Research on the Method of Optimizing the Stress and Improving the Performance for MEMS Gyroscope Based on the Cantilever-Plate Structure

Abstract

1. Introduction

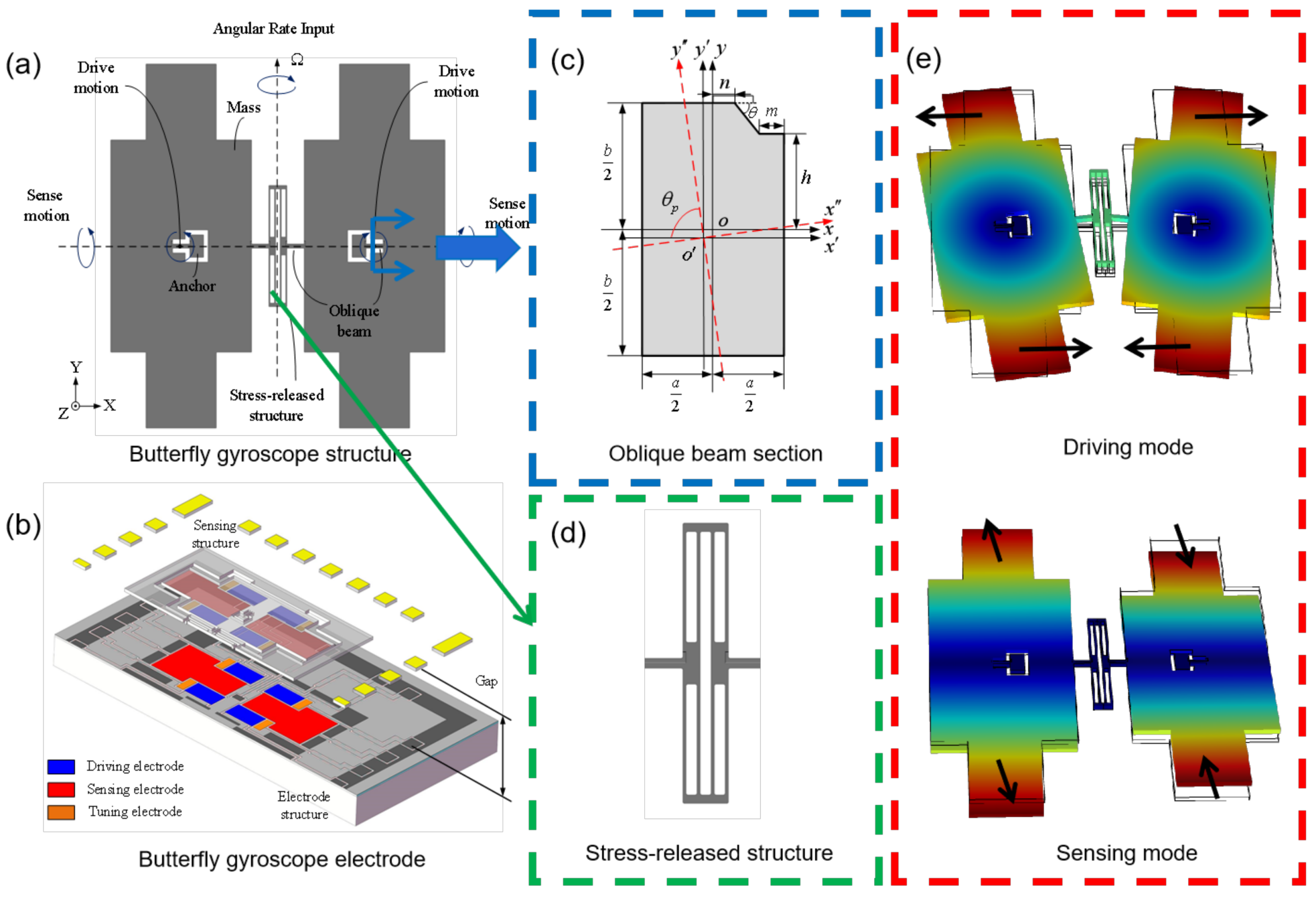

