Carbon Quantum Dot-Titanium Doped Strontium Ferrite Nanocomposite: Visible Light Active Photocatalyst to Degrade Nitroaromatics

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization

2.1.1. Structural Analysis

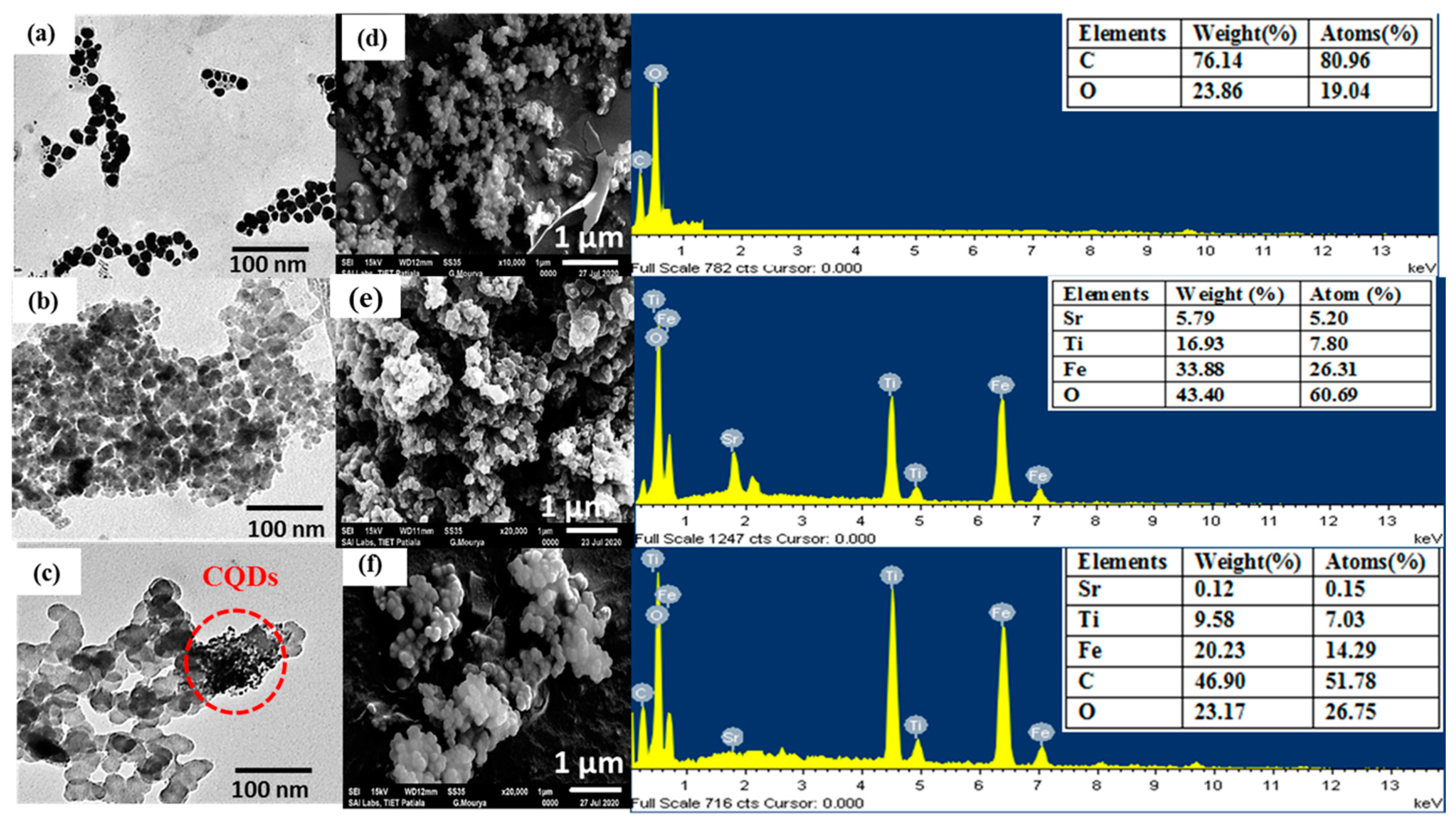

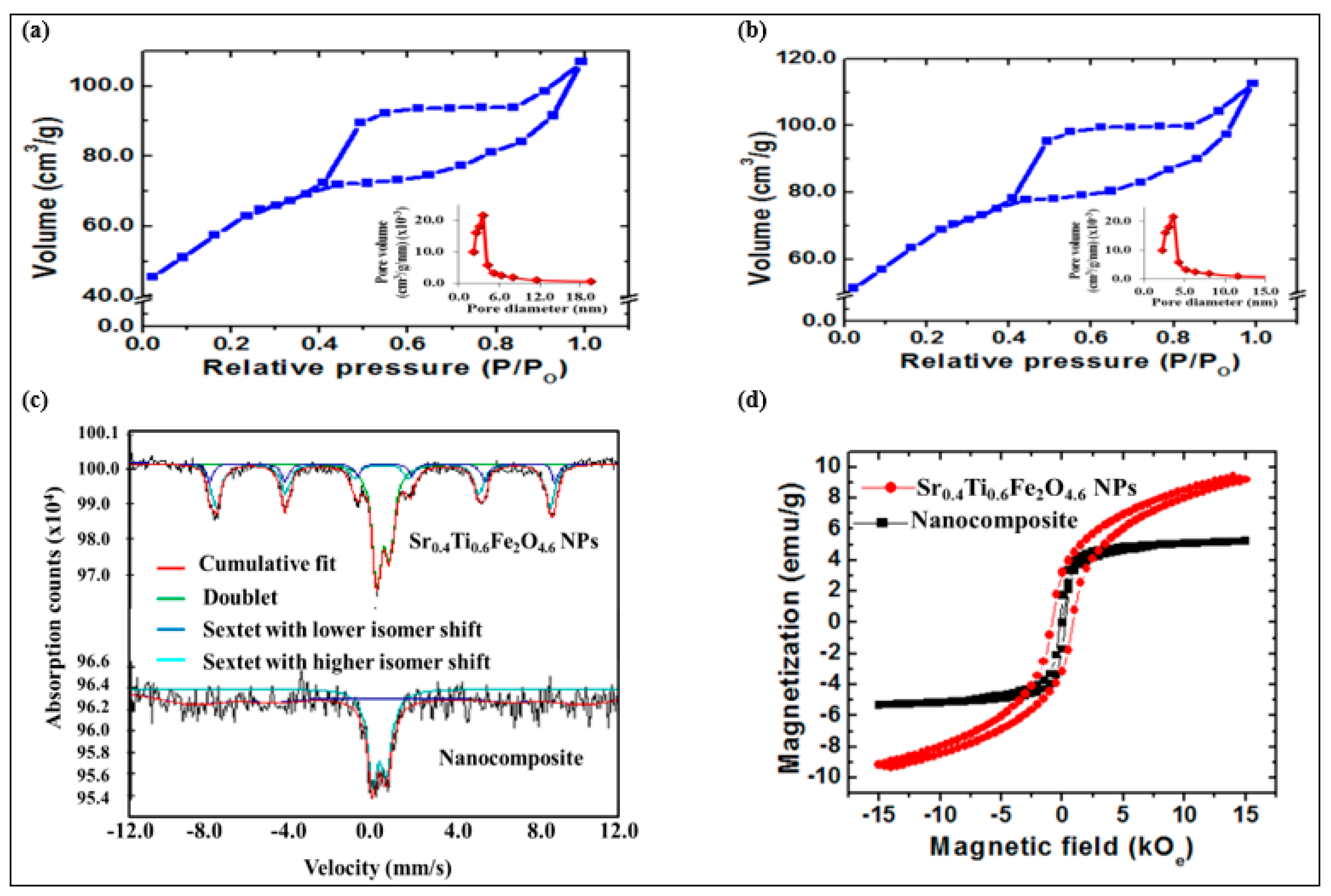

2.1.2. Morphology, Surface Area and Magnetic Studies

