C. Chemically cross-linked thin poly (vinylidene fluoride-co-trifluoroethylene) films for nonvolatile ferroelectric polymer memory. ACS Appl. Mater. Interfaces 2011, 3, 582–589. [Google Scholar] [CrossRef]

- Cho, H.; Jin, H.J.; Lee, S.; Jeon, S.; Cho, Y.; Park, S.; Jang, M.; Widiapradja, L.J.; Ryu, D.Y.; Park, J.H. 5 nm Ultrathin Crystalline Ferroelectric P (VDF-TrFE)-Brush Tuned for Hysteresis-Free Sub 60 mV dec−1 Negative-Capacitance Transistors. Adv. Mater. 2023, 35, 2300478. [Google Scholar] [CrossRef]

- Jo, J.; Shin, C. Negative capacitance field effect transistor with hysteresis-free sub-60-mV/decade switching. IEEE Electron. Device Lett. 2016, 37, 245–248. [Google Scholar] [CrossRef]

- McGuire, F.A.; Cheng, Z.; Price, K.; Franklin, A.D. Sub-60 mV/decade switching in 2D negative capacitance field-effect transistors with integrated ferroelectric polymer. Appl. Phys. Lett. 2016, 109, 093101. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Y.; Ding, S.; Wang, J.; Bao, W.; Zhang, D.W.; Zhou, P. 2D negative capacitance field-effect transistor with organic ferroelectrics. Nanotechnology 2018, 29, 244004. [Google Scholar] [CrossRef] [PubMed]

- Ha, Y.-G.; Everaerts, K.; Hersam, M.C.; Marks, T.J. Hybrid gate dielectric materials for unconventional electronic circuitry. Acc. Chem. Res. 2014, 47, 1019–1028. [Google Scholar] [CrossRef]

- Ortiz, R.P.; Facchetti, A.; Marks, T.J. High-k organic, inorganic, and hybrid dielectrics for low-voltage organic field-effect transistors. Chem. Rev. 2010, 110, 205–239. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, W.; Li, M.; He, G.; Guo, X. Interface engineering in organic field-effect transistors: Principles, applications, and perspectives. Chem. Rev. 2020, 120, 2879–2949. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.S.; Shin, J.M.; Jeon, P.J.; Lee, J.; Kim, J.S.; Hwang, H.C.; Park, E.; Yoon, W.; Ju, S.Y.; Im, S. Few-Layer MoS2–Organic Thin-Film Hybrid Complementary Inverter Pixel Fabricated on a Glass Substrate. Small 2015, 11, 2132–2138. [Google Scholar] [CrossRef]

- Li, Q.; Li, S.; Yang, D.; Su, W.; Wang, Y.; Zhou, W.; Liu, H.; Xie, S. Designing hybrid gate dielectric for fully printing high-performance carbon nanotube thin film transistors. Nanotechnology 2017, 28, 435203. [Google Scholar] [CrossRef]

- Seong, H.; Choi, J.; Kim, B.J.; Park, H.; Im, S.G. Vapor-phase synthesis of sub-15 nm hybrid gate dielectrics for organic thin film transistors. J. Mater. Chem. C 2017, 5, 4463–4470. [Google Scholar] [CrossRef]

- Sun, Q.J.; Zhuang, J.; Yan, Y.; Zhou, Y.; Han, S.T.; Zhou, L.; Roy, V.A. Investigation on the mobility and stability in organic thin film transistors consisting of bilayer gate dielectrics. Phys. Status Solidi A 2016, 213, 79–84. [Google Scholar] [CrossRef]

- Yoon, M.; Ko, K.R.; Min, S.-W.; Im, S. Polymer/oxide bilayer dielectric for hysteresis-minimized 1 V operating 2D TMD transistors. RSC Adv. 2018, 8, 2837–2843. [Google Scholar] [CrossRef] [PubMed]

