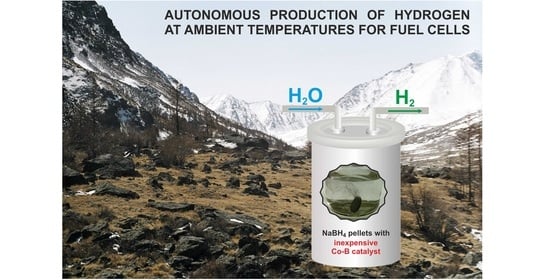

Recent Advances in Applications of Co-B Catalysts in NaBH4-Based Portable Hydrogen Generators

Abstract

:1. Introduction

2. NaBH4 as Water-Reactive Material for Hydrogen Storage and Production

3. Acid Hydrolysis of NaBH4

4. Catalytic Hydrolysis of NaBH4

5. Co-B Catalysts for the NaBH4 Hydrolysis

5.1. The Formation of Active Component in the Reaction Medium (In Situ)

5.2. The State of the In Situ Formed Active Component of Co-B Catalysts

5.3. The Role of Boron in the Activity of Co-B Catalysts for the NaBH4 Hydrolysis

5.4. Deactivation of the Co-B Catalysts in the NaBH4 Hydrolysis

6. Hydrogen Storage Systems Based on Solid-State NaBH4 Composites with Cobalt Catalysts

7. Hydrogen Generators Based on Hydrolysis of NaBH4 Using Cobalt Catalysts

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Susai, T.; Kawakami, A.; Hamada, A.; Miyake, Y.; Azegami, Y. Development of a 1 kW PEM fuel cell power source. Fuel Cells Bull. 2001, 3, 7–11. [Google Scholar] [CrossRef]

- Abdalla, A.M.; Hossain, S.; Nisfindy, O.B.; Azad, A.T.; Dawood, M.; Azad, A.K. Hydrogen production, storage, transportation and key challenges with applications: A review. Energy Convers. Manag. 2018, 165, 602–627. [Google Scholar] [CrossRef]

- Züttel, A. Hydrogen storage methods. Naturwissenschaften 2004, 91, 157–172. [Google Scholar] [CrossRef]

- Niaz, S.; Manzoor, T.; Pandith, A.H. Hydrogen storage: Materials, methods and perspectives. Renew. Sustain. Energy Rev. 2015, 50, 457–469. [Google Scholar] [CrossRef]

- Zacharia, R.; Rather, S.U. Review of solid state hydrogen storage methods adopting different kinds of novel materials. J. Nanomater. 2015, 2015, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Durbin, D.; Malardier-Jugroot, C. Review of hydrogen storage techniques for on board vehicle applications. Int. J. Hydrogen Energy 2013, 38, 14595–14617. [Google Scholar] [CrossRef]

- Pukazhselvan, D.; Kumar, V.; Singh, S. High capacity hydrogen storage: Basic aspects, new developments and milestones. Nano Energy 2012, 1, 566–589. [Google Scholar] [CrossRef]

- Jiang, H.-L.; Singh, S.K.; Yan, J.-M.; Zhang, X.-B.; Xu, Q. Liquid-phase chemical hydrogen storage: Catalytic hydrogen generation under ambient conditions. ChemSusChem 2010, 3, 541–549. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Liu, X.; Xu, P.; Liu, P.; Zhao, Y.; Yang, J. Development of high pressure gaseous hydrogen storage technologies. Int. J. Hydrogen Energy 2012, 37, 1048–1057. [Google Scholar] [CrossRef]

- Ley, M.B.; Jepsen, L.H.; Lee, Y.-S.; Cho, Y.W.; Von Colbe, J.M.B.; Dornheim, M.; Rokni, M.; Jensen, J.O.; Sloth, M.; Filinchuk, Y.; et al. Complex hydrides for hydrogen storage—New perspectives. Mater. Today 2014, 17, 122–128. [Google Scholar] [CrossRef] [Green Version]

- Mohtadi, R.; Remhof, A.; Jena, P. Complex metal borohydrides: Multifunctional materials for energy storage and conversion. J. Phys. Condens. Matter 2016, 28, 353001. [Google Scholar] [CrossRef]

- Li, H.-W.; Yan, Y.; Orimo, S.-I.; Zuettel, A.; Jensen, C.M. Recent progress in metal borohydrides for hydrogen storage. Energies 2011, 4, 185–214. [Google Scholar] [CrossRef]

- Yadav, M.; Xu, Q. Liquid-phase chemical hydrogen storage materials. Energy Environ. Sci. 2012, 5, 9698–9725. [Google Scholar] [CrossRef]

- Kong, V. Development of hydrogen storage for fuel cell generators. i: Hydrogen generation using hydrolysis hydrides. Int. J. Hydrog. Energy 1999, 24, 665–675. [Google Scholar] [CrossRef]

- Fakiolu, E. A review of hydrogen storage systems based on boron and its compounds. Int. J. Hydrog. Energy 2004, 29, 1371–1376. [Google Scholar] [CrossRef]

- Zhang, J.; Fisher, T.; Gore, J.; Hazra, D.; Ramachandran, P. Heat of reaction measurements of sodium borohydride alcoholysis and hydrolysis. Int. J. Hydrog. Energy 2006, 31, 2292–2298. [Google Scholar] [CrossRef]

- Demirci, U.B.; Akdim, O.; Andrieux, J.; Hannauer, J.; Chamoun, R.; Miele, P. Sodium borohydride hydrolysis as hydrogen generator: Issues, state of the art and applicability upstream from a fuel cell. Fuel Cells 2010, 10, 335–350. [Google Scholar] [CrossRef] [Green Version]

- Santos, D.; Sequeira, C. Sodium borohydride as a fuel for the future. Renew. Sustain. Energy Rev. 2011, 15, 3980–4001. [Google Scholar] [CrossRef]

- Rivarolo, M.; Improta, O.; Magistri, L.; Panizza, M.; Barbucci, A. Thermo-economic analysis of a hydrogen production system by sodium borohydride (NaBH4). Int. J. Hydrog. Energy 2018, 43, 1606–1614. [Google Scholar] [CrossRef]

- Hirscher, M.; Yartys, V.A.; Baricco, M.; Von Colbe, J.B.; Blanchard, D.; Bowman, R.C.; Broom, D.P.; Buckley, C.E.; Chang, F.; Chen, P.; et al. Materials for hydrogen-based energy storage—Past, recent progress and future outlook. J. Alloy. Compd. 2020, 827, 153548. [Google Scholar] [CrossRef]

- Tedds, S.; Walton, A.; Broom, D.P.; Book, D. Characterisation of porous hydrogen storage materials: Carbons, zeolites, MOFs and PIMs. Faraday Discuss. 2011, 151, 75–94. [Google Scholar] [CrossRef] [PubMed]

- Aakko-Saksa, P.T.; Cook, C.; Kiviaho, J.; Repo, T. Liquid organic hydrogen carriers for transportation and storing of renewable energy—Review and discussion. J. Power Sources 2018, 396, 803–823. [Google Scholar] [CrossRef]

- Yartys, V.; Lototskyy, M.; Akiba, E.; Albert, R.; Antonov, V.; Ares, J.; Baricco, M.; Bourgeois, N.; Buckley, C.; Von Colbe, J.B.; et al. Magnesium based materials for hydrogen based energy storage: Past, present and future. Int. J. Hydrog. Energy 2019, 44, 7809–7859. [Google Scholar] [CrossRef]

- Milanese, C.; Garroni, S.; Gennari, F.; Marini, A.; Klassen, T.; Dornheim, M.; Pistidda, C. Solid state hydrogen storage in alanates and alanate-based compounds: A Review. Metals 2018, 8, 567. [Google Scholar] [CrossRef] [Green Version]

- Puszkiel, J.; Garroni, S.; Milanese, C.; Gennari, F.; Klassen, T.; Dornheim, M.; Pistidda, C. Tetrahydroborates: Development and potential as hydrogen storage medium. Inorganics 2017, 5, 74. [Google Scholar] [CrossRef] [Green Version]

- Garroni, S.; Santoru, A.; Cao, H.; Dornheim, M.; Klassen, T.; Milanese, C.; Gennari, F.; Pistidda, C. Recent progress and new perspectives on metal amide and imide systems for solid-state hydrogen storage. Energies 2018, 11, 1027. [Google Scholar] [CrossRef] [Green Version]

- Paskevicius, M.; Jepsen, L.H.; Schouwink, P.; Černý, R.; Ravnsbæk, D.B.; Filinchuk, Y.; Dornheim, M.; Besenbacher, F.; Jensen, T.R. Metal borohydrides and derivatives—Synthesis, structure and properties. Chem. Soc. Rev. 2017, 46, 1565–1634. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Ma, H.; Lu, C.; Luo, H.; Wang, X.; Huang, X.; Lan, Z.; Guo, J. Aluminum hydride for solid-state hydrogen storage: Structure, synthesis, thermodynamics, kinetics, and regeneration. J. Energy Chem. 2021, 52, 428–440. [Google Scholar] [CrossRef]

- Demirci, U.B. Ammonia borane: An extensively studied, though not yet implemented, hydrogen carrier. Energies 2020, 13, 3071. [Google Scholar] [CrossRef]

- Demirci, U.B. About the technological readiness of the H2 generation by hydrolysis of B(−N)−H compounds. Energy Technol. 2018, 6, 470–486. [Google Scholar] [CrossRef] [Green Version]