2.2. Optical Studies

2.3. Photodegradation Studies

2.3.1. Influence of Contact Time

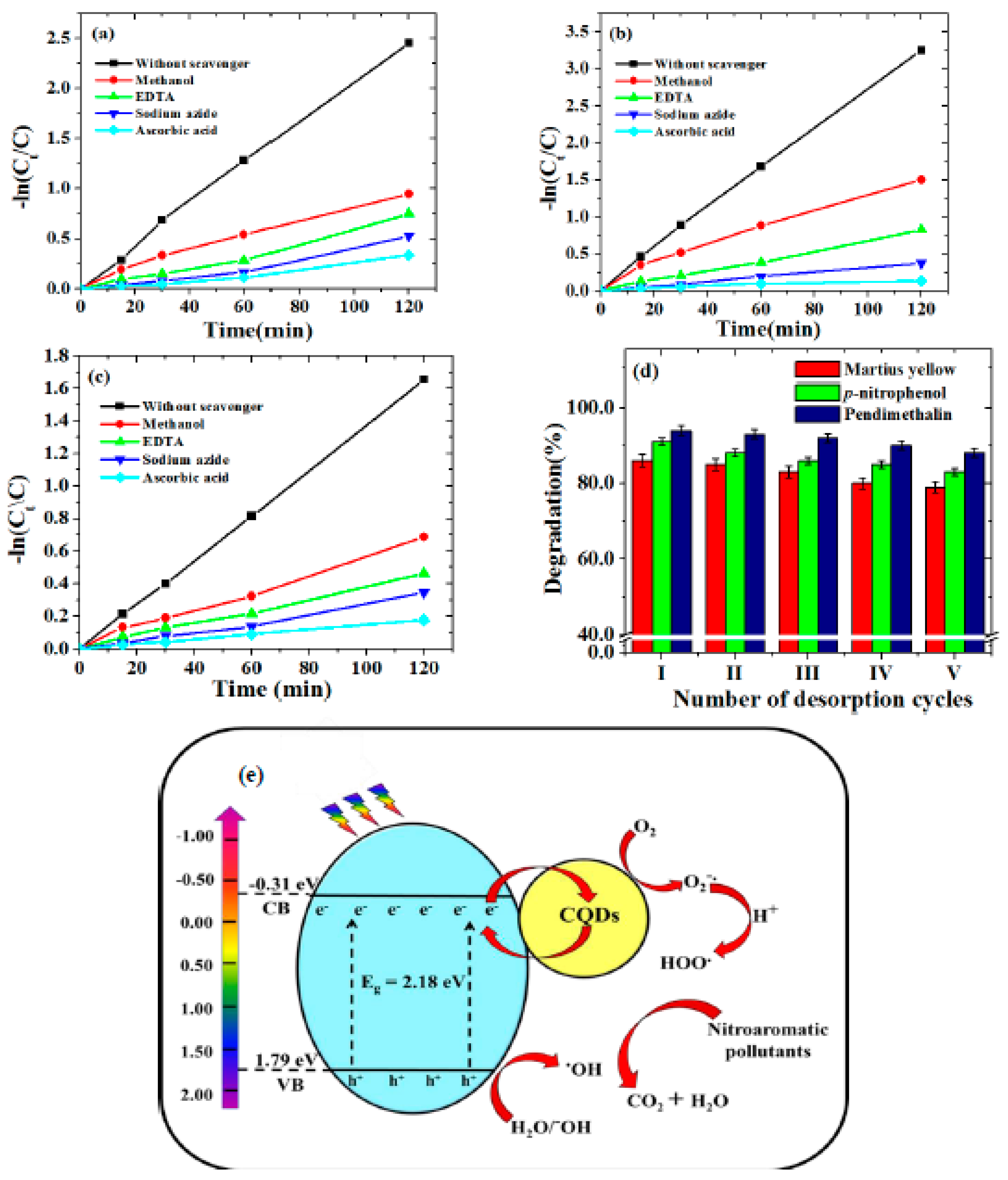

2.3.2. Identification of Reactive Oxygen Species and Photocatalysis Mechanism

2.3.3. Photodegradation Pathways of Nitroaromatic Pollutants

Photodegradation Pathway of p−Nitrophenol

Photodegradation Pathway of Pendimethalin

