Multi-Channel Electrical Discharge Machining of Ti-6Al-4V Enabled by Semiconductor Potential Differences

Abstract

1. Introduction

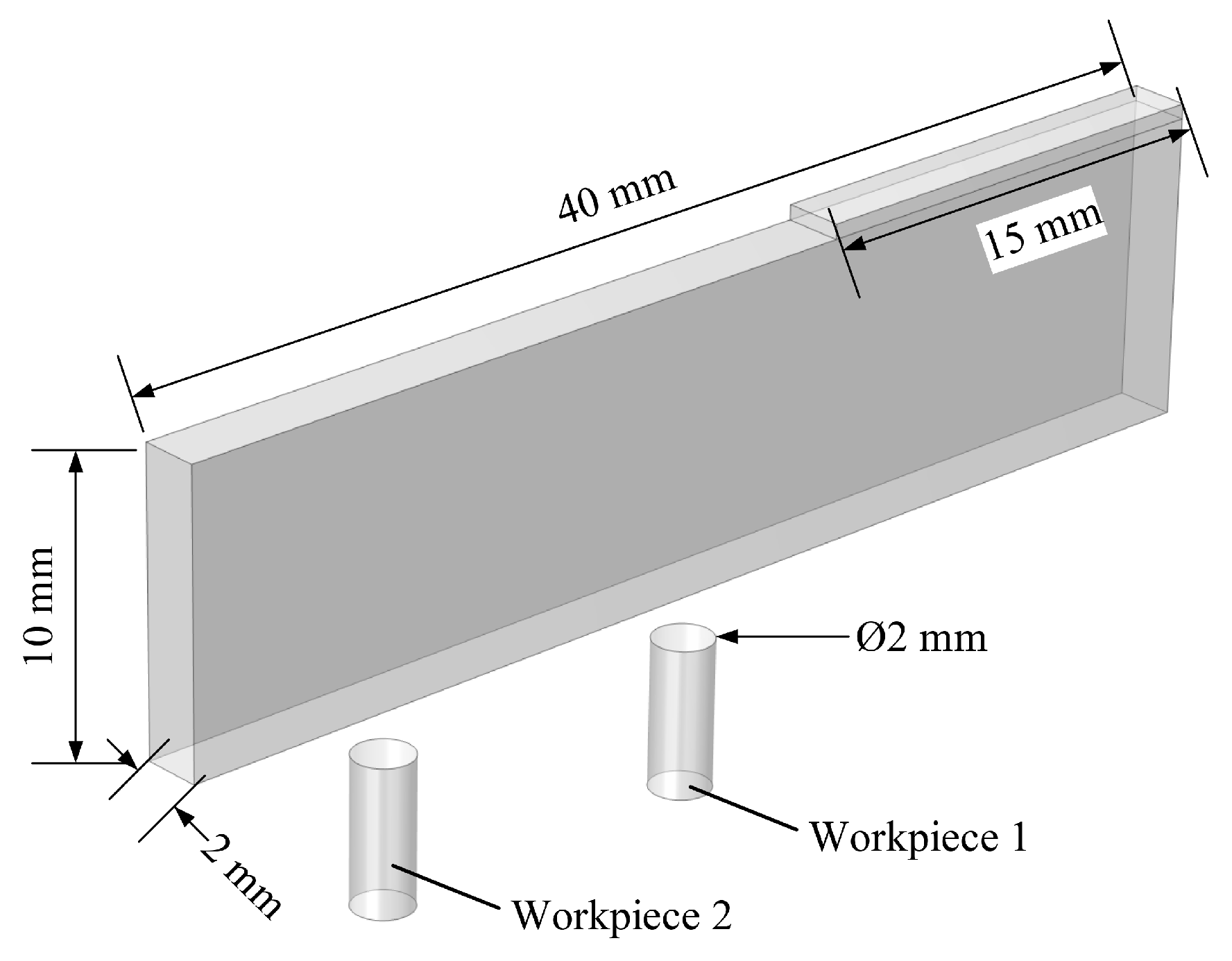

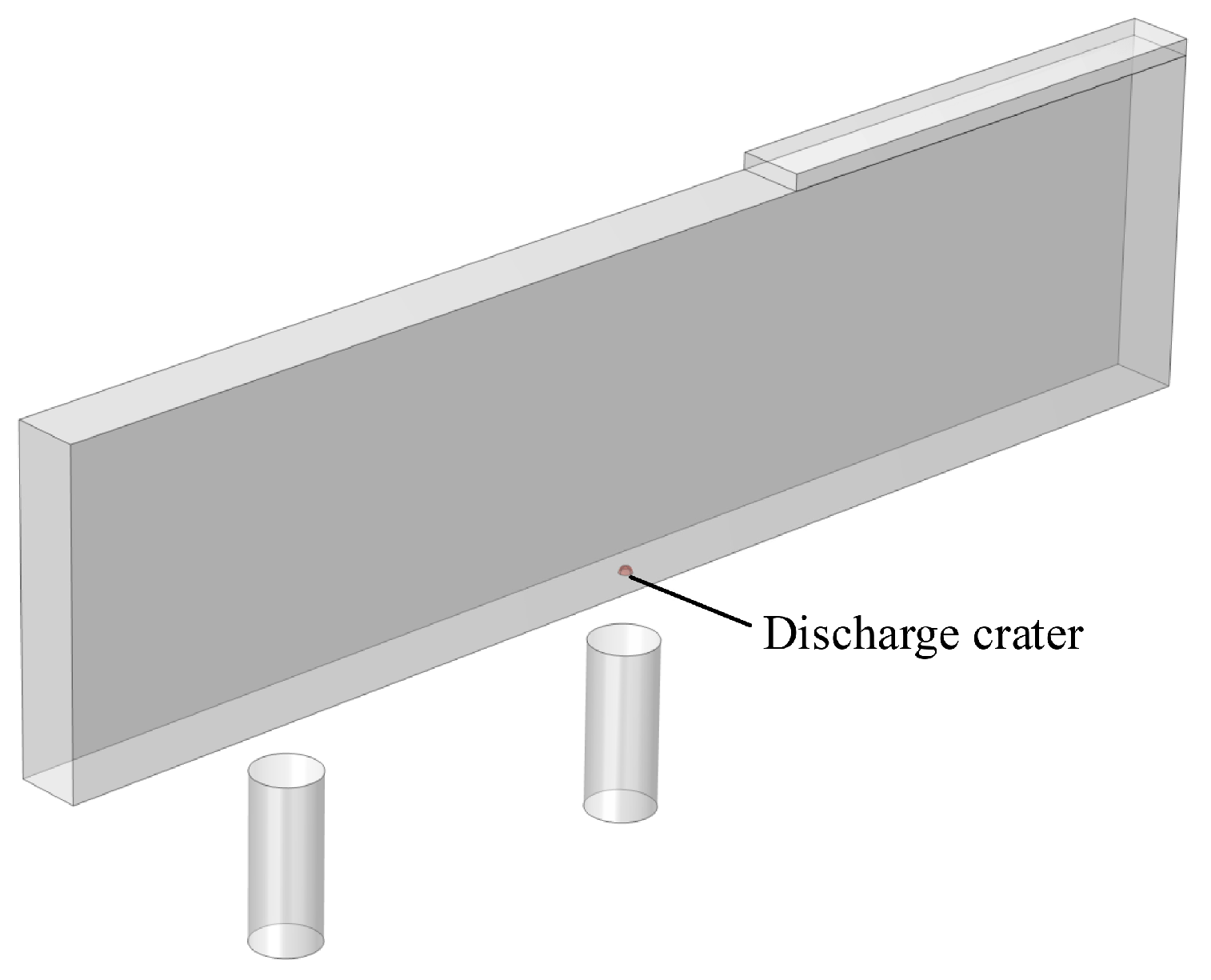

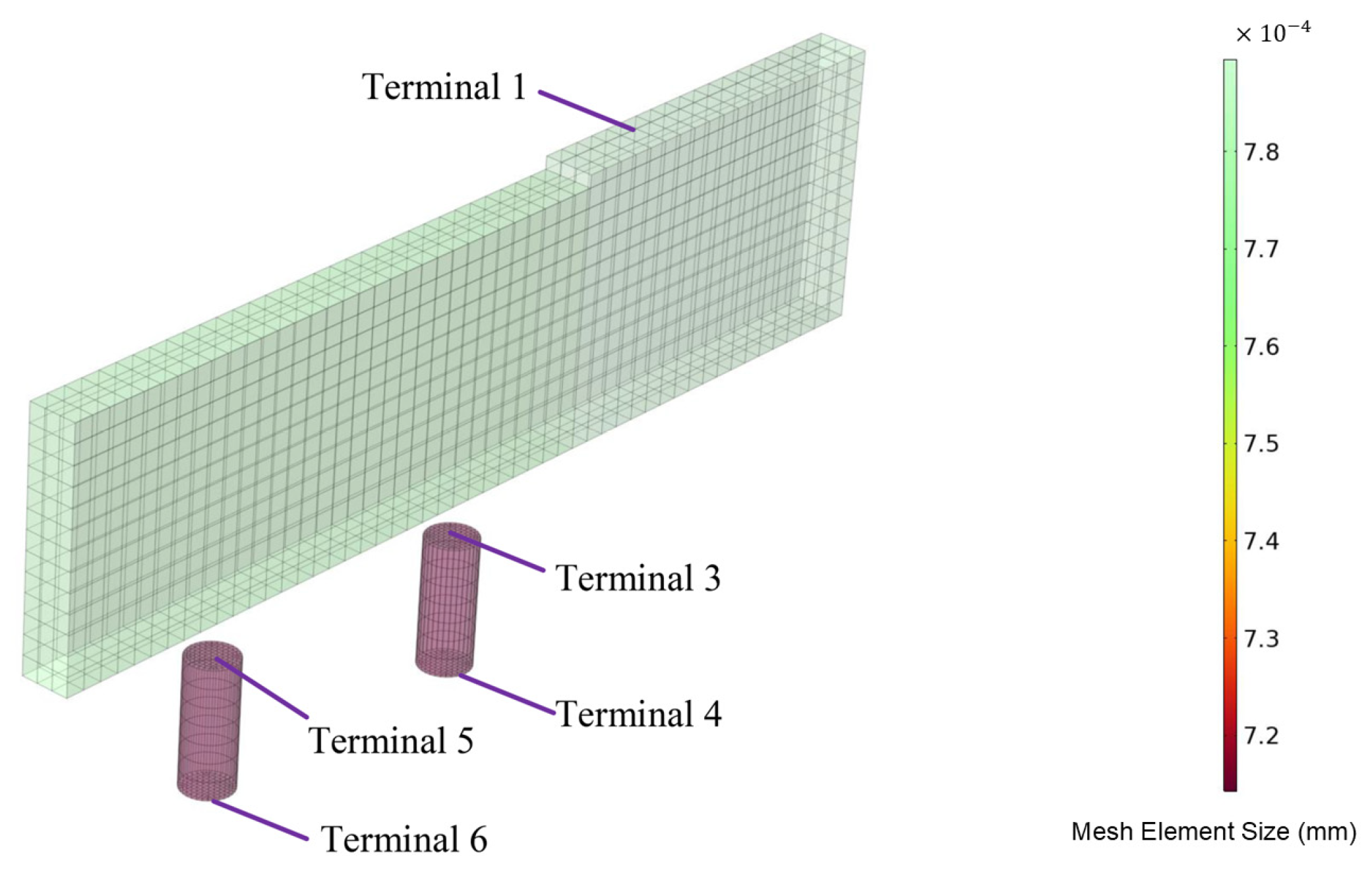

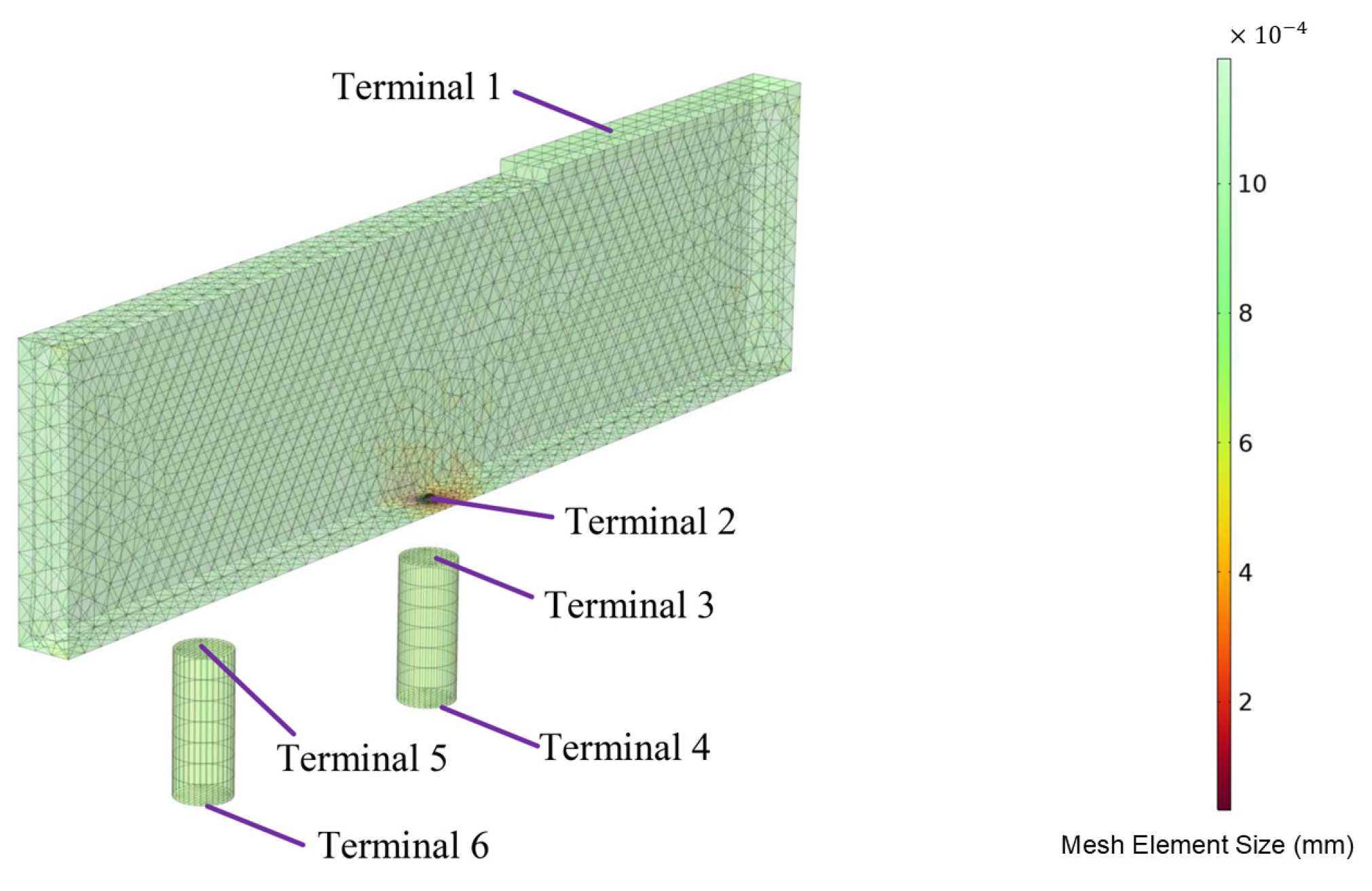

2. Materials and Methods

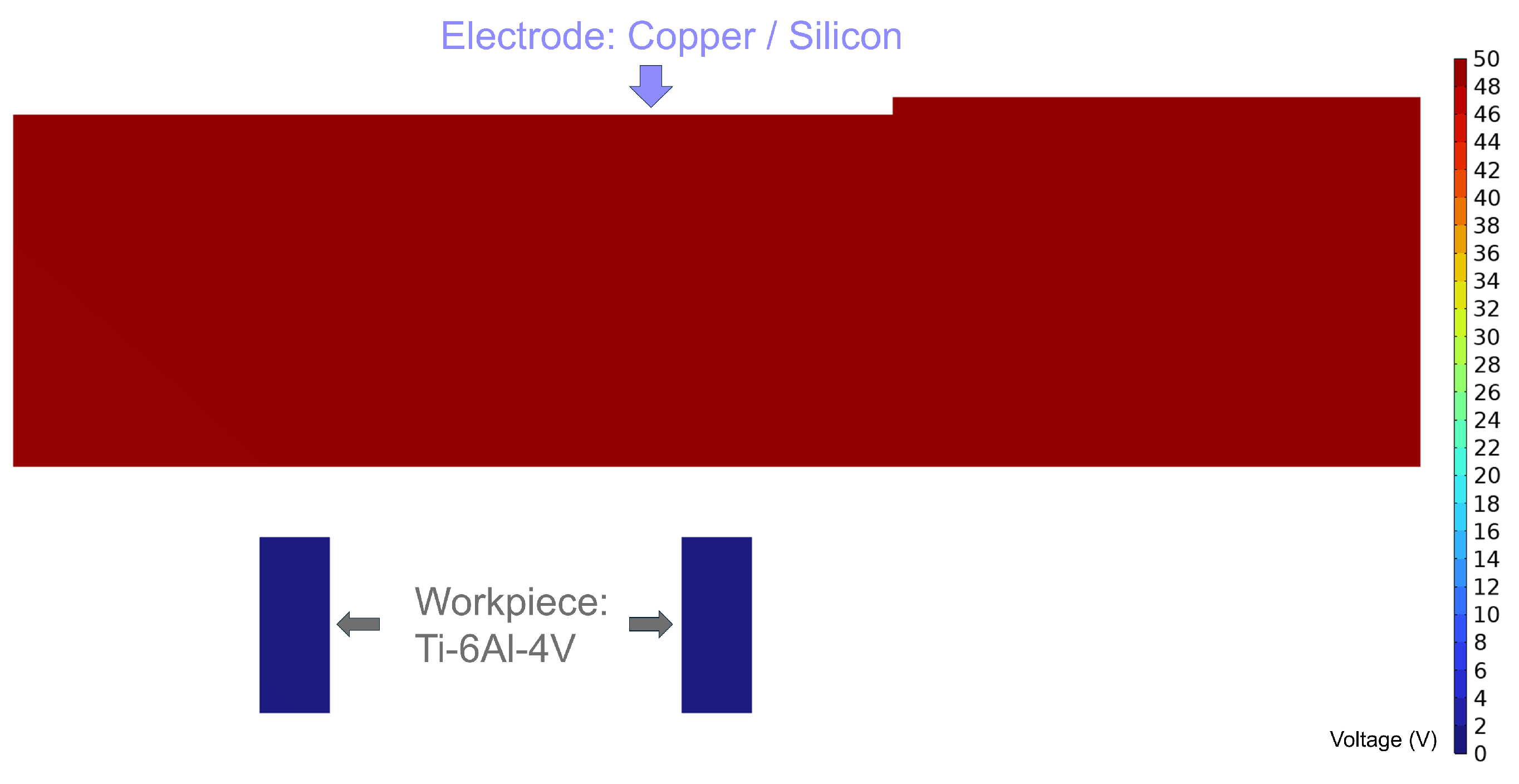

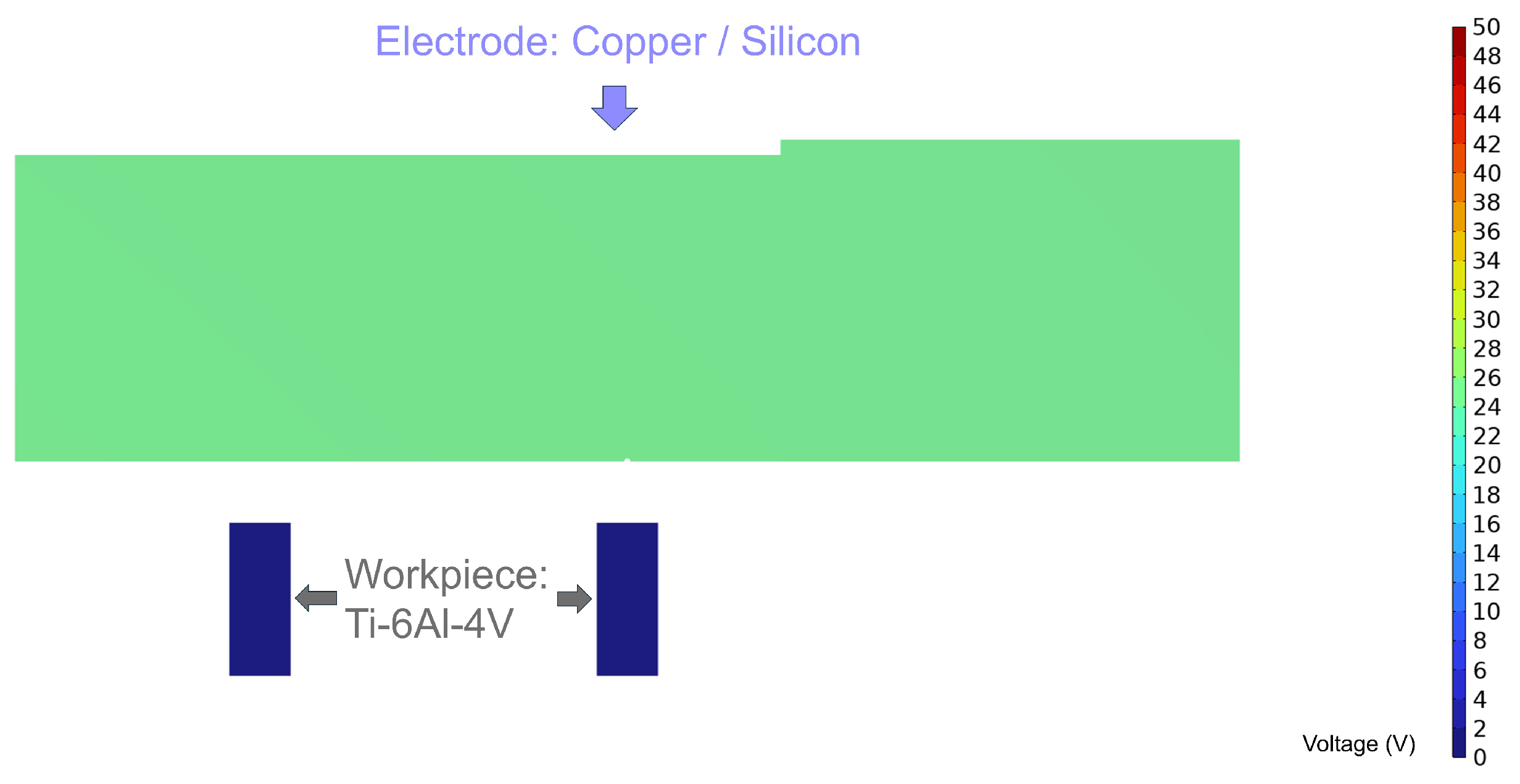

3. Experiment Results

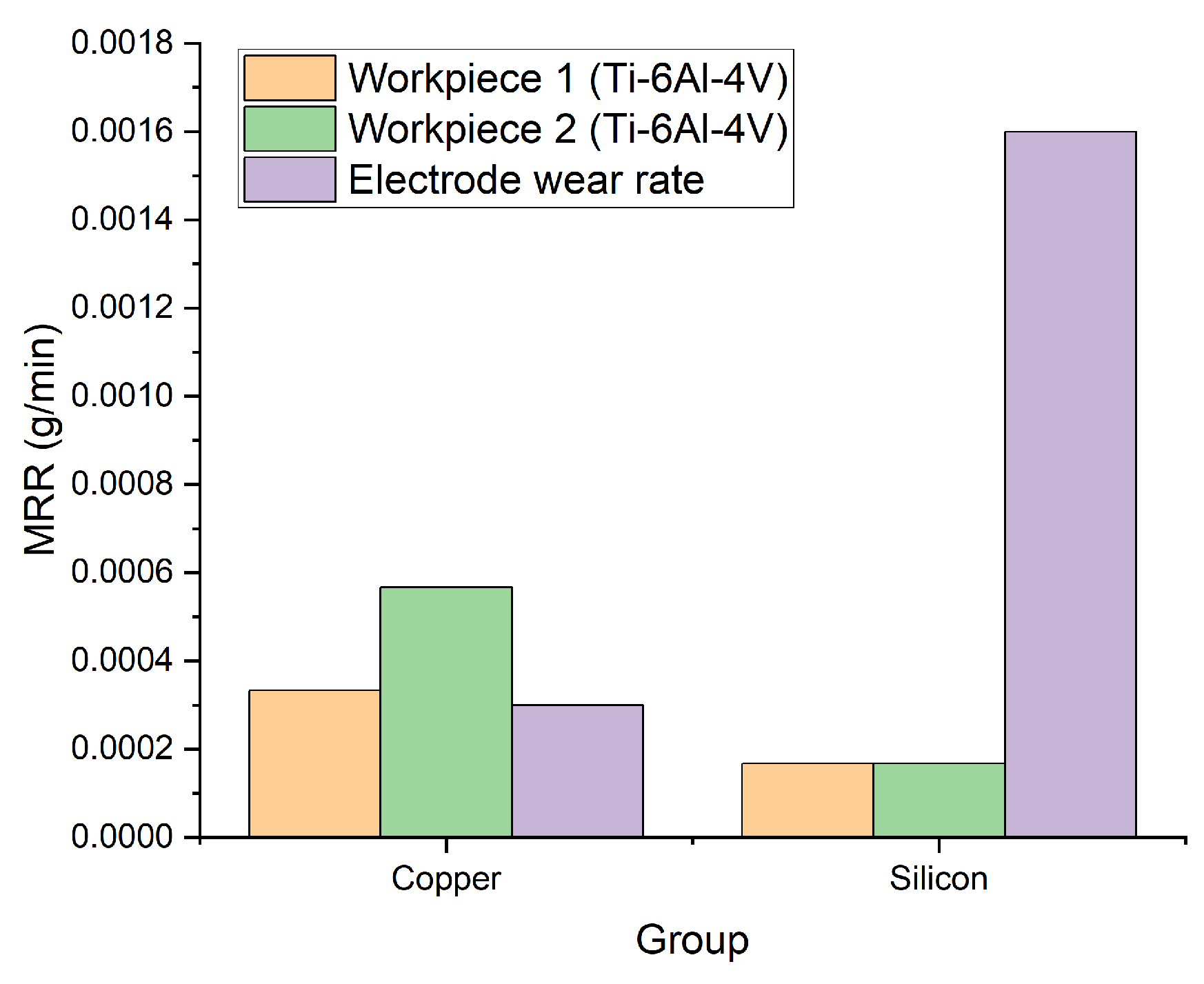

3.1. Material Removal Rate (MRR) and Electrode Wear Rate (EWR)

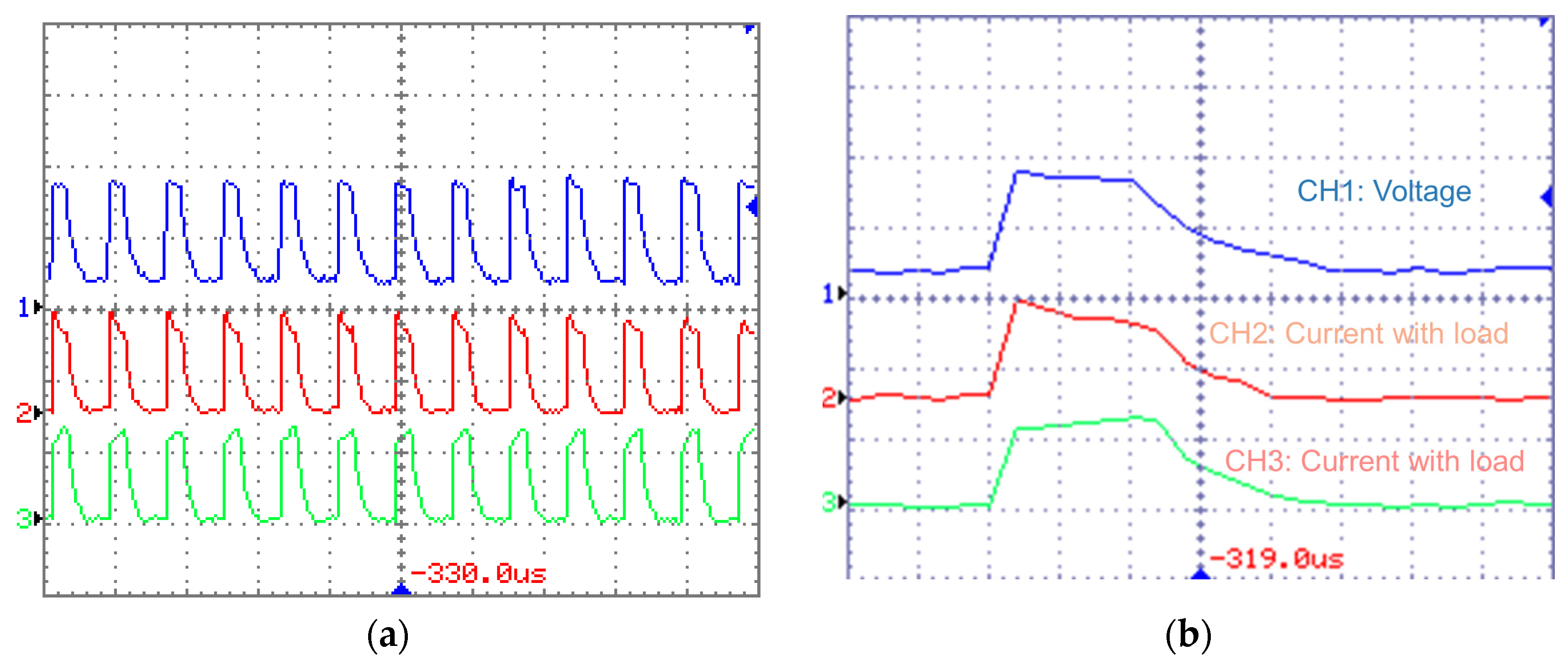

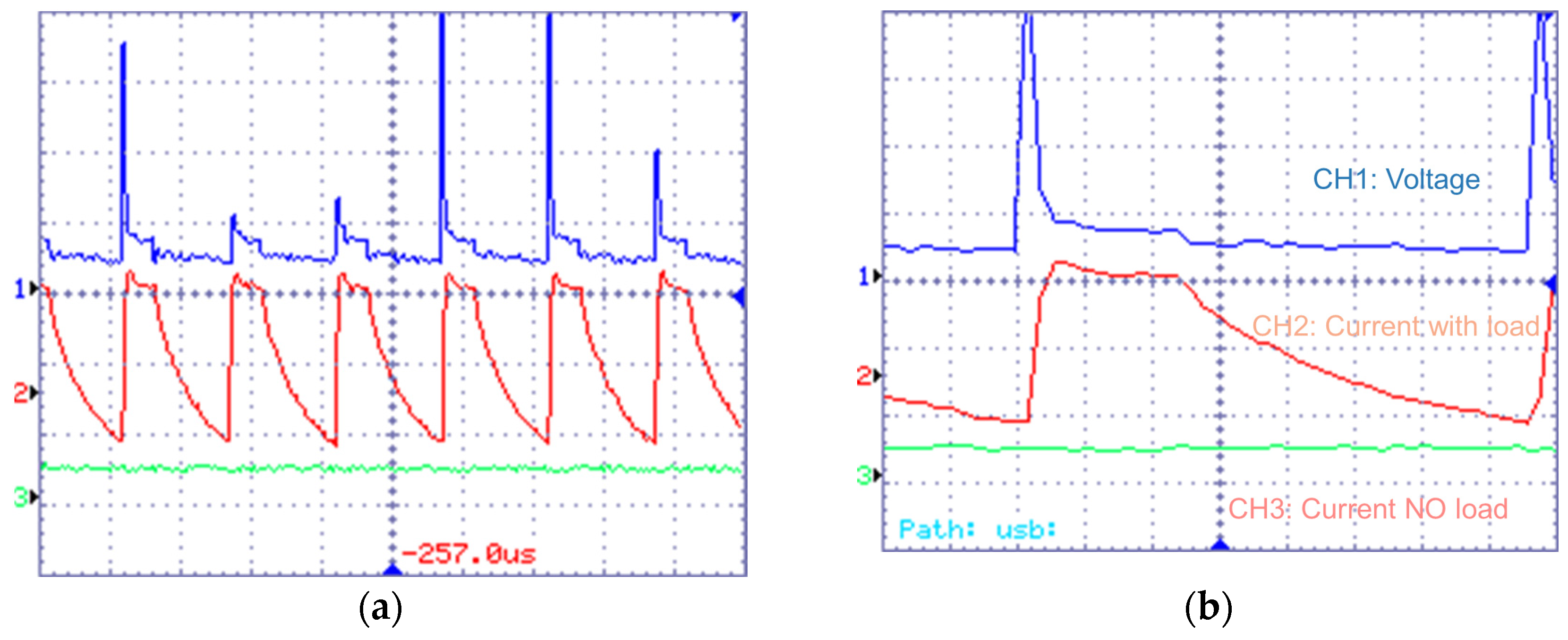

3.2. Discharge Waveform

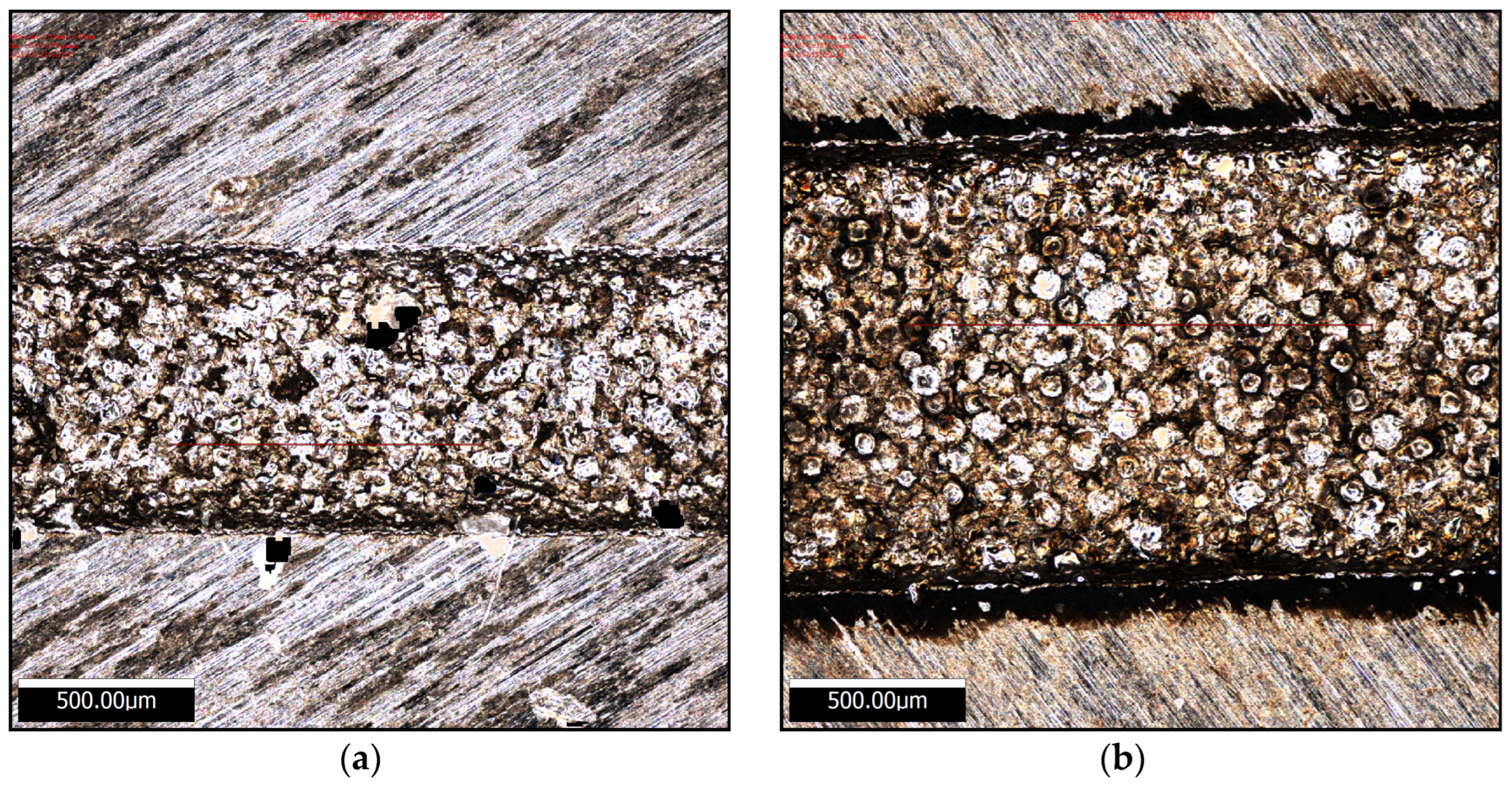

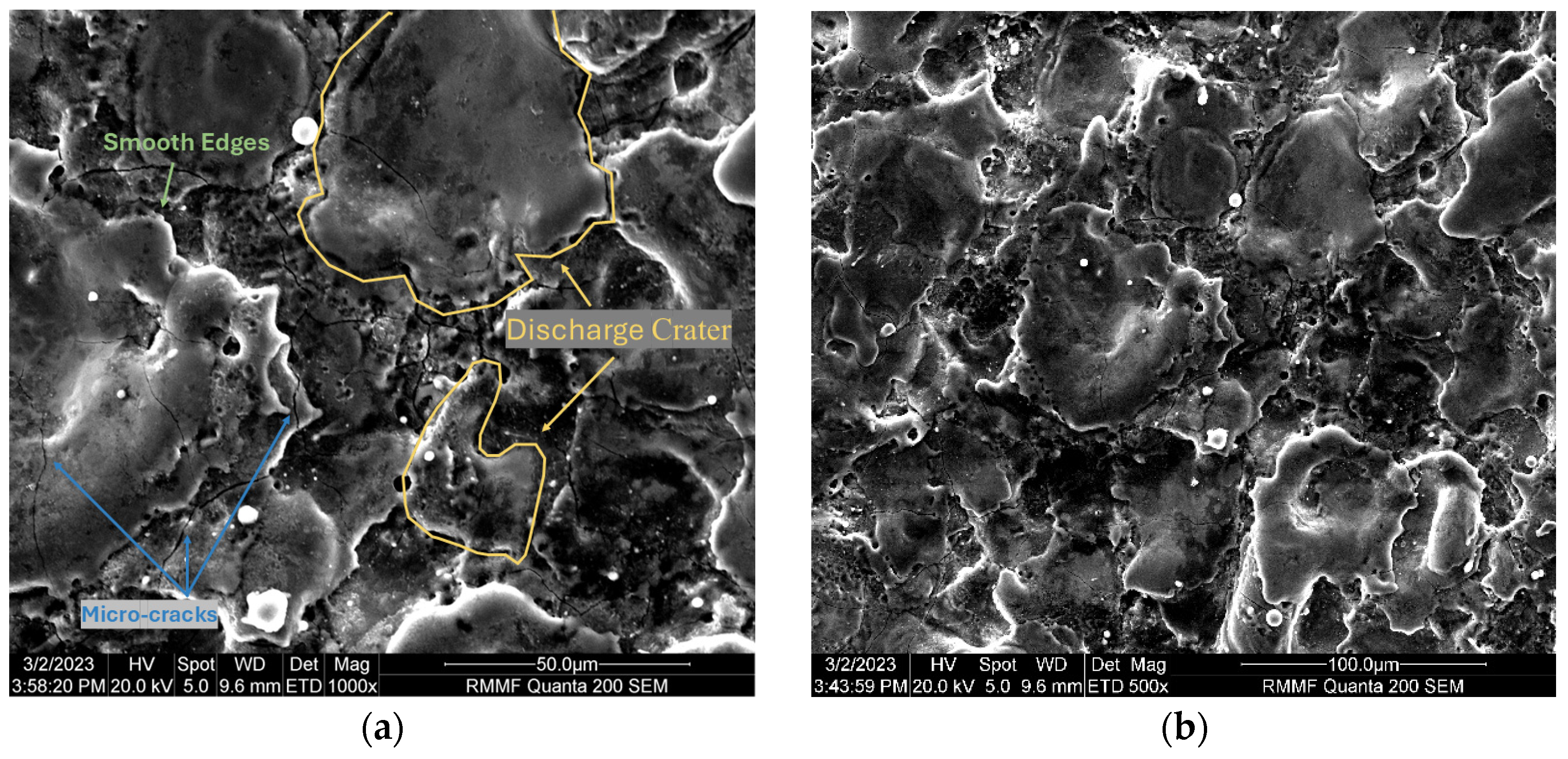

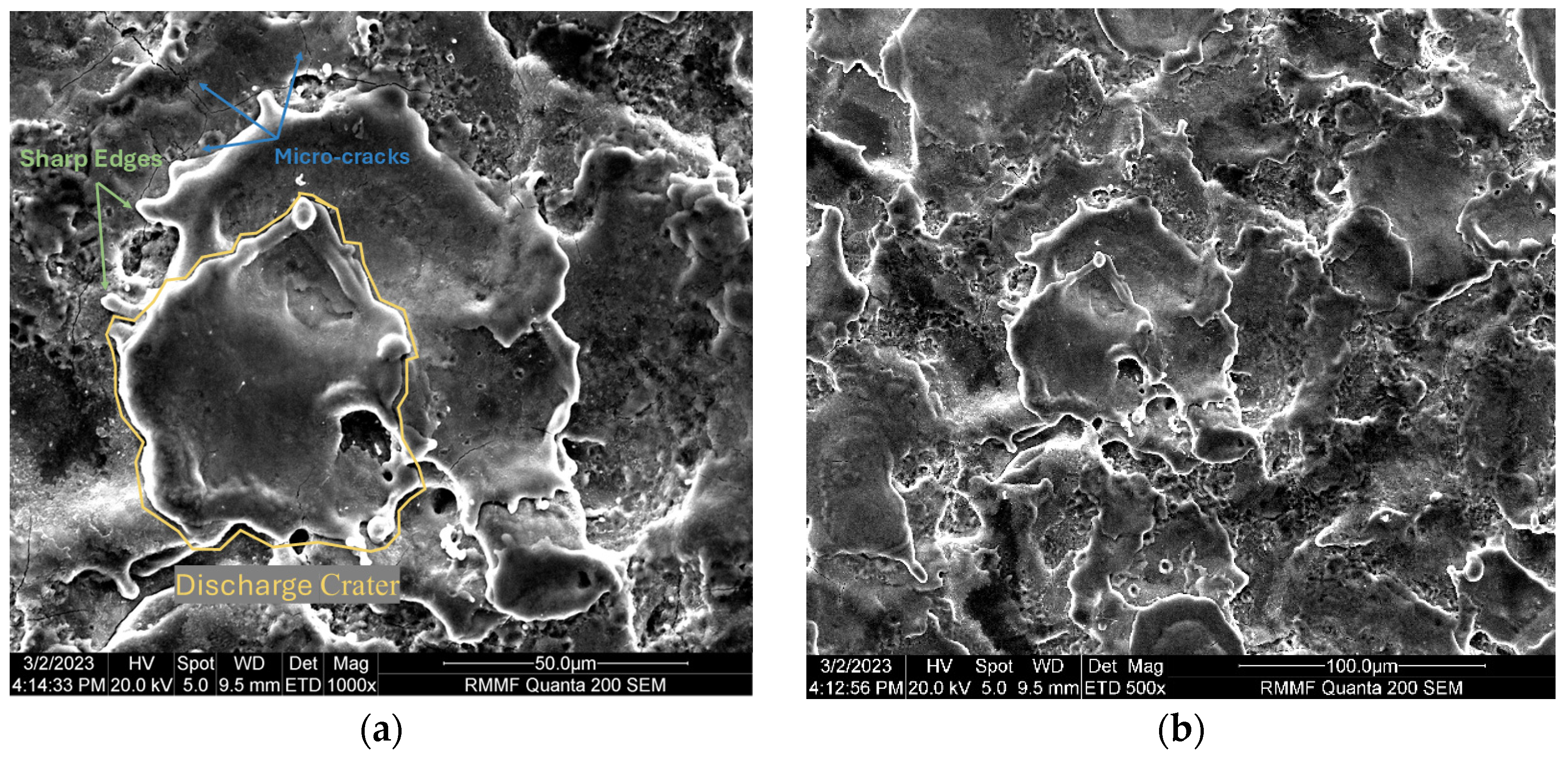