- Bulgarevich, K.; Sakamoto, K.; Yasuda, T.; Minari, T.; Takeuchi, M. Operational Stability Enhancement of Polymeric Organic Field-Effect Transistors by Amorphous Perfluoropolymers Chemically Anchored to Gate Dielectric Surfaces. Adv. Electron. Mater. 2020, 6, 2000161. [Google Scholar] [CrossRef]

- Held, M.; Schießl, S.P.; Miehler, D.; Gannott, F.; Zaumseil, J. Polymer/metal oxide hybrid dielectrics for low voltage field-effect transistors with solution-processed, high-mobility semiconductors. Appl. Phys. Lett. 2015, 107, 083301. [Google Scholar] [CrossRef]

- Kim, G.; Fuentes-Hernandez, C.; Jia, X.; Kippelen, B. Organic thin-film transistors with a bottom bilayer gate dielectric having a low operating voltage and high operational stability. ACS Appl. Electron. Mater. 2020, 2, 2813–2818. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Fuentes-Hernandez, C.; Chou, W.-F.; Kippelen, B. Top-gate organic field-effect transistors fabricated on paper with high operational stability. Org. Electron. 2017, 41, 340–344. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Fuentes-Hernandez, C.; Liu, J.-C.; Dindar, A.; Choi, S.; Youngblood, J.P.; Moon, R.J.; Kippelen, B. Stable low-voltage operation top-gate organic field-effect transistors on cellulose nanocrystal substrates. ACS Appl. Mater. Interfaces 2015, 7, 4804–4808. [Google Scholar] [CrossRef] [PubMed]

- Hwang, D.K.; Fuentes-Hernandez, C.; Kim, J.; Potscavage, W.J.; Kim, S.J.; Kippelen, B. Top-gate organic field-effect transistors with high environmental and operational stability. Adv. Mater. 2011, 10, 1293–1298. [Google Scholar] [CrossRef]

- Song, W.G.; Kwon, H.J.; Park, J.; Yeo, J.; Kim, M.; Park, S.; Yun, S.; Kyung, K.U.; Grigoropoulos, C.P.; Kim, S. High-performance flexible multilayer MoS2 transistors on solution-based polyimide substrates. Adv. Funct. Mater. 2016, 26, 2426–2434. [Google Scholar] [CrossRef]

- Kim, J.H.; Hwang, B.-U.; Kim, D.-I.; Kim, J.S.; Seol, Y.G.; Kim, T.W.; Lee, N.-E. Nanocomposites of polyimide and mixed oxide nanoparticles for high performance nanohybrid gate dielectrics in flexible thin film transistors. Electron. Mater. Lett. 2017, 13, 214–221. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Seol, Y.; Kim, T.; Lee, N.-E. High-k Nanocomposite Gate Dielectrics Highly Loaded with Inorganic Nanoparticles by Self-Assembly for Flexible Thin Film Transistors. J. Nanosci. Nanotechnol. 2016, 16, 11335–11342. [Google Scholar] [CrossRef]

- Canimkurbey, B.; Çakirlar, Ç.; Piravadili Mucur, S.; Yasin, M.; Berber, S. Influence of Al2O3 nanoparticles incorporation on the dielectric properties of solution processed PVA films for organic field effect transistor applications. J. Mater. Sci. Mater. Electron. 2019, 30, 18384–18390. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, H.; Zhang, Y.; Guan, X.; Zhang, Z.; Chen, D. Low-power flexible organic field-effect transistors with solution-processable polymer-ceramic nanoparticle composite dielectrics. Nanomaterials 2020, 10, 518. [Google Scholar] [CrossRef]

- Faraji, S.; Danesh, E.; Tate, D.J.; Turner, M.L.; Majewski, L.A. Cyanoethyl cellulose-based nanocomposite dielectric for low-voltage, solution-processed organic field-effect transistors (OFETs). J. Phys. D Appl. Phys. 2016, 49, 185102. [Google Scholar] [CrossRef]

