Effect of Support on Oxidative Esterification of 2,5-Furandiformaldehyde to Dimethyl Furan-2,5-dicarboxylate

Abstract

:1. Introduction

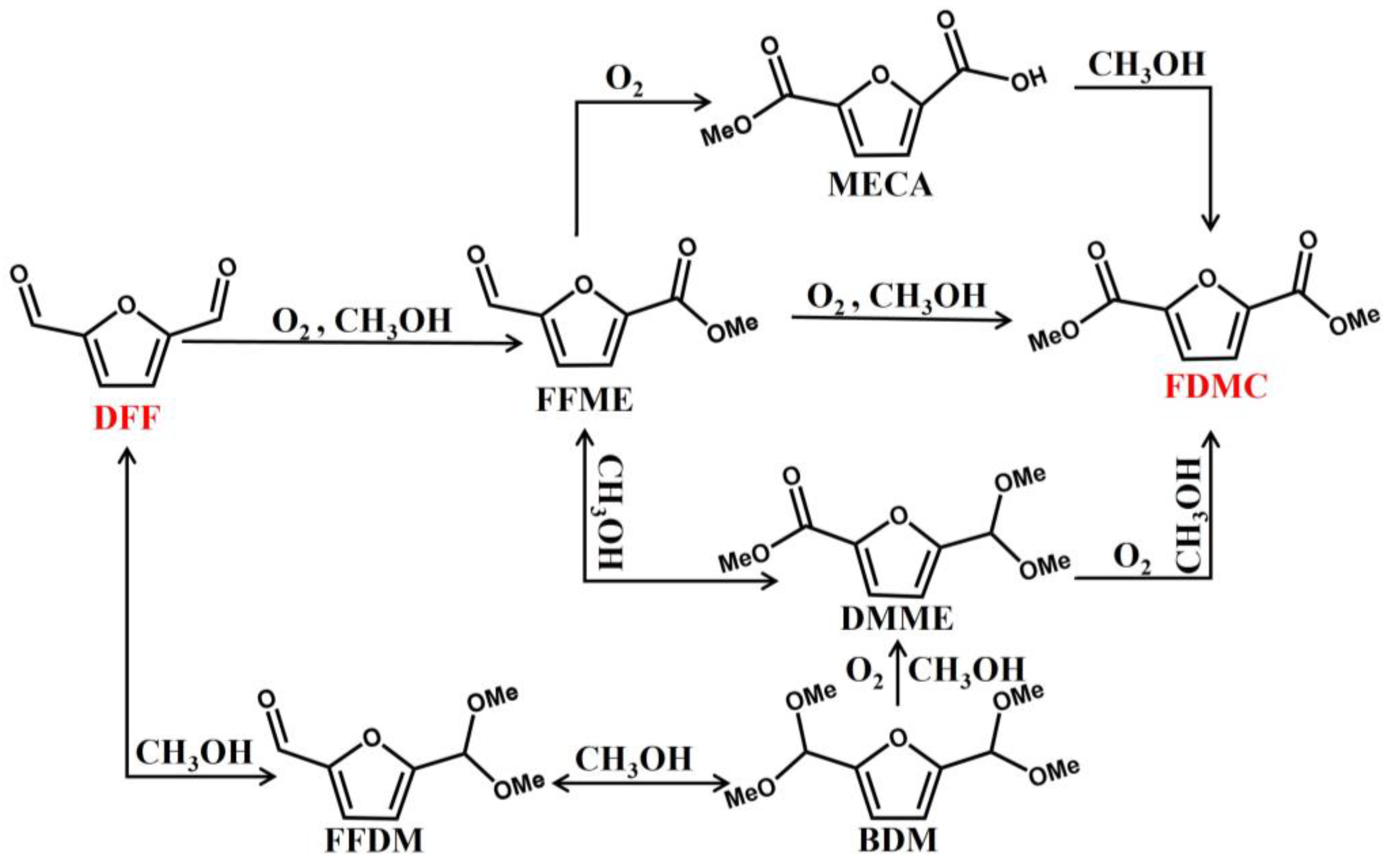

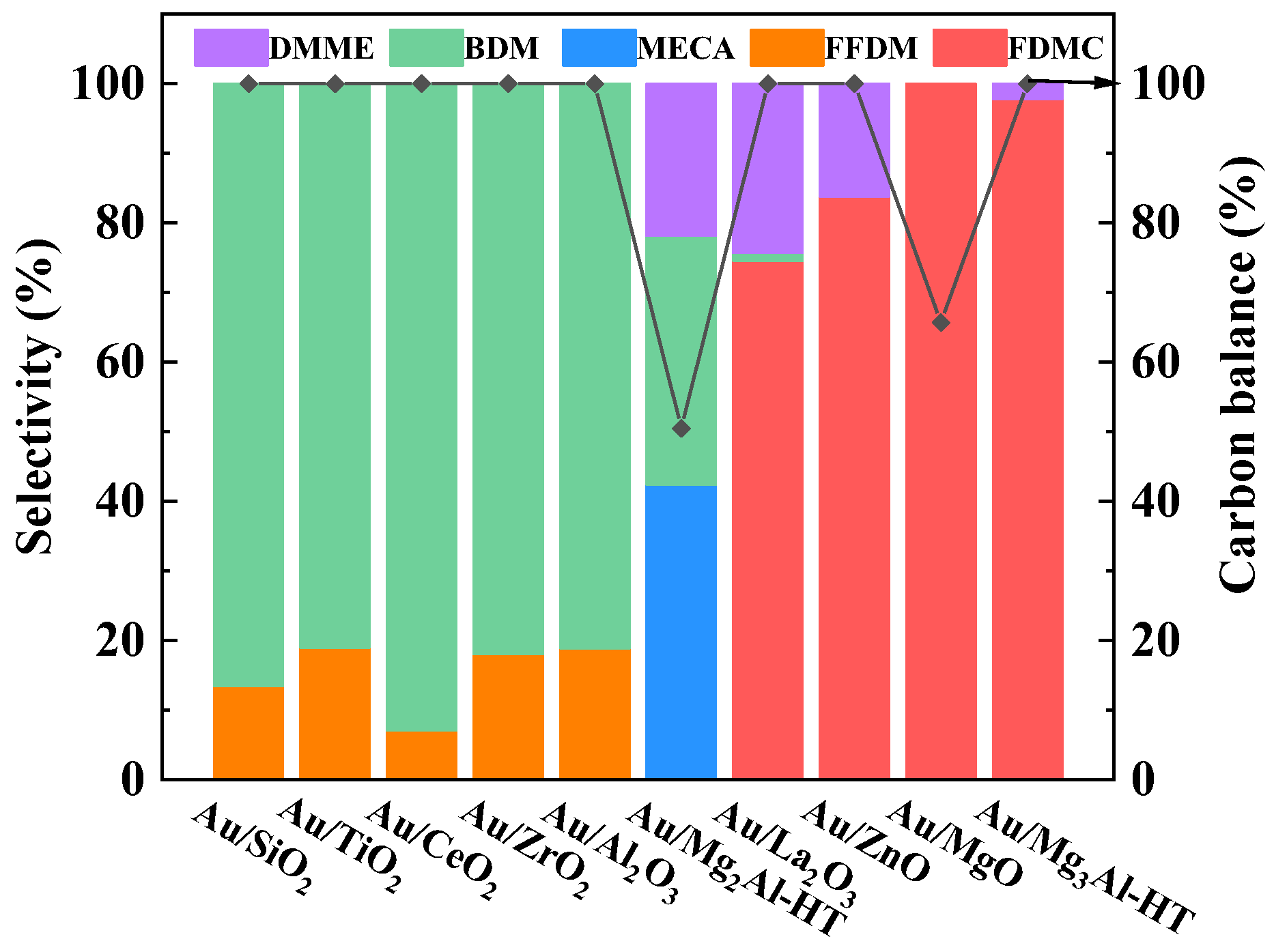

2. Results and Discussion

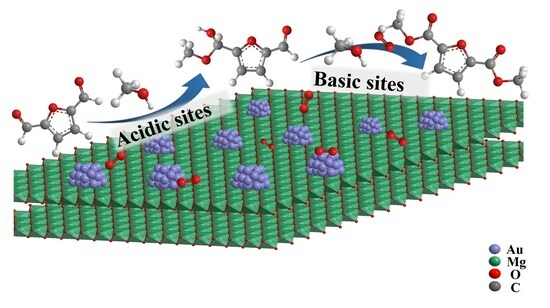

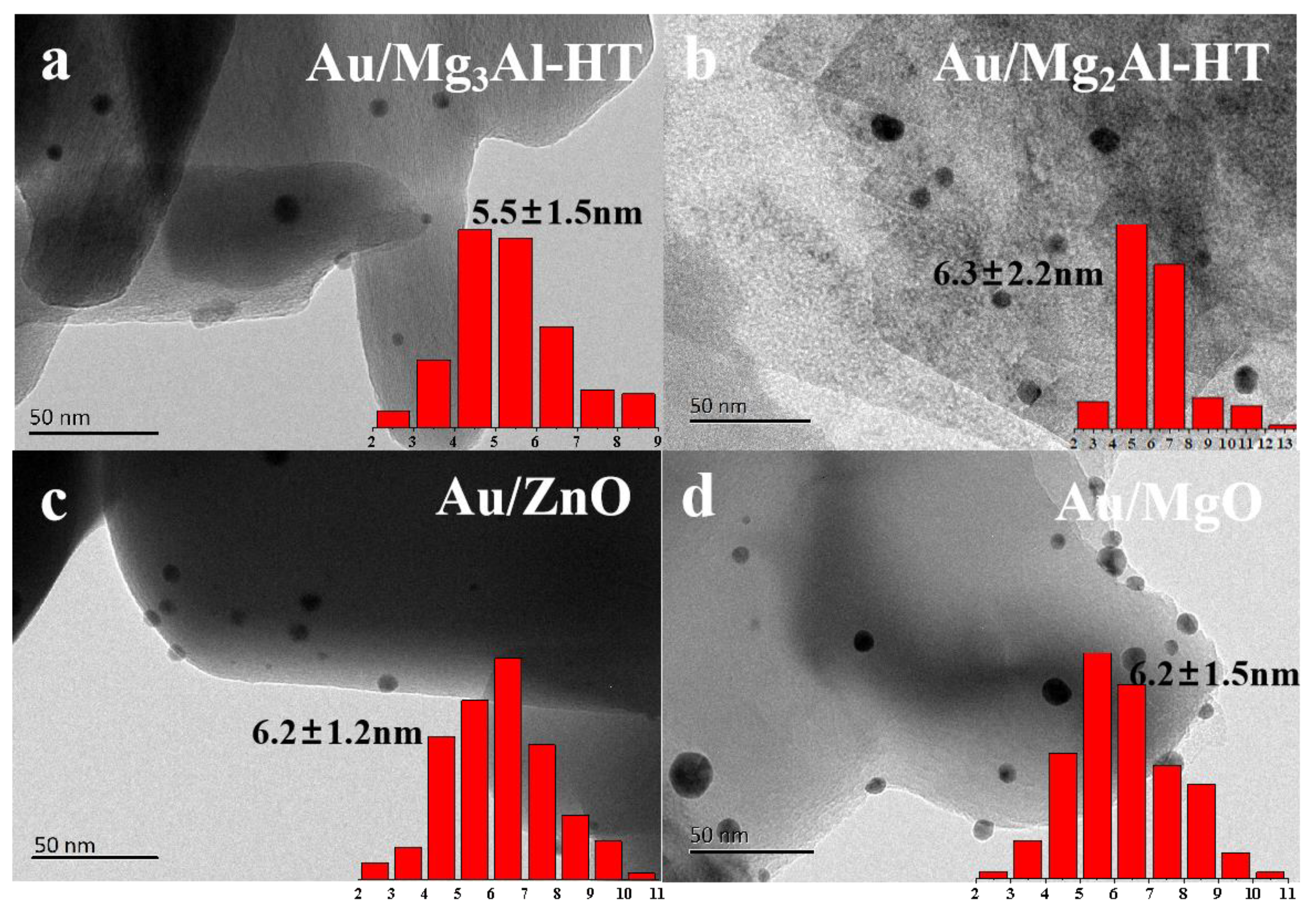

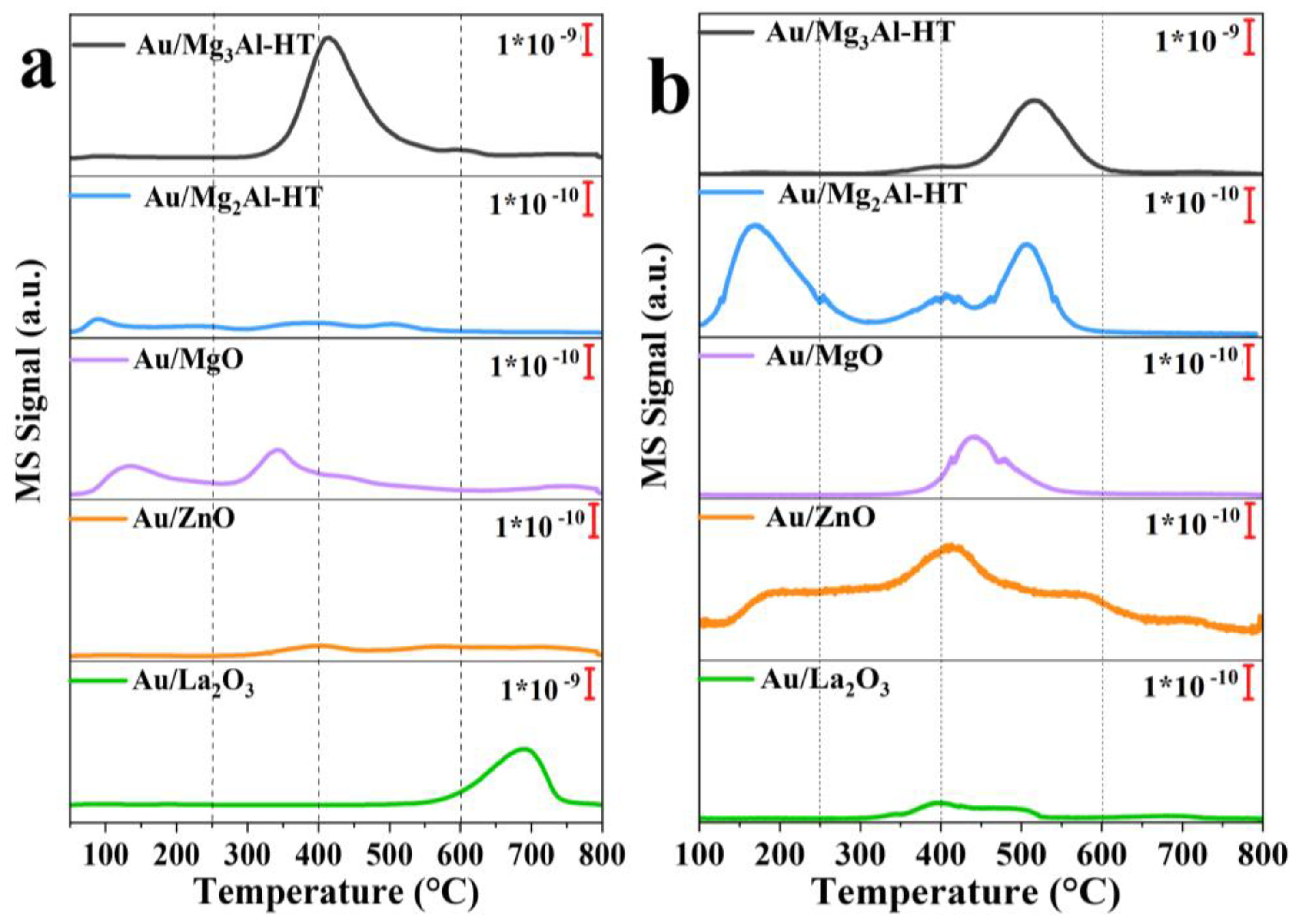

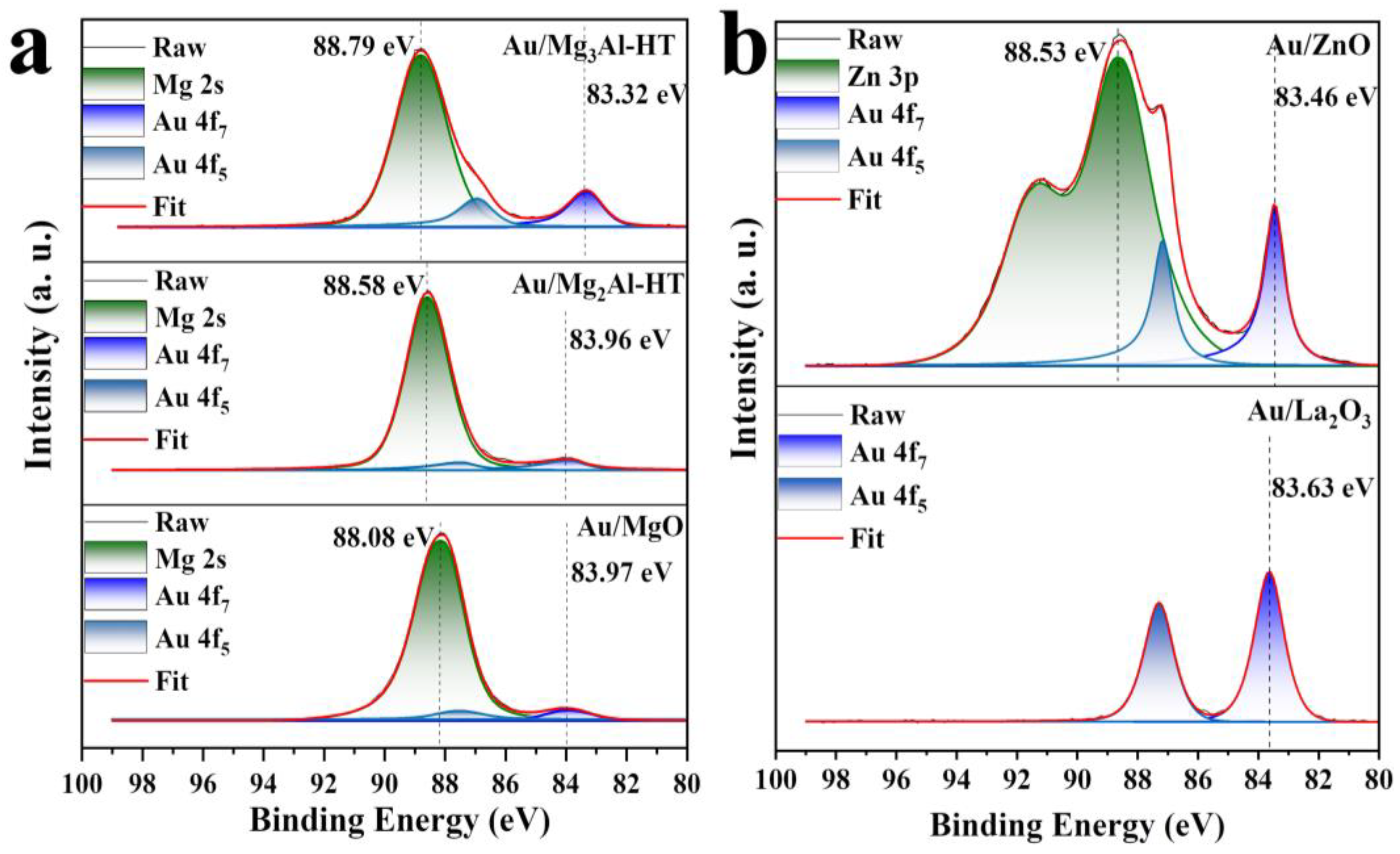

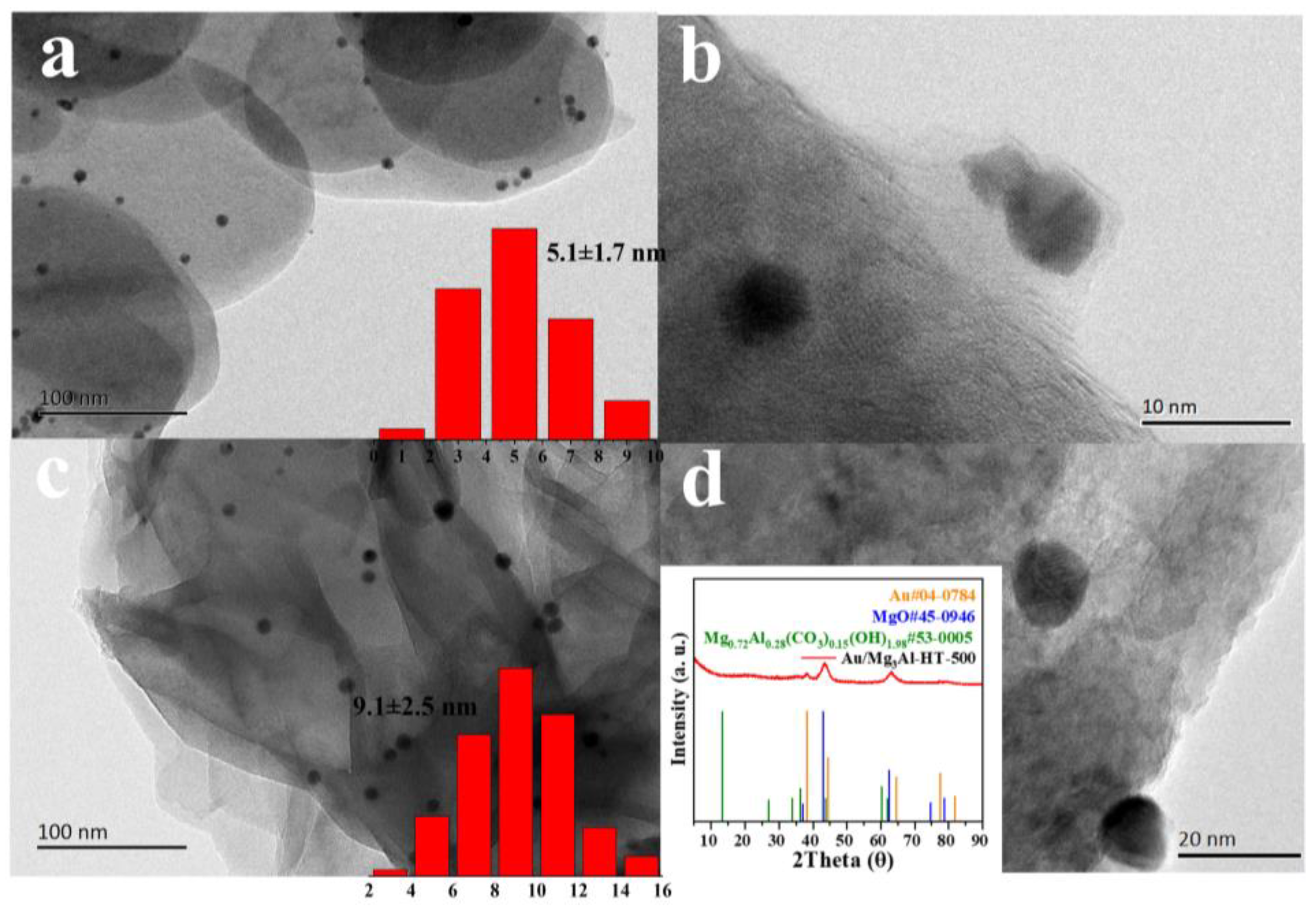

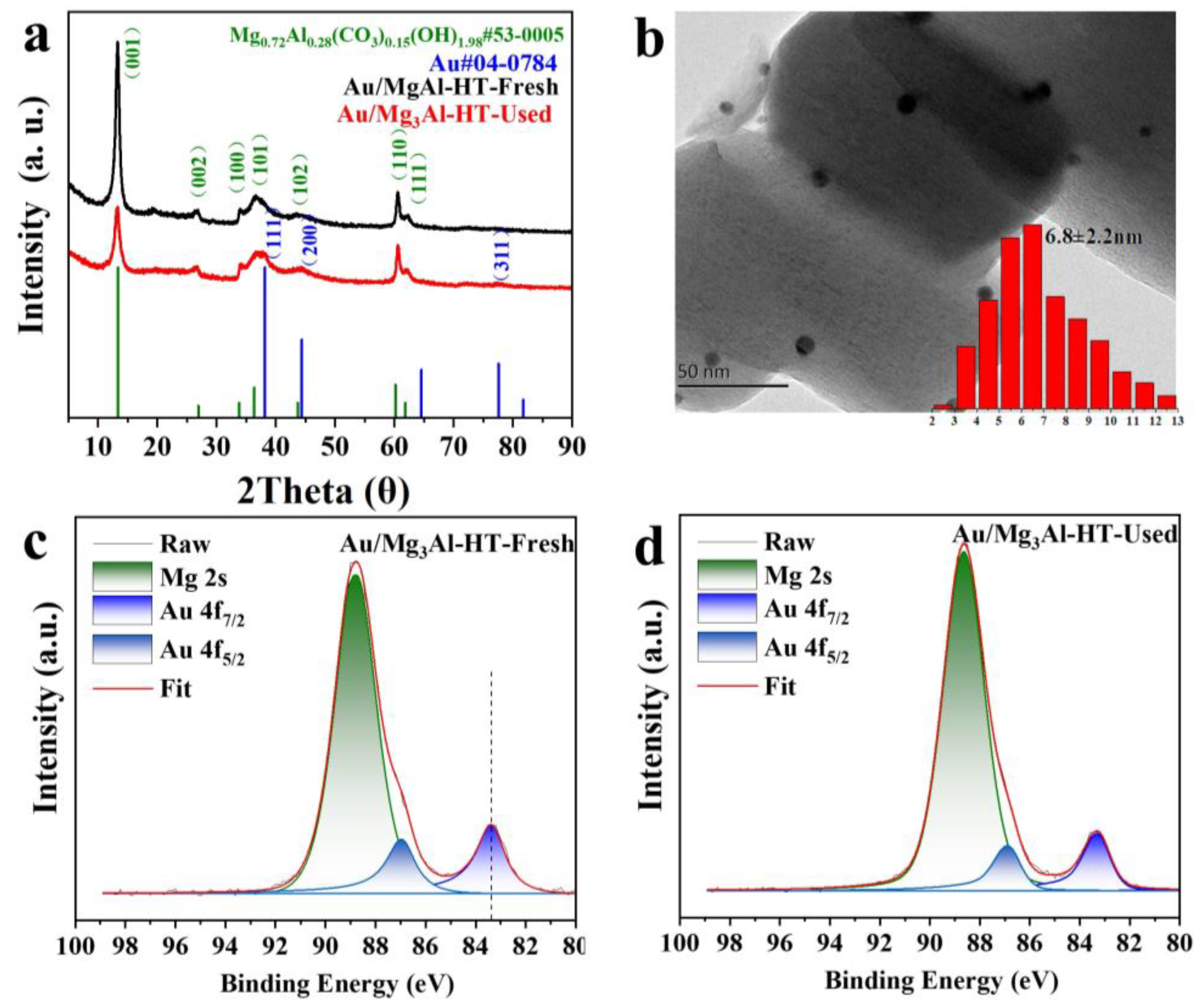

2.1. Catalysts Characterization