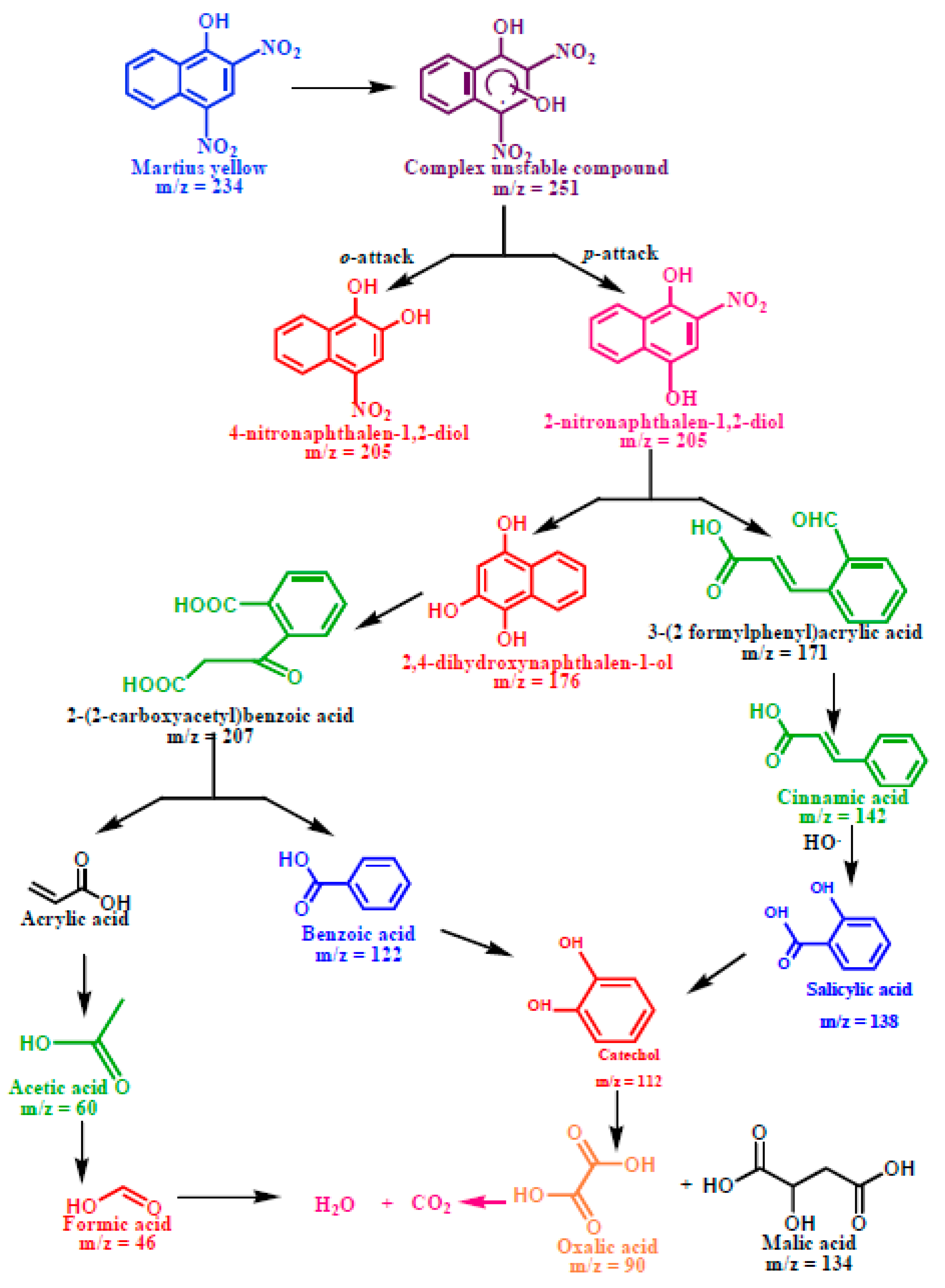

Photodegradation Pathway of Martius Yellow

2.4. Regeneration Studies

3. Materials and Methods

3.1. Materials

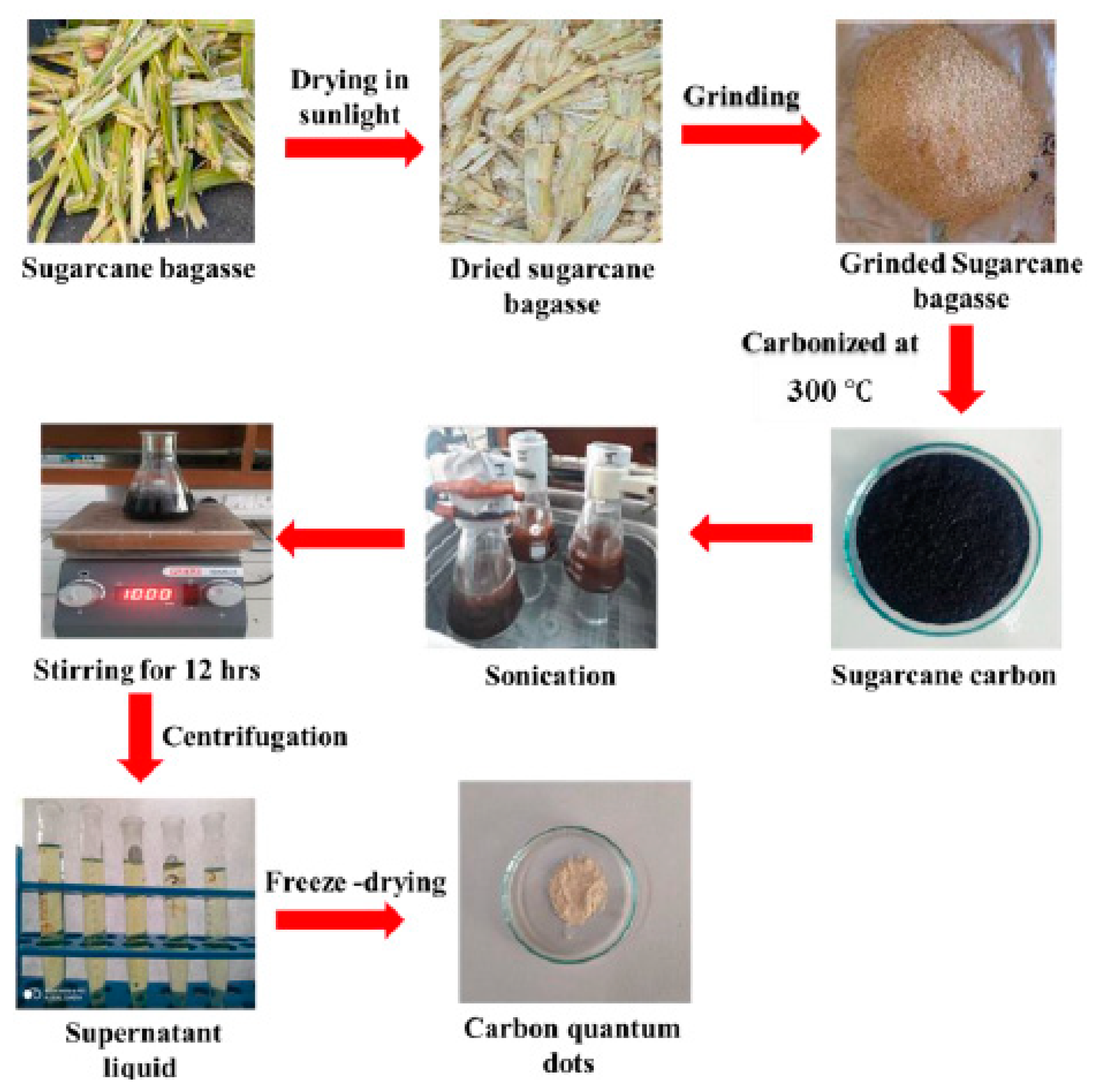

3.2. Fabrication of CQDs and CQDs—Sr0.4Ti0.6Fe2O4.6 Composite Photocatalyst

3.3. Adsorption and Photocatalytic Potential Measurements

3.4. Quantum Yield Measurement

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jabeen, A.; Kamran, U.; Noreen, S.; Park, S.J.; Bhatti, H.N. Mango seed-derived hybrid composites and sodium alginate beads for the efficient uptake of 2,4,6-trichlorophenol from simulated wastewater. Catalysts 2022, 12, 972. [Google Scholar] [CrossRef]

