Low-Pressure Chemical Vapor Deposition SiNx Process Study and Its Impact on Interface Characteristics of AlGaN/GaN MISHEMTs

Abstract

:1. Introduction

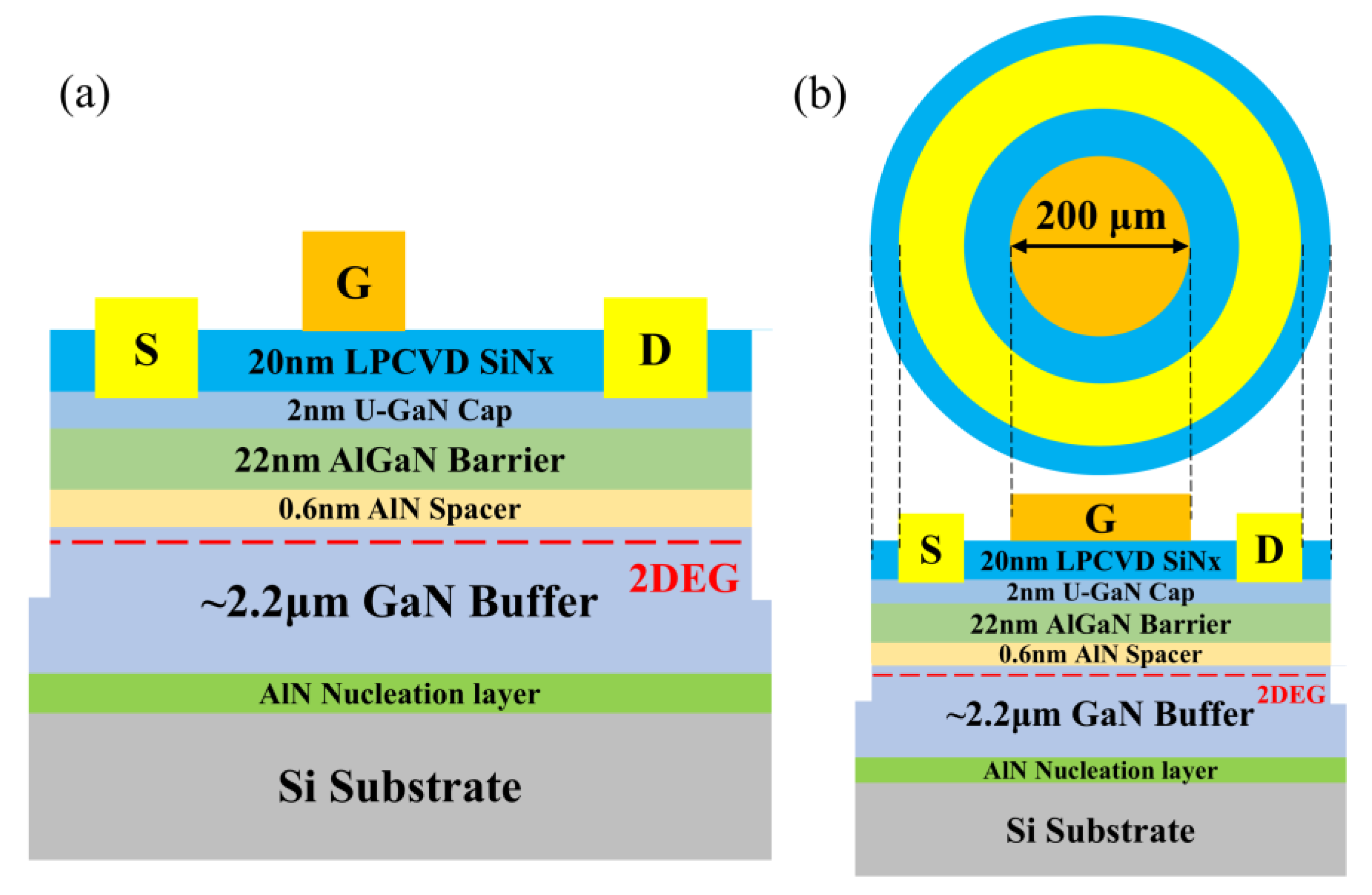

2. Materials and Methods

3. Results

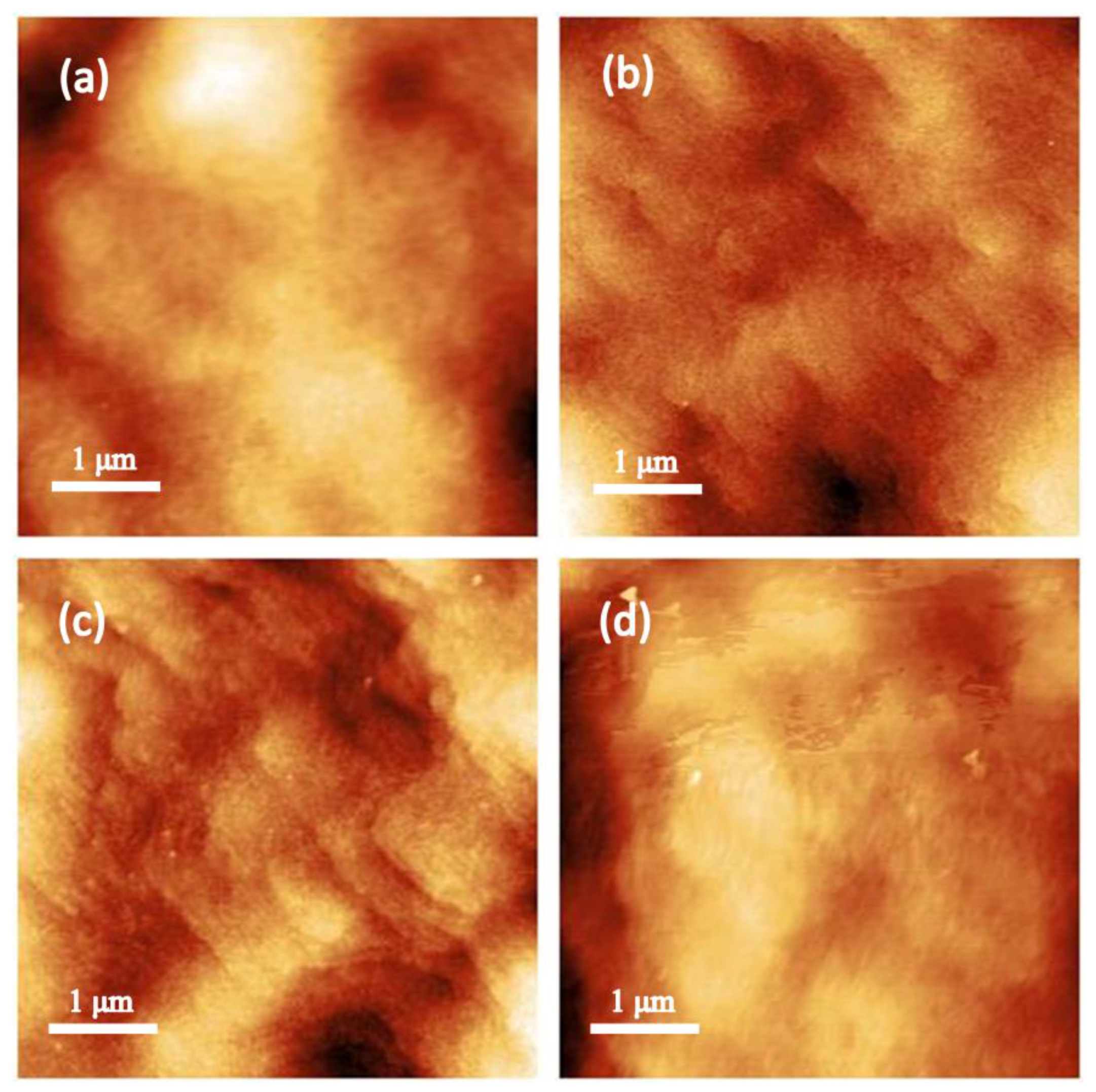

3.1. Modulation of LPCVD SiNx Growth Conditions

3.2. Influence of LPCVD SiNx Growth Conditions on 2DEG

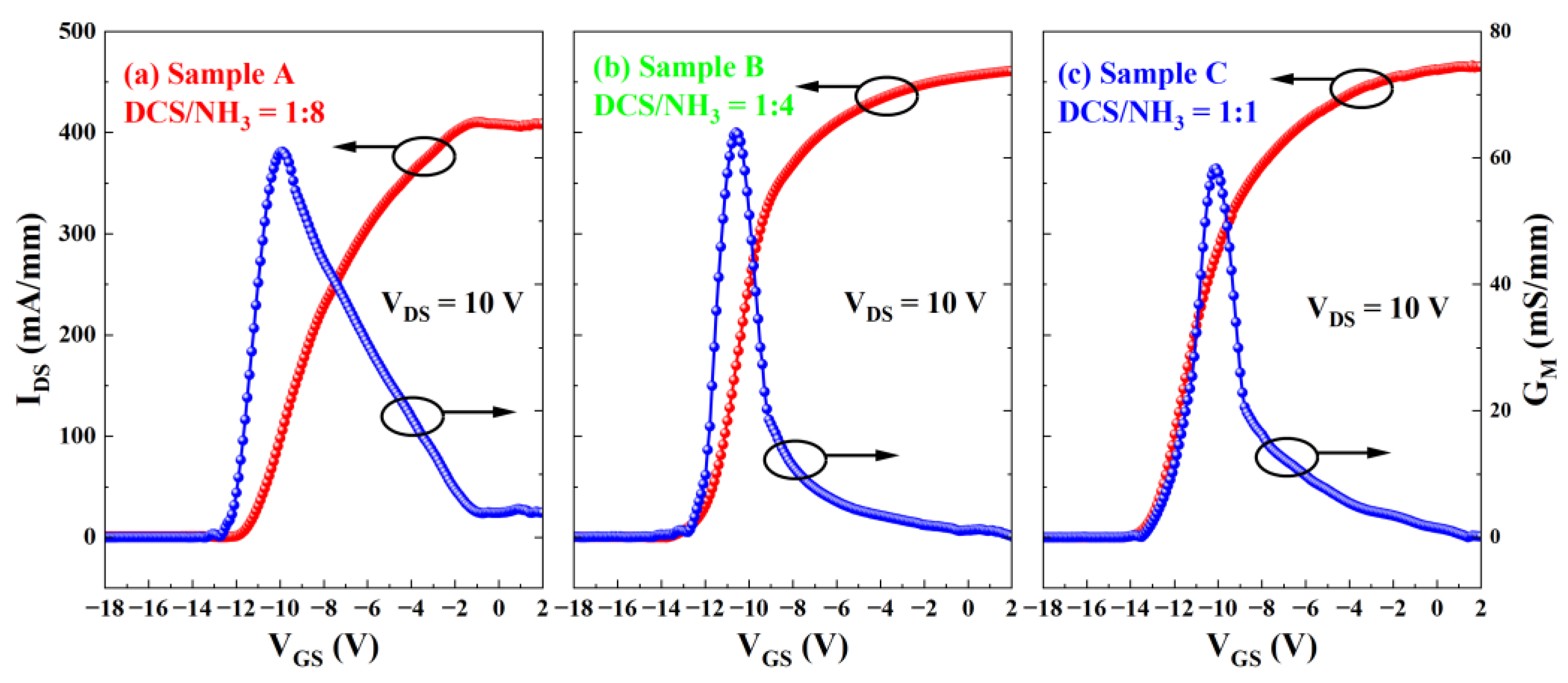

