Highly Efficient Synthesis of Cinnamamides from Methyl Cinnamates and Phenylethylamines Catalyzed by Lipozyme® TL IM under Continuous-Flow Microreactors

Abstract

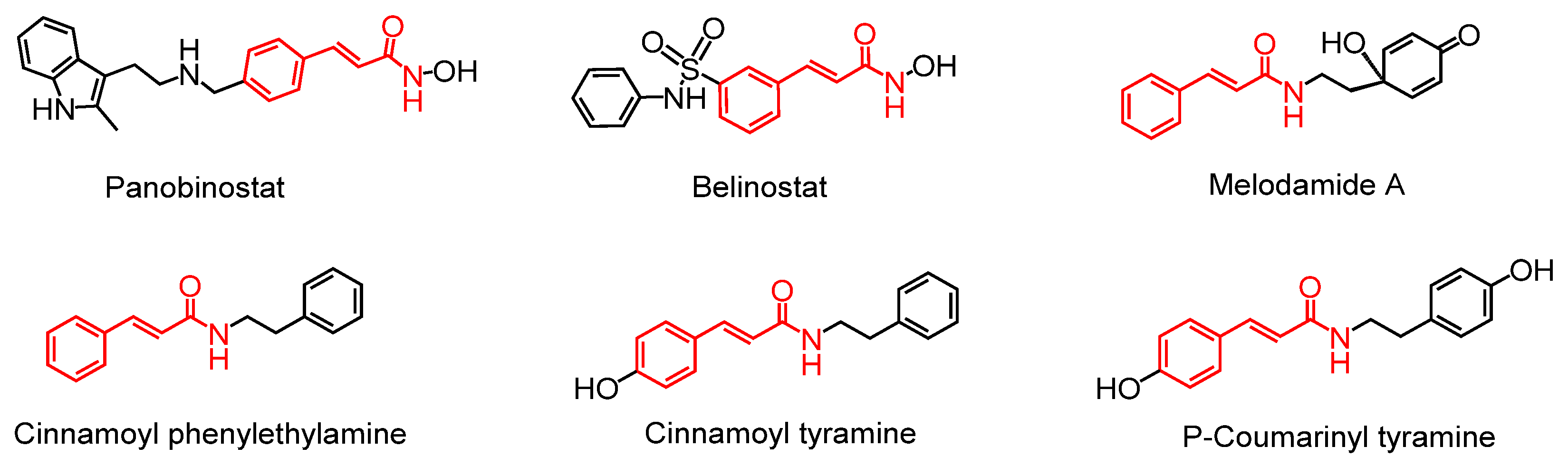

:1. Introduction

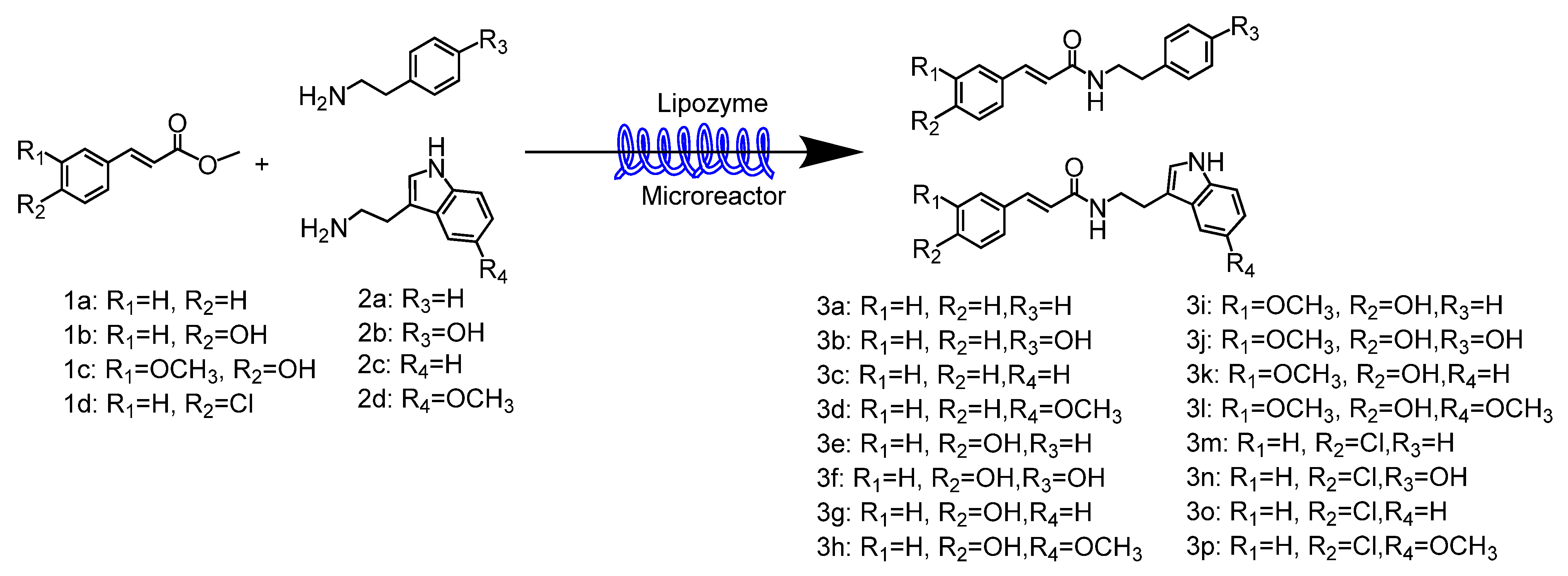

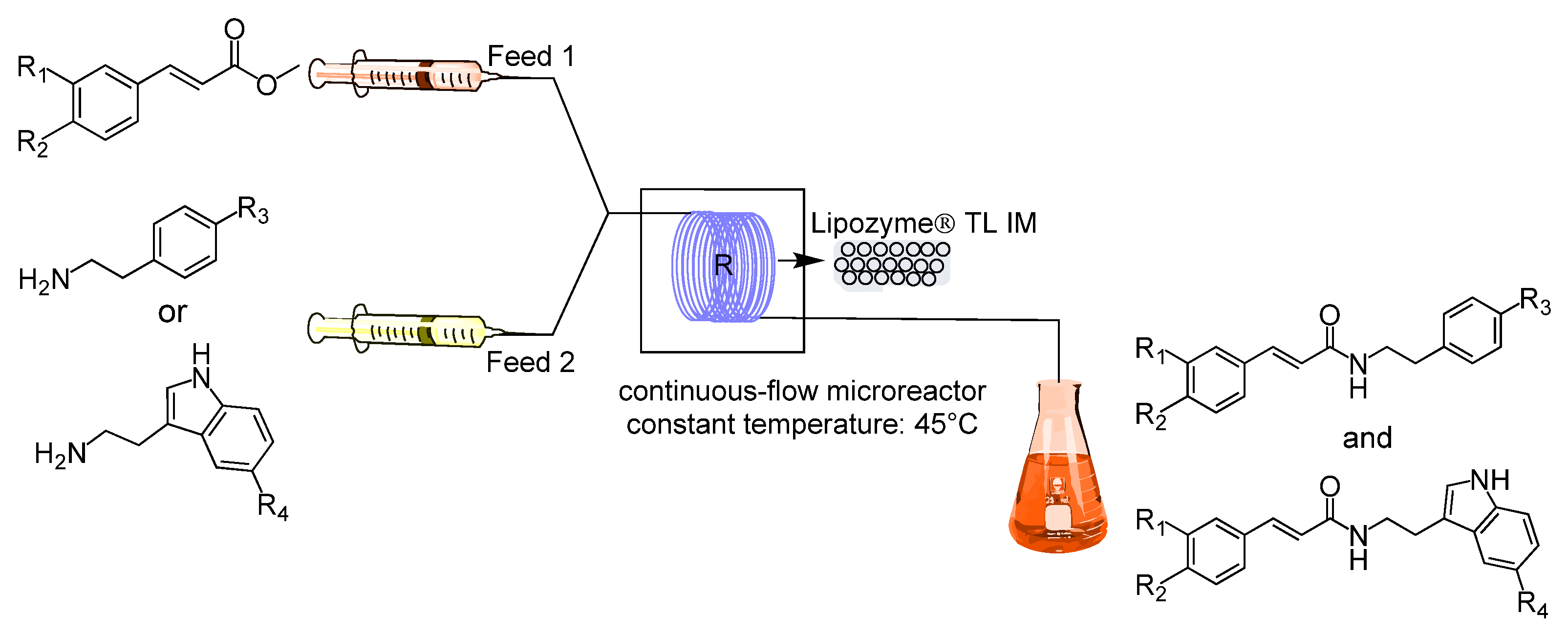

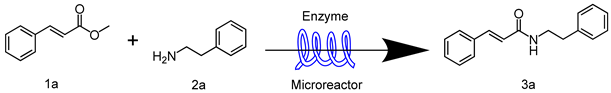

2. Results

2.1. Effect of Reaction Media and Catalyst

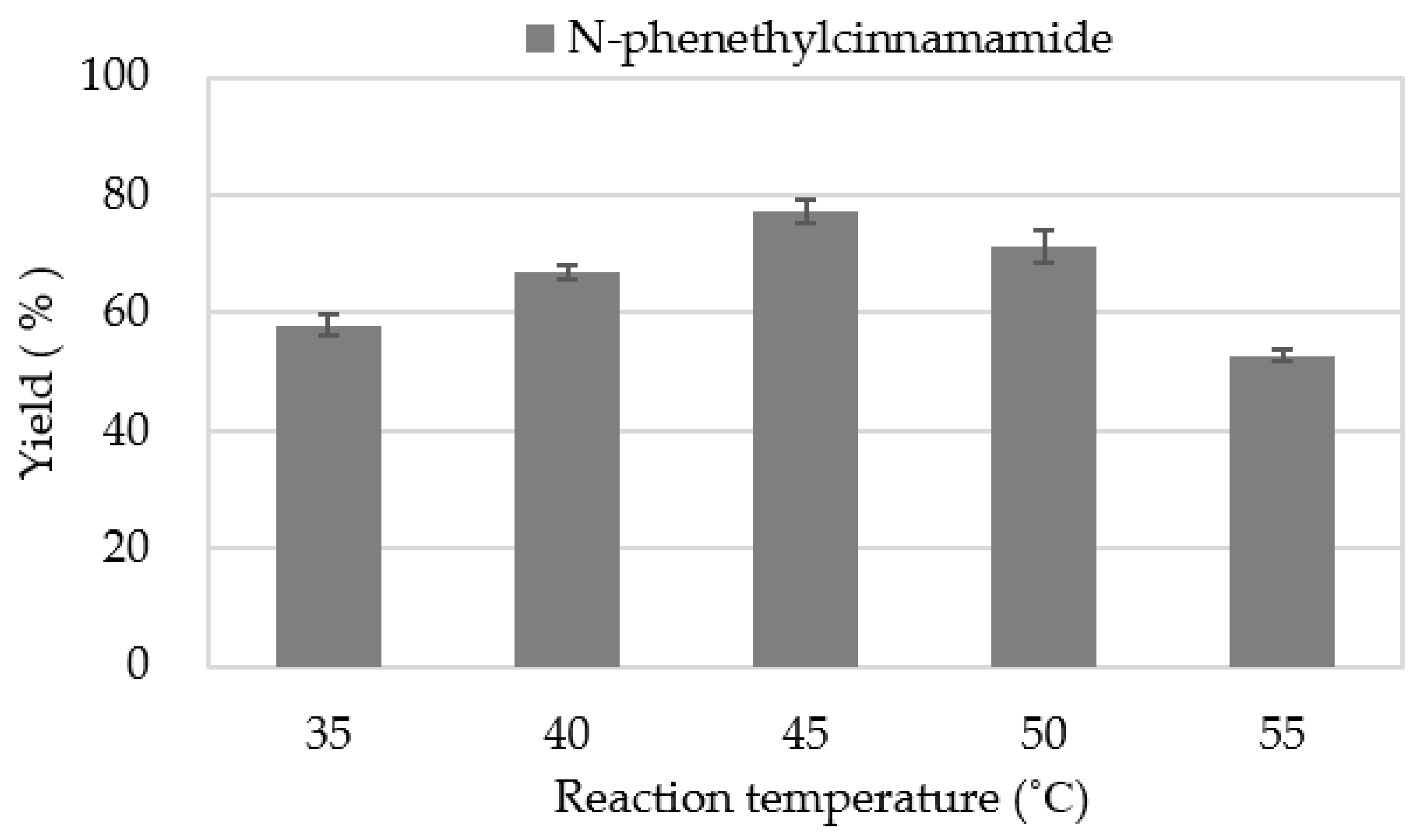

2.2. Effect of Reaction Temperature

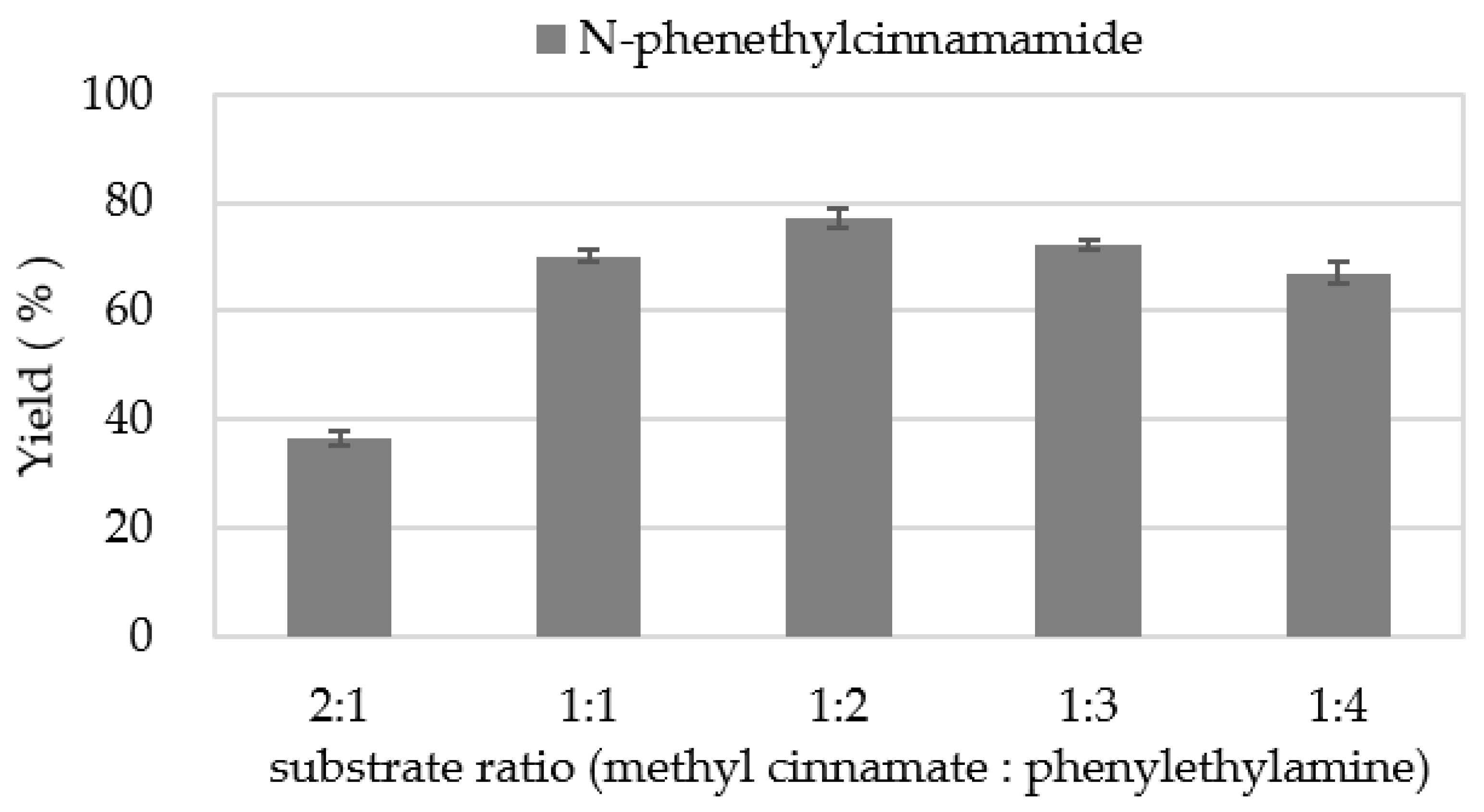

2.3. Effect of Substrate Ratio

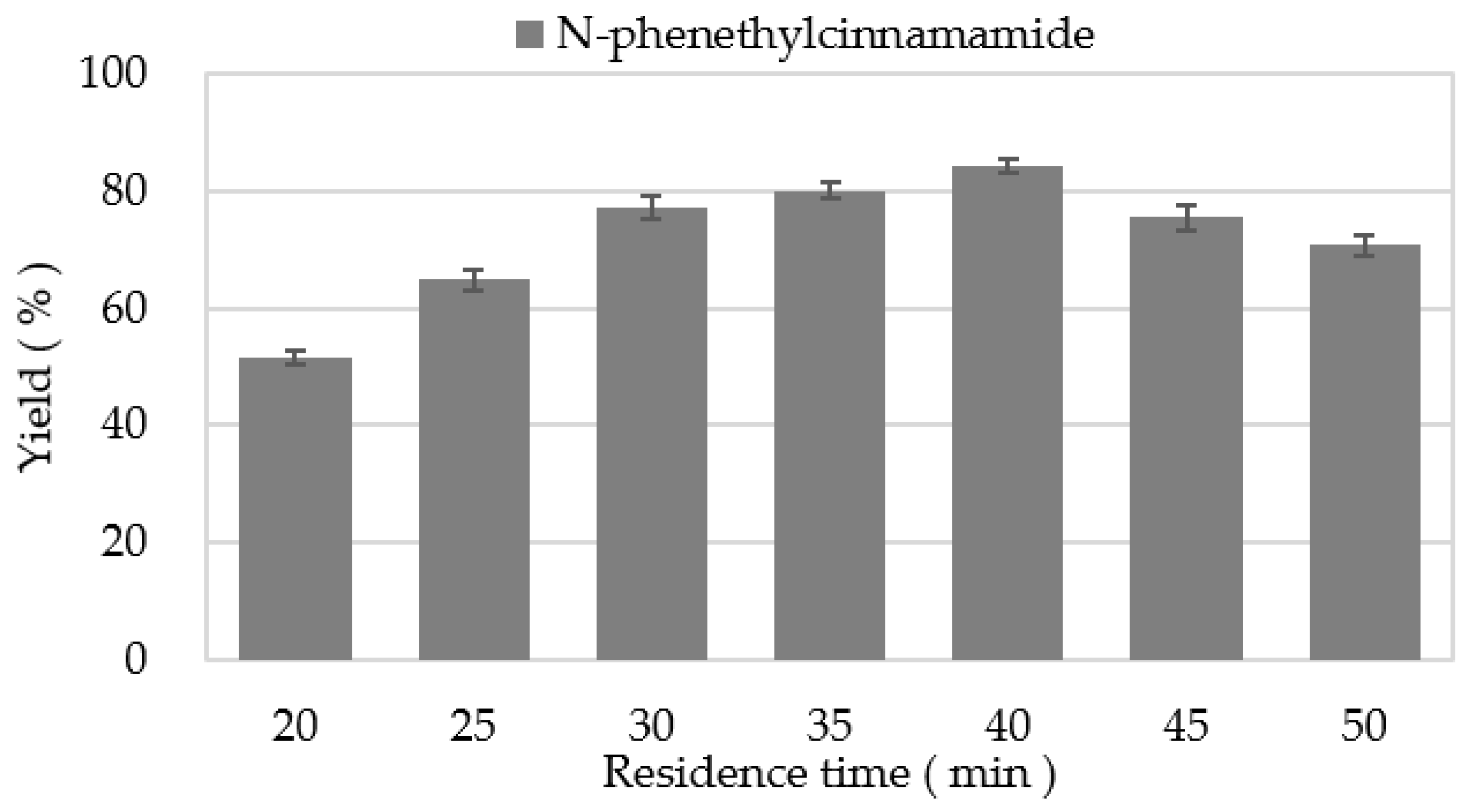

2.4. Effect of Residence Time

2.5. The Effect of Enzyme Reusability

2.6. Comparing the Synthesis of Cinnamamide Derivatives from Methyl Cinnamates and Phenylethylamines in a Continuous-Flow Microreactor and a Batch Bioreactor

