Integrated Systems Ontology (ISOnto): Integrating Engineering Design and Operational Feedback for Dependable Systems

Abstract

1. Introduction

2. Background and Related Work

2.1. FMEA Integration Within Systems Engineering: A Review of Methods and Challenges

- High system complexity: Managing interactions among numerous subsystems [29].

- Data integration: Synthesising data from CAD models, simulation environments, and test results into coherent FMEA structures [16].

- Multidisciplinary collaboration: Harmonising mechanical, electrical, and software domains within a single failure reasoning framework [45].

- Interface management: Capturing and reasoning about the interactions and dependencies between system interfaces [35].

2.2. Real-World Field Data as a Validation Source for Risk Assessment in the Design Phase

- Applicability: FMEA is resource-intensive, reliant on user expertise, and difficult to apply to complex, multidisciplinary systems. Issues such as limited tool interoperability, constrained data handling, and poor collaboration further restrict its effectiveness.

- Cause–effect relationships: Practitioners often struggle to define and trace interactions between failure types, causes, and effects, particularly when determining appropriate levels of analysis granularity.

- Risk analysis: Inconsistent evaluation criteria, subjective prioritisation, and ambiguous action guidelines lead to variable outcomes.

- Problem solving: Despite its analytical intent, FMEA frequently lacks clear objectives, structured solution pathways, and measurable outputs, weakening its decision-support capability.

2.3. Ontology-Driven Approaches in Engineering: Enhancing Knowledge Representation and System Interoperability

2.4. Function–Behaviour–Structure Reasoning and Its Extensions in Risk-Oriented Design

3. Proposed Framework and Methodology

3.1. Methodology Overview

3.2. Ontological Framework Development

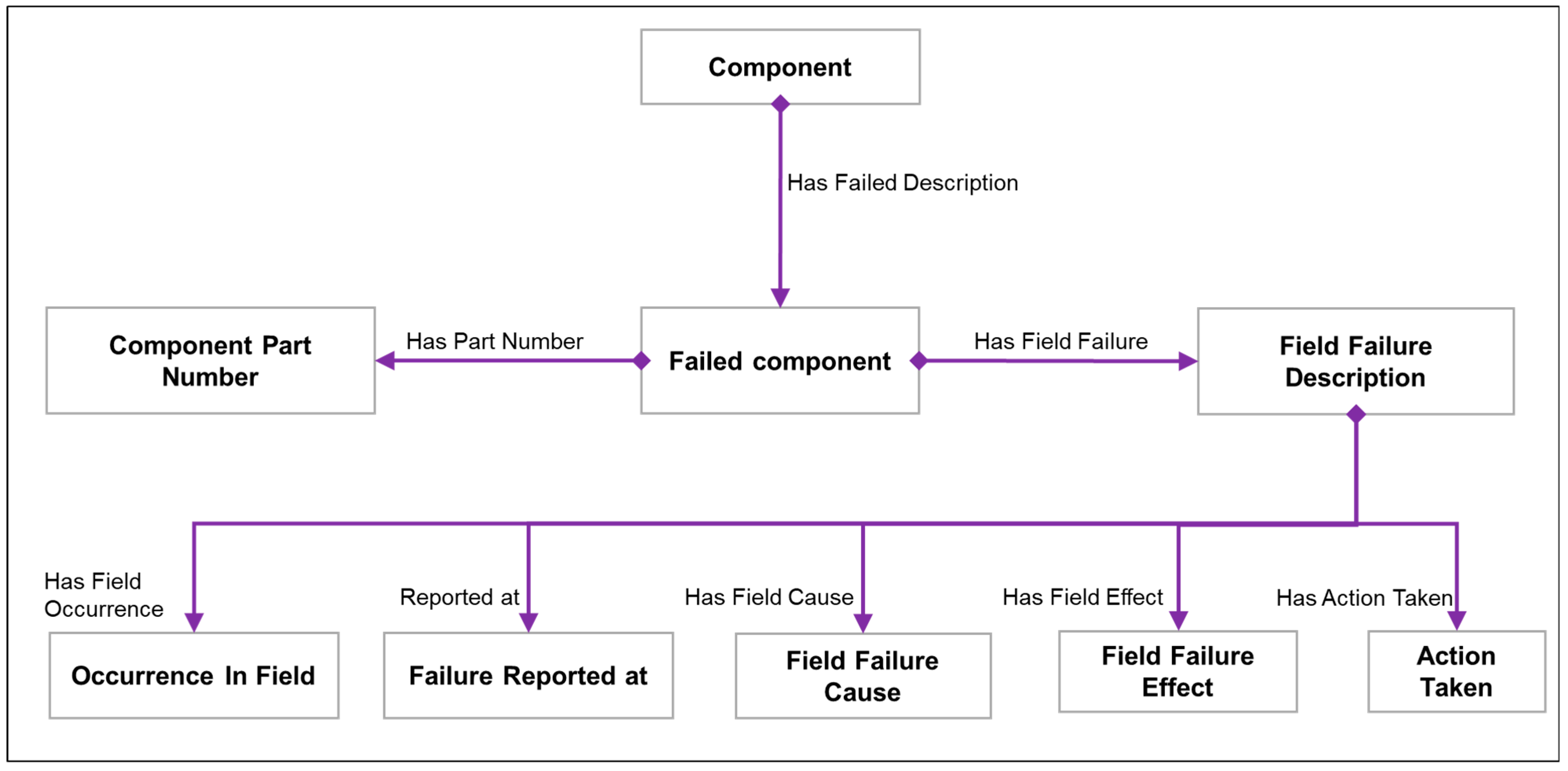

- Component “Has Failed Description” → Component Failed;

- Failed Component Component;

- Component failed = {pn1,pn2,…,pn7}, where pn ⊆ component failed.

- Failed Component “Has Field Failure” → {FM1,FM2,…,FMₙ}, where FM Field Failure Modes.

- Field Failure Description = {Effect, Cause, Action Taken, Reported At, Occurence}where:

- Effect ∈ {Customer Verbatim, Technician Verbatim};

- Cause ∈ {Technician Diagnosis, Manufacturer Analysis};

- Action Taken ∈ {Technician Action, Manufacturer Action};

- Reported At ∈ {Mileage or Age at failure};

- Occurrence ∈ (Natural Numbers).

- Mileage → Age (t) at time of failure.