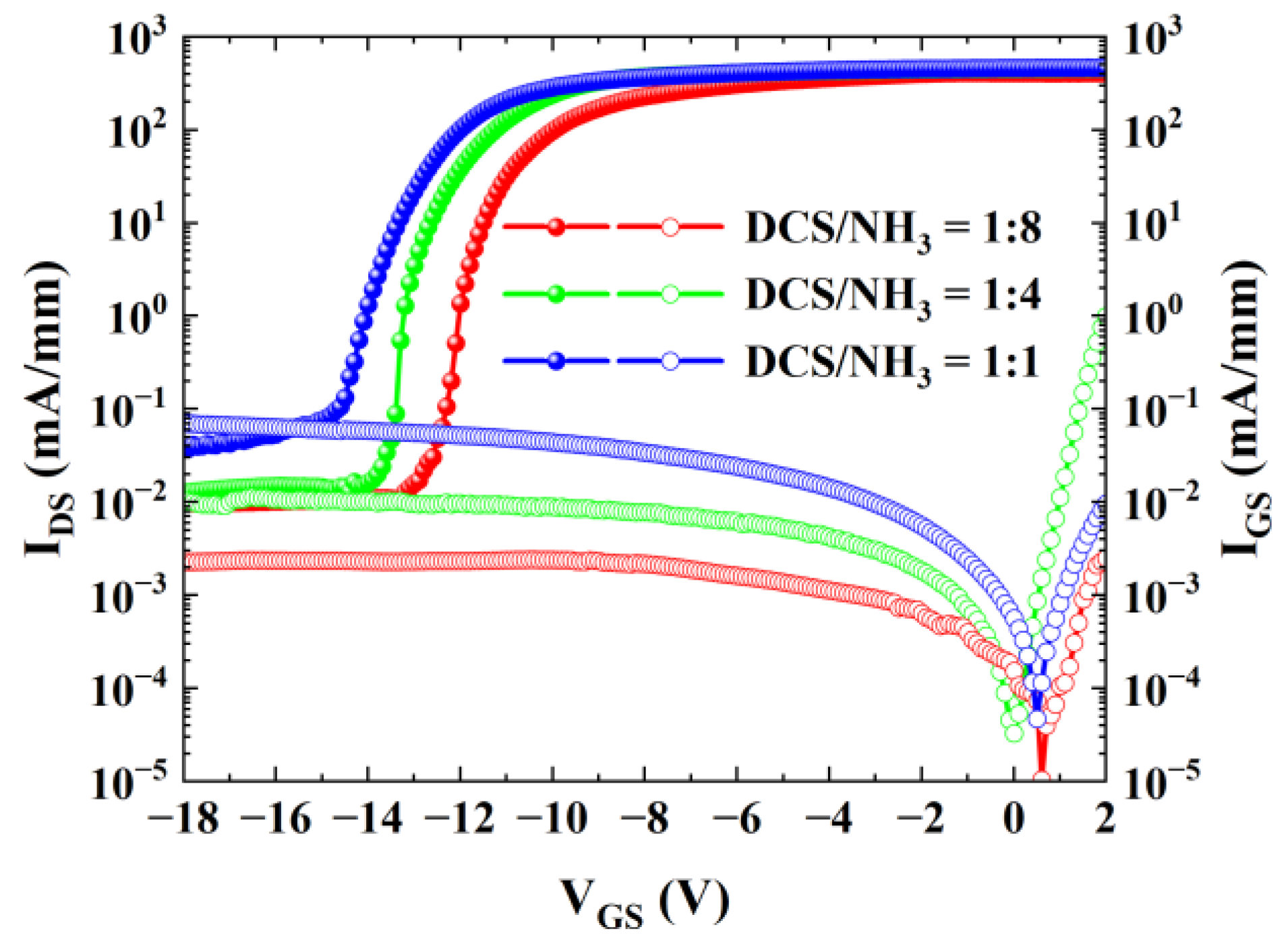

3.3. DC Characteristics of Devices

3.4. Analysis of Gate Leakage Current

3.5. Interface Trap Characterization

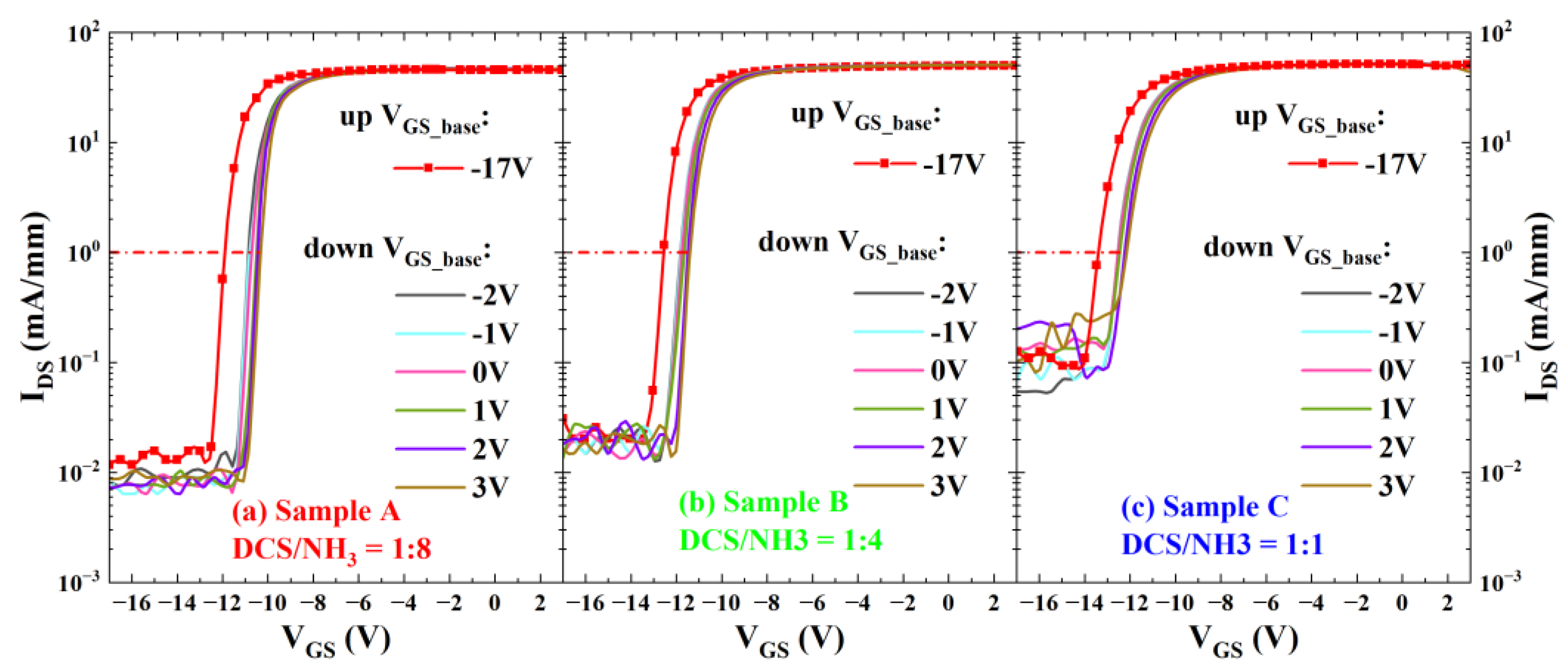

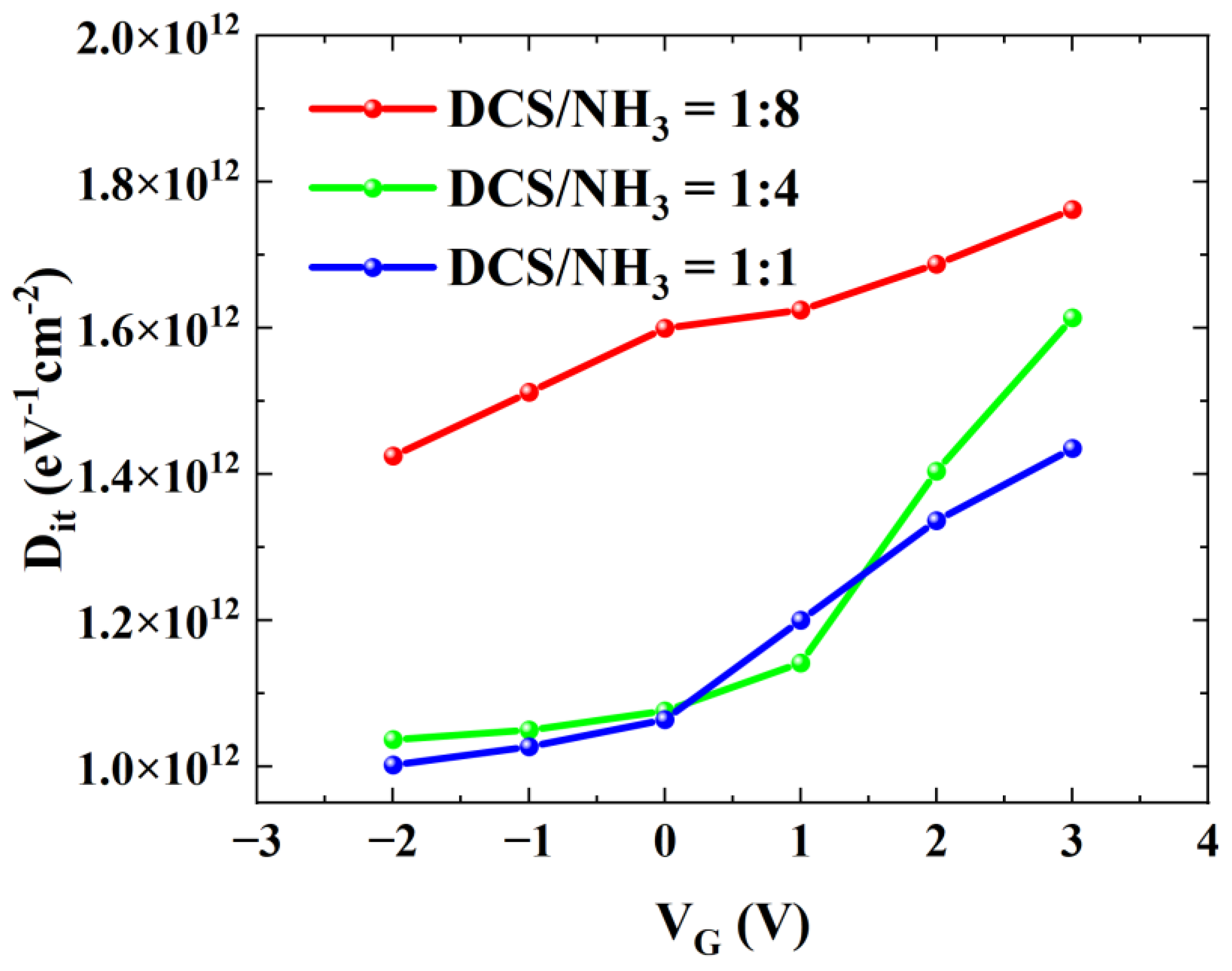

3.5.1. Pulse-Mode IDS-VGS Method

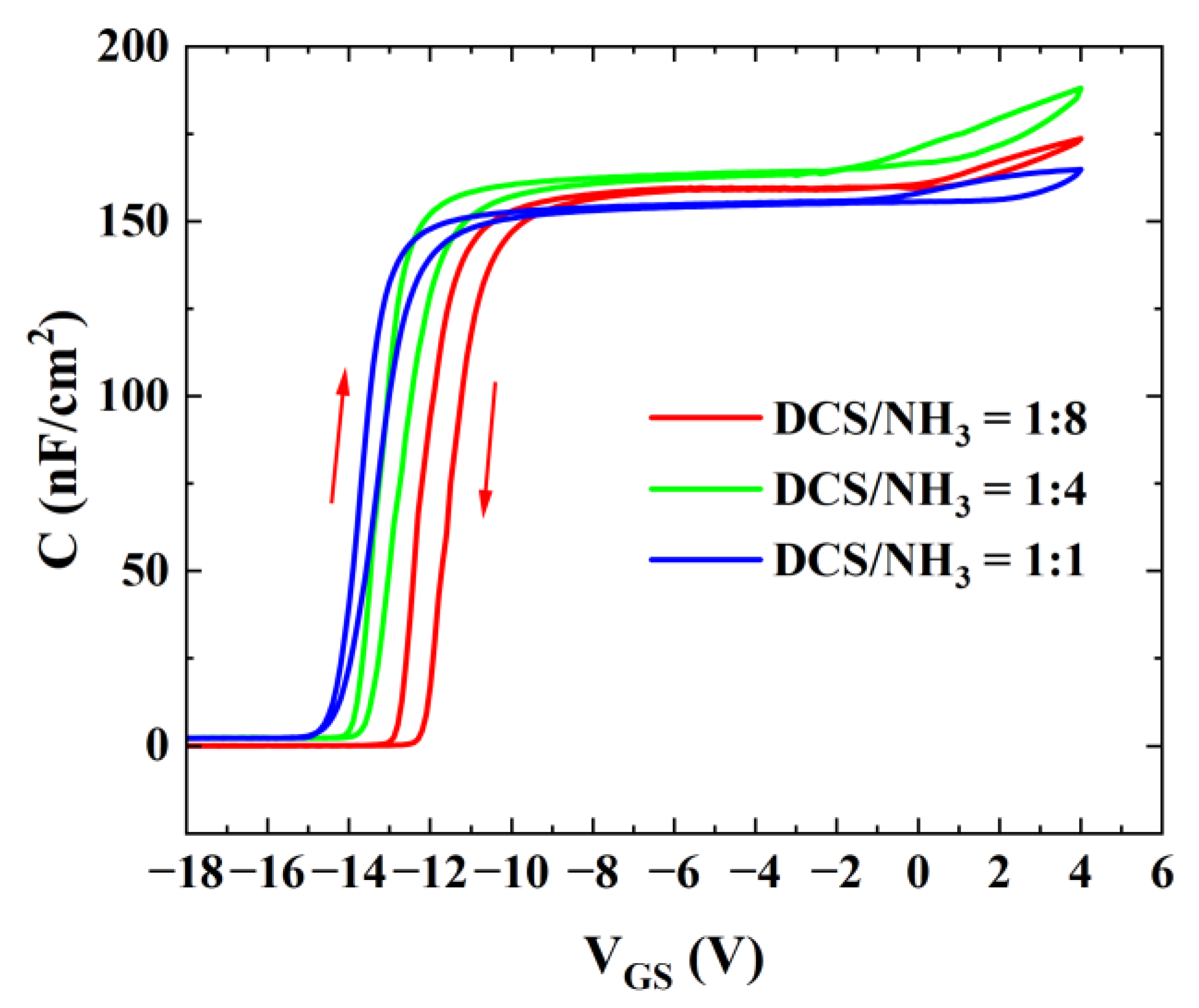

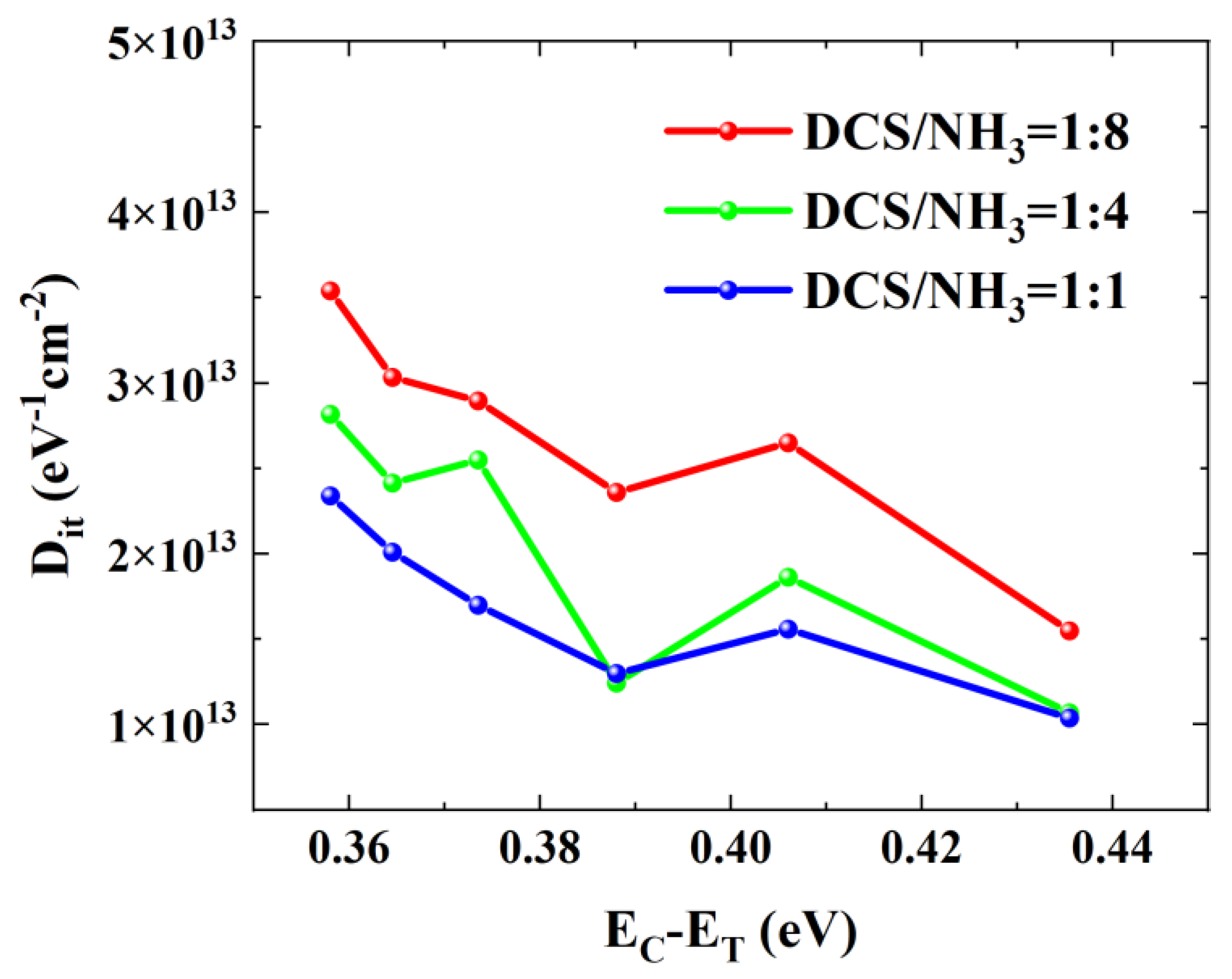

3.5.2. Frequency-Dependent C-V Measurement