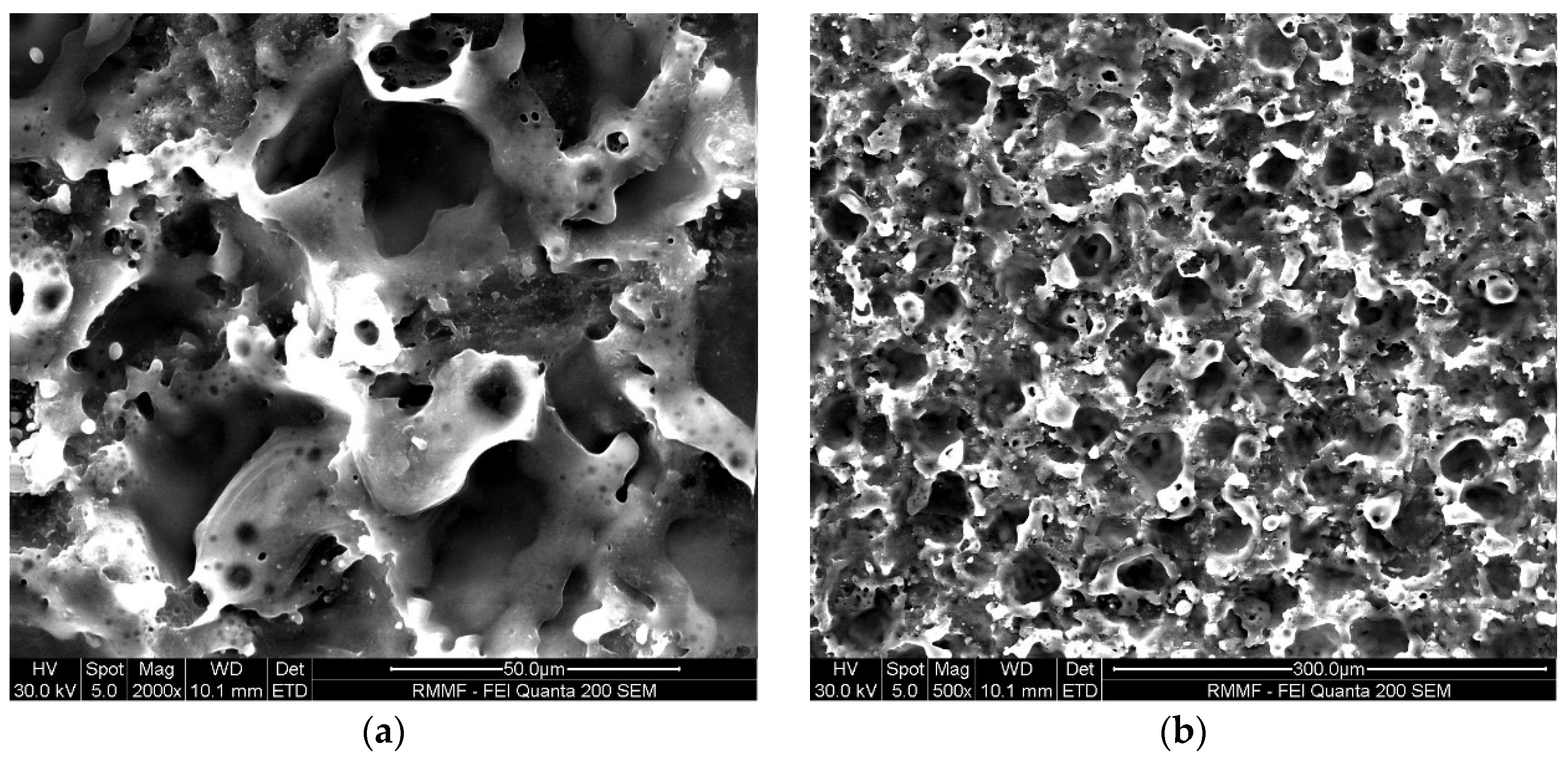

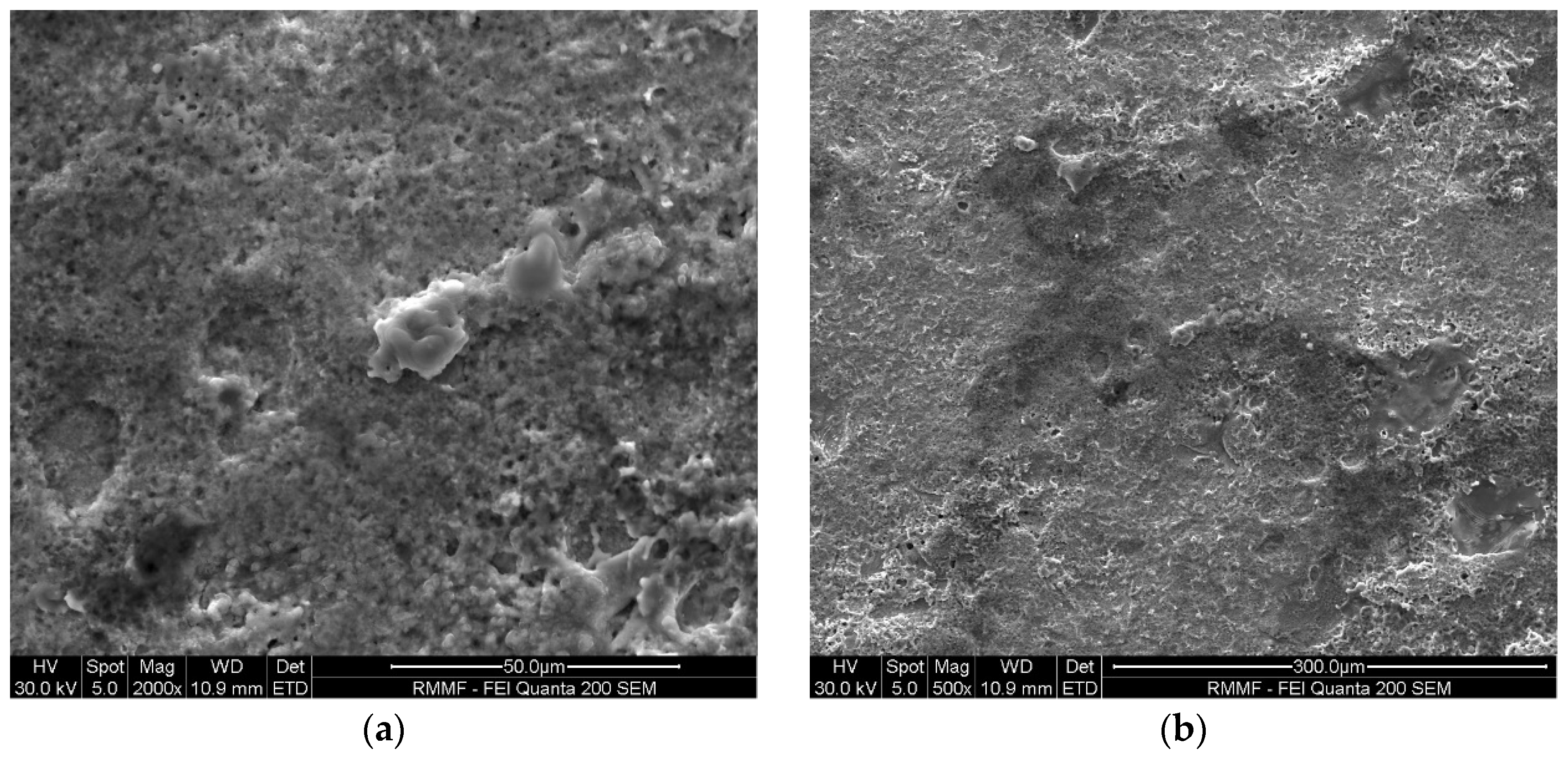

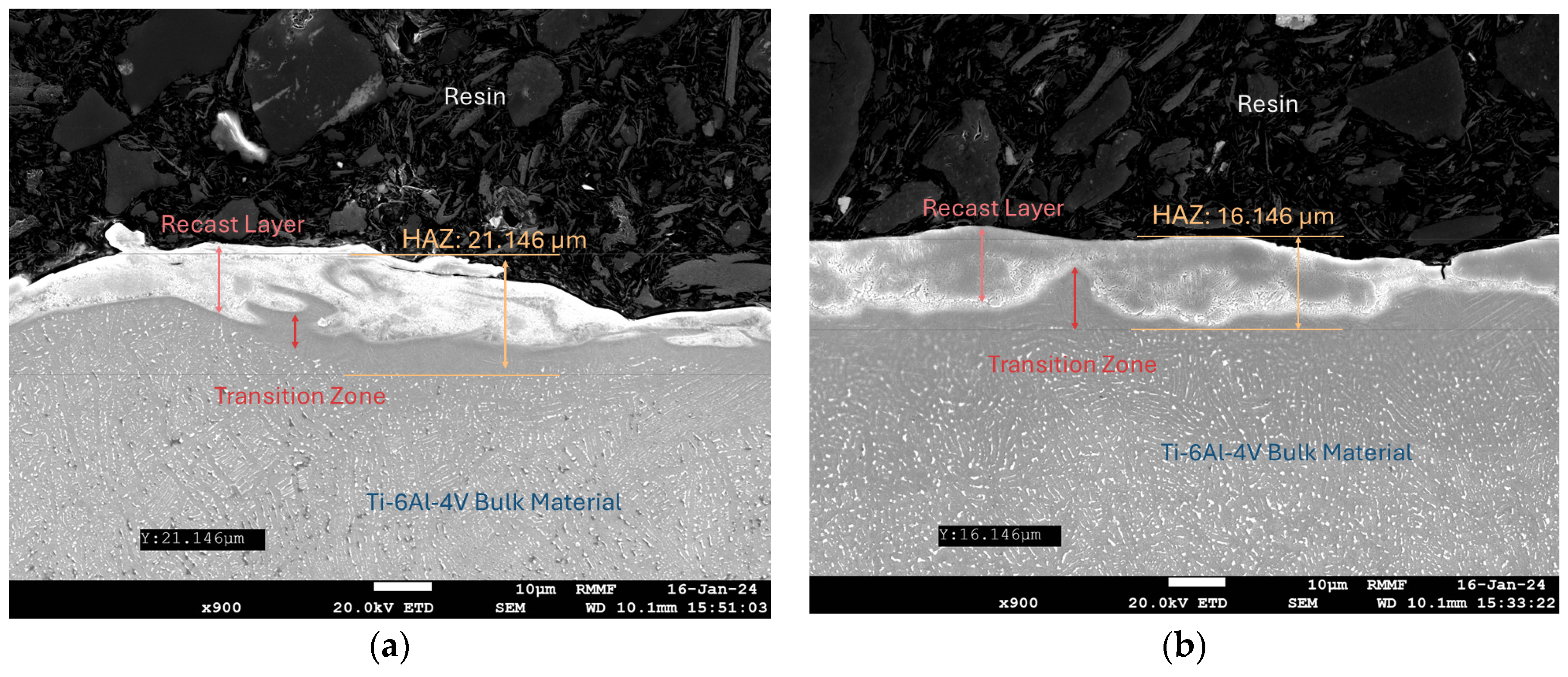

3.3. Workpiece Surface Morphology

4. Discussion

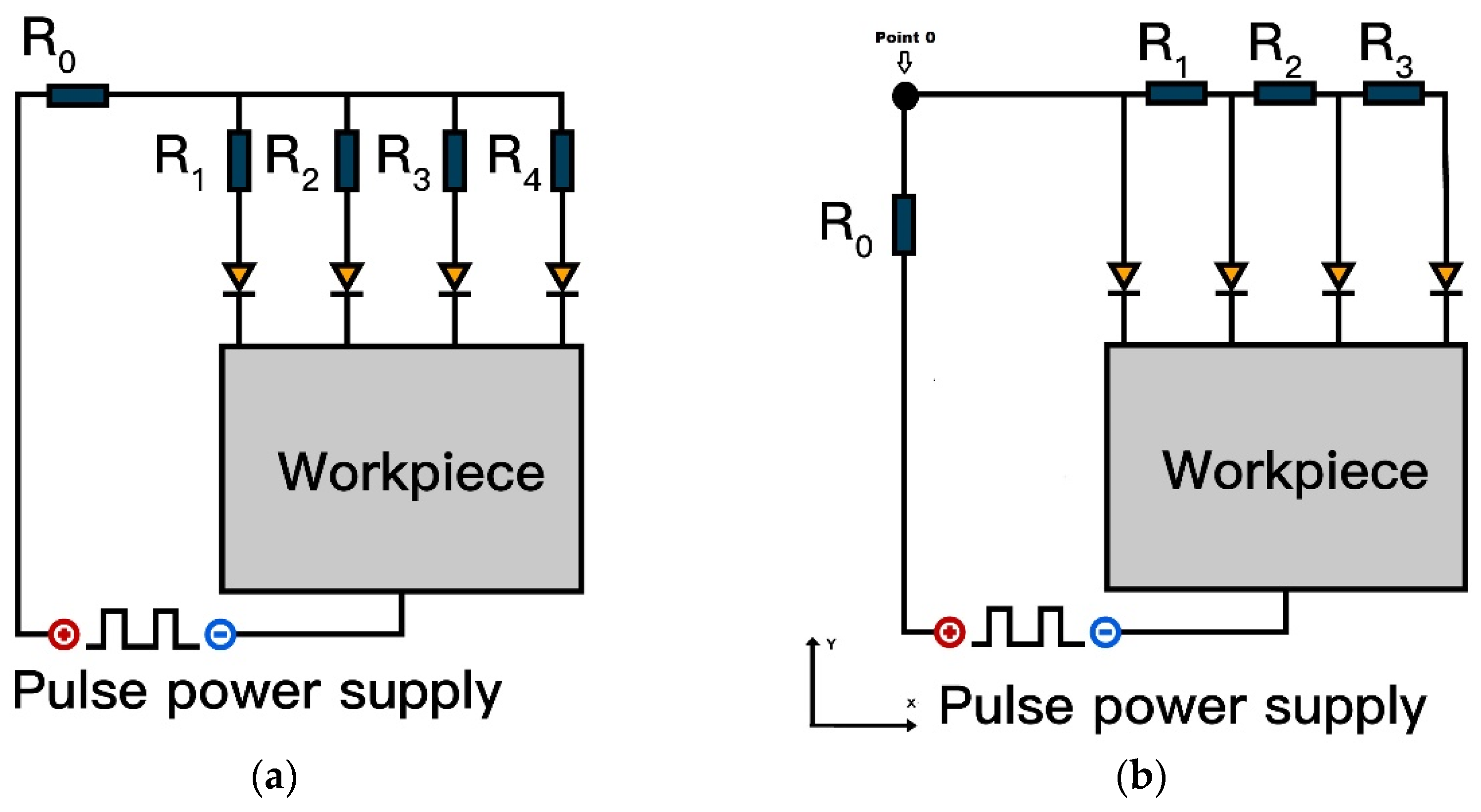

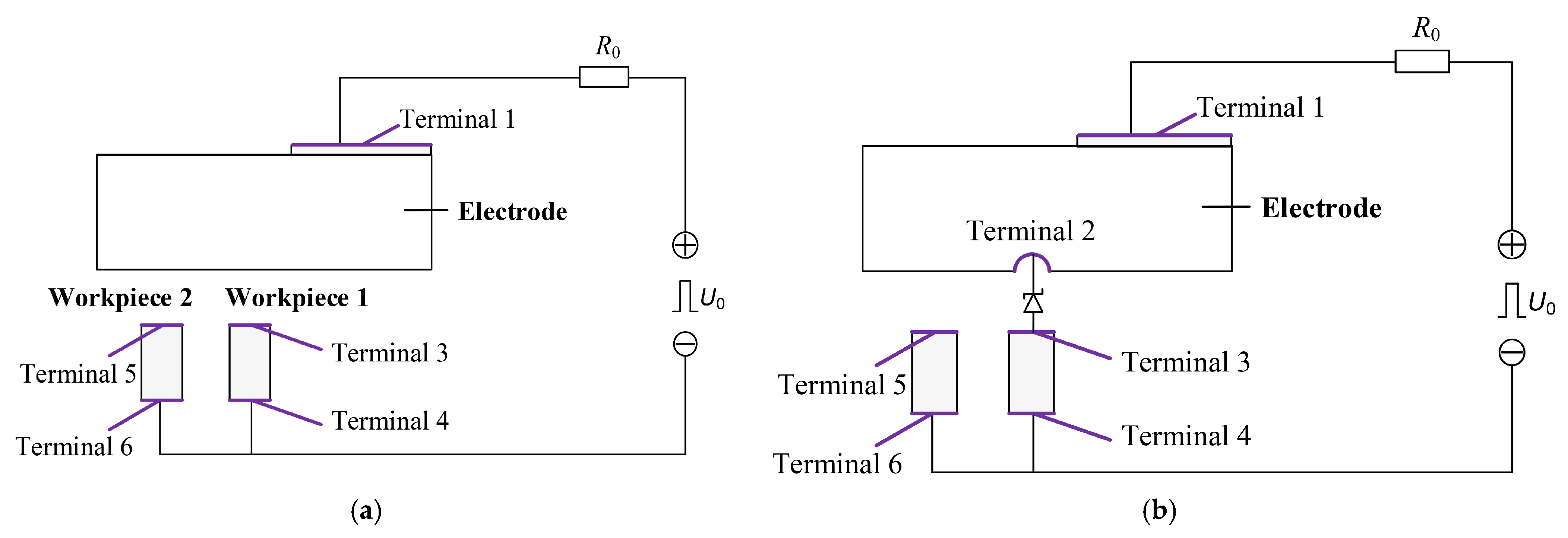

4.1. Equivalent Circuit Model of Single-Electrode Multi-Channel Discharge

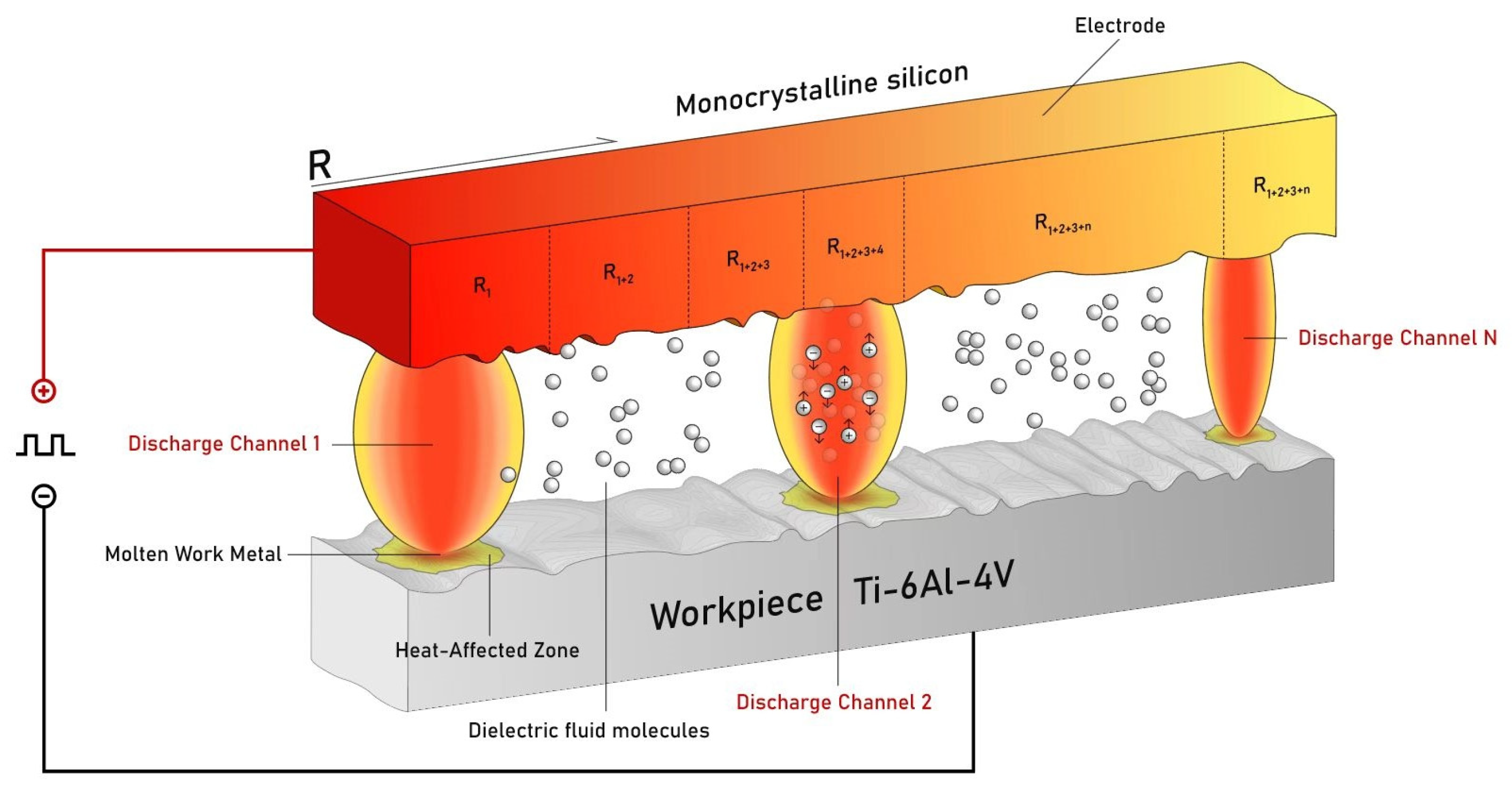

4.2. The Principle and Mechanism of Single-Electrode Multi-Channel Formation

4.3. Voltage Difference Between Electrodes

- The resistivity of the semiconductor silicon is constant.

- Discharge energy is evenly distributed across all discharge channels.

- The contact barrier between the semiconductor and metal is ignored.

5. Conclusions and Further Work

- (1)