- Najjar, A.A.; Hassan, E.A.; Zabermavi, N.M.; Almasaudi, S.B.; Moulay, M.; Harakeh, S.; El-Aal, M.A. Efficacy of the Immobilized Kocuria flava Lipase on Fe3O4/Cellulose Nanocomposite for Biodiesel Production from Cooking Oil Wastes. Catalysts 2022, 12, 977. [Google Scholar] [CrossRef]

- He, C.; Shuang, E.; Yan, H.; Li, X. Structural engineering design of carbon dots for lubrication. Chin. Chem. Lett. 2021, 32, 2693–2714. [Google Scholar] [CrossRef]

- Toma, E.E.; Stoian, G.; Cojoearu, B.; Parvulescu, V.I.; Coman, S.M. ZnO/CQDs nanocomposites for visible light photodegradation of organic pollutants. Catalysts 2022, 12, 952. [Google Scholar] [CrossRef]

- Moosavi, S.; Manta, O.; El-Badry, Y.A.; Hussein, E.E.; El-Bahy, Z.M.; Fawzi, N.F.B.M.; Urbonavicius, J.; Moosavi, S.M.H. A study on machine learning methods’ application for dye adsorption prediction onto agricultural waste activated carbon. Nanomaterials 2021, 11, 2734. [Google Scholar] [CrossRef]

- Baragau, I.A.; Power, N.P.; Morgan, D.J.; Lobo, R.A.; Roberts, C.S.; Titirici, M.M.; Middelkoop, V.; Diaz, A.; Dunn, S.; Kellichi, S. Efficient continuous hydrothermal flow synthesis of carbon quantum dots from a targeted biomass precursor for on–off metal ions nanosensing. ACS Sustain. Chem. Eng. 2021, 9, 2559–2569. [Google Scholar] [CrossRef]

- Kurian, M.; Paul, A. Recent trends in the use of green sources for carbon dot synthesis–A short review. Carbon Trends 2021, 3, 100032. [Google Scholar] [CrossRef]

- Pandiyan, S.; Arumugam, L.; Srirengan, S.P.; Pitchan, R.; Sevugan, P.; Kannan, K.; Pitchan, G.; Hegde, T.A.; Gandhirajan, V. Biocompatible carbon quantum dots derived from sugarcane industrial wastes for effective nonlinear optical behavior and antimicrobial activity applications. ACS Omega 2020, 5, 30363–30372. [Google Scholar] [CrossRef]

- Thambiraj, S.; Shankaran, D.R. Green synthesis of highly fluorescent carbon quantum dots from sugarcane bagasse pulp. Appl. Surf. Sci. 2016, 390, 435–443. [Google Scholar] [CrossRef]

- Kaur, M.; Ubhi, M.K.; Grewal, J.K.; Sharma, V.K. Boron- and phosphorus-doped graphene nanosheets and quantum dots as sensors and catalysts in environmental applications: A review. Environ. Chem. Lett. 2021, 19, 4375–4392. [Google Scholar] [CrossRef]

- Kaur, M.; Kaur, M.; Sharma, V.K. Nitrogen-doped graphene and graphene quantum dots: A review on synthesis and applications in energy, sensors and environment. Adv. Colloid Interface Sci. 2018, 259, 44–64. [Google Scholar] [CrossRef]

- Sharma, S.; Dutta, V.; Singh, P.; Raizada, P.; Rahmani-Sani, A.; Hosseini-Bandegharaei, A.; Thakur, V.K. Carbon quantum dot supported semiconductor photocatalysts for efficient degradation of organic pollutants in water: A review. J. Clean. Prod. 2019, 228, 755–769. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Shi, C.; Sun, W.; Lin, X.; Shi, W.; Hong, Y. Carbon-based quantum dots (QDs) modified ms/tz-BiVO4 heterojunction with enhanced photocatalytic performance for water purification. J. Alloys Compd. 2021, 881, 160437. [Google Scholar] [CrossRef]

- Mehta, A.; Mishra, A.; Basu, S.; Shetti, N.P.; Reddy, K.R.; Saleh, T.A.; Aminabhavi Tejraj, M. Band gap tuning and surface modification of carbon dots for sustainable environmental remediation and photocatalytic hydrogen production—A review. J. Environ. Manag. 2019, 250, 109486. [Google Scholar] [CrossRef] [PubMed]

- Rao, V.N.; Reddy, N.L.; Kumari, M.M.; Cheralathan, K.K.; Ravi, P.; Sathish, M.; Neppolian, B.; Reddy, K.R.; Shetti, N.P.; Prathap, P.; et al. Sustainable hydrogen production for the greener environment by quantum dots-based efficient photocatalysts: A review. J. Environ. Manag. 2019, 248, 109246. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, H.; Hu, K.; Nie, G.; Yang, Y.; Wang, Y.; Duan, X.; Wang, S. Carbon dots based photocatalysis for environmental applications. J. Environ. Chem. Eng. 2022, 10, 107336. [Google Scholar] [CrossRef]

- Hu, S.; Tian, R.; Wu, L.; Zhao, Q.; Yang, J.; Liu, J.; Cao, S. Chemical Regulation of Carbon Quantum Dots from Synthesis to Photocatalytic Activity. Chem. Asian J. 2013, 8, 1035–1041. [Google Scholar] [CrossRef]

