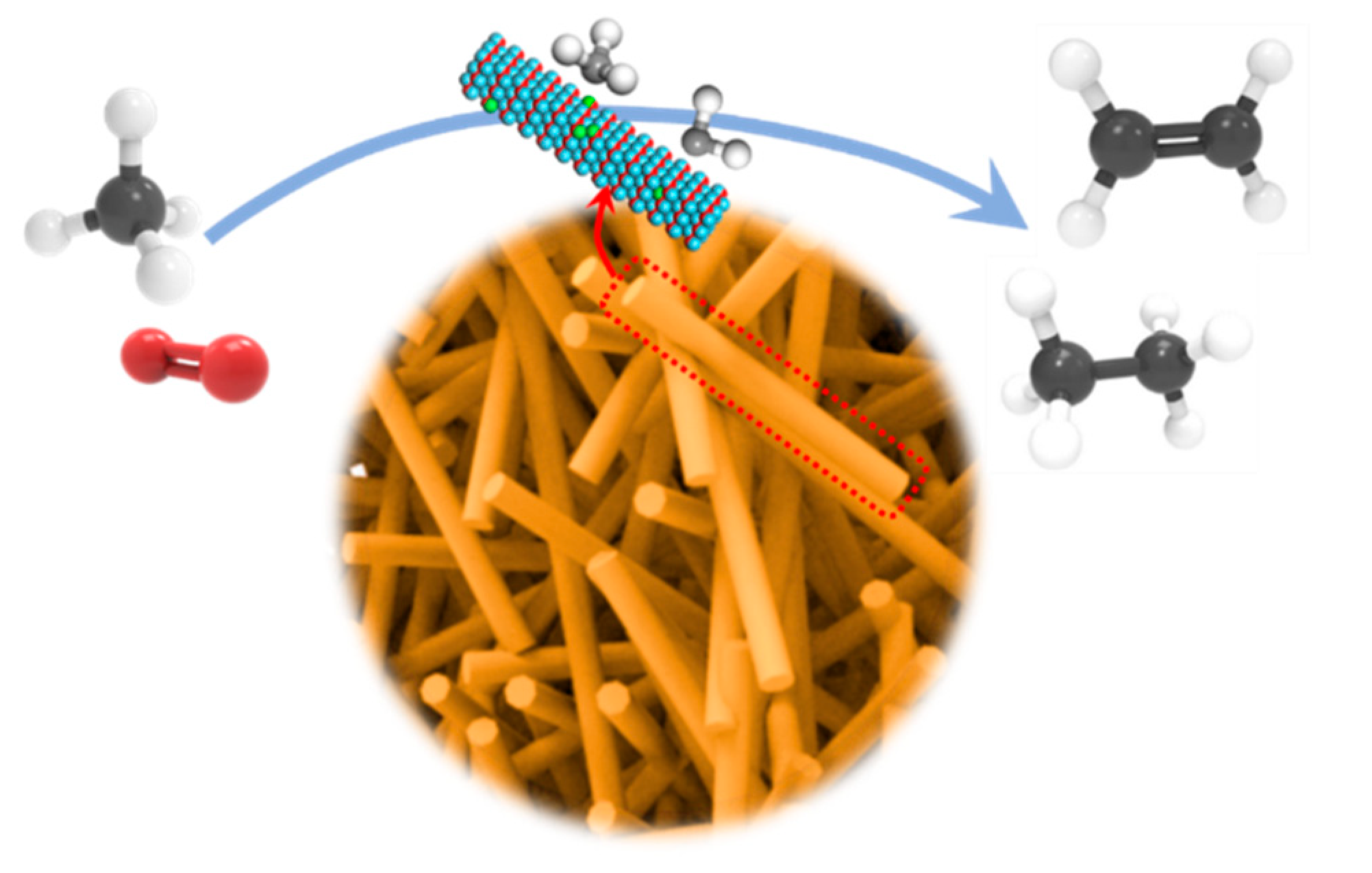

Metal Ions (Li, Mg, Zn, Ce) Doped into La2O3 Nanorod for Boosting Catalytic Oxidative Coupling of Methane