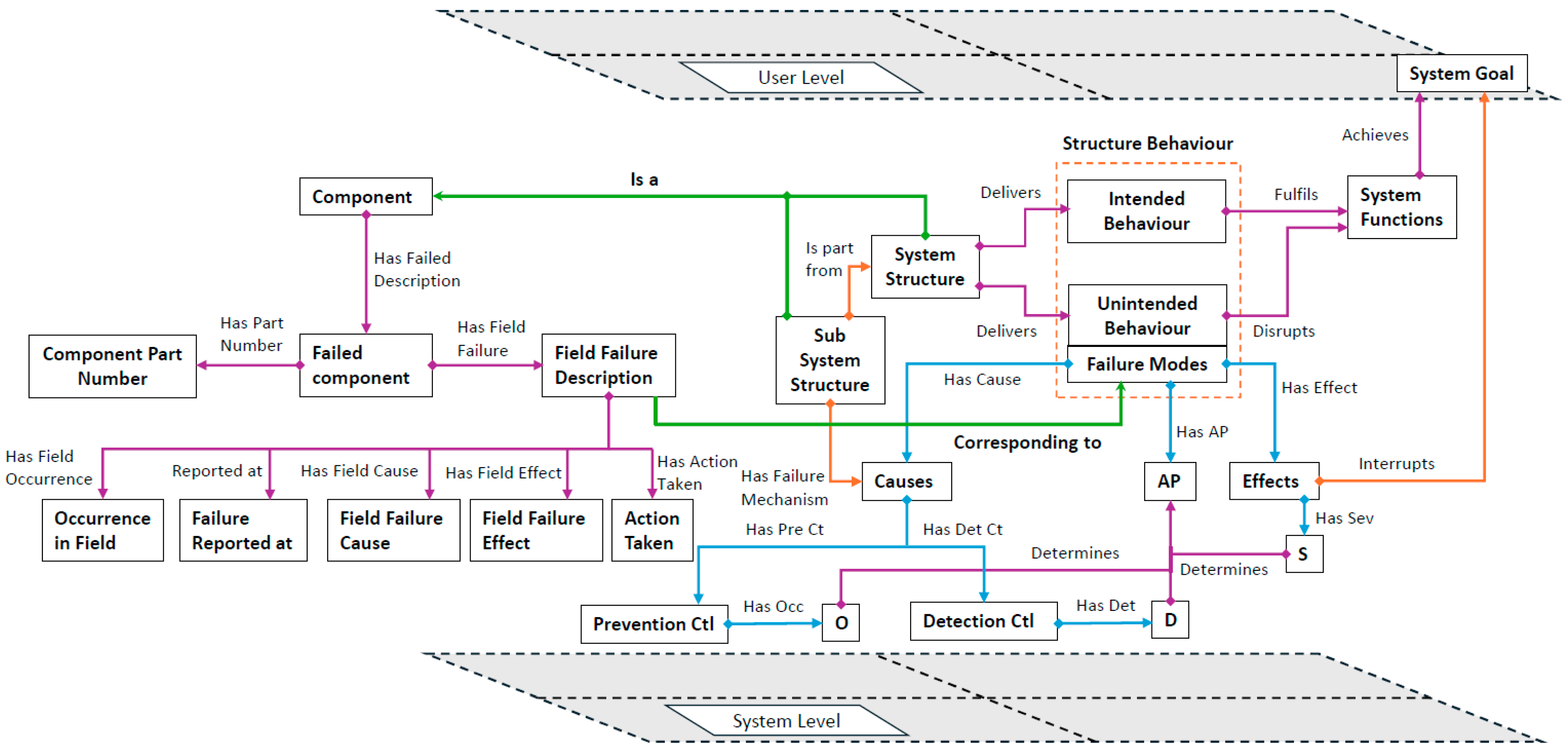

3.3. Integrated Systems Ontology ISOnto-Based Approach

- Component System Structure ∨ Subsystem Structure.

- Field Failure Description ≡ FMEA fm.

- Field Failure Description ≢ FMEA ⇒ New Failure Mode.

4. Implementation

4.1. ISOnto Ontology Development and Tools

4.1.1. Methodology for Integrating Design and Field Knowledge

- Design Layer structuring (FBSFM): Core classes were defined for Function, Expected Behaviour, Unintended Behaviour, Structure, and FMEA elements such as Failure Mode, Cause, and Effect. The Unintended Behaviour class was central to linking system deviations with failure manifestations.

- Field layer structuring (feedback ontology): Classes were created for Component, Field Failure Mode, Effect, Cause, Action Taken, Occurrence, and Part Number. This structure reflects real-world observations gathered from inspection and warranty reports.

- Cross-ontology mapping: Semantic relationships were established between the two layers. For example:

- ○

- Component System Structure;

- ○

- Field Failure Description ≡ DFMEA Failure Mode (if matched);

- ○

- Field Failure Description⇒New Failure Mode (if unmatched).