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Adesida, I.; Kumar, V. Advances in gallium nitride-based electronics. In Proceedings of the IEEE International Conference on Electron Devices and Solid-State Circuits, Tainan, Taiwan, 20–22 December 2007; pp. 1–6. [Google Scholar]

- Roccaforte, F.; Greco, G.; Fiorenza, P.; Iucolano, F. An Overview of Normally-Off GaN-Based High Electron Mobility Transistors. Materials 2019, 12, 1599. [Google Scholar] [CrossRef] [PubMed]

- Vetury, R.; Zhang, N.Q.Q.; Keller, S.; Mishra, U.K. The impact of surface states on the DC and RF characteristics of A1GaN/GaN HFETs. IEEE Trans. Electron Devices 2001, 48, 560–566. [Google Scholar] [CrossRef]

- Al Alam, E.; Cortes, I.; Besland, M.P.; Goullet, A.; Lajaunie, L.; Regreny, P.; Cordier, Y.; Brault, J.; Cazarre, A.; Isoird, K.; et al. Effect of surface preparation and interfacial layer on the quality of SiO2/GaN interfaces. J. Appl. Phys. 2011, 109, 084511. [Google Scholar] [CrossRef]

- Chang, Y.C.; Chiu, H.C.; Lee, Y.J.; Huang, M.L.; Lee, K.Y.; Hong, M.; Chiu, Y.N.; Kwo, J.; Wang, Y.H. Structural and electrical characteristics of atomic layer deposited high κ HfO2 on GaN. Appl. Phys. Lett. 2007, 90, 232904. [Google Scholar] [CrossRef]

- Hu, X.; Koudymov, A.; Simin, G.; Yang, J.; Khan, M.A.; Tarakji, A.; Shur, M.S.; Gaska, R. Si3N4/AlGaN/GaN-metal-insulator-semiconductor heterostructure field-effect transistors. Appl. Phys. Lett. 2001, 79, 28322834. [Google Scholar] [CrossRef]

- Ye, P.D.; Yang, B.; Ng, K.K.; Bude, J.; Wilk, G.D.; Halder, S.; Hwang, J.C.M. GaN metal-oxide-semiconductor high-electron-mobility-transistor with atomic layer deposited Al2O3 as gate dielectric. Appl. Phys. Lett. 2005, 86, 063501. [Google Scholar] [CrossRef]

