Polymeric materials, from the earliest years, were widely used in medicine and other areas of industry. Over three thousand different types of medical devices are manufactured from polymers [

1]. However, synthetic polymers are often the source of harmful pollutants due to their poor dispersion and excessive exposure to the natural environment [

2]. Most modern synthetic polymers are made of petrochemical products and are not biodegradable [

3,

4,

5]. For example, plastic bags have a negative impact on marine and ocean life [

6,

7]. Accumulation in the environment of toxic products resulting from the decomposition of such polymeric materials may inhibit plant growth and have a negative impact on ecosystems [

8]. Unfortunately, the recycling of plastics has an adverse environmental balance in terms of the energy and resources needed to wash, grind and process the waste [

9]. Incineration of plastic waste causes the emission of toxic compounds (e.g., dioxins) to the atmosphere and also entails certain limitations in the availability of effective and economically profitable facilities or devices for burning this type of materials [

10]. As a consequence, it leads to the determination of the environmental toxicity of pollutants, known as their ecotoxicity [

11,

12,

13,

14,

15,

16]. Natural polymers due to their excellent biocompatibility and biocompatibility have been used in medicine for many years [

17,

18,

19,

20,

21,

22]. Biodegradable polymers have a great potential in many applications including tissue engineering, gene therapy, and regeneration. They can be used in temporary devices for implantology and implant coatings [

23]. Due to their biocompatibility, biopolymeric hydrogels are also used in application materials (bandages, etc.), as well as for tissue and organ engineering and regeneration (hydrogels, alginates, etc.) [

24]. A particularly important achievement in biopolymer technology was the use of biopolymers, both fiber-forming and natural polysaccharide polymers, to create materials for the controlled release of drugs. Natural polymers that are biodegradable inside the body (biohydrolysis) are used to create a temporary therapeutic matrix containing biologically active substances that can be released in a controlled manner [

25]. These types of materials, after fulfilling their functions, biodegrade and are naturally removed from the body. Biopolymers have healing properties (biocidal, antioxidant, antiallergic, etc.), which is a great advantage over synthetic materials. Biopolymers are not only biodegradable but non-toxic. It is an important property in all applications, especially in medicine [

26,

27]. Unfortunately, biosourced polymers also have undesirable antigenic properties and are heterogeneous. Natural polymers can be classified based on the method of their synthesis. Examples of polymers derived from biomass include: agropolymers from agricultural raw materials (e.g., starch or cellulose); polymers obtained by the production of microorganisms (polyhydroxybutyrate); conventionally and chemically synthesized polymers from monomers obtained from agricultural raw materials (polylactic acid); and polymers derived from fossil fuels. Only the first three of these categories are considered sustainable [

28]. Depending on the application, the required properties and the degradation rate are the basic criteria for selecting a polymer to be used as a biodegradable biomaterial. Plastics are highly resistant to temperature, environmental pH, mechanical deformation, etc. For the polymer material to meet the compostable or biodegradable criteria, and on the other hand to be adequately durable and thermally stable, it should be chemically or physically modified at some stage of its production. One of such solutions was proposed by X. Zhang et al. [

29]. Gelatin was modified with a natural phenolic compound from the tannin group. The use of a tannin compound in the amount of 3% resulted in obtaining a stable structural network even during the thermal treatment process of the polymeric material at 100 °C. The increase in the degree of branching as a result of the grafting of the ingredients used resulted in an increase in the molecular mobility of the gelatin matrix, which consequently made it possible to obtain a protein material with plastic properties. In scientific research, [

30,

31] gelatin obtained from pig skin was also undergoing esterification with fatty acid. The chemical modification process was catalyzed by a fatty acid in an aqueous medium. In order to optimize the process, the type and concentration of the higher fatty acids used as well as the reaction time were appropriately selected. Based on the determination of the increase in acid concentration under the same conditions of time, the maximum amount of acid that is needed to esterify a given unit of gelatin mass was determined, and on this basis, it turned out that the process of blocking all gelatin hydroxyl groups with the fatty acid used was difficult, which in turn affects the cross-linking processes in gelatin matrices. Other compounds used in gelatin cross-linking are, for example, plant-derived phenolic compounds such as caffeic acid [

32,

33]. Optimization of the time and concentration of the applied acid to the gelatin system resulted in obtaining a different degree of cross-linking of the polymeric material. A lower degree of deformation at higher temperatures was achieved for gelatin cross-linked in this way as shown by rheological analysis.

