Fabrication and Performance of Aluminum-Based Composite Wicks Using a Two-Step Laser-Sintering Process

Abstract

1. Introduction

2. Manufacture and Experiments

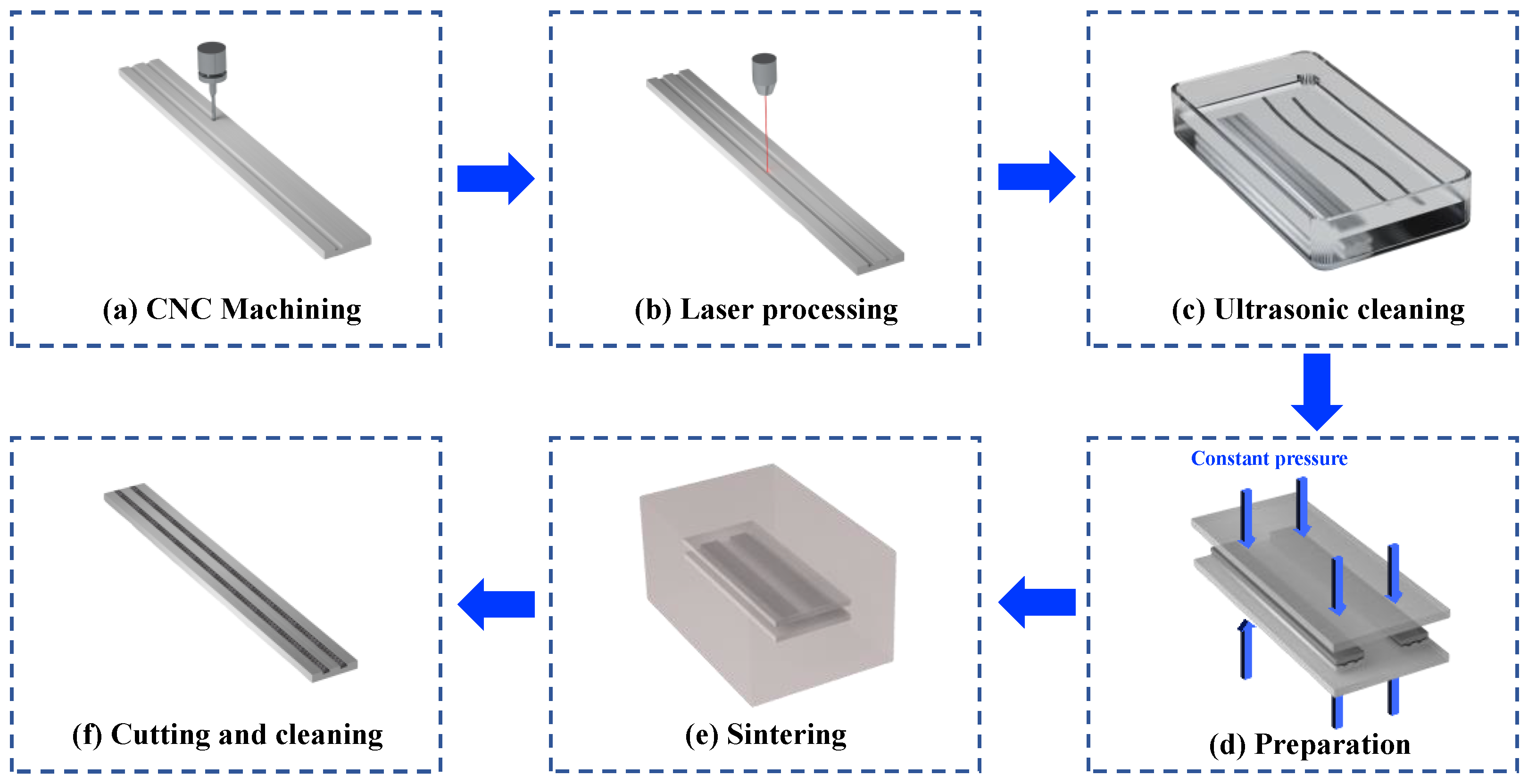

2.1. Manufacture of Samples

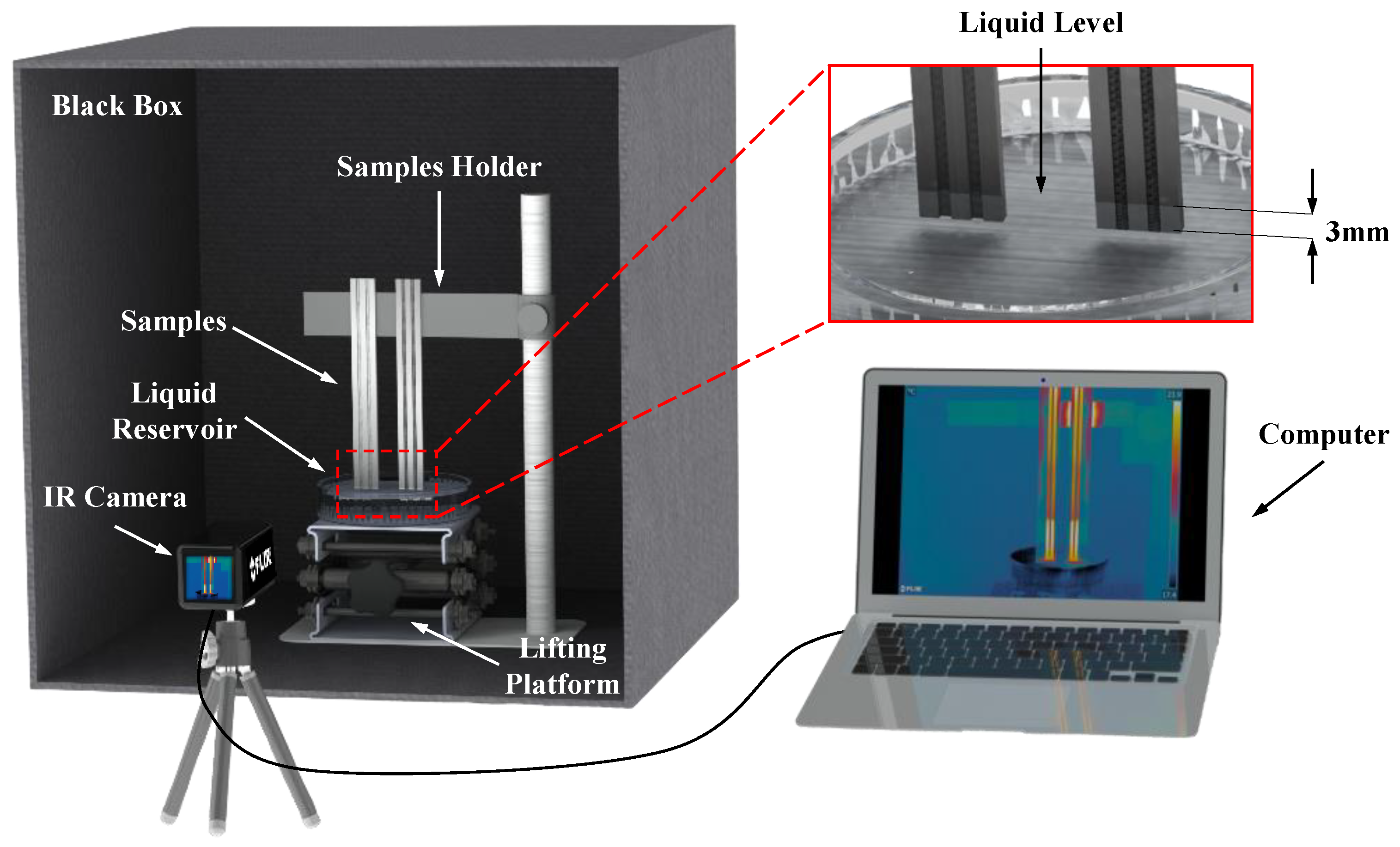

2.2. Characterization and Measurements

2.3. Theory and Data Reduction