- Li, H.; Liu, R.; Lian, S.; Liu, Y.; Huang, H.; Kang, Z. Near-infrared light controlled photocatalytic activity of carbon quantum dots for highly selective oxidation reaction. Nanoscale 2013, 5, 3289. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, S.Z.; Li, W.; Zhang, Z.H. Visible-light-mediated oxidative amidation of aldehydes by using magnetic CdS quantum dots as a photocatalyst. Chem. Eur. J. 2021, 27, 5483–5491. [Google Scholar] [CrossRef]

- Li, H.; Qing, Q.; Zheng, L.; Xie, L.; Gan, Z.; Huang, L.; Liu, S.; Wang, Z.; Lu, Y.; Chen, J. Carbon dots and carbon nitride composite for photocatalytic removal of uranium under air atmosphere. Chin. Chem. Lett. 2022, 33, 3573–3576. [Google Scholar] [CrossRef]

- Kaur, M.; Kaur, M.; Singh, D.; Oliveira, A.C.; Garg, V.K.; Sharma, V.K. Synthesis of CaFe2O4-NGO nanocomposite for effective removal of heavy metal ion and photocatalytic degradation of organic pollutants. Nanomaterials 2021, 11, 1471. [Google Scholar] [CrossRef] [PubMed]

- Belousov, A.S.; Suleimanov, E.V.; Parkhacheva, A.A. Visible light-induced degradation of organic dyes by niobium tellurium oxides ANbTeO6 (A = Rb, Cs) with β-pyrochlore structure. Mater. Lett. 2022, 327, 133081. [Google Scholar] [CrossRef]

- Weiss, M.; Hoerner, G.; Weber, B.; Marschall, R. The elemental multifariousness of the defect-pyrochlore crystal structure and application in photocatalytic hydrogen generation. Energy Technol. 2021, 10, 2100302. [Google Scholar] [CrossRef]

- Kaur, M.; Kaur, M.; Singh, D.; Feng, M.; Sharma, V.K. Magnesium ferrite-nitrogen-doped graphene oxide nanocomposite: Effective adsorptive removal of lead(II) and arsenic (III). Environ. Sci. Pollut. Res. 2022, 29, 48260–48275. [Google Scholar] [CrossRef]

- Ravi, R.; Iqbal, S.; Ghosal, A.; Ahmed, S. Novel mesoporous trimetallic strontium magnesium ferrite (Sr03Mg0.7Fe2O4) nanocubes: A selective and recoverable magnetic nanoadsorbent for Congo red. J. Alloys Compd. 2019, 791, 336–347. [Google Scholar] [CrossRef]

- Wang, A.; Zhou, K.; Liu, X.; Liu, F.; Chen, Q. Development of Mg–Al–La tri-metal mixed oxide entrapped in alginate for removal of fluoride from wastewater. RSC Adv. 2017, 7, 31221–31229. [Google Scholar] [CrossRef]

- Casbeer, E.; Sharma, V.K.; Li, X.Z. Synthesis and photocatalytic activity of ferrites under visible light: A review. Sep. Purif. Technol. 2012, 87, 1–14. [Google Scholar] [CrossRef]

- Su, M.; He, C.; Sharma, V.K.; Abou, A.M.; Xia, D.; Li, X.Z.; Deng, H.; Xiong, Y. Mesoporous zinc ferrite: Synthesis, characterization and photocatalytic activity with H2O2/ visible light. J. Hazard. Mater. 2011, 211–212, 95–103. [Google Scholar] [CrossRef]

- Fini, S.A.F.; Niasari, M.S.; Hojaghan, H.S. Hydrothermal green synthesis and photocatalytic activity of magnetic CoFe2O4–carbon quantum dots nanocomposite by turmeric precursor. J. Mater. Sci. Mater. Electron. 2017, 28, 16205–16214. [Google Scholar] [CrossRef]

- Elkodous, A.; El-Sayyad, M.; Youssry, G.S.; Nada, S.M.; Gobara, H.G.; Elsayed, M.A.; Matsuda, A. Carbon-dot-loaded CoxNi1−xFe2O4; x = 0.9/SiO2/TiO2 nanocomposite with enhanced photocatalytic and antimicrobial potential: An engineered nanocomposite for wastewater treatment. Sci. Rep. 2020, 10, 11534. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, Y.; Rao, Y.; Zhu, D.; Cao, J.; Shen, Z.; Ho, W.; Lee, S.C. Environment-Friendly Carbon Quantum Dots/ZnFe2O4 Photocatalysts: Characterization, Biocompatibility, and Mechanisms for NO Removal. Environ. Sci. Technol. 2017, 51, 2924–2933. [Google Scholar] [CrossRef] [PubMed]

- Long, M.; Zheng, L. Engineering vacancies for solar photocatalytic applications. Chin. J. Catal. 2017, 38, 617–624. [Google Scholar] [CrossRef]

- Bo, L.; Hu, Y.; Zhang, Z.; Tong, J. Efficient photocatalytic degradation of rhodamine B catalyzed by SrFe2O4/g-C3N4 composite under visible light. Polyhedron 2019, 168, 94–100. [Google Scholar] [CrossRef]