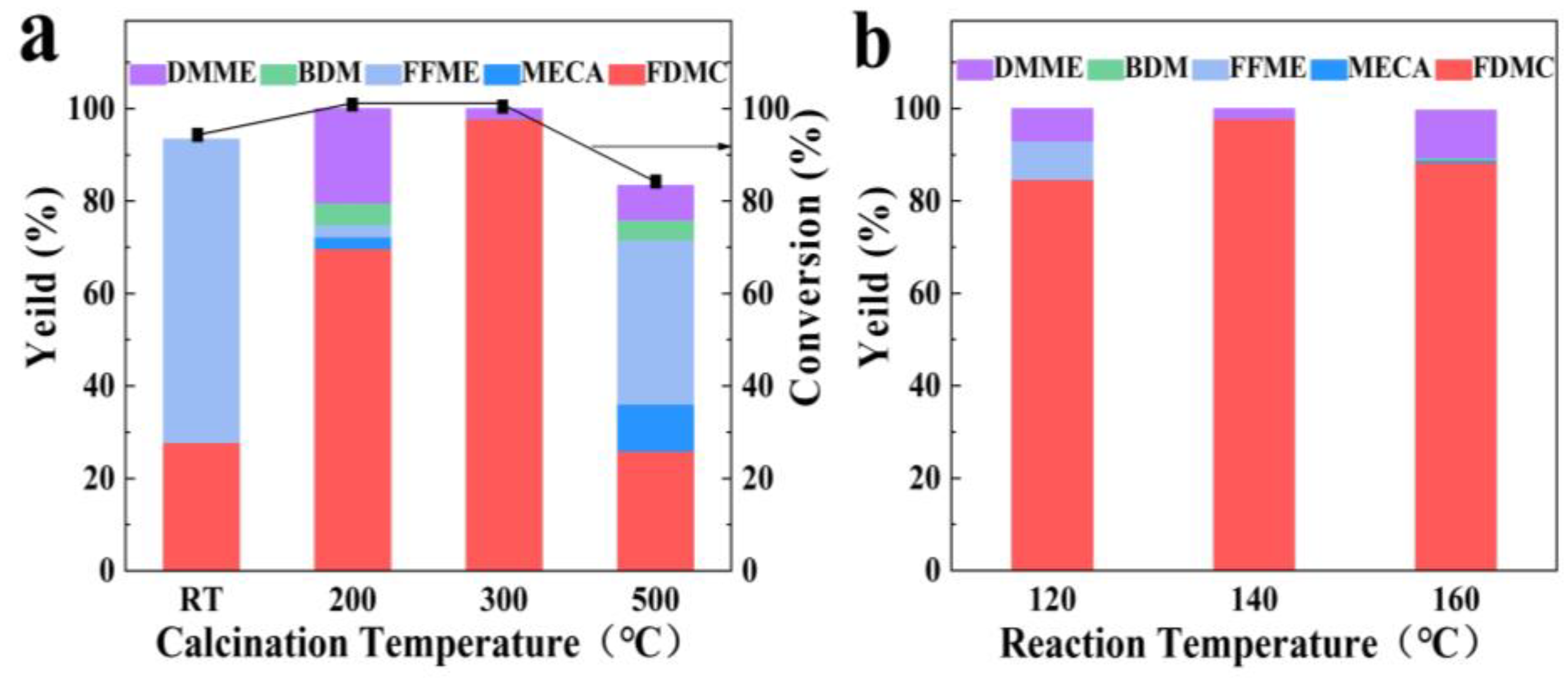

2.2. Effect of the Calcination Temperature of the Catalyst

2.3. Effect of Reaction Temperature

2.4. Catalytic Performance of Au/Mg3Al-HT on Different Substrates

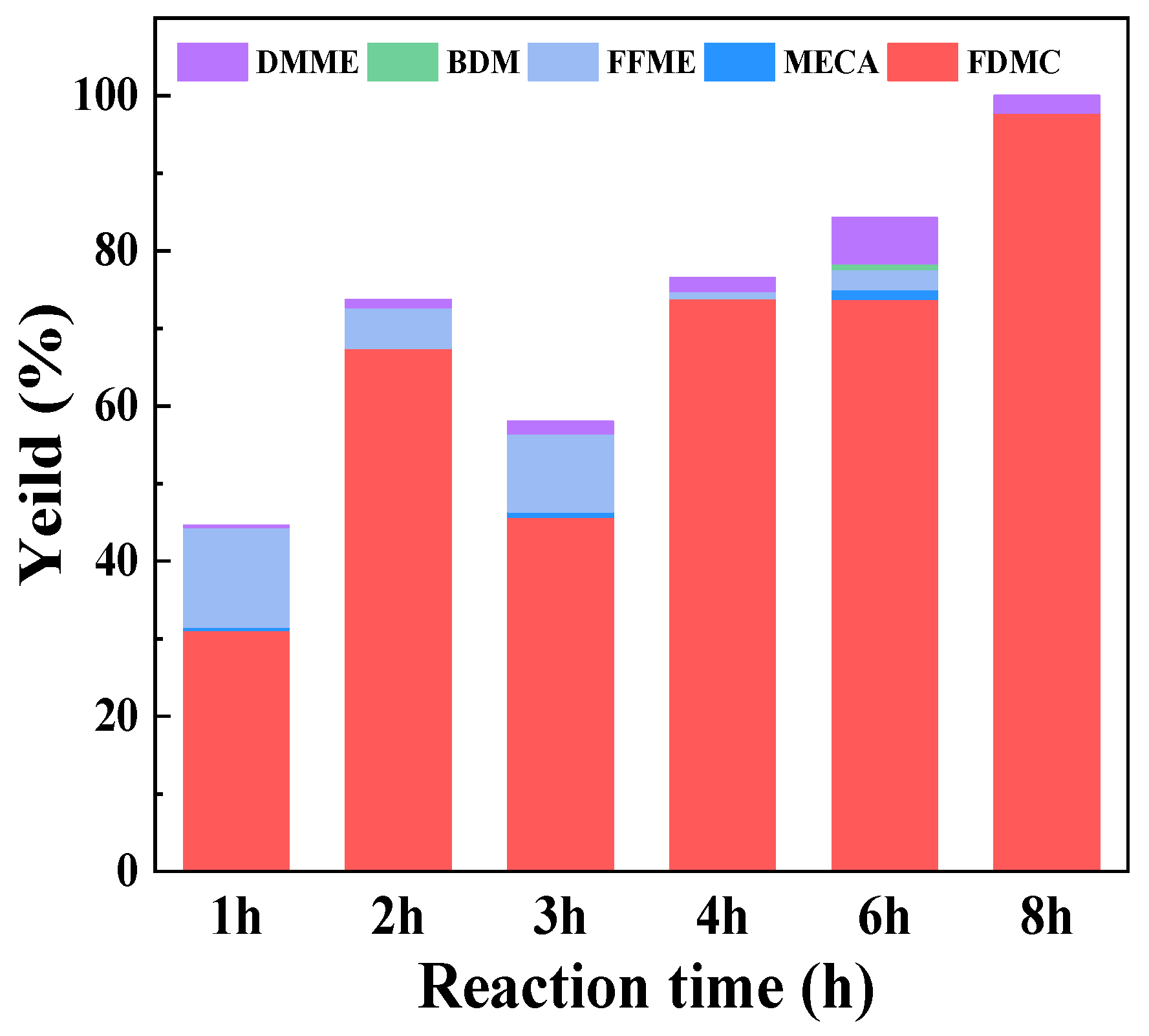

2.5. Stability of Au/Mg3Al-HT Catalyst

3. Materials and Methods

3.1. Materials

3.2. Preparation of the Catalyst

3.3. Catalytic Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burgess, S.K.; Leisen, J.E.; Kraftschik, B.E.; Mubarak, C.R.; Kriegel, R.M.; Koros, W.J. Chain