Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review

Abstract

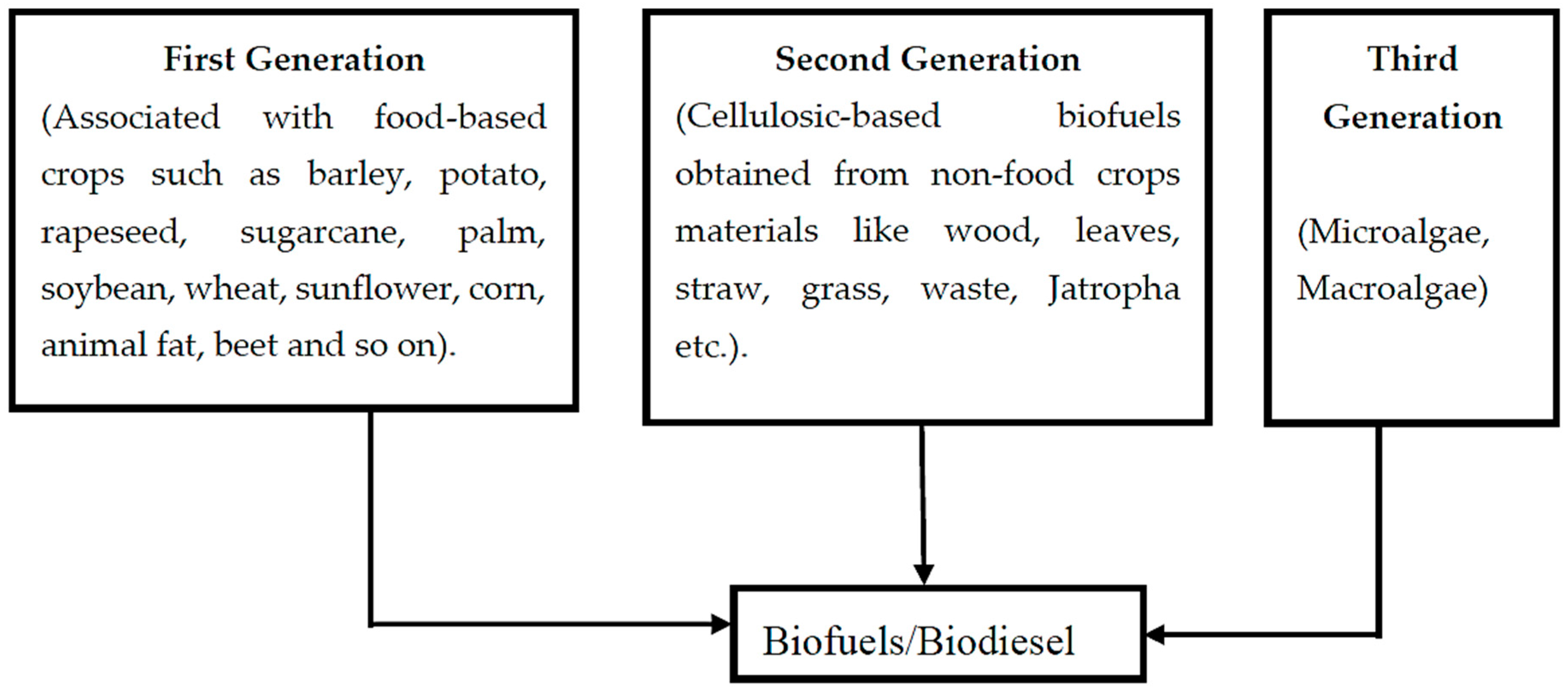

:1. Introduction

2. Microalgae Oil as Feedstock for Biodiesel Production

3. Outline of Biodiesel Production Process from Microalgae

4. Heterogeneous Catalysts for Biodiesel Production

4.1. Basic Solid Catalysts

4.1.1. MgO as a Base Heterogeneous Catalyst

4.1.2. CaO as a Base Heterogeneous Catalyst

4.1.3. SrO as a Base Heterogeneous Catalyst

4.1.4. Biodiesel Production with Mixed Metal Oxide and Derivatives

4.1.5. Biodiesel Production with Transition Metal Oxides and Derivatives

4.1.6. Waste Material-Based Heterogeneous Catalysts

4.2. Acidic Solid Catalysts

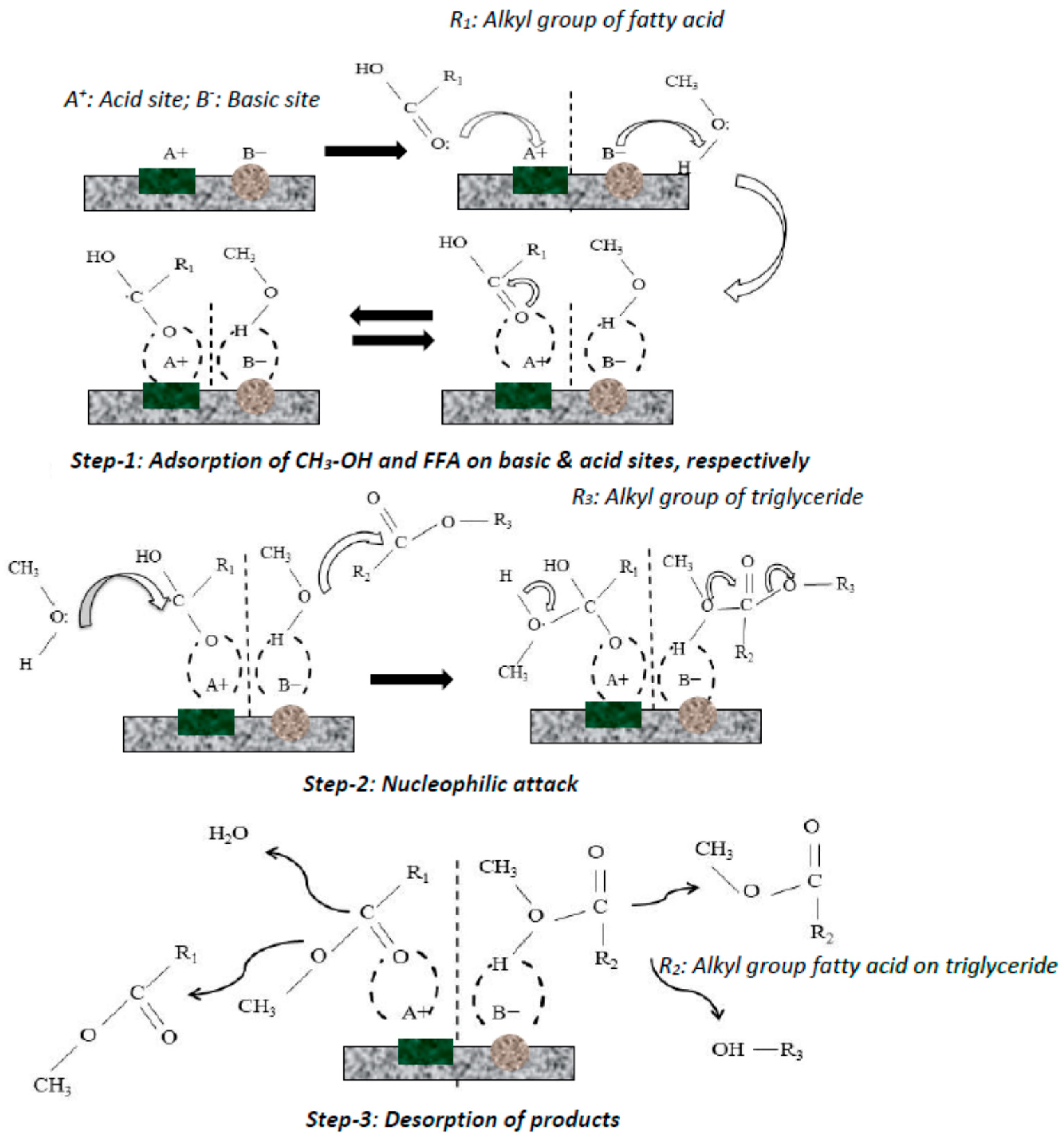

4.3. Acid−Base Solid Catalysts

5. Biocatalysts

6. Summary of the Effect of a Heterogeneous Catalyst on the Yield of Biodiesel

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wong, W.Y.; Lim, S.; Pang, Y.L.; Shuit, S.H.; Chen, W.H.; Lee, K.T. Synthesis of renewable heterogeneous acid catalyst from oil palm empty fruit bunch for glycerol-free biodiesel production. Sci. Total Environ. 2020. [Google Scholar] [CrossRef]

- Sharma, S.; Saxena, V.; Baranwal, A.; Chandra, P.; Pandey, L.M. Engineered nanoporous materials mediated heterogeneous catalysts and their implications in biodiesel production. Mater. Sci. Energy Technol. 2018. [Google Scholar] [CrossRef]

- De Bhowmick, G.; Subramanian, G.; Mishra, S.; Sen, R. Raceway pond cultivation of a marine microalga of Indian origin for biomass and lipid production: A case study. Algal Res. 2014, 6, 201–209. [Google Scholar] [CrossRef]

- Wilbanks, T.J.; Fernandez, S. Climate Change and Infrastructure, Urban Systems, and Vulnerabilities: Technical Report for the US Department of Energy in Support of the National Climate Assessment; National Climate Assessment Regional Technical Input Report Series; Island Press: Washington, DC, USA, 2014. [Google Scholar]

- Nayak, M.; Karemore, A.; Sen, R. Performance evaluation of microalgae for concomitant wastewater bioremediation, CO2 biofixation and lipid biosynthesis for biodiesel application. Algal Res. 2016, 16, 216–223. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ghazvini, M.; Nazari, M.A.; Ahmadi, M.A.; Pourfayaz, F.; Lorenzini, G.; Ming, T. Renewable energy harvesting with the application of nanotechnology: A review. Int. J. Energy Res. 2019, 43, 1387–1410. [Google Scholar] [CrossRef]

- Bouraiou, A.; Necaibia, A.; Boutasseta, N.; Mekhilef, S.; Dabou, R.; Ziane, A.; Sahouane, N.; Attoui, I.; Mostefaoui, M.; Touaba, O. Status of renewable energy potential and utilization in Algeria. J. Clean. Prod. 2020. [Google Scholar] [CrossRef]