- Pardeshi, S.K.; Pawar, R.Y. SrFe2O4 complex oxide an effective and environmentally benign catalyst for selective oxidation of styrene. J. Mol. Catal. A Chem. 2011, 334, 35–43. [Google Scholar] [CrossRef]

- Zafar, M.N.; Amjad, M.; Tabassum, M.; Ahmad, I.; Zubair, M. SrFe2O4 nanoferrites and SrFe2O4/ground eggshell nanocomposites: Fast and efficient adsorbents for dyes removal. J. Clean Prod. 2018, 199, 983–994. [Google Scholar] [CrossRef]

- Huang, S.; Jiang, S.; Pang, H.; Wen, T.; Asiri, A.M.; Alamry, K.A.; Alsaedi, A.; Wang, X.; Wang, S. Dual functional nanocomposites of magnetic MnFe2O4 and fluorescent carbon dots for efficient U(VI) removal. Chem. Eng. J. 2019, 368, 941–950. [Google Scholar] [CrossRef]

- Naghshbandi, Z.; Arsalani, N.; Sadegh, M.; Geckeler, K.E. A novel synthesis of magnetic and photoluminescent graphene quantum dots/MFe2O4 (M = Ni, Co) nanocomposites for catalytic application. Appl. Surf. Sci. 2018, 443, 484–491. [Google Scholar] [CrossRef]

- Majumdar, B.; Sarma, D.; Jain, S.; Sarma, T.K. One-pot magnetic iron oxide−carbon nanodot composite-catalyzed cyclooxidative aqueous tandem synthesis of quinazolinones in the presence of tert-butyl hydroperoxide. ACS Omega 2018, 3, 13711–13719. [Google Scholar] [CrossRef]

- Li, L.; Wang, F.; Lv, Y.; Liu, J.; Bian, H.; Wang, W.; Li, Y.; Shao, Z. CQDs-doped magnetic electrospun nanofibers: Fluorescence self-display and adsorption removal of mercury(II). ACS Omega 2018, 3, 4220–4230. [Google Scholar] [CrossRef]

- Jaleh, B.; Khalilipour, S.; Habibi, S.; Niyaifar, M.; Nasrollahzadeh, M. Synthesis, characterization, magnetic and catalytic properties of graphene oxide/Fe3O4. J. Mater. Sci. Mater. Electron. 2017, 28, 4974. [Google Scholar] [CrossRef]

- Kabel, J.; Sharma, S.; Acharya, A.; Zhang, D.; Yap, Y.K. Molybdenum disulfide quantum dots: Properties, synthesis, and applications. J. Carbon Res. 2021, 7, 45. [Google Scholar] [CrossRef]

- Jing, S.; Zhao, Y.; Sun, R.-C.; Zhong, L.; Peng, X. Facile and high-yield synthesis of carbon quantum dots from biomass-derived carbons at mild condition. ACS Sustain. Chem. Eng. 2019, 7, 7833–7843. [Google Scholar] [CrossRef]

- Mai, X.-D.; Phan, Y.T.H.; Nguyen, V.Q. Excitation-independent emission of carbon quantum dot solids. Adv. Mater. Sci. Eng. 2020, 2020, 9643168. [Google Scholar] [CrossRef]

- Tanaka, K.; Nakashima, S.; Fujita, K.; Hirao, K. High magnetization and the faraday effect for ferrimagnetism zinc ferrite thin film. J. Phys. Condens. Matter 2003, 15, L469–L474. [Google Scholar] [CrossRef]

- Pan, J.; Chen, J.; Khan, Q.; Huang, Q. Size Tunable ZnO Nanoparticles to enhance electron injection in solution processed QLEDs. ACS Photon. 2016, 3, 215–222. [Google Scholar] [CrossRef]

- Khusboo Kaur, M.; Kiranjeet. Mechanistic insight into adsorption and photocatalytic potential of magnesium ferrite-bentonite nanocomposite. J. Photochem. Photobiol. A Chem. 2022, 425, 113717. [Google Scholar] [CrossRef]

- Ubhi, M.K.; Kaur, M.; Singh, D.; Oliveira, A.C.; Garg, V.K.; Sharma, V.K. Hierarchical nanoflowers of MgFe2O4, bentonite and B-,P- co-doped graphene oxide as adsorbent and photocatalyst: Optimization of parameters by box–behnken methodology. Int. J. Mol. Sci. 2022, 23, 9678. [Google Scholar] [CrossRef]

- Ubhi, M.K.; Kaur, M.; Grewal, J.K.; Oliveira, A.C.; Garg, V.K.; Sharma, V.K. Insight into photocatalytic behavior of magnesium ferrite–bentonite nanocomposite for the degradation of organic contaminants. J. Mater. Res. 2022. [Google Scholar] [CrossRef]

- Cong, S.; Zhao, Z. Carbon Quantum Dots: A component of efficient visible light photocatalysts. In Visible-Light Photocatalysis of Carbon-Based Materials; Yao, Y., Ed.; Intech Open: Singapore, 2017. [Google Scholar] [CrossRef]

- Shahid, M. Fabrication of magnesium substituted cadmium ferrite nanoparticles decorated Graphene-Sheets with improved photocatalytic activity under visible light irradiation. Ceram. Int. 2020, 46, 10861–10870. [Google Scholar] [CrossRef]