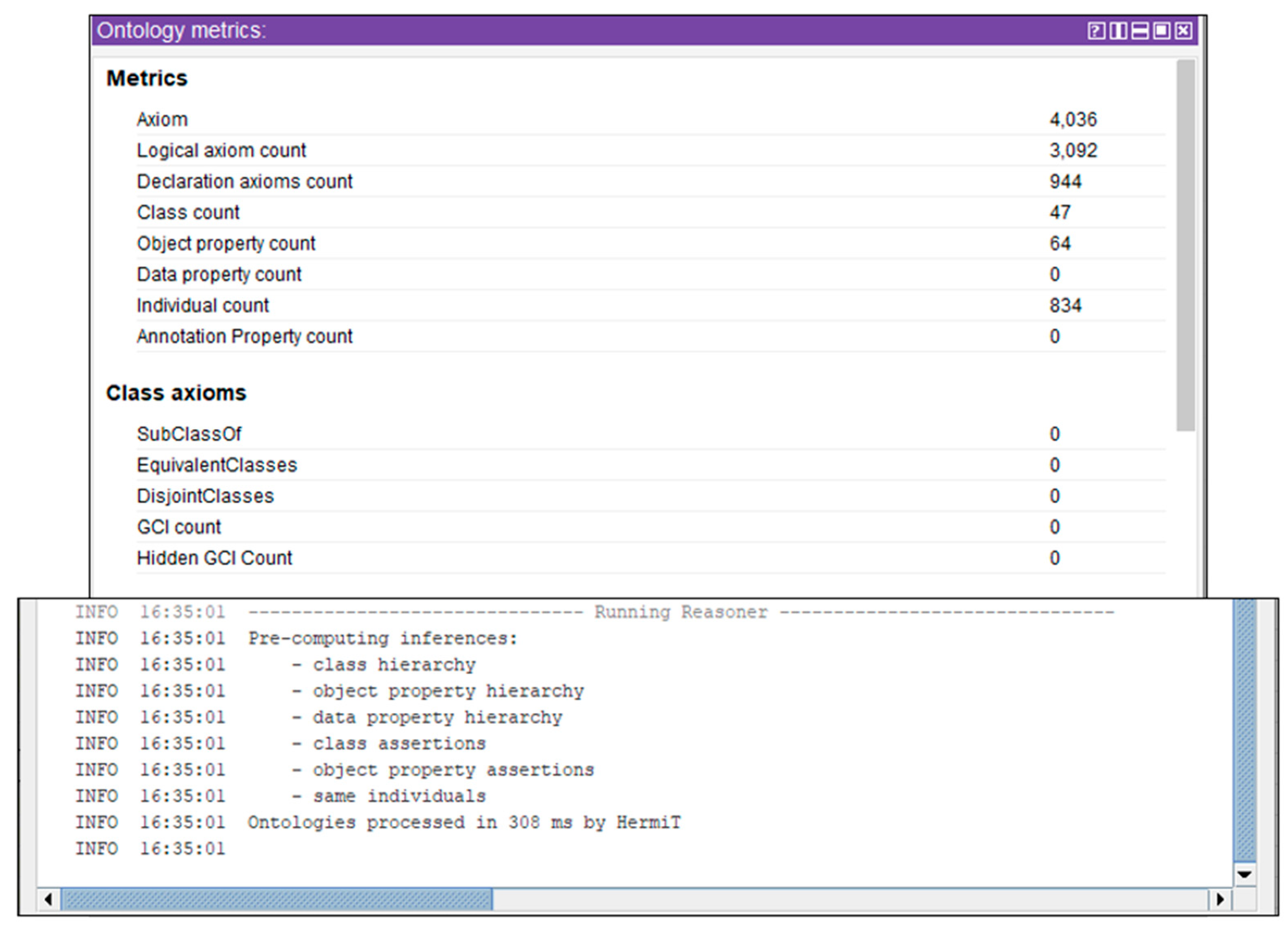

4.1.2. Tools and Formalisation Approach

- The ISOnto was developed using Protégé, an open-source ontology editor that supports OWL (Web Ontology Language). Protégé facilitated the creation of the dual-layer structure and the semantic mappings between the design and field elements:

- a.

- Definition of classes, relationships, and domain/range axioms for both ontologies.

- b.

- Use of the “Object Properties” tab to define lifecycle-spanning relations, such as “Field Failed Component Description”, “Has Field FailureMode Description”, and “Field FailureMode Description”.

- c.

- Logical validation using the HermiT reasoner ensured consistency across design and field entities and highlighted any semantic contradictions.

4.1.3. Knowledge Graph Representation

- Function, Behaviour, Structure, Failure Mode (design layer);

- Component, Field Failure Mode, Cause, Effect, Action Taken (field layer);

- Semantic bridges such as “Field Failure Mode corresponds to FMEA Failure Mode” or “Component instance of System Structure”.

4.2. Case Study Implementation

- Step 1: Preprocess and prepare the system model and FMEA data from the design phase.

- Step 2: Deploy the pre-processed design data into the FBSFM layer of the ISOnto.

- Step 3: Preprocess and prepare field data from the use phase.

- Step 4: Deploy the field feedback data into the field ontology layer of the ISOnto.

- Step 5: Save and explore the integrated ISOnto as a unified knowledge repository.

4.2.1. Case Study Analysis

- System modelling documentation: This included architectural diagrams and functional decomposition data. A structural breakdown of the headlamp system is shown in Figure 9 as a UML diagram, derived from internal system architecture documentation.

- 2.

- FMEA Spreadsheets: Provided in Excel format, these contain:

- A standard AIAG/VDA-style FMEA table;

- A system architecture matrix mapping function and behaviours;

- A list of focus element functions with their behavioural criteria.

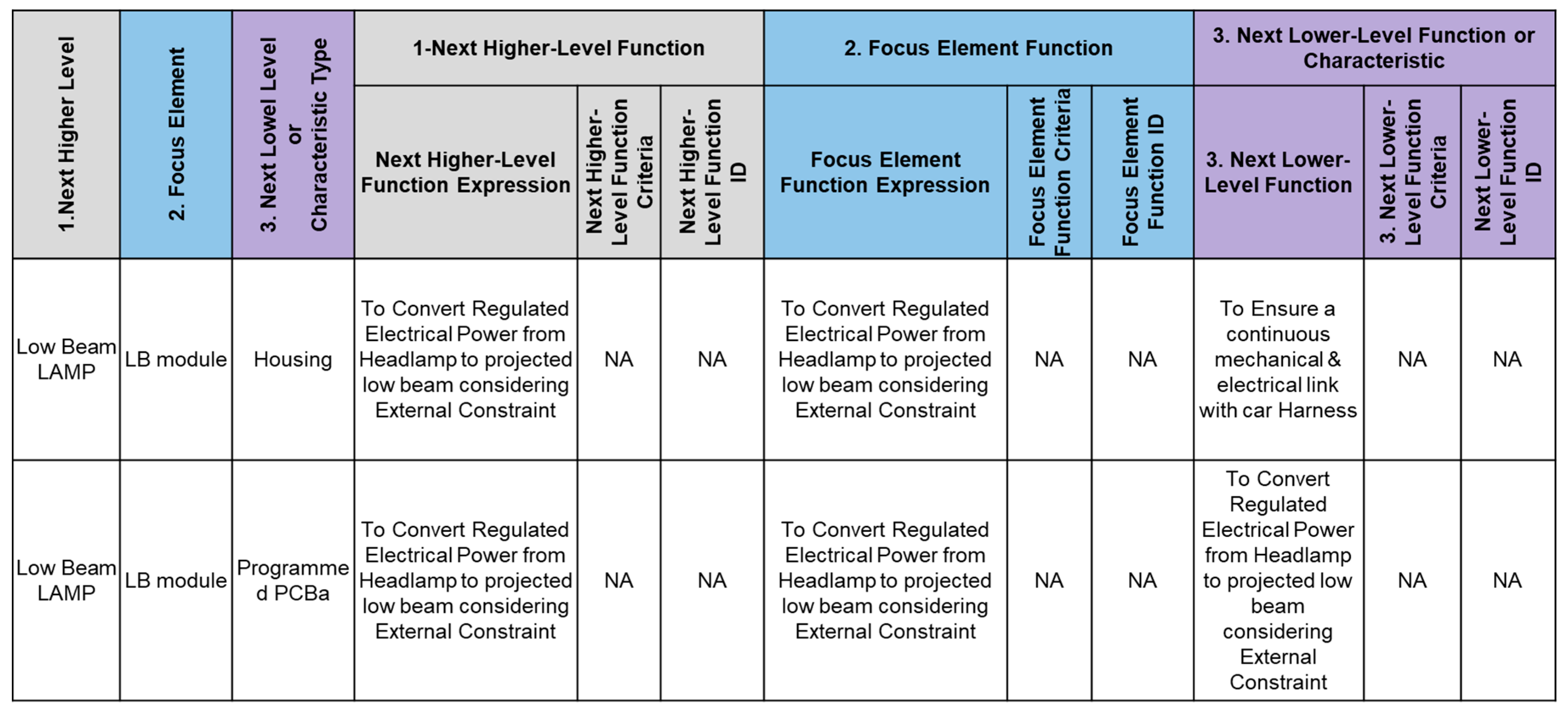

- The system is hierarchically decomposed into three levels, as reflected in the FMEA snapshot shown in Figure 10:

- ○

- Level 1: Entire headlamp system (Low Beam Lamp);

- ○

- Level 2: Focus elements, e.g., LB Module;

- ○

- Level 3: Individual components, e.g., Housing.

4.2.2. Step 1—Text Preparation and Preprocessing

- Space and special character formatting;

- Replacement of missing or null values;

- Harmonisation of terms to match ontology constraints.The preprocessing ensured semantic consistency between the Excel-based documentation and the OWL ontology structure.

4.2.3. Step 2—Data Population into the Ontology

- Column mapping: Spreadsheet columns were mapped to ontology classes such as Function, Expected Behaviour, Unintended Behaviour, Structure, Failure Mode, Failure Cause, and Failure Effect.

