Bio-Templating: An Emerging Synthetic Technique for Catalysts. A Review

Abstract

:1. Introduction

2. Applications

2.1. Adsorbents

2.2. Cancer Therapy

2.3. Bone Tissue Engineering

2.4. Light-Emitting Materials

2.5. Sensors

2.6. Energy Capture and Storage

2.7. Catalysis

- a)

- Sustainable production of hydrogen and biofuel

- b)

- Decontamination reactions

- c)

- Electrocatalysis

- d)

- Other reactions

2.8. Template Replication and Potential Application of the Material

2.9. Other Applications

3. Conclusions and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hashemizadeh, I.; Tsang, D.C.W.; Ng, Y.H.; Wu, Z.; Golovko, V.; Yip, A.C.K. Bio-mimicking TiO2 architectures for enhanced photocatalytic activity under UV and visible light †. RSC Adv. 2017, 7, 39098–39108. [Google Scholar] [CrossRef] [Green Version]

- Deshpande, A.S.; Burgert, I.; Paris, O. Natural templates. Small 2006, 2, 994–998. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.Y.; Chen, L.H.; Li, Y.; Rooke, J.C.; Sanchez, C.; Su, B.L. Hierarchically porous materials: Synthesis strategies and structure design. Chem. Soc. Rev. 2017, 46, 481–558. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Krajina, B.A.; Proctor, A.C.; Schoen, A.P.; Spakowitz, A.J.; Heilshorn, S.C. Biotemplated synthesis of inorganic materials: An emerging paradigm for nanomaterial synthesis inspired by nature. Prog. Mater. Sci. 2018, 91, 1–23. [Google Scholar] [CrossRef]

- Deuerling, S.; Kugler, S.; Klotz, M.; Zollfrank, C.; Van Opdenbosch, D. A perspective on bio-mediated material structuring. Adv. Mater. 2018, 30, 1703656. [Google Scholar] [CrossRef] [PubMed]

- Paris, O.; Fritz-Popovski, G.; Van Opdenbosch, D.; Zollfrank, C. Recent progress in the replication of hierarchical biological tissues. Adv. Funct. Mater. 2013, 23, 4408–4422. [Google Scholar] [CrossRef]

- Paris, O.; Burgert, I.; Fratzl, P. Biomimetics and biotemplating of natural materials. MRS Bull. 2010, 35, 219–225. [Google Scholar] [CrossRef]

- Freeman, A. Protein-mediated biotemplating on the nanoscale. Biomimetics 2017, 2, 14. [Google Scholar] [CrossRef] [Green Version]

- Hartje, L.F.; Snow, C.D. Protein crystal based materials for nanoscale applications in medicine and biotechnology. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnology 2019, 11, e1547. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, X.; Zhang, J.; Li, W. Nanomaterials and nanoclusters based on DNA modulation. Curr. Opin. Biotechnol. 2014, 28, 33–38. [Google Scholar] [CrossRef]

- He, Y.; Ye, T.; Ribbe, A.E.; Mao, C. DNA-Templated Fabrication of two-dimensional metallic nanostructures by thermal evaporation coating. J. Am. Ceram. Soc. 2011, 133, 1742–1744. [Google Scholar] [CrossRef]

- Lagziel-Simis, S.; Cohen-Hadar, N.; Moscovich-Dagan, H.; Wine, Y.; Freeman, A. Protein-mediated nanoscale biotemplating. Curr. Opin. Biotechnol. 2006, 17, 569–573. [Google Scholar] [CrossRef]

- Nguyen, P.Q.; Botyanszki, Z.; Tay, P.K.R.; Joshi, N.S. Programmable biofilm-based materials from engineered curli nanofibres. Nat. Commun. 2014, 5, 4945. [Google Scholar] [CrossRef] [Green Version]

- Park, J.H.; Yang, S.H.; Lee, J.; Ko, E.H.; Hong, D.; Choi, I.S. Nanocoating of single cells: From maintenance of cell viability to manipulation of cellular activities. Adv. Mater. 2014, 26, 2001–2010. [Google Scholar] [CrossRef]

- Xia, Y.; Fang, R.; Xiao, Z.; Huang, H.; Gan, Y.; Yan, R.; Lu, X.; Liang, C.; Zhang, J.; Tao, X.; et al. Confining sulfur in N-doped porous carbon microspheres derived from microalgaes for advanced lithium-sulfur batteries. ACS Appl. Mater. Interfaces 2017, 9, 23782–23791. [Google Scholar] [CrossRef]

- Adigun, O.O.; Novikova, G.; Retzlaff-Roberts, E.L.; Kim, B.S.; Miller, J.T.; Loesch-Fries, L.S.; Harris, M.T. Decoupling and elucidation of surface-driven processes during inorganic mineralization on virus templates. J. Colloid Interface Sci. 2016, 483, 165–176. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Belcher, A.M.; Loke, D.K. Simulating selective binding of a biological template to a nanoscale architecture: A core concept of a clamp-based binding-pocket-favored N-terminal-domain assembly. Nanoscale 2020, 12, 24214–24227. [Google Scholar] [CrossRef]

- Luo, M.; Gao, J.; Zhang, X.; Yang, J.; Hou, G.; Ouyang, D.; Jin, Z. Processing of porous TiN/C ceramics from biological templates. Mater. Lett. 2007, 61, 186–188. [Google Scholar] [CrossRef]

- Kang, Y.S.; Kim, D.Y.; Yoon, J.; Park, J.W.; Kim, G.; Ham, Y.; Park, I.; Koh, M.; Park, K. Shape control of hierarchical lithium cobalt oxide using biotemplates for connected nanoparticles. J. Power Sources 2019, 436, 226836. [Google Scholar] [CrossRef]

- Yan, Z.; He, J.; Guo, L.; Li, Y.; Duan, D.; Chen, Y.; Li, J.; Yuan, F.; Wang, J. Biotemplated mesoporous TiO2/SiO2 composite derived from aquatic plant leaves for efficient dye degradation. Catalysts 2017, 7, 82. [Google Scholar] [CrossRef] [Green Version]

- Hidalgo-Carrillo, J.; Martín-Gómez, J.; Herrera-Beurnio, M.C.; Estévez, R.C.; Urbano, F.J.; Marinas, A. Olive leaves as biotemplates for enhanced solar-light harvesting by a titania-based solid. Nanomaterials 2020, 10, 1057. [Google Scholar] [CrossRef]

- Green, D.W.; Lee, K.K.H.; Watson, J.A.; Kim, H.Y.; Yoon, K.S.; Kim, E.J.; Lee, J.M.; Watson, G.S.; Jung, H.S. High quality bioreplication of intricate nanostructures from a fragile gecko skin surface with bactericidal properties. Sci. Rep. 2017, 7, 41023. [Google Scholar] [CrossRef] [Green Version]

- He, Z.; Zhang, W.; Wang, W.; Tassin, M.; Gu, J.; Liu, Q.; Zhu, S.; Su, H.; Feng, C.; Zhang, D. Fabrication of Fe-wings used for micro imprinting with a natural butterfly wing structure by in situ carbothermic reduction. J. Mater. Chem. B 2013, 1, 1673–1677. [Google Scholar] [CrossRef]

- Rodríguez, R.E.; Agarwal, S.P.; An, S.; Kazyak, E.; Das, D.; Shang, W.; Skye, R.; Deng, T.; Dasgupta, N.P. Biotemplated morpho butterfly wings for tunable structurally colored photocatalysts. ACS Appl. Mater. Interfaces 2018, 10, 4614–4621. [Google Scholar] [CrossRef]

- Tong, X.; Zhou, D.; Qiu, M.; Zhou, Y.; Ai, Y.; Guo, X.; Zhang, J.; Cai, Y.; Kong, Q. Biomorphic NiO/Ni with a regular pore-array structure as a supercapacitor electrode material. Eur. J. Inorg. Chem. 2021, 2021, 562–566. [Google Scholar] [CrossRef]

- Van Opdenbosch, D.; Johannes, M.; Wu, X.; Fabritius, H.; Zollfrank, C. Fabrication of three-dimensional photonic crystals with tunable photonic properties by biotemplating. Photonics Nanostructures-Fundam. Appl. 2012, 10, 516–522. [Google Scholar] [CrossRef]

- Kamata, K.; Piao, Z.; IyodaTokyo, T. Biotemplating process for 3D structured materials. Int. Polym. Sci. Technol. 2014, 87, 140–145. [Google Scholar] [CrossRef]

- Zhou, H.; Fan, T.; Zhang, D. Biotemplated materials for sustainable energy and environment: Current status and challenges. ChemSusChem 2011, 4, 1344–1387. [Google Scholar] [CrossRef]

- Chao, J.T.; Biggs, M.J.P.; Pandit, A.S. Diatoms: A biotemplating approach to fabricating drug delivery reservoirs. Expert Opin. Drug Deliv. 2014, 11, 1687–1695. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zollfrank, C. Biotemplating: Polysaccharides in materials engineering. WIT Trans. Ecol. Environ. 2010, 138, 441–451. [Google Scholar] [CrossRef] [Green Version]

- Zollfrank, C.; Cromme, P.; Rauch, M.; Scheel, H.; Kostova, M.H.; Gutbrod, K.; Gruber, S.; van Opdenbosch, D. Biotemplating of inorganic functional materials from polysaccharides. Bioinspired Biomim. Nanobiomaterials 2012, 1, 13–25. [Google Scholar] [CrossRef]

- Boury, B.; Plumejeau, S. Metal oxides and polysaccharides: An efficient hybrid association for materials chemistry. Green Chem. 2015, 17, 72–88. [Google Scholar] [CrossRef]

- Behrens, S.S. Synthesis of inorganic nanomaterials mediated by protein assemblies. J. Mater. Chem. 2008, 18, 3788–3798. [Google Scholar] [CrossRef]

- Tao, K.; Levin, A.; Adler-Abramovich, L.; Gazit, E. Fmoc-modified amino acids and short peptides: Simple bio-inspired building blocks for the fabrication of functional materials. Chem. Soc. Rev. 2016, 45, 3935–3953. [Google Scholar] [CrossRef]

- Butt, H.; Yetisen, A.K.; Mistry, D.; Khan, S.A.; Hassan, M.U.; Yun, S.H. Morpho butterfly-inspired nanostructures. Adv. Opt. Mater. 2016, 4, 497–504. [Google Scholar] [CrossRef]

- Sotiropoulou, S.; Sierra-Sastre, Y.; Mark, S.S.; Batt, C.A. Biotemplated nanostructured materials. Chem. Mater. 2008, 20, 821–834. [Google Scholar] [CrossRef]

- Żelechowska, K. Methods of ZnO nanoparticles synthesis. BioTechnologia 2014, 95, 150–159. [Google Scholar] [CrossRef]

- Plumejeau, S.; Alauzun, J.G.; Boury, B. Hybrid metal oxide@biopolymer materials precursors of metal oxides and metal oxide-carbon composites. J. Ceram. Soc. Jpn. 2015, 123, 695–708. [Google Scholar] [CrossRef] [Green Version]

