2.1. Brookite TiO2-CeO2 Composites Characterization

As reported in the literature, the obtainment of pure brookite phase was difficult, being strongly affected by the preparation method adopted [

12]. One of the easy and consolidated approaches to prepare pure brookite is the thermohydrolysis of TiCl

4 in aqueous chloride solutions [

28,

29]. With this procedure, it is possible to obtain the brookite phase without the presence of anatase or rutile.

The confirmation of the presence of the only brookite phase was obtained with Raman spectroscopy (

Figure 1a). Indeed, this characterization technique is more sensitive to detect the presence of the brookite phase than the XRD one, that required a structure refinement method to clearly note that brookite is the only crystalline structure present [

12,

30,

31]. To investigate the change in the physico-chemical properties of brookite due to the addition of cerium oxide, three different composites were prepared with a growing amount of the hosted CeO

2 oxide (1 wt%, 3 wt% and 5 wt%).

In previous works with anatase and P25 TiO

2, we noted that a CeO

2 concentration higher than 5 wt% had a detrimental effect for the titania photoactivity [

23,

32]. Consequently, in this work, although we studied another type of TiO

2 sample, we limited our investigations to the low amounts of cerium oxide. The composites were coded as Ti/CeX where X is the weight percentage of CeO

2. This is just a code that does not identify the catalytic support which in this case could be considered to be TiO

2.

From the Raman spectra (

Figure 1a) it is possible to note that bare brookite showed, in accordance with the literature [

29,

33], 13 peaks: six A

1g: four clearly visible (153, 246, 414 and 636 cm

−1) whereas the other two bands related to this Raman optical mode were at 128 cm

−1 (as a shoulder of the main peak at 153 cm

−1 also visible in

Figure 1b) and at about 195 cm

−1 (with a very low intensity overlapping with the signal at 212 cm

−1 (B

1g mode)). The other Raman vibration modes were two B

1g (212 and 325 cm

−1), three B

2g (365, 462 and 586 cm

−1, this latter present with a very low intensity) and two B

3g (502 and 545 cm

−1). The typical signal at 153 cm

−1 is a fingerprint of the presence of brookite and the lack of the usual Raman bands at 516 and 448 cm

−1, typical of the anatase and rutile phases, respectively [

34], which indicates that brookite is the only phase present. Bare CeO

2 showed a single band at 462 cm

−1 related to the cubic fluorite structure (F

2g vibration) [

20]. All of the TiO

2-CeO

2 composites exhibited the bands of pure brookite, whereas the signal of CeO

2 at 462 cm

−1 overlapped with the second B

2g band of brookite, although it is possible to note a broadening of this band in the mixed oxide samples. A further indication of the composites formation was the slight blue shift of the main brookite Raman band (

Figure 1b), more evidently increasing the amount of ceria. The broadening and the shift of the Raman band is, in fact, correlated to the modification of the principal oxide lattice (in this case brookite TiO

2) caused by the progressive interaction with the second oxide (in this case CeO

2) [

35].

From the Raman confocal maps (

Figure 1c,d illustrating the Ti/Ce3 and the Ti/Ce5 as representative samples), it is possible to note that there are no isolated regions with a prevalence of one color (the clear violet color area represents the presence of brookite whereas the darker violet area represents the presence of CeO

2, however, which are difficult to differentiate), thus indicating as the low amount of cerium oxide is uniformly present on the brookite [

10,

18].

The good interaction of the cerium oxide with brookite TiO

2 was also confirmed by the formation of a heterojunction between the two oxides, detectable in the Ti/Ce5 sample through the HRTEM (High Resolution Transmission Electron Microscopy) image (

Figure 2), whereas in the other two composites, due to the low amount of the cerium oxide, it was not possible to discern the interface between the titania and ceria, in any case difficult to differentiate, even in the Ti/Ce5 sample, due to the similar d-space values of the examined oxides. However, from

Figure 2 it is possible to note the boundary interaction between the brookite TiO

2 (121) planes and the CeO

2 (111) planes accordingly to the d-spacing values [

33,

36]. The interplanar distance of 0.35 nm referred to the (210) or (111) planes of brookite TiO

2 [

37] was not detected in our samples utilizing the employed TEM.

The specific surface area, the mean pores diameter and the pores volume of the brookite TiO

2-CeO

2 composites are reported in

Table 1.