- Relation assignment: Semantic relationships were defined including links. These relationships established semantic coherence across the FBSFM layer, reflecting the functional decomposition and associated risk information of the system.

4.2.4. Step 3—Preprocess and Prepare Field Data from the Use Phase

- Text cleaning: Removing special characters and standardising inconsistent terminology;

- Entity normalisation: Converting natural language expressions into controlled vocabulary terms aligned with the ontology’s class labels;

- Structural parsing: Extracting key fields (e.g., Component, Failure Mode, Cause, Effect, Action Taken) and organising them into tabular form suitable for Protégé ingestion;

- Missing data handling: Identifying and managing incomplete or null values to prevent semantic errors during population.

4.2.5. Step 4—Deploy Field Feedback into the ISOnto Ontology

- Component instances were linked to System Structure via “is-a” relationships;

- Field Failure Mode entities were mapped to DFMEA Failure Modes where applicable.

4.2.6. Step 5—Save and Explore the ISOnto Ontology as a Knowledge Repository

- Replaced underscores in entity labels to improve readability;

- Removed lengthy URI paths to simplify visual outputs and query responses.

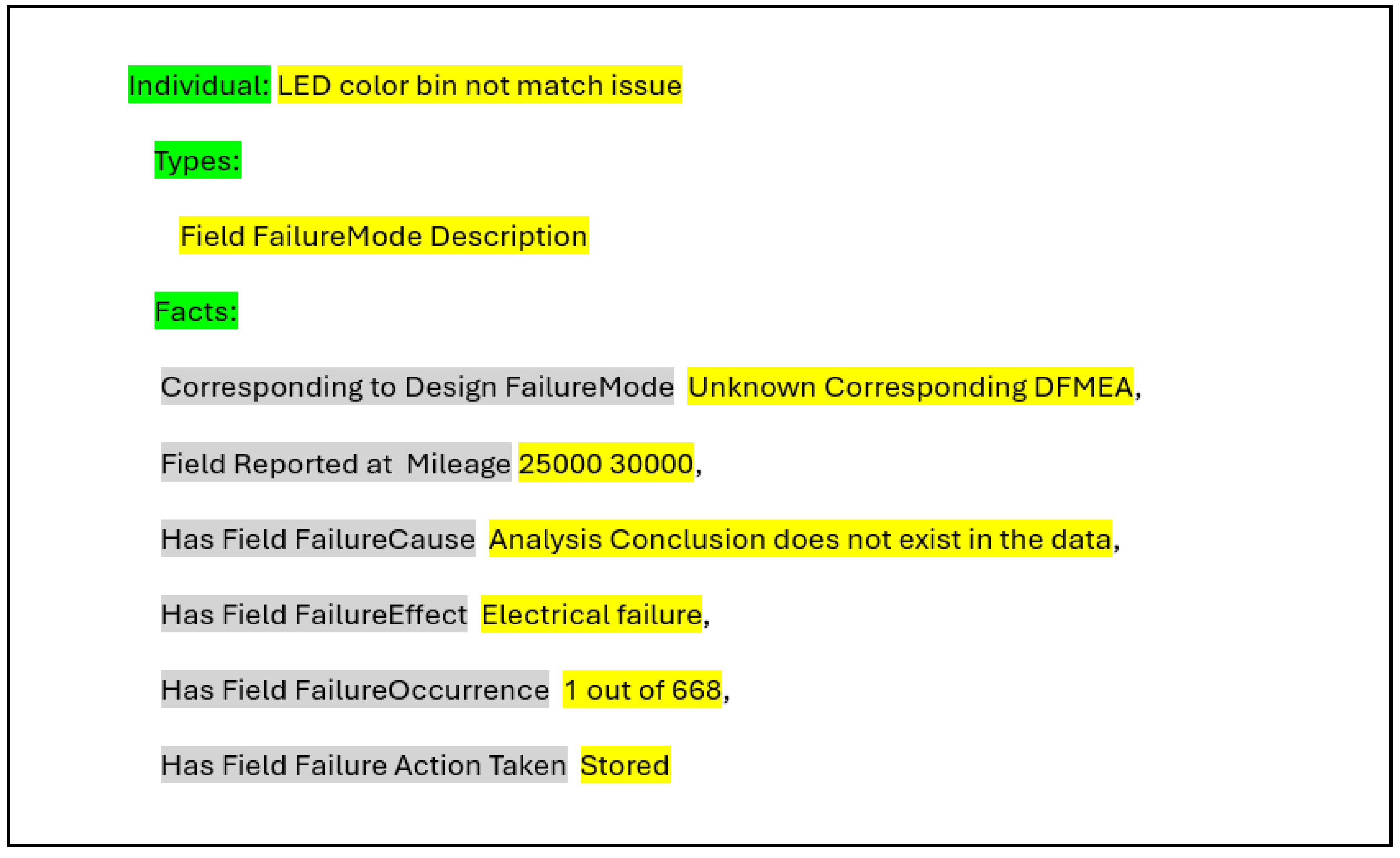

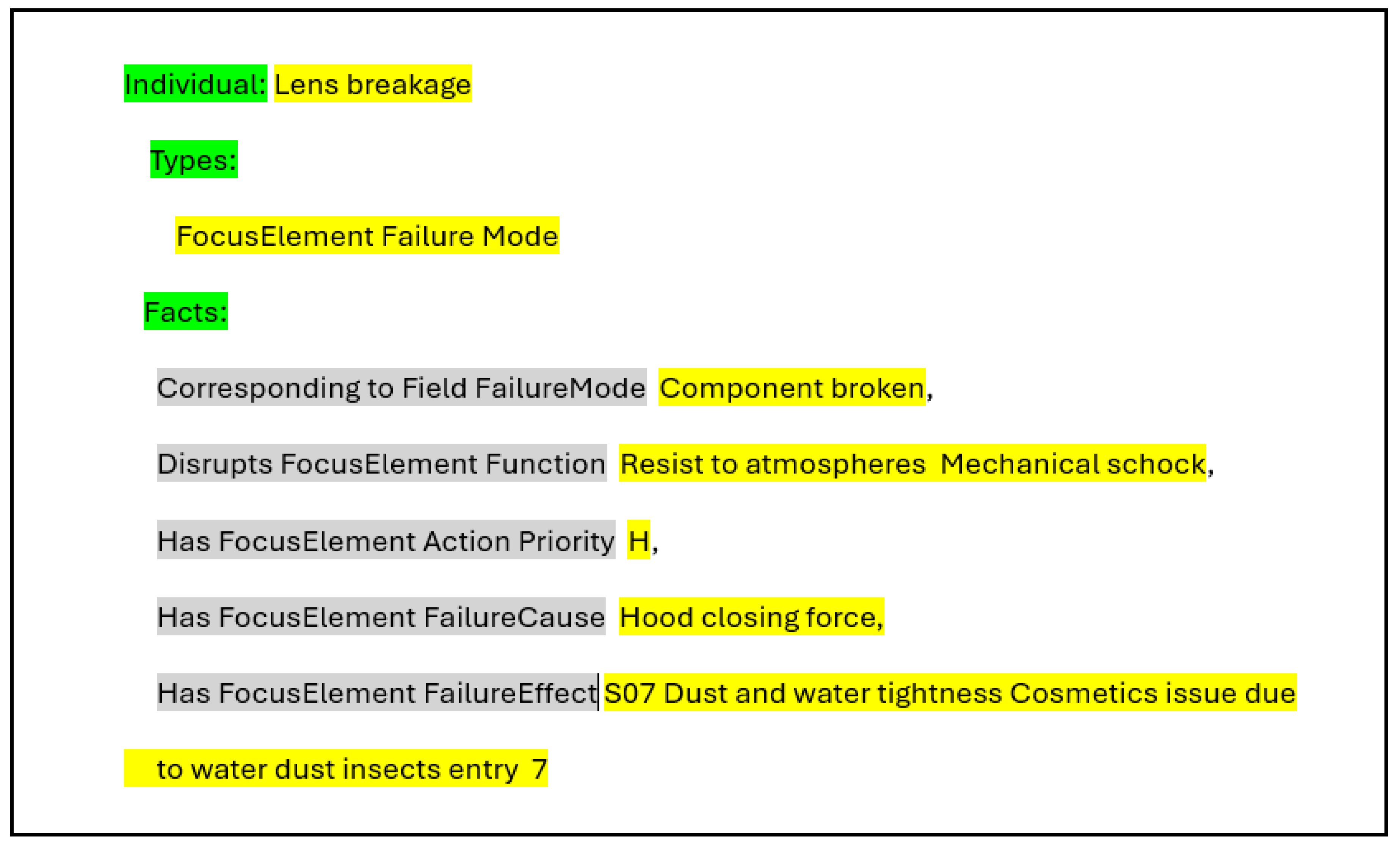

- Green: Ontology class, types, and facts;

- Grey: Object properties and semantic relations;

- Yellow: Case-specific data from the design and use phase.

4.2.7. Ontology Exploration—Example 1: LED Colour Bin Mismatch

- Individual: LED colour bin not match issue;

- Type: Field FailureMode Description.

4.2.8. Ontology Exploration—Example 2: Lens Breakage

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Theissler, A.; Pérez-Velázquez, J.; Kettelgerdes, M.; Elger, G. Predictive maintenance enabled by machine learning: Use cases and challenges in the automotive industry. Reliab. Eng. Syst. Saf. 2021, 215, 107864. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Chakraborty, S.; Jha, S.; Samii, S.; Mundhenk, P. Introduction to the special issue on automotive CPS safety & security: Part 1. ACM Trans. Cyber-Phys. Syst. 2023, 7, 1–6. [Google Scholar]

- Ebert, C.; Duarte, C.H. Digital Transformation. IEEE Softw. 2018, 35, 16–21. [Google Scholar] [CrossRef]

- Campean, F.; Neagu, D.; Doikin, A.; Soleimani, M.; Byrne, T.; Sherratt, A. Automotive IVHM: Towards Intelligent Personalised Systems Healthcare. In Proceedings of the Design Society: International Conference on Engineering Design, Delft, The Netherlands, 5–8 August 2019; Volume 1, pp. 857–866. [Google Scholar]

- AIAG-VDA. Failure Mode and Effects Analysis-FMEA Handbook: Design FMEA, Process FMEA, Supplemental FMEA for Monitoring et System Response; Automotive Industry Action Group: Southfield, MI, USA, 2019. [Google Scholar]