- Subhani, K.N.; Remesh, N.; Niranjan, S.; Raghavan, S.; Muralidharan, R.; Nath, D.N.; Bhat, K.N. Nitrogen rich PECVD silicon nitride for passivation of Si and AlGaN/GaN HEMT devices. Solid-State Electron. 2021, 186, 108188. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, C.; Chen, Y.; Lu, X.; Tang, C.W.; Lau, K.M. Investigation of In Situ SiN as Gate Dielectric and Surface Passivation for GaN MISHEMTs. IEEE Trans. Electron Devices 2017, 64, 832–839. [Google Scholar] [CrossRef]

- Siddique, A.; Ahmed, R.; Anderson, J.; Piner, E.L. Effect of reactant gas stoichiometry of in-situ SiNx passivation on structural properties of MOCVD AlGaN/GaN HEMTs. J. Cryst. Growth 2019, 517, 28–34. [Google Scholar] [CrossRef]

- Hua, M.; Liu, C.; Yang, S.; Liu, S.; Fu, K.; Dong, Z.; Cai, Y.; Zhang, B.; Chen, K.J. Characterization of Leakage and Reliability of SiNx Gate Dielectric by Low-Pressure Chemical Vapor Deposition for GaN-based MIS-HEMTs. IEEE Trans. Electron Devices 2015, 62, 3215–3222. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Zhang, Y.; Wei, K.; Zheng, Y.; Kang, X.; Jiang, H.; Li, J.; Wang, W.; Wu, X.; et al. Insight into the Near-Conduction Band States at the Crystallized Interface between GaN and SiNx Grown by Low-Pressure Chemical Vapor Deposition. Acs Appl. Mater. Interfaces 2018, 10, 21721–21729. [Google Scholar] [CrossRef] [PubMed]

- Hua, M.; Liu, C.; Yang, S.; Liu, S.; Fu, K.; Dong, Z.; Cai, Y.; Zhang, B.; Chen, K.J. GaN-Based Metal-Insulator-Semiconductor High-Electron-Mobility Transistors Using Low-Pressure Chemical Vapor Deposition SiNx as Gate Dielectric. IEEE Electron Device Lett. 2015, 36, 448–450. [Google Scholar] [CrossRef]

- Liu, Z.; Huang, S.; Bao, Q.; Wang, X.; Wei, K.; Jiang, H.; Cui, H.; Li, J.; Zhao, C.; Liu, X.; et al. Investigation of the interface between LPCVD-SiNx gate dielectric and III-nitride for AlGaN/GaN MIS-HEMTs. J. Vac. Sci. Technol. B 2016, 34, 041202. [Google Scholar] [CrossRef]

- Lu, X.; Yu, K.; Jiang, H.; Zhang, A.; Lau, K.M. Study of Interface Traps in AlGaN/GaN MISHEMTs Using LPCVD SiNx as Gate Dielectric. IEEE Trans. Electron Devices 2017, 64, 824–831. [Google Scholar] [CrossRef]

- Chen, T.; Jiang, H.; Chen, T. A Novel Ohmic Contact Techology for GaN HEMTs. Res. Prog. Solid State Electron. 2015, 35, 388–391. [Google Scholar]

- Soltani, A.; BenMoussa, A.; Touati, S.; Hoel, V.; De Jaeger, J.C.; Laureyns, J.; Cordier, Y.; Marhic, C.; Djouadi, M.A.; Dua, C. Development and analysis of low resistance ohmic contact to n-AlGaN/GaN HEMT. Diam. Relat. Mater. 2007, 16, 262–266. [Google Scholar] [CrossRef]

- Liu, X.J.; Zhang, J.J.; Sun, X.W.; Pan, Y.B.; Huang, L.P.; Jin, C.Y. Growth and properties of silicon nitride films prepared by low pressure chemical vapor deposition using trichlorosilane and ammonia. Thin Solid Film. 2004, 460, 72–77. [Google Scholar] [CrossRef]

- Temple-Boyer, P.; Rossi, C.; Saint-Etienne, E.; Scheid, E. Residual stress in low pressure chemical vapor deposition SiNx films deposited from silane and ammonia. J. Vac. Sci. Technol. A 1998, 16, 2003–2007. [Google Scholar] [CrossRef]

- Onojima, N.; Higashiwaki, M.; Suda, J.; Kimoto, T.; Mimura, T.; Matsui, T. Reduction in potential barrier height of AlGaN/GaN heterostructures by SiN passivation. J. Appl. Phys. 2007, 101, 043703. [Google Scholar] [CrossRef]

- Song, L.; Fu, K.; Zhang, Z.; Sun, S.; Li, W.; Yu, G.; Hao, R.; Fan, Y.; Shi, W.; Cai, Y.; et al. Interface Si donor control to improve dynamic performance of AlGaN/GaN MIS-HEMTs. AIP Adv. 2017, 7, 125023. [Google Scholar] [CrossRef]

- Lian, Y.-W.; Lin, Y.-S.; Yang, J.-M.; Cheng, C.-H.; Hsu, S.S.H. AlGaN/GaN Schottky Barrier Diodes on Silicon Substrates With Selective Si Diffusion for Low Onset Voltage and High Reverse Blocking. IEEE Electron Device Lett. 2013, 34, 981–983. [Google Scholar] [CrossRef]

- Zhang, D.; Cheng, X.; Zheng, L.; Shen, L.; Wang, Q.; Gu, Z.; Qian, R.; Wu, D.; Zhou, W.; Cao, D.; et al. Effects of polycrystalline AlN filmon the dynamic performance of AlGaN/GaN high electron mobility transistors. Mater. Des. 2018, 148, 1–7. [Google Scholar] [CrossRef]