Figure 3 displays the nitrogen physisorption curves (

Figure 3a) and the distribution of the pores size obtained by the Barrett, Joyner and Halenda (BJH) method (

Figure 3b). All the powders showed the characteristic mesoporous type IV isotherm (

Figure 3a) [

38] and a H1 hysteresis. The addition of cerium oxide diminished the specific surface area (

Table 1) calculated with the BET (Brunauer-Emmett-Teller) method, of brookite, reasonably due to the progressive interaction of the hosted oxide with brookite, as confirmed by the Raman measurements, and to the calcination treatment necessary for the formation of the composites.

Interestingly, the bare brookite showed a broader BJH pore size distribution curve (

Figure 3b), whereas the pure CeO

2 exhibited the lowest surface area (60 m

2/g) and pore volume (0.14 cm

3/g) with the highest mean pore diameter (32 nm) (

Table 1).

The diffuse reflectance spectra (DRS) of the materials are shown in

Figure 4 (

Figure 4a, the Kubelka-Munk function, i.e., the reflectance function, was plotted versus the wavelength; whereas

Figure 4b illustrates the estimation of their optical band-gap through the modified Kubelka-Munk function). It is possible to note (see also

Table 1) that the addition of cerium oxide resulted in a slight decrease of the optical band-gap of pure brookite, whereas, the bare CeO

2 showed the highest red shift (

Figure 4a) and consequently a lower band-gap (

Figure 4b) compared to TiO

2, in accordance with the literature data [

17,

32].

Figure 5 reports the photoluminescence (PL) spectra of the investigated samples. The band at 388 nm, assigned to the band-to-band emission of brookite TiO

2 [

39,

40,

41], was progressively quenched increasing the amount of cerium oxide on TiO

2, pointing to a lower recombination rate between the photoholes and photoelectrons in the TiO

2-CeO

2 composites. Indeed, the decrease of the PL band intensity is usually related to an enhancement of the charge carrier separation in the photoactive materials [

42,

43]. In the TiO

2-CeO

2 composites, also the intensity of the PL brookite band at about 430 nm, due to the self-trapped excitons confined in the TiO

6 octahedra [

44], decreased, whereas the PL band at 460 nm of pure brookite, attributed to the presence of oxygen vacancies in the TiO

2 lattice [

44,

45], overlapped with the band at 455 nm due to the band-to-band emission of CeO

2 [

10,

32]. Even for these bands, the intensity diminution in the composites was a further indication of the better separation of the charge carriers in the Ti/Ce powders. Finally, the PL band at about 555 nm, present in all of the samples, was related to the photoelectrons trapped in the defect centers generated by the oxygen vacancies of titania and/or ceria [

46].

2.2. Surface Properties of Brookite TiO2-CeO2 Composites

The X-ray photoelectron spectroscopy (XPS) results of pure brookite TiO

2 confirmed the presence of only this crystalline form of TiO

2. Indeed, the sharp Ti 2p

3/2,1/2 spin–orbit components at 459.3 and 465.1 eV (5.8 eV spin–orbit coupling,

Figure S1a) and the O 1s band centered at 530.8 eV (

Figure S1b), are typical of brookite phase [

47,

48]. It has been noted that the absence of broadening at low binding energy (BE) due to a doublet in the titania band (ascribed to Ti

3+) [

49]. The O 1s spectral profile suggests the presence of some Ti–OH hydroxide species, evident at a higher binding energy with respect to the main peak.

As regards the XPS ionization of the 3d cerium levels of the cerium oxide sample, six distinct signals were obtained (

Figure S1c), in accordance with the literature data for the pure CeO

2 species [

50,

51]. The ground state for Ce

4+ is represented by the 3d

104f

0 electronic configuration. In this context, the bands at 882.9, 889.2 and 898.8 eV are ascribed to the Ce 3d

5/2 states, whereas the peaks at 901.5, 907.8 and 917.3 were assigned to the Ce 3d

3/2 states (18.6 spin–orbit coupling). In accordance to the literature data [

50,

51,

52], the signals at 882.9 and 889.2 eV were due to a mixed configuration of 3d

94f

2(O 2p

4) and 3d

94f

1(O 2p

5) Ce

4+ states, while the signal at 898.8 eV corresponds to the 3d

94f

0(O 2p

6) Ce

4+ state. Finally, the peaks at 901.5, 907.8 and 917.3 were consistent with the spin–orbit components of the 3d

3/2 states of the same configurations. Therefore, only the peaks expected for pure CeO

2 were observed. Furthermore, the absence of signals at 882.9, 889.2 and 898.8 eV excludes any 3d

94f

1 (O 2p

6) and 3d

94f

2(O 2p

5) Ce

3+ final states.