2.4. Uncertainty Analysis

3. Result and Discussion

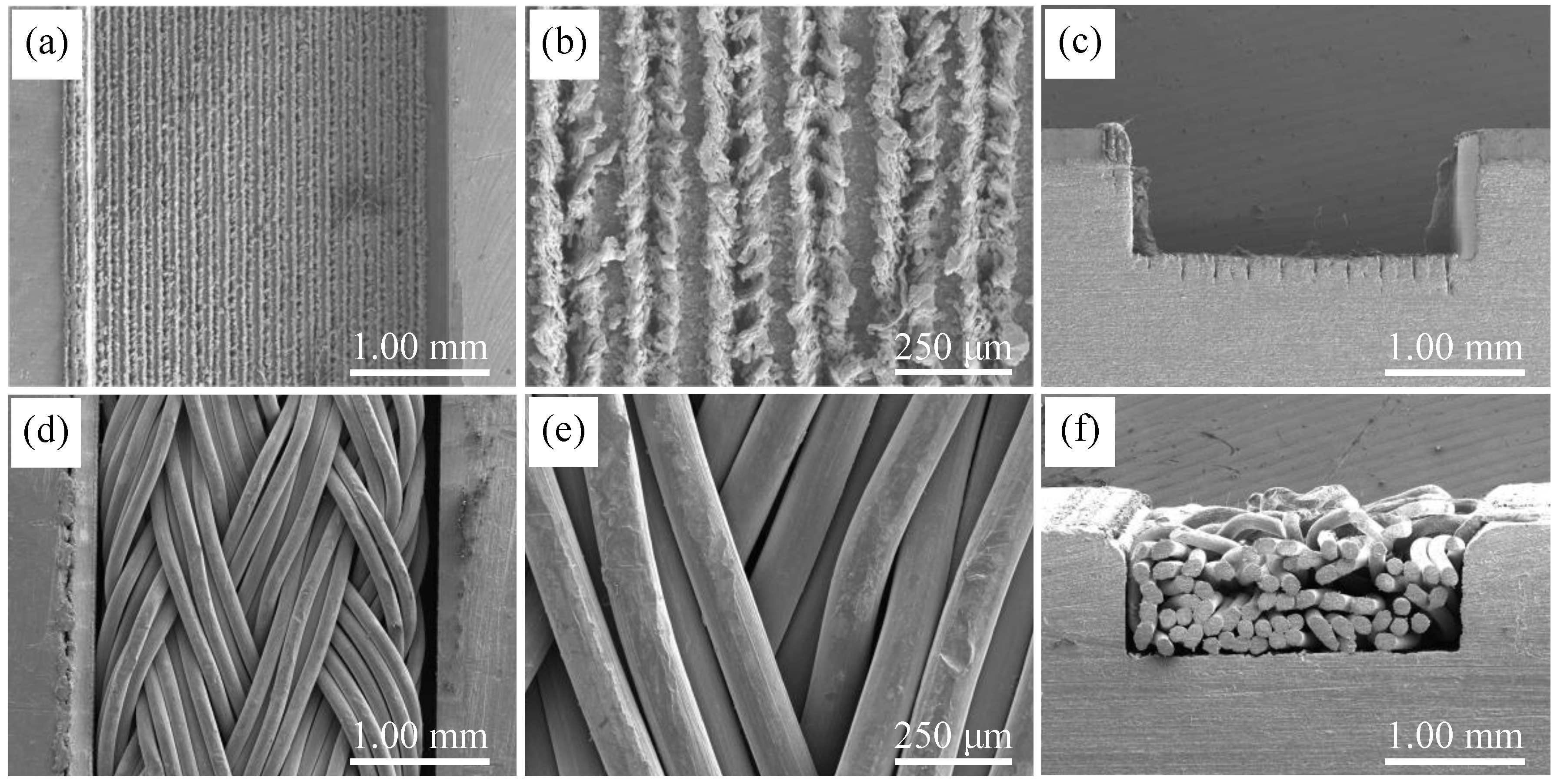

3.1. Surface Morphology Characterization

3.2. Wicking Height Characterization

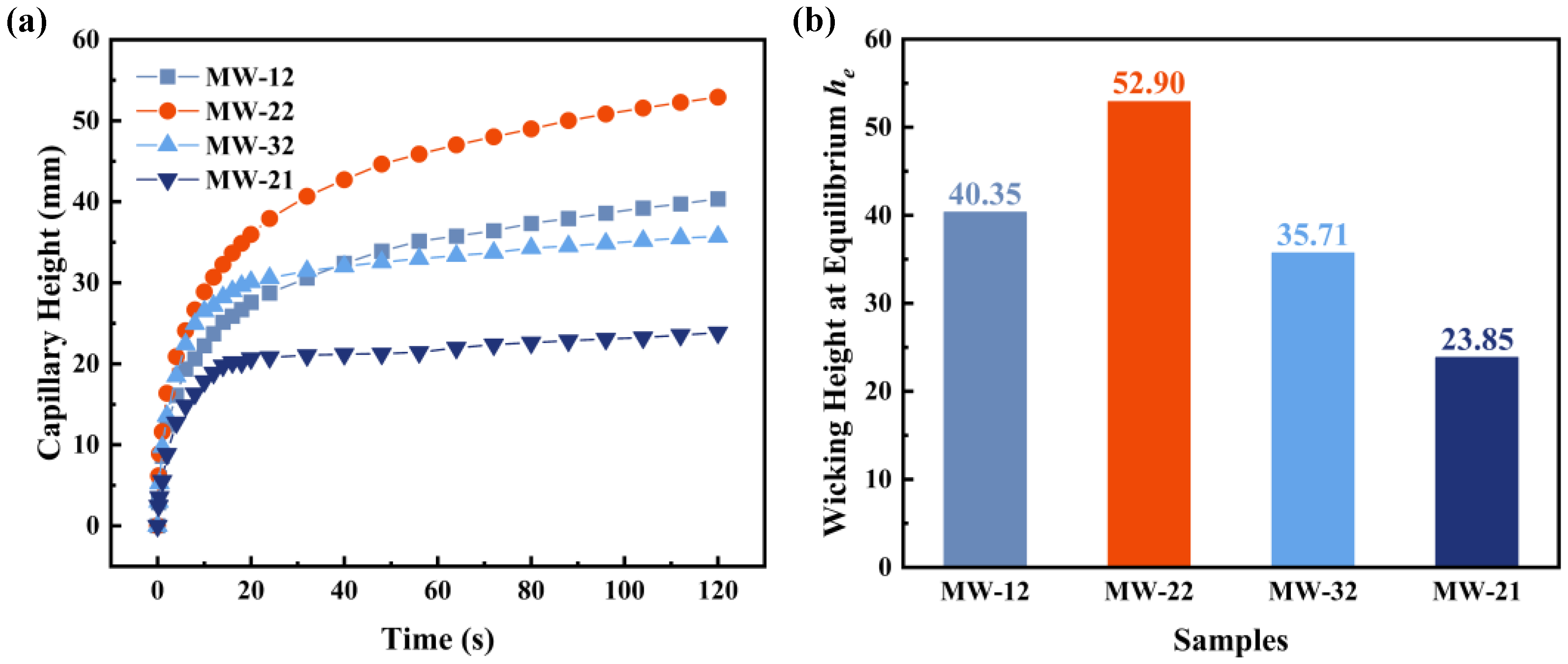

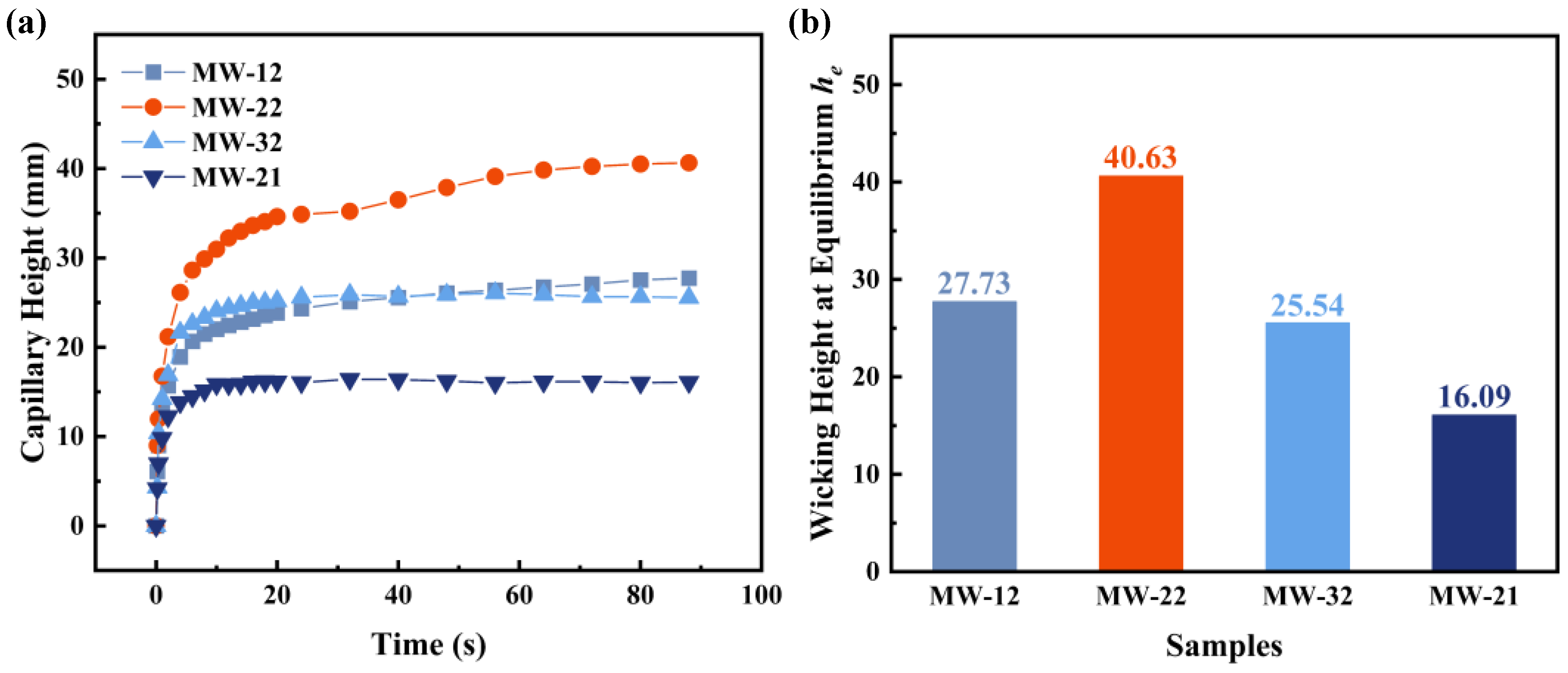

3.2.1. Capillary Performance of Different Laser Parameters