- Furlan, C.; Mortarino, C. Forecasting the impact of renewable energies in competition with non-renewable sources. Renew. Sustain. Energy Rev. 2018, 81, 1879–1886. [Google Scholar] [CrossRef]

- Singh, R.; Bux, F.; Sharma, Y.C. Optimization of biodiesel synthesis from microalgal (Spirulina platensis) oil by using a novel heterogeneous catalyst, β-strontium silicate (β-Sr2SiO4). Fuel 2020. [Google Scholar] [CrossRef]

- Mohtasham, J. Review article-renewable energies. Energy Procedia 2015, 74, 1289–1297. [Google Scholar] [CrossRef] [Green Version]

- Azarpour, A.; Suhaimi, S.; Zahedi, G.; Bahadori, A. A review on the drawbacks of renewable energy as a promising energy source of the future. Arab. J. Sci. Eng. 2013. [Google Scholar] [CrossRef]

- Manzanera, M.; Molina-Munoz, M.; Gonzalez-Lopez, J. Biodiesel: An alternative fuel. Recent Pat. Biotechnol. 2008. [Google Scholar] [CrossRef] [PubMed]

- Asri, N.P.; Machmudah, S.; Wahyudiono, S.; Budikarjono, K.; Roesyadi, A.; Goto, M. Palm oil transesterification in sub- and supercritical methanol with heterogeneous base catalyst. Chem. Eng. Process. Process Intensif. 2013. [Google Scholar] [CrossRef]

- Uddin, M.R.; Ferdous, K.; Uddin, M.R.; Khan, M.R.; Islam, M.A. Synthesis of biodiesel from waste cooking oil. Chem. Eng. Sci. 2013. [Google Scholar] [CrossRef] [Green Version]

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biomass Bioenergy 2014, 61, 276–297. [Google Scholar] [CrossRef]

- Helwani, Z.; Othman, M.R.; Aziz, N.; Fernando, W.J.N.; Kim, J. Technologies for production of biodiesel focusing on green catalytic techniques: A review. Fuel Process. Technol. 2009. [Google Scholar] [CrossRef]

- Feng, Y.; He, B.; Cao, Y.; Li, J.; Liu, M.; Yan, F.; Liang, X. Biodiesel production using cation-exchange resin as heterogeneous catalyst. Bioresour. Technol. 2010. [Google Scholar] [CrossRef]

- Nahar, G.; Kendall, K. Biodiesel formulations as fuel for internally reforming solid oxide fuel cell. Fuel Process. Technol. 2011. [Google Scholar] [CrossRef]

- Dhawane, S.H.; Kumar, T.; Halder, G. Recent advancement and prospective of heterogeneous carbonaceous catalysts in chemical and enzymatic transformation of biodiesel. Energy Convers. Manag. 2018, 167, 176–202. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Singh, B.; Upadhyay, S.N. Advancements in development and characterization of biodiesel: A review. Fuel 2008, 87, 2355–2373. [Google Scholar] [CrossRef]