- Van Opdenbosch, D.; Fritz-Popovski, G.; Plank, J.; Zollfrank, C.; Paris, O. Passive and active mechanical properties of biotemplated ceramics revisited. Bioinspiration Biomim. 2016, 11, 065001. [Google Scholar] [CrossRef]

- Davis, S.A.; Dujardin, E.; Mann, S. Biomolecular inorganic materials chemistry. Curr. Opin. Solid State Mater. Sci. 2003, 7, 273–281. [Google Scholar] [CrossRef]

- Müller, C.; Ouyang, L.; Lund, A.; Moth-Poulsen, K.; Hamedi, M.M. From single molecules to thin film electronics, nanofibers, e-textiles and power cables: Bridging length scales with organic semiconductors. Adv. Mater. 2019, 31, 1807286. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; He, J.; Shang, W.; Deng, T.; Gu, J.; Su, H.; Liu, Q.; Zhang, W.; Zhang, D. Optical functional materials inspired by biology. Adv. Opt. Mater. 2016, 4, 195–224. [Google Scholar] [CrossRef]

- Jorgensen, M.R.; Bartl, M.H. Biotemplating routes to three-dimensional photonic crystals. J. Mater. Chem. 2011, 21, 10583–10591. [Google Scholar] [CrossRef]

- Tan, K.B.; Sun, D.; Huang, J.; Odoom-Wubah, T.; Li, Q. State of arts on the bio-synthesis of noble metal nanoparticles and their biological application. Chinese J. Chem. Eng. 2021, 30, 272–290. [Google Scholar] [CrossRef]

- Ghani, M. Nanocrystalline cellulose as a biotemplate for preparation of porous titania thin film as a sorbent for thin film microextraction of ketorolac, meloxicam, diclofenac and mefenamic acid. J. Chromatogr. B 2020, 1142, 122039. [Google Scholar] [CrossRef]

- Wang, W.; Chen, B.; Huang, Y. Eggshell membrane-based biotemplating of mixed hemimicelle/admicelle as a solid-phase extraction adsorbent for carcinogenic polycyclic aromatic hydrocarbons. J. Agric. Food Chem. 2014, 62, 8051–8059. [Google Scholar] [CrossRef]

- Zwir-Ferenc, A.; Biziuk, M. Solid phase extraction technique—Trends, opportunities and applications. Polish J. Environ. Stud. 2006, 15, 677–690. [Google Scholar]

- Sun, Q.; Chen, B. Biotemplated fabrication of 3D hierarchically Porous MgAl-LDH/CF composites with effective adsorption of organic dyes from wastewater. Ind. Eng. Chem. Res. 2020, 59, 16838–16850. [Google Scholar] [CrossRef]

- Inbaraj, B.S.; Sridhar, K.; Chen, B.-H. Removal of polycyclic aromatic hydrocarbons from water by magnetic activated carbon nanocomposite from green tea waste. J. Hazard. Mater. 2021, 415, 125701. [Google Scholar] [CrossRef]

- Suvindran, N.; Li, F.; Pan, Y.; Zhao, X. Characterization and bioreplication of tradescantia pallida inspired biomimetic superwettability for dual way patterned water harvesting. Adv. Mater. Interfaces 2018, 5, 1800723. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E. Graphene nanomesh promises extremely efficient in vivo photothermal therapy. Small 2013, 9, 3593–3601. [Google Scholar] [CrossRef]

- Jiang, W.; Mo, F.; Jin, X.; Chen, L.; Xu, L.; Guo, L.; Fu, F. Tumor-targeting photothermal heating-responsive nanoplatform based on reduced graphene oxide/mesoporous silica/hyaluronic acid nanocomposite for enhanced photodynamic therapy. Adv. Mater. Interfaces 2017, 4, 1700425. [Google Scholar] [CrossRef]

- Lima-Sousa, R.; de Melo-Diogo, D.; Alves, C.G.; Costa, E.C.; Ferreira, P.; Louro, R.O.; Correía, I.J. Hyaluronic acid functionalized green reduced graphene oxide for targeted cancer photothermal therapy. Carbohydr. Polym. 2018, 200, 93–99. [Google Scholar] [CrossRef]

- Abdolahad, M.; Janmaleki, M.; Mohajerzadeh, S.; Akhavan, O.; Abbasi, S. Polyphenols attached graphene nanosheets for high efficiency NIR mediated photodestruction of cancer cells. Mater. Sci. Eng. C 2013, 33, 1498–1505. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Aghayee, S.; Fereydooni, Y.; Talebi, A. The use of a glucose-reduced graphene oxide suspension for photothermal cancer therapy. J. Mater. Chem. 2012, 22, 13773–13781. [Google Scholar] [CrossRef]

- Xue, W.; Zhou, J.; Gao, D.; Gao, F.; Wang, Z.; Luo, L.; Li, Y.; Liu, Z. Preparation of adenovirus-templated gold nanoshells and a study of their photothermal therapy efficacy. New J. Chem. 2015, 39, 3608–3614. [Google Scholar] [CrossRef]

- Shukla, S.; Eber, F.J.; Nagarajan, A.S.; DiFranco, N.A.; Schmidt, N.; Wen, A.M.; Eiben, S.; Twyman, R.M.; Wege, C.; Steinmetz, N.F. The impact of aspect ratio on the biodistribution and tumor homing of rigid soft-matter nanorods. Adv. Healthc. Mater. 2015, 4, 874–882. [Google Scholar] [CrossRef] [Green Version]

- Akhavan, O.; Ghaderi, E.; Emamy, H. Nontoxic concentrations of PEGylated graphene nanoribbons for selective cancer cell imaging and photothermal therapy. J. Mater. Chem. 2012, 22, 20626–20633. [Google Scholar] [CrossRef]

- Omidi, S.; Pirhayati, M.; Kakanejadifard, A. Co-delivery of doxorubicin and urcumin by a pH-sensitive, injectable, and in situ hydrogel composed of chitosan, graphene, and cellulose nanowhisker. Carbohydr. Polym. 2020, 231, 115745. [Google Scholar] [CrossRef]

- Ayazi, H.; Akhavan, O.; Raoufi, M.; Varshochian, R.; Hosseini Motlagh, N.S.; Atyabi, F. Graphene aerogel nanoparticles for in-situ loading/pH sensitive releasing anticancer drugs. Colloids Surfaces B Biointerfaces 2020, 186, 110712. [Google Scholar] [CrossRef]

- Qian, J.; Yong, X.; Xu, W.; Jin, X. Preparation and characterization of bimodal porous poly(γ-benzyl-L- glutamate) scaffolds for bone tissue engineering. Mater. Sci. Eng. C 2013, 33, 4587–4593. [Google Scholar] [CrossRef]

- Qian, J.; Kang, Y.; Zhang, W.; Li, Z. Fabrication, chemical composition change and phase evolution of biomorphic hydroxyapatite. J. Mater. Sci. Mater. Med. 2008, 19, 3373–3383. [Google Scholar] [CrossRef]

- Qian, J.; Kang, Y.; Wei, Z.; Zhang, W. Fabrication and characterization of biomorphic 45S5 bioglass scaffold from sugarcane. Mater. Sci. Eng. C 2009, 29, 1361–1364. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, J.J.; Shin, U.S.; Kim, H.W. Production of a biomimetic apatite nanotube mesh via biotemplating a polymer nanofiber mesh. Mater. Lett. 2010, 64, 2655–2658. [Google Scholar] [CrossRef]

- Ramay, H.R.R.; Zhang, M. Biphasic calcium phosphate nanocomposite porous scaffolds for load-bearing bone tissue engineering. Biomaterials 2004, 25, 5171–5180. [Google Scholar] [CrossRef]

- Fabbri, P.; Bondioli, F.; Messori, M.; Bartoli, C.; Dinucci, D.; Chiellini, F. Porous scaffolds of polycaprolactone reinforced with in situ generated hydroxyapatite for bone tissue engineering. J. Mater. Sci. Mater. Med. 2010, 21, 343–351. [Google Scholar] [CrossRef]

- Qian, J.; Xu, M.; Suo, A.; Yang, T.; Yong, X. An innovative method to fabricate honeycomb-like poly(ε-caprolactone)/nano-hydroxyapatite scaffolds. Mater. Lett. 2013, 93, 72–76. [Google Scholar] [CrossRef]

- Qian, J.; Suo, A.; Jin, X.; Xu, W.; Xu, M. Preparation and in vitro characterization of biomorphic silk fibroin scaffolds for bone tissue engineering. J. Biomed. Mater. Res.-Part A 2014, 102, 2961–2971. [Google Scholar] [CrossRef] [PubMed]

- Popat, K.C.; Daniels, R.H.; Dubrow, R.S.; Hardev, V.; Desai, T.A. Nanostructured surfaces for bone biotemplating applications. J. Orthop. Res. 2006, 24, 619–627. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Shahsavar, M. Graphene nanogrids for selective and fast osteogenic differentiation of human mesenchymal stem cells. Carbon 2013, 59, 200–211. [Google Scholar] [CrossRef]

- Rahighi, R.; Panahi, M.; Akhavan, O.; Mansoorianfar, M. Pressure-engineered electrophoretic deposition for gentamicin loading within osteoblast-specific cellulose nanofiber scaffolds. Mater. Chem. Phys. 2021, 272, 125018. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Shirazian, S.A.; Rahighi, R. Rolled graphene oxide foams as three-dimensional scaffolds for growth of neural fibers using electrical stimulation of stem cells. Carbon 2016, 97, 71–77. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Abouei, E.; Hatamie, S.; Ghasemi, E. Accelerated differentiation of neural stem cells into neurons on ginseng-reduced graphene oxide sheets. Carbon 2014, 66, 395–406. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, W.C.; Manga, K.K.; Ang, P.K.; Lu, J.; Liu, Y.P.; Lim, C.T.; Loh, K.P. Fluorinated graphene for promoting neuro-induction of stem cells. Adv. Mater. 2012, 24, 4285–4290. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E. Differentiation of human neural stem cells into neural networks on graphene nanogrids. J. Mater. Chem. B 2013, 1, 6291–6301. [Google Scholar] [CrossRef]

- Alipour, A.; Gholami, A. Virus Decorated Nanobiomaterials as Scaffolds for Tissue Engineering. Adv. Appl. NanoBio-Technol. 2021, 2, 79–85. [Google Scholar]

- Zhang, Y.; Dong, Y.; Zhou, J.; Li, X.; Wang, F. Application of plant viruses as a biotemplate for nanomaterial fabrication. Molecules 2018, 23, 2311. [Google Scholar] [CrossRef] [Green Version]

- Young, M.; Willits, D.; Uchida, M.; Douglas, T. Plant viruses as biotemplates for materials and their use in nanotechnology. Annu. Rev. Phytopathol. 2008, 46, 361–384. [Google Scholar] [CrossRef]