Figure S1d shows the high-resolution O 1s band for the pure cerium oxide that involves two signals at 529.4 and 531.6 eV, respectively. The first peak is due to the O

2− species for CeO

2, whereas the latter is assigned to the OH

− species [

52].

The spectrum of the Ti/Ce5 sample displays the Ti 2p 3/2 and 1/2 spin–orbit peaks at 459.0 and 464.8 eV (

Figure 6a) [

48,

53]. Therefore, these Ti 2p levels were just 0.3 eV at lower binding energies compared to the bare brookite catalyst and can be rationalized in terms of the higher electronegativity of Ti (1.5) with respect to that of Ce (1.1). This sizeable shift suggests some electronic interaction between titanium and cerium cations. Moreover, these XPS binding energies are the same also considering the Ti/Ce1 and the Ti/Ce3 catalysts (

Table 2).

The high-resolution spectrum of the O 1s core level for the Ti/Ce5 sample (

Figure 6b), and those for both Ti/Ce1 and Ti/Ce3 analogues (

Table 2), show a sharp O 1s peak at 530.5 eV, similar to the bare brookite [

47,

48]. Moreover, this peak suffers a 0.3 eV lower binding energy shift, compared to the un-modified titania.

The Ce 3d binding energy region of Ti/Ce5 (

Figure 6c) shows the typical superimposition of Ce

4+ and Ce

3+ contributions [

48,

51,

53]. The lower binding energy doublet at 883.2 and 901.8 eV (18.6 eV spin-orbit coupling) is attributed to the state of Ce(IV) 3d

94f

2(O 2p

4) [

48,

51], while the doublet at 886.5 and 905.1 eV (18.6 eV spin-orbit coupling) is attributed to the state of Ce(III) 3d

94f

2(O 2p

5) [

50,

53]. Moreover, the presence of Ce

4+ is confirmed by the characteristic low peak at 917.5 eV [

48,

51]. All these observations are in agreement with those previously reported for the XPS of Ce

4+ and Ce

3+ mixed valence state systems [

32,

50,

53].

For similar systems, it was reported that the presence of Ce

3+ species may be attributed to electronic interactions between TiO

2 and CeO

2 that cause the partial reduction of the Ce tetravalent cation [

32,

53]. Obviously, the presence of some Ti

3+ cations on the TiO

2 surface must be considered why this redox process takes place. Even though we have no XPS evidence of such Ti species, it is widely recognized that the not complete axial coordination of the surface Ti cation in TiO

2 leads to some surface Ti reduction [

54,

55]. Reasonably, any chemical interaction between the two oxides should be confined to the topmost ionic layers of each oxide nanoparticles, and this is consistent with the formation of a heterojunction between the titania and ceria interfaces as confirmed by the HRTEM (

Figure 2).

On the basis of the above observation, we noted that the Ti 2p levels of the mixed oxides are shifted at a 0.3 eV lower BE compared to bare brookite, while the binding energy of the Ce

4+ 3d levels in the TiO

2-CeO

2 mixed oxides are 0.3 eV at higher BE in comparison to the same signal detected in CeO

2 (882.9 eV). This confirms the existence of an electronic interaction between the Ti and Ce (both Ce

3+ and Ce

4+) ions [

32,

48].

Interestingly, as also already reported in the literature [

47], the increase of the amount of ceria in the composites parallelly decreases the intensity of the XPS peaks of Ce

4+ whilst it enhances those of Ce

3+. The XPS Ce(III)/Ce(IV) atomic ratio was investigated using a method already reported [

53]. This method considers the relative intensities of the Ce(III) and Ce(IV) XPS 3d bands, obtained by the fitting of the experimental spectrum. We are aware that all the final states of the ionizations of the Ce (IV), already discussed for the blank CeO

2 sample (

Figure S1c, vide supra), must be included in the band fitting. Moreover, the low intensity high binding energy band (

Figure 6c) at 917.5 eV is with no doubt due to the ionic 3d

94f

0 (O 2p

6) 3d

3/2 Ce

4+ state. By taking all these considerations into account, from the XPS spectral fitting of the Ti/Ce5 sample (

Figure S1e) we obtained a Ce(III)/Ce(IV) = 1.4 value that stresses a Ce(III) prevalence on the sample surface [

56,

57]. Finally, the surface composition of the five analyzed powders, was calculated. Results indicate that the Ce/Ti ratios are 0.007, 0.010 and 0.030 for the Ti/Ce1, Ti/Ce3 and Ti/Ce5 systems. These ratios are consistent to the nominal molar ratio of the investigated materials.