- Rizwanul Fattah, I.M.; Ong, H.C.; Mahlia, T.M.I.; Mofijur, M.; Silitonga, A.S.; Rahman, S.M.A.; Ahmad, A. State of the art of catalysts for biodiesel production. Front. Energy Res. 2020, 8, 101. [Google Scholar] [CrossRef]

- Sianipar, R.N.R.; Ariyani, D.; Nata, I.F. Conversion of palm oil sludge to biodiesel using alum and KOH as catalysts. Sustain. Environ. Res. 2017. [Google Scholar] [CrossRef]

- Chamola, R.; Khan, M.F.; Raj, A.; Verma, M.; Jain, S. Response surface methodology based optimization of in situ transesterification of dry algae with methanol, H2SO4 and NaOH. Fuel 2019. [Google Scholar] [CrossRef]

- Shi, W.; Li, J.; He, B.; Yan, F.; Cui, Z.; Wu, K.; Lin, L.; Qian, X.; Cheng, Y. Biodiesel production from waste chicken fat with low free fatty acids by an integrated catalytic process of composite membrane and sodium methoxide. Bioresour. Technol. 2013. [Google Scholar] [CrossRef] [PubMed]

- Celante, D.; Schenkel, J.V.D.; de Castilhos, F. Biodiesel production from soybean oil and dimethyl carbonate catalyzed by potassium methoxide. Fuel 2018. [Google Scholar] [CrossRef]

- Fukuda, H.; Kondo, A.; Noda, H. Biodiesel fuel production by transesterification of oils. J. Biosci. Bioeng. 2001, 92, 405–416. [Google Scholar] [CrossRef]

- Granados, M.L.; Poves, M.D.Z.; Alonso, D.M.; Mariscal, R.; Galisteo, F.C.; Moreno-Tost, R.; Santamaría, J.; Fierro, J.L.G. Biodiesel from sunflower oil by using activated calcium oxide. Appl. Catal. B Environ. 2007. [Google Scholar] [CrossRef]

- Ji, J.; Wang, J.; Li, Y.; Yu, Y.; Xu, Z. Preparation of biodiesel with the help of ultrasonic and hydrodynamic cavitation. Ultrasonics 2006. [Google Scholar] [CrossRef]

- Karmee, S.K.; Chadha, A. Preparation of biodiesel from crude oil of Pongamia pinnata. Bioresour. Technol. 2005. [Google Scholar] [CrossRef]

- Lee, J.S.; Saka, S. Biodiesel production by heterogeneous catalysts and supercritical technologies. Bioresour. Technol. 2010, 101, 7191–7200. [Google Scholar] [CrossRef]

- Dossin, T.F.; Reyniers, M.F.; Berger, R.J.; Marin, G.B. Simulation of heterogeneously MgO-catalyzed transesterification for fine-chemical and biodiesel industrial production. Appl. Catal. B Environ. 2006. [Google Scholar] [CrossRef]

- Mbaraka, I.K.; Shanks, B.H. Conversion of oils and fats using advanced mesoporous heterogeneous catalysts. JAOCS J. Am. Oil Chem. Soc. 2006, 83, 79–91. [Google Scholar] [CrossRef]

- Colombo, K.; Ender, L.; Barros, A.A.C. The study of biodiesel production using CaO as a heterogeneous catalytic reaction. Egypt. J. Pet. 2017, 26, 341–349. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Yang, J. Transesterification of soybean oil with nano-MgO or not in supercritical and subcritical methanol. Fuel 2007. [Google Scholar] [CrossRef]

- Endalew, A.K.; Kiros, Y.; Zanzi, R. Heterogeneous catalysis for biodiesel production from Jatropha curcas oil (JCO). Energy 2011, 36, 2693–2700. [Google Scholar] [CrossRef]

- Kansedo, J.; Lee, K.T.; Bhatia, S. Cerbera odollam (sea mango) oil as a promising non-edible feedstock for biodiesel production. Fuel 2009. [Google Scholar] [CrossRef]

- Viriya-Empikul, N.; Krasae, P.; Nualpaeng, W.; Yoosuk, B.; Faungnawakij, K. Biodiesel production over Ca-based solid catalysts derived from industrial wastes. Fuel 2012. [Google Scholar] [CrossRef]

- Razzak, S.A.; Hossain, M.M.; Lucky, R.A.; Bassi, A.S.; De Lasa, H. Integrated CO2 capture, wastewater treatment and biofuel production by microalgae culturing—A review. Renew. Sustain. Energy Rev. 2013, 27, 622–653. [Google Scholar] [CrossRef]

- Zhang, X.; Rong, J.; Chen, H.; He, C.; Wang, Q. Current status and outlook in the application of microalgae in biodiesel production and environmental protection. Front. Energy Res. 2014, 2, 32. [Google Scholar] [CrossRef] [Green Version]

- Mata, T.M.; Martins, A.A.; Caetano, N.S. Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 2010, 14, 217–232. [Google Scholar] [CrossRef] [Green Version]

- Rittmann, B.E. Opportunities for renewable bioenergy using microorganisms. Biotechnol. Bioeng. 2008, 100, 203–212. [Google Scholar] [CrossRef]

- Meher, L.C.; Vidya Sagar, D.; Naik, S.N. Technical aspects of biodiesel production by transesterification—A review. Renew. Sustain. Energy Rev. 2006, 10, 248–268. [Google Scholar] [CrossRef]

- Schenk, P.M.; Thomas-Hall, S.R.; Stephens, E.; Marx, U.C.; Mussgnug, J.H.; Posten, C.; Kruse, O.; Hankamer, B. Second generation biofuels: High-efficiency microalgae for biodiesel production. BioEnergy Res. 2008. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Demirbas, M.F. Biofuels from algae for sustainable development. Appl. Energy 2011. [Google Scholar] [CrossRef]

- Hidalgo, P.; Toro, C.; Ciudad, G.; Schober, S.; Mittelbach, M.; Navia, R. Evaluation of different operational strategies for biodiesel production by direct transesterification of microalgal biomass. Energy Fuels 2014, 28, 3814–3820. [Google Scholar] [CrossRef]

- Williams, P.J.L.B.; Laurens, L.M.L. Microalgae as biodiesel & biomass feedstocks: Review & analysis of the biochemistry, energetics & economics. Energy Environ. Sci. 2010, 3, 554–590. [Google Scholar]

- Kim, J.; Yoo, G.; Lee, H.; Lim, J.; Kim, K.; Kim, C.W.; Park, M.S.; Yang, J.W. Methods of downstream processing for the production of biodiesel from microalgae. Biotechnol. Adv. 2013, 31, 862–876. [Google Scholar] [CrossRef]