Abstract

:1. Introduction

2. Results and Discussions

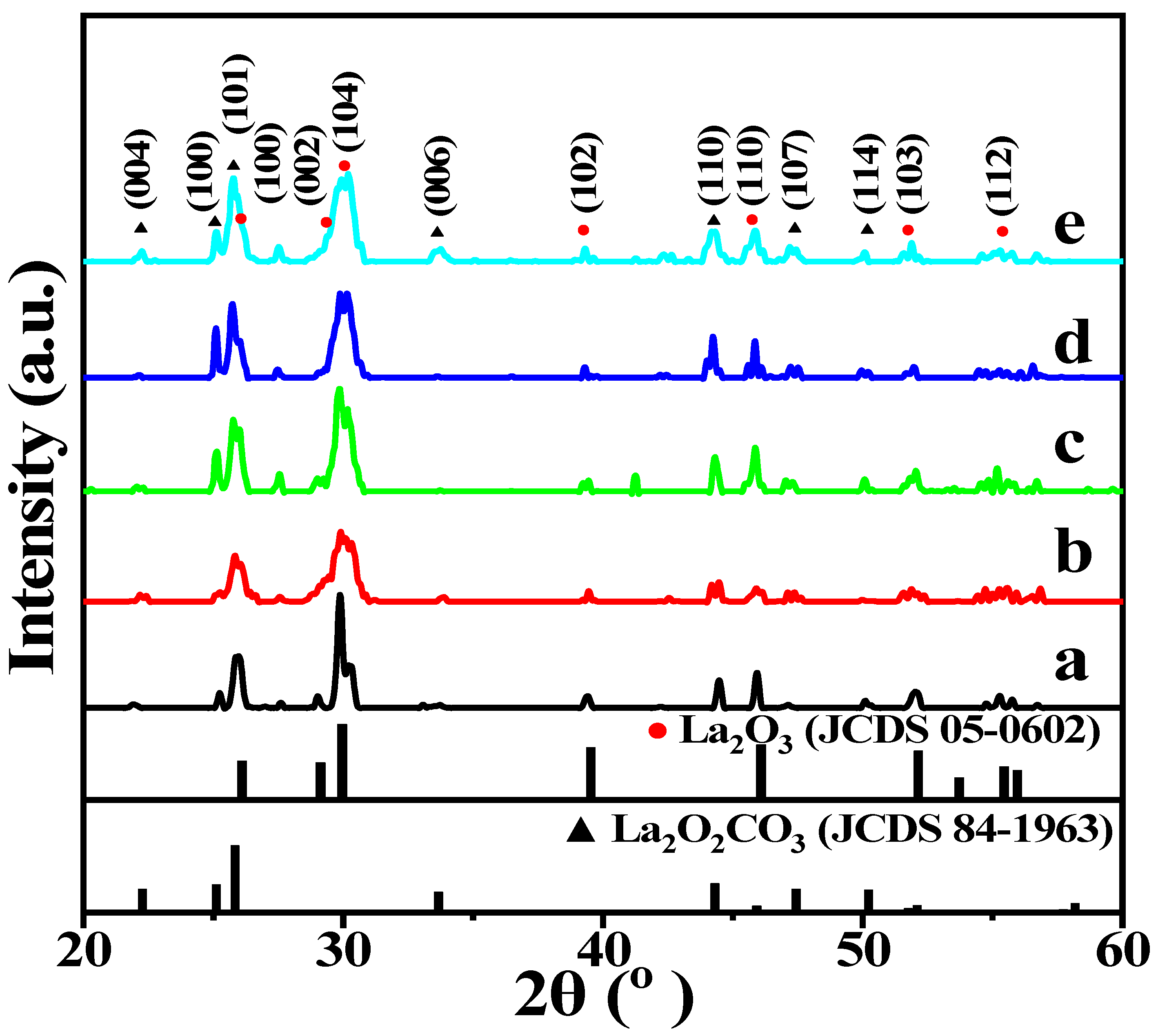

2.1. XRD Patterns

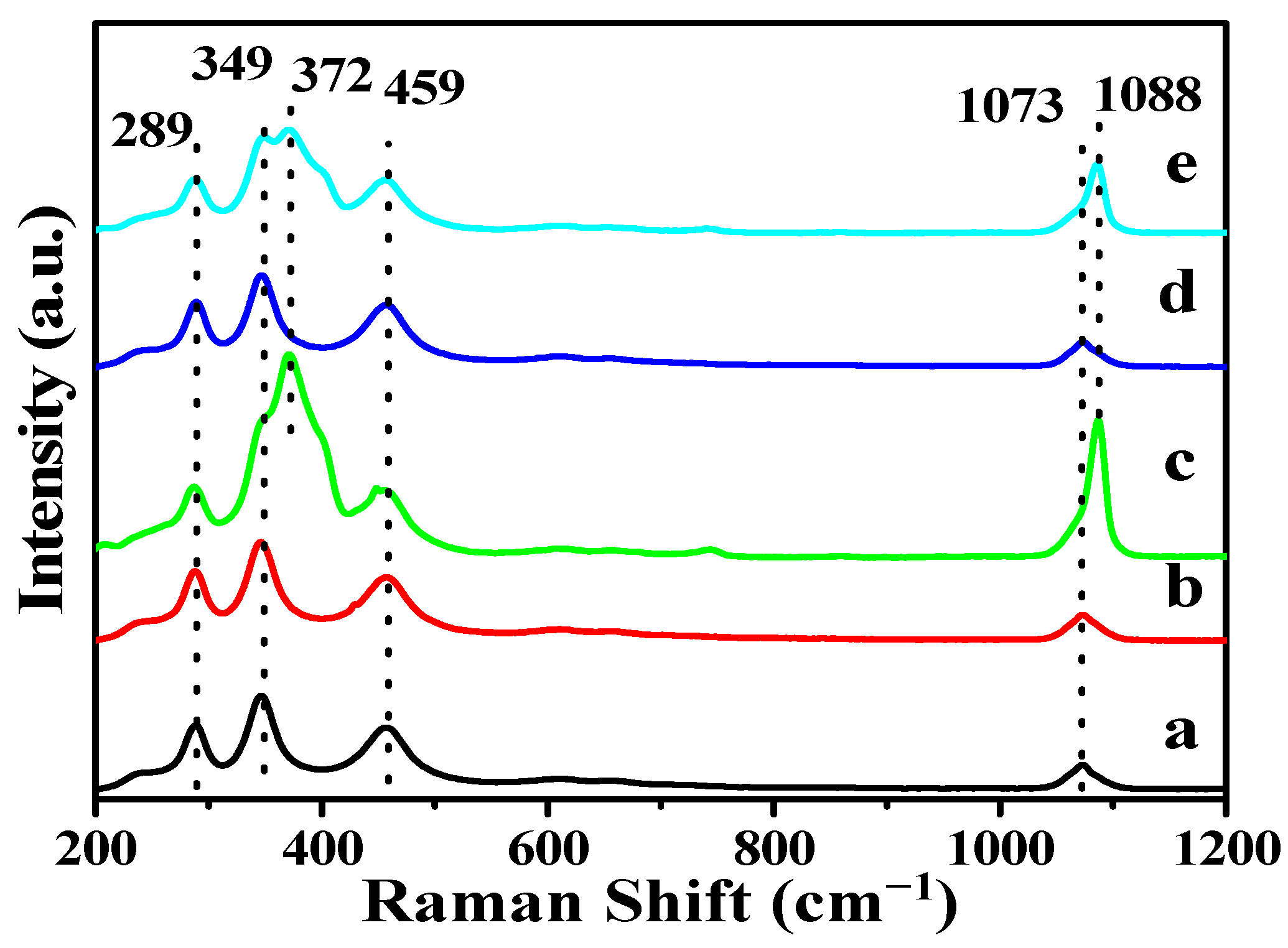

2.2. Raman Spectra

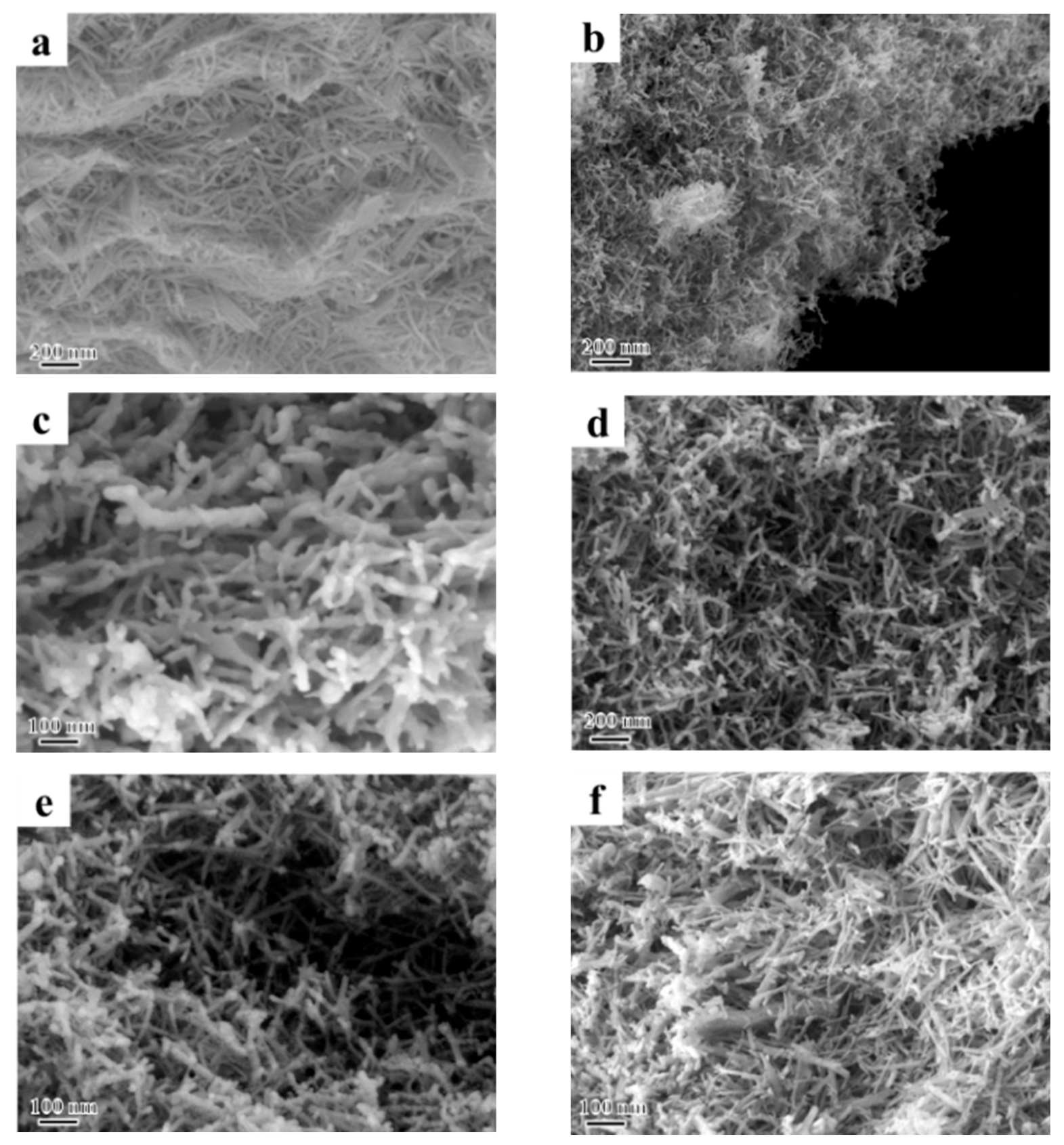

2.3. SEM Images

2.4. TEM Images

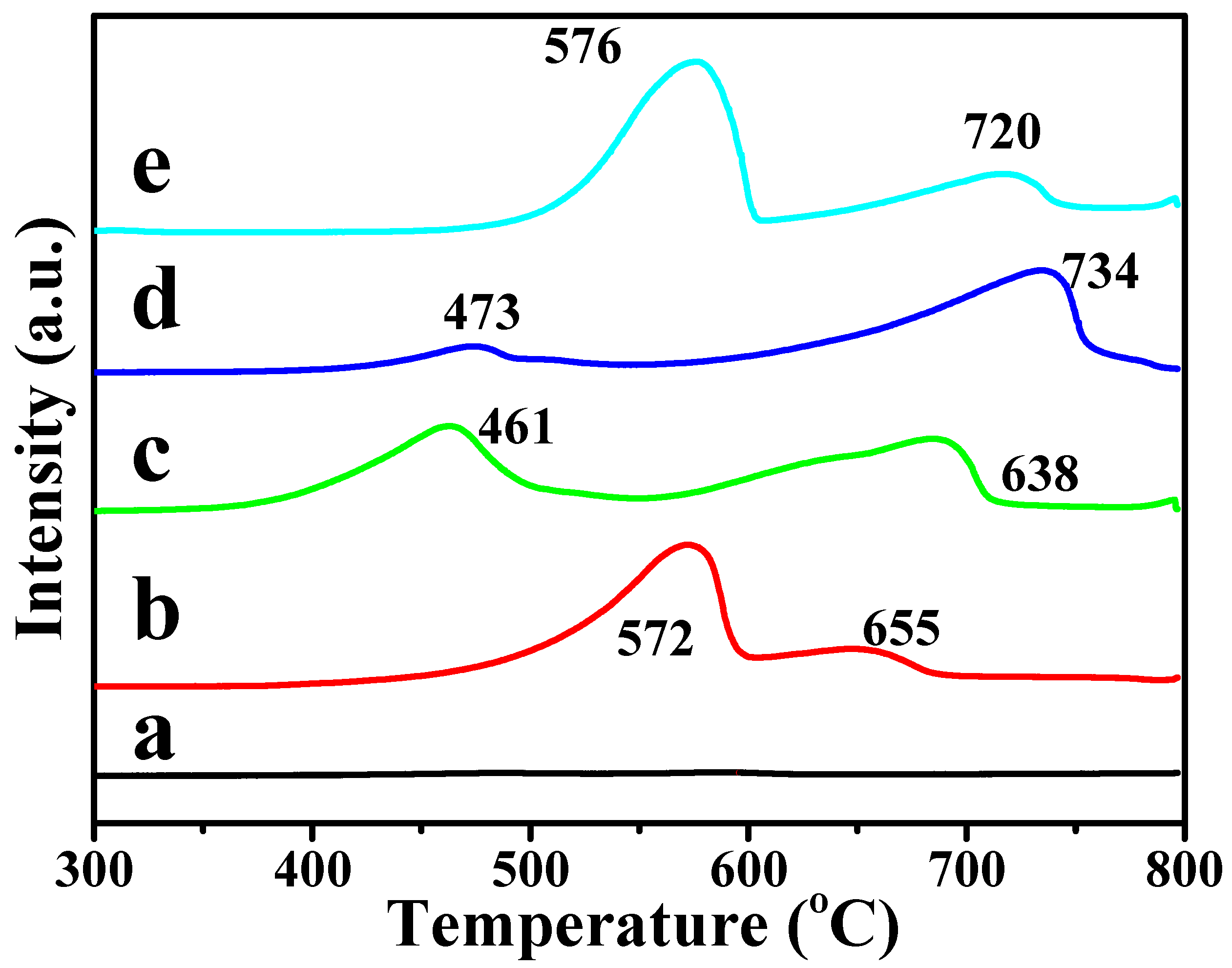

2.5. H2-TPR Profiles

2.6. N2 Adsorption-Desorption Results

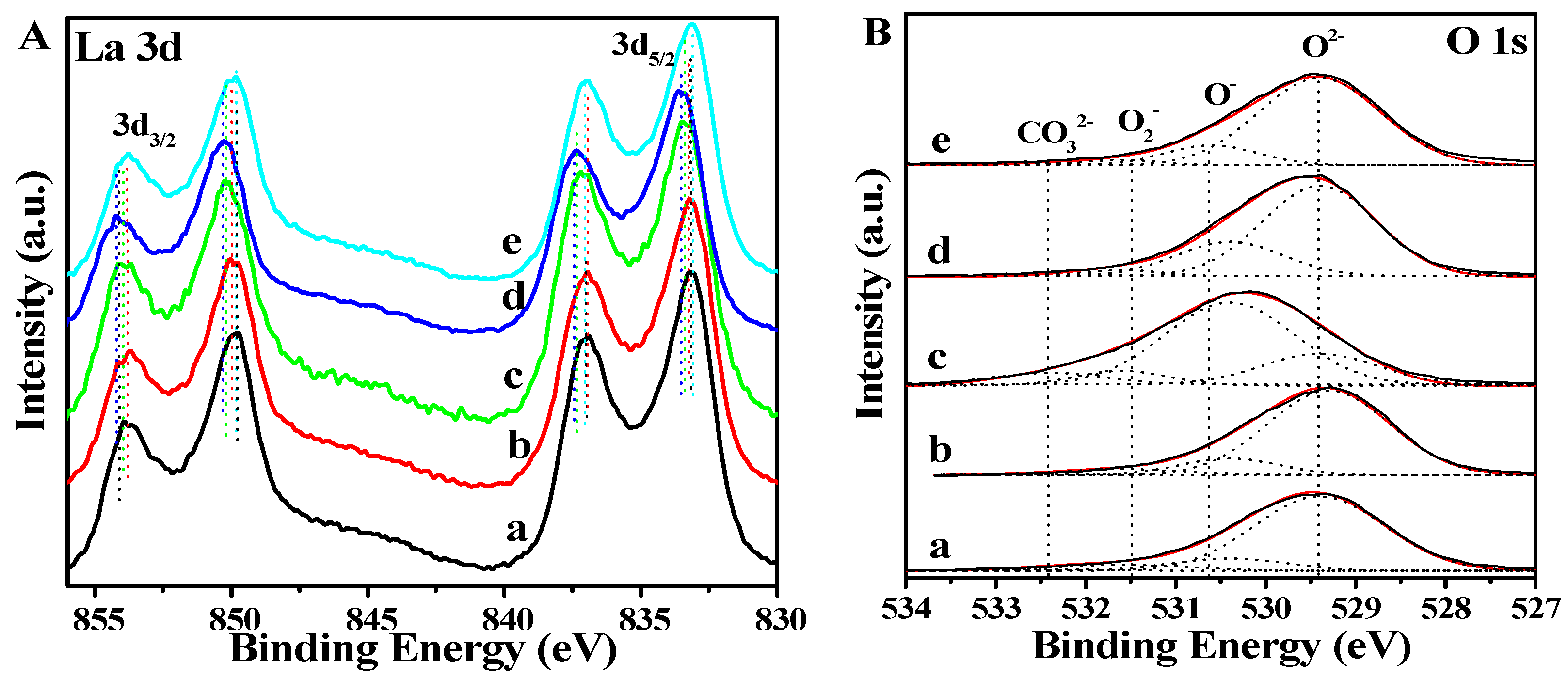

2.7. XPS Results

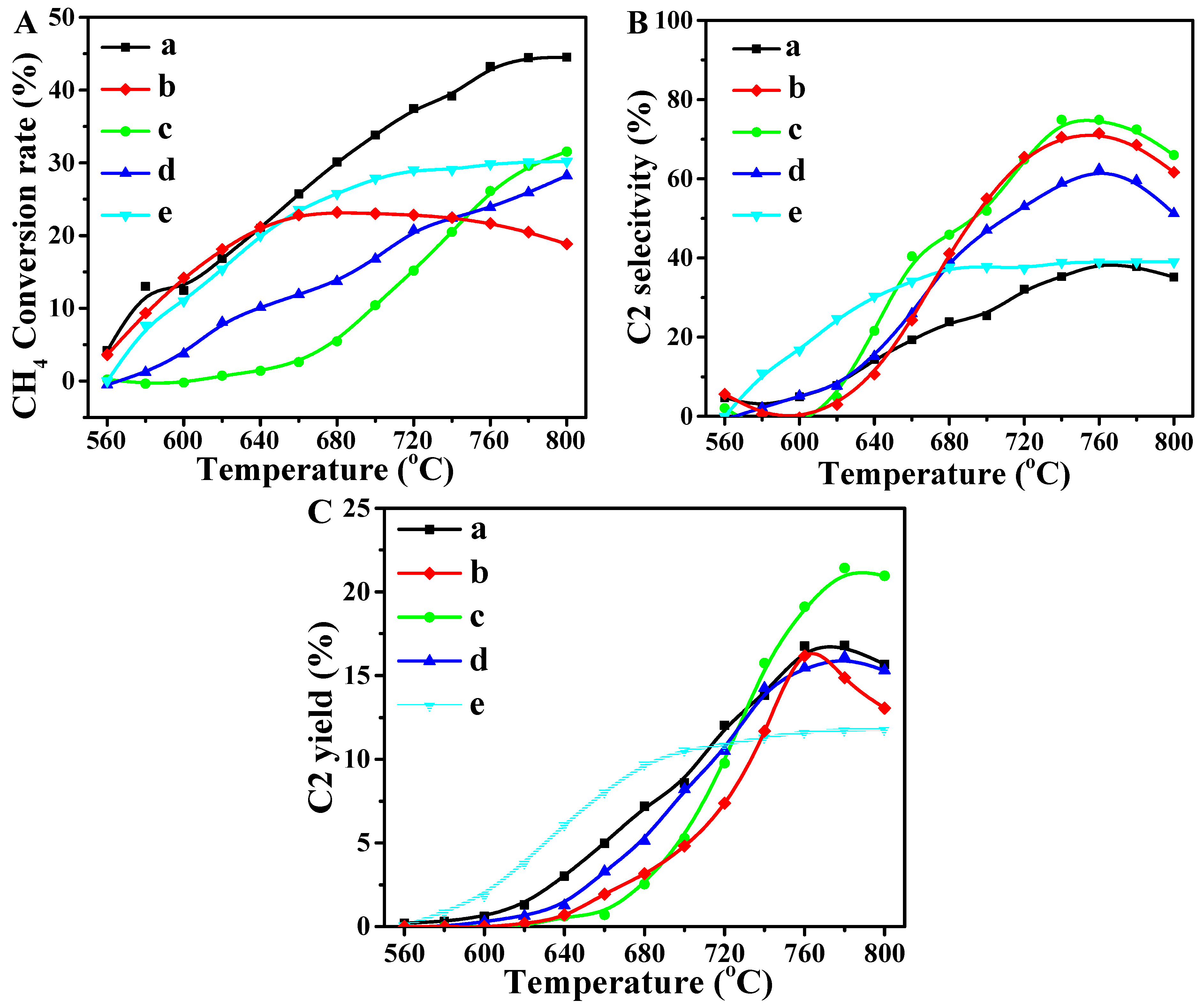

2.8. Catalytic Performances

2.9. Discussion on the Effect of Doped Metal Ions

3. Experimental Sections

3.1. Catalyst Preparation