2.3. (Photo)Catalytic Oxidation of 2-Propanol

The results of the thermocatalytic oxidation in the gas phase of 2-propanol are reported in the

Table 3, where the T

10, T

50 and T

90 are the temperatures at which the 10%, 50% and 90% of conversion is achieved (the relative conversion curves for all the analyzed samples are reported in the supporting information,

Figure S2). Interestingly, the high surface area of bare brookite TiO

2 (100 m

2/g,

Table 1) allowed to obtain a T

90 of 258 °C in the alcohol conversion and of 323 °C in the conversion to CO

2, which are 22 °C and 65 °C lower compared to the T

90 of P25 TiO

2 (80% anatase-20% rutile) under the same experimental conditions [

23]. Although the addition of CeO

2 decreased the surface area of brookite (

Table 1) the synergism between the two oxides permitted to decrease the 2-propanol conversion temperature that was the lowest for the Ti/Ce3 sample with a T

90 of 253 °C.

The catalytic combustion of 2-propanol can follow two pathways that led to obtain as intermediate products propene and water or acetone and water [

23,

58]. In our experimental conditions, acetone was the main detected reaction intermediate, whereas the amount of propene was negligible. Interestingly, the addition of cerium oxide on brookite favored the total oxidation to CO

2. Indeed, the maximum of acetone conversion decreased by increasing the amount of ceria in the brookite. This maximum varies from 93% (at 261 °C) for pure brookite to 41% for Ti/Ce5, similar to bare CeO

2 (39%), but was achieved at a much lower temperature (221 °C instead of 365 °C). Contextually, the T

10, T

50 and T

90 values related to the conversion to CO

2 over the composites were lower than those of the bare brookite (

Table 3) with the Ti/Ce5 that exhibited the lowest T

90 (281 °C).

The results of the photocatalytic oxidation of 2-propanol after 2 h of simulated solar irradiation at room temperature are reported in the

Figure 7. In this case, the brookite TiO

2-CeO

2 composites showed a similar 2-propanol conversion to bare brookite with only a slight increase in the conversion values with the increase of the amount of cerium oxide. The alcohol conversion varies from 60% of pure brookite to 62% of Ti/Ce1 and 66% of Ti/Ce3 and Ti/Ce5. In addition, also in this case acetone was the main intermediate produced, in accordance with the literature data [

59,

60]. The bare CeO

2 showed the lowest photocatalytic activity with the 22% of 2-propanol conversion, but with the highest selectivity to CO

2 (36%). The presence of ceria allowed to increase the selectivity to CO

2 with respect to the bare brookite (from the 3% of bare brookite to 21% of the Ti/Ce5 sample). This is another indication of a mutual synergism between titania and ceria, while pure brookite was an optimal photocatalyst for the partial oxidation to acetone (selectivity of 95%).

The synergism between TiO

2 and CeO

2 was even more exploited in the photo-thermo catalytic oxidation, i.e., with the contemporaneous use of the simulated solar irradiation and the thermal heating of the reactor. The thermal catalysis favored the total oxidization of the 2-propanol to CO

2, limiting the formation of acetone to a close range of temperatures, whereas the contemporaneous utilization of the solar light permitted to decrease the conversion temperatures. In particular, from

Table 4 (conversion curves illustrated in the

Figure S3) it is possible to note for all of the samples a decrease of the conversion temperatures with respect to the thermocatalytic tests (

Table 3), most relevant for the mixed oxides catalysts. The T

90 of brookite decreased by 40 °C and 20 °C for the 2-propanol conversion and for the conversion to CO

2, respectively; for the Ti/Ce1 the T

90 decrease was of 48 °C for the alcohol conversion and 19 °C for the conversion to carbon dioxide. The Ti/Ce3 and the Ti/Ce5 composites showed a higher decrease of T

90 (see

Table 3 and

Table 4). The diminution was of about 60 °C (2-propanol conversion) and 70 °C (conversion to CO

2) for both samples. The positive effect of the photothermal approach was less effective for the bare CeO

2 (T

90 diminution of 7 °C for the 2-propanol conversion and of 18 °C for the conversion to carbon dioxide).