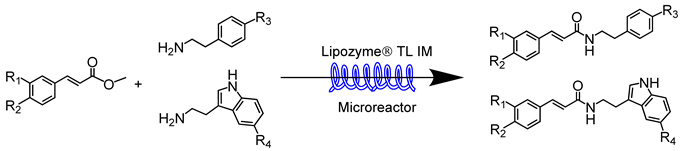

2.7. The Scope and Limitation of the Synthesis of Cinnamamide Derivatives Catalyzed by Lipozyme® TL IM in Continuous-Flow Microreactors

3. Materials and Methods

3.1. Materials

3.2. Experimental Setup and Experiment Conditions

3.3. Analytical Methods

3.3.1. Thin-Layer Chromatography (TLC)

3.3.2. Nuclear Magnetic Resonance (NMR)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gaspar, A.; Garrido, E.M.; Esteves, M.E.; Quezada, E.; Milhazes, N.; Garrido, J.; Borges, F. New insights into the antioxidant activity of hydroxycinnamic acids: Synthesis and physicochemical characterization of novel halogenated derivatives. Eur. J. Med. Chem. 2009, 44, 2092–2099. [Google Scholar] [CrossRef] [PubMed]

- Guzman, J.D. Natural cinnamic acids, synthetic derivatives and hybrids with antimicrobial activity. Molecules 2014, 19, 19292–19349. [Google Scholar] [CrossRef] [PubMed]

- De, P.; Baltas, M.; Bedos-Belval, F. Cinnamic Acid Derivatives as Anticancer Agents—A Review. Curr. Med. Chem. 2011, 18, 1672–1703. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.C.; Deng, J.S.; Chiu, C.S.; Hou, W.C.; Huang, S.S.; Shie, P.H.; Huang, G.J. Anti-Inflammatory Activities of Cinnamomum cassia Constituents In Vitro and In Vivo. Evid. Based Complement. Altern. Med. 2012, 2012, 429320. [Google Scholar] [CrossRef] [Green Version]

- Chen, D.D.; Zhang, B.Y.; Liu, X.X.; Li, X.Q.; Yang, X.J.; Zhou, L. Bioactivity and structure-activity relationship of cinnamic acid derivatives and its heteroaromatic ring analogues as potential high-efficient acaricides against Psoroptes cuniculi. Bioorganic Med. Chem. Lett. 2018, 28, 1149–1153. [Google Scholar] [CrossRef]

- Chen, G.Z.; Zhang, Y.L.; Liu, X.; Fang, Q.L.; Wang, Z.; Fu, L.L.; Liu, Z.G.; Wang, Y.; Zhao, Y.J.; Li, X.K.; et al. Discovery of a New Inhibitor of Myeloid Differentiation 2 from Cinnamamide Derivatives with Anti-Inflammatory Activity in Sepsis and Acute Lung Injury. J. Med. Chem. 2016, 59, 2436–2451. [Google Scholar] [CrossRef]

- Chan, H.H.; Hwang, T.L.; Thang, T.D.; Leu, Y.L.; Kuo, P.C.; Nguyet, B.T.M.; Dai, D.N.; Wu, T.S. Isolation and synthesis of melodamide A, a new anti-inflammatory phenolic amide from the leaves of Melodorum fruticosum. Planta Med. 2013, 79, 288–294. [Google Scholar] [CrossRef] [Green Version]