3.2. Catalyst Characterizations

3.3. Catalyst Activity Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Sadjadi, S.; Jašo, S.; Godini, H.R.; Arndt, S.; Wollgarten, M.; Blume, R.; Görke, O.; Schomäcker, R.; Wozny, G.; Simon, U. Feasibility study of the Mn-Na2WO4/SiO2 catalytic system for the oxidative coupling of methane in a fluidized-bed reactor. Catal. Sci. Technol. 2015, 5, 942–952. [Google Scholar] [CrossRef]

- Hou, Y.; Han, W.; Xia, W.; Wan, H. Structure Sensitivity of La2O2CO3 Catalysts in the Oxidative Coupling of Methane. ACS Catal. 2015, 5, 1663–1674. [Google Scholar] [CrossRef]

- Sato, A.; Ogo, S.; Takeno, Y.; Takise, K.; Seo, J.G.; Sekine, Y. Electric Field and Mobile Oxygen Promote Low-Temperature Oxidative Coupling of Methane over La1–xCaxAlO3-x Perovskite Catalysts. ACS Omega 2019, 4, 10438–10443. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zou, S.; Li, Z.; Zhou, Q.; Pan, Y.; Yuan, W.; He, L.; Wang, S.; Wen, W.; Liu, J.; Wang, Y.; et al. Surface coupling of methyl radicals for efficient low-temperature oxidative coupling of methane. Chin. J. Catal. 2021, 42, 1117–1125. [Google Scholar] [CrossRef]

- Li, Z.; He, L.; Wang, S.; Yi, W.; Zou, S.; Xiao, L.; Fan, J. Fast Optimization of LiMgMnOx/La2O3 Catalysts for the Oxidative Coupling of Methane. ACS Comb. Sci. 2017, 19, 15–24. [Google Scholar] [CrossRef]

- Gambo, Y.; Jalil, A.A.; Triwahyono, S.; Abdulrasheed, A.A. Recent advances and future prospect in catalysts for oxidative coupling of methane to ethylene: A review. J. Ind. Eng. Chem. 2018, 59, 218–229. [Google Scholar] [CrossRef]

- Ghose, R.; Hwang, H.T.; Varma, A. Oxidative coupling of methane using catalysts synthesized by solution combustion method. Appl. Catal. A-Gen. 2013, 452, 147–154. [Google Scholar] [CrossRef]

