Investigating Tungsten Carbide Micro-Hole Drilling Characteristics by Desktop Micro-ECM with NaOH Solution

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

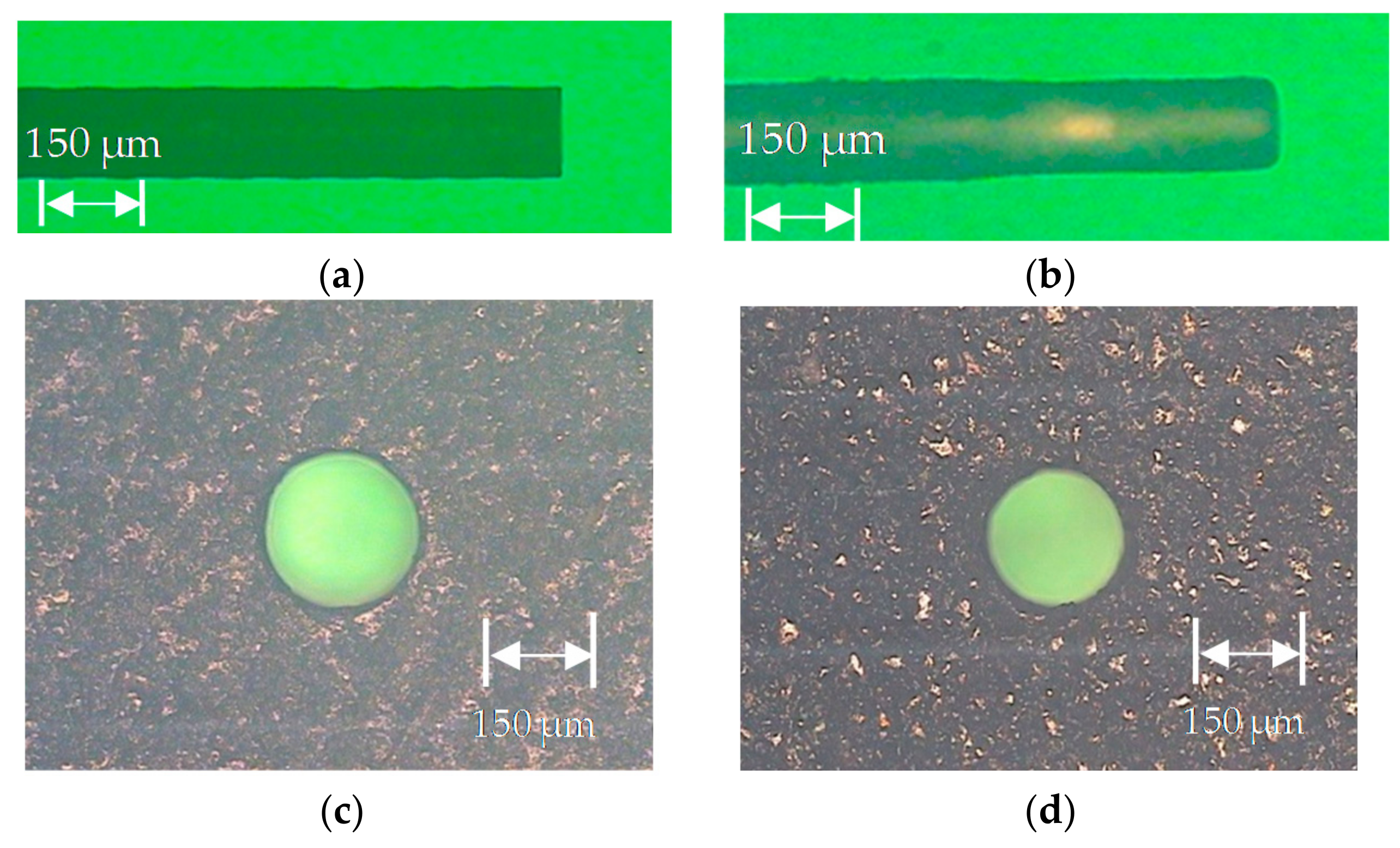

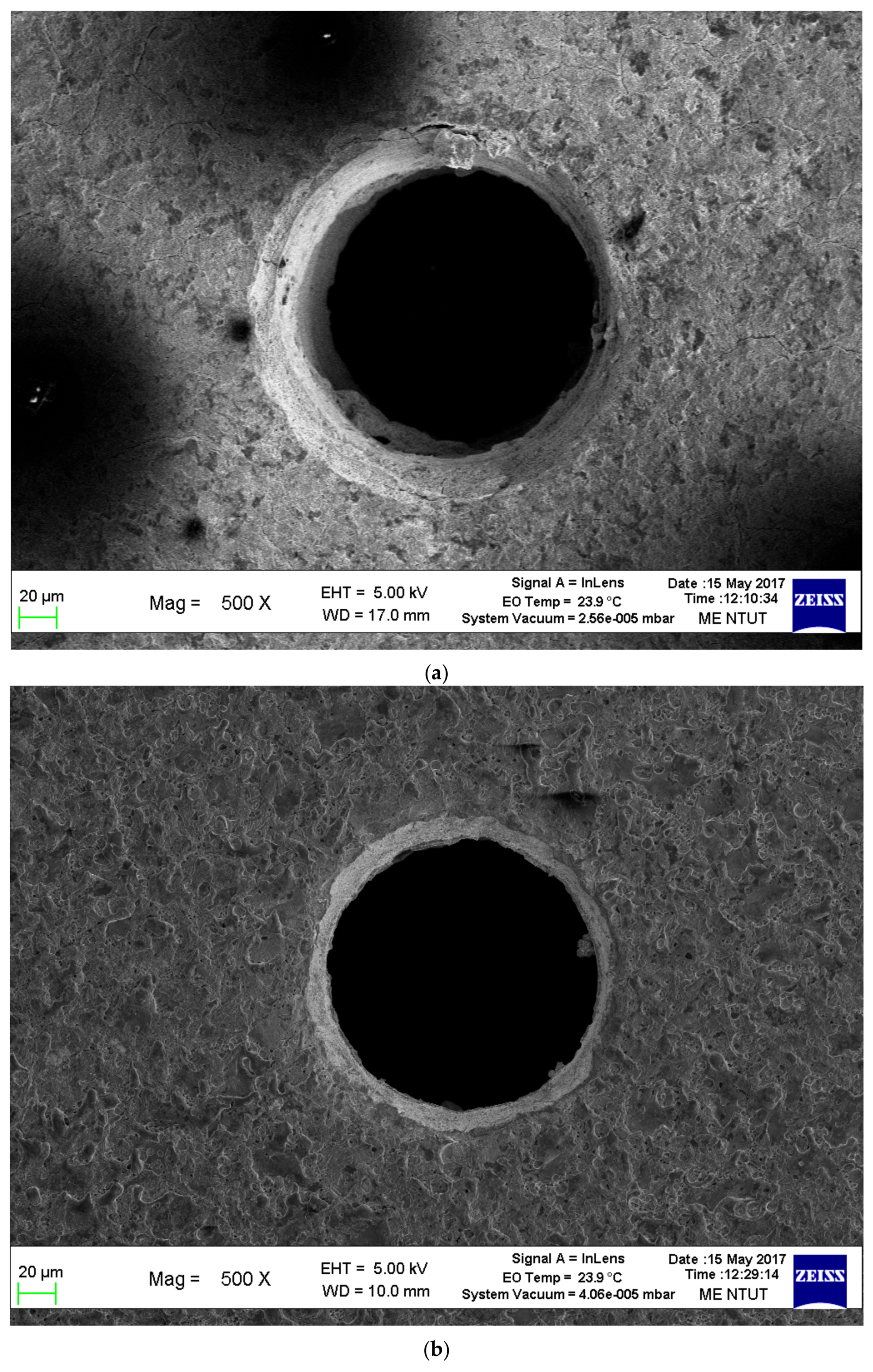

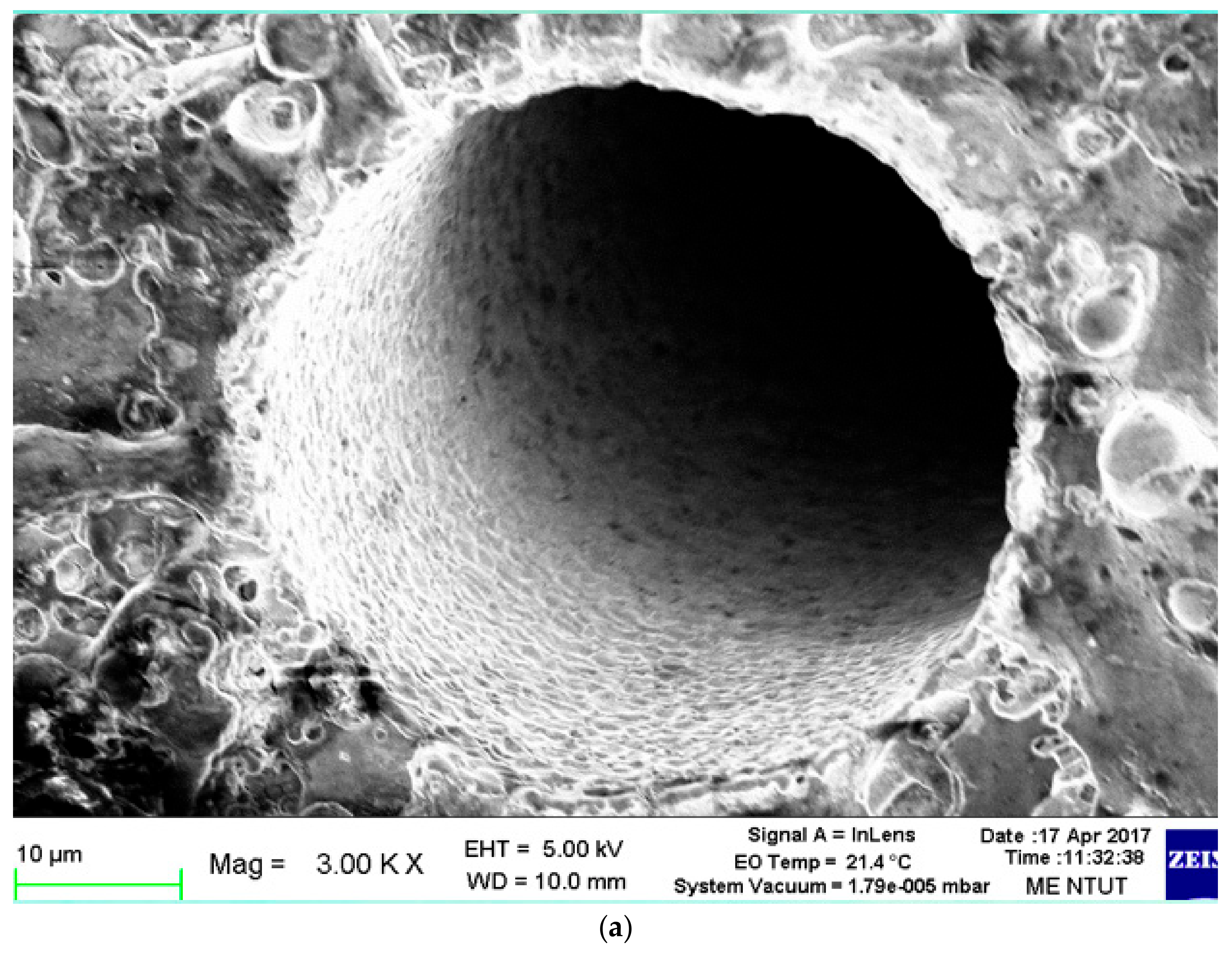

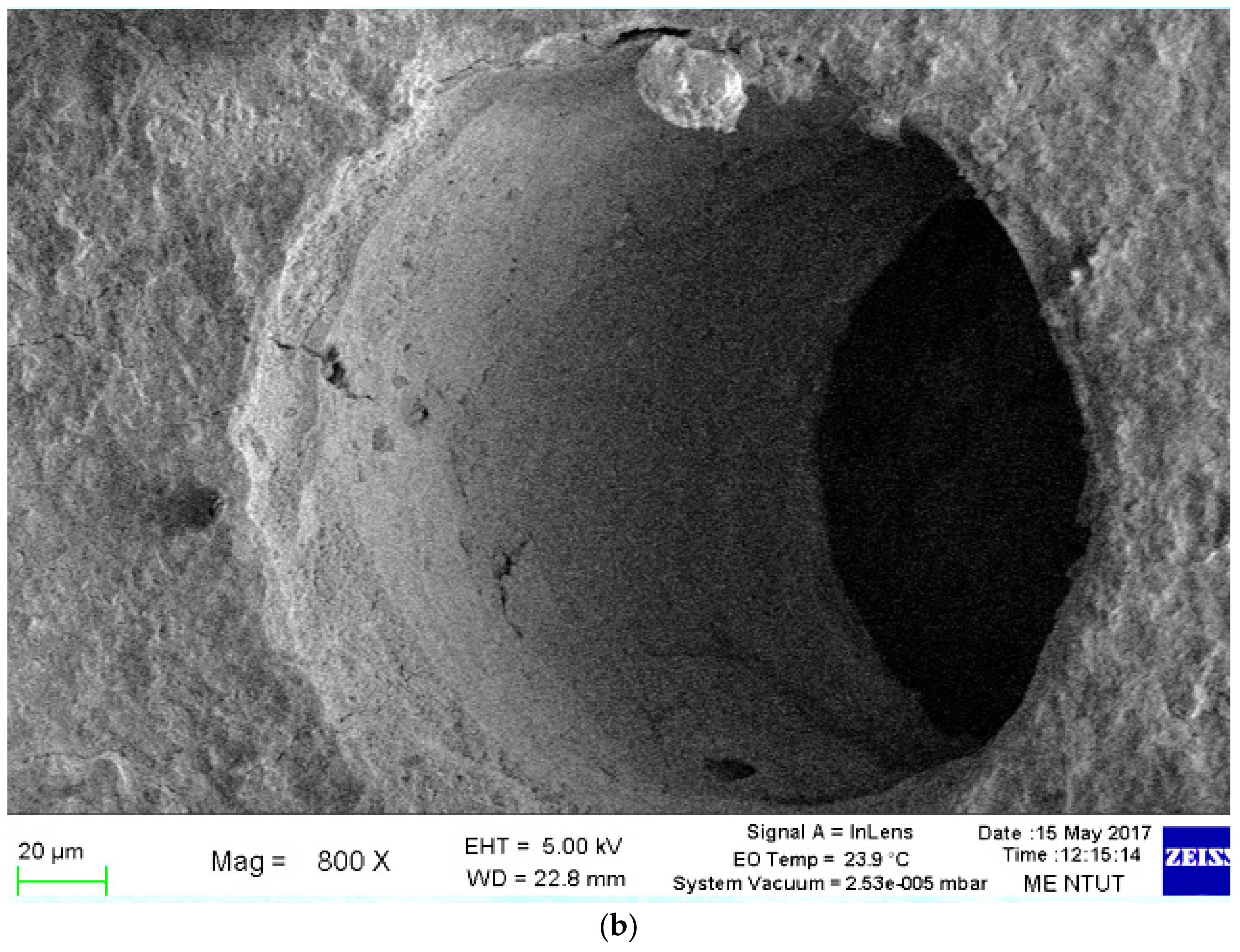

3.1. Micro-Hole Drilling by Desktop Micro-ECM

3.2. Limitations of Machining Depth

3.3. Electrode Tool Wear and Roundness