- He, F.C.; Chou, J.; Scheiner, M.; Poeta, E.; Chen, N.Y.; Gunesch, S.; Hoffmann, M.; Sotriffer, C.; Monti, B.; Maurice, T.; et al. Melatonin- and Ferulic Acid-Based HDAC6 Selective Inhibitors Exhibit Pronounced Immunomodulatory Effects In Vitro and Neuroprotective Effects in a Pharmacological Alzheimer’s Disease Mouse Model. J. Med. Chem. 2021, 64, 3794–3812. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, J.L.; Zhao, B.; Fan, Z.J.; Hu, M.X.; Li, Q.; Hu, W.H.; Li, J.W. Discovery of Novel Isothiazole, 1,2,3-Thiadiazole, and Thiazole-Based Cinnamamides as Fungicidal Candidates. J. Agric. Food Chem. 2019, 67, 12357–12365. [Google Scholar] [CrossRef]

- Wang, D.; Zhu, J.; Xu, J.R.; Ji, D.D. Synthesis of N-hydroxycinnamoyl amide derivatives and evaluation of their anti-oxidative and anti-tyrosinase activities. Bioorganic Med. Chem. 2019, 27, 114918. [Google Scholar] [CrossRef]

- Kim, J.K.; Heo, H.Y.; Park, S.; Kim, H.; Oh, J.J.; Sohn, E.H.; Jung, S.H.; Lee, K. Characterization of Phenethyl Cinnamamide Compounds from Hemp Seed and Determination of Their Melanogenesis Inhibitory Activity. ACS Omega 2021, 6, 31945–31954. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Song, G.Z.; Liu, Z.Q. Synthesis and antioxidant capacities of hydroxyl derivatives of cinnamoylphenethylamine in protecting DNA and scavenging radicals. Free Radic. Res. 2011, 45, 445–453. [Google Scholar] [CrossRef]

- Han, E.H.; Kim, J.Y.; Kim, H.G.; Choi, J.H.; Im, J.H.; Woo, E.R.; Jeong, H.G. Dihydro-N-caffeoyltyramine down-regulates cyclooxygenase-2 expression by inhibiting the activities of C/EBP and AP-1 transcription factors. Food Chem. Toxicol. 2010, 48, 579–586. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.H.; Kim, D.W.; Long, M.J.; Park, C.; Son, M.; Kim, J.K.; Yuk, H.J.; Lee, K.W.; Park, K.H. Cinnamic acid amides from Tribulus terrestris displaying uncompetitive α-glucosidase inhibition. Eur. J. Med. Chem. 2016, 114, 201–208. [Google Scholar] [CrossRef]

- Thomas, J.B.; Fall, M.J.; Cooper, J.B.; Burgess, J.P.; Carroll, F.I. Rapid In-Plate Generation of Benzimidazole Libraries and Amide Formation Using EEDQ. Tetrahedron Lett. 1997, 38, 5099–5102. [Google Scholar] [CrossRef]

- Kunishima, M.; Kawachi, C.; Morita, J.; Terao, K.; Iwasaki, F.; Tani, S. 4-(4,6-Dimethoxy-1,3,5-triazin-2-yl)-4-methylmorpholinium Chloride: An Efficient Condensing Agent Leading to the Formation of Amides and Esters. Tetrahedron 1999, 55, 13159–13170. [Google Scholar] [CrossRef]

- Garrett, C.E.; Jiang, X.L.; Prasad, K.; Repič, O. New observations on peptide bond formation using CDMT. Tetrahedron Lett. 2002, 43, 4161–4165. [Google Scholar] [CrossRef]

- Hioki, K.; Kameyama, S.; Tani, S.; Kunishima, M. Immobilized Triazine-Type Dehydrocondensing Reagents for Carboxamide Formation: ROMP-Trz-Cl and ROMP(OH)-Trz-Cl. Chem. Pharm. Bull. 2007, 55, 825–828. [Google Scholar] [CrossRef] [Green Version]

- Yoshimitsu, Y.; Yasuhiro, K.; Masami, U. Induction of adiponectin by natural and synthetic phenolamides in mouse and human preadipocytes and its enhancement by docosahexaenoic acid. Life Sci. 2008, 82, 290–300. [Google Scholar] [CrossRef]

- Muramatsu, W.; Hattori, T.; Yamamoto, H. Amide bond formation: Beyond the dilemma between activation and racemization. Chem. Commun. 2021, 57, 6346. [Google Scholar] [CrossRef]

- Marco, T.S.; Boulton, L.T.; Sneddon, H.F.; Sheppard, T.D. A green chemistry perspective on catalytic amide bond formation. Nat. Catal. 2019, 2, 10–17. [Google Scholar] [CrossRef]

- Munetaka, K.; Kazuhito, H.; Ayako, W.; Hiroko, K.; Shohei, T. Approach to green chemistry of DMT-MM: Recovery and recycle of coproduct to chloromethane-free DMT-MM. Tetrahedron Lett. 2002, 43, 3323–3326. [Google Scholar] [CrossRef]

- Munetaka, K.; Kazuyoshi, Y.; Yasunobu, W.; Kazuhito, H.; Shohei, T. Development of novel polymer-type dehydrocondensing reagents comprised of chlorotriazines. Chem. Commun. 2005, 21, 2698–2700. [Google Scholar] [CrossRef]

- Munetaka, K.; Kazuyoshi, Y.; Kazuhito, H.; Tomohito, K.; Masumi, H.; Shohei, T. Development of chlorotriazine polymer dehydrocondensing reagents (Poly-Trzs). Tetrahedron 2007, 63, 2604–2612. [Google Scholar] [CrossRef]

- Driller, K.M.; Prateeptongkum, S.; Jackstell, R.; Beller, M. A general and selective iron-catalyzed aminocarbonylation of alkynes: Synthesis of acryl- and cinnamides. Angew. Chem. Int. Ed. Engl. 2011, 50, 537–541. [Google Scholar] [CrossRef]

- Ishihara, K.; Lua, Y. Boronic acid-DMAPO cooperative catalysis for dehydrative condensation between carboxylic acids and amines. Chem. Sci. 2016, 7, 1276–1280. [Google Scholar] [CrossRef] [Green Version]