Mobility, Thermal, and Mechanical Properties of Poly (ethylene furanoate) Compared to Poly (ethylene terephthalate). Macromolecules 2014, 47, 1383–1391. [Google Scholar] [CrossRef]

- Casanova, O.; Iborra, S.; Corma, A. Biomass into chemicals: One pot-base free oxidative esterification of 5-hydroxymethyl-2-furfural into 2,5-dimethylfuroate with gold on nanoparticulated ceria. J. Catal. 2009, 265, 109–116. [Google Scholar] [CrossRef]

- Jia, W.; Chen, J.; Yu, X.; Zhao, X.; Feng, Y.; Zuo, M.; Li, Z.; Yang, S.; Sun, Y.; Tang, X.; et al. Toward an integrated conversion of fructose for two-step production of 2,5-furandicarboxylic acid or furan-2,5-dimethylcarboxylate with air as oxidant. Chem. Eng. J. 2022, 450, 138172. [Google Scholar] [CrossRef]

- Li, F.; Li, X.-L.; Li, C.; Shi, J.; Fu, Y. Aerobic oxidative esterification of 5-hydroxymethylfurfural to dimethyl furan-2,5-dicarboxylate by using homogeneous and heterogeneous PdCoBi/C catalysts under atmospheric oxygen. Green Chem. 2018, 20, 3050–3058. [Google Scholar] [CrossRef]