- Kumar, D.; Muthukumar, K. An overview on activation of aluminium-water reaction for enhanced hydrogen production. J. Alloy. Compd. 2020, 835, 155189. [Google Scholar] [CrossRef]

- Xie, X.; Ni, C.; Wang, B.; Zhang, Y.; Zhao, X.; Liu, L.; Wang, B.; Du, W. Recent advances in hydrogen generation process via hydrolysis of Mg-based materials: A short review. J. Alloy. Compd. 2020, 816, 152634. [Google Scholar] [CrossRef]

- Tegel, M.; Schöne, S.; Kieback, B.; Röntzsch, L. An efficient hydrolysis of MgH2-based materials. Int. J. Hydrog. Energy 2017, 42, 2167–2176. [Google Scholar] [CrossRef]

- Agrawal, T.; Ajitkumar, R.; Prakash, R.; Nandan, G. Sodium silicide as a hydrogen source for portable energy devices: A review. Mater. Today Proc. 2018, 5, 3563–3570. [Google Scholar] [CrossRef]

- Demirci, U.B. The hydrogen cycle with the hydrolysis of sodium borohydride: A statistical approach for highlighting the scientific/technical issues to prioritize in the field. Int. J. Hydrog. Energy 2015, 40, 2673–2691. [Google Scholar] [CrossRef]

- Sahin, Ö.; Dolas, H.; Özdemir, M. The effect of various factors on the hydrogen generation by hydrolysis reaction of potassium borohydride. Int. J. Hydrog. Energy 2007, 32, 2330–2336. [Google Scholar] [CrossRef]

- Li, C.; Peng, P.; Zhou, D.; Wan, L. Research progress in LiBH4 for hydrogen storage: A review. Int. J. Hydrog. Energy 2011, 36, 14512–14526. [Google Scholar] [CrossRef]

- Moury, R.; Demirci, U.B. Hydrazine borane and hydrazinidoboranes as chemical hydrogen storage materials. Energies 2015, 8, 3118–3141. [Google Scholar] [CrossRef]

- Amendola, S. A safe, portable, hydrogen gas generator using aqueous borohydride solution and Ru catalyst. Int. J. Hydrog. Energy 2000, 25, 969–975. [Google Scholar] [CrossRef]

- Kojima, Y.; Suzuki, K.I.; Fukumoto, K.; Sasaki, M.; Yamamoto, T.; Kawai, Y.; Hayashi, H. Hydrogen generation using sodium borohydride solution and metal catalyst coated on metal oxide. Int. J. Hydrog. Energy 2002, 27, 1029–1034. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, Y.; Gore, J.P.; Mudawar, I.; Fisher, T.S. 1 kWe sodium borohydride hydrogen generation system. Part II: Reactor modeling. J. Power Sources 2007, 170, 150–159. [Google Scholar] [CrossRef]

- Richardson, B.S.; Birdwell, J.F.; Pin, F.G.; Jansen, J.F.; Lind, R.F. Sodium borohydride based hybrid power system. J. Power Sources 2005, 145, 21–29. [Google Scholar] [CrossRef]

- Liu, B.H.; Li, Z.P.; Suda, S. Solid sodium borohydride as a hydrogen source for fuel cells. J. Alloys Compd. 2009, 468, 493–498. [Google Scholar] [CrossRef]

- Oh, T.H.; Gang, B.G.; Kim, H.; Kwon, S. Sodium borohydride hydrogen generator using Co-P/Ni foam catalysts for 200 W proton exchange membrane fuel cell system. Energy 2015, 90, 1163–1170. [Google Scholar] [CrossRef]

- Gang, B.G.; Jung, W.; Kwon, S. Transient behavior of proton exchange membrane fuel cells over a cobalt-phosphorous/nickel foam catalyst with sodium borohydride. Int. J. Hydrog. Energy 2016, 41, 524–533. [Google Scholar] [CrossRef]

- Kim, T. Fully-integrated micro PEM fuel cell system with NaBH4 hydrogen generator. Int. J. Hydrog. Energy 2012, 37, 2440–2446. [Google Scholar] [CrossRef]

- Akdim, O.; Demirci, U.B.; Miele, P. More reactive cobalt chloride in the hydrolysis of sodium borohydride. Int. J. Hydrog. Energy 2009, 34, 9444–9449. [Google Scholar] [CrossRef]

- Nunes, H.X.; Ferreira, M.J.F.; Rangel, C.M.; Pinto, A.M.F.R. Hydrogen generation and storage by aqueous sodium borohydride (NaBH4) hydrolysis for small portable fuel cells (H2—PEMFC). Int. J. Hydrog. Energy 2016, 41, 15426–15432. [Google Scholar] [CrossRef]

- Sousa, T.; Fernandes, V.R.; Pinto, P.J.R.; Slavkov, Y.; Bosukov, L.; Rangel, C.M. A sodium borohydride hydrogen generation reactor for stationary applications: Experimental and reactor simulation studies. Chem. Eng. Sci. 2012, 84, 70–79. [Google Scholar] [CrossRef] [Green Version]

- Galli, S.; De Francesco, M.; Monteleone, G.; Oronzio, R.; Pozio, A. Development of a compact hydrogen generator from sodium borohydride. Int. J. Hydrog. Energy 2010, 35, 7344–7349. [Google Scholar] [CrossRef]

- Gislon, P.; Prosini, P.P. Devices for producing hydrogen via NaBH4 and LiH hydrolysis. Int. J. Hydrog. Energy 2011, 36, 240–246. [Google Scholar] [CrossRef]

- Hsueh, C.L.; Liu, C.H.; Chen, B.H.; Lee, M.S.; Chen, C.Y.; Lu, Y.W.; Tsau, F.; Ku, J.R. A novel design of solid-state NaBH4 composite as a hydrogen source for 2 W PEMFC applications. J. Power Sources 2011, 196, 3530–3538. [Google Scholar] [CrossRef]

- Simagina, V.I.; Ozerova, A.M.; Komova, O.V.; Odegova, G.V.; Kellerman, D.G.; Fursenko, R.V.; Odintsov, E.S.; Netskina, O.V. Cobalt boride catalysts for small-scale energy application. Catal. Today 2015, 242, 221–229. [Google Scholar] [CrossRef]

- Netskina, O.V.; Fursenko, R.V.; Komova, O.V.; Odintsov, E.S.; Simagina, V.I. NaBH4 generator integrated with energy conversion device based on hydrogen combustion. J. Power Sources 2015, 273, 278–281. [Google Scholar] [CrossRef]

- Komova, O.V.; Netskina, O.V.; Ozerova, A.M.; Odegova, G.V.; Arzumanov, S.S.; Simagina, V.I. The effect of storage-induced changes in ammonia borane on hydrogen release during its low-temperature thermolysis. Inorganics 2019, 7, 96. [Google Scholar] [CrossRef] [Green Version]

- Damjanović, L.; Bennici, S.; Auroux, A. A direct measurement of the heat evolved during the sodium and potassium borohydride catalytic hydrolysis. J. Power Sources 2010, 195, 3284–3292. [Google Scholar] [CrossRef]

- Marrero-Alfonso, E.Y.; Beaird, A.M.; Davis, T.A.; Matthews, M.A. Hydrogen generation from chemical hydrides. Ind. Eng. Chem. Res. 2009, 48, 3703–3712. [Google Scholar] [CrossRef]

- Marrero-Alfonso, E.Y.; Gray, J.R.; Davis, T.A.; Matthewa, M.A. Minimizing water utilization in hydrolysis of sodium borohydride: The role of sodium metaborate hydrates. Int. J. Hydrog. Energy 2007, 32, 4723–4730. [Google Scholar] [CrossRef]

- Minkina, V.G.; Shabunya, S.I.; Kalinin, V.I.; Martynenko, V.V.; Smirnova, A.L. Long-term stability of sodium borohydrides for hydrogen generation. Int. J. Hydrog. Energy 2008, 33, 5629–5635. [Google Scholar] [CrossRef]

- Minkina, V.G.; Shabunya, S.I.; Kalinin, V.I.; Martynenko, V.V.; Smirnova, A.L. Stability of alkaline aqueous solutions of sodium borohydride. Int. J. Hydrog. Energy 2012, 37, 3313–3318. [Google Scholar] [CrossRef]

- Schlesinger, H.I.; Brown, H.C.; Finholt, A.E.; Gilbreath, J.R.; Hoekstra, H.R.; Hyde, E.K. Sodium borohydride, its hydrolysis and its use as a reducing agent and in the generation of hydrogen. J. Am. Chem. Soc. 1953, 75, 215–219. [Google Scholar] [CrossRef]

- DOE Technical Targets for Onboard Hydrogen Storage for Light-Duty Vehicles | Department of Energy. Available online: https://www.energy.gov/eere/fuelcells/doe-technical-targets-onboard-hydrogen-storage-light-duty-vehicles (accessed on 6 June 2020).