- Lim, S.; Lee, K.H.; Kim, H.; Kim, S.H. Optimization of nanocomposite gate insulators for organic thin film transistors. Org. Electron. 2015, 17, 144–150. [Google Scholar] [CrossRef]

- Yu, Y.-Y.; Jiang, A.-H.; Lee, W.-Y. Organic/inorganic nano-hybrids with high dielectric constant for organic thin film transistor applications. Nanoscale Res. Lett. 2016, 11, 488. [Google Scholar] [CrossRef]

- Alvarado-Beltrán, C.G.; Almaral-Sánchez, J.L.; Mejia, I.; Quevedo-López, M.A.; Ramirez-Bon, R. Sol–gel PMMA–ZrO2 hybrid layers as gate dielectric for low-temperature ZnO-based thin-film transistors. ACS Omega 2017, 2, 6968–6974. [Google Scholar] [CrossRef]

- Kim, G.I.; Jung, J.; Min, W.K.; Kim, M.S.; Jung, S.; Choi, D.H.; Chung, J.; Kim, H.J. Mechanically durable organic/high-k inorganic hybrid gate dielectrics enabled by plasma-polymerization of PTFE for flexible electronics. ACS Appl. Mater. Interfaces 2022, 14, 28085–28096. [Google Scholar] [CrossRef]

- Kim, K.; Song, H.W.; Shin, K.; Kim, S.H.; Park, C.E. Photo-cross-linkable organic–inorganic hybrid gate dielectric for high performance organic thin film transistors. J. Phys. Chem. C 2016, 120, 5790–5796. [Google Scholar] [CrossRef]

- Kim, M.J.; Lee, C.; Jeong, J.; Kim, S.; Lee, T.I.; Shin, E.J.; Hwang, W.S.; Im, S.G.; Cho, B.J. Hf-and Ti-Based Organic/Inorganic Hybrid Dielectrics Synthesized via Chemical Vapor Phase for Advanced Gate Stack in Flexible Electronic Devices. Adv. Electron. Mater. 2021, 7, 2001197. [Google Scholar] [CrossRef]

- Kim, M.J.; Pak, K.; Choi, J.; Lee, T.I.; Hwang, W.S.; Im, S.G.; Cho, B.J. Ultrathin ZrO x-organic hybrid dielectric (EOT 3.2 nm) via initiated chemical vapor deposition for high-performance flexible electronics. ACS Appl. Mater. Interfaces 2019, 11, 44513–44520. [Google Scholar] [CrossRef]

- Jang, J.; Cho, W.; Kim, B.; Shin, J.H.; Kim, S.; Go, M.; Choi, S.S.; Kim, S.-W.; Kim, J.K.; Jeong, U. Design to secure temporal invariance of triboelectric sensing signals. Nano Energy 2023, 117, 108926. [Google Scholar] [CrossRef]

- Cha, S.; Cho, Y.; Kim, J.G.; Choi, H.; Ahn, D.; Sun, J.; Kang, D.s.; Pak, C.; Park, J.J. Controllable Triboelectric Series Using Gradient Positive and Negative Charge-Confinement Layer with Different Particle Sizes of Mesoporous Carbon Materials. Small Methods 2022, 6, 2101545. [Google Scholar] [CrossRef] [PubMed]

- Song, G.; Kim, Y.; Yu, S.; Kim, M.-O.; Park, S.-H.; Cho, S.M.; Velusamy, D.B.; Cho, S.H.; Kim, K.L.; Kim, J. Molecularly engineered surface triboelectric nanogenerator by self-assembled monolayers (METS). Chem. Mater. 2015, 27, 4749–4755. [Google Scholar] [CrossRef]

- Wang, C.-C.; Chang, C.-Y. Enhanced output performance and stability of triboelectric nanogenerators by employing silane-based self-assembled monolayers. J. Mater. Chem. C 2020, 8, 4542–4548. [Google Scholar] [CrossRef]