Another interesting effect verified with the multi catalytic approach was the increase of the maximum of acetone conversion occurring for all of the samples at a lower temperature in comparison to the thermocatalytic tests (see

Table 3 and

Table 4). The presence of the solar radiation facilitated the 2-propanol conversion to acetone, as also detected in the photocatalytic test at room temperature (

Figure 7). However, similarly to the thermocatalytic tests, the increase of cerium oxide in the composites decreased the maximum of acetone conversion, (from the 97% at 225 °C of Ti/Ce1 to the 57% at 165 °C of Ti/Ce5), confirming that the addition of ceria favors the 2-propanol conversion to CO

2 more than the conversion to acetone.

2.4. (Photo)Catalytic Oxidation of Ethanol

With respect to 2-propanol, ethanol, being a primary alcohol, required a higher temperature for the thermocatalytic oxidation (

Table 5,

Figure S4). In this case, acetaldehyde was the main intermediate. Similar to the 2-propanol thermocatalytic oxidation, the Ti/Ce5 and the Ti/Ce3 were the best active samples with the following order of activity both for the ethanol conversion and for the conversion to CO

2: Ti/Ce5 > Ti/Ce3 > Ti/Ce1 > TiO

2 > CeO

2.

The lowest T90 temperatures were obtained with the Ti/Ce5 sample (270 °C for the ethanol conversion and 292 °C for the conversion to CO2). Moreover, also in this case the presence of cerium oxide favored the conversion to CO2, and consequently the maximum of acetaldehyde conversion decreased from 69% at 271 °C with bare brookite to 41% at 232 °C with the TiCe/5 composite.

Likewise, in the solar photocatalytic oxidation of ethanol (

Figure 8) the conversion values were lower compared to those of 2-propanol. Similar to the previous cases, the main difference in the photocatalytic behavior of the composites compared to the bare brookite was the high selectivity to CO

2 that was 20% for the Ti/Ce5, 15% for the Ti/Ce3 and 10% for the Ti/Ce1, higher than that measured for the bare brookite (8%).

The lower acidity of ceria compared to that of TiO

2 [

61,

62,

63] enhanced the formation of carbon dioxide, as also stated by the (photo)catalytic oxidation of 2-propanol. Indeed, similarly to the 2-propanol solar photocatalytic oxidation, the bare CeO

2 showed the highest CO

2 selectivity (30%) (

Figure 8). In the same employed experimental conditions, the bare brookite exhibited higher ethanol photocatalytic conversion at room temperature (27%) with respect to P25 TiO

2 (≈17%) and commercial anatase TiO

2 (≈18%) [

27,

64].

In the photothermo-catalytic oxidation of ethanol (

Table 6,

Figure S5) a decrease of the conversion temperatures with respect to the thermocatalytic tests was detected. This diminution was lower compared to the 2-propanol photothermo-oxidation, but however, it was consistent especially in the samples with the highest amount of cerium oxide, confirming the occurrence of a synergism between the cerium oxide and the brookite TiO

2. The Ti/Ce5 catalyst showed a decrease of the T

90 temperatures of 44 °C for the alcohol conversion and of 42 °C for the conversion to CO

2, the Ti/Ce3 sample displayed a decrease of about 40 °C for both temperatures, whereas the diminution was less marked for the Ti/Ce1 and the bare brookite samples (decrease of ≈ 25 °C). Additionally, in this case, a contextual decrease of the temperature of maximum conversion to the intermediate was verified, whereas only a slight variation (temperatures decrease in the range 5–8 °C) was detected for the bare CeO

2.