2. Theoretical Effect of Thermal Stress in the MEMS Butterfly Gyroscope

2.1. Structure and Working Principle of the MEMS Butterfly Gyroscope

2.2. Theoretical Effect of Thermal Stress on the MEMS Butterfly Gyroscope

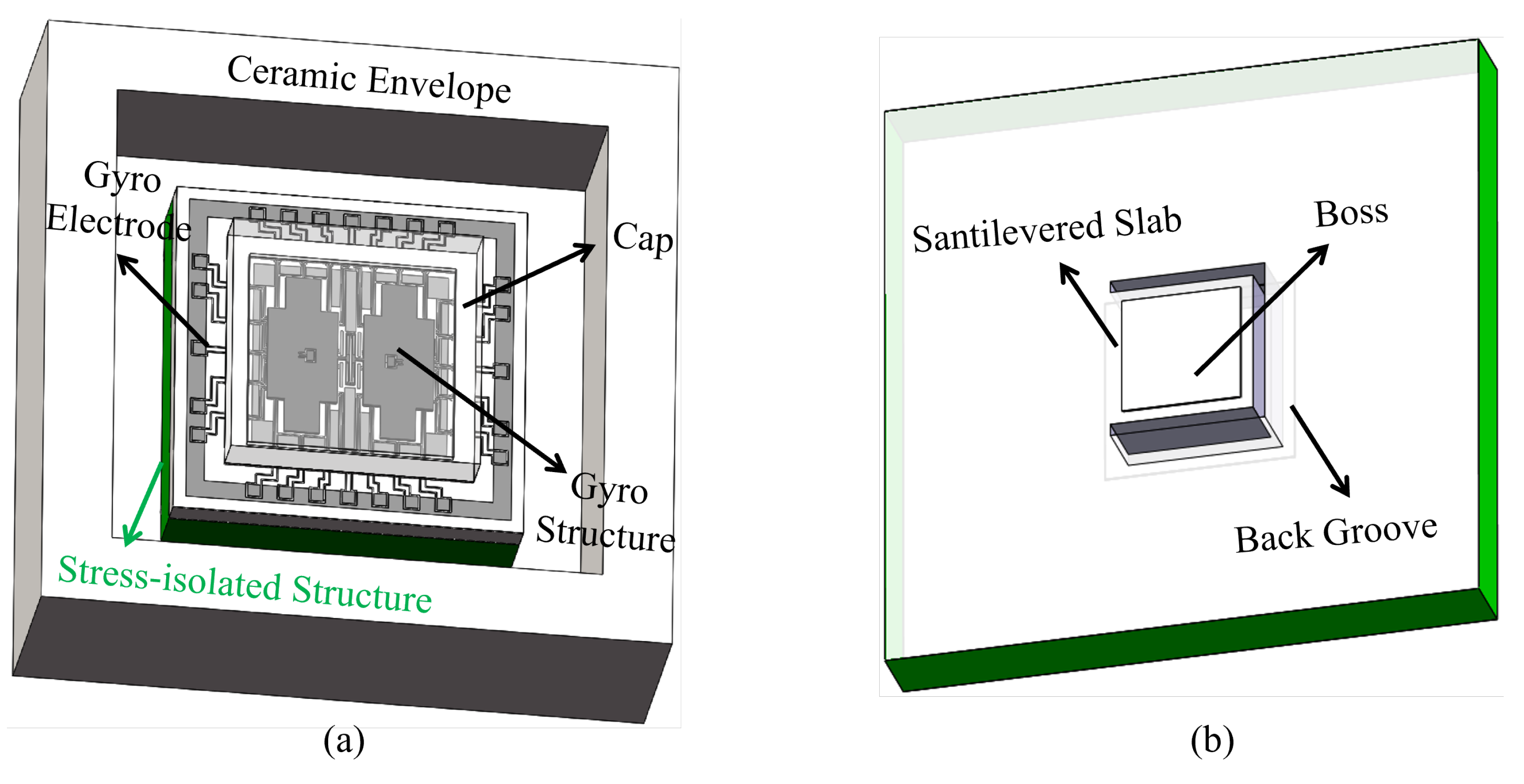

