Influence of Substrate Concentration on Kinetic Parameters of Ethanol Dehydration in MFI and CHA Zeolites and Relation of These Kinetic Parameters to Acid–Base Properties

Abstract

:1. Introduction

2. Results and Discussions

2.1. Materials Characterization

2.2. FTIR Ethane H/D Exchange Study

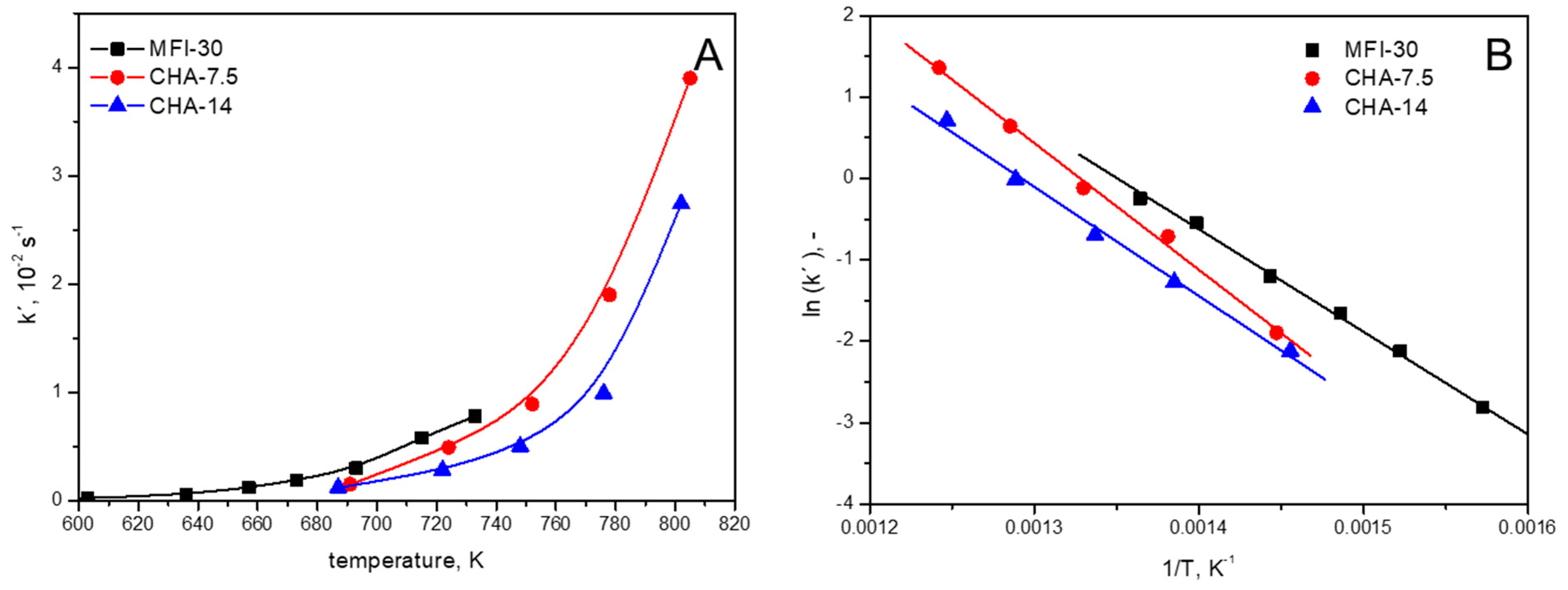

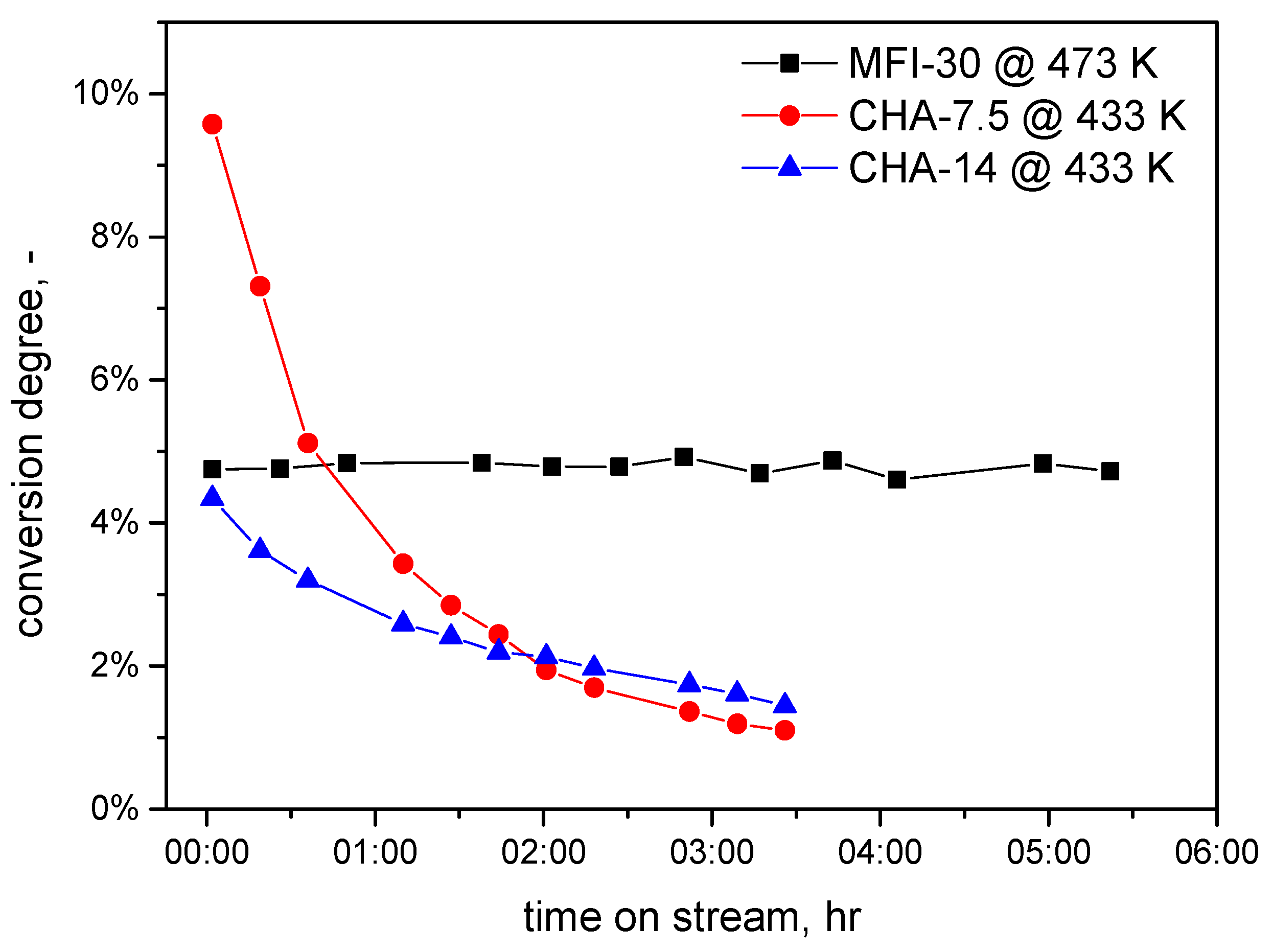

2.3. Fixed Bed Ethanol Dehydration Tests

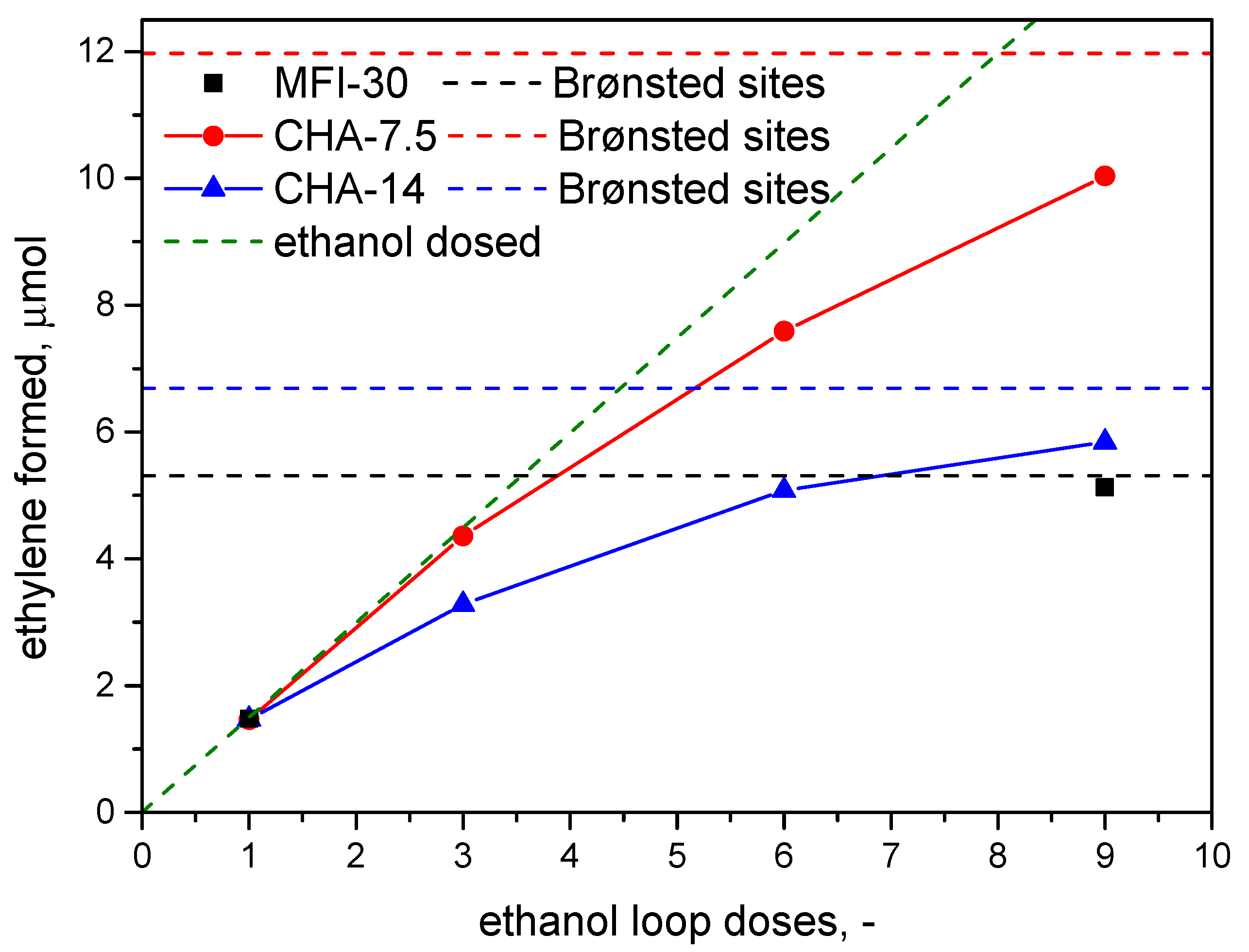

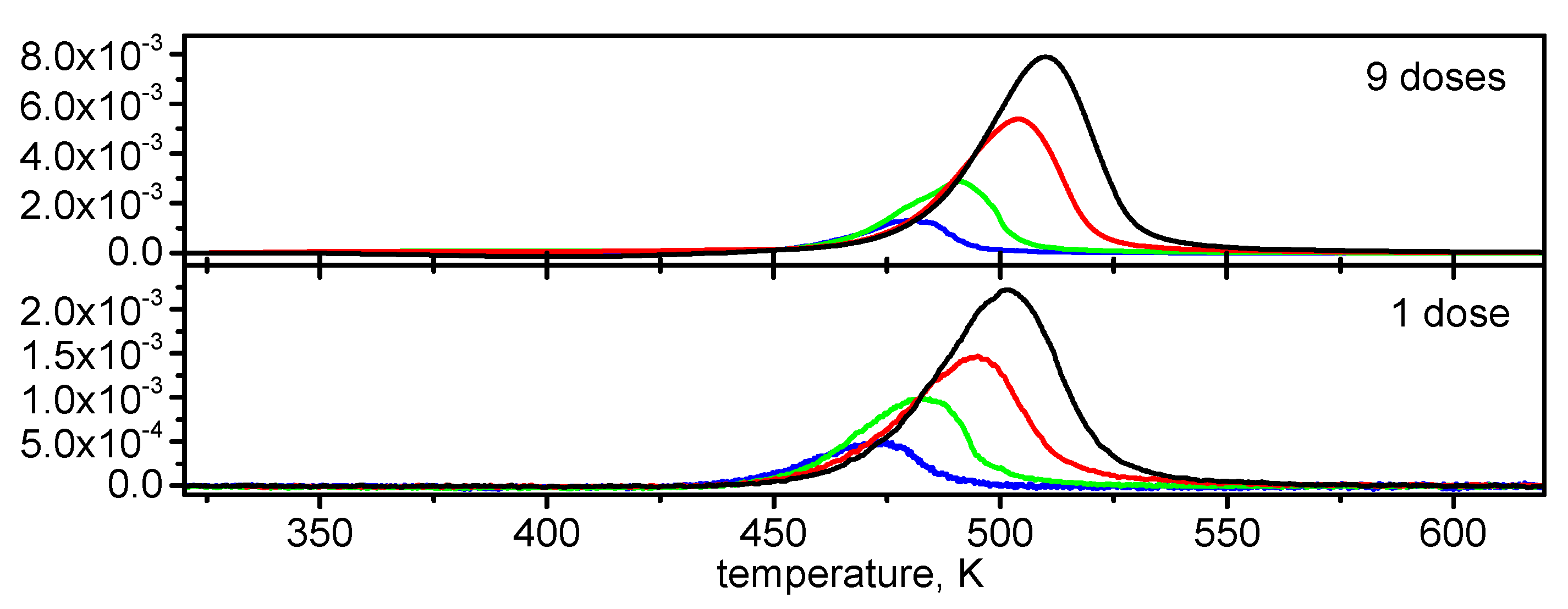

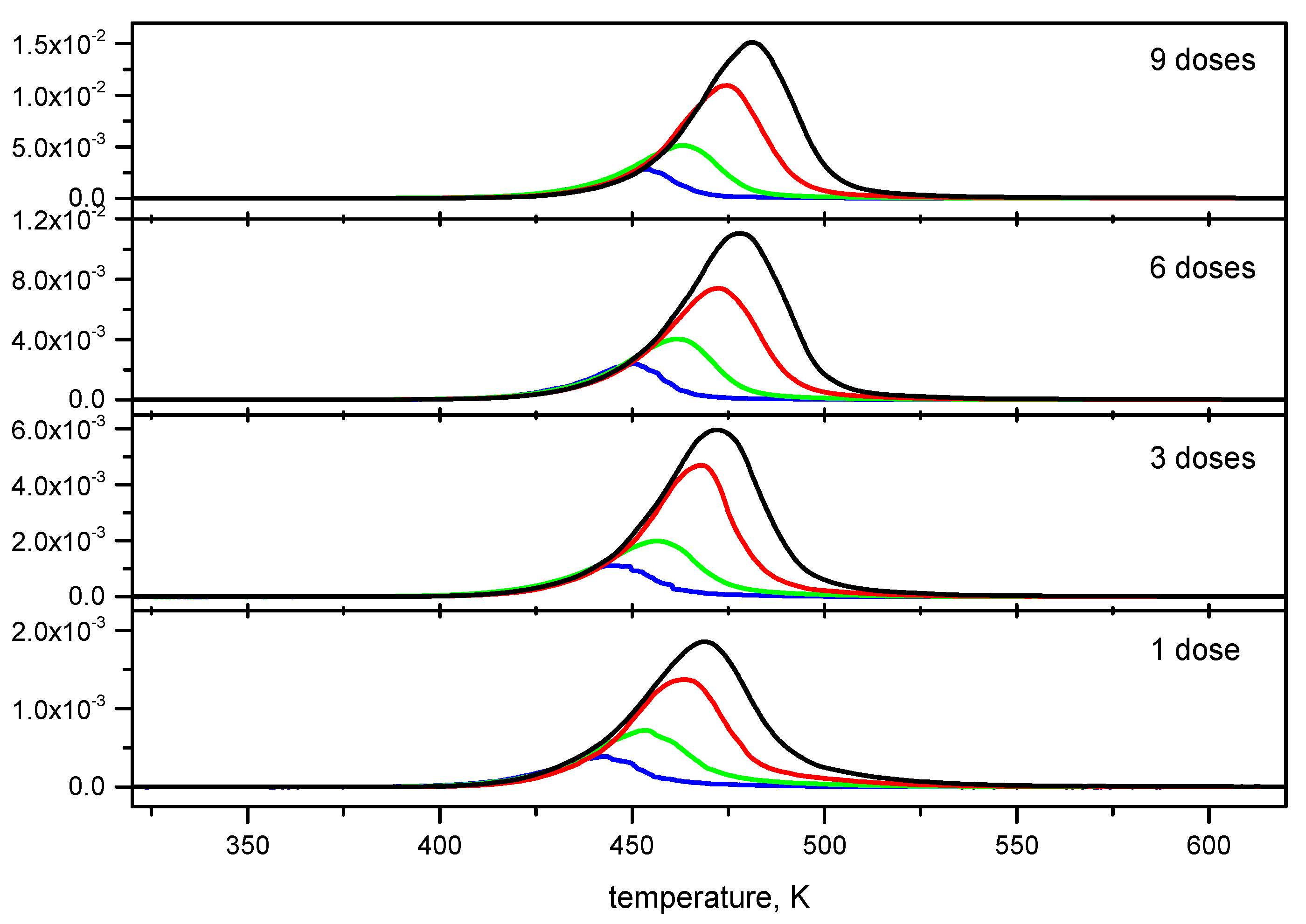