- Akdim, O.; Demirci, U.; Miele, P. Acetic acid, a relatively green single-use catalyst for hydrogen generation from sodium borohydride. Int. J. Hydrog. Energy 2009, 34, 7231–7238. [Google Scholar] [CrossRef]

- Kim, H.J.; Shin, K.-J.; Kim, H.-J.; Han, M.; Kim, H.; Shul, Y.-G.; Jung, K.T. Hydrogen generation from aqueous acid-catalyzed hydrolysis of sodium borohydride. Int. J. Hydrog. Energy 2010, 35, 12239–12245. [Google Scholar] [CrossRef]

- Murugesan, S.; Subramanian, V.R. Effects of acid accelerators on hydrogen generation from solid sodium borohydride using small scale devices. J. Power Sources 2009, 187, 216–223. [Google Scholar] [CrossRef]

- Kwon, S.-M.; Kim, M.J.; Kang, S.; Kim, T. Development of a high-storage-density hydrogen generator using solid-state NaBH4 as a hydrogen source for unmanned aerial vehicles. Appl. Energy 2019, 251, 113331. [Google Scholar] [CrossRef]

- Lee, C.J.; Kim, T. Hydrogen supply system employing direct decomposition of solid-state NaBH4. Int. J. Hydrog. Energy 2015, 40, 2274–2282. [Google Scholar] [CrossRef]

- Xia, Z.; Shen, Y.; Wang, Y.; Poh, C.K.; Lin, J. Development of a portable hydrogen generator with differential pressure-driven control. Int. J. Hydrog. Energy 2014, 39, 16187–16194. [Google Scholar] [CrossRef]

- Shavi, R.; Jadhav, A.H.; Lee, K.; Gil Seo, J. Sulfonated nanolayers of H+-montmorillonite as an efficient acidic catalyst for hydrogen generation from hydrolysis of sodium borohydride. J. Nanosci. Nanotechnol. 2016, 16, 10980–10985. [Google Scholar] [CrossRef]

- Manna, J.; Roy, B.; Sharma, P. Efficient hydrogen generation from sodium borohydride hydrolysis using silica sulfuric acid catalyst. J. Power Sources 2015, 275, 727–733. [Google Scholar] [CrossRef]

- Chen, J.; Wang, C.; Wu, Y.; Fu, H.; Zheng, J.; Li, X. Hydrogen generation from reactions of hydrides with hydrated solids in the solid state. RSC Adv. 2016, 6, 36863–36869. [Google Scholar] [CrossRef]

- Wang, M.; Ouyang, L.; Liu, J.; Wang, H.; Zhu, M. Hydrogen generation from sodium borohydride hydrolysis accelerated by zinc chloride without catalyst: A kinetic study. J. Alloy. Compd. 2017, 717, 48–54. [Google Scholar] [CrossRef]

- Balbay, A.; Saka, C. Effect of phosphoric acid addition on the hydrogen production from hydrolysis of NaBH4 with Cu based catalyst. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 794–804. [Google Scholar] [CrossRef]

- Balbay, A.; Saka, C. Effect of phosphoric acid and acetic acid addition on the hydrogen evolution using Ni based catalyst prepared in ethanol, methanol, and water solvents. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 2442–2450. [Google Scholar] [CrossRef]

- Saka, C.; Balbay, A. Efficient hydrogen production with controlled hydrochloric acid addition using Ni-based catalyst synthesized in ethanol solvent. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 42, 1193–1205. [Google Scholar] [CrossRef]

- Abdul-Majeed, W.S.; Arslan, M.T.; Zimmerman, W.B. Application of acidic accelerator for production of pure hydrogen from NaBH4. Int. J. Ind. Chem. 2014, 5, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Duke, B.J.; Gilbert, J.R.; Read, I.A. Preparation and purification of diborane. J. Chem. Soc. 1964, 540–541. [Google Scholar]

- Netskina, O.V.; Filippov, T.N.; Komova, O.V.; Simagina, V.I. Hydrogen generation by both acidic and catalytic hydrolysis of sodium borohydride. Catal. Sustain. Energy 2018, 5, 41–48. [Google Scholar] [CrossRef]

- Carenco, S.; Portehault, D.; Boissière, C.; Mézailles, N.; Sanchez, C. Nanoscaled metal borides and phosphides: Recent developments and perspectives. Chem. Rev. 2013, 113, 7981–8065. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Li, Z. A review: Hydrogen generation from borohydride hydrolysis reaction. J. Power Sources 2009, 187, 527–534. [Google Scholar] [CrossRef]

- Muir, S.S.; Yao, X. Progress in sodium borohydride as a hydrogen storage material: Development of hydrolysis catalysts and reaction systems. Int. J. Hydrog. Energy 2011, 36, 5983–5997. [Google Scholar] [CrossRef]

- Brack, P.; Dann, S.E.; Wijayantha, K.G.U. Heterogeneous and homogenous catalysts for hydrogen generation by hydrolysis of aqueous sodium borohydride (NaBH4) solutions. Energy Sci. Eng. 2015, 3, 174–188. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.H.; Li, Z.P.; Suda, S. Thermal properties of alkaline sodium borohydride solutions. Thermochim. Acta 2008, 471, 103–105. [Google Scholar] [CrossRef]

- Demirci, U.B.; Miele, P. Reaction mechanisms of the hydrolysis of sodium borohydride: A discussion focusing on cobalt-based catalysts. Comptes Rendus Chim. 2014, 17, 707–716. [Google Scholar] [CrossRef]

- Retnamma, R.; Novais, A.Q.; Rangel, C. Kinetics of hydrolysis of sodium borohydride for hydrogen production in fuel cell applications: A review. Int. J. Hydrog. Energy 2011, 36, 9772–9790. [Google Scholar] [CrossRef]

- Patel, N.; Miotello, A. Progress in Co–B related catalyst for hydrogen production by hydrolysis of boron-hydrides: A review and the perspectives to substitute noble metals. Int. J. Hydrog. Energy 2015, 40, 1429–1464. [Google Scholar] [CrossRef]

- Holbrook, K.A.; Twist, P.J. Hydrolysis of the borohydride ion catalyzed by metal–boron alloys. J. Chem. Soc. A 1971, 890–894. [Google Scholar] [CrossRef]

- Guella, G.; Zanchetta, C.; Patton, B.; Miotello, A. New insights on the mechanism of palladium-catalyzed hydrolysis of sodium borohydride from 11B NMR measurements. J. Phys. Chem. B 2006, 110, 17024–17033. [Google Scholar] [CrossRef] [PubMed]

- Walter, J.C.; Zurawski, A.; Montgomery, D.; Thornburg, M.; Revankar, S. Sodium borohydride hydrolysis kinetics comparison for nickel, cobalt, and ruthenium boride catalysts. J. Power Sources 2008, 179, 335–339. [Google Scholar] [CrossRef]

- Penaalonso, R.; Sicurelli, A.; Callone, E.; Carturan, G.; Raj, R. A picoscale catalyst for hydrogen generation from NaBH4 for fuel cells. J. Power Sources 2007, 165, 315–323. [Google Scholar] [CrossRef]

- Sun, H.; Meng, J.; Jiao, L.; Cheng, F.; Chen, J. A review of transition-metal boride/phosphide-based materials for catalytic hydrogen generation from hydrolysis of boron-hydrides. Inorg. Chem. Front. 2018, 5, 760–772. [Google Scholar] [CrossRef]

- Andrieux, J.; Demirci, U.; Miele, P. Langmuir–Hinshelwood kinetic model to capture the cobalt nanoparticles-catalyzed hydrolysis of sodium borohydride over a wide temperature range. Catal. Today 2011, 170, 13–19. [Google Scholar] [CrossRef]

- Netskina, O.V.; Kochubey, D.I.; Prosvirin, I.P.; Kellerman, D.G.; Simagina, V.I.; Komova, O.V. Role of the electronic state of rhodium in sodium borohydride hydrolysis. J. Mol. Catal. A Chem. 2014, 390, 125–132. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, B.; Chan, S.H.; Tang, E.H.; Hong, L. Pt and Ru dispersed on LiCoO2 for hydrogen generation from sodium borohydride solutions. J. Power Sources 2008, 176, 306–311. [Google Scholar] [CrossRef]

- Özkar, S.; Zahmakıran, M. Hydrogen generation from hydrolysis of sodium borohydride using Ru(0) nanoclusters as catalyst. J. Alloys Compd. 2005, 404–406, 728–731. [Google Scholar] [CrossRef]

- Simagina, V.I.; Storozhenko, P.A.; Netskina, O.V.; Komova, O.V.; Odegova, G.V.; Larichev, Y.V.; Ishchenko, A.V.; Ozerova, A.M. Development of catalysts for hydrogen generation from hydride compounds. Catal. Today 2008, 138, 253–259. [Google Scholar] [CrossRef]

- Simagina, V.I.; Storozhenko, P.A.; Netskina, O.V.; Komova, O.V.; Odegova, G.V.; Samoilenko, T.Y.; Gentsler, A.G. Effect of the nature of the active component and support on the activity of catalysts for the hydrolysis of sodium borohydride. Kinet. Catal. 2007, 48, 168–175. [Google Scholar] [CrossRef]

- Rodrigues, T.S.; Zhao, M.; Yang, T.; Gilroy, K.D.; Da Silva, A.G.M.; Camargo, P.H.C.; Xia, Y. Synthesis of colloidal metal nanocrystals: A comprehensive review on the reductants. Chem. A Eur. J. 2018, 24, 16944–16963. [Google Scholar] [CrossRef]

- Ewers, T.D.; Sra, A.K.; Norris, B.C.; Cable, R.E.; Cheng, C.-H.; Shantz, D.F.; Schaak, R.E. Spontaneous hierarchical assembly of rhodium nanoparticles into spherical aggregates and superlattices. Chem. Mater. 2005, 17, 514–520. [Google Scholar] [CrossRef]