- He, W.; Qian, Y.; Lee, B.S.; Zhang, F.; Rasheed, A.; Jung, J.-E.; Kang, D.J. Ultrahigh output piezoelectric and triboelectric hybrid nanogenerators based on ZnO nanoflakes/polydimethylsiloxane composite films. ACS Appl. Mater. Interfaces 2018, 10, 44415–44420. [Google Scholar] [CrossRef]

- Aazem, I.; Mathew, D.T.; Radhakrishnan, S.; Vijoy, K.; John, H.; Mulvihill, D.M.; Pillai, S.C. Electrode materials for stretchable triboelectric nanogenerator in wearable electronics. RSC Adv. 2022, 12, 10545–10572. [Google Scholar] [CrossRef]

- Kuang, X.; Gao, Q.; Zhu, H. Effect of calcination temperature of TiO2 on the crystallinity and the permittivity of PVDF-TrFE/TiO2 composites. J. Appl. Polym. Sci. 2013, 129, 296–300. [Google Scholar] [CrossRef]

- Choi, Y.S.; Kim, S.K.; Smith, M.; Williams, F.; Vickers, M.E.; Elliott, J.A.; Kar-Narayan, S. Unprecedented dipole alignment in α-phase nylon-11 nanowires for high-performance energy-harvesting applications. Sci. Adv. 2020, 6, eaay5065. [Google Scholar] [CrossRef]

- Guo, H.; Ma, C.; Liu, X.; Tan, X. Electrical poling below coercive field for large piezoelectricity. Appl. Phys. Lett. 2013, 102, 092902. [Google Scholar] [CrossRef]

- Li, L.; Xie, L.; Pan, X. Real-time studies of ferroelectric domain switching: A review. Rep. Prog. Phys. 2019, 82, 126502. [Google Scholar] [CrossRef] [PubMed]

- Bouza, M.; Li, Y.; Wu, C.; Guo, H.; Wang, Z.L.; Fernández, F.M. Large-Area Triboelectric Nanogenerator Mass Spectrometry: Expanded Coverage, Double-Bond Pinpointing, and Supercharging. J. Am. Soc. Mass Spectrom. 2020, 31, 727–734. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Xu, L.; Bai, Y.; Wang, Z.L. Pumping up the charge density of a triboelectric nanogenerator by charge-shuttling. Nat. Commun. 2020, 11, 4203. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Xu, Q.; Zheng, Y.; Jia, X.; Qin, Y. A self-improving triboelectric nanogenerator with improved charge density and increased charge accumulation speed. Nat. Commun. 2018, 9, 3773. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Lee, J.; Han, S.; Li, Y.; Park, J.-J.; Bae, J. Output Performance Enhanced Triboelectric Nanogenerators Induced by Magnetic Ink Trapping Property Act as Wearable Sensors. ACS Omega 2024, 9, 3565–3573. [Google Scholar] [CrossRef]

- Menge, H.G.; Huynh, N.D.; Hwang, H.J.; Han, S.; Choi, D.; Park, Y.T. Designable skin-like triboelectric nanogenerators using layer-by-layer self-assembled polymeric nanocomposites. ACS Energy Lett. 2021, 6, 2451–2459. [Google Scholar] [CrossRef]

- Zhou, J.; Gao, M.; Choi, J. Enhancement of output power and durability of DLC-based sliding TENGs modified with self-assembled monolayers. ACS Appl. Electron. Mater. 2023, 5, 2853–2861. [Google Scholar] [CrossRef]

- Hajra, S.; Padhan, A.M.; Sahu, M.; Alagarsamy, P.; Lee, K.; Kim, H.J. Lead-free flexible Bismuth Titanate-PDMS composites: A multifunctional colossal dielectric material for hybrid piezo-triboelectric nanogenerator to sustainably power portable electronics. Nano Energy 2021, 89, 106316. [Google Scholar] [CrossRef]