- Yu, Y.; Zheng, X.T.; Yee, B.W.; Tan, Y.N. Biomimicking synthesis of photoluminescent molecular lantern catalyzed by in-situ formation of nanogold catalysts. Mater. Sci. Eng. C 2017, 77, 1111–1116. [Google Scholar] [CrossRef]

- Rambo, C.R.; Hotza, D.; da Cunha, C.R.; Zollfrank, C. Directed photoluminescent emission of ZnO tetrapods on biotemplated Al2O3. Opt. Mater. 2013, 36, 562–567. [Google Scholar] [CrossRef]

- Santos, S.C.; Yamagata, C.; Silva, A.C.; Setz, L.F.G.; Mello-Castanho, S.R.H. Yttrium disilicate micro-cellular architecture from biotemplating of luffa cylindrica. J. Ceram. Sci. Technol. 2014, 5, 203–208. [Google Scholar] [CrossRef]

- Santos, S.C.; Yamagata, C.; Campos, L.L.; Mello-Castanho, S.R.H. Processing and thermoluminescent response of porous biomorphic dysprosium doped yttrium disilicate burner. Mater. Chem. Phys. 2016, 177, 505–511. [Google Scholar] [CrossRef]

- Ivanova, A.; Frka-Petesic, B.; Paul, A.; Wagner, T.; Jumabekov, A.N.; Vilk, Y.; Weber, J.; Schmedt Auf Der Günne, J.; Vignolini, S.; Tiemann, M.; et al. Cellulose nanocrystal-templated tin dioxide thin films for gas sensing. ACS Appl. Mater. Interfaces 2020, 12, 12639–12647. [Google Scholar] [CrossRef]

- Zhu, Y.; Su, H.; Chen, Y.; Jin, Z.; Xu, J.; Zhang, D. A facile synthesis of PdO-decorated SnO2 nanocomposites with open porous hierarchical architectures for gas sensors. J. Am. Ceram. Soc. 2016, 99, 3770–3774. [Google Scholar] [CrossRef]

- Yu, S.; Li, L.; Wang, J.; Liu, E.; Zhao, J.; Xu, F.; Cao, Y.; Lu, C. Light-boosting highly sensitive pressure sensors based on bioinspired multiscale surface structures. Adv. Funct. Mater. 2020, 30, 1907091. [Google Scholar] [CrossRef]

- Shi, J.; Lv, S.; Wang, L.; Dai, Z.; Yang, S.; Zhao, L.; Tian, H.; Du, M.; Li, H.; Fang, Y. Crack Control in Biotemplated Gold Films for Wide-Range, Highly Sensitive Strain Sensing. Adv. Mater. Interfaces 2019, 6, 1901223. [Google Scholar] [CrossRef]

- Kostovski, G.; White, D.J.; Mitchell, A.; Austin, M.W.; Stoddart, P.R. Nanoimprinted optical fibres: Biotemplated nanostructures for SERS sensing. Biosens. Bioelectron. 2008, 24, 1531–1535. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Rahighi, R. Toward Single-DNA electrochemical biosensing by graphene nanowalls. ACS Nano 2012, 6, 2904–2916. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Hashemi, E.; Rahighi, R. Ultra sensitive detection of leukemia by graphene. Nanoscale 2014, 6, 14810–14819. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Rahighi, R.; Abdolahad, M. Spongy graphene electrode in electrochemical detection of leukemia at single-cell levels. Carbon 2014, 79, 654–663. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E. Copper oxide nanoflakes as highly sensitive and fast response self-sterilizing biosensors. J. Mater. Chem. 2011, 21, 12935–12940. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E. Escherichia coli bacteria reduce graphene oxide to bactericidal graphene in a self-limiting manner. Carbon 2011, 50, 1853–1860. [Google Scholar] [CrossRef]

- Xue, G.; Yu, W.; Yutong, L.; Qiang, Z.; Xiuying, L.; Yiwei, T.; Jianrong, L. Construction of novel xanthine biosensor by using Zinc Oxide (ZnO) by biotemplate method for fish freshness detection. Anal. Methods 2019, 11, 1021–1026. [Google Scholar] [CrossRef]

- Barannikova, E.A.; Riley, S.J.; Allen, M.A. Bioprospecting solid binding polypeptides for lithium ion battery cathode materials. Biointerphases 2019, 14, 051007–1–8. [Google Scholar] [CrossRef]

- Jeong, C.K.; Kim, I.; Park, K.I.; Oh, M.H.; Paik, H.; Hwang, G.T.; No, K.; Nam, Y.S.; Lee, K.J. Virus-directed design of a flexible BaTiO3 nanogenerator. ACS Nano 2013, 7, 11016–11025. [Google Scholar] [CrossRef]

- Gan, Y.; Xu, F.; Luo, J.; Yuan, H.; Jin, C.; Zhang, L.; Fang, C.; Sheng, O.; Huang, H.; Xia, Y.; et al. One-pot biotemplate synthesis of FeS2 decorated sulfur-doped carbon fiber as high capacity anode for lithium-ion batteries. Electrochim. Acta 2016, 209, 201–209. [Google Scholar] [CrossRef]

- Mirvaux, B.; Recham, N.; Miot, J.; Courty, M.; Bernard, S.; Beyssac, O.; Davoisne, C.; Sougrati, M.; Demortiere, A.; Guyot, F.; et al. Iron phosphate/bacteria composites as precursors for textured electrode materials with enhanced electrochemical properties. J. Electochemical Soc. 2016, 163, A2139–A2148. [Google Scholar] [CrossRef]

- Dylla, A.G.; Henkelman, G.; Stevenson, K.J. Lithium insertion in nanostructured TiO2 (B) architectures. Acc. Chem. Res. 2013, 46, 1104–1112. [Google Scholar] [CrossRef]

- Henry, A.; Plumejeau, S.; Heux, L.; Louvain, N.; Monconduit, L.; Stievano, L.; Boury, B. Conversion of nanocellulose aerogel into TiO2 and TiO2@C nano-thorns by direct anhydrous mineralization with TiCl4. Evaluation of electrochemical properties in li batteries. ACS Appl. Mater. Interfaces 2015, 7, 14584–14592. [Google Scholar] [CrossRef]

- Kim, S.W.; Han, T.H.; Kim, J.; Gwon, H.; Moon, H.S.; Kang, S.W.; Kim, S.O.; Kang, K. Fabrication and electrochemical characterization of TiO2 three- dimensional nanonetwork based on peptide assembly. ACS Nano 2009, 3, 1085–1090. [Google Scholar] [CrossRef]

- Li, B.; Zai, J.; Xiao, Y.; Han, Q.; Qian, X. SnO2/C composites fabricated by a biotemplating method from cotton and their electrochemical performances. CrystEngComm 2014, 16, 3318–3322. [Google Scholar] [CrossRef]

- Ping, H.; Poudel, L.; Xie, H.; Fang, W.; Zou, Z.; Zhai, P.; Wagermaier, W.; Fratzl, P.; Wang, W.; Wang, H.; et al. Synthesis of monodisperse rod-shaped silica particles through biotemplating of surface-functionalized bacteria. Nanoscale 2020, 12, 8732–8741. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, W.; Xiao, Z.; Huang, H.; Zeng, H.; Chen, X.; Chen, F.; Gan, Y.; Tao, X. Biotemplated fabrication of hierarchically porous NiO/C composite from lotus pollen grains for lithium-ion batteries. J. Mater. Chem. 2012, 22, 9209–9215. [Google Scholar] [CrossRef]

- Wang, J.; Liu, W.; Liu, S.; Chen, J.; Wang, H.; Zhao, S. Biomass derived fabrication of a novel sea cucumber-like LiMn2O4/C composite with a hierarchical porous structure as the cathode for lithium-ion batteries. Electrochim. Acta 2016, 188, 645–652. [Google Scholar] [CrossRef]

- Wang, J.; Liu, W.; Chen, J.; Wang, H.; Liu, S.; Chen, S. Biotemplated MnO/C microtubes from spirogyra with improved electrochemical performance for lithium-ion batterys. Electrochim. Acta 2016, 188, 210–217. [Google Scholar] [CrossRef]

- Xia, Y.; Xiao, Z.; Dou, X.; Huang, H.; Lu, X.; Yan, R.; Gan, Y.; Zhu, W.; Tu, J.; Zhang, W.; et al. Green and facile fabrication of hollow porous MnO/C microspheres from microalgaes for lithium-ion batteries. ACS Nano 2013, 7, 7083–7092. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, W.; Huang, H.; Gan, Y.; Xiao, Z.; Qian, L.; Tao, X. Biotemplating of phosphate hierarchical rechargeable LiFePO4/C spirulina microstructures. J. Mater. Chem. 2011, 21, 6498–6501. [Google Scholar] [CrossRef]

- Yan, D.; Luo, X.; Zhang, H.; Zhu, G.; Chen, L.; Chen, G.; Xu, H.; Yu, A. Single-crystalline a-MoO3 microbelts derived from a bio-templating method for superior lithium storage application. J. Alloys Compd. 2016, 688, 481–486. [Google Scholar] [CrossRef]

- Zhu, W.; Huang, H.; Zhang, W.; Tao, X.; Gan, Y.; Xia, Y.; Yang, H.; Guo, X. Synthesis of MnO/C composites derived from pollen template for advanced lithium-ion batteries. Electrochim. Acta 2015, 152, 286–293. [Google Scholar] [CrossRef]

- Xia, Y.; Fang, R.; Xiao, Z.; Ruan, L.; Yan, R.; Huang, H.; Liang, C.; Gan, Y.; Zhang, J.; Tao, X.; et al. Supercritical fluid assisted biotemplating synthesis of SI-O-C microspheres from microalgae for advanced Li-ion batteries. RSC Adv. 2016, 6, 69764–69772. [Google Scholar] [CrossRef]

- Xia, Y.; Zhong, H.; Fang, R.; Liang, C.; Xiao, Z.; Huang, H.; Gan, Y.; Zhang, J.; Tao, X.; Zhang, W. Biomass derived Ni(OH)2 @ porous carbon/sulfur composites synthesized by a novel sulfur impregnation strategy based on supercritical CO2 technology for advanced Li-S batteries. J. Power Sources 2018, 378, 73–80. [Google Scholar] [CrossRef]

- Fang, R.; Xia, Y.; Liang, C.; He, X.; Huang, H.; Gan, Y.; Zhang, J.; Tao, X.; Zhang, W. Supercritical CO2-assisted synthesis of 3D porous SiOC/Se cathode for ultrahigh areal capacity and long cycle life Li–Se batteries. J. Mater. Chem. A 2018, 6, 24773–24782. [Google Scholar] [CrossRef]

- Dong, B.; Driscoll, L.L.; Stockham, M.P.; Kendrick, E.; Slater, P.R. Low temperature synthesis of garnet solid state electrolytes: Implications on aluminium incorporation in Li7La3Zr2O12. Solid State Ionics 2020, 350, 115317. [Google Scholar] [CrossRef]