- Bozkurt, G.; Özer, A.; Yurtcan, A.B. Development of effective catalysts for hydrogen generation from sodium borohydride: Ru, Pt, Pd nanoparticles supported on Co3O4. Energy 2019, 180, 702–713. [Google Scholar] [CrossRef]

- Lee, D.-S.; Liu, T.-K. Characteristics of nanosized ruthenium metal by chemical reduction method. J. Non-Crystalline Solids 2002, 311, 323–327. [Google Scholar] [CrossRef]

- Tan, Y.; Yu, X. Chemical regeneration of hydrogen storage materials. RSC Adv. 2013, 3, 23879–23894. [Google Scholar] [CrossRef]

- Ouyang, L.; Zhong, H.; Li, H.-W.; Zhu, M. A Recycling hydrogen supply system of NaBH4 based on a facile regeneration process: A review. Inorganics 2018, 6, 10. [Google Scholar] [CrossRef] [Green Version]

- Ou, T.; Giuliano, A.; Panizza, M.; Barbucci, A.; Cerisola, G. Thermochemical recycling of hydrolyzed NaBH4. Part I: In-situ and ex-situ evaluations. Int. J. Hydrog. Energy 2013, 38, 15269–15274. [Google Scholar] [CrossRef]

- Ou, T.; Panizza, M.; Barbucci, A. Thermochemical recycling of hydrolyzed NaBH4. Part II: Systematical study of parameters dependencies. Int. J. Hydrog. Energy 2013, 38, 15940–15945. [Google Scholar] [CrossRef]

- Liu, B.; Li, Z.; Morigasaki, N.; Suda, S. Kinetic characteristics of sodium borohydride formation when sodium meta-borate reacts with magnesium and hydrogen. Int. J. Hydrog. Energy 2008, 33, 1323–1328. [Google Scholar] [CrossRef]

- Kojima, Y.; Haga, T. Recycling process of sodium metaborate to sodium borohydride. Int. J. Hydrog. Energy 2003, 28, 989–993. [Google Scholar] [CrossRef]

- Liu, B.H.; Li, Z.P.; Suda, S. Improving MgH2 formation kinetics and its effect on NaBH4 synthesis. J. Alloy. Compd. 2009, 474, 321–325. [Google Scholar] [CrossRef]

- Eom, K.; Cho, E.; Kim, M.; Oh, S.; Nam, S.-W.; Kwon, H. Thermochemical production of sodium borohydride from sodium metaborate in a scaled-up reactor. Int. J. Hydrog. Energy 2013, 38, 2804–2809. [Google Scholar] [CrossRef]

- Hsueh, C.-L.; Liu, C.-H.; Chen, B.-H.; Chen, C.-Y.; Kuo, Y.-C.; Hwang, K.-J.; Ku, J.-R. Regeneration of spent-NaBH4 back to NaBH4 by using high-energy ball milling. Int. J. Hydrog. Energy 2009, 34, 1717–1725. [Google Scholar] [CrossRef]

- Çakanyıldırım, Ç.; Gürü, M. Processing of NaBH4 from NaBO2 with MgH2 by ball milling and usage as hydrogen carrier. Renew. Energy 2010, 35, 1895–1899. [Google Scholar] [CrossRef]

- Lang, C.; Jia, Y.; Liu, J.; Wang, H.; Ouyang, L.; Zhu, M.; Yao, X. NaBH4 regeneration from NaBO2 by high-energy ball milling and its plausible mechanism. Int. J. Hydrog. Energy 2017, 42, 13127–13135. [Google Scholar] [CrossRef]

- Demirci, U.B.; Miele, P. Cobalt in NaBH4 hydrolysis. Phys. Chem. Chem. Phys. 2010, 12, 14651–14665. [Google Scholar] [CrossRef]

- Simagina, V.I.; Komova, O.V.; Netskina, O.V. Nanosized Cobalt Catalysts for Hydrogen Storage Systems Based on Ammonia Borane and Sodium Borohydride. In Metal Nanopowders; Gromov, A., Teipel, U., Eds.; Wiley: Hoboken, NJ, USA, 2014; pp. 199–226. [Google Scholar]

- Demirci, U.B.; Akdim, O.; Hannauer, J.; Chamoun, R.; Miele, P. Cobalt, a reactive metal in releasing hydrogen from sodium borohydride by hydrolysis: A short review and a research perspective. Sci. China Ser. B Chem. 2010, 53, 1870–1879. [Google Scholar] [CrossRef]

- Dragieva, I.; Mehandjiev, D.; Lefterova, E.; Stoycheva, M.; Stoynov, Z. Mechanism of borohydride reduction process and properties of obtained nanosized ferromagnetic particles. J. Magn. Magn. Mater. 1995, 140, 455–456. [Google Scholar] [CrossRef]

- Lefterova, E.; Dragieva, I.; Tchanev, V.; Mehandjiev, D.; Mikhov, M. Crystallographic phases in nanosized ferromagnetic particles obtained by two different methods. J. Magn. Magn. Mater. 1995, 140, 457–458. [Google Scholar] [CrossRef]

- Chen, Y. Chemical preparation and characterization of metal–metalloid ultrafine amorphous alloy particles. Catal. Today 1998, 44, 3–16. [Google Scholar] [CrossRef]

- Akdim, O.; Demirci, U.; Muller, D.; Miele, P. Cobalt (II) salts, performing materials for generating hydrogen from sodium borohydride. Int. J. Hydrog. Energy 2009, 34, 2631–2637. [Google Scholar] [CrossRef]

- Cavaliere, S.; Hannauer, J.; Demirci, U.B.; Akdim, O.; Miele, P. Ex situ characterization of N2H4-, NaBH4- and NH3BH3-reduced cobalt catalysts used in NaBH4 hydrolysis. Catal. Today 2011, 170, 3–12. [Google Scholar] [CrossRef]

- Liu, B.H.; Li, Z.P.; Suda, S. Nickel- and cobalt-based catalysts for hydrogen generation by hydrolysis of borohydride. J. Alloy. Compd. 2006, 415, 288–293. [Google Scholar] [CrossRef]

- Wu, C.; Bai, Y.; Wu, F.; Yi, B.-L.; Zhang, H.-M. Highly active cobalt-based catalysts in situ prepared from CoX2 (X=Cl−, NO3−) and used for promoting hydrogen generation from NaBH4 solution. Int. J. Hydrog. Energy 2010, 35, 2675–2679. [Google Scholar] [CrossRef]

- Ozerova, A.M.; Bulavchenko, O.A.; Komova, O.V.; Netskina, O.V.; Zaikovskii, V.I.; Odegova, G.V.; Simagina, V.I. Cobalt boride catalysts for hydrogen storage systems based on NH3BH3 and NaBH4. Kinet. Catal. 2012, 53, 511–520. [Google Scholar] [CrossRef]

- Yan, J.-M.; Zhang, X.-B.; Shioyama, H.; Xu, Q. Room temperature hydrolytic dehydrogenation of ammonia borane catalyzed by Co nanoparticles. J. Power Sources 2010, 195, 1091–1094. [Google Scholar] [CrossRef]

- Jeong, S.; Cho, E.; Nam, S.; Oh, I.; Jung, U.; Kim, S. Effect of preparation method on Co–B catalytic activity for hydrogen generation from alkali NaBH4 solution. Int. J. Hydrog. Energy 2007, 32, 1749–1754. [Google Scholar] [CrossRef]

- Ingersoll, J.; Mani, N.; Thenmozhiyal, J.; Muthaiah, A. Catalytic hydrolysis of sodium borohydride by a novel nickel–cobalt–boride catalyst. J. Power Sources 2007, 173, 450–457. [Google Scholar] [CrossRef]

- Liu, B.H.; Li, Q. A highly active Co-B catalyst for hydrogen generation from sodium borohydride hydrolysis. Int. J. Hydrog. Energy 2008, 33, 7385–7391. [Google Scholar] [CrossRef]

- Shen, X.; Dai, M.; Gao, M.; Zhao, B.; Ding, W. Solvent effects in the synthesis of CoB catalysts on hydrogen generation from hydrolysis of sodium borohydride. Chin. J. Catal. 2013, 34, 979–985. [Google Scholar] [CrossRef]

- Glavee, G.N.; Klabunde, K.J.; Sorensen, C.M.; Hadjipanayis, G.C. Borohydride reduction of cobalt ions in water. Chemistry leading to nanoscale metal, boride, or borate particles. Langmuir 1993, 9, 162–169. [Google Scholar] [CrossRef]

- Glavee, G.N.; Klabunde, K.J.; Sorensen, C.M.; Hadjapanayis, G.C. Borohydride reductions of metal ions. A new understanding of the chemistry leading to nanoscale particles of metals, borides, and metal borates. Langmuir 1992, 8, 771–773. [Google Scholar] [CrossRef]

- Netskina, O.V.; Komova, O.V.; Simagina, V.I.; Odegova, G.V.; Prosvirin, I.P.; Bulavchenko, O.A. Aqueous-alkaline NaBH4 solution: The influence of storage duration of solutions on reduction and activity of cobalt catalysts. Renew. Energy 2016, 99, 1073–1081. [Google Scholar] [CrossRef]