- Cheng, K.; Leys, M.; Derluyn, J.; Degroote, S.; Xiao, D.P.; Lorenz, A.; Boeykens, S.; Germain, M.; Borghs, G. AlGaN/GaN HEMT grown on large size silicon substrates by MOVPE capped with in-situ deposited Si3N4. J. Cryst. Growth 2007, 298, 822–825. [Google Scholar] [CrossRef]

- Siddique, A.; Ahmed, R.; Anderson, J.; Holtz, M.; Piner, E.L. Improved Electrical Properties of AlGaN/GaN High-Electron-Mobility Transistors by In Situ Tailoring the SiNx Passivation Layer. Acs Appl. Mater. Interfaces 2021, 13, 18264–18273. [Google Scholar] [CrossRef]

- Zhu, L.; Zhou, Q.; Chen, K.; Gao, W.; Cai, Y.; Cheng, K.; Li, Z.; Zhang, B. The Modulation Effect of LPCVD-SixNy Stoichiometry on 2-DEG Characteristic of UTB AlGaN/GaN Heterostructure. IEEE Trans. Electron Devices 2022, 69, 4828–4834. [Google Scholar] [CrossRef]

- Shockley, W.; Read, W.T. Statistics of the recombinations of holes and electrons. Phys. Rev. 1952, 87, 835–842. [Google Scholar] [CrossRef]

- Yang, S.; Liu, S.; Lu, Y.; Liu, C.; Chen, K.J. AC-Capacitance Techniques for Interface Trap Analysis in GaN-Based Buried-Channel MIS-HEMTs. IEEE Trans. Electron Devices 2015, 62, 1870–1878. [Google Scholar] [CrossRef]

- Osenbach, J.W.; Knolle, W.R. A model describing the electrical behavior of A-Sin-H alloys. J. Appl. Phys. 1986, 60, 1408–1416. [Google Scholar] [CrossRef]

| DCS/NH₃ | T (°C) | P (mtorr) | Refractive Index | Thickness (nm) | Ns (×1013 cm−2) | µn (cm2/V∙s) | Rs (Ω/□) | |

|---|---|---|---|---|---|---|---|---|

| Sample A | 35/280 | 795 | 300 | 1.96 | 21 | 0.82 ± 0.03 | 1822 ± 20 | 496 ± 15 |

| Sample B | 70/280 | 795 | 300 | 1.99 | 22.5 | 0.86 ± 0.02 | 1882 ± 18 | 442 ± 12 |

| Sample C | 150/150 | 795 | 300 | 2.04 | 23 | 0.90 ± 0.02 | 1963 ± 26 | 388 ± 8 |

| Sample D | 150/75 | 795 | 300 | 2.05 | 22 | 0.91 ± 0.02 | 1992 ± 21 | 373 ± 14 |

| Sample E | 6/280 | 795 | 300 | 1.95 | 20 | 0.84 ± 0.02 | 1792 ± 22 | 462 ± 12 |

| Sample F | 70/280 | 780 | 300 | 1.99 | 23 | 0.85 ± 0.02 | 1852 ± 16 | 455 ± 10 |

| Sample G | 70/280 | 795 | 160 | 1.97 | 22 | 0.86 ± 0.02 | 1866 ± 23 | 448 ± 11 |

| REF | 0.73 ± 0.03 | 1690 ± 20 | 522 ± 9 |

| Ns (×1013 cm−2) | µn (cm2/V∙s) | Rs (Ω/□) | ||

|---|---|---|---|---|

| Sample H | Without SiNx | 0.73 ± 0.02 | 1902 ± 21 | 443 ± 12 |

| With SiNx | 0.88 ± 0.02 | 1744 ± 23 | 418 ± 11 | |

| Sample I | Without SiNx | 0.83 ± 0.03 | 1837 ± 22 | 407 ± 11 |

| With SiNx | 0.88 ± 0.03 | 1778 ± 26 | 372 ± 10 | |

| Sample J | Without SiNx | 0.81 ± 0.02 | 1670 ± 23 | 488 ± 13 |

| With SiNx | 0.87 ± 0.02 | 1590 ± 21 | 453 ± 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Fan, Q.; Ni, X.; Luo, Q.; Gu, X. Low-Pressure Chemical Vapor Deposition SiNx Process Study and Its Impact on Interface Characteristics of AlGaN/GaN MISHEMTs. Micromachines 2025, 16, 442. https://doi.org/10.3390/mi16040442

Sun H, Fan Q, Ni X, Luo Q, Gu X. Low-Pressure Chemical Vapor Deposition SiNx Process Study and Its Impact on Interface Characteristics of AlGaN/GaN MISHEMTs. Micromachines. 2025; 16(4):442. https://doi.org/10.3390/mi16040442

Chicago/Turabian StyleSun, Hu, Qian Fan, Xianfeng Ni, Qiang Luo, and Xing Gu. 2025. "Low-Pressure Chemical Vapor Deposition SiNx Process Study and Its Impact on Interface Characteristics of AlGaN/GaN MISHEMTs" Micromachines 16, no. 4: 442. https://doi.org/10.3390/mi16040442

APA StyleSun, H., Fan, Q., Ni, X., Luo, Q., & Gu, X. (2025). Low-Pressure Chemical Vapor Deposition SiNx Process Study and Its Impact on Interface Characteristics of AlGaN/GaN MISHEMTs. Micromachines, 16(4), 442. https://doi.org/10.3390/mi16040442