- Salazar, A.; Hünemörder, P.; Rabeah, J.; Quade, A.; Jagadeesh, R.V.; Mejia, E. Synergetic Bimetallic Oxidative Esterification of 5-Hydroxymethylfurfural under Mild Conditions. ACS Sustain. Chem. Eng. 2019, 7, 12061–12068. [Google Scholar] [CrossRef]

- Takei, T.; Akita, T.; Nakamura, I.; Fujitani, T.; Haruta, M. Heterogeneous Catalysis by Gold. Adv. Catal. 2012, 55, 1–126. [Google Scholar] [CrossRef]

- Davis, S.E.; Houk, L.R.; Tamargo, E.C.; Datye, A.K.; Davis, R.J. Oxidation of 5-hydroxymethylfurfural over supported Pt, Pd and Au catalysts. Catal. Today 2011, 160, 55–60. [Google Scholar] [CrossRef]

- Taarning, E.; Nielsen, I.S.; Egeblad, K.; Madsen, R.; Christensen, C.H. Chemicals from Renewables: Aerobic Oxidation of Furfural and Hydroxymethylfurfural over Gold Catalysts. ChemSusChem 2008, 1, 75–78. [Google Scholar] [CrossRef]

- Buonerba, A.; Impemba, S.; Litta, A.D.; Capacchione, C.; Milione, S.; Grassi, A. Aerobic Oxidation and Oxidative Esterification of 5-Hydroxymethylfurfural by Gold Nanoparticles Supported on Nanoporous Polymer Host Matrix. ChemSusChem 2018, 11, 3139–3149. [Google Scholar] [CrossRef]

- Weerathunga, H.; Sarina, S.; Zhu, H.Y.; Waclawik, E.R. Oxidative Esterification of 5-Hydroxymethylfurfural into Dimethyl 2,5-Furandicarboxylate Using Gamma Alumina-Supported Gold Nanoparticles. ACS Omega 2021, 6, 4740–4748. [Google Scholar] [CrossRef]

- Dimitratos, N.; Villa, A.; Wang, D.; Porta, F.; Su, D.; Prati, L. Pd and Pt catalysts modified by alloying with Au in the selective oxidation of alcohols. J. Catal. 2006, 244, 113–121. [Google Scholar] [CrossRef]