- Zhu, P.; Han, J.; Liu, L.; Lombardi, F. A stochastic approach for the analysis of dynamic fault trees with spare gates under probabilistic common cause failures. IEEE Trans. Reliab. 2015, 64, 878–892. [Google Scholar] [CrossRef]

- Liu, H.-C.; You, J.-X.; Li, P.; Su, Q. Failure mode and effect analysis under uncertainty: An integrated multiple criteria decision making approach. IEEE Trans. Reliab. 2016, 65, 1380–1392. [Google Scholar] [CrossRef]

- Huang, J.; Li, Z.S.; Liu, H.-C. New approach for failure mode and effect analysis using linguistic distribution assessments and TODIM method. Reliab. Eng. Syst. Saf. 2017, 167, 302–309. [Google Scholar] [CrossRef]

- Huang, J.; You, J.-X.; Liu, H.-C.; Song, M.-S. Failure mode and effect analysis improvement: A systematic literature review and future research agenda. Reliab. Eng. Syst. Saf. 2020, 199, 106885. [Google Scholar] [CrossRef]

- Korsunovs, A.; Doikin, A.; Campean, F.; Kabir, S.; Hernandez, E.; Taggart, D.; Parker, S.; Mills, G. Towards a Model-Based Systems Engineering Approach for Robotic Manufacturing Process Modelling with Automatic FMEA Generation. Proc. Des. Soc. 2022, 2, 1905–1914. [Google Scholar] [CrossRef]

- Parlatan, F.; Burgt, O.V.D. FMEA & FTA Integration in MBSE Approach for Healthcare Systems & Solutions. In Proceedings of the 2024 Annual Reliability and Maintainability Symposium (RAMS), Albuquerque, NM, USA, 22–25 January 2024; pp. 1–6. [Google Scholar]

- Winton, D.B.; Huang, Z.C. MBSE and FMEA Integration Using GENESYS. In Proceedings of the 2021 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 24–27 May 2021; pp. 1–7. [Google Scholar]

- Huang, Z.; Hansen, R.; Huang, Z. Toward FMEA and MBSE integration. In Proceedings of the 2018 Annual Reliability and Maintainability Symposium (RAMS), Reno, NV, USA, 22–25 January 2018; pp. 1–7. [Google Scholar]

- Huang, Z.; Swalgen, S.; Davidz, H.; Murray, J. MBSE-assisted FMEA approach—Challenges and opportunities. In Proceedings of the 2017 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23–26 January 2017; pp. 1–8. [Google Scholar]

- Filz, M.-A.; Langner, J.E.B.; Herrmann, C.; Thiede, S. Data-driven failure mode and effect analysis (FMEA) to enhance maintenance planning. Comput. Ind. 2021, 129, 103451. [Google Scholar] [CrossRef]

- Yang, F.; Cao, N.; Young, L.; Howard, J.; Logan, W.; Arbuckle, T.; Sponseller, P.; Korssjoen, T.; Meyer, J.; Ford, E. Validating FMEA output against incident learning data: A study in stereotactic body radiation therapy. Med. Phys. 2015, 42, 2777–2785. [Google Scholar] [CrossRef]

- Rajpathak, D.; Xu, Y.; Gibbs, I. An integrated framework for automatic ontology learning from unstructured repair text data for effective fault detection and isolation in automotive domain. Comput. Ind. 2020, 123, 103338. [Google Scholar] [CrossRef]

- Qian, L.; Gero, J.S. Function–behavior–structure paths and their role in analogy-based design. AI EDAM 1996, 10, 289–312. [Google Scholar] [CrossRef]