- Multiple discharge channels can be generated within one voltage pulse using a single semiconductor electrode, whereas only one discharge channel can be generated by the metal electrode.

- (2)

- When using semiconductor electrodes, the discharge waveforms appear at the beginning of the pulse voltage, usually in an inverted U-shape, which is different from those achieved by using metal electrodes where the current has some hysteresis and a more defined ON/OFF point.

- (3)

- In comparison to metallic copper electrodes, silicon semiconductor electrodes exhibit greater material migration and higher electrode wear.

- (4)

- The number of discharge channels in potential-difference-based multi-channel discharge is primarily determined by a combination of factors, including the open-circuit voltage, the bulk resistivity of the electrode material, contact resistance, anisotropic properties, electrode dimensions, and the electrode layout.

- (5)

- In multi-channel discharge EDM, the current is distributed over multi-channels, resulting in more dispersed discharge energy, higher surface quality of the workpiece, and smaller diameter of the corrosion pits. In single-channel EDM, the current is not distributed, which results in more concentrated discharge energy, lower surface quality of the workpiece, and larger diameter of the corrosion pits.

- (6)

- Due to the energy re-distribution in multi-channel discharge machining, the HAZ is relatively shallow, and the recast layer on the workpiece exhibits a distinct dendritic structure with a thin transition zone. In contrast, workpieces machined with single-channel discharge show a thicker HAZ, accompanied by coarse equiaxed grains and finer surface grains.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yi, S.; Li, G.; Ding, S.; Mo, J. Performance and mechanisms of graphene oxide suspended cutting fluid in the drilling of titanium alloy Ti-6Al-4V. J. Manuf. Process. 2017, 29, 182–193. [Google Scholar] [CrossRef]

- Li, G.; Rahim, M.Z.; Pan, W.; Wen, C.; Ding, S. The manufacturing and the application of polycrystalline diamond tools—A comprehensive review. J. Manuf. Process. 2020, 56, 400–416. [Google Scholar] [CrossRef]

- Hasan, M.; Zhao, J.; Jiang, Z. Micromanufacturing of composite materials: A review. Int. J. Extrem. Manuf. 2019, 1, 012004. [Google Scholar] [CrossRef]