- Galadima, A.; Muraza, O. Biodiesel production from algae by using heterogeneous catalysts: A critical review. Energy 2014, 78, 72–83. [Google Scholar] [CrossRef]

- Babu, B.V. Biomass pyrolysis: A state-of-the-art review. Biofuels Bioprod. Biorefin. 2008, 2, 393–414. [Google Scholar] [CrossRef]

- Bahadur, N.P.; Boocock, D.G.B.; Konar, S.K. Liquid hydrocarbons from catalytic pyrolysis of sewage sludge lipid and canola oil: Evaluation of fuel properties. Energy Fuels 1995. [Google Scholar] [CrossRef]

- Boateng, A.A.; Mullen, C.A.; Goldberg, N.; Hicks, K.B.; Jung, H.J.G.; Lamb, J.F.S. Production of bio-oil from alfalfa stems by fluidized-bed fast pyrolysis. Ind. Eng. Chem. Res. 2008. [Google Scholar] [CrossRef]

- Nautiyal, P.; Subramanian, K.A.; Dastidar, M.G. Production and characterization of biodiesel from algae. Fuel Process. Technol. 2014. [Google Scholar] [CrossRef]

- Ma, F.; Hanna, M.A. Biodiesel production: A review. Bioresour. Technol. 1999, 70, 1–15. [Google Scholar] [CrossRef]

- Haas, M. The interplay between feedstock quality and esterification technology in biodiesel production. Lipid Technol. 2004, 16, 7–11. [Google Scholar]

- Diasakou, M.; Louloudi, A.; Papayannakos, N. Kinetics of the non-catalytic transesterification of soybean oil. Fuel 1998. [Google Scholar] [CrossRef]

- Kusdiana, D.; Saka, S. Kinetics of transesterification in rapeseed oil to biodiesel fuel as treated in supercritical methanol. Fuel 2001. [Google Scholar] [CrossRef]

- Borges, M.E.; Díaz, L. Recent developments on heterogeneous catalysts for biodiesel production by oil esterification and transesterification reactions: A review. Renew. Sustain. Energy Rev. 2012, 16, 2839–2849. [Google Scholar] [CrossRef]

- Guldhe, A.; Moura, C.V.R.; Singh, P.; Rawat, I.; Moura, E.M.; Sharma, Y.; Bux, F. Conversion of microalgal lipids to biodiesel using chromium-aluminum mixed oxide as a heterogeneous solid acid catalyst. Renew. Energy 2017. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Wu, X.; Leung, M.K.H. A review on biodiesel production using catalyzed transesterification. Appl. Energy 2010, 87, 1083–1095. [Google Scholar] [CrossRef]

- Ono, Y.; Baba, T. Selective reactions over solid base catalysts. Catal. Today 1997, 38, 321–337. [Google Scholar] [CrossRef]

- Yoo, S.J.; Lee, H.S.; Veriansyah, B.; Kim, J.; Kim, J.D.; Lee, Y.W. Synthesis of biodiesel from rapeseed oil using supercritical methanol with metal oxide catalysts. Bioresour. Technol. 2010. [Google Scholar] [CrossRef] [PubMed]

- Chouhan, A.P.S.; Sarma, A.K. Modern heterogeneous catalysts for biodiesel production: A comprehensive review. Renew. Sustain. Energy Rev. 2011, 15, 4378–4399. [Google Scholar] [CrossRef]

- López, D.E.; Goodwin, J.G.; Bruce, D.A.; Lotero, E. Transesterification of triacetin with methanol on solid acid and base catalysts. Appl. Catal. A Gen. 2005. [Google Scholar] [CrossRef]

- Di Serio, M.; Tesser, R.; Dimiccoli, M.; Cammarota, F.; Nastasi, M.; Santacesaria, E. Synthesis of biodiesel via homogeneous Lewis acid catalyst. J. Mol. Catal. A Chem. 2005. [Google Scholar] [CrossRef]

- Liu, X.; He, H.; Wang, Y.; Zhu, S.; Piao, X. Transesterification of soybean oil to biodiesel using CaO as a solid base catalyst. Fuel 2008. [Google Scholar] [CrossRef]

- Kouzu, M.; Hidaka, J.S. Transesterification of vegetable oil into biodiesel catalyzed by CaO: A review. Fuel 2012, 93, 1–12. [Google Scholar] [CrossRef]

- Veljković, V.B.; Stamenković, O.S.; Todorović, Z.B.; Lazić, M.L.; Skala, D.U. Kinetics of sunflower oil methanolysis catalyzed by calcium oxide. Fuel 2009. [Google Scholar] [CrossRef]

- Viola, E.; Blasi, A.; Valerio, V.; Guidi, I.; Zimbardi, F.; Braccio, G.; Giordano, G. Biodiesel from fried vegetable oils via transesterification by heterogeneous catalysis. Catal. Today 2012, 179, 185–190. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, Z.; Chen, Y.; Zhang, P.; Duan, S.; Liu, X.; Mao, Z. Preparation of biodiesel catalyzed by solid super base of calcium oxide and its refining process. Chin. J. Catal. 2006. [Google Scholar] [CrossRef]

- Kawashima, A.; Matsubara, K.; Honda, K. Acceleration of catalytic activity of calcium oxide for biodiesel production. Bioresour. Technol. 2009. [Google Scholar] [CrossRef] [PubMed]

- Puna, J.F.; Gomes, J.F.; Correia, M.J.N.; Soares Dias, A.P.; Bordado, J.C. Advances on the development of novel heterogeneous catalysts for transesterification of triglycerides in biodiesel. Fuel 2010. [Google Scholar] [CrossRef]

- Liu, X.; He, H.; Wang, Y.; Zhu, S. Transesterification of soybean oil to biodiesel using SrO as a solid base catalyst. Catal. Commun. 2007. [Google Scholar] [CrossRef]

- Umdu, E.S.; Tuncer, M.; Seker, E. Transesterification of Nannochloropsis oculata microalga’s lipid to biodiesel on Al2O3 supported CaO and MgO catalysts. Bioresour. Technol. 2009, 100, 2828–2831. [Google Scholar] [CrossRef] [Green Version]

- Zabeti, M.; Daud, W.M.A.W.; Aroua, M.K. Biodiesel production using alumina-supported calcium oxide: An optimization study. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Wen, Z.; Yu, X.; Tu, S.T.; Yan, J.; Dahlquist, E. Biodiesel production from waste cooking oil catalyzed by TiO2-MgO mixed oxides. Bioresour. Technol. 2010. [Google Scholar] [CrossRef]

- Li, Y.; Lian, S.; Tong, D.; Song, R.; Yang, W.; Fan, Y.; Qing, R.; Hu, C. One-step production of biodiesel from Nannochloropsis sp. on solid base Mg-Zr catalyst. Appl. Energy 2011. [Google Scholar] [CrossRef]