- Han, S.A.; Seung, W.; Kim, J.H.; Kim, S.-W. Ultrathin noncontact-mode triboelectric nanogenerator triggered by giant dielectric material adaption. ACS Energy Lett. 2021, 6, 1189–1197. [Google Scholar] [CrossRef]

- Liu, J.; Yu, D.; Zheng, Z.; Huangfu, G.; Guo, Y. Lead-free BiFeO3 film on glass fiber fabric: Wearable hybrid piezoelectric-triboelectric nanogenerator. Ceram. Int. 2021, 47, 3573–3579. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, W.; Deng, L.; Zhang, H. A triboelectric nanogenerator based on temperature-stable high dielectric BaTiO3-based ceramic powder for energy harvesting. Nano Energy 2021, 87, 106176. [Google Scholar] [CrossRef]

- Küchler, A. High Voltage Engineering: Fundamentals-Technology-Applications; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Wang, S.; Xie, Y.; Niu, S.; Lin, L.; Liu, C.; Zhou, Y.S.; Wang, Z.L. Maximum Surface Charge Density for Triboelectric Nanogenerators Achieved by Ionized-Air Injection: Methodology and Theoretical Understanding. Adv. Mater. 2014, 26, 6720–6728. [Google Scholar] [CrossRef]

- Shin, S.-H.; Bae, Y.E.; Moon, H.K.; Kim, J.; Choi, S.-H.; Kim, Y.; Yoon, H.J.; Lee, M.H.; Nah, J. Formation of Triboelectric Series via Atomic-Level Surface Functionalization for Triboelectric Energy Harvesting. ACS Nano 2017, 11, 6131–6138. [Google Scholar] [CrossRef]

- Patnam, H.; Dudem, B.; Graham, S.A.; Yu, J.S. High-performance and robust triboelectric nanogenerators based on optimal microstructured poly (vinyl alcohol) and poly (vinylidene fluoride) polymers for self-powered electronic applications. Energy 2021, 223, 120031. [Google Scholar] [CrossRef]

- Chen, F.; Wu, Y.; Ding, Z.; Xia, X.; Li, S.; Zheng, H.; Diao, C.; Yue, G.; Zi, Y. A novel triboelectric nanogenerator based on electrospun polyvinylidene fluoride nanofibers for effective acoustic energy harvesting and self-powered multifunctional sensing. Nano Energy 2019, 56, 241–251. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.H.; Ryu, H.; Lee, J.H.; Khan, U.; Kim, H.; Kwak, S.S.; Kim, S.W. High-performance piezoelectric, pyroelectric, and triboelectric nanogenerators based on P (VDF-TrFE) with controlled crystallinity and dipole alignment. Adv. Funct. Mater. 2017, 27, 1700702. [Google Scholar] [CrossRef]

- Granzow, T.; Kounga, A.; Aulbach, E.; Rödel, J. Electromechanical poling of piezoelectrics. Appl. Phys. Lett. 2006, 88, 252907. [Google Scholar] [CrossRef]

- Kamel, T.M.; de With, G. Poling of hard ferroelectric PZT ceramics. J. Eur. Ceram. Soc. 2008, 28, 1827–1838. [Google Scholar] [CrossRef]

- Park, Y.; Shin, Y.-E.; Park, J.; Lee, Y.; Kim, M.P.; Kim, Y.-R.; Na, S.; Ghosh, S.K.; Ko, H. Ferroelectric multilayer nanocomposites with polarization and stress concentration structures for enhanced triboelectric performances. ACS Nano 2020, 14, 7101–7110. [Google Scholar] [CrossRef]