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Malyshev, V.V.; Gab, A.I. Resource-saving methods for recycling waste tungsten carbide-cobalt cermet’s and extraction of tungsten from tungsten concentrates. Theor. Found. Chem. Eng. 2007, 41, 436–441. [Google Scholar] [CrossRef]

- Masuzawa, T.; Tsukamoto, J.; Fujino, M. Drilling of deep microholes by EDM. CIRP Ann. Manuf. Technol. 1989, 38, 195–198. [Google Scholar] [CrossRef]

- Konyashin, I.; Zaitsev, A.A.; Sidorenko, D.; Levashov, E.A.; Ries, B.; Konishev, S.N.; Sorokin, M.; Mazilkin, A.A.; Herrmann, M.; Kaiser, A. Wettability of tungsten carbide by liquid binders in WC-Co cemented carbides: Is it complete for all carbon contents? Int. J. Refract. Met. Hard Mater. 2017, 62, 134–148. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Zhu, D.; McGeough, J.A.; Kozak, J.; De Silva, A. New developments in electro-chemical machining. CIRP Ann. Manuf. Technol. 1999, 48, 567–579. [Google Scholar] [CrossRef]

- Sundaram, M.M.; Rajurkar, K. Electrical and electrochemical processes. In Intelligent Energy Field Manufacturing; CRC Press: Boca Raton, FL, USA, 2010; pp. 173–212. [Google Scholar]

- Mithu, M.A.H.; Fantoni, G.; Ciampi, J. The effect of high frequency and duty cycle in electrochemical microdrilling. Int. J. Adv. Manuf. Technol. 2011, 55, 921–933. [Google Scholar] [CrossRef]