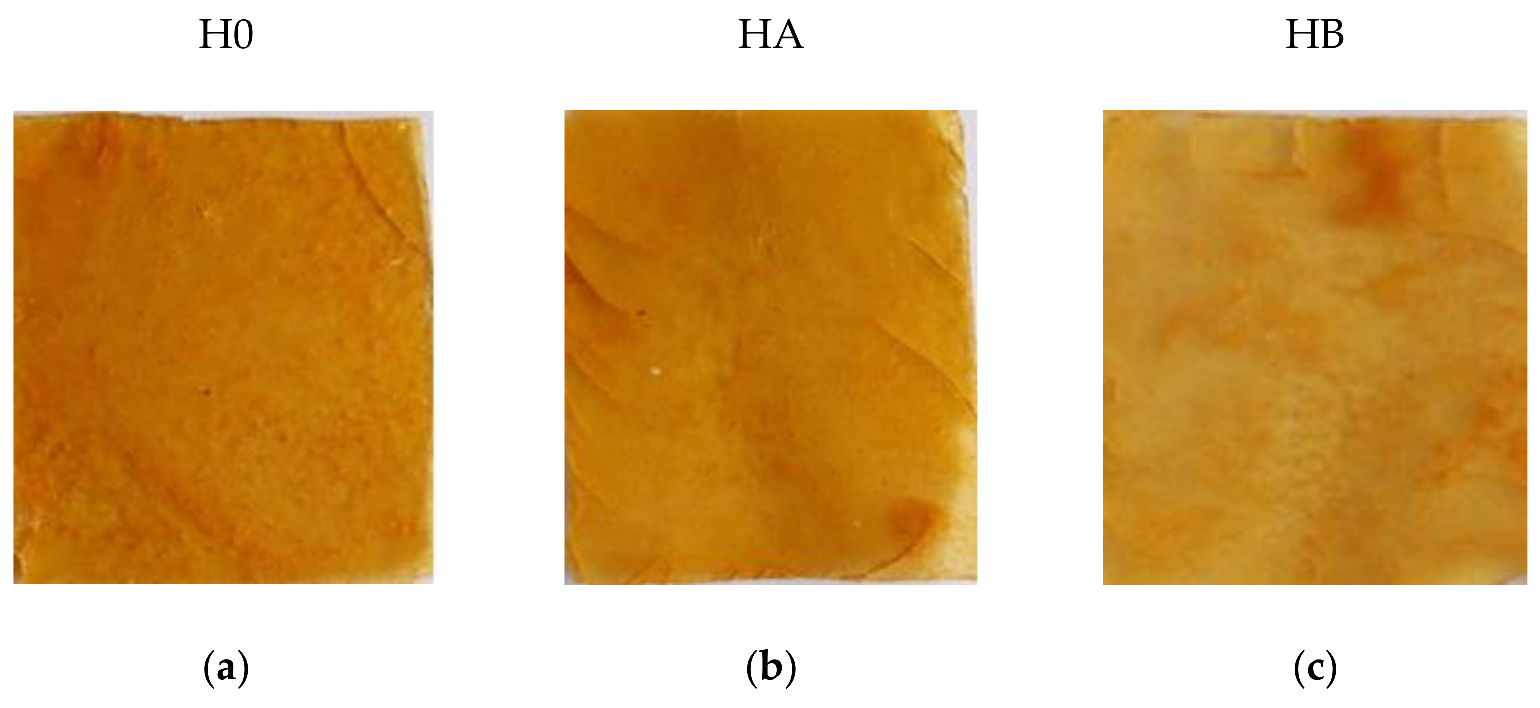

In this article, we present the method of producing polymer films based on a gelatin matrix with the use of waste skin tissue of animal origin (“WĘDLINKA Sp. z o.o.” Wieruszów, Poland). The films were enriched with casein, chitosan, agar, cellulose acetate, and glycerin plasticizer to obtain durable film-like coatings with a uniform shape and good mechanical parameters. In the designed chemical preparation, a specific type of catalyst was proposed—a proteolytic enzyme (Novo Unhairing Enzyme NUE 12 MP Activity 8.37 KNPU (E)/g [

33] 130,000 LVU g

−1 [

34,

35] and acetic acid. The purpose of the biocatalyst introduced into the mixture with fragments of fractionated collagen tissues was to accelerate the catalytic partial disintegration reaction and obtain a homogeneous mixture. On the other hand, the introduction of the organic acid was aimed at loosening the fibrillar structure of collagen fibers without leading to complete conformational denaturation of the roll helix. In this way, we have obtained a composite with the desired performance parameters, thermally stable, with limited water absorption. This type of material could be used in tissue engineering. Potential application of this film is the base for growth factor sequestration, biomimetic composites, scaffolds for bone tissue or basis for bone substitute [

36,

37,

38].