- Lee, A.F.; Bennett, J.A.; Manayil, J.C.; Wilson, K. Heterogeneous catalysis for sustainable biodiesel production via esterification and transesterification. Chem. Soc. Rev. 2014, 43, 7887–7916. [Google Scholar] [CrossRef] [Green Version]

- Deka, D.C.; Basumatary, S. High quality biodiesel from yellow oleander (Thevetia peruviana) seed oil. Biomass Bioenergy 2011. [Google Scholar] [CrossRef]

- Cho, Y.B.; Seo, G. High activity of acid-treated quail eggshell catalysts in the transesterification of palm oil with methanol. Bioresour. Technol. 2010. [Google Scholar] [CrossRef]

- Verziu, M.; Coman, S.M.; Richards, R.; Parvulescu, V.I. Transesterification of vegetable oils over CaO catalysts. Catal. Today 2011, 167, 64–70. [Google Scholar] [CrossRef]

- Encinar, J.M.; González, J.F.; Pardal, A.; Martínez, G. Rape oil transesterification over heterogeneous catalysts. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Liu, C.; Lv, P.; Yuan, Z.; Yan, F.; Luo, W. The nanometer magnetic solid base catalyst for production of biodiesel. Renew. Energy 2010. [Google Scholar] [CrossRef]

- Wen, Z.; Yu, X.; Tu, S.T.; Yan, J.; Dahlquist, E. Synthesis of biodiesel from vegetable oil with methanol catalyzed by Li-doped magnesium oxide catalysts. Appl. Energy 2010. [Google Scholar] [CrossRef]

- Mutreja, V.; Singh, S.; Ali, A. Biodiesel from mutton fat using KOH impregnated MgO as heterogeneous catalysts. Renew. Energy 2011. [Google Scholar] [CrossRef]

- Ngamcharussrivichai, C.; Nunthasanti, P.; Tanachai, S.; Bunyakiat, K. Biodiesel production through transesterification over natural calciums. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Ilgen, O. Dolomite as a heterogeneous catalyst for transesterification of canola oil. Fuel Process. Technol. 2011. [Google Scholar] [CrossRef]

- Taufiq-Yap, Y.H.; Lee, H.V.; Hussein, M.Z.; Yunus, R. Calcium-based mixed oxide catalysts for methanolysis of Jatropha curcas oil to biodiesel. Biomass Bioenergy 2011. [Google Scholar] [CrossRef]

- Gao, L.; Teng, G.; Xiao, G.; Wei, R. Biodiesel from palm oil via loading KF/Ca-Al hydrotalcite catalyst. Biomass Bioenergy 2010, 34, 1283–1288. [Google Scholar] [CrossRef]

- Silva, C.C.C.M.; Ribeiro, N.F.P.; Souza, M.M.V.M.; Aranda, D.A.G. Biodiesel production from soybean oil and methanol using hydrotalcites as catalyst. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Deng, X.; Fang, Z.; Liu, Y.H.; Yu, C.L. Production of biodiesel from Jatropha oil catalyzed by nanosized solid basic catalyst. Energy 2011. [Google Scholar] [CrossRef]

- Samart, C.; Chaiya, C.; Reubroycharoen, P. Biodiesel production by methanolysis of soybean oil using calcium supported on mesoporous silica catalyst. Energy Convers. Manag. 2010. [Google Scholar] [CrossRef]

- Guo, F.; Peng, Z.G.; Dai, J.Y.; Xiu, Z.L. Calcined sodium silicate as solid base catalyst for biodiesel production. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Boro, J.; Thakur, A.J.; Deka, D. Solid oxide derived from waste shells of Turbonilla striatula as a renewable catalyst for biodiesel production. Fuel Process. Technol. 2011. [Google Scholar] [CrossRef]

- Wei, Z.; Xu, C.; Li, B. Application of waste eggshell as low-cost solid catalyst for biodiesel production. Bioresour. Technol. 2009. [Google Scholar] [CrossRef]

- Lotero, E.; Liu, Y.; Lopez, D.E.; Suwannakarn, K.; Bruce, D.A.; Goodwin, J.G. Synthesis of biodiesel via acid catalysis. Ind. Eng. Chem. Res. 2005. [Google Scholar] [CrossRef]

- Meher, L.C.; Churamani, C.P.; Arif, M.; Ahmed, Z.; Naik, S.N. Jatropha curcas as a renewable source for bio-fuels—A review. Renew. Sustain. Energy Rev. 2013, 26, 397–407. [Google Scholar] [CrossRef]

- Furuta, S.; Matsuhashi, H.; Arata, K. Biodiesel fuel production with solid superacid catalysis in fixed bed reactor under atmospheric pressure. Catal. Commun. 2004. [Google Scholar] [CrossRef]

- Helwani, Z.; Othman, M.R.; Aziz, N.; Kim, J.; Fernando, W.J.N. Solid heterogeneous catalysts for transesterification of triglycerides with methanol: A review. Appl. Catal. A Gen. 2009, 363, 1–10. [Google Scholar] [CrossRef]

- Muthu, H.; Selvabala, V.S.; Varathachary, T.K.; Selvaraj, D.K.; Nandagopal, J.; Subramanian, S. Synthesis of biodiesel from neem oil using sulfated zirconia via tranesterification. Braz. J. Chem. Eng. 2010. [Google Scholar] [CrossRef] [Green Version]

- Shu, Q.; Gao, J.; Nawaz, Z.; Liao, Y.; Wang, D.; Wang, J. Synthesis of biodiesel from waste vegetable oil with large amounts of free fatty acids using a carbon-based solid acid catalyst. Appl. Energy 2010, 87, 2589–2596. [Google Scholar] [CrossRef]

- Brucato, A.; Busciglio, A.; Di Stefano, F.; Grisafi, F.; Micale, G.; Scargiali, F. High temperature solid-catalized transesterification for biodiesel production. Chem. Eng. Trans. 2010, 19, 31–36. [Google Scholar]

- Yan, S.; Dimaggio, C.; Mohan, S.; Kim, M.; Salley, S.O.; Ng, K.Y.S. Advancements in heterogeneous catalysis for biodiesel synthesis. Top. Catal. 2010. [Google Scholar] [CrossRef]

- Kiss, A.A.; Dimian, A.C.; Rothenberg, G. Solid acid catalysts for biodiesel production—Towards sustainable energy. Adv. Synth. Catal. 2006. [Google Scholar] [CrossRef]

- Park, Y.M.; Lee, D.W.; Kim, D.K.; Lee, J.S.; Lee, K.Y. The heterogeneous catalyst system for the continuous conversion of free fatty acids in used vegetable oils for the production of biodiesel. Catal. Today 2008. [Google Scholar] [CrossRef]