- Kong, Y.; Luo, J.; Jin, C.; Yuan, H.; Sheng, O.; Zhang, L.; Fang, C.; Zhang, W.; Huang, H.; Xia, Y.; et al. Enhanced sulfide chemisorption by conductive Al-doped ZnO decorated carbon nanoflakes for advanced Li–S. Nano Res. 2018, 11, 477–489. [Google Scholar] [CrossRef]

- Tao, X.; Wang, J.; Liu, C.; Wang, H.; Yao, H.; Zheng, G.; Seh, Z.W.; Cai, Q.; Li, W.; Zhou, G.; et al. Balancing surface adsorption and diffusion of lithium-polysulfides on nonconductive oxides for lithium—sulfur battery design. Nat. Commun. 2016, 7, 11203. [Google Scholar] [CrossRef]

- Tao, X.; Wu, R.; Xia, Y.; Huang, H.; Chai, W.; Feng, T.; Gan, Y.; Zhang, W. Biotemplated fabrication of Sn@C anode materials based on the unique metal biosorption behavior of microalgae. ACS Appl. Mater. Interfaces 2014, 6, 3696–3702. [Google Scholar] [CrossRef]

- Hu, J.; Yuan, X.; Wang, C.; Shao, X.; Yang, B.; Razzaq, A.A.; Zhao, X.; Lian, Y.; Deng, Z.; Chen, M.; et al. Self-phosphorization of MOF-armored microbes for advanced energy storage. Small 2020, 16, 2000755. [Google Scholar] [CrossRef]

- Oh, D.; Ozgit-Akgun, C.; Akca, E.; Thompson, L.E.; Tadesse, L.F.; Kim, H.C.; Demirci, G.; Miller, R.D.; Maune, H. Biotemplating pores with size and shape diversity for Li-oxygen battery cathodes. Sci. Rep. 2017, 7, 45919. [Google Scholar] [CrossRef]

- Atalay, F.E.; Asma, D.; Kaya, H.; Ozbey, E. The fabrication of metal oxide nanostructures using Deinococcus radiodurans bacteria for supercapacitor. Mater. Sci. Semicond. Process. 2015, 38, 314–318. [Google Scholar] [CrossRef]

- Gong, L.; Liu, X.; Su, L.; Wang, L. Synthesis and electrochemical capacitive behaviors of Co3O4 nanostructures from a novel biotemplating technique. J. Solid State Electrochem. 2012, 16, 297–304. [Google Scholar] [CrossRef]

- Kong, L.; Zhang, C.; Wang, J.; Long, D.; Qiao, W.; Ling, L. Ultrahigh intercalation pseudocapacitance of mesoporous orthorhombic niobium pentoxide from a novel cellulose nanocrystal template. Mater. Chem. Phys. 2015, 149–150, 495–504. [Google Scholar] [CrossRef]

- Hao, J.; Huang, Y.; He, C.; Xu, W.; Yuan, L.; Shu, D.; Song, X.; Meng, T. Bio-templated fabrication of three-dimensional network activated carbons derived from mycelium pellets for supercapacitor applications. Sci. Rep. 2018, 8, 562. [Google Scholar] [CrossRef] [Green Version]

- Chang, C.M.; Hu, Z.H.; Lee, T.Y.; Huang, Y.A.; Ji, W.F.; Liu, W.R.; Yeh, J.M.; Wei, Y. Biotemplated hierarchical polyaniline composite electrodes with high performance for flexible supercapacitors. J. Mater. Chem. A 2016, 4, 9133–9145. [Google Scholar] [CrossRef]

- Gerasopoulos, K.; Pomerantseva, E.; Mccarthy, M.; Brown, A.; Wang, C.; Culver, J.; Ghodssi, R. Hierarchical three-dimensional microbattery electrodes combining bottom-up self-assembly and top-down micromachining. ACS Nano 2012, 6, 6422–6432. [Google Scholar] [CrossRef]

- Records, W.C.; Wei, S.; Belcher, A.M. Virus-templated nickel phosphide nanofoams as additive-free, thin-film Li-ion microbattery anodes. Small 2019, 15, 1903166. [Google Scholar] [CrossRef] [Green Version]

- Xue, W.; Li, Y.; Zhou, J.; Wang, Z.; Liu, Y.; Zhang, X.; Liu, Z.; Gao, F.; Gao, D. Self-assembly of adenovirus-templated platinum nanoshells and evaluation of their biocompatibilities. RSC Adv. 2015, 5, 86381–86386. [Google Scholar] [CrossRef]

- Gao, Z.D.; Liu, H.F.; Song, Y.Y. Biotemplated synthesis of Au nanoparticles-TiO2 nanotube junctions for enhanced direct electochemistry of heme proteins. Chem. Commun. 2013, 49, 774–776. [Google Scholar] [CrossRef]

- Brotto, J.O.; Padoin, N.; Rambo, C.R.; Soares, C. Biomorphic microchanneled electrodes for enhanced water desalination through capacitive deionization. Water Supply 2019, 19, 1221–1228. [Google Scholar] [CrossRef]

- Dorval Courchesne, N.M.; Klug, M.T.; Huang, K.J.; Weidman, M.C.; Cantú, V.J.; Chen, P.Y.; Kooi, S.E.; Yun, D.S.; Tisdale, W.A.; Fang, N.X.; et al. Constructing multifunctional virus-templated nanoporous composites for thin film solar cells: Contributions of morphology and optics to photocurrent generation. J. Phys. Chem. 2015, 119, 13987–14000. [Google Scholar] [CrossRef]

- Han, T.H.; Moon, H.S.; Hwang, J.O.; Seok, S.I.; Im, S.H.; Kim, S.O. Peptide-templating dye-sensitized solar cells. Nanotechnology 2010, 21, 185601. [Google Scholar] [CrossRef]

- Niu, H.; Zhou, R.; Cheng, C.; Zhang, G.; Hu, Y.; Huang, B.; Zhang, S.; Shang, X.; Xia, M.; Xu, J. Magnetron sputtering in the creation of photonic nanostructures derived from Sasakia Charonda Formosana-butterfly wings for applied in dye-sensitized solar cells. J. Power Sources 2016, 325, 598–608. [Google Scholar] [CrossRef]

- Zhang, G.; Wei, S.; Belcher, A.M. Biotemplated zinc sulfide nano fibers as anode materials for sodium-ion batteries. ACS Appl. Nanomater. 2018, 1, 5631–5639. [Google Scholar] [CrossRef]

- Zilinskaite, S.; Rennie, A.J.R.; Boston, R.; Reeves-McLaren, N. Biotemplating: A sustainable synthetic methodology for Na-ion battery materials. J. Mater. Chem. A 2018, 6, 5346–5355. [Google Scholar] [CrossRef]

- Xue, J.; Dou, G.; Ziade, E.; Goldfarb, J.L. Integrating sustainable biofuel and silver nanomaterial production for in situ upgrading of cellulosic biomass pyrolysis. Energy Convers. Manag. 2017, 142, 143–152. [Google Scholar] [CrossRef]

- Ashman, C.H.; Gao, L.; Goldfarb, J.L. Silver nitrate in situ upgrades pyrolysis biofuels from brewer’s spent grain via biotemplating. J. Anal. Appl. Pyrolysis 2020, 146, 104729. [Google Scholar] [CrossRef]

- Chen, L.; Wang, X. Bio-templated Fabrication of Metal-Free Boron Carbonitride Tubes for Visible Light Photocatalysis. Chem. Commun. 2017, 53, 11988–11991. [Google Scholar] [CrossRef] [PubMed]

- Hashemizadeh, I.; Golovko, V.B.; Choi, J.; Tsang, D.C.W.; Yip, A.C.K. Photocatalytic reduction of CO2 to hydrocarbons using bio-templated porous TiO2 architectures under UV and visible light. Chem. Eng. J. 2018, 347, 64–73. [Google Scholar] [CrossRef]

- Martín-Gómez, J.; Hidalgo-Carrillo, J.; Estévez, R.C.; Urbano, F.J.; Marinas, A. Hydrogen photoproduction on TiO2-CuO artificial olive leaves. Appl. Catal. A Gen. 2021, 620, 118178. [Google Scholar] [CrossRef]

- Lu, X.; Zhai, T.; Cui, H.; Shi, J.; Xie, S.; Huang, Y.; Liang, C.; Tong, Y. Redox cycles promoting photocatalytic hydrogen evolution of CeO2 nanorods. J. Mater. Chem. 2011, 21, 5569–5572. [Google Scholar] [CrossRef]