2.5. (Photo)Catalytic Oxidation of Toluene

To test the reactivity of the brookite TiO

2–CeO

2 composites towards aromatic VOCs, the thermocatalytic (

Figure 9a), photocatalytic (

Figure 9b) and photothermo-catalytic oxidation (

Figure 9c) of toluene was investigated. As expected, due to the minor reactivity of the aromatic compounds with respect to the alcohols, the conversion temperatures for toluene were higher than those measured for the 2-propanol and ethanol oxidation [

65,

66]. In all experiments, including the solar photocatalytic tests at room temperature, only the CO

2 and water were detected with a very low selectivity (1–3%) to benzaldehyde [

67,

68,

69,

70]. The catalytic trend observed in the (photo)catalytic oxidation of alcohols was further confirmed in the toluene thermocatalytic oxidation with an order of activity that was Ti/Ce5 > Ti/Ce3 > Ti/Ce1 ≥ TiO

2 > CeO

2, with the most active catalysts (Ti/Ce5 and Ti/Ce1) exhibiting a T

90 of 374 °C and 378 °C, respectively. Furthermore, in this case, the addition of cerium oxide had a beneficial effect, the T

90 temperatures being lower compared to pure brookite (411 °C), whereas the Ti/Ce1 showed only a slightly better activity (T

90 = 403 °C).

In the photocatalytic tests under solar irradiation (

Figure 9b), the composites with the higher amount of cerium oxide improved the photoactivity of pure single oxides, although the degradation percentages were lower compared to the photoconversion of alcohols.

In the photothermo-catalytic tests (

Figure 9c) with the Ti/Ce5 and the Ti/Ce3 samples, a decrease of the T

90 temperature compared to the thermal catalytic tests of about 20 °C and 13 °C was verified, respectively, whereas in the other samples, the decrease of the conversion temperatures was smaller.

To have a general idea of the catalytic stability of the TiCe/5 after the photothermo oxidation of toluene (as stated before the most difficult VOC to oxidize among those used in this work), the toluene conversion was measured after long-time on-stream measurements at T = 350 °C (i.e., the T

90 of the sample,

Figure 10a) and after five consecutive runs (

Figure 10b). Only a little decrease from 90% to 84% of toluene conversion was measured after 45 h of the test, and also a little shift of T

90 at a higher temperature (about 8 °C) was verified after five consecutive runs, pointing to the discrete stability of the investigated composite.

The XPS results after the photothermo catalytic oxidation of 2-propanol (as representative alcohol) and after the long-time on-stream toluene tests of the Ti/Ce5 sample showed no significant variations (

Figure S6) in the Ce 3d and Ti 2p regions compared to the sample analyzed before the catalytic tests. In the O 1s and C 1s regions, a small contribution ascribed to the carbonation process was verified after the toluene tests, and reasonably the occurrence of this process can be the cause of the little decrease of the conversion values after a long time and consecutive tests of toluene photothermo-catalytic oxidation.

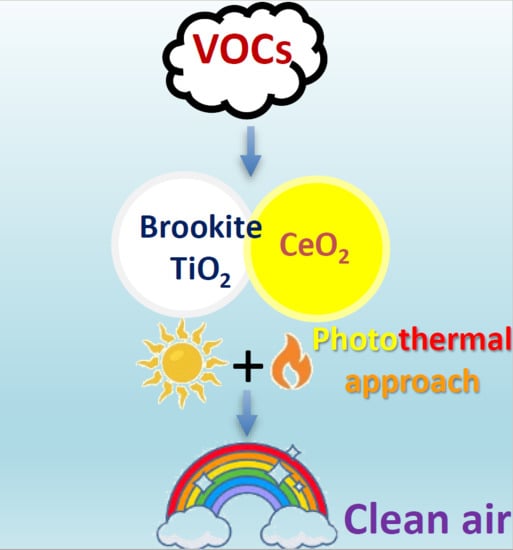

2.6. Photothermo-Catalytic Mechanisms

The (photo)catalytic data of the VOC oxidation have shown as the main result that the addition of even small amounts of cerium oxide in brookite TiO2 has led to an increase in activity, with also an improvement in the formation of CO2. The good affinity between TiO2 and CeO2 was further exploited in the photothermo-catalytic tests, where the synergism between the catalytic and the photocatalytic mechanism also played a crucial role.