- Peng, B.X.; Shu, Q.; Wang, J.F.; Wang, G.R.; Wang, D.Z.; Han, M.H. Biodiesel production from waste oil feedstocks by solid acid catalysis. Process Saf. Environ. Prot. 2008. [Google Scholar] [CrossRef]

- Kafuku, G.; Lee, K.T.; Mbarawa, M. The use of sulfated tin oxide as solid superacid catalyst for heterogeneous transesterification of Jatropha curcas oil. Chem. Pap. 2010. [Google Scholar] [CrossRef]

- Kafuku, G.; Lam, M.K.; Kansedo, J.; Lee, K.T.; Mbarawa, M. Heterogeneous catalyzed biodiesel production from Moringa oleifera oil. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Kafuku, G.; Lam, M.K.; Kansedo, J.; Lee, K.T.; Mbarawa, M. Croton megalocarpus oil: A feasible non-edible oil source for biodiesel production. Bioresour. Technol. 2010. [Google Scholar] [CrossRef]

- Yee, K.F.; Lee, K.T.; Ceccato, R.; Abdullah, A.Z. Riccardo Ceccato Production of biodiesel from Jatropha curcas L. oil catalyzed by SO42-/ZrO2 catalyst: Effect of interaction between process variables. Bioresour. Technol. 2011, 102, 4285–4289. [Google Scholar] [CrossRef]

- Zanette, A.F.; Barella, R.A.; Pergher, S.B.C.; Treichel, H.; Oliveira, D.; Mazutti, M.A.; Silva, E.A.; Oliveira, J.V. Screening, optimization and kinetics of Jatropha curcas oil transesterification with heterogeneous catalysts. Renew. Energy 2011. [Google Scholar] [CrossRef]

- Semwal, S.; Arora, A.K.; Badoni, R.P.; Tuli, D.K. Biodiesel production using heterogeneous catalysts. Bioresour. Technol. 2011, 102, 2151–2161. [Google Scholar] [CrossRef] [PubMed]

- Rabiah Nizah, M.F.; Taufiq-Yap, Y.H.; Rashid, U.; Teo, S.H.; Shajaratun Nur, Z.A.; Islam, A. Production of biodiesel from non-edible Jatropha curcas oil via transesterification using Bi2O3-La2O3 catalyst. Energy Convers. Manag. 2014. [Google Scholar] [CrossRef]

- Lin, V.S.-Y.; Nieweg, J.A.; Kern, C.; Trewyn, B.G.; Wiench, J.W.; Pruski, M. Acid-base mesoporous calcia-silica catalysts for cooperative conversion of bio-based feedstocks into biodiesel. Prepr. Symp. Am. Chem. Soc. Div. Fuel Chem. 2006, 51, 426–427. [Google Scholar]

- Wan Omar, W.N.N.; Amin, N.A.S. Biodiesel production from waste cooking oil over alkaline modified zirconia catalyst. Fuel Process. Technol. 2011. [Google Scholar] [CrossRef]

- Lin, V.S.Y.; Nieweg, J.A.; Verkade, J.G.; Venkat, R.; Reddy, C.; Kern, C. New Composite Based Catalysts for Biodiesel Production. Patent WO 2008/013551 A1, 31 January 2008. [Google Scholar]

- Lee, H.V.; Juan, J.C.; Taufiq-Yap, Y.H. Preparation and application of binary acid-base CaO-La2O3 catalyst for biodiesel production. Renew. Energy 2015. [Google Scholar] [CrossRef]

- Salinas, D.; Guerrero, S.; Araya, P. Transesterification of canola oil on potassium-supported TiO2 catalysts. Catal. Commun. 2010. [Google Scholar] [CrossRef]

- Jiménez-López, A.; Jiménez-Morales, I.; Santamaría-González, J.; Maireles-Torres, P. Biodiesel production from sunflower oil by tungsten oxide supported on zirconium doped MCM-41 silica. J. Mol. Catal. A Chem. 2011. [Google Scholar] [CrossRef]

- Cannilla, C.; Bonura, G.; Rombi, E.; Arena, F.; Frusteri, F. Highly effective MnCeOx catalysts for biodiesel production by transesterification of vegetable oils with methanol. Appl. Catal. A Gen. 2010. [Google Scholar] [CrossRef]

- Gonçalves, A.P.V.; Lopes, J.M.; Lemos, F.; Ramôa Ribeiro, F.; Prazeres, D.M.F.; Cabrai, J.M.S.; Aires-Barros, M.R. Zeolites as supports for enzymatic hydrolysis reactions. Comparative study of several zeolites. J. Mol. Catal. B Enzym. 1996. [Google Scholar] [CrossRef]

- Huge-Jensen, B.; Galluzzo, D.R.; Jensen, R.G. Studies on free and immobilized lipases from Mucor miehei. J. Am. Oil Chem. Soc. 1988. [Google Scholar] [CrossRef]

- Oliveira, A.C.; Rosa, M.F.; Cabral, J.M.S.; Aires-Barros, M.R. Immobilization of saccharomyces cerevisiae cells and rhizomocur miehei lipase for the production and extractive biocatalysis of ethanol. Bioprocess Eng. 1997. [Google Scholar] [CrossRef]

- Fukuda, H.; Hama, S.; Tamalampudi, S.; Noda, H. Whole-cell biocatalysts for biodiesel fuel production. Trends Biotechnol. 2008, 26, 668–673. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, P.M.; Brask, J.; Fjerbaek, L. Enzymatic biodiesel production: Technical and economical considerations. Eur. J. Lipid Sci. Technol. 2008, 110, 692–700. [Google Scholar] [CrossRef]

- Sarno, M.; Iuliano, M. Active biocatalyst for biodiesel production from spent coffee ground. Bioresour. Technol. 2018. [Google Scholar] [CrossRef]

- Saranya, G.; Ramachandra, T.V. Novel biocatalyst for optimal biodiesel production from diatoms. Renew. Energy 2020. [Google Scholar] [CrossRef]

- Chen, G.; Liu, J.; Yao, J.; Qi, Y.; Yan, B. Biodiesel production from waste cooking oil in a magnetically fluidized bed reactor using whole-cell biocatalysts. Energy Convers. Manag. 2017. [Google Scholar] [CrossRef]

- Zhong, L.; Feng, Y.; Wang, G.; Wang, Z.; Bilal, M.; Lv, H.; Jia, S.; Cui, J. Production and use of immobilized lipases in/on nanomaterials: A review from the waste to biodiesel production. Int. J. Biol. Macromol. 2020, 152, 207–222. [Google Scholar] [CrossRef]