- Li, G.; Rahim, M.Z.; Ding, S.; Sun, S.; Mo, J. Experimental study on quality of PCD tools machined by different electric discharge grinding processes. Cogent Eng. 2016, 3, 1228234. [Google Scholar] [CrossRef]

- Rahim, M.Z.; Ding, S.; Mo, J. Electrical discharge grinding of polycrystalline diamond-effect of machining parameters and finishing in-feed. J. Manuf. Sci. Eng. Trans. ASME 2015, 137, 021017. [Google Scholar] [CrossRef]

- Pan, W.; Ding, S.; Mo, J. Thermal characteristics in milling Ti6Al4V with polycrystalline diamond tools. Int. J. Adv. Manuf. Technol. 2014, 75, 1077–1087. [Google Scholar] [CrossRef]

- Li, G.; Rahim, M.Z.; Ding, S.; Sun, S. Performance and wear analysis of polycrystalline diamond (PCD) tools manufactured with different methods in turning titanium alloy Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2016, 85, 825–841. [Google Scholar] [CrossRef]

- Peta, K. Multiscale Wettability of Microtextured Irregular Surfaces. Materials 2024, 17, 5716. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.S.; Mahdavian, S.M.; Aswin, D.; Ding, S. Experimental study of temperature and clamping force during Nd:YAG laser butt welding. Opt. Laser Technol. 2009, 41, 794–799. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Guo, H.; Yi, S.; Kong, L.; Ding, S. Alternating Energy Electrical Discharge Machining of Titanium Alloy Using a WC-PCD Electrode. J. Manuf. Process. 2020, 60, 37–47. [Google Scholar] [CrossRef]