- Gero, J.S.; Kannengiesser, U. A function–behavior–structure ontology of processes. AI EDAM 2007, 21, 379–391. [Google Scholar] [CrossRef]

- van Beek, T.J.; Erden, M.S.; Tomiyama, T. Modular design of mechatronic systems with function modeling. Mechatronics 2010, 20, 850–863. [Google Scholar] [CrossRef]

- Goel, A.K.; Rugaber, S.; Vattam, S. Structure, behavior, and function of complex systems: The structure, behavior, and function modeling language. AI EDAM 2009, 23, 23–35. [Google Scholar] [CrossRef]

- Hezla, L.; Gurina, R.; Hezla, M.; Rezaeian, N.; Nohurov, M.; Aouati, S. The Role of Artificial Intelligence in Improving Failure Mode and Effects Analysis (FMEA) Efficiency in Construction Safety Management. In Artificial Intelligence and Virtual Reality: Proceedings of 7th International Conference on Artificial Intelligence and Virtual Reality (AIVR 2023), Kumamoto, Japan, 21–23 July 2023; Springer: Singapore, 2023; pp. 397–411. [Google Scholar]

- Grabill, N.; Wang, S.; Olayinka, H.A.; De Alwis, T.P.; Khalil, Y.F.; Zou, J. AI-augmented failure modes, effects, and criticality analysis (AI-FMECA) for industrial applications. Reliab. Eng. Syst. Saf. 2024, 250, 110308. [Google Scholar] [CrossRef]

- Chari, S.; Seneviratne, O.; Gruen, D.M.; Foreman, M.A.; Das, A.K.; Mcguinness, D.L. Explanation Ontology: A Model of Explanations for User-Centered AI; Springer International Publishing: Cham, Swizerland, 2020; pp. 228–243. [Google Scholar]

- Ebrahimipour, V.; Rezaie, K.; Shokravi, S. An ontology approach to support FMEA studies. Expert Syst. Appl. 2010, 37, 671–677. [Google Scholar] [CrossRef]

- Ebrahimipour, V. Lexical Semantic Analysis to support Ontology Maintenance Modeling of FMEA. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Mauritius, Mauritius, 7–8 October 2021; pp. 377–382. [Google Scholar]

- Rehman, Z.; Kifor, C.V. An ontology to support semantic management of FMEA knowledge. Int. J. Comput. Commun. Control 2016, 11, 507–521. [Google Scholar] [CrossRef]

- Younus, H.; Doikin, A.; Campean, F.; Kabir, S.; Abdullatif, A.; Delaux, D.; Bonnaud, P. An Extended Function-Behaviour-Structure Ontology to support FMEA within a System Engineering Context. Procedia CIRP 2024, 128, 644–649. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, W.; Nie, W. Literature review and prospect of the development and application of FMEA in manufacturing industry. Int. J. Adv. Manuf. Technol. 2021, 112, 1409–1436. [Google Scholar] [CrossRef]

- SAE-J1739; Potential Failure Mode and Effects Analysis (FMEA) Including Design FMEA, Supplemental FMEA-MSR, and Process FMEA. SAE: Warrendale, PA, USA, 2009.

- IEC 60812; Failure Modes and Effects Analysis (FMEA and FMECA). IEC: Geneva, Switzerland, 2018.

- Baklouti, A.; Nguyen, N.; Mhenni, F.; Choley, J.-Y.; Mlika, A. Improved safety analysis integration in a systems engineering approach. Appl. Sci. 2019, 9, 1246. [Google Scholar] [CrossRef]

- Campean, I.F.; Henshall, E.; Rutter, B. Systems engineering excellence through design: An integrated approach based on failure mode avoidance. SAE Int. J. Mater. Manuf. 2013, 6, 389–401. [Google Scholar] [CrossRef]

- Henshall, E.; Campean, I.F.; Rutter, B. A Systems Approach to the Development and Use of FMEA in Complex Automotive Applications. SAE Int. J. Mater. Manuf. 2014, 7, 280–290. [Google Scholar] [CrossRef]

- Hecht, M.; Dimpfl, E.; Pinchak, J. Automated generation of failure modes and effects analysis from SysML models. In Proceedings of the 2014 IEEE International Symposium on Software Reliability Engineering Workshops, Naples, Italy, 3–6 November 2014; pp. 62–65. [Google Scholar]

- Girard, G.; Baeriswyl, I.; Hendriks, J.J.; Scherwey, R.; Müller, C.; Hönig, P.; Lunde, R. Model based safety analysis using SysML with automatic generation of FTA and FMEA artifacts. In Proceedings of the 30th European Safety and Reliability Conference and the 15th Probabilistic Safety Assessment and Management Conference (Esrel 2020 PSAM 15), Venice, Italy, 1–5 November 2020. [Google Scholar]

- Day, J.; Donahue, K.; Ingham, M.; Kadesch, A.; Kennedy, A.; Post, E. Modeling Off-Nominal Behavior in SysML; Infotech@ Aerospace: Houston, TX, USA, 2012; pp. 1–10. [Google Scholar]

- Campean, F. Systems Engineering Design through Failure Mode Avoidance-an Automotive Industry Perspective. In Proceedings of the 1st International Conference in Through Life Engineering Services, Shrivenham, UK, 5–6 November 2012. [Google Scholar]

- Sierla, S.; Tumer, I.; Papakonstantinou, N.; Koskinen, K.; Jensen, D. Early integration of safety to the mechatronic system design process by the functional failure identification and propagation framework. Mechatronics 2012, 22, 137–151. [Google Scholar] [CrossRef]

- Mansoor, A.; Diao, X.; Smidts, C. A method for backward failure propagation in conceptual system design. Nucl. Sci. Eng. 2023, 197, 2751–2777. [Google Scholar] [CrossRef]

- Russomanno, D.J.; Bonnell, R.D.; Bowles, J.B. Functional reasoning in a failure modes and effects analysis (FMEA) expert system. In Proceedings of the Annual Reliability and Maintainability Symposium 1993 Proceedings, Atlanta, GA, USA, 26–28 January 1993; pp. 339–347. [Google Scholar]

- Tumer, I.Y.; Stone, R.B. Mapping function to failure mode during component development. Res. Eng. Des. 2003, 14, 25–33. [Google Scholar] [CrossRef]

- Stone, R.B.; Tumer, I.Y.; van Wie, M. The function-failure design method. ASME. J. Mech. Des. 2005, 127, 397–407. [Google Scholar] [CrossRef]

- Jiménez López, E.; Cuenca Jiménez, F.; Luna Sandoval, G.; Ochoa Estrella, F.J.; Maciel Monteón, M.A.; Muñoz, F.; Limón Leyva, P.A. Technical Considerations for the Conformation of Specific Competences in Mechatronic Engineers in the Context of Industry 4.0 and 5.0. Processes 2022, 10, 1445. [Google Scholar] [CrossRef]

- Spreafico, C.; Russo, D.; Rizzi, C. A state-of-the-art review of FMEA/FMECA including patents. Comput. Sci. Rev. 2017, 25, 19–28. [Google Scholar] [CrossRef]