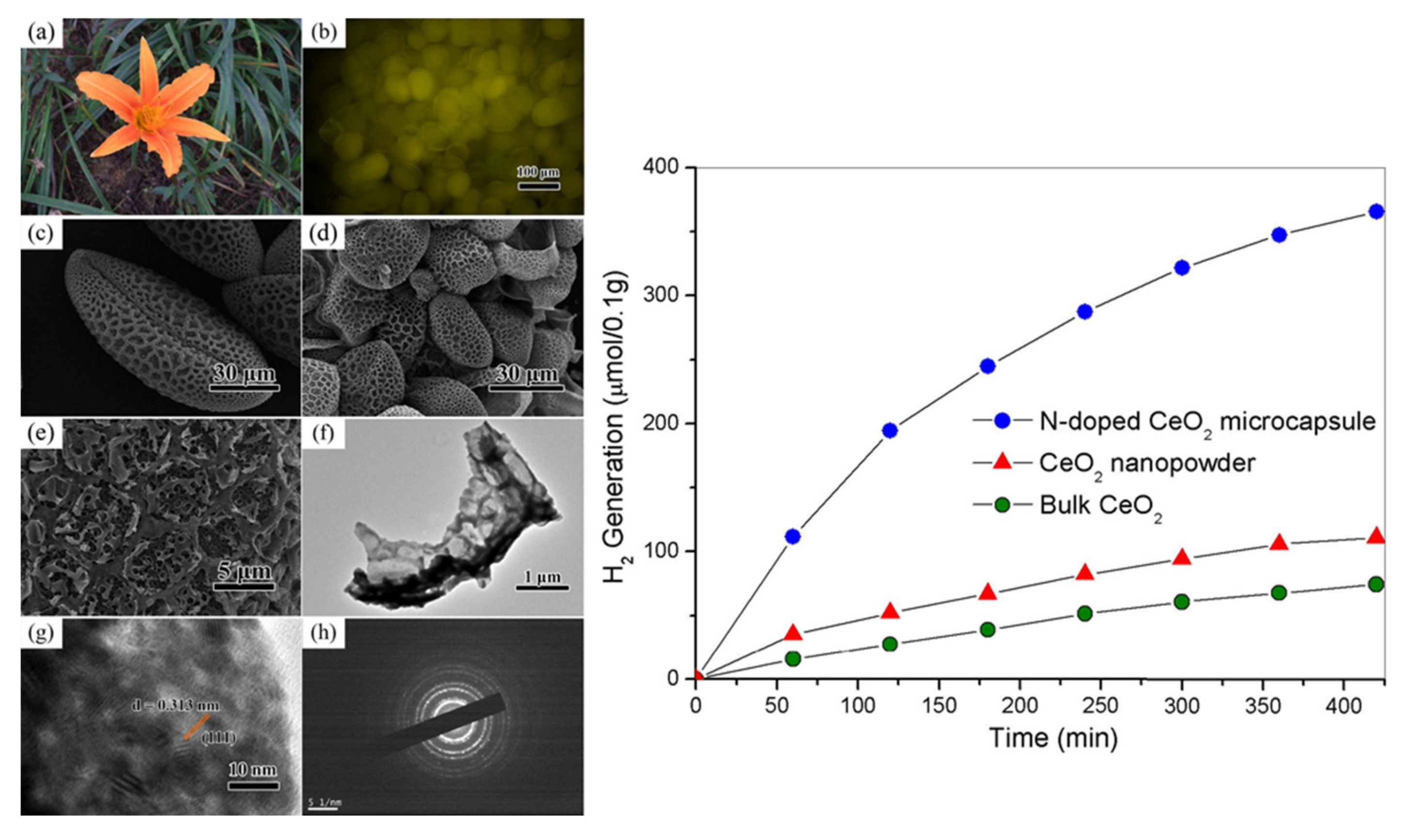

- Liu, C.; Sun, H.; Qian, J.; Chen, Z.; Lv, Y.; Chen, F.; Lu, X.; Wu, Z. Biotemplating synthesis and photocatalytic activities of N-doped CeO2 microcapsule tailored by hemerocallis pollen. Adv. Powder Technol. 2017, 28, 2741–2746. [Google Scholar] [CrossRef]

- Van Benthem, K.; Elsässer, C.; French, R.H. Bulk electronic structure of SrTiO3: Experiment and theory. J. Appl. Phys. 2001, 90, 6156–6164. [Google Scholar] [CrossRef] [Green Version]

- Nuraje, N.; Lei, Y.; Belcher, A. Virus-templated visible spectrum active perovskite photocatalyst. Catal. Commun. 2014, 44, 68–72. [Google Scholar] [CrossRef]

- Qin, L.; Si, G.; Li, X.; Kang, S.Z. Synergetic effect of Cu-Pt bimetallic cocatalyst on SrTiO3 for efficient photocatalytic hydrogen production from water. RSC Adv. 2015, 5, 102593–102598. [Google Scholar] [CrossRef]

- Azmy, H.A.M.; Razuki, N.A.; Aziz, A.W.; Satar, N.S.A.; Kaus, N.H.M. Visible light photocatalytic activity of BiFeO3 nanoparticles for degradation of methylene blue. J. Phys. Sci. 2017, 28, 85–103. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Kang, J.; Li, L.; Guo, L. A biotemplating route for the synthesis of hierarchical Fe2O3 with highly dispersed carbon as electron-transfer channel. Chempluschem 2020, 85, 258–263. [Google Scholar] [CrossRef]

- Gutbrod, K.; Greil, P.; Zollfrank, C. Carbon auto-doping improves photocatalytic properties of biotemplated ceramics. Appl. Catal. B Environ. 2011, 103, 240–245. [Google Scholar] [CrossRef]

- Ivanova, A.; Fattakhova-Rohlfing, D.; Kayaalp, B.E.; Rathouský, J.; Bein, T. Tailoring the morphology of mesoporous titania thin films through biotemplating with nanocrystalline cellulose. J. Am. Chem. Soc. 2014, 136, 5930–5937. [Google Scholar] [CrossRef]

- He, Z.; Que, W.; Chen, J.; He, Y.; Wang, G. Surface chemical analysis on the carbon-doped mesoporous TiO2 photocatalysts after post-thermal treatment: XPS and FTIR characterization. J. Phys. Chem. Solids 2013, 74, 924–928. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Salleh, W.N.W.; Jaafar, J.; Mohd Hir, Z.A.; Rosmi, M.S.; Mutalib, M.A.; Ismail, A.F.; Tanemura, M. Regenerated cellulose membrane as bio-template for in-situ growth of visible-light driven C-modified mesoporous titania. Carbohydr. Polym. 2016, 146, 166–173. [Google Scholar] [CrossRef]

- Cai, Q.; Liu, C.; Yin, C.; Huang, W.; Cui, L.; Shi, H.; Fang, X.; Zhang, L.; Kang, S.; Wang, Y. Biotemplating synthesis of graphitic Carbon-coated TiO2 and its application as efficient visible-light-driven photocatalyst for Cr6+ remove. ACS Sustain. Chem. Eng. 2017, 5, 3938–3944. [Google Scholar] [CrossRef]

- Magnabosco, G.; Papiano, I.; Aizenberg, M.; Aizenberg, J.; Falini, G. Beyond biotemplating: Multiscale porous inorganic materials with high catalytic efficiency. Chem. Commun. 2020, 56, 3389–3392. [Google Scholar] [CrossRef]

- Xue, J.; Song, F.; Yin, X.W.; Zhang, Z.L.; Liu, Y.; Wang, X.L.; Wang, Y.Z. Cellulose nanocrystal-templated synthesis of mesoporous TiO2 with dominantly exposed (001) facets for efficient catalysis. ACS Sustain. Chem. Eng. 2017, 5, 3721–3725. [Google Scholar] [CrossRef]

- Shahini, P.; Ashkarran, A.A. TiO2 nanofibers assembled on graphene-silver platform as a visible-light photo and bio-active nanostructure. Ceram. Int. 2017, 43, 8655–8663. [Google Scholar] [CrossRef]

- Shafaee, M.; Goharshadi, E.K.; Mashreghi, M.; Sadeghinia, M. TiO2 nanoparticles and TiO2@graphene quantum dots nancomposites as effective visible/solar light photocatalysts. J. Photochem. Photobiol. A Chem. 2018, 357, 90–102. [Google Scholar] [CrossRef]

- Lu, X.; Li, X.; Chen, F.; Chen, Z.; Qian, J.; Zhang, Q. Biotemplating synthesis of N-doped two-dimensional CeO2–TiO2 nanosheets with enhanced visible light photocatalytic desulfurization performance. J. Alloys Compd. 2020, 815, 152326. [Google Scholar] [CrossRef]

- Serrà, A.; Artal, R.; García-Amorós, J.; Sepúlveda, B.; Gómez, E.; Nogués, J.; Philippe, L. Hybrid Ni@ZnO@ZnS-microalgae for circular economy: A smart route to the efficient integration of solar photocatalytic water decontamination and bioethanol production. Adv. Sci. 2020, 7, 1902447. [Google Scholar] [CrossRef]

- Serrà, A.; Gómez, E.; Michler, J.; Philippe, L. Facile cost-effective fabrication of Cu@Cu2O@CuO–microalgae photocatalyst with enhanced visible light degradation of tetracycline. Chem. Eng. J. 2021, 413. [Google Scholar] [CrossRef]

- Posa, V.R.; Annavaram, V.; Koduru, J.R.; Ammireddy, V.R.; Somala, A.R. Graphene-ZnO nanocomposite for highly efficient photocatalytic degradation of methyl orange dye under solar light irradiation. Korean J. Chem. Eng. 2016, 33, 456–464. [Google Scholar] [CrossRef]

- Juárez, J.; Cambón, A.; Goy-López, S.; Topete, A.; Taboada, P.; Mosquera, V. Obtention of metallic nanowires by protein biotemplating and their catalytic application. J. Phys. Chem. Lett. 2010, 1, 2680–2687. [Google Scholar] [CrossRef]

- Pushpavanam, K.; Santra, S.; Rege, K. Biotemplating Plasmonic nanoparticles using intact microfluidic vasculature of leaves. Langmuir 2014, 30, 14095–14103. [Google Scholar] [CrossRef]

- Inbaraj, B.S.; Chen, B.; Liao, C.-W.; Chen, B.-H. Green synthesis, characterization and evaluation of catalytic and antibacterial activities of chitosan, glycol chitosan and poly (γ-glutamic acid) capped gold nanoparticles. Int. J. Biol. Macromol. 2020, 161, 1484–1495. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.; Liu, M.; Wu, Y.; Xu, Z.; Guo, X.; Zhang, G. Bioinspired hollow and hierarchically porous MOx(M =Ti, Si)/carbon microellipsoids supported with Fe2O3 for heterogenous photochemical oxidation. Appl. Catal. B Environ. 2016, 194, 50–60. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, G.; Yang, W.; Yang, J.; Li, J. Biotemplated synthesis of hierarchically porous ZnAl-CLDH/FeWO4 for effective removal of dyes from water. Water. Air. Soil Pollut. 2019, 230, 89. [Google Scholar] [CrossRef]

- Jeevitha, G.; Abhinayaa, R.; Mangalaraj, D.; Ponpandian, N. Tungsten oxide-graphene oxide (WO3-GO) nanocomposite as an efficient photocatalyst, antibacterial and anticancer agent. J. Phys. Chem. Solids 2018, 116, 137–147. [Google Scholar] [CrossRef]

- Qiu, Z.; Huang, H.; Du, J.; Tao, X.; Xia, Y.; Feng, T.; Gan, Y.; Zhang, W. Biotemplated synthesis of bark-structured TiC nanowires as Pt catalyst supports with enhanced electrocatalytic activity and durability for methanol oxidation. J. Mater. Chem. A 2014, 2, 8003–8008. [Google Scholar] [CrossRef]

- Peng, M.; Qiao, Y.; Luo, M.; Wang, M.; Chu, S.; Zhao, Y.; Liu, P.; Liu, J.; Tan, Y. Bioinspired Fe3C@C as highly efficient electrocatalyst for nitrogen reduction reaction under ambient conditions. ACS Appl. Mater. Interfaces 2019, 11, 40062–40068. [Google Scholar] [CrossRef]

- Records, W.C.; Yoon, Y.; Ohmura, J.F.; Chanut, N.; Belcher, A.M. Virus-templated Pt–Ni(OH)2 nanonetworks for enhanced electrocatalytic reduction of water. Nano Energy 2019, 58, 167–174. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Wang, X.; Mao, T.; Sima, J.; Gong, C.; Fan, G. Precise casting of biomorphic La0.9K0.1CoO3 catalysts derived from pinewood for diesel soot combustion. RSC Adv. 2016, 6, 87856–87862. [Google Scholar] [CrossRef]

- Bedford, N.M.; Ramezani-Dakhel, H.; Slocik, J.M.; Briggs, B.D.; Ren, Y.; Frenkel, A.I.; Petkov, V.; Heinz, H.; Naik, R.R.; Knecht, M.R. Elucidation of peptide-directed palladium surface structure for biologically tunable nanocatalysts. ACS Nano 2015, 9, 5082–5092. [Google Scholar] [CrossRef]