2.4. Temperature Programmed Surface Reaction (TPSR)

3. Materials and Methods

3.1. Materials

3.2. Common Materials Characterization Techniques

3.3. FTIR Measurement of H/D Ethane Exchange

3.4. Fixed Bed Ethanol Dehydration Reaction Tests

3.5. Temperature Programmed Surface Reaction (TPSR)

4. Conclusions

- It is practically impossible to obtain relevant kinetic data about the ethanol dehydration process from ordinary catalytic measurements for CHA-type zeolites, due to the large influence of internal diffusion and cracking processes during catalytic tests.

- Even for zeolites with larger pores (such as MFI), where it is possible to suppress the effect of internal diffusion by choosing reaction conditions, kinetics parameters (especially activation barriers), obtained from steady-state catalytic tests, are not in good agreement with acidity descriptors derived from the H/D isotopic exchange probe reaction or theoretical calculations.

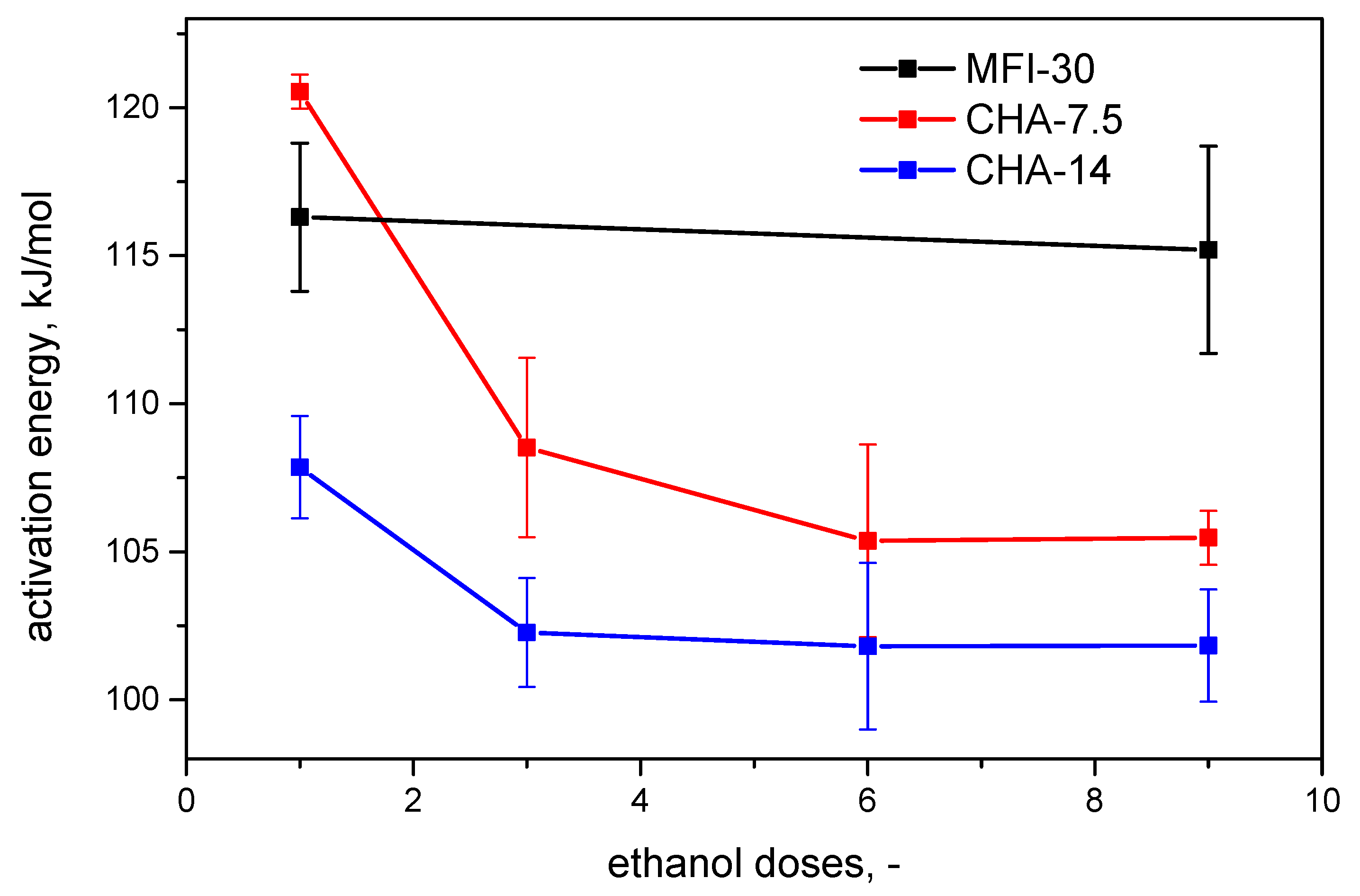

- The TPSR technique gives the opportunity to obtain values of apparent activation energy that are not burdened by internal diffusion and agree with the results of H/D exchange method.

- For chabazite samples, the TPSR method showed that the value of activation energy depends on the number of ethanol molecules in the unit cell of zeolite and decreases from values similar to those determined from the H/D methodology to values of about 102–105 kJ·mol−1. This effect is most likely due to the formation of the interparticle clusters mentioned in other studies [37,38,39], which promote the deprotonation of chabazite zeolitic acid sites.