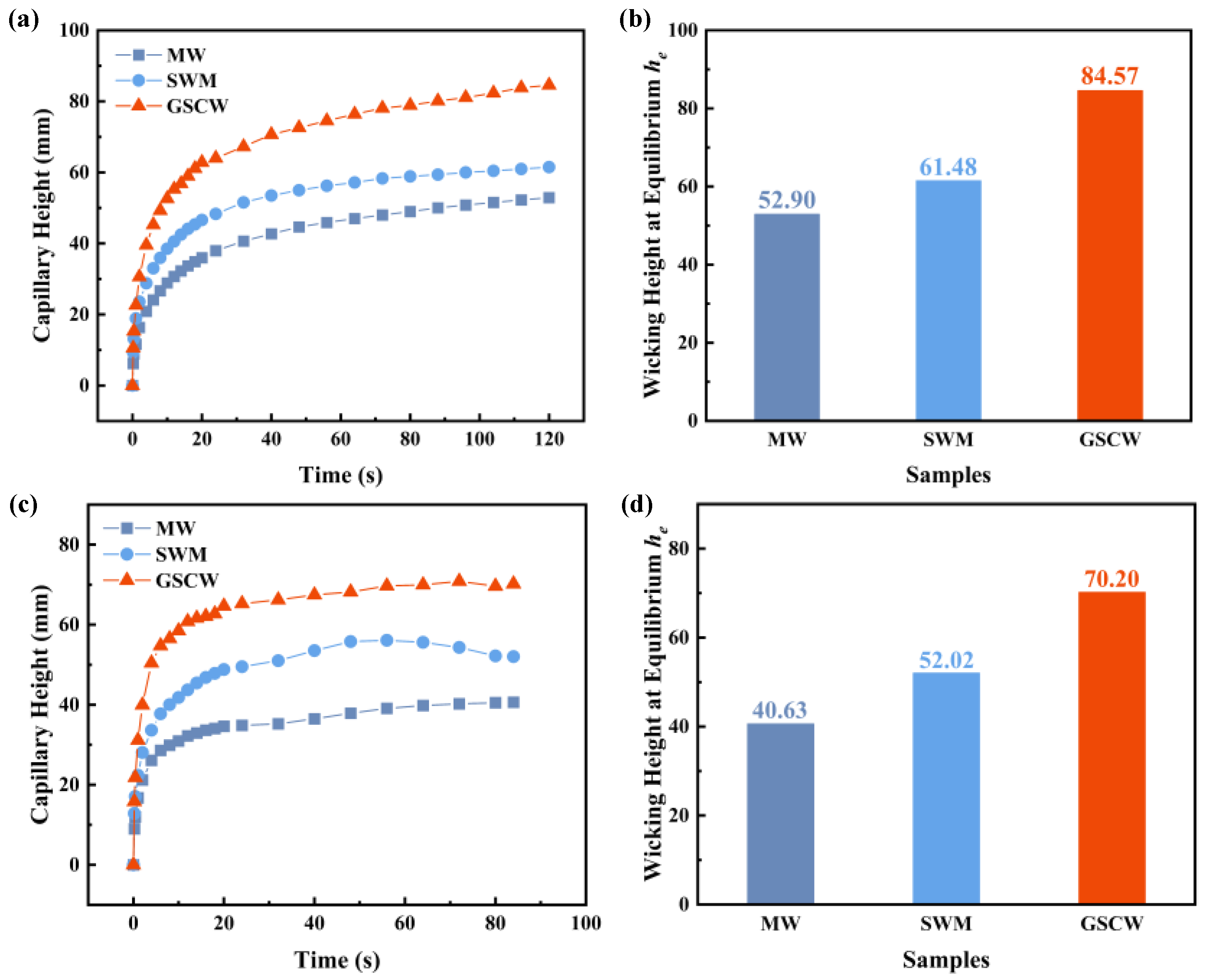

3.2.2. Capillary Performance of Different Wicks

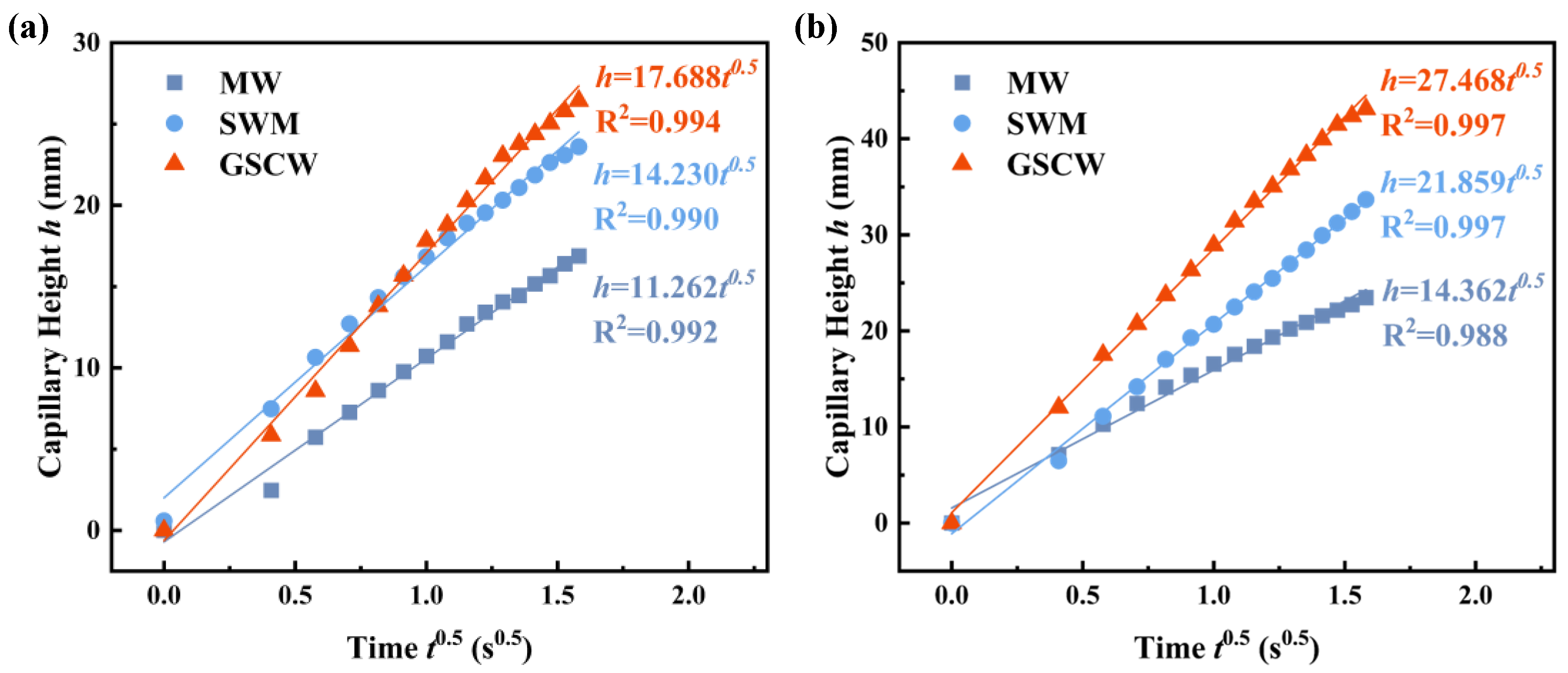

3.3. Wicking Capability

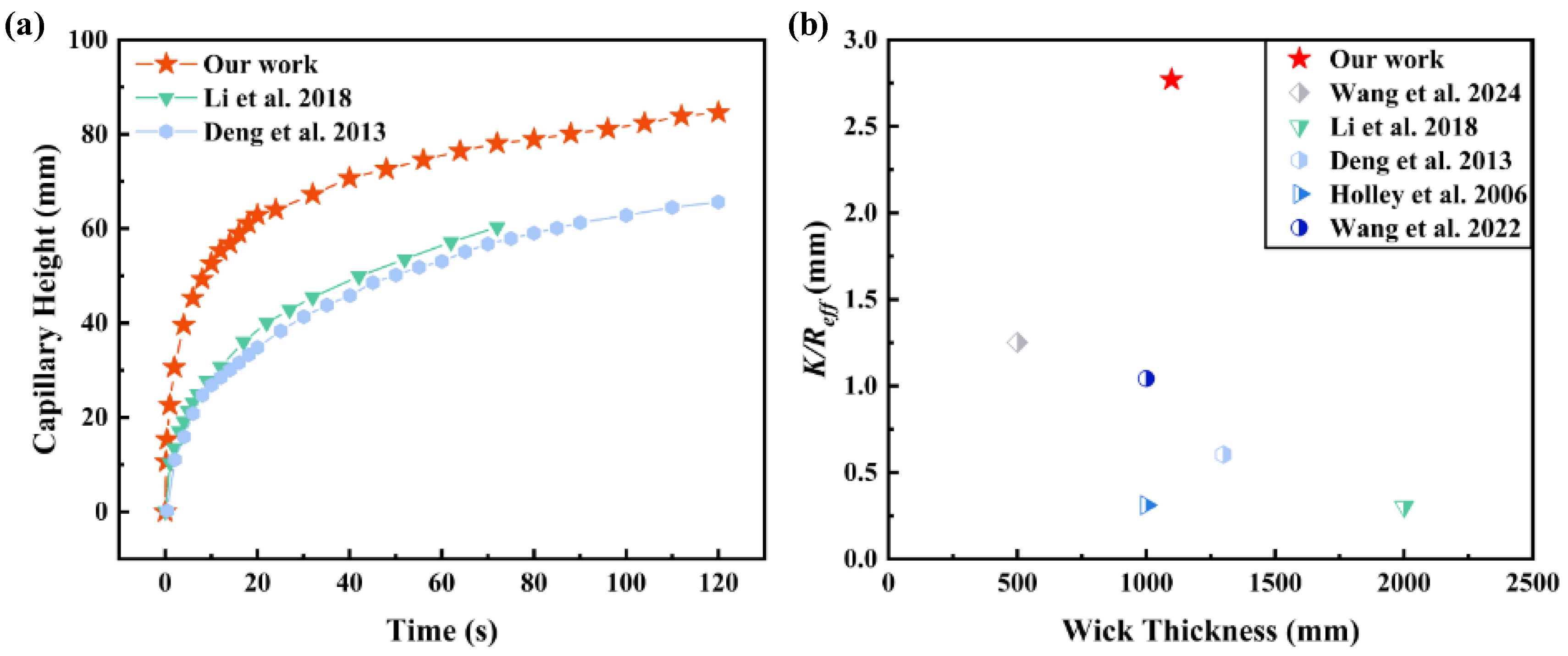

3.4. Comparison with Previous Studies

4. Conclusions

- (1)

- Laser processing of the aluminum alloy substrate enabled the precise fabrication of parallel porous microgrooves. The solid-state sintering technology effectively integrated the MW with SWM to form composite wicks with superior capillary performance;

- (2)

- The MW-22 sample demonstrated the highest capillary performance among the MWs when the laser-scanning line spacing is 0.2 mm and the scanning passes are two. The capillary performance parameter of MW-22 reaches 1.456 μm, reflecting an increase of 58.21% compared to MW-21. This improvement is attributed to the formation of new microgrooves created by adjacent ridge-like protrusions in the MW, where parallel microscale grooves enhanced the capillary performance of wicks;