3. Design and Optimization of the Cantilever Plate Structure

3.1. Design of the Cantilever Plate Structure

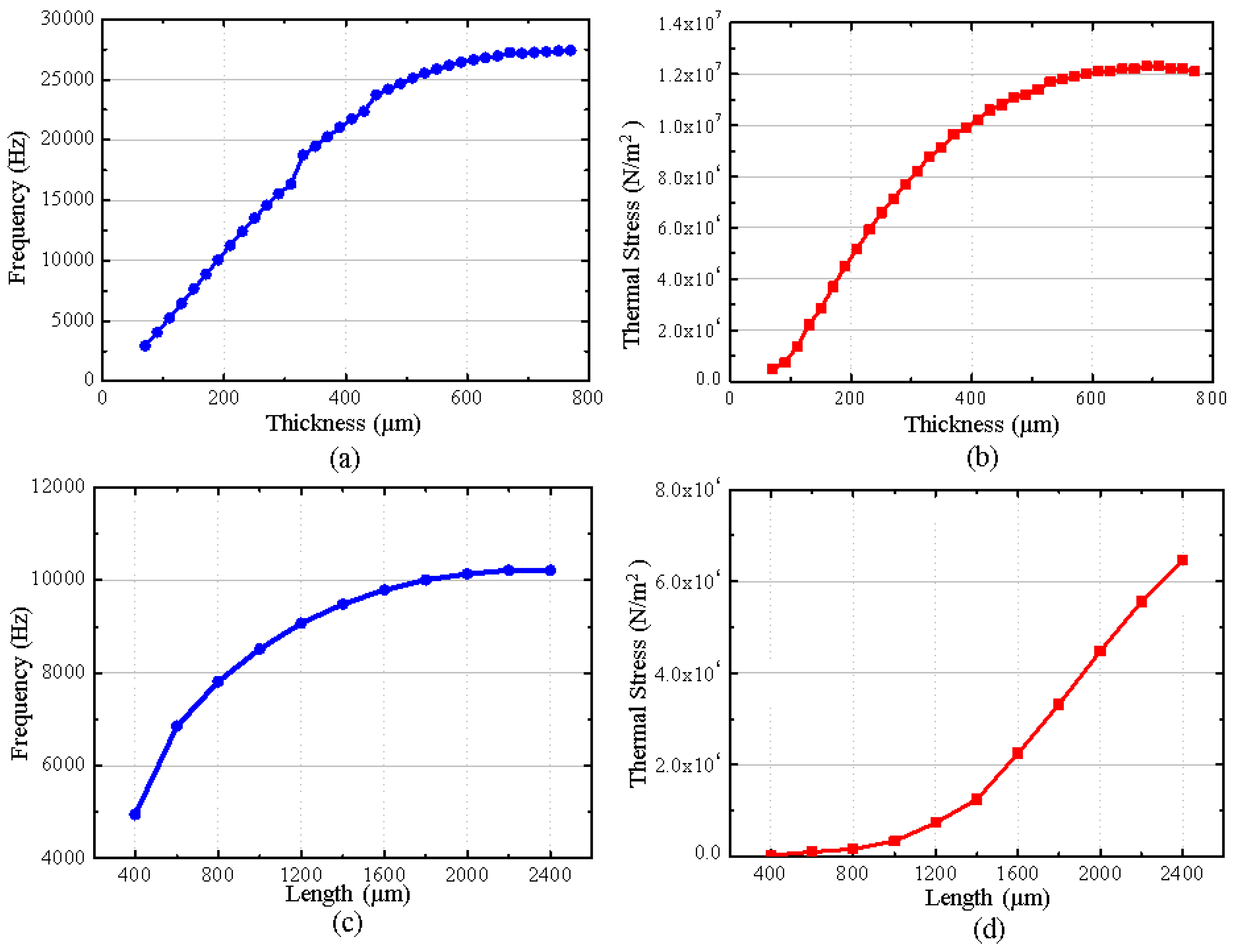

3.2. Optimization of the Critical Sizes

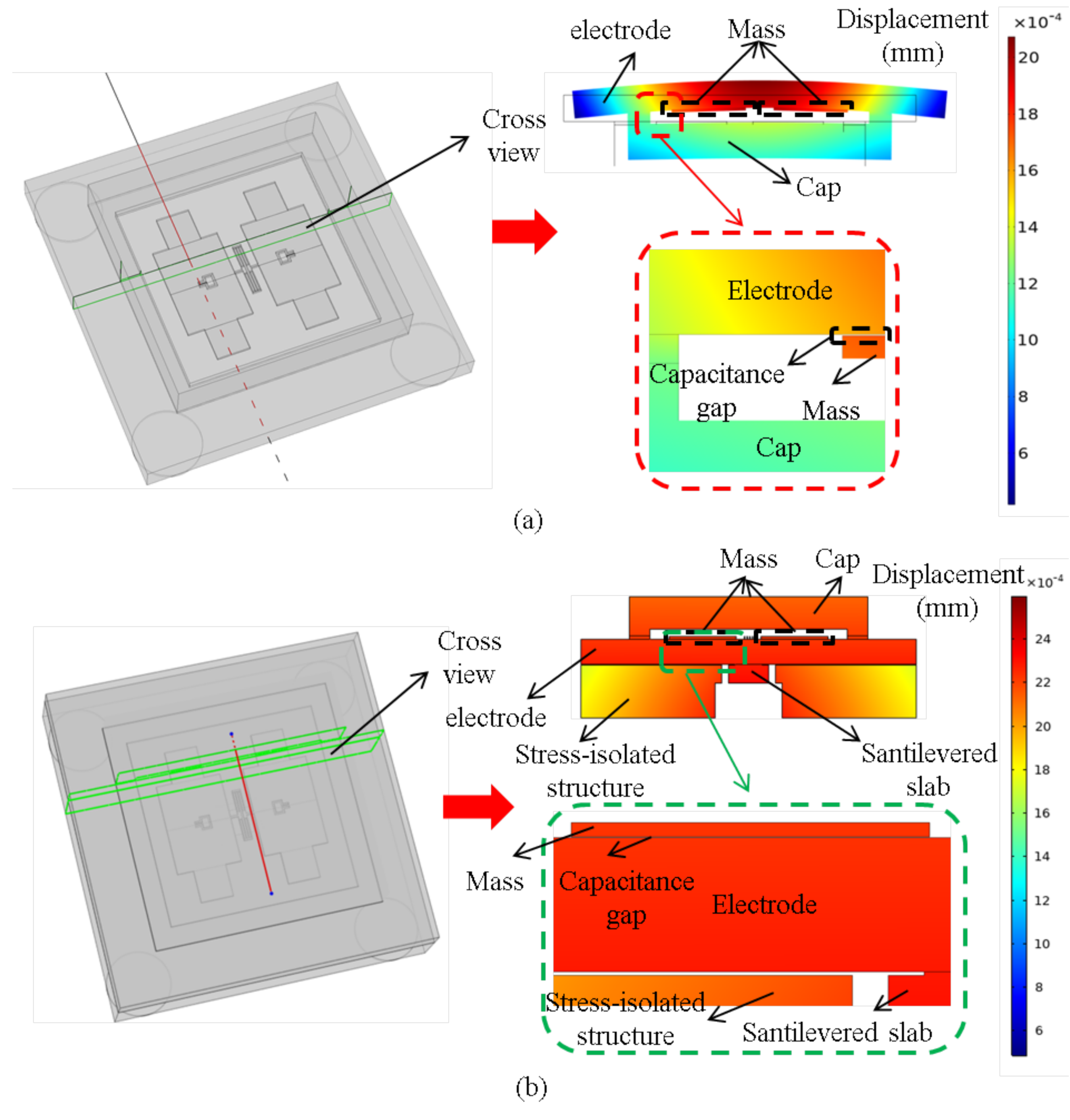

3.3. Simulation of the Stress Isolated Effect