- Linsha, V.; Aboo Shuhailath, K.; Mahesh, K.V.; Mohamed, A.A.P.; Ananthakumar, S. Biocatalytic conversion efficiency of steapsin lipase immobilized on hierarchically porous biomorphic aerogel supports. ACS Sustain. Chem. Eng. 2016, 4, 4692–4703. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E. Photocatalytic reduction of graphene oxide nanosheets on TiO2 thin film for photoinactivation of bacteria in solar light irradiation. J. Phys. Chem. C 2009, 113, 20214–20220. [Google Scholar] [CrossRef]

- Akhavan, O.; Choobtashani, M.; Ghaderi, E. Protein degradation and RNA efflux of viruses photocatalyzed by graphene-tungsten oxide composite under visible light irradiation. J. Phys. Chem. C 2012, 116, 9653–9659. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Rahimi, K. Adverse effects of graphene incorporated in TiO2 photocatalyst on minuscule animals under solar light irradiation. J. Mater. Chem. 2012, 22, 23260–23266. [Google Scholar] [CrossRef]

- Akhavan, O. Lasting antibacterial activities of Ag-TiO2/Ag/a-TiO2 nanocomposite thin film photocatalysts under solar light irradiation. J. Colloid Interface Sci. 2009, 336, 117–124. [Google Scholar] [CrossRef]

- Galusha, J.W.; Richey, L.R.; Jorgensen, M.R.; Gardner, J.S.; Bartl, M.H. Study of natural photonic crystals in beetle scales and their conversion into inorganic structures via a sol-gel bio-templating route. J. Mater. Chem. 2010, 20, 1277–1284. [Google Scholar] [CrossRef]

- Zampieri, A.; Mabande, G.T.P.; Selvam, T.; Schwieger, W.; Rudolph, A.; Hermann, R.; Sieber, H.; Greil, P. Biotemplating of Luffa cylindrica sponges to self-supporting hierarchical zeolite macrostructures for bio-inspired structured catalytic reactors. Mater. Sci. Eng. C 2006, 26, 130–135. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, S.; Zhang, Y.; Wang, Q.; Ren, T. Biotemplate-directed fabrication of size-controlled monodisperse magnetic silica microspheres. Colloids Surfaces B Biointerfaces 2015, 131, 129–135. [Google Scholar] [CrossRef]

- Hussein, M.Z.; Azmin, W.H.W.N.; Mustafa, M.; Yahaya, A.H. Bacillus cereus as a biotemplating agent for the synthesis of zinc oxide with raspberry- and plate-like structures. J. Inorg. Biochem. 2009, 103, 1145–1150. [Google Scholar] [CrossRef]

- Nomura, T.; Bando, M.; Konishi, Y. Facile fabrication of hollow titania microparticles using wet yeast cells as templates. Colloids Surf. A Physicochem. Eng. Asp. 2015, 487, 215–220. [Google Scholar] [CrossRef]

- Korkmaz, N.; Arslan, T. Genetically engineered Fd viruses for site specific material binding. Bionanoscience 2019, 9, 862–872. [Google Scholar] [CrossRef]

- Lu, Z.X.; Wood, L.F.; Ohman, D.E.; Collinson, M.M. Bio-inspired chemical reactors for growing aligned gold nanoparticle-like wires. Chem. Commun. 2009, 28, 4200–4202. [Google Scholar] [CrossRef]

- Zhou, J.C.; Soto, C.M.; Chen, M.S.; Bruckman, M.A.; Moore, M.H.; Barry, E.; Ratna, B.R.; Pehrsson, P.E.; Spies, B.R.; Confer, T.S. Biotemplating rod-like viruses for the synthesis of copper nanorods and nanowires. J. Nanobiotechnology 2012, 10, 18. [Google Scholar] [CrossRef] [Green Version]

- Kamata, K.; Piao, Z.; Suzuki, S.; Fujimori, T.; Tajiri, W.; Nagai, K.; Iyoda, T.; Yamada, A.; Hayakawa, T.; Ishiwara, M.; et al. Spirulina-templated metal microcoils with controlled helical structures for THz electromagnetic responses. Sci. Rep. 2014, 4, 4919. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ölçeroǧlu, E.; Hsieh, C.Y.; Rahman, M.M.; Lau, K.K.S.; McCarthy, M. Full-field dynamic characterization of superhydrophobic condensation on biotemplated nanostructured surfaces. Langmuir 2014, 30, 7556–7566. [Google Scholar] [CrossRef] [PubMed]

- Zeni, T.L.; Rambo, C.R.; Magalhaẽs, W.L.E.; Hotza, D. Control of porosity and permeability of wood by fungi action for biotemplating of SiC. J. Wood Chem. Technol. 2013, 33, 33–43. [Google Scholar] [CrossRef]

- Alloyeau, D.; Stéphanidis, B.; Zhao, X.; Larquet, E.; Boisset, N.; Ricolleau, C. Biotemplated synthesis of metallic nanoclusters organized in tunable two-dimensional superlattices. J. Phys. Chem. C 2011, 115, 20926–20930. [Google Scholar] [CrossRef]

- Bird, S.M.; Galloway, J.M.; Rawlings, A.E.; Bramble, J.P.; Staniland, S.S. Taking a hard line with biotemplating: Cobalt-doped magnetite magnetic nanoparticle arrays. Nanoscale 2015, 7, 7340–7351. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deplanche, K.; Woods, R.D.; Mikheenko, I.P.; Sockett, R.; Macaskie, L.E. Manufacture of Stable palladium and gold nanoparticles on native and genetically engineered flagella scaffolds. Biotechnol. Bioeng. 2008, 101, 873–880. [Google Scholar] [CrossRef]

- Hüttl, R.; Ullrich, F.; Wolf, G.; Kirchner, A.; Mertig, M.; Pompe, W. Calorimetric methods for catalytic investigations of novel catalysts based on metallized S-layer preparations. Thermochim. Acta 2006, 440, 13–18. [Google Scholar] [CrossRef]

- Kasotakis, E.; Mitraki, A. Silica biotemplating by self-assembling peptides via serine residues activated by the peptide amino terminal group. Biopolymers 2012, 98, 501–509. [Google Scholar] [CrossRef]

- Jiang, Y.; Fu, J.; Pan, J.; An, Z.; Cai, J.; Zhang, D. Biopattern transfer using diatom frustules for fabrication of functional micro/nanostructures. J. Micro Nanolithography MEMS MOEMS 2015, 14, 014502. [Google Scholar] [CrossRef]

- Juárez, J.; Cambón, A.; Topete, A.; Taboada, P.; Mosquera, V. One-dimensional magnetic nanowires obtained by protein fibril biotemplating. Chem.-Eur. J. 2011, 17, 7366–7373. [Google Scholar] [CrossRef]

- Leroux, F.; Gysemans, M.; Bals, S.; Batenburg, K.J.; Snauwaert, J.; Verbiest, T.; Van Haesendonck, C.; Van Tendeloo, G. Three-dimensional characterization of helical silver nanochains mediated by protein assemblies. Adv. Mater. 2010, 22, 2193–2197. [Google Scholar] [CrossRef]

- Liu, C.; Chung, S.H.; Jin, Q.; Sutton, A.; Yan, F.; Hoffmann, A.; Kay, B.K.; Bader, S.D.; Makowski, L.; Chen, L. Magnetic viruses via nano-capsid templates. J. Magn. Magn. Mater. 2006, 302, 47–51. [Google Scholar] [CrossRef]

- Wnȩk, M.; Górzny, M.Ł.; Ward, M.B.; Wälti, C.; Davies, A.G.; Brydson, R.; Evans, S.D.; Stockley, P.G. Fabrication and characterization of gold nano-wires templated on virus-like arrays of tobacco mosaic virus coat proteins. Nanotechnology 2013, 24, 025605. [Google Scholar] [CrossRef] [Green Version]

- Huggins, K.N.L.; Schoen, A.P.; Arunagirinathan, M.A.; Heilshorn, S.C. Multi-site functionalization of protein scaffolds for bimetallic nanoparticle templating. Adv. Funct. Mater. 2014, 24, 7737–7744. [Google Scholar] [CrossRef]

- Malisauskas, M.; Meskys, R.; Morozova-Roche, L.A. Ultrathin silver nanowires produced by amyloid biotemplating. Biotechnol. Prog. 2008, 24, 1166–1170. [Google Scholar] [CrossRef]

- Schoen, A.P.; Schoen, D.T.; Huggins, K.N.L.; Arunagirinathan, M.A.; Heilshorn, S.C. Template engineering through epitope recognition: A modular, biomimetic strategy for inorganic nanomaterial synthesis. J. Am. Chem. Soc. 2011, 133, 18202–18207. [Google Scholar] [CrossRef]

- Shindel, M.M.; Mumm, D.R.; Wang, S.W. Biotemplating of metallic nanoparticle arrays through site-specific electrostatic adsorption on streptavidin crystals. Langmuir 2010, 26, 11103–11112. [Google Scholar] [CrossRef]

- Tang, J.; Badelt-Lichtblau, H.; Ebner, A.; Preiner, J.; Kraxberger, B.; Gruber, H.J.; Sleytr, U.B.; Ilk, N.; Hinterdorfer, P. Fabrication of highly ordered gold nanoparticle arrays templated by crystalline lattices of bacterial S-layer protein. ChemPhysChem 2008, 9, 2317–2320. [Google Scholar] [CrossRef]

- Zhou, J.C.; Wang, X.; Xue, M.; Xu, Z.; Hamasaki, T.; Yang, Y.; Wang, K.; Dunn, B. Characterization of gold nanoparticle binding to microtubule filaments. Mater. Sci. Eng. C 2010, 30, 20–26. [Google Scholar] [CrossRef]

- Sierra-Sastre, Y.; Choi, S.; Picraux, S.T.; Batt, C.A. Vertical growth of Ge nanowires from biotemplated Au nanoparticle catalysts. J. Am. Chem. Soc. 2008, 130, 10488–10489. [Google Scholar] [CrossRef] [PubMed]

- Galloway, J.M.; Bird, S.M.; Talbot, J.E.; Shepley, P.M.; Bradley, R.C.; El-Zubir, O.; Allwood, D.A.; Leggett, G.J.; Miles, J.J.; Staniland, S.S.; et al. Nano- and micro-patterning biotemplated magnetic CoPt arrays. Nanoscale 2016, 8, 11738–11747. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, T.H.; Oh, J.K.; Park, J.S.; Kwon, S.H.; Kim, S.W.; Kim, S.O. Highly entangled hollow TiO2 nanoribbons templating diphenylalanine assembly. J. Mater. Chem. 2009, 19, 3512–3516. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Tang, D.; D’Acierno, F.; Michal, C.A.; MacLachlan, M.J. Biotemplated lightweight γ-Alumina aerogels. Chem. Mater. 2018, 30, 1602–1609. [Google Scholar] [CrossRef]