- Simagina, V.I.; Komova, O.V.; Ozerova, A.M.; Netskina, O.V.; Odegova, G.V.; Kellerman, D.G.; Bulavchenko, O.A.; Ishchenko, A.V. Cobalt oxide catalyst for hydrolysis of sodium borohydride and ammonia borane. Appl. Catal. A Gen. 2011, 394, 86–92. [Google Scholar] [CrossRef]

- Krishnan, P.; Advani, S.G.; Prasad, A.K. Cobalt oxides as Co2B catalyst precursors for the hydrolysis of sodium borohydride solutions to generate hydrogen for PEM fuel cells. Int. J. Hydrog. Energy 2008, 33, 7095–7102. [Google Scholar] [CrossRef]

- Netskina, O.V.; Komova, O.V.; Mukha, S.A.; Simagina, V.I. Aqueous-alkaline NaBH4 solutions: The influence of hydride decomposition on catalytic properties of Co3O4. Catal. Commun. 2016, 85, 9–12. [Google Scholar] [CrossRef]

- Demirci, U.B.; Miele, P. Cobalt-based catalysts for the hydrolysis of NaBH4 and NH3BH3. Phys. Chem. Chem. Phys. 2014, 16, 6872–6885. [Google Scholar] [CrossRef] [PubMed]

- Petit, C.; Pileni, M. Nanosize cobalt boride particles: Control of the size and properties. J. Magn. Magn. Mater. 1997, 166, 82–90. [Google Scholar] [CrossRef]

- Saida, J.; Inoue, A.; Masumoto, T. The effect of reaction condition on composition and properties of ultrafine amorphous powders in (Fe, Co, Ni)-B systems prepared by chemical reduction. Met. Mater. Trans. A 1991, 22, 2125–2132. [Google Scholar] [CrossRef]

- Lu, J.; Dreisinger, D.; Cooper, W. Cobalt precipitation by reduction with sodium borohydride. Hydrometall. 1997, 45, 305–322. [Google Scholar] [CrossRef] [Green Version]

- Garron, A.; Swierczynski, D.; Bennici, S.; Auroux, A. New insights into the mechanism of H2 generation through NaBH4 hydrolysis on Co-based nanocatalysts studied by differential reaction calorimetry. Int. J. Hydrog. Energy 2009, 34, 1185–1199. [Google Scholar] [CrossRef]

- Corrias, A.; Ennas, G.; Musinu, A.; Marongiu, G.; Paschina, G. Amorphous transition metal-boron ultrafine particles prepared by chemical methods. Chem. Mater. 1993, 5, 1722–1726. [Google Scholar] [CrossRef]

- Petit, C.; Pileni, M.P.A. Cobalt nanosized particles organized in a 2D superlattice: Synthesis, characterization, and magnetic properties. J. Phys. Chem. B 1999, 103, 1805–1810. [Google Scholar] [CrossRef]

- Metin, O.; Özkar, S. Hydrogen generation from the hydrolysis of ammonia-borane and sodium borohydride using water-soluble polymer-stabilized cobalt(0) nanoclusters catalyst. Energy Fuels 2009, 23, 3517–3526. [Google Scholar] [CrossRef]

- Patel, N.; Guella, G.; Kale, A.; Miotello, A.; Patton, B.; Zanchetta, C.; Mirenghi, L.; Rotolo, P. Thin films of Co–B prepared by pulsed laser deposition as efficient catalysts in hydrogen producing reactions. Appl. Catal. A Gen. 2007, 323, 18–24. [Google Scholar] [CrossRef]

- Dávila-Ibáñez, A.B.; Legido-Soto, J.L.; Rivas, J.; Salgueirino, V. Amorphous tunable-size Co–B magnetic nanoparticles from the cobalt-catalyzed NaBH4 hydrolysis. Phys. Chem. Chem. Phys. 2011, 13, 20146–20154. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Ge, S. Facile synthesis of a Co–B nanoparticle catalyst for efficient hydrogen generation via borohydride hydrolysis. Catal. Commun. 2011, 13, 40–43. [Google Scholar] [CrossRef]

- Wu, C.; Wu, F.; Bai, Y.; Yi, B.; Zhang, H. Cobalt boride catalysts for hydrogen generation from alkaline NaBH4 solution. Mater. Lett. 2005, 59, 1748–1751. [Google Scholar] [CrossRef]

- Netskina, O.V.; Kochubey, D.I.; Prosvirin, I.P.; Malykhin, S.E.; Komova, O.V.; Kanazhevskiy, V.V.; Chukalkin, Y.G.; Bobrovskii, V.I.; Kellerman, D.G.; Ishchenko, A.V.; et al. Cobalt-boron catalyst for NaBH4 hydrolysis: The state of the active component forming from cobalt chloride in a reaction medium. Mol. Catal. 2017, 441, 100–108. [Google Scholar] [CrossRef]

- Netskina, O.V.; Kellerman, D.G.; Ishchenko, A.V.; Komova, O.V.; Simagina, V.I. Amorphous ferromagnetic cobalt-boron composition reduced by sodium borohydride: Phase transformation at heat-treatment and its influence on the catalytic properties. Colloids Surf A Physicochem. Eng. Asp. 2018, 537, 485–494. [Google Scholar] [CrossRef]

- Arzac, G.M.; Rojas, T.C.; Fernández, A. Boron compounds as stabilizers of a complex microstructure in a Co-B-based catalyst for NaBH4 hydrolysis. ChemCatChem 2011, 3, 1305–1313. [Google Scholar] [CrossRef] [Green Version]

- Ozerova, A.M.; Simagina, V.I.; Komova, O.V.; Netskina, O.V.; Odegova, G.V.; Bulavchenko, O.A.; Rudina, N.A. Cobalt borate catalysts for hydrogen production via hydrolysis of sodium borohydride. J. Alloy. Compd. 2012, 513, 266–272. [Google Scholar] [CrossRef]

- Xue, T.; Lee, J.-M. Capacitive behavior of mesoporous Co(OH)2 nanowires. J. Power Sources 2014, 245, 194–202. [Google Scholar] [CrossRef]

- Mavel, G.; Escard, J.; Costa, P.; Castaing, J. ESCA surface study of metal borides. Surf. Sci. 1973, 35, 109–116. [Google Scholar] [CrossRef]

- Geng, J.; Jefferson, D.A.; Johnson, B.F.G. Exploring the structural complexities of metal-metalloid nanoparticles: The case of NiB as catalyst. Chem. A Eur. J. 2008, 15, 1134–1143. [Google Scholar] [CrossRef] [PubMed]

- Yiping, L.; Hadjipanayis, G.; Sorensen, C.; Klabunde, K. Magnetic and structural properties of ultrafine Co-B particles. J. Magn. Magn. Mater. 1989, 79, 321–326. [Google Scholar] [CrossRef]

- Hasegawa, R.; Ray, R. Magnetization of glassy Co-B alloys. J. Appl. Phys. 1979, 50, 1586–1588. [Google Scholar] [CrossRef]

- Zhurakovskii, E.A.; Shashkina, T.B.; Kotlyar, V.I. X-ray absorption spectra of cobalt in ferromagnetic borides. Russ. Phys. J. 1970, 13, 14–17. [Google Scholar] [CrossRef]

- Mizutani, U.; Hasegawa, M.; Fukamichi, K.; Hattori, Y.; Yamada, Y.; Tanaka, H.; Takayama, S. Magnetic, electronic, and electron-transport properties of amorphous (Co0.85B0.15)100−xXx(X = B, Al, Si, and V) alloys. Phys. Rev. B 1993, 47, 2678–2688. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, H.; Takayama, S.; Hasegawa, M.; Fukunaga, T.; Mizutani, U.; Fujita, A.; Fukamichi, K. Electronic structure and magnetism of amorphousCo1−xBx alloys. Phys. Rev. B 1993, 47, 2671–2677. [Google Scholar] [CrossRef] [PubMed]

- Komova, O.V.; Simagina, V.I.; Netskina, O.V.; Kellerman, D.G.; Ishchenko, A.V.; Rudina, N.A. LiCoO2-based catalysts for generation of hydrogen gas from sodium borohydride solutions. Catal. Today 2008, 138, 260–265. [Google Scholar] [CrossRef]

- Maybury, P.C.; Mitchell, R.W.; Hawthorne, M.F. Hydrogen adducts of cobalt and nickel boride. J. Chem. Soc. Chem. Commun. 1974, 534–535. [Google Scholar] [CrossRef]

- Netskina, O.V.; Ozerova, A.M.; Komova, O.V.; Kochubey, D.I.; Kanazhevskiy, V.V.; Ishchenko, A.V.; Simagina, V.I. The Effect of heat-treatment temperature of cobalt–boron catalysts on their activity in sodium borohydride hydrolysis. Top. Catal. 2016, 59, 1431–1437. [Google Scholar] [CrossRef]

- Beachell, H.C.; Haugh, J.F. The pyrolysis of decaborane. J. Am. Chem. Soc. 1958, 80, 2939–2942. [Google Scholar] [CrossRef]

- Paladini, M.; Godinho, V.; Arzac, G.M.; Haro, M.D.C.J.D.; Beltrán, A.M.; Fernández-Camacho, A. Tailor-made preparation of Co–C, Co–B, and Co catalytic thin films using magnetron sputtering: Insights into structure–composition and activation effects for catalyzed NaBH4 hydrolysis. RSC Adv. 2016, 6, 108611–108620. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, T.; Bai, S.; Qi, K.; Cao, Z.; Zhang, K.; Wu, S.; Wang, D. Catalytic hydrolysis of sodium borohydride via nanostructured cobalt–boron catalysts. Int. J. Hydrog. Energy 2016, 41, 276–284. [Google Scholar] [CrossRef]