- Gualtierotti, J.B.; Schumacher, X.; Fontaine, P.; Masson, G.; Wang, Q.; Zhu, J. Amidation of aldehydes and alcohols through alpha-iminonitriles and a sequential oxidative three-component Strecker reaction/thio-Michael addition/alumina-promoted hydrolysis process to access beta-mercaptoamides from aldehydes, amines, and thiols. Chem. Eur. J. 2012, 18, 14812–14819. [Google Scholar] [CrossRef]

- Prasad, V.; Kale, R.R.; Mishra, B.B.; Kumar, D.; Tiwari, V.K. Diacetoxyiodobenzene Mediated One-Pot Synthesis of Diverse Carboxamides from Aldehydes. Org. Lett. 2012, 4, 2936–2939. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Bao, G.; Yu, C.; Liu, Y.; He, Z.; Wang, P.; Ma, W.; Xie, J.; Sun, W.; et al. NDTP Mediated Direct Rapid Amide and Peptide Synthesis without Epimerization. Org. Lett. 2022, 24, 1169–1174. [Google Scholar] [CrossRef]

- Yoon, S.; Patil, M.D.; Sarak, S.; Jeon, H.; Kim, G.-H.; Khobragade, T.P.; Sung, S.; Yunl, H. Deracemization of Racemic Amines to Enantiopure (R)- and (S)-amines by Biocatalytic Cascade Employing ω-Transaminase and Amine Dehydrogenase. ChemCatChem 2019, 11, 1898–1902. [Google Scholar] [CrossRef]

- Bavandi, H.; Shahedi, M.; Habibi, Z.; Yousefi, M.; Brask, J.; Mohammadi, M. Biocatalytic decarboxylative Michael addition for synthesis of 1,4-benzoxazinone derivatives. Sci. Rep. 2022, 12, 12713. [Google Scholar] [CrossRef] [PubMed]

- Simić, S.; Zukić, E.; Schmermund, L.; Faber, K.; Winkler, C.K.; Kroutil, W. Shortening Synthetic Routes to Small Molecule Active Pharmaceutical Ingredients Employing Biocatalytic Methods. Chem. Rev. 2022, 122, 1052–1126. [Google Scholar] [CrossRef] [PubMed]

- Hanefeld, U.; Hollmann, F.; Paul, C.E. Biocatalysis making waves in organic chemistry. Chem. Soc. Rev. 2022, 51, 594–627. [Google Scholar] [CrossRef] [PubMed]

- Petchey, M.R.; Grogan, G. Enzyme-catalyzed Synthesis of Secondary and Tertiary Amides. Adv. Synth. Catal. 2019, 361, 3895–3914. [Google Scholar] [CrossRef]

- Burke, A.J.; Burke, A.J.; Birmingham, W.R.; Zhuo, Y.; Thorpe, T.W.; Costa, B.Z.; Crawshaw, R.; Rowles, I.; Finnigan, J.D.; Young, C.; et al. An Engineered Cytidine Deaminase for Biocatalytic Production of a Key Intermediate of the COVID-19 Antiviral Molnupiravir. J. Am. Chem. Soc. 2022, 144, 3761–3765. [Google Scholar] [CrossRef]

- Sabi, G.J.; Gama, R.S.; Fernandez-Lafuente, R.; Cancino-Bernardi, J.; Mendes, A.A. Decyl esters production from soybean-based oils catalyzed by lipase immobilized on differently functionalized rice husk silica and their characterization as potential biolubricants. Enzyme Microb. Technol. 2022, 157, 110019. [Google Scholar] [CrossRef]

- Holm, H.C.; Cowan, D. The evolution of enzymatic interesterification in the oils and fats industry. Eur. J. Lipid Sci. Technol. 2008, 110, 679–691. [Google Scholar] [CrossRef]

- He, J.; Hong, B.; Lu, R.; Zhang, R.; Fang, H.; Huang, W.; Bai, K.; Sun, J. Separation of saturated fatty acids from docosahexaenoic acid-rich algal oil by enzymatic ethanolysis in tandem with molecular distillation. Food Sci. Nutr. 2020, 8, 2234–2241. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Gu, H.; Zhou, L.; Cui, C.; Gao, J. Novel in Situ Batch Reactor with a Facile Catalyst Separation Device for Biodiesel Production. Ind. Eng. Chem. Res. 2012, 51, 14935–14940. [Google Scholar] [CrossRef]

- Wang, Z.-Y.; Bi, Y.-H.; Yang, R.-L.; Zhao, X.-J.; Jiang, L.; Ding, C.-X.; Zheng, S.-Y. Highly efficient enzymatic synthesis of novel polydatin prodrugs with potential anticancer activity. Process Biochem. 2017, 52, 209–213. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.; Son, J.; Lee, H.; Song, J.H.; Lee, T.; Jeon, H.; Kim, H.S.; Park, S.J.; Yoo, H.Y.; et al. Improved Productivity of Naringin Oleate with Flavonoid and Fatty Acid by Efficient Enzymatic Esterification. Antioxidants 2022, 11, 242. [Google Scholar] [CrossRef] [PubMed]

- Zeng, F.; Zhang, H.K.; Xu, M.M.; Huang, K.D.; Zhang, T.; Duan, J.N. Immobilized lipase catalytic synthesis of phenolamides and their potential against α-glucosidase. J. Biotechnol. 2021, 334, 51–57. [Google Scholar] [CrossRef] [PubMed]

- Sheldon, R.A.; Woodley, J.M. Role of Biocatalysis in Sustainable Chemistry. Chem. Rev. 2018, 118, 801–838. [Google Scholar] [CrossRef] [PubMed]

- Ferlin, F.; Lanari, D.; Vaccaro, L. Sustainable flow approaches to active pharmaceutical ingredients. Green Chem. 2020, 22, 5937–5955. [Google Scholar] [CrossRef]