- In contrast to catalytic tests, the dominant product in TPSR experiments is ethylene, which indicates that ethanol molecules in the gas phase play a very significant role in the dehydration mechanism in classical catalytic tests, probably involved in surface “cleaning” in reaction with adsorbed ethoxy complex. In addition, at least under the conditions of TPSR experiments, ethylene ↔ diethyl ether interconversion appears to be insignificant.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Maesen, T.; Marcus, B. Chapter 1 The Zeolite Scene—An Overview; Elsevier: Amsterdam, The Netherlands, 2001; Volume 137. [Google Scholar]

- Čejka, J.; Bekkum, H.v.; Corma, A.; Schueth, F. Introduction to Zeolite Molecular Sieves, 3nd ed.; Elsevier: Amsterdam, The Netherlands, 2007; Volume 168. [Google Scholar]

- Xu, Z.Q.; Ma, H.F.; Huang, Y.X.; Qian, W.X.; Zhang, H.T.; Ying, W.Y. Synthesis of Submicron SSZ-13 with Tunable Acidity by the Seed-Assisted Method and Its Performance and Coking Behavior in the MTO Reaction. ACS Omega 2020, 5, 24574–24583. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.J.; Kondo, J.N.; Tatsumi, T. Co-reaction of methanol and ethylene over MFI and CHA zeolitic catalysts. Microporous Mesoporous Mater. 2018, 255, 174–184. [Google Scholar] [CrossRef]

- Borodina, E.; Meirer, F.; Lezcano-Gonzalez, I.; Mokhtar, M.; Asiri, A.M.; Al-Thabaiti, S.A.; Basahel, S.N.; Ruiz-Martinez, J.; Weckhuysen, B.M. Influence of the Reaction Temperature on the Nature of the Active and Deactivating Species during Methanol to Olefins Conversion over H-SSZ-13. ACS Catal. 2015, 5, 992–1003. [Google Scholar] [CrossRef]

- Chen, J.Q.; Bozzano, A.; Glover, B.; Fuglerud, T.; Kvisle, S. Recent advancements in ethylene and propylene production using the UOP/Hydro MTO process. Catal. Today 2005, 106, 103–107. [Google Scholar] [CrossRef]

- Chen, D.; Moljord, K.; Holmen, A. A methanol to olefins review: Diffusion, coke formation and deactivation SAPO type catalysts. Microporous Mesoporous Mater. 2012, 164, 239–250. [Google Scholar] [CrossRef]

- Abdo, S.F.; Wilson, S.T. Zeolites in Industrial Catalysis. In Zeolites in Catalysis: Properties and Applications; The Royal Society of Chemistry: London, UK, 2017; Chapter 9; pp. 310–350. [Google Scholar]

- Arvidsson, A.A.; Plessow, P.N.; Studt, F.; Hellman, A. Influence of Acidity on the Methanol-to-DME Reaction in Zeotypes: A First Principles-Based Microkinetic Study. J. Phys. Chem. C 2020, 124, 14658–14663. [Google Scholar] [CrossRef]

- Liu, C.; Tranca, I.; van Santen, R.A.; Hensen, E.J.M.; Pidko, E.A. Scaling Relations for Acidity and Reactivity of Zeolites. J. Phys. Chem. C 2017, 121, 23520–23530. [Google Scholar] [CrossRef]

- Kester, P.M.; Crum, J.T.; Li, S.C.; Schneider, W.F.; Gounder, R. Effects of Bronsted acid site proximity in chabazite zeolites on OH infrared spectra and protolytic propane cracking kinetics. J. Catal. 2021, 395, 210–226. [Google Scholar] [CrossRef]

- Li, S.H.; Zhao, Z.C.; Li, S.K.; Xing, Y.D.; Zhang, W.P. Aluminum Distribution and Bronsted Acidity of Al-Rich SSZ-13 Zeolite: A Combined DFT Calculation and Solid-State NMR Study. Acta Phys.-Chim. Sin. 2020, 36, 1903021. [Google Scholar] [CrossRef]

- Wang, S.; He, Y.; Jiao, W.Y.; Wang, J.G.; Fan, W.B. Recent experimental and theoretical studies on Al siting/acid site distribution in zeolite framework. Curr. Opin. Chem. Eng. 2019, 23, 146–154. [Google Scholar] [CrossRef]

- Potter, M.E.; Cholerton, M.E.; Kezina, J.; Bounds, R.; Carravetta, M.; Manzoli, M.; Gianotti, E.; Lefenfeld, M.; Raja, R. Role of Isolated Acid Sites and Influence of Pore Diameter in the Low-Temperature Dehydration of Ethanol. ACS Catal. 2014, 4, 4161–4169. [Google Scholar] [CrossRef]

- Suzuki, K.; Nishio, T.; Katada, N.; Sastre, G.; Niwa, M. Ammonia IRMS-TPD measurements on Bronsted acidity of proton-formed SAPO-34. PCCP Phys. Chem. Chem. Phys. 2011, 13, 3311–3318. [Google Scholar] [CrossRef]

- Katada, N.; Nouno, K.; Lee, J.K.; Shin, J.; Hong, S.B.; Niwa, M. Acidic Properties of Cage-Based, Small-Pore Zeolites with Different Framework Topologies and Their Silicoaluminophosphate Analogues. J. Phys. Chem. C 2011, 115, 22505–22513. [Google Scholar] [CrossRef]

- Bordiga, S.; Lamberti, C.; Bonino, F.; Travert, A.; Thibault-Starzyk, F. Probing zeolites by vibrational spectroscopies. Chem. Soc. Rev. 2015, 44, 7262–7341. [Google Scholar] [CrossRef]

- Boronat, M.; Corma, A. What Is Measured When Measuring Acidity in Zeolites with Probe Molecules? ACS Catal. 2019, 9, 1539–1548. [Google Scholar] [CrossRef] [PubMed]