4. Fabrication and Performance Tests of the Cantilever Plate Structure

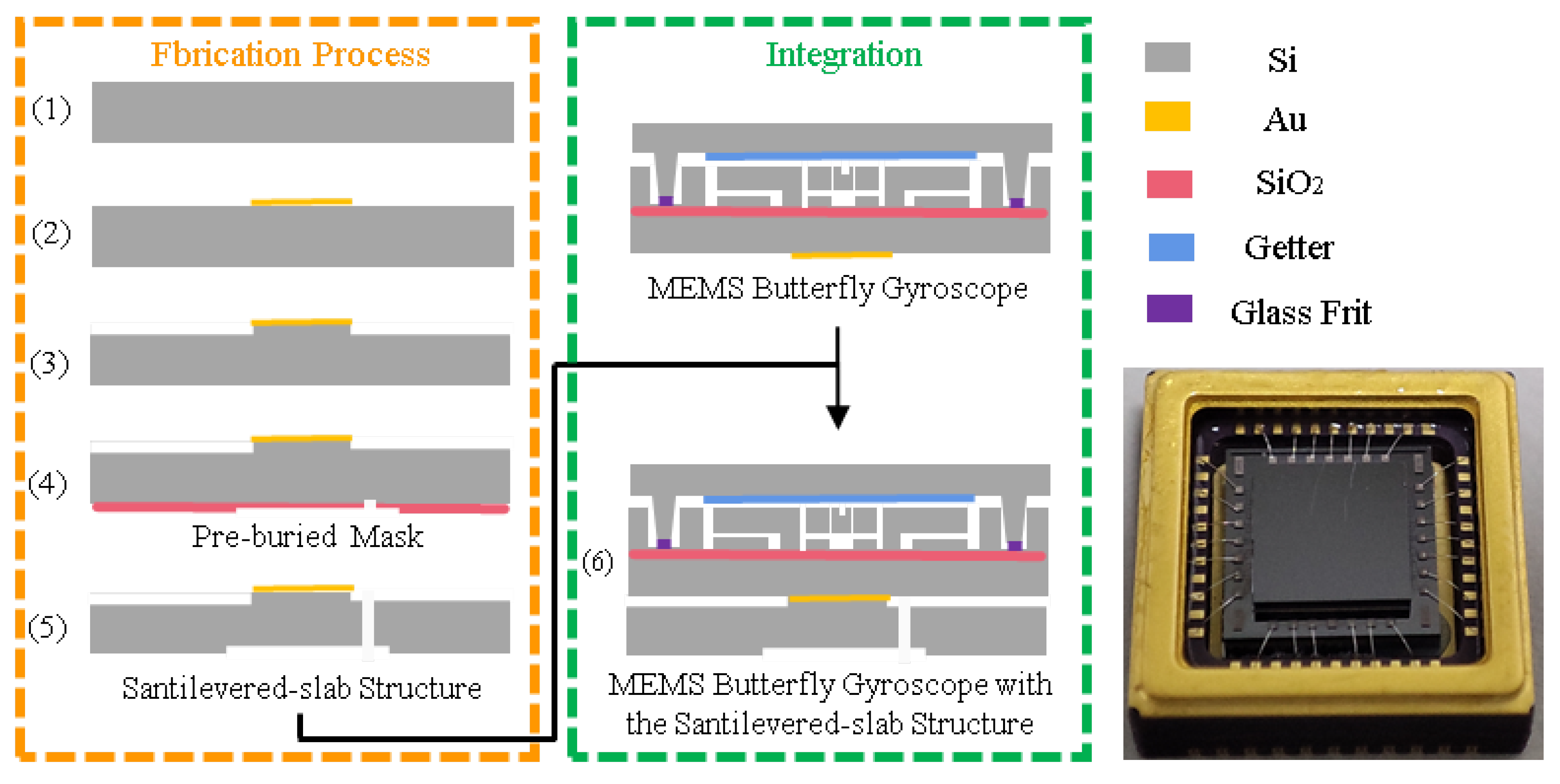

4.1. Fabrication and Integration

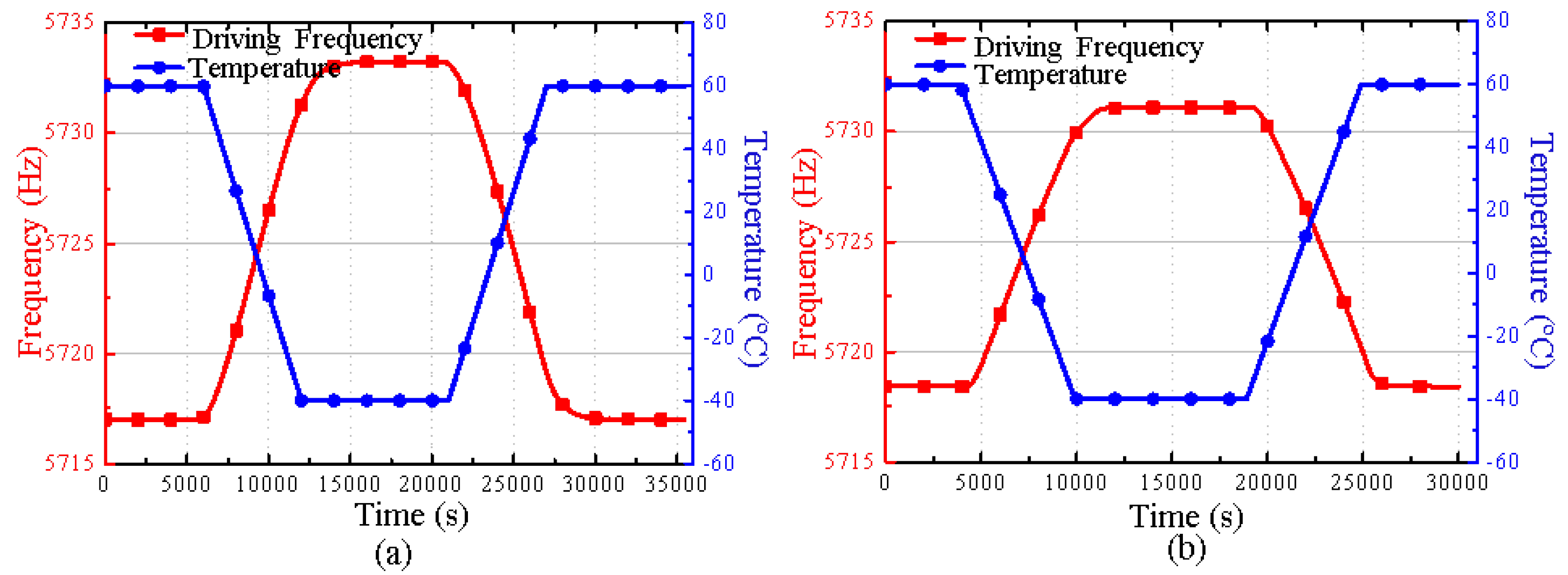

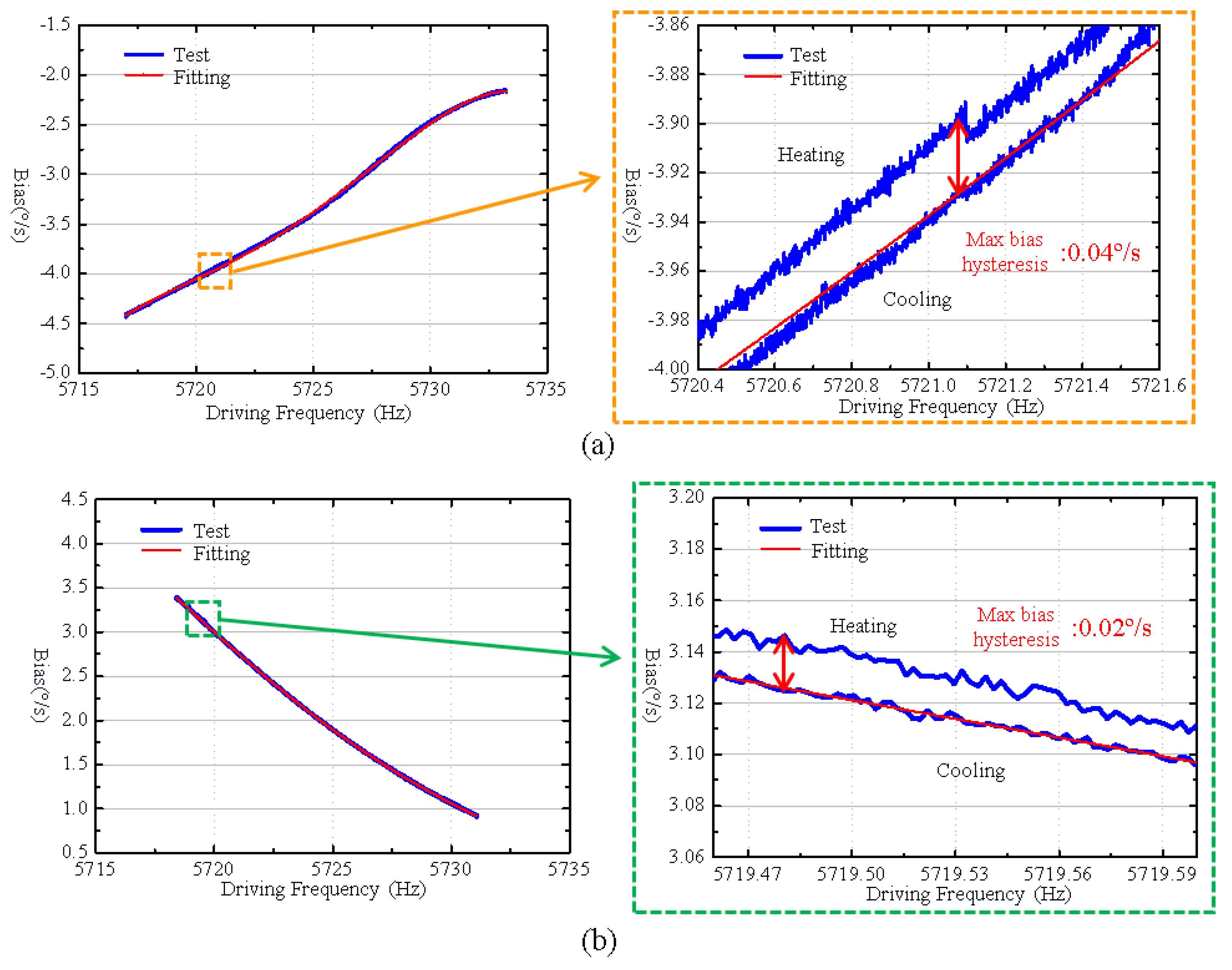