- Song, J.; Sun, Y.; Ba, R.B.; Huang, S.; Zhao, Y.; Zhang, J.; Sun, Y.; Zhu, Y. Monodisperse Sr-La2O3 hybrid nanofibers for oxidative coupling of methane to synthesize C2 hydrocarbons. Nanoscale 2015, 7, 2260–2264. [Google Scholar] [CrossRef]

- Khodadadian, M.; Taghizadeh, M.; Hamidzadeh, M. Effects of various barium precursors and promoters on catalytic activity of Ba–Ti perovskite catalysts for oxidative coupling of methane. Fuel. Process. Technol. 2011, 92, 1164–1168. [Google Scholar] [CrossRef]

- He, J.; Xu, T.; Wang, Z.; Zhang, Q.; Deng, W.; Wang, Y. Transformation of Methane to Propylene: A Two-Step Reaction Route Catalyzed by Modified CeO2 Nanocrystals and Zeolites. Angew. Chem. Int. Ed. 2012, 51, 2438–2442. [Google Scholar] [CrossRef]

- Wang, K.; Ji, S.; Shi, X.; Tang, J. Autothermal oxidative coupling of methane on the SrCO3/Sm2O3 catalysts. Catal. Commun. 2009, 10, 807–810. [Google Scholar] [CrossRef]

- Lei, Y.; Chu, C.; Li, S.; Sun, Y. Methane Activations by Lanthanum Oxide Clusters. J. Phys. Chem. C 2014, 118, 7932–7945. [Google Scholar] [CrossRef]

- Sollier, B.M.; Bonne, M.; Khenoussi, N.; Michelin, L.; Miro, E.E.; Gomez, L.E.; Boix, A.V.; Lebeau, B. Synthesis and Characterization of Electrospun Nanofibers of Sr-La-Ce Oxides as Catalysts for the Oxidative Coupling of Methane. Ind. Eng. Chem. Res. 2020, 59, 11419–11430. [Google Scholar] [CrossRef]

- Hou, S.; Cao, Y.; Xiong, W.; Liu, H.; Kou, Y. Site Requirements for the Oxidative Coupling of Methane on SiO2-Supported Mn Catalysts. Ind. Eng. Chem. Res. 2006, 45, 7077–7083. [Google Scholar] [CrossRef]

- Chung, E.Y.; Wang, W.K.; Nadgouda, S.G.; Baser, D.S.; Sofranko, J.A.; Fan, L. Catalytic Oxygen Carriers and Process Systems for Oxidative Coupling of Methane Using the Chemical Looping Technology. Ind. Eng. Chem. Res. 2016, 55, 12750–12764. [Google Scholar] [CrossRef]

- Ma, X.; Sun, K.; Liu, J.; Li, W.; Cai, X.; Su, H. Single Ru Sites-Embedded Rutile TiO2 Catalyst for Non-Oxidative Direct Conversion of Methane: A First-Principles Study. J. Phys. Chem. C 2019, 123, 14391–14397. [Google Scholar] [CrossRef]

- Cheng, Z.; Baser, D.S.; Nadgouda, S.G.; Qin, L.; Fan, J.A.; Fan, L. C2 Selectivity Enhancement in Chemical Looping Oxidative Coupling of Methane over a Mg–Mn Composite Oxygen Carrier by Li-Doping-Induced Oxygen Vacancies. ACS Energy Lett. 2018, 3, 1730–1736. [Google Scholar] [CrossRef]

- Kiani, D.; Sourav, S.; Baltrusaitis, J.; Wachs, I.E. Oxidative Coupling of Methane (OCM) by SiO2-Supported Tungsten Oxide Catalysts Promoted with Mn and Na. ACS Catal. 2019, 9, 5912–5928. [Google Scholar] [CrossRef]

- Wang, S.; Li, S.; Dixon, D.A. Mechanism of selective and complete oxidation in La2O3-catalyzed oxidative coupling of methane. Catal. Sci. Technol. 2020, 10, 2602–2614. [Google Scholar] [CrossRef]

- Aljama, H.; Nørskov, J.K.; Abild-Pedersen, F. Tuning Methane Activation Chemistry on Alkaline Earth Metal Oxides by Doping. J. Phys. Chem. C 2018, 122, 22544–22548. [Google Scholar] [CrossRef]

- Liu, W.C.; Ralston, W.T.; Melaet, G.; Somorjai, G.A. Oxidative coupling of methane (OCM): Effect of noble metal (M = Pt, Ir, Rh) doping on the performance of mesoporous silica MCF-17 supported MnxOy-Na2WO4 catalysts. Appl. Catal. A 2017, 545, 17–23. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Gong, X. Strategies to Improve the Activity While Maintaining the Selectivity of Oxidative Coupling of Methane at La2O3: A Density Functional Theory Study. ACS Catal. 2019, 10, 586–594. [Google Scholar] [CrossRef]

- Yoon, S.; Lim, S.; Choi, J.; Suh, D.J.; Song, K.H.; Ha, J. Study on the unsteady state oxidative coupling of methane: Effects of oxygen species from O2, surface lattice oxygen, and CO2 on the C2+ selectivity. RSC Adv. 2020, 10, 35889–35897. [Google Scholar] [CrossRef] [PubMed]

- Chu, C.; Zhao, Y.; Li, S.; Sun, Y. Correlation between the acid-base properties of the La2O3 catalyst and its methane reactivity. Phys. Chem. Chem. Phys. 2016, 18, 16509–16517. [Google Scholar] [CrossRef]

- Ferreira, V.J.; Tavares, P.; Figueiredo, J.L.; Faria, J.L. Ce-Doped La2O3 based catalyst for the oxidative coupling of methane. Catal. Commun. 2013, 42, 50–53. [Google Scholar] [CrossRef]

- Kondratenko, E.V.; Schlvter, M.; Baerns, M.; Linke, D.; Holena, M. Developing catalytic materials for the oxidative coupling of methane through statistical analysis of literature data. Catal. Sci. Technol. 2015, 5, 1668–1677. [Google Scholar] [CrossRef] [Green Version]