- Bleken, F.; Bjorgen, M.; Palumbo, L.; Bordiga, S.; Svelle, S.; Lillerud, K.P.; Olsbye, U. The Effect of Acid Strength on the Conversion of Methanol to Olefins over Acidic Microporous Catalysts with the CHA Topology. Top. Catal. 2009, 52, 218–228. [Google Scholar] [CrossRef]

- Martins, G.V.A.; Berlier, G.; Bisio, C.; Coluccia, S.; Pastore, H.O.; Marchese, L. Quantification of bronsted acid sites in microporous catalysts by a combined FTIR and NH3-TPD study. J. Phys. Chem. C 2008, 112, 7193–7200. [Google Scholar] [CrossRef]

- Regli, L.; Bordiga, S.; Zeechina, A.; Bjorgen, M.; Lillerud, K.P. Acidity properties of CHA-zeolites (SAPO-34 and SSZ-13): An FTIR spectroscopic study. In Oxide Based Materials: New Sources, Novel Phases, New Applications; Gamble, A., Colella, C., Coluccia, S., Eds.; Studies in Surface Science and Catalysis; Elsevier Science BV: Amsterdam, The Netherlands, 2005; Volume 155, pp. 471–479. [Google Scholar]

- Kadam, S.A.; Li, H.G.; Wormsbecher, R.F.; Travert, A. Impact of Zeolite Structure on Entropic-Enthalpic Contributions to Alkane Monomolecular Cracking: An IR Operando Study. Chem.-Eur. J. 2018, 24, 5489–5492. [Google Scholar] [CrossRef]

- Guan, L.; Huang, C.; Han, D.; Zhu, L.; Mei, Y.; He, D.; Zu, Y. Reaction pathways of n-butane cracking over the MFI, FER and TON zeolites: Influence of regional differences in Brønsted acid sites. Microporous Mesoporous Mater. 2022, 330, 111605. [Google Scholar] [CrossRef]

- Masih, D.; Rohani, S.; Kondo, J.N.; Tatsumi, T. Low-temperature methanol dehydration to dimethyl ether over various small-pore zeolites. Appl. Catal. B-Environ. 2017, 217, 247–255. [Google Scholar] [CrossRef]

- Zhong, J.W.; Han, J.F.; Wei, Y.X.; Liu, Z.M. Catalysts and shape selective catalysis in the methanol-to-olefin (MTO) reaction. J. Catal. 2021, 396, 23–31. [Google Scholar] [CrossRef]

- Kadam, S.A.; Shamzhy, M.V. IR Operando Study of Ethanol Dehydration over MFI Zeolites: Structure-Activity Relationships. J. Phys. Chem. C 2018, 122, 24055–24067. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Zhang, J.; Su, Z.R.; Wang, P.Z.; Tan, T.W.; Xiao, F.S. Low-Temperature Dehydration of Ethanol to Ethylene over Cu-Zeolite Catalysts Synthesized from Cu-Tetraethylenepentamine. Ind. Eng. Chem. Res. 2020, 59, 17300–17306. [Google Scholar] [CrossRef]

- Batchu, R.; Galvita, V.V.; Alexopoulos, K.; Glazneva, T.S.; Poelman, H.; Reyniers, M.F.; Marin, G.B. Ethanol dehydration pathways in H-ZSM-5: Insights from temporal analysis of products. Catal. Today 2020, 355, 822–831. [Google Scholar] [CrossRef]

- Knaeble, W.; Iglesia, E. Kinetic and Theoretical Insights into the Mechanism of Alkanol Dehydration on Solid Bronsted Acid Catalysts. J. Phys. Chem. C 2016, 120, 3371–3389. [Google Scholar] [CrossRef]

- Kubota, T.; Osuga, R.; Yokoi, T.; Kondo, J.N. Consideration of Acid Strength of a Single OH Group on Zeolites by Isotope Exchange Reaction with Ethane at High Temperatures. Top. Catal. 2017, 60, 1496–1505. [Google Scholar] [CrossRef]

- Wang, C.; Li, S.; Mao, X.Y.; Caratzoulas, S.; Gorte, R.J. H-D Exchange of Simple Aromatics as a Measure of BrOnsted-Acid Site Strengths in Solids. Catal. Lett. 2018, 148, 3548–3556. [Google Scholar] [CrossRef]

- Bulanek, R.; Kubu, M.; Vaculik, J.; Cejka, J. H/D reactivity and acidity of Bronsted acid sites of MWW zeolites: Comparison with MFI zeolite. Appl. Catal. A: Gen. 2019, 575, 180–186. [Google Scholar] [CrossRef]

- Mildner, T.; Freude, D. Proton transfer between bronsted sites and benzene molecules in zeolites H-Y studies by In Situ MAS NMR. J. Catal. 1998, 178, 309–314. [Google Scholar] [CrossRef] [Green Version]

- Thibault-Starzyk, F.; Travert, A.; Saussey, J.; Lavalley, J.C. Correlation between activity and acidity on zeolites: A high temperature infrared study of adsorbed acetonitrile. Top. Catal. 1998, 6, 111–118. [Google Scholar] [CrossRef]

- Bordiga, S.; Regli, L.; Lamberti, C.; Zecchina, A.; Bjorgen, M.; Lillerud, K.P. FTIR adsorption studies of H2O and CH3OH in the isostructural H-SSZ-13 and H-SAPO-34: Formation of H-bonded adducts and protonated clusters. J. Phys. Chem. B 2005, 109, 7724–7732. [Google Scholar] [CrossRef]

- Di Iorio, J.R.; Hoffman, A.J.; Nimlos, C.T.; Nystrom, S.; Hibbitts, D.; Gounder, R. Mechanistic origins of the high-pressure inhibition of methanol dehydration rates in small-pore acidic zeolites. J. Catal. 2019, 380, 161–177. [Google Scholar] [CrossRef]