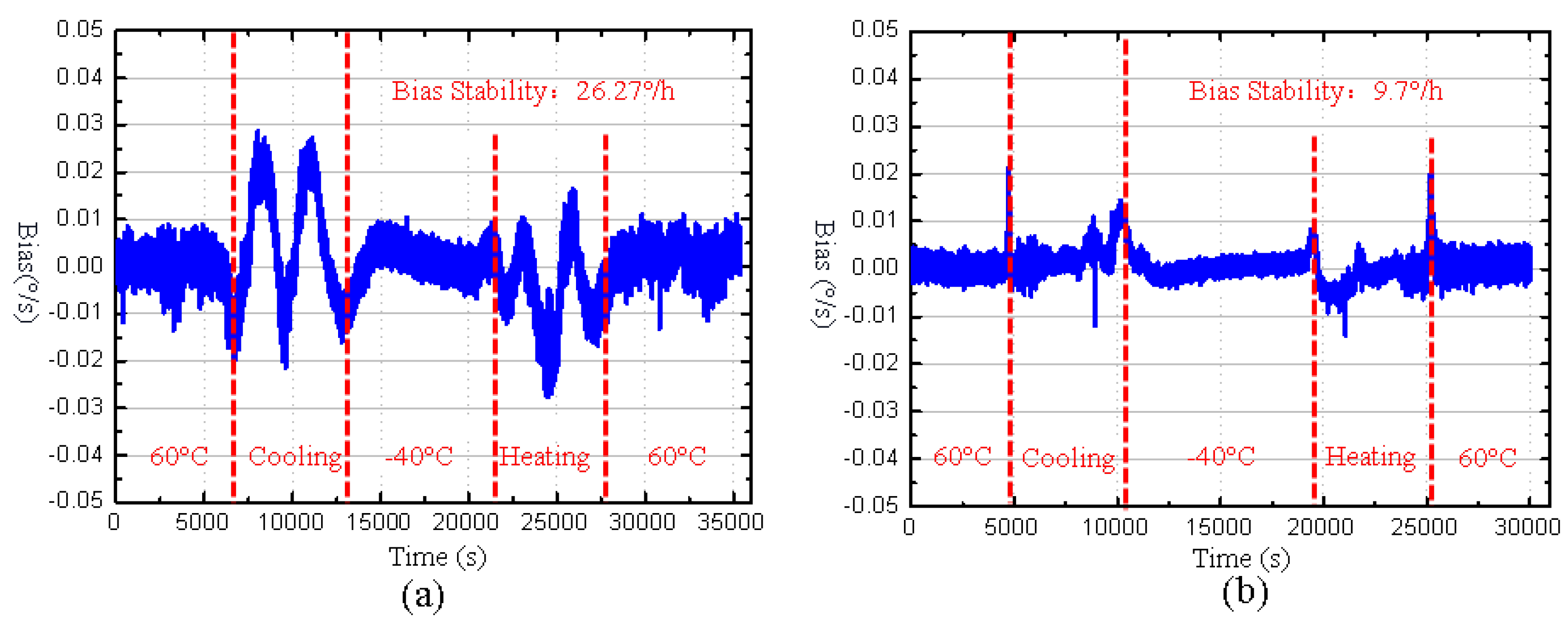

4.2. Performance Tests

4.3. Analysis of Experimental Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hunt, C.L.; Sharma, A.; Osborn, L.E.; Kaliki, R.R.; Thakor, N.V. Predictive trajectory estimation during rehabilitative tasks in augmented reality using inertial sensors. In Proceedings of the 2018 IEEE Biomedical Circuits and Systems Conference (BioCAS), Cleveland, OH, USA, 17–19 October 2018; pp. 1–4. [Google Scholar]