- Kadrekar, R.; Patel, N.; Arya, A. Understanding the role of boron and stoichiometric ratio in the catalytic performance of amorphous Co-B catalyst. Appl. Surf. Sci. 2020, 518, 146199. [Google Scholar] [CrossRef]

- Garron, A.; Bennici, S.; Auroux, A. In situ generated catalysts for NaBH4 hydrolysis studied by liquid-phase calorimetry: Influence of the nature of the metal. Appl. Catal. A Gen. 2010, 378, 90–95. [Google Scholar] [CrossRef]

- Vernekar, A.A.; Bugde, S.T.; Tilve, S. Sustainable hydrogen production by catalytic hydrolysis of alkaline sodium borohydride solution using recyclable Co–Co2B and Ni–Ni3B nanocomposites. Int. J. Hydrog. Energy 2012, 37, 327–334. [Google Scholar] [CrossRef]

- Tong, D.G.; Chu, W.; Wu, P.; Zhang, L. Honeycomb-like Co–B amorphous alloy catalysts assembled by a solution plasma process show enhanced catalytic hydrolysis activity for hydrogen generation. RSC Adv. 2012, 2, 2369–2376. [Google Scholar] [CrossRef]

- Sahiner, N.; Ozay, O.; Inger, E.; Aktas, N. Superabsorbent hydrogels for cobalt nanoparticle synthesis and hydrogen production from hydrolysis of sodium boron hydride. Appl. Catal. B Environ. 2011, 102, 201–206. [Google Scholar] [CrossRef]

- Tian, H.; Guo, Q.; Xu, D. Hydrogen generation from catalytic hydrolysis of alkaline sodium borohydride solution using attapulgite clay-supported Co-B catalyst. J. Power Sources 2010, 195, 2136–2142. [Google Scholar] [CrossRef]

- Akdim, O.; Demirci, U.B.; Miele, P. Deactivation and reactivation of cobalt in hydrolysis of sodium borohydride. Int. J. Hydrog. Energy 2011, 36, 13669–13675. [Google Scholar] [CrossRef]

- Liang, J.; Li, Y.; Huang, Y.; Yang, J.; Tang, H.; Wei, Z.; Shen, P.K. Sodium borohydride hydrolysis on highly efficient Co–B/Pd catalysts. Int. J. Hydrog. Energy 2008, 33, 4048–4054. [Google Scholar] [CrossRef]

- Krishnan, P.; Advani, S.G.; Prasad, A.K. Thin-film CoB catalyst templates for the hydrolysis of NaBH4 solution for hydrogen generation. Appl. Catal. B Environ. 2009, 86, 137–144. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, K.-T.; Kang, Y.-M.; Kim, H.-S.; Song, M.-S.; Lee, Y.-J.; Lee, P.S.; Lee, J.-Y. Study on degradation of filamentary Ni catalyst on hydrolysis of sodium borohydride. J. Alloys Compd. 2004, 379, 222–227. [Google Scholar] [CrossRef]

- Arzac, G.M.; Hufschmidt, D.; Jiménez De Haro, M.C.; Fernández, A.; Sarmiento, B.; Jiménez, M.A.; Jiménez, M.M. Deactivation, reactivation and memory effect on Co–B catalyst for sodium borohydride hydrolysis operating in high conversion conditions. Int. J. Hydrog. Energy 2012, 37, 14373–14381. [Google Scholar] [CrossRef] [Green Version]

- Dai, H.-B.; Liang, Y.; Wang, P.; Cheng, H.M. Amorphous cobalt–boron/nickel foam as an effective catalyst for hydrogen generation from alkaline sodium borohydride solution. J. Power Sources 2008, 177, 17–23. [Google Scholar] [CrossRef]

- Lee, J.; Kong, K.Y.; Jung, C.R.; Cho, E.; Yoon, S.P.; Han, J.; Lee, T.G.; Nam, S.W. A structured Co-B catalyst for hydrogen extraction from NaBH4 solution. Catal. Today 2007, 120, 305–310. [Google Scholar] [CrossRef]

- Paladini, M.; Arzac, G.M.; Godinho, V.; De Haro, M.C.J.; Fernández, A. Supported Co catalysts prepared as thin films by magnetron sputtering for sodium borohydride and ammonia borane hydrolysis. Appl. Catal. B Environ. 2014, 158–159, 400–409. [Google Scholar] [CrossRef] [Green Version]

- Glavee, G.N.; Klabunde, K.J.; Sorensen, C.M.; Hadjipanayis, G.C. Sodium borohydride reduction of cobalt ions in nonaqueous media. Formation of ultrafine particles (nanoscale) of cobalt metal. Inorg. Chem. 1993, 32, 474–477. [Google Scholar] [CrossRef]

- Netskina, O.V.; Ozerova, A.M.; Komova, O.V.; Odegova, G.V.; Simagina, V.I. Hydrogen storage systems based on solid-state NaBH4/CoxB composite: Influence of catalyst properties on hydrogen generation rate. Catal. Today 2015, 245, 86–92. [Google Scholar] [CrossRef]

- Liu, C.-H.; Kuo, Y.-C.; Chen, B.-H.; Hsueh, C.-L.; Hwang, K.-J.; Ku, J.-R.; Tsau, F.; Jeng, M.-S. Synthesis of solid-state NaBH4/Co-based catalyst composite for hydrogen storage through a high-energy ball-milling process. Int. J. Hydrog. Energy 2010, 35, 4027–4040. [Google Scholar] [CrossRef]

- Delmas, J.; Laversenne, L.; Rougeaux, I.; Capron, P.; Garron, A.; Bennici, S.; Swierczynski, D.; Auroux, A. Improved hydrogen storage capacity through hydrolysis of solid NaBH4 catalyzed with cobalt boride. Int. J. Hydrog. Energy 2011, 36, 2145–2153. [Google Scholar] [CrossRef]

- Demirci, U.B. Impact of H.I. Schlesinger’s discoveries upon the course of modern chemistry on B−(N−)H hydrogen carriers. Int. J. Hydrog. Energy 2017, 42, 21048–21062. [Google Scholar] [CrossRef]

- Netskina, O.V.; Tayban, E.S.; Prosvirin, I.P.; Komova, O.V.; Simagina, V.I. Hydrogen storage systems based on solid-state NaBH4/Co composite: Effect of catalyst precursor on hydrogen generation rate. Renew. Energy 2020, 151, 278–285. [Google Scholar] [CrossRef]

- Netskina, O.V.; Tayban, E.S.; Ozerova, A.M.; Komova, O.V.; Simagina, V.I. Solid-state NaBH4/Co composite as hydrogen storage material: Effect of the pressing pressure on hydrogen generation rate. Energies 2019, 12, 1184. [Google Scholar] [CrossRef] [Green Version]

- Netskina, O.V.; Pochtar, A.A.; Komova, O.V.; Simagina, V.I. Solid-state NaBH4 composites as hydrogen generation material: Effect of thermal treatment of a catalyst precursor on the hydrogen generation rate. Catal. 2020, 10, 201. [Google Scholar] [CrossRef] [Green Version]

- Netskina, O.V.; Komova, O.V.; Prosvirin, I.P.; Pochtar, A.A.; Ozerova, A.M.; Simagina, V.I. Solid-state hydrogen-generating composites based on sodium borohydride: Effect of the heat treatment of boron–cobalt catalysts on the hydrogen generation rate. Russ. J. Appl. Chem. 2017, 90, 1666–1673. [Google Scholar] [CrossRef]

- Netskina, O.V.; Komova, O.V.; Simagina, V.I. Developing effective cobalt catalysts for hydrogen-generating solid-state NaBH4 composite. Catal. Ind. 2018, 10, 166–172. [Google Scholar] [CrossRef]

- Wang, Y.; Diaz, D.F.R.; Chen, K.S.; Wang, Z.; Adroher, X.C. Materials, technological status, and fundamentals of PEM fuel cells—A review. Mater. Today 2020, 32, 178–203. [Google Scholar] [CrossRef]

- Arzac, G.; Fernandez, A.; Justo, A.; Sarmiento, B.; Jimenez, M.M. Optimized hydrogen generation in a semicontinuous sodium borohydride hydrolysis reactor for a 60W-scale fuel cell stack. J. Power Sources 2011, 196, 4388–4395. [Google Scholar] [CrossRef]

- Lee, J.; Kim, T. Micro PEM fuel cell system with NaBH4 hydrogen generator. Sens. Actuators A Phys. 2012, 177, 54–59. [Google Scholar] [CrossRef]

- Kim, T. NaBH4 (sodium borohydride) hydrogen generator with a volume-exchange fuel tank for small unmanned aerial vehicles powered by a PEM (proton exchange membrane) fuel cell. Energy 2014, 69, 721–727. [Google Scholar] [CrossRef]

- Kim, J.; Kim, T. Compact PEM fuel cell system combined with all-in-one hydrogen generator using chemical hydride as a hydrogen source. Appl. Energy 2015, 160, 945–953. [Google Scholar] [CrossRef]