Indeed, the thermo-driven oxidation of VOCs, with reducible oxides (as CeO

2) followed a Mars–van Krevelen (MvK) redox mechanism, where the surface reducible oxygens of the employed catalyst directly participate in the oxidation of the organic compound, facilitating the total oxidation to CO

2 [

17,

71]. In particular, for the CeO

2-based catalyst, the high reactivity of its oxygens was strictly connected with its redox properties: the Ce

4+→ Ce

3+ reduction releases oxygens (that will oxidize the VOC) with a consequent formation of oxygen vacancies in the ceria lattice. These vacancies will be successively filled by oxygens in the gas phase, thus exploiting the redox properties of cerium oxide [

23,

72] (

Figure 11a). In the photocatalytic oxidation of VOCs with semiconductor catalysts, the generation of highly reactive species as the hydroxide and the superoxide radicals after the irradiation of the photoactive materials allows to degrade the dangerous pollutants [

73,

74] (

Figure 11b).

In our case, in the thermocatalytic tests, the good interaction between titania and ceria permitted to increase the performance compared to the single oxides, whereas when the photo-oxidation route was also activated, the presence of the oxygen radicals boosted up the total oxidation of VOCs, simultaneously favoring the redox cycle of CeO

2 [

18,

23,

32,

36] (

Figure 11c). Indeed, the oxygen radicals, more reactive compared to the oxygen in the gas phase, interact with the cerium oxide surface, accelerating its redox cycle [

19,

75]. Therefore, the redox process on the cerium oxide is speeded up in the photothermo-catalytic tests. The solar light-driven photothermo-catalytic oxidation rate of VOCs was in this way significantly enhanced, thus explaining the decrease of the conversion temperatures with respect to the thermocatalytic tests, observed for all of the composite materials. This strong affinity between the TiO

2 and CeO

2 strongly affected the selectivity of products after the (photo)catalytic oxidation of VOCs. Indeed, whereas with the bare brookite, the partial oxidation of alcohols was favored (

Table 3,

Table 4,

Table 5 and

Table 6,

Figure 7 and

Figure 8), a crescent amount of cerium oxide allowed to increase the selectivity to CO

2, facilitating the total oxidation of VOCs. This catalytic behavior was further promoted in the photothermal tests and in the oxidation of toluene where no intermediate products were formed. With the TiO

2-CeO

2 composites, it was possible to exploit a double effect: the photoactivity of TiO

2 allowed to start the oxidation of VOCs, whereas the redox properties of CeO

2 boosted up the VOC conversion towards the total oxidation to CO

2.

The occurrence of this mutual synergism between the brookite TiO

2 and the CeO

2 was also confirmed by XPS. This strong interaction in fact favored the formation of the Ce

3+ species increasing the amount of cerium oxide in the brookite. This feature is advantageous for the thermo-catalytic and even more for the photothermo-catalytic reactions, since the redox cycle of ceria was even more promoted by the continuous interaction with TiO

2, thus explaining the higher activity of the Ti/Ce3 and Ti/Ce5 samples. Although the bare CeO

2 showed the lowest optical band-gap (2.87 instead of the 3.22 eV of brookite), only the combination with brookite allowed to increase its photocatalytic performance. The good dispersion of ceria in the TiO

2, and the formation of an efficient heterojunction between the two oxides (as verified by the Raman and HRTEM characterizations) resulted in an improvement of the charge carrier separation, as confirmed by the PL measurements, that allowed to efficiently activate the photo-oxidation mechanism. Moreover, with the multi catalytic approach and the contemporary exploitation of the photocatalytic properties of brookite and the redox properties of the ceria, the TiO

2-photogenerated electrons can be moved to the empty 4f energy levels of CeO

2 or can be trapped by the ceria oxygen vacancies that are formed during the oxidation reactions, further increasing the separation of the charge carriers, and simultaneously promoting the oxidation of VOCs by the titania and ceria photoholes [

76] (

Figure 11d).

In this context, the utilization of brookite was advantageous because a moderate depth of photoelectron trap with respect to anatase or rutile TiO

2 was reported, and consequently both the electrons and holes are highly reactive [

31,

77]. This is beneficial for the oxidation of VOCs because the residual free photoelectrons of brookite can reduce the gas-phase oxygens to further increase the formation of superoxide radicals that in turn can re-oxidize the cerium oxide, enhancing in this way the overall performance of the brookite TiO

2-CeO

2 composite.

The combination of the peculiar photocatalytic properties of brookite TiO2 together with the redox properties of CeO2 activated with a multi-catalytic approach can be a fascinating strategy to increase the efficiency of the catalytic VOC degradation.