- Kumar, S.; Batish, A.; Singh, R.; Singh, T. A hybrid Taguchi-artificial neural network approach to predict surface roughness during electric discharge machining of titanium alloys. J. Mech. Sci. Technol. 2014, 28, 2831–2844. [Google Scholar] [CrossRef]

- Karmiris-Obratański, P.; Papazoglou, E.L.; Leszczyńska-Madej, B.; Zagórski, K.; Markopoulos, A.P. A Comprehensive Study on Processing Ti-6Al-4V ELI with High Power EDM. Materials 2021, 14, 303. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, Z.; Xue, R.; Tian, Z.; Huang, Y. Research on the influence of dielectric characteristics on the EDM of titanium alloy. Int. J. Adv. Manuf. Technol. 2014, 72, 979–987. [Google Scholar] [CrossRef]

- Kunieda, M.; Muto, H. Development of Multi-Spark EDM. CIRP Ann. 2000, 49, 119–122. [Google Scholar] [CrossRef]

- Yilmaz, O.; Okka, M.A. Effect of single and multi-channel electrodes application on EDM fast hole drilling performance. Int. J. Adv. Manuf. Technol. 2010, 51, 185–194. [Google Scholar] [CrossRef]

- Bozdana, A.T.; Ulutas, T. The Effectiveness of Multichannel Electrodes on Drilling Blind Holes on Inconel 718 by EDM Process. Mater. Manuf. Process. 2016, 31, 504–513. [Google Scholar] [CrossRef]

- Yu, X.; Qiu, M.; Fu, J.; Kong, L.; Han, Y. Multi-channel aerosol dielectric electrical discharge machining ablation based on discrete electrode. Int. J. Adv. Manuf. Technol. 2018, 99, 1037–1045. [Google Scholar] [CrossRef]

- Deng, C.; Liu, Z.; Zhang, M. Effect of multi-channel discharge distribution on surface homogeneity in super-high-thickness WEDM. Chin. J. Aeronaut. 2023, 36, 442–450. [Google Scholar] [CrossRef]

- Fu, J.; Qiu, M.; Shen, L.; Kong, L.; Ma, J. On processing of Inconel718 through multi-channel discharge ablation. J. Manuf. Process. 2020, 57, 462–468. [Google Scholar] [CrossRef]

- Yang, X.; Yang, K.; Liu, Y.; Wang, L. Study on Characteristic of Multi-spark EDM Method by Using Capacity Coupling. Procedia CIRP 2016, 42, 40–45. [Google Scholar] [CrossRef]

- Wang, X.; Yi, S.; Guo, H.; Li, C.; Ding, S. Erosion characteristics of electrical discharge machining using graphene powder in deionized water as dielectric. Int. J. Adv. Manuf. Technol. 2020, 108, 357–368. [Google Scholar] [CrossRef]

- Ming, Q.Y.; He, L.Y. Powder-suspension dielectric fluid for EDM. J. Mater. Process. Technol. 1995, 52, 44–54. [Google Scholar] [CrossRef]

- Shabgard, M.; Khosrozadeh, B. Investigation of carbon nanotube added dielectric on the surface characteristics and machining performance of Ti-6Al-4V alloy in EDM process. J. Manuf. Process. 2017, 25, 212–219. [Google Scholar] [CrossRef]

- Wang, X.; Qiu, M.; Guo, H.; Ding, S. Powder-mixed multi-channel discharge wire electrical discharge machining. Int. J. Adv. Manuf. Technol. 2022, 119, 6275–6286. [Google Scholar] [CrossRef]

- Zhu, X.; Li, G.; Mo, J.; Ding, S. Electrical discharge machining of semiconductor materials: A review. J. Mater. Res. Technol. 2023, 25, 4354–4379. [Google Scholar] [CrossRef]

- Pan, H.; Liu, Z.; Qiu, M.; Zhang, M.; Deng, C. Extreme wire electrical discharge machining based on semiconductor characteristics. Int. J. Adv. Manuf. Technol. 2021, 115, 2477–2489. [Google Scholar] [CrossRef]

- Chen, H.-R.; Liu, Z.-D.; Huang, S.-J.; Pan, H.-J.; Qiu, M.-B. Study of the mechanism of multi-channel discharge in semiconductor processing by WEDM. Mater. Sci. Semicond. Process. 2015, 32, 125–130. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Z.; Pan, H.; Deng, C.; Qiu, M. Multi-channel discharge characteristics cutting by ultra-fine wire-EDM. Chin. J. Aeronaut. 2022, 35, 308–319. [Google Scholar] [CrossRef]

- Mu, X.; Zhou, M.; Ye, Q. Improving surface integrity and surface roughness by forming multi-discharging channels from one pulse in EDM. Int. J. Adv. Manuf. Technol. 2019, 102, 3181–3195. [Google Scholar] [CrossRef]

- Zhang, L.; Kong, L.; Lei, W.; Li, Q. Review of electrochemical discharge machining technology for insulating hard and brittle materials. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 143. [Google Scholar] [CrossRef]

- Flaño, O.; Zhao, Y.; Kunieda, M.; Abe, K. Approaches for improvement of EDM cutting performance of SiC with foil electrode. Precis. Eng. 2017, 49, 33–40. [Google Scholar] [CrossRef]

- Qin, L.; Huo, W.; Li, Z.; Zhang, Y.-O.; Xi, X.; Zhao, W. Study on energy distribution of discharge plasma and its effect on crater formation in EDM. Int. J. Adv. Manuf. Technol. 2022, 121, 5563–5585. [Google Scholar] [CrossRef]

- Chouirfa, H.; Bouloussa, H.; Migonney, V.; Falentin-Daudré, C. Review of titanium surface modification techniques and coatings for antibacterial applications. Acta Biomater. 2019, 83, 37–54. [Google Scholar] [CrossRef] [PubMed]

- Heer, B.; Bandyopadhyay, A. Silica coated titanium using Laser Engineered Net Shaping for enhanced wear resistance. Addit. Manuf. 2018, 23, 303–311. [Google Scholar] [CrossRef]

- Ding, S.; Yang, D.C.H.; Han, Z. Boundary-conformed machining of turbine blades. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2005, 219, 255–263. [Google Scholar] [CrossRef]

- Pan, W.; Kamaruddin, A.; Ding, S.; Mo, J. Experimental investigation of end milling of titanium alloys with polycrystalline diamond tools. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 832–844. [Google Scholar] [CrossRef]

- Ding, S.; Yuanz, R.; Li, Z.; Wang, K. CNC electrical discharge rough machining of turbine blades. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1027–1034. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S.; Sharma, S.; Narendranath, S. Recast Layer Formation during Wire Electrical Discharge Machining of Titanium (Ti-Al6-V4) Alloy. J. Mater. Eng. Perform. 2021, 30, 8926–8935. [Google Scholar] [CrossRef]

- Li, C.; Xu, X.; Li, Y.; Tong, H.; Ding, S.; Kong, Q.; Zhao, L.; Ding, J. Effects of dielectric fluids on surface integrity for the recast layer in high speed EDM drilling of nickel alloy. J. Alloys Compd. 2019, 783, 95–102. [Google Scholar] [CrossRef]

- Li, L.; Feng, L.; Bai, X.; Li, Z.Y. Surface characteristics of Ti-6Al-4V alloy by EDM with Cu–SiC composite electrode. Appl. Surf. Sci. 2016, 388, 546–550. [Google Scholar] [CrossRef]

- Hatem, A.; Lin, J.; Wei, R.; Torres, R.D.; Laurindo, C.; de Souza, G.B.; Soares, P. Tribocorrosion behavior of low friction TiSiCN nanocomposite coatings deposited on titanium alloy for biomedical applications. Surf. Coat. Technol. 2018, 347, 1–12. [Google Scholar] [CrossRef]

| Elements | Al | C | V | Mn | Fe | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Composition % | 6.28 | 0.008 | 4.24 | 0.0058 | 0.09 | 0.008 | 0.001 | 0.138 | Remaining |

| Item | Parameter |

|---|---|

| Workpiece material | Ti-6Al-4V bar |

| Machining polarity | Workpiece (-) |

| Electrode | Intrinsic monocrystalline Silicon/Copper |

| Dielectric fluid | EDM 244 (Manufacturer: Quaker Houghton, Moorabbin, VIC, Australia) |

| Pulse width (μs) | 20 |

| Machining voltage (V) | 50 |

| Machining current (A) | 3 |

| Response time of hall sensor (ns) | ≤23 |

| Rise time of Oscilloscope (ns) | ≤3.5 |

| Elements | Content (wt.%) | |

|---|---|---|

| Silicon Electrode | Copper Electrode | |

| Ti | 29.9 | 32.6 |

| Cu | 3.4 | |

| Si | 7.5 | |

| V | 1.2 | 2.5 |

| Al | 2.3 | 2 |

| Workpiece material (cathode) (−) | Ti-6Al-4V |

| Electrode material (anode) (+) | Silicon, Copper |

| Radius of discharge crater (mm) | 0.1 |

| Silicon resistivity (Ω·cm) | 1 |

| Open-circuit voltage (V) | 50 |

| Current-limiting resistor (Ω) | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Wei, T.; Li, S.; Li, G.; Ding, S. Multi-Channel Electrical Discharge Machining of Ti-6Al-4V Enabled by Semiconductor Potential Differences. Micromachines 2025, 16, 147. https://doi.org/10.3390/mi16020147

Zhu X, Wei T, Li S, Li G, Ding S. Multi-Channel Electrical Discharge Machining of Ti-6Al-4V Enabled by Semiconductor Potential Differences. Micromachines. 2025; 16(2):147. https://doi.org/10.3390/mi16020147

Chicago/Turabian StyleZhu, Xuyang, Tao Wei, Sipei Li, Guangxian Li, and Songlin Ding. 2025. "Multi-Channel Electrical Discharge Machining of Ti-6Al-4V Enabled by Semiconductor Potential Differences" Micromachines 16, no. 2: 147. https://doi.org/10.3390/mi16020147

APA StyleZhu, X., Wei, T., Li, S., Li, G., & Ding, S. (2025). Multi-Channel Electrical Discharge Machining of Ti-6Al-4V Enabled by Semiconductor Potential Differences. Micromachines, 16(2), 147. https://doi.org/10.3390/mi16020147