- Okumus, E.; San, F.G.B.; Okur, O.; Turk, B.E.; Cengelci, E.; Kilic, M.; Karadag, C.; Cavdar, M.; Turkmen, A.; Yazici, M.S. Development of boron-based hydrogen and fuel cell system for small unmanned aerial vehicle. Int. J. Hydrog. Energy 2017, 42, 2691–2697. [Google Scholar] [CrossRef]

- Oronzio, R.; Monteleone, G.; Pozio, A.; De Francesco, M.; Galli, S. New reactor design for catalytic sodium borohydride hydrolysis. Int. J. Hydrog. Energy 2009, 34, 4555–4560. [Google Scholar] [CrossRef]

- Li, H.-Y.; Chen, Y.-T.; Lu, M.-T.; Lai, Y.-H.; Yang, J.-T. Design and testing of a novel catalytic reactor to generate hydrogen. Int. J. Hydrog. Energy 2014, 39, 11945–11954. [Google Scholar] [CrossRef]

- Kim, H.; Oh, T.H.; Kwon, S. Simple catalyst bed sizing of a NaBH4 hydrogen generator with fast startup for small unmanned aerial vehicles. Int. J. Hydrog. Energy 2016, 41, 1018–1026. [Google Scholar] [CrossRef]

- Jung, E.S.; Kim, H.; Kwon, S.; Oh, T.H. Fuel cell system with sodium borohydride hydrogen generator for small unmanned aerial vehicles. Int. J. Green Energy 2018, 15, 385–392. [Google Scholar] [CrossRef]

- Gang, B.G.; Kwon, S. All-in-one portable electric power plant using proton exchange membrane fuel cells for mobile applications. Int. J. Hydrog. Energy 2018, 43, 6331–6339. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Lin, J.-C. Reactant feeding strategy analysis of sodium borohydride hydrolysis reaction systems for instantaneous hydrogen generation. Energies 2020, 13, 4674. [Google Scholar] [CrossRef]

- Kim, T. Hydrogen production from solid sodium borohydride with hydrogen peroxide decomposition reaction. Int. J. Hydrog. Energy 2010, 35, 12870–12877. [Google Scholar] [CrossRef]

- Li, S.-C.; Wang, F.-C. The development of a sodium borohydride hydrogen generation system for proton exchange membrane fuel cell. Int. J. Hydrog. Energy 2016, 41, 3038–3051. [Google Scholar] [CrossRef]

- Kim, K.; Kim, T.; Lee, K.; Kwon, S. Fuel cell system with sodium borohydride as hydrogen source for unmanned aerial vehicles. J. Power Sources 2011, 196, 9069–9075. [Google Scholar] [CrossRef]

- Kim, T.; Kwon, S. Design and development of a fuel cell-powered small unmanned aircraft. Int. J. Hydrog. Energy 2012, 37, 615–622. [Google Scholar] [CrossRef]

- Shang, Y.; Chen, R. Hydrogen storage via the hydrolysis of NaBH4 basic solution: Optimization of NaBH4 concentration. Energy Fuels 2006, 20, 2142–2148. [Google Scholar] [CrossRef]

- Shabunya, S.I.; Nesteruk, A.A. Hydrolysis of aqueous-alkaline solutions of sodium borohydride. Asymptotics of low concentrations of the alkali. J. Eng. Phys. Thermophys. 2012, 85, 73–78. [Google Scholar] [CrossRef]

- Patel, N.; Fernandes, R.; Miotello, A. Hydrogen generation by hydrolysis of NaBH4 with efficient Co–P–B catalyst: A kinetic study. J. Power Sources 2009, 188, 411–420. [Google Scholar] [CrossRef]

- Petit, E.; Miele, P.; Demirci, U.B. By-product carrying humidified hydrogen: An underestimated issue in the hydrolysis of sodium borohydride. ChemSusChem 2016, 9, 1777–1780. [Google Scholar] [CrossRef] [PubMed]

| Material | Reaction | ∆H, kJ/mol H2 | Calc. GHSC, wt.% | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Al [31] | 2Al + 6H2O → 2Al(OH)3 + 3H2 | −280 (at ~50–100 °C) | 3.7 | + low cost, abundance on the earth + light weight + environmental-friendly products, may be raw materials of ceramics + improved and tunable properties at additions of dopants (salts, metals, oxides, hydrides, carbon materials, etc.), alloying with metals, reducing the particle size (BM), etc. | − surface passivation of native oxide layer (more relevant to Al) − the hydrolysis products deposition on metal particles surface (more relevant to Mg) − heat and mass transfer problem − unpromising regeneration process of solid hydrolysis products |

| Mg [32] | Mg + 2H2O → Mg(OH)2 + H2 | −354 | 3.3 | ||

| MgH2 [33] | MgH2 + 2H2O → Mg(OH)2 + 2H2 | −160 | 6.4 | + low cost + can be industrially produced with a high energy efficiency + improved and tunable properties at addition of Brønsted acids, salts, metal catalysts, and alloying with rare earth elements, BM, etc. | − unstable in the presence of moisture − reacts with water very slowly and incompletely − formation of dense passivation layers of Mg(OH)2 − complicated regeneration process Mg(OH)2 to Mg (by reactive hydrogen plasma process) |

| NaSi [34] | 2NaSi + 5H2O → Na2Si2O5 + 5H2 | −35 | 5.2 | + commercial availability + no activation procedure is required + by-product is of market value | − unstable in the presence of moisture − use of liquid hydrocarbons for stabilization − excess water is required − problem with design of the reactor to control the rate of gas evolution |

| NaBH4 [17,18,35] | NaBH4 + 2H2O → NaBO2 + 4H2 | −60 | 10.8 | + commercial availability + high GHSC + safe and controllable on-board H2 generation, commercialized generators + producing pure H2 at ambient temperatures without energy supply + inflammable + high solubility (14.5 mol·L−1): 30 wt.% NaBH4 solution contains 6.7 wt.% H2 + improved and tunable properties at addition of catalysts or acids + concentrated water solutions or solid pellets with catalysts may be used as H2 sources | − instability of aqueous solutions, stabilization with NaOH is required − deactivation of catalysts − hydrolysis products deposition on the catalyst surface and reactor walls in limited water conditions − off-board and high-cost regeneration of solid hydrolysis products − heat and mass transport problem at design of reactors for NaBH4 interaction with stoichiometric amount of water |

| KBH4 [36] | KBH4 + 2H2O → KBO2 + 4H2 | −55 | 8.9 | + improved properties at addition of catalysts | − instability of aqueous solutions − low solubility (3.5 mol·L−1): low GHSC |

| LiBH4 [37] | LiBH4 + 2H2O → LiBO2 + 4H2 | −90 | 13.8 | + high GHSC + improved properties at addition of catalysts, dopants (MWCNTs 1, NH3BH3), use of double-solvents, etc. | − preparation from NaBH4 − flammable and unstable in the presence of moisture, instability of water solutions − high exothermic hydrolysis process − incomplete hydrolysis − hydrolysis products deposition on the catalyst surface and reactor walls in limited water conditions |

| NH3BH3 [29] | NH3BH3 + 2H2O → NH4BO2 + 3H2 | <−50 | 9 | + high stability of aqueous solution + high solubility (11.4 mol·L−1) + improved and tunable properties at addition of catalysts | − high cost − the presence of NH3 impurity in the H2 stream − deactivation of catalysts − hydrolysis products deposition on the catalyst surface and reactor walls in limited water conditions − off-board and high-cost regeneration of solid hydrolysis products |

| N2H4BH3 [38] | N2H4BH3 + 3H2O → N2H4 + B(OH)3 + 3H2 N2H4BH3 + 3H2O → N2 + B(OH)3 + 5H2 | 81.5 39 | 6 10 | + possibility of catalytic dehydrogenation of the N2H4 moiety + high theoretical GHSC + stability of water solutions at pH ≥ 7/5 + improved properties at addition of catalysts | − high cost − search for effective, low-cost, and stable catalysts for the hydrolytic dehydrogenation of both the BH3 moiety and the N2H4 moiety − low solubility (1.3 mol·L−1) − lack of knowledge of the characteristics of the process in limited water conditions, providing GHSC |

| Catalyst | Test Conditions | The Number of Cycles or Test Duration | % of Initial Activity | Ref. |

|---|---|---|---|---|

| Co-B obtained in situ from CoCl2 | 2% NaBH4, 4% NaOH, 30 °C | 3 | 89 | [166] |

| 19% NaBH4, 4% NaOH, 30 °C | 3 | 89 | ||

| Co-B obtained in situ from LiCoO2 | 0.5% NaBH4, 40 °C | 6 | 100 | [159] |

| 14 | 40 | |||

| Co-Co2B obtained by reduction of CoCl2 in a methanol solution of NH3BH3 | 0.76% NaBH4, 0,1% NaOH, 30 °C | 12 | 100 | [167] |

| Honeycomb Co-B obtained by plasma treatment of Co(NH3)62+ + KBH4 + triethanolamine solution | 2% NaBH4, 7% NaOH, 25 °C | 30 h | 100 | [168] |

| then | deactivation | |||

| Co-B obtained in situ from Co3O4 | 10% NaBH4, 5% NaOH, 25 °C | 3 h | ≈70 | [133] |

| 20 h | ≈70 | |||

| Co-B in hydrogel obtained by impregnation with CoCl2 solution and reduced by NaBH4 | 0.2% NaBH4, 5% NaOH, 30 °C | 5 | 93 | [169] |