- El Hassani, I.; Masrour, T.; Kourouma, N.; Motte, D.; Tavčar, J. Integrating large language models for improved failure mode and effects analysis (FMEA): A framework and case study. Proc. Des. Soc. 2024, 4, 2019–2028. [Google Scholar] [CrossRef]

- Amrutha, H.; Ajinkya, J.; Surabhi, M. Application of failure modes and effects analysis (FMEA) in automated spot welding process of an automobile industry: A case study. J. Eng. Educ. Transform. 2021, 34, 281–289. [Google Scholar] [CrossRef]

- Jomthanachai, S.; Wong, W.P.; Lim, C.P. An Application of Data Envelopment Analysis and Machine Learning Approach to Risk Management. IEEE Access 2021, 9, 85978–85994. [Google Scholar] [CrossRef]

- Sader, S.; Husti, I.; Daróczi, M. Enhancing failure mode and effects analysis using auto machine learning: A case study of the agricultural machinery industry. Processes 2020, 8, 224. [Google Scholar] [CrossRef]

- Gheraibia, Y.; Kabir, S.; Aslansefat, K.; Sorokos, I.; Papadopoulos, Y. Safety+ AI: A novel approach to update safety models using artificial intelligence. IEEE Access 2019, 7, 135855–135869. [Google Scholar] [CrossRef]

- Brahim, I.B.; Addouche, S.-A.; El Mhamedi, A.; Boujelbene, Y. Build a Bayesian network from FMECA in the production of automotive parts: Diagnosis and prediction. IFAC-Pap. 2019, 52, 2572–2577. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Z.; Dai, Z.; Peng, Z.; Li, S. Using data mining and root cause analysis method for failure analysis in electronic components. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1043, 022024. [Google Scholar] [CrossRef]

- Karim, R.; Suzuki, K. Analysis of warranty claim data: A literature review. Int. J. Qual. Reliab. Manag. 2005, 22, 667–686. [Google Scholar] [CrossRef]

- Hines, J.W.; Seibert, R. Technical Review of On-Line Monitoring Techniques for Performance Assessment. Volume 1. State-of-the-Art; United States Nuclear Regulatory Commission: Washington DC, USA, 2006. [Google Scholar]

- Prytz, R.; Nowaczyk, S.; Rögnvaldsson, T.; Byttner, S. Predicting the need for vehicle compressor repairs using maintenance records and logged vehicle data. Eng. Appl. Artif. Intell. 2015, 41, 139–150. [Google Scholar] [CrossRef]

- Khoshkangini, R.; Pashami, S.; Nowaczyk, S. Warranty claim rate prediction using logged vehicle data. In Progress in Artificial Intelligence: 19th EPIA Conference on Artificial Intelligence, EPIA 2019, Vila Real, Portugal, 3–6 September 2019; Proceedings, Part I 19; Springer: Cham, Switzerland, 2019; pp. 663–674. [Google Scholar]

- Rajpathak, D.; De, S. A data-and ontology-driven text mining-based construction of reliability model to analyze and predict component failures. Knowl. Inf. Syst. 2016, 46, 87–113. [Google Scholar] [CrossRef]

- Lu, J.; Ma, J.; Zheng, X.; Wang, G.; Li, H.; Kiritsis, D. Design ontology supporting model-based systems engineering formalisms. IEEE Syst. J. 2021, 16, 5465–5476. [Google Scholar] [CrossRef]

- Chen, J.; Chen, Y.; Hu, Z.; Lu, J.; Zheng, X.; Zhang, H.; Kiritsis, D. A semantic ontology-based approach to support model-based systems engineering design for an aircraft prognostic health management system. Front. Manuf. Technol. 2022, 2, 886518. [Google Scholar] [CrossRef]

- Hodkiewicz, M.; Klüwer, J.W.; Woods, C.; Smoker, T.; Low, E. An ontology for reasoning over engineering textual data stored in FMEA spreadsheet tables. Comput. Ind. 2021, 131, 103496. [Google Scholar] [CrossRef]

- Booshehri, M.; Emele, L.; Flügel, S.; Förster, H.; Frey, J.; Frey, U.; Glauer, M.; Hastings, J.; Hofmann, C.; Hoyer-Klick, C. Introducing the Open Energy Ontology: Enhancing data interpretation and interfacing in energy systems analysis. Energy AI 2021, 5, 100074. [Google Scholar] [CrossRef]

- Suárez-Figueroa, M.C.; Gómez-Pérez, A.; Fernández-López, M. The NeOn methodology for ontology engineering. In Ontology Engineering in a Networked World; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Poveda-Villalón, M.; Fernández-Izquierdo, A.; Fernández-López, M.; García-Castro, R. LOT: An industrial oriented ontology engineering framework. Eng. Appl. Artif. Intell. 2022, 111, 104755. [Google Scholar] [CrossRef]

- Pinto, H.S.; Staab, S.; Tempich, C. DILIGENT: Towards a fine-grained methodology for DIstributed, Loosely-controlled and evolvInG Engineering of oNTologies. In Proceedings of the 16th Eureopean Conference on Artificial Intelligence, ECAI’2004, including Prestigious Applicants of Intelligent Systems, PAIS 2004, Valencia, Spain, 22–27 August 2004; p. 393. [Google Scholar]

- Hamraz, B.; Caldwell, N.H.; Ridgman, T.W.; Clarkson, P.J. FBS Linkage ontology and technique to support engineering change management. Res. Eng. Des. 2015, 26, 3–35. [Google Scholar] [CrossRef]

- Eisenbart, B.; Gericke, K. Function in Engineering. In The Routledge Handbook of the Philosophy of Engineering; Routledge: Abingdon, UK, 2020. [Google Scholar]

- Gero, J.S. Design prototypes: A knowledge representation schema for design. AI Mag. 1990, 11, 26. [Google Scholar]

- Umeda, Y.; Ishii, M.; Yoshioka, M.; Shimomura, Y.; Tomiyama, T. Supporting conceptual design based on the function-behavior-state modeler. Artif. Intell. Eng. Des. Anal. Manuf. 1996, 10, 275–288. [Google Scholar] [CrossRef]

- Umeda, Y.; Takeda, H.; Tomiyama, T.; Yoshikawa, H. Function, behaviour, and structure. Appl. Artif. Intell. Eng. 1990, 1, 177–194. [Google Scholar]

- Gero, J.S.; Kannengiesser, U. The situated function–behaviour–structure framework. Des. Stud. 2004, 25, 373–391. [Google Scholar] [CrossRef]

- INCOSE. INCOSE Systems Engineering Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2023. [Google Scholar]

- Limon, S.; Yadav, O.P.; Zuo, M.J.; Muscha, J.; Honeyman, R. Reliability estimation considering usage rate profile and warranty claims. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2016, 230, 297–308. [Google Scholar] [CrossRef]

- Rajpathak, D.; Chougule, R.; Bandyopadhyay, P. A domain-specific decision support system for knowledge discovery using association and text mining. Knowl. Inf. Syst. 2012, 31, 405–432. [Google Scholar] [CrossRef]