- Bates, J.S.; Gounder, R. Kinetic effects of molecular clustering and solvation by extended networks in zeolite acid catalysis. Chem. Sci. 2021, 12, 4699–4708. [Google Scholar] [CrossRef] [PubMed]

- Bates, J.S.; Gounder, R. Clustering of alkanols confined in chabazite zeolites: Kinetic implications for dehydration of methanol-ethanol mixtures. J. Catal. 2020, 390, 178–183. [Google Scholar] [CrossRef]

- Bates, J.S.; Bukowski, B.C.; Greeley, J.; Gounder, R. Structure and solvation of confined water and water-ethanol clusters within microporous Bronsted acids and their effects on ethanol dehydration catalysis. Chem. Sci. 2020, 11, 7102–7122. [Google Scholar] [CrossRef] [PubMed]

- Baerlocher, C.; McCusker, L.B. Database of Zeolite Structures. Available online: http://www.iza-structure.org/databases/ (accessed on 1 December 2021).

- Rouquerol, J.; Rouquerol, F.; Llewellyn, P.; Maurin, G.; Sing, K. Adsorption by Powders and Porous Solids. Principles, Methodology and Applications, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Meng, L.; Zhu, X.; Mezari, B.; Pestman, R.; Wannapakdee, W.; Hensen, E.J.M. On the Role of Acidity in Bulk and Nanosheet [T]MFI (T = Al3+, Ga3+, Fe3+, B3+) Zeolites in the Methanol-to-Hydrocarbons Reaction. ChemCatChem 2017, 9, 3942–3954. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Shao, Y.; Li, G.; Li, T.; Wang, H.; Wang, J.-G. Synthesis of high-micropore-volume pure-silica zeolites from a polymer near-neutral medium free of fluoride ions for VOCs capture. Microporous Mesoporous Mater. 2019, 286, 149–154. [Google Scholar] [CrossRef]

- Rutkowska, M.; Duda, M.; Kowalczyk, A.; Chmielarz, L. Modification of the physicochemical properties of the commercial CHA zeolite and examination of its activity in nitrogen oxide abatement. C. R. Chim. 2017, 20, 850–859. [Google Scholar] [CrossRef]

- Florindo, B.R.; Catuzo, G.L.; Martins, L. Porosity of CHA Zeolite Driving the Formation of Polyaromatic Coke Species in the Methanol to Olefiins Reaction. J. Braz. Chem. Soc. 2021, 32, 1051–1059. [Google Scholar] [CrossRef]

- Vaculik, J.; Setnicka, M.; Bulanek, R. Study of Bronsted acid site in H-MCM-22 zeolite by temperature-programmed desorption of ammonia. J. Therm. Anal. Calorim. 2016, 125, 1217–1224. [Google Scholar] [CrossRef]

- Wang, C.; Xu, J.; Wang, Q.; Zhou, X.; Qi, G.D.; Feng, N.D.; Liu, X.L.; Meng, X.J.; Xiao, F.S.; Deng, F. Host-Guest Interactions and Their Catalytic Consequences in Methanol to Olefins Conversion on Zeolites Studied by C-13-Al-27 Double-Resonance Solid-State NMR Spectroscopy. ACS Catal. 2017, 7, 6094–6103. [Google Scholar] [CrossRef]

- Qian, Q.; Ruiz-Martinez, J.; Mokhtar, M.; Asiri, A.M.; Al-Thabaiti, S.A.; Basahel, S.N.; Weckhuysen, B.M. Single-catalyst particle spectroscopy of alcohol-to-olefins conversions: Comparison between SAPO-34 and SSZ-13. Catal. Today 2014, 226, 14–24. [Google Scholar] [CrossRef]

- Zhu, Q.J.; Kondo, J.N.; Inagaki, S.; Tatsumi, T. Catalytic Activities of Alcohol Transformations Over 8-Ring Zeolites. Top. Catal. 2009, 52, 1272–1280. [Google Scholar] [CrossRef]

- Park, J.W.; Seo, G. IR study on methanol-to-olefin reaction over zeolites with different pore structures and acidities. Appl. Catal. A-Gen. 2009, 356, 180–188. [Google Scholar] [CrossRef]

- Seo, G.; Kim, J.H.; Jang, H.G. Methanol-to-Olefin Conversion over Zeolite Catalysts: Active Intermediates and Deactivation. Catal. Surv. Asia 2013, 17, 103–118. [Google Scholar] [CrossRef]

- Di Iorio, J.R.; Nimlos, C.T.; Gounder, R. Introducing Catalytic Diversity into Single-Site Chabazite Zeolites of Fixed Composition via Synthetic Control of Active Site Proximity. ACS Catal. 2017, 7, 6663–6674. [Google Scholar] [CrossRef]

- Zhang, K.; Lively, R.P.; Dose, M.E.; Li, L.W.; Koros, W.J.; Ruthven, D.M.; McCool, B.A.; Chance, R.R. Diffusion of water and ethanol in silicalite crystals synthesized in fluoride media. Microporous Mesoporous Mater. 2013, 170, 259–265. [Google Scholar] [CrossRef]

- Vannice, M.A. Kinetics of Catalytic Reactions; Springer: New York, NY, USA, 2005. [Google Scholar]

- Choudhary, V.R.; Mayadevi, S. Adsorption of methane, ethane, ethylene, and carbon-dioxide on high-silica pentasil zeolites and zeolite-like materials using gas-chromatography pulse technique. Sep. Sci. Technol. 1993, 28, 2197–2209. [Google Scholar] [CrossRef]

- Yeh, Y.-H.; Rzepa, C.; Rangarajan, S.; Gorte, R.J. Influence of Bronsted-acid and cation-exchange sites on ethene adsorption in ZSM-5. Microporous Mesoporous Mater. 2019, 284, 336–342. [Google Scholar] [CrossRef]

- Alexopoulos, K.; John, M.; Van der Borght, K.; Galvita, V.; Reyniers, M.-F.; Marin, G.B. DFT-based microkinetic modeling of ethanol dehydration in H-ZSM-5. J. Catal. 2016, 339, 173–185. [Google Scholar] [CrossRef]