- Pei, J.-Y.; Zhong, S.-L.; Zhao, Y.; Yin, L.-J.; Feng, Q.-K.; Huang, L.; Liu, D.-F.; Zhang, Y.-X.; Dang, Z.-M. All-organic dielectric polymer films exhibiting superior electric breakdown strength and discharged energy density by adjusting the electrode–dielectric interface with an organic nano-interlayer. Energy Environ. Sci. 2021, 14, 5513–5522. [Google Scholar] [CrossRef]

- Lee, K.Y.; Kim, S.K.; Lee, J.H.; Seol, D.; Gupta, M.K.; Kim, Y.; Kim, S.W. Controllable charge transfer by ferroelectric polarization mediated triboelectricity. Adv. Funct. Mater. 2016, 26, 3067–3073. [Google Scholar] [CrossRef]

- Bai, P.; Zhu, G.; Zhou, Y.S.; Wang, S.; Ma, J.; Zhang, G.; Wang, Z.L. Dipole-moment-induced effect on contact electrification for triboelectric nanogenerators. Nano Res. 2014, 7, 990–997. [Google Scholar] [CrossRef]

- Shin, K.S.; Kim, T.Y.; Yoon, G.C.; Gupta, M.K.; Kim, S.K.; Seung, W.; Kim, H.; Kim, S.; Kim, S.; Kim, S.W. Ferroelectric Coupling Effect on the Energy-Band Structure of Hybrid Heterojunctions with Self-Organized P (VDF-TrFE) Nanomatrices. Adv. Mater. 2014, 26, 5619–5625. [Google Scholar] [CrossRef] [PubMed]

- Cui, N.; Gu, L.; Lei, Y.; Liu, J.; Qin, Y.; Ma, X.; Hao, Y.; Wang, Z.L. Dynamic behavior of the triboelectric charges and structural optimization of the friction layer for a triboelectric nanogenerator. ACS Nano 2016, 10, 6131–6138. [Google Scholar] [CrossRef]

- Kornfeld, M. Frictional electrification. J. Phys. D Appl. Phys. 1976, 9, 1183. [Google Scholar] [CrossRef]

- Park, H.-W.; Huynh, N.D.; Kim, W.; Lee, C.; Nam, Y.; Lee, S.; Chung, K.-B.; Choi, D. Electron blocking layer-based interfacial design for highly-enhanced triboelectric nanogenerators. Nano Energy 2018, 50, 9–15. [Google Scholar] [CrossRef]

- Lee, J.-H.; Hinchet, R.; Kim, T.Y.; Ryu, H.; Seung, W.; Yoon, H.-J.; Kim, S.-W. Control of Skin Potential by Triboelectrification with Ferroelectric Polymers. Adv. Mater. 2015, 27, 5553–5558. [Google Scholar] [CrossRef]

- Khan, U.; Kim, T.H.; Ryu, H.; Seung, W.; Kim, S.W. Graphene tribotronics for electronic skin and touch screen applications. Adv. Mater. 2017, 29, 1603544. [Google Scholar] [CrossRef]

- Kim, Y.W.; Lee, H.B.; Yoon, J.; Park, S.-H. 3D customized triboelectric nanogenerator with high performance achieved via charge-trapping effect and strain-mismatching friction. Nano Energy 2022, 95, 107051. [Google Scholar] [CrossRef]

- Wu, C.; Kim, T.W.; Choi, H.Y. Reduced graphene-oxide acting as electron-trapping sites in the friction layer for giant triboelectric enhancement. Nano Energy 2017, 32, 542–550. [Google Scholar] [CrossRef]

- Qiao, Y.; Yin, X.; Zhu, T.; Li, H.; Tang, C. Dielectric polymers with novel chemistry, compositions and architectures. Prog. Polym. Sci. 2018, 80, 153–162. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, Z.; Tseng, J.-K.; Treufeld, I.; Liu, X.; Litt, M.H.; Zhu, L. Achieving high dielectric constant and low loss property in a dipolar glass polymer containing strongly dipolar and small-sized sulfone groups. ACS Appl. Mater. Interfaces 2015, 7, 5248–5257. [Google Scholar] [CrossRef] [PubMed]