- Sachse, A.; Cardoso, L.; Kostov, K.L.; Gérardin, C.; Belamie, E.; Alonso, B. Mesoporous alumina from colloidal biotemplating of Al clusters. Chem.-Eur. J. 2015, 21, 3206–3210. [Google Scholar] [CrossRef]

- Sachse, A.; Hulea, V.; Kostov, K.L.; Belamie, E.; Alonso, B. Improved silica-titania catalysts by chitin biotemplating. Catal. Sci. Technol. 2015, 5, 415–427. [Google Scholar] [CrossRef]

- Bai, H.; Xu, F.; Anjia, L.; Matsui, H. Low temperature synthesis of ZnO nanowires by using a genetically-modified collagen-like triple helix as a catalytic template. Soft Matter 2009, 5, 966–969. [Google Scholar] [CrossRef]

- Kim, J.W.; Choi, S.H.; Lillehei, P.T.; Chu, S.H.; King, G.C.; Watt, G.W. Cobalt oxide hollow nanoparticles derived by bio-templating. Chem. Commun. 2005, 28, 4101–4103. [Google Scholar] [CrossRef]

- Li, D.; Mathew, B.; Mao, C. Biotemplated synthesis of hollow double-layered core/shell titania/silica nanotubes under ambient conditions. Small 2012, 8, 3691–3697. [Google Scholar] [CrossRef] [Green Version]

- Maheshkumar, J.; Sreedhar, B.; Nair, B.U.; Dhathathreyan, A. Supported lipid bilayers as templates to design manganese oxide nanoparticles. J. Chem. Sci. 2012, 124, 979–984. [Google Scholar] [CrossRef] [Green Version]

- Ge, D.; Mu, J.; Huang, S.; Liang, P.; Gcilitshana, O.U.; Ji, S.; Linkov, V.; Shi, W. Electrochemical synthesis of polypyrrole nanowires in the presence of gelatin. Synth. Met. 2011, 161, 166–172. [Google Scholar] [CrossRef]

- Chen, J.Y.; Yang, C.Y.; Chen, P.Y. Synthesis of hierarchically porous structured CaCO3 and TiO2 replicas by sol-gel method using lotus root as template. Mater. Sci. Eng. C 2016, 67, 85–97. [Google Scholar] [CrossRef]

- Li, J.; Kwong, F.L.; Zhu, J.; Ng, D.H.L. Synthesis of biomorphic ZnO nanostructures by using the cetyltrimethylammonium bromide modified silk templates. J. Am. Ceram. Soc. 2010, 93, 3726–3731. [Google Scholar] [CrossRef]

- Rambo, C.R.; Hotza, D. Microchanneled biomorphic AlN-coated Al2O3 by pressureless infiltration-nitridation. Ceram. Int. 2014, 40, 12567–12571. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Paineau, E.; Laachachi, A.; Colbeau-Justin, C.; Remita, H.; Ghazzal, M.N. Sol-gel biotemplating route with cellulose nanocrystals to design a photocatalyst boosting the hydrogen generation. J. Mater. Chem. A 2020, 8, 10779–10786. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, Y.; Wang, Y.; Bu, X.; Wang, H.; Zhang, M. Morphology-controlled fabrication of hierarchical LDH/C microspheres derived from rape pollen grain. Appl. Clay Sci. 2015, 103, 67–70. [Google Scholar] [CrossRef]

- He, X.H.; Qi, L.H.; Wang, J.B.; Shen, M.Q.; Chang, W.; Fu, C.; Yang, M.G.; Su, X.L. Preparation of SnO2/C biomorphic materials by biotemplating from ramie fibres. Bull. Mater. Sci. 2011, 34, 1157–1162. [Google Scholar] [CrossRef]

- Klaithong, S.; Van Opdenbosch, D.; Zollfrank, C.; Plank, J. Preparation of magnesium oxide and magnesium silicate replicas retaining the hierarchical structure of pine wood. Zeitschrift fur Naturforsch. B 2017, 72, 341–349. [Google Scholar] [CrossRef]

- Ramimoghadam, D.; Hussein, M.Z.B.; Taufiq-Yap, Y.H. Synthesis and characterization of ZnO nanostructures using palm olein as biotemplate. Chem. Cent. J. 2013, 7, 71. [Google Scholar] [CrossRef] [Green Version]

- Gruber, S.; Taylor, R.N.K.; Scheel, H.; Greil, P.; Zollfrank, C. Cellulose-biotemplated silica nanowires coated with a dense gold nanoparticle layer. Mater. Chem. Phys. 2011, 129, 19–22. [Google Scholar] [CrossRef]

- Onyestyák, G. Pinewood char templated mordenite/carbon honeycomb composite. New J. Chem. 2006, 30, 1058–1064. [Google Scholar] [CrossRef]

- Van Opdenbosch, D.; Fritz-Popovski, G.; Wagermaier, W.; Paris, O.; Zollfrank, C. Moisture-driven ceramic bilayer actuators from a biotemplating approach. Adv. Mater. 2016, 28, 5235–5240. [Google Scholar] [CrossRef] [PubMed]

- Zampieri, A.; Kullmann, S.; Selvam, T.; Bauer, J.; Schwieger, W.; Sieber, H.; Fey, T.; Greil, P. Bioinspired Rattan-derived SiSiC/Zeolite monoliths: Preparation and characterisation. Microporous Mesoporous Mater. 2006, 90, 162–174. [Google Scholar] [CrossRef]

- Zampieri, A.; Sieber, H.; Selvam, T.; Mabande, G.T.P.; Schwieger, W.; Scheffler, F.; Scheffler, M.; Greil, P. Biomorphic cellular SiSiC/Zeolite ceramic composites: From rattan palm to bioinspired structured monoliths for catalysis and sorption. Adv. Mater. 2005, 17, 344–349. [Google Scholar] [CrossRef]

- Mroz, M.; Ali, M.; Howard, J.; Carlson, K.; Naleway, S.E. Biotemplating of a highly porous Cellulose–Silica composite from apium graveolens by a Low-Toxicity Sol–Gel technique. JOM 2021, 73, 1736–1744. [Google Scholar] [CrossRef]

- Fritz-Popovski, G.; Morak, R.; Schöberl, T.; Van Opdenbosch, D.; Zollfrank, C.; Paris, O. Pore characteristics and mechanical properties of silica templated by wood. Bioinspired Biomim. Nanobiomaterials 2014, 3, 160–168. [Google Scholar] [CrossRef]

- Onyestyák, G.; Valyon, J.; Papp, K. Novel biomorphous zeolite/carbon composite having honeycomb structure. Mater. Sci. Eng. A 2005, 412, 48–52. [Google Scholar] [CrossRef]

- Qian, J.; Wang, J.; Hou, G.; Qiao, G.; Jin, Z. Preparation and characterization of biomorphic SiC hollow fibers from wood by chemical vapor infiltration. Scr. Mater. 2005, 53, 1363–1368. [Google Scholar] [CrossRef]

- Cao, J.; Rambo, C.R.; Sieber, H. Preparation of porous Al2O3 ceramics by biotemplating of wood. J. Porous Mater. 2004, 11, 163–172. [Google Scholar] [CrossRef]

- Rambo, C.R.; Cao, J.; Sieber, H. Preparation and properties of highly porous, biomorphic YSZ ceramics. Mater. Chem. Phys. 2004, 87, 345–352. [Google Scholar] [CrossRef]

- Sieber, H.; Rambo, C.; Cao, J.; Vogli, E.; Greil, P. Manufacturing of porous oxide ceramics by replication of plant morphologies. Key Eng. Mater. 2001, 206–213, 2009–2012. [Google Scholar] [CrossRef]

- Vogli, E.; Sieber, H.; Greil, P. Biomorphic SiC-Ceramic prepared by Si-Gas phase infiltration of wood. J. Eur. Ceram. Soc. 2002, 22, 2663–2668. [Google Scholar] [CrossRef]

- Zollfrank, C.; Kladny, R.; Sieber, H.; Greil, P. Biomorphous SiOC/C-ceramic composites from chemically modified wood templates. J. Eur. Ceram. Soc. 2004, 24, 479–487. [Google Scholar] [CrossRef]

- Rambo, C.R.; Bernardes, J.C.; Sieber, H.; Müller, D. Synthesis of biomorphic ZrC/C ceramics from rattan through zirconium oxychloride infiltration and carbothermal reduction. J. Porous Mater. 2021, 28, 157–163. [Google Scholar] [CrossRef]

- Gómez-Martín, A.; Orihuela, M.P.; Ramírez-Rico, J.; Chacartegui, R.; Martínez-Fernández, J. Thermal conductivity of porous biomorphic SiC derived from wood precursors. Ceram. Int. 2016, 42, 16220–16229. [Google Scholar] [CrossRef]

- Rambo, C.R.; Cao, J.; Rusina, O.; Sieber, H. Manufacturing of biomorphic (Si, Ti, Zr)-carbide ceramics by sol-gel processing. Carbon 2005, 43, 1174–1183. [Google Scholar] [CrossRef]

- Sieber, H.; Hoffmann, C.; Kaindl, A.; Greil, P. Biomorphic cellular ceramics. Adv. Eng. Mater. 2000, 2, 105–109. [Google Scholar] [CrossRef]

- Zhurinsh, A.; Locs, J.; Berzina-Cimdina, J. Investigation of the feasibility of pyrolytic obtaining of porous biomorphic SiC ceramics. J. Anal. Appl. Pyrolysis 2009, 85, 544–548. [Google Scholar] [CrossRef]

- Zollfrank, C.; Sieber, H. Microstructure and phase morphology of wood derived biomorphous SiSiC-ceramics. J. Eur. Ceram. Soc. 2004, 24, 495–506. [Google Scholar] [CrossRef]

- Du, J.; Yang, Y.; Fan, Z.; Xia, Y.; Cheng, X.; Gan, Y.; Hang, H.; Dong, L.; Li, X.; Zhang, W.; et al. Biotemplating fabrication, mechanical and electrical characterizations of NbC nanowire arrays from the bamboo substrate. J. Alloys Compd. 2013, 560, 142–146. [Google Scholar] [CrossRef]

- Kamata, K.; Suzuki, S.; Ohtsuka, M.; Nakagawa, M.; Iyoda, T.; Yamada, A. Fabrication of left-handed metal microcoil from spiral vessel of vascular plant. Adv. Mater. 2011, 23, 5509–5513. [Google Scholar] [CrossRef]

- Schnepp, Z.; Yang, W.; Antonietti, M.; Giordano, C. Biotemplating of metal carbide microstructures: The magnetic leaf. Angew. Chem.-Int. Ed. 2010, 49, 6564–6566. [Google Scholar] [CrossRef]

- Zheng, C.; Li, Z.; Xu, T.; Chen, L.; Fang, F.; Wang, D.; Dai, P.; Wang, Q.; Wu, X.; Yan, X. Spirulina-templated porous hollow carbon@magnetite core-shell microswimmers. Appl. Mater. Today 2021, 22, 100962. [Google Scholar] [CrossRef]