- Masuzawaa, T.; Fujinoa, M.; Kobayashia, K.; Suzuki, T.; Kinoshita, N. Wire electro-discharge grinding for micro-machining. CIRP Ann. Manuf. Technol. 1985, 34, 431–434. [Google Scholar] [CrossRef]

- Spieser, A.; Ivanov, A. Recent developments and research challenges in electrochemical micromachining (µECM). Int. J. Adv. Manuf. Technol. 2013, 69, 563–581. [Google Scholar] [CrossRef]

- Schubert, N.; Schneider, M.; Michaelis, A. Electrochemical machining of cemented carbides. Int. J. Refract. 2014, 47, 54–60. [Google Scholar] [CrossRef]

- Masuzawa, T.; Kimura, M. Electrochemical surface finishing of tungsten carbide alloy. CIRP Ann. Manuf. Technol. 1991, 40, 199–202. [Google Scholar] [CrossRef]

- Leese, R.J.; Ivanov, A. Electrochemical micromachining: An introduction. Adv. Mech. Eng. 2016, 8, 1–13. [Google Scholar] [CrossRef]

- Choi, S.H.; Kim, B.H.; Shin, H.S.; Chu, C.N. Analysis of the electrochemical behaviors of WC–Co alloy for micro ECM. J. Mater. Process. Technol. 2013, 213, 621–630. [Google Scholar] [CrossRef]

| Machining Type | DC-ECM |

|---|---|

| Workpiece Material | WC-Co |

| Electrolyte | Sodium hydroxide (NaOH) solution |

| Concentration | 5% |

| Workpiece Thickness | 0.3 mm |

| Tool Diameter | 150 μm |

| Machining Depth | 455 μm |

| Machining Voltage | 5 V, 10 V, 15 V, 20 V |

| Current (A) | Time (min) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.00 | 5.00 | 10.00 | 15.00 | 20.00 | 25.00 | 30.00 | 35.00 | 40.00 | |

| 1 (0.5 A) | 0 | 30 | 80 | 110 | 160 | 210 | 260 | 340 | 455 |

| 2 (1 A) | 0 | 60 | 145 | 180 | 245 | 350 | 455 | - | - |

| 3 (2 A) | 0 | 150 | 200 | 300 | 370 | 455 | - | - | - |

| 4 (3 A) | 0 | 170 | 255 | 345 | 455 | - | - | - | - |

| Tool (μm) | Voltage (V) | |||

|---|---|---|---|---|

| 5 V | 10 V | 15 V | 20 V | |

| Before Machining | 3645 | 3620 | 3615 | 3632 |

| After Machining | 3620 | 3615 | 3637 | 3647 |

| Tool Change | −25 | −5 | 12 | 15 |

| Diameter (μm) | Times | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| Horizontal Inlet Diameter | 163 | 164 | 164 | 157 | 178 | 161 | 167 |

| Vertical Inlet Diameter | 162 | 165 | 158 | 158 | 177 | 178 | 159 |

| Horizontal Outlet Diameter | 154 | 155 | 156 | 121 | 123 | 141 | 128 |

| Vertical Outlet Diameter | 153 | 160 | 161 | 122 | 124 | 142 | 130 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.-Y.; Sheu, D.-Y. Investigating Tungsten Carbide Micro-Hole Drilling Characteristics by Desktop Micro-ECM with NaOH Solution. Micromachines 2018, 9, 512. https://doi.org/10.3390/mi9100512

Wu Y-Y, Sheu D-Y. Investigating Tungsten Carbide Micro-Hole Drilling Characteristics by Desktop Micro-ECM with NaOH Solution. Micromachines. 2018; 9(10):512. https://doi.org/10.3390/mi9100512

Chicago/Turabian StyleWu, Yung-Yi, and Dong-Yea Sheu. 2018. "Investigating Tungsten Carbide Micro-Hole Drilling Characteristics by Desktop Micro-ECM with NaOH Solution" Micromachines 9, no. 10: 512. https://doi.org/10.3390/mi9100512

APA StyleWu, Y. -Y., & Sheu, D. -Y. (2018). Investigating Tungsten Carbide Micro-Hole Drilling Characteristics by Desktop Micro-ECM with NaOH Solution. Micromachines, 9(10), 512. https://doi.org/10.3390/mi9100512