- Stich, I.; Gale, J.D.; Terakura, K.; Payne, M.C. Role of the zeolitic environment in catalytic activation of methanol. J. Am. Chem. Soc. 1999, 121, 3292–3302. [Google Scholar] [CrossRef]

| Sample | SBET *, m2·g−1 | SEXT **, m2·g−1 | Vμ **, cm3·g−1 | H+ from NH3-TPD, μmol per 10 mg | EA of H/D Exchange, kJ·mol−1 |

|---|---|---|---|---|---|

| MFI-30 | 408 | 24.8 | 0.124 | 5.31 | 104 ± 1 |

| CHA-7.5 | 478 | 2.9 | 0.244 | 11.97 | 130 ± 1 |

| CHA-14 | 510 | 51.5 | 0.234 | 6.69 | 109 ± 3 |

| Sample | 1% of Ethanol | 10% of Ethanol | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T K | SDE,0 * % | X0 * % | TOF0 * min−1 | EA kJ·mol−1 | T K | SDE,0 % | X0 % | TOF0 min−1 | EA kJ·mol−1 | |

| MFI-30 | 413 | 99.8 | 1.1 | 0.09 | 66 | 413 | 99.8 | 0.1 | 0.08 | 104 |

| 433 | 99.8 | 2.9 | 0.24 | 433 | 99.8 | 0.4 | 0.34 | |||

| 453 | 99.4 | 6.1 | 0.51 | 453 | 99.7 | 1.4 | 1.18 | |||

| 473 | 98.0 | 12.8 | 1.08 | 473 | 99.3 | 4.7 | 3.95 | |||

| CHA-7.5 | 393 | 98.5 | 9.3 | 0.35 | 70 | 393 | 98.5 | 1.1 | 0.41 | |

| 413 | 94.1 | 26.3 | 0.98 | 413 | 93.6 | 3.7 | 1.38 | 77 | ||

| 433 | 91.3 | 44.2 ** | 1.65 | / | 433 | 92.4 | 9.6 | 3.58 | ||

| CHA-14 | 393 | 94.5 | 5.7 | 0.38 | 393 | 95.1 | 0.9 | 0.60 | ||

| 413 | 93.6 | 12.0 | 0.8 | 51 | 413 | 94.8 | 2.0 | 1.33 | 55 | |

| 433 | 92.4 | 23.8 | 1.59 | 433 | 93.3 | 4.3 | 2.87 | |||

| Sample | Ethanol Doses | Compound Evolved μmol per 10 mg | Temperature of TPSR Peak Maximum-Tmax, K β Values in K·min−1 | EA kJ·mol−1 | |||||

|---|---|---|---|---|---|---|---|---|---|

| - | μmol per 10 mg | Ethanol * | Ethylene | β = 2.5 | β = 5 | β = 10 | β = 15 | ||

| MFI-30 | 1 | 1.50 | 0.00 | 1.48 | 473.0 | 483.0 | 494.5 | 501.5 | 116 ± 3 |

| 9 | 13.47 | 7.67 | 5.13 | 481.0 | 491.0 | 504.0 | 510.0 | 115 ± 4 | |

| CHA-7.5 | 1 | 1.50 | 0.00 | 1.46 | 443.0 | 452.0 | 461.5 | 467.0 | 121 ± 1 |

| 3 | 4.49 | 0.13 | 4.36 | 445.0 | 456.0 | 466.0 | 472.0 | 109 ± 3 | |

| 6 | 8.98 | 0.61 | 7.59 | 450.0 | 461.0 | 472.5 | 478.0 | 105 ± 3 | |

| 9 | 13.47 | 2.15 | 10.04 | 452.5 | 463.0 | 474.5 | 481.0 | 105 ± 1 | |

| CHA-14 | 1 | 1.50 | 0.00 | 1.47 | 454.5 | 465.0 | 475.5 | 483.0 | 108 ± 2 |

| 3 | 4.49 | 0.44 | 3.28 | 457.0 | 468.0 | 479.5 | 487.0 | 102 ± 2 | |

| 6 | 8.98 | 2.48 | 5.08 | 459.0 | 469.5 | 482.5 | 489.0 | 102 ± 3 | |

| 9 | 13.47 | 5.03 | 5.84 | 459.5 | 471.5 | 482.5 | 490.5 | 102 ± 2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Čičmanec, P.; Kotera, J.; Vaculík, J.; Bulánek, R. Influence of Substrate Concentration on Kinetic Parameters of Ethanol Dehydration in MFI and CHA Zeolites and Relation of These Kinetic Parameters to Acid–Base Properties. Catalysts 2022, 12, 51. https://doi.org/10.3390/catal12010051

Čičmanec P, Kotera J, Vaculík J, Bulánek R. Influence of Substrate Concentration on Kinetic Parameters of Ethanol Dehydration in MFI and CHA Zeolites and Relation of These Kinetic Parameters to Acid–Base Properties. Catalysts. 2022; 12(1):51. https://doi.org/10.3390/catal12010051

Chicago/Turabian StyleČičmanec, Pavel, Jiří Kotera, Jan Vaculík, and Roman Bulánek. 2022. "Influence of Substrate Concentration on Kinetic Parameters of Ethanol Dehydration in MFI and CHA Zeolites and Relation of These Kinetic Parameters to Acid–Base Properties" Catalysts 12, no. 1: 51. https://doi.org/10.3390/catal12010051

APA StyleČičmanec, P., Kotera, J., Vaculík, J., & Bulánek, R. (2022). Influence of Substrate Concentration on Kinetic Parameters of Ethanol Dehydration in MFI and CHA Zeolites and Relation of These Kinetic Parameters to Acid–Base Properties. Catalysts, 12(1), 51. https://doi.org/10.3390/catal12010051