- (3)

- The GSCW exhibited excellent capillary performance, with a maximum capillary rise height of 84.57 mm and K/Reff of 2.769 μm when using ethanol as the working fluid. Compared to the non-composite MW, the capillary rise height and the capillary performance parameter K/Reff were enhanced by 59.86% and 90.15%, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature | |

| Diameter of each aluminum wire in the wick, m | |

| Equivalent diameter of the wick, m | |

| Measurement error of the variable . | |

| Gravitational acceleration at the current state, m/s2 | |

| Height of the liquid working medium at the current state, m | |

| Wicking height at equilibrium, m | |

| Permeability of the wicking structure, m2 | |

| Length of the aluminum wire in the wick, m | |

| Number of the aluminum wire in the wick | |

| Number of aluminum spiral woven mesh | |

| Pressure drop, Pa | |

| Capillary pressure, Pa | |

| Viscous frictional pressure loss, Pa | |

| Hydrostatic pressure loss, Pa | |

| Effective pore radius, m | |

| Pore radius, m | |

| Original measurement time, s | |

| Volume, m3 | |

| Volume of the aluminum wire, m3 | |

| Total volume of the wick, m3 | |

| Total volume of all the aluminum spiral woven mesh, m3 | |

| Capillary coefficient, m/s0.5 | |

| Greek symbols | |

| Density of liquid working medium, kg/m3 | |

| Surface tension of the liquid working medium, N/m | |

| Contact angle of the liquid on the wicking structure surface, ° | |

| Porosity of the wicking structure | |

| Dynamic viscosity of the saturated liquid working medium, N·s/m2 | |

| Abbreviations | |

| Microgroove wick | |

| Spiral woven mesh | |

| Groove–spiral woven mesh composite wick | |

| Scanning electron microscope | |

References

- Sohel Murshed, S.M.; Nieto de Castro, C.A. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew. Sustain. Energy Rev. 2017, 78, 821–833. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Y.; Zhou, W.; Deng, L.; Yan, Y. Design, fabrication and thermal performance of a novel ultra-thin vapour chamber for cooling electronic devices. Energy Convers. Manag. 2019, 187, 221–231. [Google Scholar] [CrossRef]

- Marcinichen, J.B.; Olivier, J.A.; Oliveira, V.d.; Thome, J.R. A review of on-chip micro-evaporation: Experimental evaluation of liquid pumping and vapor compression driven cooling systems and control. Appl. Energy 2012, 92, 147–161. [Google Scholar] [CrossRef]

- Zhou, G.H.; Zhou, J.Z.; Huai, X.L.; Zhou, F.; Jiang, Y.W. A two-phase liquid immersion cooling strategy utilizing vapor chamber heat spreader for data center servers. Appl. Therm. Eng. 2022, 210, 118289. [Google Scholar] [CrossRef]

- Liang, Y.; Huang, H.; Yan, C.; Yuan, X.; Tang, Y.; Bai, J.; Zhang, S. An efficient aluminum gradient mesh wick for enhancing boiling heat transfer performance. Int. Commun. Heat. Mass. Transf. 2024, 152, 107320. [Google Scholar] [CrossRef]

- Van Erp, R.; Soleimanzadeh, R.; Nela, L.; Kampitsis, G.; Matioli, E. Co-designing electronics with microfluidics for more sustainable cooling. Nature 2020, 585, 211–216. [Google Scholar] [CrossRef]

- Bai, J.; Li, Y.; Zhao, Y.; Luo, F.; Sun, T.; Liang, Y.; Tang, Y.; Zhang, S. Experimental study of an integrated aluminum flat plate heat pipe for lightweight thermal management in electronic devices. Appl. Therm. Eng. 2024, 257, 124332. [Google Scholar] [CrossRef]

- Lee, S.; Mudawar, I. Investigation of flow boiling in large micro-channel heat exchangers in a refrigeration loop for space applications. Int. J. Heat. Mass. Transf. 2016, 97, 110–129. [Google Scholar] [CrossRef]

- Sarris, A.; Bhatti, B.; Ciampa, F. Thermoelectric energy harvesting using vapour chamber coolers for aerospace applications. J. Intell. Mater. Syst. Struct. 2022, 33, 1602–1612. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, Z.P.; Jian, B.X.; Bai, X.Y.; Jian, Q.F. Thermal performance enhancement of air-cooled proton exchange membrane fuel cells by vapor chambers. Energy Convers. Manag. 2020, 213, 112830. [Google Scholar] [CrossRef]

- Huang, B.; Jian, Q.F.; Luo, L.Z.; Bai, X.Y. Research on the in-plane temperature distribution in a PEMFC stack integrated with flat-plate heat pipe under different startup strategies and inclination angles. Appl. Therm. Eng. 2020, 179, 115741. [Google Scholar] [CrossRef]

- Luo, F.; Bai, J.; Yan, C.; Sun, T.; Li, Y.; Tang, Y.; Zhang, S. A novel aluminum boss vapor chamber with 3D bioinspired wick for thermal management in electronic chip. Appl. Therm. Eng. 2025, 259, 124853. [Google Scholar] [CrossRef]

- Luo, J.L.; Mo, D.C.; Wang, Y.Q.; Lyu, S.S. Biomimetic Copper Forest Wick Enables High Thermal Conductivity Ultrathin Heat Pipe. ACS Nano 2021, 15, 6614–6621. [Google Scholar] [CrossRef]

- Li, Q.F.; Lan, Z.; Chun, J.; Lian, S.J.; Wen, R.F.; Ma, X.H. Fabrication and capillary characterization of multi-scale micro-grooved wicks with sintered copper powder. Int. Commun. Heat. Mass. Transf. 2021, 121, 105123. [Google Scholar] [CrossRef]