- Noon, D.; Zohour, B.; Senkan, S. Oxidative coupling of methane with La2O3–CeO2 nanofiber fabrics: A reaction engineering study. J. Nat. Gas Sci. Eng. 2014, 18, 406–411. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, Y. Transmission protocol for secure big data in two-hop wireless networks with cooperative jamming. Inform. Sci. 2014, 281, 201–210. [Google Scholar] [CrossRef]

- Wu, Q.; Xiong, J.; Zhang, Y.; Mei, X.; Wei, Y.; Zhao, Z.; Liu, J.; Li, J. Interaction-Induced Self-Assembly of Au@La2O3 Core–Shell Nanoparticles on La2O2CO3 Nanorods with Enhanced Catalytic Activity and Stability for Soot Oxidation. ACS Catal. 2019, 9, 3700–3715. [Google Scholar] [CrossRef]

- Cui, J.; Hope, G.A. Raman and Fluorescence Spectroscopy of CeO2, Er2O3, Nd2O3, Tm2O3, Yb2O3, La2O3, and Tb4O7. J. Spectrosc. 2015, 2015, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Palmer, M.S.; Neurock, M.; Olken, M.M. Periodic Density Functional Theory Study of Methane Activation over La2O3: Activity of O2−, O−, O22−, Oxygen Point Defect, and Sr2+ Doped Surface Sites. J. Am. Chem. Soc. 2002, 124, 8452–8461. [Google Scholar] [CrossRef] [PubMed]

- Geo, J.K.; Joshua, T.A.; Hyun, T.H. Effect of TiO2 on the Performance of Mn/Na2WO4 Catalysts in Oxidative Coupling of Methane. Ind. Eng. Chem. Res. 2021, 60, 3914–3921. [Google Scholar]

- Gao, Z.; Shi, Y. Suppressed formation of CO2 and H2O in the oxidative coupling of methane over La2O3/MgO catalyst by surface modification. J. Nat. Gas. Chem. 2010, 19, 173–178. [Google Scholar] [CrossRef]

- Yildiz, M.; Simon, U.; Otremba, T.; Aksu, Y.; Kailasam, K.; Thomas, A.; Schomäcker, R.; Arndt, S. Support material variation for the MnxOy-Na2WO4/SiO2 catalyst. Catal. Today 2014, 228, 5–14. [Google Scholar] [CrossRef]

- Vandewalle, L.A.; Van Geem, K.M.; Marin, G.B.; Bos, R. A Boudart Number for the Assessment of Irreducible Pellet-Scale Mass Transfer Limitations: Application to Oxidative Coupling of Methane. Ind. Eng. Chem. Res. 2021, 60, 6538–6553. [Google Scholar] [CrossRef]

- Nguyen, T.N.; Nhat, T.T.P.; Takimoto, K.; Thakur, A.; Nishimura, S.; Ohyama, J.; Miyazato, I.; Takahashi, L.; Fujima, J.; Takahashi, K.; et al. High-Throughput Experimentation and Catalyst Informatics for Oxidative Coupling of Methane. ACS Catal. 2019, 10, 921–932. [Google Scholar] [CrossRef]

- Daneshpayeh, M.; Khodadadi, A.; Mostoufi, N.; Mortazavi, Y.; Sotudeh-Gharebagh, R.; Talebizadeh, A. Kinetic modeling of oxidative coupling of methane over Mn/Na2WO4/SiO2 catalyst. Fuel Process. Technol. 2009, 90, 403–410. [Google Scholar] [CrossRef]

- Silva, A.M.T.; Machado, B.F.; Gomes, H.T.; Figueiredo, J.L.; Dražić, G.; Faria, J.L. Pt nanoparticles supported over Ce–Ti–O: The solvothermal and photochemical approaches for the preparation of catalytic materials. J. Nanopart. Res. 2010, 12, 121–133. [Google Scholar] [CrossRef]

- Jiang, T.; Song, J.; Huo, M.; Yang, N.; Liu, J.; Zhang, J.; Sun, Y.; Zhu, Y. La2O3 catalysts with diverse spatial dimensionality for oxidative coupling of methane to produce ethylene and ethane. RSC Adv. 2016, 6, 34872–34876. [Google Scholar] [CrossRef]

- Ferreira, V.J.; Tavares, P.; Figueiredo, J.L.; Faria, J.L. Effect of Mg, Ca, and Sr on CeO2 Based Catalysts for the Oxidative Coupling of Methane: Investigation on the Oxygen Species Responsible for Catalytic Performance. Ind. Eng. Chem. Res. 2012, 51, 10535–10541. [Google Scholar] [CrossRef]

- Chrétien, S.; Metiu, H. Hydrogen Dissociative Adsorption on Lanthana: Polaron Formation and the Role of Acid−Base Interactions. J. Phys. Chem. C 2015, 119, 19876–19882. [Google Scholar] [CrossRef]

- Kwapien, K.; Paier, J.; Sauer, J.; Geske, M.; Zavyalova, U.; Horn, R.; Schwach, P.; Trunschke, A.; Schlögl, R. Sites for Methane Activation on Lithium-Doped Magnesium Oxide Surfaces. Angew. Chem. Int. Ed. 2014, 53, 8774–8778. [Google Scholar] [CrossRef] [PubMed]

- Mohammad, S.S.; Maryam, A.; Hamid, R.G.; Oliver, G.; Günter, W. Sustainable Process Design for Oxidative Coupling of Methane (OCM): Comprehensive Reactor Engineering via Computational Fluid Dynamics (CFD) Analysis of OCM Packed-Bed Membrane Reactors. Ind. Eng. Chem. Res. 2016, 55, 3287–3299. [Google Scholar]

- Xu, J.; Zhang, Y.; Xu, X.; Fang, X.; Xi, R.; Liu, Y.; Zheng, R.; Wang, X. Constructing La2B2O7 (B = Ti, Zr, Ce) Compounds with Three Typical Crystalline Phases for the Oxidative Coupling of Methane: The Effect of Phase Structures, Superoxide Anions, and Alkalinity on the Reactivity. ACS Catal. 2019, 9, 4030–4045. [Google Scholar]