- Prikhodko, I.P.; Bearss, B.; Merritt, C.; Bergeron, J.; Blackmer, C. Towards self-navigating cars using MEMS IMU: Challenges and opportunities. In Proceedings of the 2018 IEEE International Symposium on Inertial Sensors and Systems (INERTIAL), Lake Como, Italy, 26–29 March 2018; pp. 1–4. [Google Scholar]

- de Alteriis, G.; Accardo, D.; Moriello, R.S.L.; Ruggiero, R.; Angrisani, L. Redundant configuration of low-cost inertial sensors for advanced navigation of small unmanned aerial systems. In Proceedings of the 2019 IEEE 5th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Torino, Italy, 19–21 June 2019; pp. 672–676. [Google Scholar]

- Komianos, A. The autonomous shipping era. operational, regulatory, and quality challenges. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2018, 12, 335–348. [Google Scholar]

- Gadola, M.; Buffoli, A.; Sansa, M.; Berthelot, A.; Robert, P.; Langfelder, G. 1.3 mm 2 nav-grade NEMS-based gyroscope. J. Microelectromechan. Syst. 2021, 30, 513–520. [Google Scholar]

- Ou, F.; Hou, Z.; Miao, T.; Xiao, D.; Wu, X. A new stress-released structure to improve the temperature stability of the butterfly vibratory gyroscope. Micromachines 2019, 10, 82. [Google Scholar] [CrossRef] [PubMed]

- Xing, B.; Zhou, B.; Wei, Q.; Hou, B.; Li, D.; Zhang, T.; Zhang, R. Study on the effect of quadrature error on in-phase output based on electrostatic compensation. In Proceedings of the 2020 IEEE International Symposium on Inertial Sensors and Systems (INERTIAL), Hiroshima, Japan, 23–26 March 2020; pp. 1–3. [Google Scholar]

- Jia, J.; Ding, X.; Qin, Z.; Ruan, Z.; Li, W.; Liu, X.; Li, H. Overview and analysis of MEMS Coriolis vibratory ring gyroscope. Measurement 2021, 182, 109704. [Google Scholar]

- Shi, Y.; Lu, K.; Li, B.; Chen, Y.; Xi, X.; Wu, Y.; Wu, X.; Xiao, D. Ultrafast laser in fabrication of micro hemispherical resonators with quality factor over millions. J. Micromechan. Microeng. 2021, 31, 055002. [Google Scholar] [CrossRef]

- Ho, G.K.; Sundaresan, K.; Pourkamali, S. Micromechanical IBARs: Tunable High-Q Resonators for Temperature-Compensated Reference Oscillators. J. Microelectromechan. Syst. 2010, 19, 503–515. [Google Scholar] [CrossRef]

- Xu, P.; Wei, Z.; Jia, L.; Zhao, Y.; Han, G.; Si, C.; Ning, J.; Yang, F. Zro drift reduction of mems gyroscopes via internal and packaging stress release. Micromachines 2021, 12, 1329. [Google Scholar] [CrossRef] [PubMed]

- Maeda, D.; Ono, K.; Giner, J.; Matsumoto, M.; Kanamaru, M.; Sekiguchi, T.; Hayashi, M. MEMS Gyroscope with Less Than 1-deg/h Bias Instability Variation in Temperature Range from −40 °C to 125 °C. IEEE Sens. J. 2018, 8, 1006–1015. [Google Scholar] [CrossRef]

- Xing, B.; Zhou, B.; Zhang, X.; Zhang, W.; Hou, B.; Wei, Q.; Zhang, T.; Zhang, R. Thermal Deformation Suppression Chip Based on Material Symmetry Design for Single Center Supported MEMS Devices. IEEE Access 2020, 8, 43314–43324. [Google Scholar]

- Hou, Z.; Ou, F.; Xu, Q.; Miao, T.; Xiao, D.; Wu, X. A quadrature compensation method to improve the performance of the butterfly vibratory gyroscope. Sens. Actuators A Phys. 2021, 319, 112527. [Google Scholar] [CrossRef]

- Ou, F.; Hou, Z.; Wu, X.; Xiao, D. Analysis and design of a polygonal oblique beam for the butterfly vibratory gyroscope with improved robustness to fabrication imperfections. Micromachines 2018, 9, 198. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Hou, Z.; Kuang, Y.; Miao, T.; Ou, F.; Zhuo, M.; Xiao, D.; Wu, X. A tuning fork gyroscope with a polygon-shaped vibration beam. Micromachines 2019, 10, 813. [Google Scholar] [CrossRef] [PubMed]

- Lapadatu, D.; Blixhavn, B.; Holm, R.; KvisterÌüy, T. SAR500-A high-precision high-stability butterfly gyroscope with north seeking capability. In Proceedings of the IEEE/ION PLANS 2010, Palm Springs, CA, USA, 4–6 May 2010; pp. 6–13. [Google Scholar]