- Ferilli, S. Integration strategy and tool between formal ontology and graph database technology. Electronics 2021, 10, 2616. [Google Scholar] [CrossRef]

- Hogan, A.; Blomqvist, E.; Cochez, M.; D’amato, C.; Melo, G.D.; Gutierrez, C.; Kirrane, S.; Gayo, J.E.L.; Navigli, R.; Neumaier, S. Knowledge graphs. ACM Comput. Surv. 2021, 54, 1–37. [Google Scholar] [CrossRef]

- Ferilli, S.; Redavid, D.; Di Pierro, D. LPG-based Ontologies as Schemas for Graph DBs. In Proceedings of the SEBD 2022: The 30th Italian Symposium on Advanced Database Systems, Tirrenia, Italy 19–22 June 2022; pp. 256–267. [Google Scholar]

- Compagno, F.; Borgo, S. Towards a formal ontology of engineering functions, behaviours, and capabilities. Semant. Web 2024, 15, 285–318. [Google Scholar] [CrossRef]

- Borgo, S.; Ferrario, R.; Gangemi, A.; Guarino, N.; Masolo, C.; Porello, D.; Sanfilippo, E.M.; Vieu, L. DOLCE: A descriptive ontology for linguistic and cognitive engineering. Appl. Ontol. 2022, 17, 45–69. [Google Scholar] [CrossRef]

- Keet, M. Examples: DOLCE and BFO in DL and Manchester syntax. Tech. Rep. 2009, 1–66. Available online: http://www.meteck.org/files/swt09/DolceliteBFOinDLandMSyntax.pdf (accessed on 16 August 2025).

- Loebe, F.; Burek, P.; Herre, H. GFO: The general formal ontology. Appl. Ontol. 2022, 17, 71–106. [Google Scholar] [CrossRef]

| Ontology Engineering Methodology | Key Characteristics | Ontology Reuse | Evaluation Focus |

|---|---|---|---|

| NeOn Methodology [63] | Scenario-based, supports collaborative and networked ontology engineering | Strong support for reuse, modularisation, and alignment | Iterative, use-case driven validation |

| Methontology [64] | Structured, waterfall-like phases from specification to maintenance | Encourages reuse, often within well-defined lifecycle stages | Emphasises completeness, clarity, and consistency |

| DILIGENT [65] | Designed for distributed, loosely controlled, and evolving settings using argumentation | Reuse via controlled adaptation and consensus-based evolution | Consensus-building and traceability through rhetorical argumentation |

| Aspect | Structure–Behaviour–Function (SBF) | Function–Behaviour–State (FBSta) | Function–Behaviour–Structure (FBStr) |

|---|---|---|---|

| Key Publications | [22] | [21,69,70] | [19,68,71] |

| Function Definition | Describes the role an element plays in a device’s operation; function linked to behaviour through a schema [22] | Abstracted from behaviour and typically described in “to do” form [70] | Defined as the teleological goal of the system, described in a verb-object form [71] |

| FunctionBehaviour Relationship | One-to-one rational relation | Many-to-many subjective relation (designer’s choice) | Many-to-many subjective relation (designer’s choice) |

| Behaviour Definition | Internal behaviours, described as state transitions within a system | Output behaviours, represented as sequences of state transitions | Attributes derived from the system structure [71] |

| Behaviour–Structure (State) Relationship | Causal and objective, governed by physical laws | Many-to-many relationship; behaviour is governed by physical laws within different views | Many-to-many relationship; behaviour can be derived from structure using heuristics or physical laws |

| Structure (State) Definition | Defined by components, substances, and their relations | Defined by entities, attributes, and relations | Defined by elements, attributes, and their interconnections |

| Examples | Function: transfer angular momentum | Function: generate light | Function: control noise, enhance solar gain |

| Vehicle Serial Number | LC | LC Description | Vehicle Age at Failure (days) | Vehicle Mileage at Failure | Cost of Repair ($) | Technician Verbatim |

|---|---|---|---|---|---|---|

| V1 | LC1 | Headlamp repl. | 20 | 500 | C1 | Filament burnt…ch.. |

| V2 | LC2 | Headlamp repl. | 55 | 1500 | C2 | Bulb blown…re.. |

| … | … | … | … | … | … | … |

| Vi | LCi | Headlamp repl. | 231 | 2800 | Ci | Bulb blown…repl. |

| Component | Component Part Number | Failed Component | Field Failure Modes | Field Failure Effect | Field Failure Cause | Action Taken | Occurrence in Field | Reported at |

|---|---|---|---|---|---|---|---|---|

| PCBA | YQR SSH2E | FR4 | Terminal deform or damage | Unknown customer effect | Non-normal mass-producing lamp | Unknown Decision | 1 out of 668 | 20,000–25,000 |

| Lens | YWR SSH0E | Visible surface | Component broken | There is a moist fog foreign body inside | The welding day Bo Ft Helens cracked. | Scrapped | 31 out of 668 | 15,000–20,000 |

| Aspect | FBSFM Framework | ISOnto (Integrated Extension) |

|---|---|---|

| Scope | Captures design-phase knowledge of functions, behaviours, structures, and failure modes. | Extends to integrate design-phase knowledge with operational field data (e.g., warranty claims, inspections). |

| Lifecycle coverage | Limited to early stage conceptual design. | Provides lifecycle-wide traceability, linking design assumptions with real-world performance and failures. |

| Failure modes | Represents failure assumptions derived from functional and behavioural analysis. | Validates FMEA entries against field failures and identifies previously undocumented failure modes. |

| Traceability | One-way traceability (function → behaviour → structure → failure mode). | Two-way traceability between design intent and operational reality. |

| Ontology scope | Ontology classes are limited to FBS concepts and FMEA constructs. | Dual-layer ontology: FBSFM + field feedback ontology, semantically integrated. |

| Contribution | Provides a structured representation for early failure reasoning. | Creates a unified, machine-readable knowledge base enabling reasoning across design and operational phases. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Younus, H.; Campean, F.; Kabir, S.; Bonnaud, P.; Delaux, D. Integrated Systems Ontology (ISOnto): Integrating Engineering Design and Operational Feedback for Dependable Systems. Computers 2025, 14, 451. https://doi.org/10.3390/computers14110451

Younus H, Campean F, Kabir S, Bonnaud P, Delaux D. Integrated Systems Ontology (ISOnto): Integrating Engineering Design and Operational Feedback for Dependable Systems. Computers. 2025; 14(11):451. https://doi.org/10.3390/computers14110451

Chicago/Turabian StyleYounus, Haytham, Felician Campean, Sohag Kabir, Pascal Bonnaud, and David Delaux. 2025. "Integrated Systems Ontology (ISOnto): Integrating Engineering Design and Operational Feedback for Dependable Systems" Computers 14, no. 11: 451. https://doi.org/10.3390/computers14110451

APA StyleYounus, H., Campean, F., Kabir, S., Bonnaud, P., & Delaux, D. (2025). Integrated Systems Ontology (ISOnto): Integrating Engineering Design and Operational Feedback for Dependable Systems. Computers, 14(11), 451. https://doi.org/10.3390/computers14110451