- Balasubramanian, R.; Smith, S.M.; Rawat, S.; Yatsunyk, L.A.; Stemmler, T.L.; Rosenzweig, A.C. Oxidation of methane by a biological dicopper centre. Nature 2010, 465, 115–119. [Google Scholar]

- Ahari, J.S.; Ahmadi, R.; Mikami, H.; Inazu, K.; Zarrinpashne, S.; Suzuki, S.; Aika, K. Application of a simple kinetic model for the oxidative coupling of methane to the design of effective catalysts. Catal. Today 2009, 145, 45–54. [Google Scholar]

- Aritani, H.; Yamada, H.; Nishio, T.; Shiono, T.; Imamura, S.; Kudo, M.; Hasegawa, S.; Tanaka, T.; Yoshida, S. Characterization of Li-Doped MgO Catalysts for Oxidative Coupling of Methane by Means of Mg K-Edge XANES. J. Phys. Chem. B 2000, 104, 10133–10143. [Google Scholar] [CrossRef]

- Tang, L.; Yamaguchi, D.; Wong, L.; Burke, N.; Chiang, K. The promoting effect of ceria on Li/MgO catalysts for the oxidative coupling of methane. Catal. Today 2011, 178, 172–180. [Google Scholar]

- Elkins, T.W.; Hagelin-Weaver, H.E. Characterization of Mn–Na2WO4/SiO2 and Mn–Na2WO4/MgO catalysts for the oxidative coupling of methane. Appl. Catal. A-Gen. 2015, 497, 96–106. [Google Scholar] [CrossRef]

- Gawande, M.B.; Goswami, A.; Asefa, T.; Guo, H.; Biradar, A.V.; Peng, D.; Zboril, R.; Varma, R.S. Core–shell nanoparticles: Synthesis and applications in catalysis and electrocatalysis. Chem. Soc. Rev. 2015, 44, 7540–7590. [Google Scholar] [CrossRef]

- Schucker, R.C.; Derrickson, K.J.; Ali, A.K.; Caton, N.J. Identification of the Optimum Catalyst and Operating Conditions for Oxidative Coupling of Methane: Activity and Selectivity of Alkaline Earth-Doped Lanthanides. Ind. Eng. Chem. Res. 2020, 59, 18434–18446. [Google Scholar] [CrossRef]

- Wang, W.; Ji, S.; Pan, D.; Li, C. A novel particle/monolithic two-stage catalyst bed reactor and their catalytic performance for oxidative coupling of methane. Fuel Process. Technol. 2011, 92, 541–546. [Google Scholar] [CrossRef]

- Huang, P.; Zhao, Y.; Zhang, J.; Zhu, Y.; Sun, Y. Exploiting shape effects of La2O3 nanocatalysts for oxidative coupling of methane reaction. Nanoscale 2013, 5, 10844. [Google Scholar] [CrossRef] [PubMed]

| Sample | SBET/m2·g−1 | Dp/nm | Vp /cm3·c−1 | DSEM /nm | LSEM/nm |

|---|---|---|---|---|---|

| La2O3 | 37 | 8.6 | 0.12 | 10 ± 5 | 150 ± 20 |

| Li-La2O3 | 35 | 9 | 0.14 | 10 ± 5 | 150 ± 20 |

| Mg-La2O3 | 32 | 9.2 | 0.16 | 10 ± 5 | 150 ± 20 |

| Zn-La2O3 | 33 | 8.8 | 0.13 | 10 ± 5 | 150 ± 20 |

| Ce-La2O3 | 36 | 8.3 | 0.11 | 10 ± 5 | 150 ± 20 |

| Catalysts | O Species (%) | |||

|---|---|---|---|---|

| O2− | O2− | CO32− | O−/O22− | |

| La2O3 | 80 | 6.9 | 1.5 | 12 |

| Li-La2O3 | 81 | 5.2 | 0.4 | 13 |

| Mg-La2O3 | 21 | 7.9 | 7.9 | 63 |

| Zn-La2O3 | 71 | 3.2 | 1.1 | 25 |

| Ce-La2O3 | 83 | 3.1 | 1.3 | 13 |

| Catalyst | Conversion % | C2 Selectivity % | C2 Yield % |

|---|---|---|---|

| La2O3 | 43 | 39 | 17 |

| Li-La2O3 | 22 | 67 | 15 |

| Mg-La2O3 | 25 | 78 | 19 |

| Zn-La2O3 | 23 | 62 | 14 |

| Ce-La2O3 | 29 | 39 | 11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, J.; Yu, H.; Wei, Y.; Xie, C.; Lai, K.; Zhao, Z.; Liu, J. Metal Ions (Li, Mg, Zn, Ce) Doped into La2O3 Nanorod for Boosting Catalytic Oxidative Coupling of Methane. Catalysts 2022, 12, 713. https://doi.org/10.3390/catal12070713

Xiong J, Yu H, Wei Y, Xie C, Lai K, Zhao Z, Liu J. Metal Ions (Li, Mg, Zn, Ce) Doped into La2O3 Nanorod for Boosting Catalytic Oxidative Coupling of Methane. Catalysts. 2022; 12(7):713. https://doi.org/10.3390/catal12070713

Chicago/Turabian StyleXiong, Jing, Hongbin Yu, Yuechang Wei, Chengshu Xie, Kezhen Lai, Zhen Zhao, and Jian Liu. 2022. "Metal Ions (Li, Mg, Zn, Ce) Doped into La2O3 Nanorod for Boosting Catalytic Oxidative Coupling of Methane" Catalysts 12, no. 7: 713. https://doi.org/10.3390/catal12070713

APA StyleXiong, J., Yu, H., Wei, Y., Xie, C., Lai, K., Zhao, Z., & Liu, J. (2022). Metal Ions (Li, Mg, Zn, Ce) Doped into La2O3 Nanorod for Boosting Catalytic Oxidative Coupling of Methane. Catalysts, 12(7), 713. https://doi.org/10.3390/catal12070713