- Wu, Y.X.; Zou, G.S.; Du, C.J.; Xiao, Y.; Zhou, X.H.; Geng, R.K.; Yu, H.; Lv, C.J.; Liu, L. Enhanced capillary performance of multiscale ultrathin titanium wicks guided by modified wicking dynamics. Int. J. Heat. Mass. Transf. 2024, 221, 125000. [Google Scholar] [CrossRef]

- Wong, S.C.; Deng, M.S.; Liu, M.C. Characterization of composite mesh-groove wick and its performance in a visualizable flat-plate heat pipe. Int. J. Heat. Mass. Transf. 2022, 184, 122259. [Google Scholar] [CrossRef]

- Jafari, D.; Wits, W.W.; Geurts, B.J. Metal 3D-printed wick structures for heat pipe application: Capillary performance analysis. Appl. Therm. Eng. 2018, 143, 403–414. [Google Scholar] [CrossRef]

- Park, Y.Y.; Bang, I.C. Experimental study on 3D printed heat pipes with hybrid screen-groove combined capillary wick structure. Appl. Therm. Eng. 2023, 232, 121037. [Google Scholar] [CrossRef]

- Cao, Z.; Xie, X.; Huang, J.; Liao, H.; He, J.; Zheng, Y.; Long, J.; Huang, Y. Ultra-thin vapor chambers with composite wick fabricated by ultrafast laser for enhancing thermal performance. Int. J. Heat. Mass. Transf. 2024, 233, 126035. [Google Scholar] [CrossRef]

- Long, J.Y.; Chu, P.C.; Li, Y.; Lin, J.H.; Cao, Z.; Xu, M.F.; Ren, Q.L.; Xie, X.Z. Dual-scale porous/grooved microstructures prepared by nanosecond laser surface texturing for high-performance vapor chambers. J. Manuf. Process. 2022, 73, 914–923. [Google Scholar] [CrossRef]

- Chang, B.; Feng, Y.; Jin, J.; Zhou, Q. Low-Cost Laser Micromachining Super Hydrophilic–Super Hydrophobic Microgrooves for Robotic Capillary Micromanipulation of Microfibers. Micromachines 2021, 12, 854. [Google Scholar] [CrossRef]

- Guo, H.; Ji, X.; Xu, J. Enhancement of loop heat pipe heat transfer performance with superhydrophilic porous wick. Int. J. Therm. Sci. 2020, 156, 106466. [Google Scholar] [CrossRef]

- Liu, E.-C.; Yu, J.-C.; Chiang, C.-Y.; Liao, C.-N. Enhancing capillary performance of copper wicks by electrodeposition of superhydrophilic dendritic structures. Mater. Chem. Phys. 2023, 307, 128217. [Google Scholar] [CrossRef]

- Huang, G.W.; Liu, W.Y.; Luo, Y.Q.; Li, Y.; Chen, H.Y. Fabrication and capillary performance of a novel composite wick for ultra-thin heat pipes. Int. J. Heat. Mass. Transf. 2021, 176, 121467. [Google Scholar] [CrossRef]

- He, G.C.; Sheng, Y.X.; Ye, G.M.; He, B.H.; Yu, B.W.; Tian, M.; Jian, Q.F.; Yu, X. Heat transfer performance analysis of an ultra-thin aluminum vapor chamber with serrated microgrooves. Appl. Therm. Eng. 2023, 229, 120604. [Google Scholar] [CrossRef]

- Lou, L.; Kang, Z.; Zhang, H.; Wang, P.; Fan, J. Nano-capillary aluminum finned heat sink for ultra-efficient evaporative cooling. Mater. Today Phys. 2023, 36, 101175. [Google Scholar] [CrossRef]

- Li, H.W.; Ren, J.; Yin, D.D.; Lu, G.L.; Du, C.H.; Jin, X.; Jia, Y.T. Effects of inclination angle and heat power on heat transfer behavior of flat heat pipe with bionic grading microchannels. Appl. Therm. Eng. 2022, 206, 118079. [Google Scholar] [CrossRef]

- Liu, X.M.; Chai, Y.E.; Li, J.P.; Gu, J.S.; Zhu, J.J.; Yang, L.Y.; Wei, W.; Liu, C.J.; Liu, Y.R. Effect of evaporation and condensation section length ratio on thermal performance of aluminum flat plate heat pipe with different micro grooved wicks. Appl. Therm. Eng. 2023, 233, 121115. [Google Scholar] [CrossRef]

- He, H.D.; Li, J.P.; He, Z.Y.; Shi, J.C.; Liu, X.Y.; Lu, K.J.; Fan, X.L.; Chen, F.; Wu, Q.; Wang, C.J.; et al. Preparation of hierarchical microgroove textures on the surface of Al-based wicks by roller pressing and laser scanning irradiation. Surf. Coat. Technol. 2024, 487, 131008. [Google Scholar] [CrossRef]

- Jiang, G.C.; Tian, Z.; Luo, X.; Chen, C.H.; Hu, X.Y.; Wang, L.Z.; Peng, R.; Zhang, H.J.; Zhong, M.L. Ultrathin aluminum wick with dual-scale microgrooves for enhanced capillary performance. Int. J. Heat. Mass. Transf. 2022, 190, 122762. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Y.; Bennett, P.; Cheng, J.; Yang, Q.; Liu, D. Capillary performance of vertically grooved wicks on laser-processed aluminum surfaces with different wettability. J. Phys. D Appl. Phys. 2023, 56, 425501. [Google Scholar] [CrossRef]

- Liang, Y.F.; Bai, J.J.; Yan, C.M.; Tang, Y.; Zhong, G.S.; Zhang, S.W. Experimental investigation on a 0.5-metre-long aluminum flat heat pipe for thermal management in electronic devices. Appl. Therm. Eng. 2024, 241, 122211. [Google Scholar] [CrossRef]

- Henry, M.; Merlis, T.M. The Role of the Nonlinearity of the Stefan-Boltzmann Law on the Structure of Radiatively Forced Temperature Change. J. Clim. 2019, 32, 335–348. [Google Scholar] [CrossRef]

- Nam, Y.; Sharratt, S.; Byon, C.; Kim, S.J.; Ju, Y.S. Fabrication and Characterization of the Capillary Performance of Superhydrophilic Cu Micropost Arrays. J. Microelectromechanical Syst. 2010, 19, 581–588. [Google Scholar] [CrossRef]