- Jiao, X.Y.; Li, L.S.; Qin, S.; Zhang, Y.; Huang, K.; Xu, L. The synthesis of fluorescent carbon dots from mango peel and their multiple applications. Colloids Surf. A Physicochem. Eng. Asp. 2019, 577, 306–314. [Google Scholar] [CrossRef]

- Surendran, P.; Lakshmanan, A.; Vinitha, G.; Ramalingam, G.; Rameshkumar, P. Facile preparation of high fluorescent carbon quantum dots from orange waste peels for nonlinear optical applications. Luminescence 2019, 35, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Wael, A.A.; Ahmed, F.R.; Mona, E.A.; Nagy, L.T.; Ahmed, S.A.; Mohamad, M.A. Green synthesis of carbon quantum dots from purslane leaves for the detection of formaldehyde using quartz crystal microbalance. Carbon 2021, 179, 159–171. [Google Scholar]

- Bandi, R.; Gangapuram, B.R.; Dadigala, R.; Eslavath, R.; Singh, S.S.; Guttena, V. Facile and green synthesis of fluorescent carbon dots from onion waste and their potential applications as sensor and multicolour imaging agents. RSC Adv. 2016, 6, 28633–28639. [Google Scholar] [CrossRef]

- Boruah, A.; Saikia, M.; Das, T.; Goswamee, R.L.; Saikia, B.K. Blue-emitting fluorescent carbon quantum dots from waste biomass sources and their application in fluoride ion detection in water. J. Photochem. Photobiol. B Biol. 2020, 209, 111940. [Google Scholar] [CrossRef]

- Bano, D.; Kumar, V.; Singh, V.K.; Hasan, S.H. Green synthesis of fluorescent carbon quantum dots for the detection of mercury (II) and glutathione. New J. Chem. 2018, 42, 5814–5821. [Google Scholar] [CrossRef]

| Nanomaterial | Lattice Constant (A°) | Experimental Density (ρexp in g/cm3) | Average Particle Size (nm) | XRD Density (ρXRD in g/cm3) |

|---|---|---|---|---|

| Sr0.4Ti0.6Fe2O4.6 | 9.05 ± 0.03 | 2.43 ± 0.2 | 23.86 ± 1.8 | 4.28 ± 0.3 |

| CQDs | 8.04 ± 0.02 | 3.27 ± 0.3 | - | - |

| CQDs− Sr0.4Ti0.6Fe2O4.6 | 8.26 ± 0.04 | 3.06 ± 0.3 | 21.26 ± 1.4 | - |

| Nanomaterial | Surface Area (m2/g) | Pore Volume (cm3/g) | Pore Diameter (nm) | Saturation Magnetization Ms (emug−1) | Retentivity Mr (emug−1) | Coercivity Hc (Oe) |

|---|---|---|---|---|---|---|

| Sr0.4Ti0.6Fe2O4.6 | 77.62 | 0.071 | 3.629 | 9.352 | 0.5963 | 72.59 |

| CQDs | 91.27 | 0.074 | 3.362 | - | - | - |

| CQDs− Sr0.4Ti0.6Fe2O4.6 | 101.27 | 0.089 | 3.194 | 4.25 | 0.5198 | 35.74 |

| Nanomaterial | Isomer Shift (δ, mm/s) | Q. Splitting (Δ, mm/s) | Magnetic Field (B, T) | Area (%) |

|---|---|---|---|---|

| Sr0.4Ti0.6Fe2O4.6 | 0.4 ± 0.01 (S) | −0.1 ± 0.02 | 51.0 ± 0.17 | 16.20 |

| 0.3 ± 0.01 (S) | 0.1 ± 0.02 | 49.3 ± 0.17 | 41.60 | |

| 0.3 ± 0.00 (D) | 0.6 ± 0.00 | - | 42.20 | |

| CQDs− Sr0.4Ti0.6Fe2O4.6 | 0.8 ± 0.41 (S) | −0.0 ± 0.49 | 59.5 ± 4.07 | 70.2 |

| 0.3 ± 0.03 (D) | 0.7 ± 0.03 | - | 29.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grewal, J.K.; Kaur, M.; Mandal, K.; Sharma, V.K. Carbon Quantum Dot-Titanium Doped Strontium Ferrite Nanocomposite: Visible Light Active Photocatalyst to Degrade Nitroaromatics. Catalysts 2022, 12, 1126. https://doi.org/10.3390/catal12101126

Grewal JK, Kaur M, Mandal K, Sharma VK. Carbon Quantum Dot-Titanium Doped Strontium Ferrite Nanocomposite: Visible Light Active Photocatalyst to Degrade Nitroaromatics. Catalysts. 2022; 12(10):1126. https://doi.org/10.3390/catal12101126

Chicago/Turabian StyleGrewal, Jaspreet Kaur, Manpreet Kaur, Kousik Mandal, and Virender K. Sharma. 2022. "Carbon Quantum Dot-Titanium Doped Strontium Ferrite Nanocomposite: Visible Light Active Photocatalyst to Degrade Nitroaromatics" Catalysts 12, no. 10: 1126. https://doi.org/10.3390/catal12101126