- Du, L.H.; Dong, Z.; Long, R.J.; Chen, P.F.; Xue, M.; Luo, X.P. The convenient Michael addition of imidazoles to acrylates catalyzed by Lipozyme TL IM from Thermomyces lanuginosus in a continuous flow microreactor. Org. Biomol. Chem. 2019, 17, 807. [Google Scholar] [CrossRef]

- Du, L.H.; Xue, M.; Yang, M.J.; Pan, Y.; Zheng, L.Y.; Ou, Z.M.; Luo, X.P. Ring-Opening of Epoxides with Amines for Synthesis of β-Amino Alcohols in a Continuous-Flow Biocatalysis System. Catalysts 2020, 10, 1419. [Google Scholar] [CrossRef]

- Du, L.H.; Yang, M.J.; Pan, Y.; Zheng, L.Y.; Zhang, S.Y.; Sheng, Z.K.; Chen, P.F.; Luo, X.P. Continuous Flow Biocatalysis: Synthesis of Coumarin Carboxamide Derivatives by Lipase TL IM from Thermomyces lanuginosus. Catalysts 2022, 12, 339. [Google Scholar] [CrossRef]

- DiCosimo, R.; McAuliffe, J.; Poulose, A.J.; Bohlmann, G. Industrial use of immobilized enzymes. Chem. Soc. Rev. 2013, 42, 6437–6474. [Google Scholar] [CrossRef]

- Carvalho, W.C.A.; Luiz, J.H.H.; Fernandez-Lafuente, R.; Hirata, D.B.; Mendes, A.A. Eco-friendly production of trimethylolpropane triesters from refined and used soybean cooking oils using an immobilized low-cost lipase (Eversa>® Transform 2.0) as heterogeneous catalyst. Biomass Bioenergy 2021, 155, 106302. [Google Scholar] [CrossRef]

- Zhang, K.P.; Lai, J.Q.; Huang, Z.L.; Yang, Z. Penicillium expansum lipase-catalyzed production of biodiesel in ionic liquids. Bioresour. Technol. 2011, 102, 2767–2772. [Google Scholar] [CrossRef]

- Mendoza-Ortiz, P.A.; Gama, R.S.; Gómez, O.C.; Luiz, J.H.H.; Fernandez-Lafuente, R.; Cren, E.C.; Mendes, A.A. Sustainable Enzymatic Synthesis of a Solketal Ester—Process Optimization and Evaluation of Its Antimicrobial Activity. Catalysts 2020, 10, 218. [Google Scholar] [CrossRef] [Green Version]

- Bansode, S.R.; Rathod, V.K. An intensified technique for lipase catalysed amide synthesis. Chem. Eng. Process. Process Intensif. 2019, 143, 107605. [Google Scholar] [CrossRef]

- Guedes Júnior, J.G.E.; Mattos, F.R.; Sabi, G.J.; Carvalho, W.C.A.; Luiz, J.H.H.; Cren, É.C.; Fernandez-Lafuente, R.; Mendes, A.A. Design of a sustainable process for enzymatic production of ethylene glycol diesters via hydroesterification of used soybean cooking oil. J. Environ. Chem. Eng. 2022, 10, 107062. [Google Scholar] [CrossRef]

- Lin, H.H.; Cheng, Y.; Huo, J.; Shanks, B.H. Selective Ammonolysis of Bioderived Esters for Biobased Amide Synthesis. ACS Omega 2021, 6, 30040–30049. [Google Scholar] [CrossRef]

- de Araujo-Silva, R.; Vieira, A.C.; de Campos Giordano, R.; Fernandez-Lafuente, R.; Tardioli, P.W. Enzymatic Synthesis of Fatty Acid Isoamyl Monoesters from Soybean Oil Deodorizer Distillate: A Renewable and Ecofriendly Base Stock for Lubricant Industries. Molecules 2022, 27, 2692. [Google Scholar] [CrossRef]

- Benítez-Mateos, A.I.; Contente, M.L.; Roura Padrosa, D.; Paradisi, F. Flow biocatalysis 101: Design, development and applications. React. Chem. Eng. 2021, 6, 599–611. [Google Scholar] [CrossRef]

- Coloma, J.; Guiavarc’h, Y.; Hagedoorn, P.L.; Hanefeld, U. Immobilisation and flow chemistry: Tools for implementing biocatalysis. Chem. Commun. 2021, 57, 11416–11428. [Google Scholar] [CrossRef]

- Boodhoo, K.V.K.; Flickinger, M.C.; Woodley, J.M.; Emanuelsson, E.A.C. Bioprocess intensification: A route to efficient and sustainable biocatalytic transformations for the future. Chem. Eng. Process. Process Intensif. 2022, 172, 108793. [Google Scholar] [CrossRef]

- Sen, N.; Singh, K.K.; Mukhopadhyay, S.; Shenoy, K.T. Solvent-Free Synthesis of [DMIM]DMP Ionic Liquid in a Microreactor and Scale-Up Aspects. Ind. Eng. Chem. Res. 2022, 61, 2973–2985. [Google Scholar] [CrossRef]

- Stradomska, D.; Coloma, J.; Hanefeld, U.; Szymańska, K. Continuous flow for enantioselective cyanohydrin synthesis. Catal. Sci. Technol. 2022, 12, 3356–3362. [Google Scholar] [CrossRef]

- Kiviranta, P.H.; Salo, H.S.; Leppanen, J.; Rinne, V.M.; Kyrylenko, S.; Kuusisto, E.; Suuronen, T.; Salminen, A.; Poso, A.; Lahtela-Kakkonen, M.; et al. Characterization of the binding properties of SIRT2 inhibitors with a N-(3-phenylpropenoyl)-glycine tryptamide backbone. Bioorganic Med. Chem. 2008, 16, 8054–8062. [Google Scholar] [CrossRef] [PubMed]

- Padrosa, D.R.; Contente, M.L. Multi-gram preparation of cinnamoyl tryptamines as skin whitening agents through a chemo-enzymatic flow process. Tetrahedron Lett. 2021, 86, 153453. [Google Scholar] [CrossRef]