| C-B/attapulgite clay obtained by impregnation with Co(NO3)2 and reduced by NaBH4 | 10% NaBH4, 5% NaOH, 25 °C | 9 | 31 | [170] |

| Co/nickel foam obtained by electrodeposition from CoCl2 | 10% NaBH4, 2% NaOH, 80 °C | 2 | 53 | [171] |

| 3 | 35 | |||

| Co-B/Pd-nickel foam obtained by dip-coating from CoSO4 and reduced by NaBH4 | 20% NaBH4, 0.4% NaOH, 30 °C | 70 | ≈100 | [172] |

| Co-B/nickel foam obtained by electrodeposition from CoSO4 | 5% NaBH4, 5% NaOH, 25 °C | 4 | ≈88 | [173] |

| 10% NaBH4, 5% NaOH, 25 °C | 5 h | ≈60–70 | ||

| 60 h | ≈60–70 |

| Solid Phase Composition | H2O:NaBH4 in Moles | Conversion (%) | GHSC (wt.%) | Reference |

|---|---|---|---|---|

| 80 wt.% NaBH4, 20 wt.% CoCl2 | 9:1 | 78 | 3.4 | [47] |

| 85 wt.% NaBH4 16 wt.% CoCl2·6H2O 1 | 4:1 | 81.2 | 6.7 | [43] |

| 87.5 wt.% NaBH4, 12.5 wt.% Co2+/IR-120 | 4:1 | 90.95 | 6.7 | [181] |

| 90 wt.% NaBH4, 10 wt.% Co2B | 3:1 | - | 8.7 | [182] |

| Hydrogen Generator Design | Catalyst | Conditions | Operating Time | Comments | Output Characteristics | Ref. |

|---|---|---|---|---|---|---|

| Semicontinuous reactor, H2 washing flask (water) | Co-B/Ni foam | 19% NaBH4, 4.5% NaOH, 2.5 mL/min | 3 cycles of 60 min | Stable H2 generation with cat. re-activation between cycles | 1160 mL H2/min, conversion 90%, start-up time 1 < 5 min | [190] |

| Flow catalytic reactor, gas–liquid separator, mesh filter, H2 dehumidifier (silica) | Co/Al2O3 pellets | 15% NaBH4, 5% NaOH, 3 mL/min | 2.5 h UAV flying test | Crushing Al2O3 | 946 mL H2/min, integration with 100 W PEMFC stack, specific energy density 165 Wh/kg | [185,186] |

| Flow catalytic microreactor, hydrogen separator with gas–liquid separation membrane | Co-P-B/Ni foam | 10% NaBH4, 5% NaOH, 0.06 mL/min | 10 cycles of 30 min | Decrease in max power output by 8% in 6 cycles | 16.1 mL H2/min, conversion 98.8%, integration with micro PEMFC, max power output 174.6 mW | [191] |

| Flow catalytic reactor with cooling fans, volume-exchange fuel tank (fuel and spent fuel exchange the volume within a single fuel tank) | Co-B/ ISOLITE monolith | Alkaline 15% NaBH4, 2.5 mL/min | 2 cycles of 30 min with 5 min rest in between, 1 h UAV flying test | Restart of H2 generation with quick start-up time and decrease in rate by 9% | 1331 mL H2/min, integration with 100-W PEMFC stack | [192] |

| All-in-one reactor (cat., chamber of pressurized H2 (4–5 bar) and by-product separator are combined in single space) with cooling devices, H2 wash tank; periodic pressure regulation be NaBH4 supply; autonomous operation | Co-B/Ni foam | Alkaline 25% NaBH4 | 2 cycles of 5 min | Increase in start-up time, stable pressure in H2 chamber with cycles; cat. washing between cycles; stable HGR 2 and temperature during 17 min operation | ≈1200 mL H2/min, integration with 100 W PEMFC stack, total energy density 360 Wh/kg | [193] |

| Flow catalytic reactor with cooling jacket, by-product level sensor, H2 cooling device, resin for capture of sodium from H2; removed water fed back to the reactor | Co-Fe-Ni powder | 20% NaBH4, 3% NaOH | 20 cycles of 2 h, 3 h FC stack operating | Decrease in HGR by 1% in 10 cycles, constant rate over next 10 cycles | 5400 mL H2/min, integration with 200 W PEMFC stack, total energy density 325 Wh/kg | [194] |

| Reactor with inner magnet attracting the magnetic cat. powder, H2 filter and drying device; recycling spent fuel back to fuel tank | Modified comm. Co catalyst | 20% NaBH4, 10% NaOH, 10 mL/min, preheated to 35 °C | 20 h | Good cat. stability | 25 mL H2/min, conversion 90% | [195] |

| π-shaped catalytic reactor, gas–liquid separator, H2 dehumidifier (silica) | CoOx + Ni + PVDF 3/Ni foam | Alkaline 15% NaBH4, 0.5–2 mL/min | Improved characteristics compared to conventional reactor via rapid H2 discharge from cat. surface | conversion 90.2% | [196] | |

| Flow catalytic reactor, by-product separator, H2 wash (water) and dehumidifier (silica) tanks | Co-P/Ni foam | 20% NaBH4, 5% NaOH, 5.22 mL/min, preheated to 30 °C | 3 h | Cat. high durability | 2670 mL H2/min, conversion 90%, start-up time 71 s, integration with 200 W PEMFC stack, energy density 252.1 Wh/kg | [44] |

| 20% NaBH4, 1% NaOH, 2.5 mL/min for start-up, 12.9 mL/min next, thermostated to 20 °C | 2 cycles of 2 h with 2 h rest in between | Restart of H2 generation with the same start-up time (2.5 min) and decrease in rate by 12.4%; NaBO2 deposition on cat. | ≈6500 mlH2/min, conversion 94%, start-up time 2.5 min | [197] | ||

| 15–18% NaBH4, 5% NaOH, 3.07–3.5 mL/min, preheated to 30 °C | 2 cycles of 1 h, 3 h FC stack operating | Cat. washing and drying in air between cycles; increase in start-up time, decrease in conversion by 42.5% in 2nd cycle; stable H2 generation during cycle | 1570 mL H2/min, 97.8% conversion, integration with 100 W PEMFC stack, specific energy density 185.2 Wh/kg, max power 95.96 W | [198] | ||

| Flow catalytic reactor, liquid–gas separator with purge pump, H2 cooling device (finned container with water + cooling fan), H2 dehumidifier (silica) | Co/Al2O3 on the top of Co-P/Ni foam | 20% NaBH4, 12 mL/min | 2 h | 2 catalysts provide fast start-up | 5900 mL H2/min, integration with 500 W PEMFC stack, specific energy density 211 Wh/kg | [199] |

| Packed-bed catalytic reactor with two exit channels (top for H2 and side for byproduct) placed in water bath (70 °C), 2 water traps, dessicator | Co-B/ IR-120 | 5% NaBH4, 2% NaOH, 2.4 mL/min for start-up, 1.02 mL/min next | 3 cycles for ≈30 min | Modeling and validating a strategy of combining reactant feed rates for instant and stable H2 generation | 130 mL H2/min, conversion 99.3%, start-up time 70 s | [200] |

| Batch reactor with NaBH4 pellets, injection of Co(NO3)2 solution, H2 separator | Co-B reduced in situ | 1.6 g of NaBH4 pellets, 2 mL of 0.1 M Co(NO3)2 solution | 30 min | Instable HGR | Max 913.5 mL H2/min, 100% conversion, integration with 100 W PEMFC stack | [201] |

| Batch reactor with pills of solid-state NaBH4 composites, rapid injection of water | Co-B/IR-120 reduced in situ | NaBH4 (3 g), cat. (0.6 g) and silicon rubber (2.5 g) mixed in 20 solid-state pills composites; 20 g H2O | 2 h | Regulation HGR depending on the composition, shape and number of solid-state composites | 25 mL H2/min, integration with 2 W PEMFC stack to power cellular phone | [52] |

| Batch reactor with cat., heat exchanger, H2 buffer tank, batch control module | CoOx/Ni foam | 15% NaBH4 | 6 cycles for 6 min; 1 h FC stack operating | Efficiency depends on NaBH4 concentration, volume of bath reactor and algorithm of next batch addition | Max 128 L H2/min, conversion > 90%, integration with 3 kW PEMFC stack | [202] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simagina, V.I.; Ozerova, A.M.; Komova, O.V.; Netskina, O.V. Recent Advances in Applications of Co-B Catalysts in NaBH4-Based Portable Hydrogen Generators. Catalysts 2021, 11, 268. https://doi.org/10.3390/catal11020268

Simagina VI, Ozerova AM, Komova OV, Netskina OV. Recent Advances in Applications of Co-B Catalysts in NaBH4-Based Portable Hydrogen Generators. Catalysts. 2021; 11(2):268. https://doi.org/10.3390/catal11020268

Chicago/Turabian StyleSimagina, Valentina I., Anna M. Ozerova, Oksana V. Komova, and Olga V. Netskina. 2021. "Recent Advances in Applications of Co-B Catalysts in NaBH4-Based Portable Hydrogen Generators" Catalysts 11, no. 2: 268. https://doi.org/10.3390/catal11020268

APA StyleSimagina, V. I., Ozerova, A. M., Komova, O. V., & Netskina, O. V. (2021). Recent Advances in Applications of Co-B Catalysts in NaBH4-Based Portable Hydrogen Generators. Catalysts, 11(2), 268. https://doi.org/10.3390/catal11020268