- Byon, C.; Kim, S.J. Capillary performance of bi-porous sintered metal wicks. Int. J. Heat. Mass. Transf. 2012, 55, 4096–4103. [Google Scholar] [CrossRef]

- Huang, G.; Liao, J.; Fan, C.; Liu, S.; Miao, W.; Zhang, Y.; Ta, S.; Yang, G.; Cui, C. Gradient-Pattern Micro-Grooved Wicks Fabricated by the Ultraviolet Nanosecond Laser Method and Their Enhanced Capillary Performance. Micromachines 2024, 15, 165. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Cheng, H.; Luan, T.; Yang, T.; Xue, H. Experimental study on the influence of surface modification methods of carbon fiber felt on the operation and heat transfer characteristics of loop heat pipes. Appl. Therm. Eng. 2023, 233, 121121. [Google Scholar] [CrossRef]

- Lou, D.Y.; Chen, P.J.; Jiang, H.L.; Yang, D.C.; Yang, Q.B.; Tao, Q.; Liu, D. Enhancement in the Capillary Performance of Aluminum Groove through Laser Textured Deposition. Crystals 2023, 13, 1397. [Google Scholar] [CrossRef]

- Singh, R.; Akbarzadeh, A.; Mochizuki, M. Experimental Determination of Wick Properties for Loop Heat Pipe Applications. J. Porous Media 2009, 12, 759–776. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Cai, J.C.; Jin, T.X.; Kou, J.S.; Zou, S.M.; Xiao, J.F.; Meng, Q.B. Lucas-Washburn Equation-Based Modeling of Capillary-Driven Flow in Porous Systems. Langmuir 2021, 37, 1623–1636. [Google Scholar] [CrossRef]

- Liang, S.; Zhang, L.; Cui, Z.; Ma, X. Investigation of spontaneous capillary flow and heat transfer characteristics in parallel microchannels based on phase-field model. Therm. Sci. Eng. Progress. 2022, 36, 101517. [Google Scholar] [CrossRef]

- Kim, B.S.; Lee, H.; Shin, S.; Choi, G.; Cho, H.H. Interfacial wicking dynamics and its impact on critical heat flux of boiling heat transfer. Appl. Phys. Lett. 2014, 105, 191601. [Google Scholar] [CrossRef]

- Gregorcic, P.; Setina-Batic, B.; Hocevar, M. Controlling the stainless steel surface wettability by nanosecond direct laser texturing at high fluences. Appl. Phys. A Mater. Sci. Process. 2017, 123, 766. [Google Scholar] [CrossRef]

- Ma, H.B.; Peterson, G.P. The Minimum Meniscus Radius and Capillary Heat Transport Limit in Micro Heat Pipes. J. Heat. Transf. 1998, 120, 227–233. [Google Scholar] [CrossRef]

- Wang, J.X.; Tang, Y.; Huang, H.Y.; Xi, X.Q.; Li, H.M.; Yan, C.M.; Zhang, S.W. Rice-inspired oriented copper fiber wick with excellent capillary performance for ultra-thin vapor chamber. Appl. Therm. Eng. 2024, 236, 121573. [Google Scholar] [CrossRef]

- Li, H.; Fang, X.T.; Li, G.F.; Zhou, G.F.; Tang, Y. Investigation on fabrication and capillary performance of multi-scale composite porous wick made by alloying-dealloying method. Int. J. Heat. Mass. Transf. 2018, 127, 145–153. [Google Scholar] [CrossRef]

- Deng, D.X.; Liang, D.J.; Tang, Y.; Peng, J.M.; Han, X.D.; Pan, M.Q. Evaluation of capillary performance of sintered porous wicks for loop heat pipe. Exp. Therm. Fluid. Sci. 2013, 50, 1–9. [Google Scholar] [CrossRef]

- Holley, B.; Faghri, A. Permeability and effective pore radius measurements for heat pipe and fuel cell applications. Appl. Therm. Eng. 2006, 26, 448–462. [Google Scholar] [CrossRef]

- Wang, H.W.; Tang, Y.F.; Bai, P.F.; Guo, W.; Luo, Y.H.; Li, S.X.; Zhang, X.T.; Zhou, G.F. A multiscale composite silicon carbide wick with excellent capillary performance. Int. Commun. Heat. Mass. Transf. 2022, 139, 106478. [Google Scholar] [CrossRef]

| Calculated Parameter | Equation | Result |

|---|---|---|

| porosity | 1.92% | |

| wicking coefficient | 4.47% | |

| 4.28% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Wei, Y.; Sun, T.; Bai, J.; Luo, F.; Qiu, H.; Li, Y.; Yuan, W.; Zhang, S. Fabrication and Performance of Aluminum-Based Composite Wicks Using a Two-Step Laser-Sintering Process. Micromachines 2025, 16, 370. https://doi.org/10.3390/mi16040370

Tang Y, Wei Y, Sun T, Bai J, Luo F, Qiu H, Li Y, Yuan W, Zhang S. Fabrication and Performance of Aluminum-Based Composite Wicks Using a Two-Step Laser-Sintering Process. Micromachines. 2025; 16(4):370. https://doi.org/10.3390/mi16040370

Chicago/Turabian StyleTang, Yong, Yuxin Wei, Tong Sun, Jingjing Bai, Fangqiong Luo, Huarong Qiu, Yiming Li, Wei Yuan, and Shiwei Zhang. 2025. "Fabrication and Performance of Aluminum-Based Composite Wicks Using a Two-Step Laser-Sintering Process" Micromachines 16, no. 4: 370. https://doi.org/10.3390/mi16040370

APA StyleTang, Y., Wei, Y., Sun, T., Bai, J., Luo, F., Qiu, H., Li, Y., Yuan, W., & Zhang, S. (2025). Fabrication and Performance of Aluminum-Based Composite Wicks Using a Two-Step Laser-Sintering Process. Micromachines, 16(4), 370. https://doi.org/10.3390/mi16040370