- Takao, K.; Toda, K.; Saito, T.; Sugita, Y. Synthesis of Amide and Ester Derivatives of Cinnamic Acid and Its Analogs: Evaluation of Their Free Radical Scavenging and Monoamine Oxidase and Cholinesterase Inhibitory Activities. Chem. Pharm. Bull. 2017, 65, 1020–1027. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, L.; Jin, Y.; Chen, H.; Sun, C.; Fu, W.; Zheng, L.; Lu, M.; Chen, P.; Chen, G.; Zhang, Y.; et al. Discovery of caffeic acid phenethyl ester derivatives as novel myeloid differentiation protein 2 inhibitors for treatment of acute lung injury. Eur. J. Med. Chem. 2018, 143, 361–375. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Zhu, X.; Mao, H.; Zou, X.; Kong, L.; Li, X. Features and applications of reactions of α,β-unsaturated N-acylbenzotriazoles with amino compounds. Tetrahedron 2008, 64, 6510–6521. [Google Scholar] [CrossRef]

- Song, J. Synthesis and Anti—Itch Activity Evaluation of 5—Methoxytryptamine Derivatives. Guangzhou Chem. Ind. 2012, 40, 92–94. [Google Scholar]

| ||||

|---|---|---|---|---|

| Entry | Solvent | Catalysts | Log P | Yield b (%) |

| 1 | tert-amyl alcohol | Lipozyme® TL IM | 1.04 | 71.2 ± 1.5 |

| 2 | tert-butanol | Lipozyme® TL IM | 0.51 | 36.2 ± 0.8 |

| 3 | acetonitrile | Lipozyme® TL IM | −0.33 | 33.5 ± 1.1 |

| 4 | n-hexane | Lipozyme® TL IM | 3.9 | n.d. |

| 5 | DMF | Lipozyme® TL IM | −1.0 | n.d. |

| 6 | DMSO | Lipozyme® TL IM | −1.3 | n.d. |

| 7 | tert-amyl alcohol | Subtilisin® | 1.04 | n.d. |

| 8 | tert-amyl alcohol | None | 1.04 | n.d. |

| |||

|---|---|---|---|

| Entry | Method | STY (g L−1 h−1) | Yield b (%) |

| 1 | A | 20.68 | 84.2 ± 1.2 |

| 2 | B | 1.09 | 64.3 ± 0.8 |

| ||||

|---|---|---|---|---|

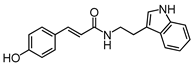

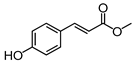

| Entry | Methyl Cinnamates | Amine Compounds | Product | Yield b (%) |

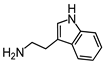

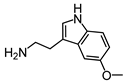

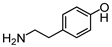

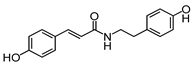

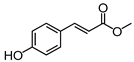

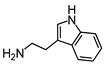

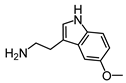

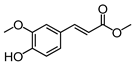

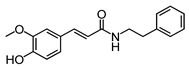

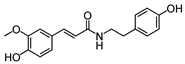

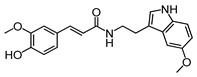

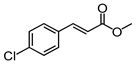

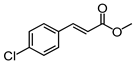

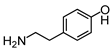

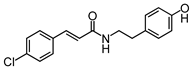

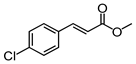

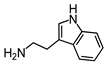

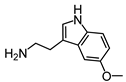

| 1 |  |  |  | 84.2 ± 1.2 |

| 2 |  |  |  | 80.4 ± 0.8 |

| 3 |  |  |  | 60.2 ± 0.7 |

| 4 |  |  |  | 55.2 ± 1.3 |

| 5 |  |  |  | 72.8 ± 0.9 |

| 6 |  |  |  | 67.9 ± 0.6 |

| 7 |  |  |  | 54.4 ± 1.2 |

| 8 |  |  |  | 49.8 ± 0.9 |

| 9 |  |  |  | 62.5 ± 2.4 |

| 10 |  |  |  | 54.5 ± 1.6 |

| 11 |  |  |  | 44.9 ± 0.9 |

| 12 |  |  |  | 44.4 ± 0.8 |

| 13 |  |  |  | 91.3 ± 1.3 |

| 14 |  |  |  | 85.3 ± 1.1 |

| 15 |  |  |  | 67.6 ± 0.7 |

| 16 |  |  |  | 62.6 ± 1.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, L.; Zheng, L.; Pan, Y.; Sheng, Z.; Zhang, S.; Lin, H.; Zhang, A.; Xie, H.; Luo, X. Highly Efficient Synthesis of Cinnamamides from Methyl Cinnamates and Phenylethylamines Catalyzed by Lipozyme® TL IM under Continuous-Flow Microreactors. Catalysts 2022, 12, 1265. https://doi.org/10.3390/catal12101265

Du L, Zheng L, Pan Y, Sheng Z, Zhang S, Lin H, Zhang A, Xie H, Luo X. Highly Efficient Synthesis of Cinnamamides from Methyl Cinnamates and Phenylethylamines Catalyzed by Lipozyme® TL IM under Continuous-Flow Microreactors. Catalysts. 2022; 12(10):1265. https://doi.org/10.3390/catal12101265

Chicago/Turabian StyleDu, Lihua, Lingyan Zheng, Yue Pan, Zhikai Sheng, Shiyi Zhang, Hang Lin, Aoying Zhang, Hanjia Xie, and Xiping Luo. 2022. "Highly Efficient Synthesis of Cinnamamides from Methyl Cinnamates and Phenylethylamines Catalyzed by Lipozyme® TL IM under Continuous-Flow Microreactors" Catalysts 12, no. 10: 1265. https://doi.org/10.3390/catal12101265

APA StyleDu, L., Zheng, L., Pan, Y., Sheng, Z., Zhang, S., Lin, H., Zhang, A., Xie, H., & Luo, X. (2022). Highly Efficient Synthesis of Cinnamamides from Methyl Cinnamates and Phenylethylamines Catalyzed by Lipozyme® TL IM under Continuous-Flow Microreactors. Catalysts, 12(10), 1265. https://doi.org/10.3390/catal12101265