- Koutsiaki, C.; Kaimakamis, T.; Zachariadis, A.; Papamichail, A.; Kamaraki, C.; Fachouri, S.; Gravalidis, C.; Laskarakis, A.; Logothetidis, S. Efficient combination of Roll-to-Roll compatible techniques towards the large area deposition of a polymer dielectric film and the solution-processing of an organic semiconductor for the field-effect transistors fabrication on plastic substrate. Org. Electron. 2019, 73, 231–239. [Google Scholar] [CrossRef]

- Yu, S.J.; Pak, K.; Kwak, M.J.; Joo, M.; Kim, B.J.; Oh, M.S.; Baek, J.; Park, H.; Choi, G.; Kim, D.H. Initiated chemical vapor deposition: A versatile tool for various device applications. Adv. Eng. Mater. 2018, 20, 1700622. [Google Scholar] [CrossRef]

- Chun, J.; Kim, J.W.; Jung, W.-s.; Kang, C.-Y.; Kim, S.-W.; Wang, Z.L.; Baik, J.M. Mesoporous pores impregnated with Au nanoparticles as effective dielectrics for enhancing triboelectric nanogenerator performance in harsh environments. Energy Environ. Sci. 2015, 8, 3006–3012. [Google Scholar] [CrossRef]

- Kwak, S.S.; Kim, S.M.; Ryu, H.; Kim, J.; Khan, U.; Yoon, H.-J.; Jeong, Y.H.; Kim, S.-W. Butylated melamine formaldehyde as a durable and highly positive friction layer for stable, high output triboelectric nanogenerators. Energy Environ. Sci. 2019, 12, 3156–3163. [Google Scholar] [CrossRef]

- Lee, Y.; Cha, S.H.; Kim, Y.-W.; Choi, D.; Sun, J.-Y. Transparent and attachable ionic communicators based on self-cleanable triboelectric nanogenerators. Nat. Commun. 2018, 9, 1804. [Google Scholar] [CrossRef]

| Active Materials (Method) | Resistance on/off Ratio | Switching Cycles | Retention Time (s) | Working Temperature (°C) | Air Stability (Days) | Biodegradable | [Ref.] |

|---|---|---|---|---|---|---|---|

| PVA (Spin-coating) | N/A | 5 × 103 | 104 | From 20 to 80 | N/A | ○ | [71] |

| PPT−NMI+Br− 1 (Spin-coating) | N/A | 102 | 104 | Room temperature | N/A | ○ | [10] |

| MDMO-PPV (Spin-coating) | N/A | 104 | 104 | From −196 to 300 | N/A | ✕ | [79] |

| PEI (Spin-coating) | ~105 | 103 | 105 | From 25 to 150 | N/A | ✕ | [76] |

| PTPA (Spin-coating) | ~108 | <10 | 8 × 103 | From −243 to 117 | N/A | ✕ | [77] |

| PEI-AgClO4 (Spin-coating) | ~103 | 5 × 102 | 7 × 102 | Room temperature | 30 | ✕ | [83] |

| BPQDs@PDA-PVP 3 (Spin-coating) | N/A | 2 × 102 | 2 × 104 | Room temperature | 90 | ✕ | [84] |

| pV3D3 (iCVD) | ~109 | 105 | 105 | From 27 to 85 | N/A | ✕ | [51] |

| pV3D3 (iCVD) | ~108 | 105 | 105 | From 27 to 87 | 27 | ✕ | [85] |

| pEDGMA 2 (iCVD) | 2.5 × 102 | 5 × 102 | 107 | Room temperature | N/A | ✕ | [86] |

| Charge Trap Structure | Device Type | Current on/off Ratio | Memory Window (Operating Voltage) | Switching Cycles | Retention Time (s) | [Ref.] |