- Li, X.; Ono, T.; Wang, Y.; Esashi, M. Study on ultra-thin NEMS cantilevers—High yield fabrication and size-effect on Young’s modulus of silicon. In Proceedings of the Technical Digest. MEMS 2002 IEEE International Conference. Fifteenth IEEE International Conference on Micro Electro Mechanical Systems (Cat. No.02CH37266), Las Vegas, NV, USA, 24 January 2002. [Google Scholar]

- Kuang, Y.; Xiao, D.; Hou, Z.; Wu, X.; Liu, G. Research on the Temperature-dependent Performance Improvement of Butterfly Gyroscope with Stress Isolation. In Proceedings of the 2023 IEEE 18th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Jeju Island, Republic of Korea, 14–17 May 2023. [Google Scholar]

- Hou, Z. Study on Key Technologies of Improvement in Bias Stability of the Micromachined Butterfly Gyroscope. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2012. [Google Scholar]

- Uzunoglu, B.E.; Erkan, D.; Tatar, E. A Ring Gyroscope With On-Chip Capacitive Stress Compensation. J. Microelectromechan. Syst. 2022, 31, 741–752. [Google Scholar]

- Chen, L.; Miao, T.; Li, Q.; Wang, P.; Wu, X.; Xi, X.; Xiao, D. A Temperature Drift Suppression Method of Mode-Matched MEMS Gyroscope Based on a Combination of Mode Reversal and Multiple Regression. Micromachines 2022, 13, 1557. [Google Scholar] [CrossRef] [PubMed]

| Samples | Driving Frequency (Hz) | Frequency Drift (Hz) | Maximum Bias Hysteresis Error (°/s) | Bias Stability (°/h) |

|---|---|---|---|---|

| No. 1 (original) | 5733.3–5717 | 16.3 | 0.054 | 26.27 |

| No. 1 (improved) | 5731.1–5718.4 | 12.7 | 0.022 | 9.7 |

| No. 2 (original) | 5725.5–5710 | 15.5 | 0.097 | 42.13 |

| No. 2 (improved) | 5723.1–5711.6 | 12.5 | 0.052 | 24.21 |

| No. 3 (original) | 5711.3–5692.5 | 18.8 | 0.11 | 45.32 |

| No. 3 (improved) | 5709.1–5695.9 | 13.2 | 0.08 | 33.56 |

| No. 4 (original) | 5730.6–5713.1 | 17.5 | 0.068 | 29.03 |

| No. 4 (improved) | 5728.2–5714.4 | 13.8 | 0.035 | 15.3 |

| No. 5 (original) | 5729.2–5713.4 | 15.8 | 0.074 | 31.25 |

| No. 5 (improved) | 5727.1–5714.7 | 12.4 | 0.04 | 16.17 |

| No. 6 (original) | 5728.8–5712 | 16.8 | 0.065 | 28.72 |

| No. 6 (improved) | 5726.1–5713 | 13.1 | 0.037 | 14.7 |

| No. 7 (original) | 5726.3–5710.5 | 15.8 | 0.09 | 35.24 |

| No. 7 (improved) | 5724.7–5711.1 | 13.6 | 0.055 | 27.63 |

| No. 8 (original) | 5735.2–5718 | 17.2 | 0.058 | 28.56 |

| No. 8 (improved) | 5733.6–5720.2 | 13.4 | 0.03 | 12.62 |

| No. 9 (original) | 5733.7–5718 | 15.7 | 0.075 | 31.68 |

| No. 9 (improved) | 5731.9–5719.4 | 12.5 | 0.039 | 14.83 |

| No. 10 (original) | 5736.9–5719.7 | 17.2 | 0.085 | 32.56 |

| No. 10 (improved) | 5734.5–5721.1 | 13.4 | 0.041 | 16.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuang, Y.; Huo, X.; Guo, W.; Li, X.; He, J.; Mao, Q.; Ma, X.; Liu, J. Research on the Method of Optimizing the Stress and Improving the Performance for MEMS Gyroscope Based on the Cantilever-Plate Structure. Micromachines 2025, 16, 372. https://doi.org/10.3390/mi16040372

Kuang Y, Huo X, Guo W, Li X, He J, Mao Q, Ma X, Liu J. Research on the Method of Optimizing the Stress and Improving the Performance for MEMS Gyroscope Based on the Cantilever-Plate Structure. Micromachines. 2025; 16(4):372. https://doi.org/10.3390/mi16040372

Chicago/Turabian StyleKuang, Yunbin, Xiaoyan Huo, Weitao Guo, Xiaoxing Li, Jiangyan He, Qiong Mao, Xiaolin Ma, and Jie Liu. 2025. "Research on the Method of Optimizing the Stress and Improving the Performance for MEMS Gyroscope Based on the Cantilever-Plate Structure" Micromachines 16, no. 4: 372. https://doi.org/10.3390/mi16040372

APA StyleKuang, Y., Huo, X., Guo, W., Li, X., He, J., Mao, Q., Ma, X., & Liu, J. (2025). Research on the Method of Optimizing the Stress and Improving the Performance for MEMS Gyroscope Based on the Cantilever-Plate Structure. Micromachines, 16(4), 372. https://doi.org/10.3390/mi16040372