- Elfwing, A.; Ponseca, C.S.; Ouyang, L.; Urbanowicz, A.; Krotkus, A.; Tu, D.; Forchheimer, R.; Inganäs, O. Conducting helical structures from celery decorated with a metallic conjugated polymer give resonances in the terahertz range. Adv. Funct. Mater. 2018, 28, 1706595. [Google Scholar] [CrossRef]

- Kostova, M.H.; Batentschuk, M.; Goetz-Neunhoeffer, F.; Gruber, S.; Winnacker, A.; Greil, P.; Zollfrank, C. Biotemplating of BaFBr:Eu2+ for X-ray storage phosphor applications. Mater. Chem. Phys. 2010, 123, 166–171. [Google Scholar] [CrossRef]

- Krzesińska, M.; Pilawa, B.; Pusz, S.; Ng, J. Physical characteristics of carbon materials derived from pyrolysed vascular plants. Biomass Bioenergy 2006, 30, 166–176. [Google Scholar] [CrossRef]

- Raja, M.W.; Islam, Q.A.; Basu, R.N. Oxygen separation membrane derived from aquatic weed: A novel bio-inspired approach to synthesize BaBi0.2Co0.35Fe0.45O3-δ perovskite from water hyacinth (Eichhornia crassipes). J. Memb. Sci. 2017, 522, 168–174. [Google Scholar] [CrossRef]

- Cohen-Hadar, N.; Wine, Y.; Lagziel-Simis, S.; Moscovich-Dagan, H.; Dror, Y.; Frolow, F.; Freeman, A. Protein Crystal-mediated biotemplating. J. Porous Media 2009, 12, 213–220. [Google Scholar] [CrossRef]

- Prekajski, M.; Babić, B.; Bučevac, D.; Pantić, J.; Gulicovski, J.; Miljković, M.; Matović, B. Synthesis and characterization of biomorphic CeO2 obtained by using egg shell membrane as template. Process. Appl. Ceram. 2014, 8, 81–85. [Google Scholar] [CrossRef] [Green Version]

- Sabu, U.; Tripathi, N.; Logesh, G.; Rashad, M.; Joy, A.; Balasubramanian, M. Development of biomorphic C-ZnO with in situ formation of ZnS using eggshell membrane as bio-template. Ceram. Int. 2020, 46, 22869–22875. [Google Scholar] [CrossRef]

- Sabu, U.; Kumar, C.N.S.; Logesh, G.; Rashad, M.; Melinte, G.; Joy, A.; Kübel, C.; Balasubramanian, M. On the formation of α-alumina single crystal platelets through eggshell membrane bio-templating. Scr. Mater. 2021, 195, 113716. [Google Scholar] [CrossRef]

- Dong, Q.; Su, H.; Zhang, D.; Liu, Z.; Lai, Y. Synthesis of hierarchical mesoporous titania with interwoven networks by eggshell membrane directed sol-gel technique. Microporous Mesoporous Mater. 2007, 98, 344–351. [Google Scholar] [CrossRef]

- Dietrich, D.; Viney, M.; Lampke, T. Petrifactions and wood-templated ceramics: Comparisons between natural and artificial silicification. IAWA J. 2015, 36, 167–185. [Google Scholar] [CrossRef]

- Matovic, B.; Nikolic, D.; Labus, N.; Ilic, S.; Maksimovic, V.; Lukovic, J.; Bucevac, D. Preparation and properties of porous, biomorphic, ceria ceramics for immobilization of Sr isotopes. Ceram. Int. 2013, 39, 9645–9649. [Google Scholar] [CrossRef]

- Hoppe, R.H.W.; Petrova, S.I. Optimal shape design in biomimetics based on homogenization and adaptivity. Math. Comput. Simul. 2004, 65, 257–272. [Google Scholar] [CrossRef]

- Cohen-Hadar, N.; Wine, Y.; Nachliel, E.; Huppert, D.; Gutman, M.; Frolow, F.; Freeman, A. Monitoring The stability of crosslinked protein crystals biotemplates: A feasibility study. J. Anat. 2006, 94, 1005–1011. [Google Scholar] [CrossRef]

- Rahman, M.M.; Ölçeroglu, E.; McCarthy, M. Role of wickability on the critical heat flux of structured superhydrophilic surfaces. Langmuir 2014, 30, 11225–11234. [Google Scholar] [CrossRef]

- Mathew, M.; Wisner, B.; Ridwan, S.; McCarthy, M.; Bartoli, I.; Kontsos, A. A Bio-inspired frequency-based approach for tailorable and scalable speckle pattern generation. Exp. Mech. 2020, 60, 1103–1117. [Google Scholar] [CrossRef]

- Cai, J.; Wang, Z.; Wang, M.; Zhang, D. Au nanoparticle-grafted hierarchical pillars array replicated from diatom as reliable SERS substrates. Appl. Surf. Sci. 2021, 541, 148374. [Google Scholar] [CrossRef]

- Engbert, A.; Plank, J. Templating effect of alginate and related biopolymers as hydration accelerators for calcium alumina cement—A mechanistic study. Mater. Des. 2020, 195, 109054. [Google Scholar] [CrossRef]

- Northcutt, R.G.; Sundaresan, V.B. Phospholipid vesicles as soft templates for electropolymerization of nanostructured polypyrrole membranes with long range order. J. Mater. Chem. A 2014, 2, 11784–11791. [Google Scholar] [CrossRef]

- Nergiz, S.Z.; Slocik, J.M.; Naik, R.R.; Singamaneni, S. Surface defect sites facilitate fibrillation: An insight into adsorption of gold-binding peptides on Au(111). Phys. Chem. Chem. Phys. 2013, 15, 11629–11633. [Google Scholar] [CrossRef] [PubMed]

| Template | Type of Material Created Using These Templates | Potential Application |

|---|---|---|

| Bio-organisms | Zeolites and silicon-based materials | Production of photonic materials [175]. |

| Catalysis [176]. | ||

| Not specified [177]. | ||

| Biopolymer and polystyrene solutions | Production of super-surfaces for antimicrobial, self-cleaning, and eukaryotic cell modulation [22]. | |

| Metal oxides | Nanobiotechnology [178]. | |

| Not specified [179]. | ||

| Metallic structures | Targeted drug delivery, development of biosensors [180]. | |

| Chemical sensing, building blocks for nanostructures [181]. | ||

| Nanoelectronics, cancer therapy [182]. | ||

| Not specified [16,23,183,184]. | ||

| Ceramics | Not specified [185]. | |

| Cellular components and structures | Metallic structures | Fundamental studies [186]. |

| Ultra-high-density data-storage [187]. | ||

| Catalysis [188,189,190]. | ||

| Nanoelectronics and nanodevices [11]. | ||

| Microfluidics [191]. | ||

| MRI contrast imaging [192]. | ||

| Large-scale production of chiral materials with optical properties [193]. | ||

| Biosensing, MRI [194]. | ||

| Production of nanometer-scale electronic devices [195]. | ||

| Fabrication of customized materials [13]. | ||

| Not specified [196,197,198,199,200,201,202]. | ||

| Metal oxides | Sensing, cell-manipulation [203]. | |

| Photochemistry and optoelectronics [204]. | ||

| Catalysts supports and thermal isolation [205]. | ||

| Heterogeneous catalysis molecular separation membranes [206]. | ||

| Catalysis [207]. | ||

| Not specified [208,209,210,211]. | ||

| Zeolites and silicon-based | Drug delivery, hydrogen storage [190]. | |

| Others | Not specified [212]. | |

| Plants, vegetable structures and products | Metal oxides | Gas/liquid purification or pollutant decomposition [213]. |

| Solar cells, photoelectric diodes, chemical sensors [214]. | ||

| Substrates in microelectronic applications [215]. | ||

| Production of nanostructures for catalysis and solar energy conversion [216]. | ||

| Purification reactions, catalysis, adsorption, energy storage [217]. | ||

| Not specified [218,219,220]. | ||

| Zeolites and silicon-based materials | Synthesis of gold nanowires with optical properties [221]. | |

| Synthesis of adsorbents and catalysis [222]. | ||

| Fluid sensing [223]. | ||

| Catalysis [224,225]. | ||

| Catalysis and filtration [226]. | ||

| Not specified [227,228,229]. | ||

| Ceramics | Sensing, catalyst carriers, support for enzyme immobilization [230]. | |

| Nitride wood ceramics preparation [18]. | ||

| Production of filters, sensors, catalysts carriers [231]. | ||

| Low density heat insulation structures, catalyst carriers [232]. | ||

| High temperature filters and catalyst support structures [233]. | ||

| Microtools, chemical reaction or catalyst support structures [234]. | ||

| Composites manufacturing [235]. | ||

| Not specified [236,237,238,239,240]. | ||

| Metallic structures | Catalysis [241]. | |

| Development of terahertz electromagnetic devices [242]. | ||

| Synthesis of microstructured objects for catalysis and electrochemistry [243]. | ||

| Photothermal antibacterial therapy, biological detoxification, targeted delivery [244]. | ||

| Others | Tunable terahertz antennas design [245]. | |

| X-Ray image storage improvement [246]. | ||

| Production of eco-materials for wood ceramics design [247]. | ||

| Not specified [248]. | ||

| Eggs and egg structures | Metal oxides | Fabrication of novel composites materials [249]. |

| Storage of radioactive isotopes [250]. | ||

| Photocatalysis [251]. | ||

| Tailored development of ceramic materials [252]. | ||

| Not specified [253]. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herrera-Beurnio, M.C.; Hidalgo-Carrillo, J.; López-Tenllado, F.J.; Martin-Gómez, J.; Estévez, R.C.; Urbano, F.J.; Marinas, A. Bio-Templating: An Emerging Synthetic Technique for Catalysts. A Review. Catalysts 2021, 11, 1364. https://doi.org/10.3390/catal11111364

Herrera-Beurnio MC, Hidalgo-Carrillo J, López-Tenllado FJ, Martin-Gómez J, Estévez RC, Urbano FJ, Marinas A. Bio-Templating: An Emerging Synthetic Technique for Catalysts. A Review. Catalysts. 2021; 11(11):1364. https://doi.org/10.3390/catal11111364

Chicago/Turabian StyleHerrera-Beurnio, M. Carmen, Jesús Hidalgo-Carrillo, Francisco J. López-Tenllado, Juan Martin-Gómez, Rafael C. Estévez, Francisco J. Urbano, and Alberto Marinas. 2021. "Bio-Templating: An Emerging Synthetic Technique for Catalysts. A Review" Catalysts 11, no. 11: 1364. https://doi.org/10.3390/catal11111364

APA StyleHerrera-Beurnio, M. C., Hidalgo-Carrillo, J., López-Tenllado, F. J., Martin-Gómez, J., Estévez, R. C., Urbano, F. J., & Marinas, A. (2021). Bio-Templating: An Emerging Synthetic Technique for Catalysts. A Review. Catalysts, 11(11), 1364. https://doi.org/10.3390/catal11111364