- Akubude, V.C.; Nwaigwe, K.N.; Dintwa, E. Production of biodiesel from microalgae via nanocatalyzed transesterification process: A review. Mater. Sci. Energy Technol. 2019. [Google Scholar] [CrossRef]

- Liu, D.M.; Dong, C. Recent advances in nano-carrier immobilized enzymes and their applications. Process Biochem. 2020, 92, 464–475. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, O.K.; Lee, E.Y. Nano-immobilized biocatalysts for biodiesel production from renewable and sustainable resources. Catalysts 2018, 8, 68. [Google Scholar]

- Miao, C.; Yang, L.; Wang, Z.; Luo, W.; Li, H.; Lv, P.; Yuan, Z. Lipase immobilization on amino-silane modified superparamagnetic Fe3O4 nanoparticles as biocatalyst for biodiesel production. Fuel 2018. [Google Scholar] [CrossRef]

- Nematian, T.; Salehi, Z.; Shakeri, A. Conversion of bio-oil extracted from Chlorella vulgaris micro algae to biodiesel via modified superparamagnetic nano-biocatalyst. Renew. Energy 2020. [Google Scholar] [CrossRef]

- Narayanan, C.M.; Pandey, A. Studies on biodiesel synthesis using nanosilica immobilised lipase in inverse fluidized bed bioreactors. J. Adv. Chem. 2018. [Google Scholar] [CrossRef]

- Banerjee, S.; Rout, S.; Banerjee, S.; Atta, A.; Das, D. Fe2O3 nanocatalyst aided transesterification for biodiesel production from lipid-intact wet microalgal biomass: A biorefinery approach. Energy Convers. Manag. 2019. [Google Scholar] [CrossRef]

- Antunes, W.M.; de Oliveira Veloso, C.; Henriques, C.A. Transesterification of soybean oil with methanol catalyzed by basic solids. Catal. Today 2008. [Google Scholar] [CrossRef]

- Sreeprasanth, P.S.; Srivastava, R.; Srinivas, D.; Ratnasamy, P. Hydrophobic, solid acid catalysts for production of biofuels and lubricants. Appl. Catal. A Gen. 2006. [Google Scholar] [CrossRef]

- Yang, Z.; Xie, W. Soybean oil transesterification over zinc oxide modified with alkali earth metals. Fuel Process. Technol. 2007. [Google Scholar] [CrossRef]

- Xu, L.; Yang, X.; Yu, X.; Guo, Y. Maynurkader preparation of mesoporous polyoxometalate-tantalum pentoxide composite catalyst for efficient esterification of fatty acid. Catal. Commun. 2008. [Google Scholar] [CrossRef]

- Petchmala, A.; Laosiripojana, N.; Jongsomjit, B.; Goto, M.; Panpranot, J.; Mekasuwandumrong, O.; Shotipruk, A. Transesterification of palm oil and esterification of palm fatty acid in near- and super-critical methanol with SO4-ZrO2 catalysts. Fuel 2010. [Google Scholar] [CrossRef]

- McNeff, C.V.; McNeff, L.C.; Yan, B.; Nowlan, D.T.; Rasmussen, M.; Gyberg, A.E.; Krohn, B.J.; Fedie, R.L.; Hoye, T.R. A continuous catalytic system for biodiesel production. Appl. Catal. A Gen. 2008. [Google Scholar] [CrossRef]

- Sani, Y.M.; Daud, W.M.A.W.; Abdul Aziz, A.R. Solid acid-catalyzed biodiesel production from microalgal oil—The dual advantage. J. Environ. Chem. Eng. 2013, 1, 113–121. [Google Scholar] [CrossRef]

- Dong, T.; Wang, J.; Miao, C.; Zheng, Y.; Chen, S. Two-step in situ biodiesel production from microalgae with high free fatty acid content. Bioresour. Technol. 2013. [Google Scholar] [CrossRef] [PubMed]

| Catalyst | Feedstock | Optimum Reaction Conditions | Biodiesel Yield | Reference | |||

|---|---|---|---|---|---|---|---|

| Temp. | Time | Methanol/Oil | Catalyst Amount | ||||

| CaO from eggshells | Palm oil | 65 °C | 2 h | 12:1 | 1.5 wt% | 98% | [81] |

| CaO | Sunflower oil | 80 °C | 5.5 h | 6:1 | 1 wt% | 91% | [82] |

| KNO3 /CaO | Rapeseed oil | 65 °C | 3 h | 6:1 | 1 wt% | 98% | [83] |

| CaO/Al2O3 | Palm oil | 64.29 °C | 5 h | 12.14:1 | 5.97 wt% | 98.64% | [76] |

| CaO/Fe3O4 | Jatropha curcas oil | 70 °C | 1.3 h | 15:1 | 2 wt% | 95% | [84] |

| Li/MgO | Soybean oil | 60 °C | 2 h | 12:1 | 9 wt% | 93.9% | [85] |

| KOH/MgO | Mutton fat | 65 °C | 0.3 h | 22:1 | 4 wt% | 98% | [86] |

| Dolomite | Palm kernel oil | 60 °C | 3 h | 30:1 | 6 wt% | 98% | [87] |

| Dolomite | Canola oil | 67.5 °C | 3 h | 6:1 | 3 wt% | 91.78% | [88] |

| CaMgO and CaZnO | Jatropha curcas oil | 65 °C | 6 h | 15:1 | 4 wt% | 80% | [89] |

| KF/Ca-Al hydrotalcite | Palm oil | 65 °C | 5 h | 12:1 | 5 wt% | 97.98% | [90] |

| Mg-Al hydrotalcite | Soybean oil | 230 °C | 1 h | 13:5 | 5 wt% | 90% | [91] |

| Mg-Al hydrotalcite | Jatropha oil | 45 °C | 1.5 h | 4:1 | 1 wt% | 95.2% | [92] |

| CaO/mesoporous silica | Soybean oil | 60 °C | 8 h | 16:1 | 5 wt% | 95.2% | [93] |

| Sodium silicate | Soybean oil | 60 °C | 1 h | 7.5:1 | 3 wt% | ≈100% | [94] |

| Catalyst | Feedstock | Optimum Reaction Conditions | Biodiesel Yield | Reference | |||

|---|---|---|---|---|---|---|---|

| Temp | Time | Methanol/Oil | Catalyst Amount | ||||

| SO42−/TiO2-SiO2 | Acidified cottonseed oil | 200 °C | 6 h | 9:1 | 3 wt% | 92% | [107] |

| SO42−/ZrO | Cerberra odollam | 180 °C | 3 h | 8:1 | 6 wt% | 84% | [37] |

| SO42−/SnO2−-SiO2 | Jatropha curcas | 180 °C | 2 h | 15:1 | 3 wt% | 97% | [108] |

| SO42−/SnO2−-SiO2 | Moringa oleifera | 150 °C | 2.5 h | 5:1 | 3 wt% | 84% | [109] |

| SO42−/SnO2−-SiO2 | Croton megalocarpus | 180 °C | 2 h | 15:1 | 3 wt% | 95% | [110] |

| ZrO2-Al2O3 | Jatropha curcas | 150 °C | 4 h | 9:1 | 7.61 wt% | 90.32% | [111] |

| KSF clay Amberlyst | Jatropha curcas | 160 °C | 6 h | 12:1 | 5 wt% | 70% | [112] |

| Sulfated zirconia (SZ) | Neem oil | 65 °C | 2 h | 9:1 | 1 wt% | 95% | [101] |

| Carbon-based solid acid catalyst | Waste vegetable oil | 220 °C | 4.4 h | 16.8:1 | 0.2 wt% | 94.8% | [102] |

| Catalyst | Feedstock | FFA (wt%) | Optimum Reaction Conditions | Biodiesel Yield | Reference | |||

|---|---|---|---|---|---|---|---|---|

| Temp °C | Time h | Methanol/Oil | Catalyst Amount | |||||

| Bi2O3-La2O3 | Jatropha curcas | 14.5 | 150 | 4 | 15:1 | 2 wt% | 93% | [114] |

| CaO-La2O3 | Jatropha curcas | 14.5 | 160 | 3 | 25:1 | 3 wt% | 98.76% | [118] |

| K/TiO2 | Canola oil | - | 70 | 5 | 36:1 | 6 wt% | 100% | [119] |

| MgO/TiO2 | Waste cooking oil | 3.6 | 170 | 6 | 50:1 | 10 wt% | 91.6% | [85] |

| WO3/Zr MCM-41 | Sunflower oil | 9.1 | 115.5 | 2.5 | 12:1 | 10 wt% | 79.7% | [120] |

| Sr/ZrO2 | Waste cooking palm oil | 5.08 | 115.4 | 1.2 | 29:1 | 2.7 wt% | 79.7% | [116] |

| MnCeOx | Sunflower oil | 0.07 | 140 | 5 | 12:1 | 1 wt% | ≈86% | [121] |

| Feedstock | Catalyst | Optimum Reaction Conditions | Yield (wt%) | Reference |

|---|---|---|---|---|

| Sunflower oil | Fe–Zn double metal cyanide (DMC) | MeOH/Oil = 15:1, Cat. = 3 wt%, t = 8 h, T =170 °C | 92 | [63] |

| Sunflower oil | ZrO2 supported La2O3 catalyst | MeOH/Oil = 3:1, Cat. = 2 wt%, t = 5 h, T = 60 °C | 84.9 | [138] |

| Soybean oil | ZnO loaded with Sr(NO3)2 | MeOH/Oil = 12:1, Cat. = 5 wt%, t = 4 h, T = 65 °C | 94.7 | [139] |

| Soybean oil | S–ZrO2 | MeOH/Oil = 20:1, Cat. = 5 wt%, t = 1 h, T = 120 °C | 98.6 | [140] |

| Palm oil | CaO from eggshells | MeOH/Oil = 18:1, Cat. = 10 wt%, t = 2 h, T = 65 °C | 98 | [81] |

| Palm oil | CaO/Al2O3 | MeOH/Oil = 12:1, Cat. = 1.3 wt%, t = 5 h, T = 64.29 °C | 98.64 | [76] |

| Palm oil | KF/Ca–Al hydrotalcite | MeOH/Oil = 12:1, Cat. = 4 wt%, t = 5 h, T = 65 °C | 97.98 | [90] |

| Rapeseed oil | KNO3/CaO | MeOH/Oil = 6:1, Cat. = 1 wt%, t = 3 h, T = 65 °C | 98 | [83] |

| Waste cooking oil | MgO/TiO2 | MeOH/Oil = 50:1, Cat. = 10 wt%, t = 6 h, T = 170 °C | 91.6 | [77] |

| Jatropha oil | Mg–Al hydrotalcite | MeOH/Oil = 4:1, Cat. = 1 wt%, t = 1.5 h, T = 45 °C | 95.2 | [141] |

| Soybean oil | Sodium silicate | MeOH/Oil = 7.5:1, Cat. = 3 wt%, t = 1 h, T = 60 °C | 100 | [94] |

| Moringa oleifera oil | SO42−/SnO2-SiO2 | MeOH/Oil = 19.5:1, Cat. = 3 wt%, t = 2.5 h, T = 150 °C | 84 | [109] |

| Purified palm oil | SO4–ZrO2 | MeOH/Oil = 25:1, Cat. = 0.5 wt%, t = 10 min, T = 250 °C | 90 | [142] |

| Sunflower oil | SO42−/ZrO2/SiO2 | Ethanol/Oil = 12:1, Cat. = 4.6 wt%, t = 6 h, T = 200 °C | 91.5 | [120] |

| Cottonseed oil | Carbon based solid acid | MeOH/Oil = 16.8:1, Cat. = 0.2 wt%, t = 4.5 h, T = 220 °C | 94.8 | [102] |

| Croton megalocarpus oil | SO42−/SnO2-SiO2 | MeOH/Oil = 15:1, Cat. = 3 wt%, t = 2 h, T = 180 °C | 95 | [110] |

| Algae oil | Zirconia, titania | Not reported | 90.20 | [143] |

| Algae oil | 4% NiO, 18% MoO3/alumina | T = 370 °C | 99.00 | [144] |

| Algae oil | Amberlyst-15 | Not reported | 98 | [145] |

| Algae oil | Hierarchical H-Beta zeolites | Not reported | 99.5 | [144] |

| Algae oil | Microporous titania | Not reported | 94.7 | [144] |

| Microalgal’s lipid | Modified Alumina | Not reported | 97.5 | [75] |

| Freshwater microalgae oil | Modified titania | Not reported | 95 | [64] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faruque, M.O.; Razzak, S.A.; Hossain, M.M. Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review. Catalysts 2020, 10, 1025. https://doi.org/10.3390/catal10091025

Faruque MO, Razzak SA, Hossain MM. Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review. Catalysts. 2020; 10(9):1025. https://doi.org/10.3390/catal10091025

Chicago/Turabian StyleFaruque, Mohammed O., Shaikh A. Razzak, and Mohammad M. Hossain. 2020. "Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review" Catalysts 10, no. 9: 1025. https://doi.org/10.3390/catal10091025

APA StyleFaruque, M. O., Razzak, S. A., & Hossain, M. M. (2020). Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review. Catalysts, 10(9), 1025. https://doi.org/10.3390/catal10091025