- Song, F.; Cen, S.; Wan, C.; Wang, L. Nano-Au Anchored in Organic Base Group-Grafted Silica Aerogel: A Durable and Robust Catalysts for Green Oxidative Esterification of Furfural. ChemCatChem 2022, 14, e202200704. [Google Scholar] [CrossRef]

- Ferraz, C.P.; Braga, A.H.; Ghazzal, M.N.; Zieliński, M.; Pietrowski, M.; Itabaiana, I.; Dumeignil, F.; Rossi, L.M.; Wojcieszak, R. Efficient Oxidative Esterification of Furfural Using Au Nanoparticles Supported on Group 2 Alkaline Earth Metal Oxides. Catalysts 2020, 10, 430. [Google Scholar] [CrossRef]

- Mishra, D.K.; Cho, J.K.; Yi, Y.; Lee, H.J.; Kim, Y.J. Hydroxyapatite supported gold nanocatalyst for base-free oxidative esterification of 5-hydroxymethyl-2-furfural to 2,5-furan dimethylcarboxylate with air as oxidant. J. Ind. Eng. Chem. 2019, 70, 338–345. [Google Scholar] [CrossRef]

- Guo, X.; Si, Y.; Huang, Y.; Zhang, J.; Lyu, X.; Cheng, Y.; Li, X. Base-Free Oxidative Esterification of HMF Using Mg–Al Hydrotalcite-Supported Gold Catalyst. Ind. Eng. Chem. Res. 2023, 62, 16309–16318. [Google Scholar] [CrossRef]

- Yang, W.; Fu, M.; Yang, C.; Zhang, Y.; Shen, C. Au−–Ov–Ti3+: Active site of MO-Au/TiO2 catalysts for the aerobic oxidation of 5-hydroxymethylfurfural. Green Energy Environ. 2023, 8, 785–797. [Google Scholar] [CrossRef]

- Menegazzo, F.; Fantinel, T.; Signoretto, M.; Pinna, F.; Manzoli, M. On the process for furfural and HMF oxidative esterification over Au/ZrO2. J. Catal. 2014, 319, 61–70. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, Y.; Yan, C.; Liu, W.; Chen, Y.; Guan, W.; Wang, F.; Liu, Y.; Huo, P. Rationally designed Au-ZrOx interaction for boosting 5-hydroxymethylfurfural oxidation. Chem. Eng. J. 2023, 459, 141644. [Google Scholar] [CrossRef]

- Campisi, S.; Bellomi, S.; Chinchilla, L.E.; Prati, L.; Villa, A. Base-free Oxidative Esterification of HMF over AuPd/nNiO-TiO2. When Alloying Effects and Metal-Support Interactions Converge in Producing Effective and Stable Catalysts. ChemCatChem 2022, 14, e202200494. [Google Scholar] [CrossRef]

- Ide, M.S.; Davis, R.J. The Important Role of Hydroxyl on Oxidation Catalysis by Gold Nanoparticles. Acc. Chem. Res. 2014, 47, 825–833. [Google Scholar] [CrossRef]

- Zhu, Z.; Gao, X.; Wang, X.; Yin, M.; Wang, Q.; Ren, W.; Wang, B.; Lü, H.; Liao, W. Rational construction of metal–base synergetic sites on Au/Mg-beta catalyst for selective aerobic oxidation of 5-hydroxymethylfurfural. J. Energy Chem. 2021, 62, 599–609. [Google Scholar] [CrossRef]

- Ren, J.; Mebrahtu, C.; Palkovits, R. Ni-based catalysts supported on Mg–Al hydrotalcites with different morphologies for CO2 methanation: Exploring the effect of metal–support interaction. Catal. Sci. Technol. 2020, 10, 1902–1913. [Google Scholar] [CrossRef]

- Dębek, R.; Radlik, M.; Motak, M.; Galvez, M.E.; Turek, W.; Da Costa, P.; Grzybek, T. Ni-containing Ce-promoted hydrotalcite derived materials as catalysts for methane reforming with carbon dioxide at low temperature—On the effect of basicity. Catal. Today 2015, 257, 59–65. [Google Scholar] [CrossRef]

- Liu, H.; Jia, W.; Yu, X.; Tang, X.; Zeng, X.; Sun, Y.; Lei, T.; Fang, H.; Li, T.; Lin, L. Vitamin C-Assisted Synthesized Mn–Co Oxides with Improved Oxygen Vacancy Concentration: Boosting Lattice Oxygen Activity for the Air-Oxidation of 5-(Hydroxymethyl)furfural. ACS Catal. 2021, 11, 7828–7844. [Google Scholar] [CrossRef]

- Liao, Y.; Yan, H.; Zhou, J.; Yue, Y.; Sun, Y.; Peng, T.; Yuan, X.; Zhou, X.; Liu, Y.; Feng, X.; et al. Interfacial Auδ−-OV-Zr3+ structure promoted C H bond activation for oxidative esterification of methacrolein to Methyl methacrylate. Chem. Eng. J. 2023, 454, 140322. [Google Scholar] [CrossRef]

- Wan, Q.; Wang, X.; Zhao, B.; Zhao, G.; Zhao, G.; Gao, E.; Gong, Y.; Yu, H.; Wang, X.; Liu, D.; et al. Influence of calcination temperature on the cooperative catalysis of base sites and gold nanoparticles on hydrotalcite-supported gold materials for the base-free oxidative esterification of 1,3-propanediol with methanol to methyl 3-hydroxypropionate. React. Kinet. Mech. Catal. 2021, 134, 109–125. [Google Scholar] [CrossRef]

- Sankar, M.; He, Q.; Engel, R.V.; Sainna, M.A.; Logsdail, A.J.; Roldan, A.; Willock, D.J.; Agarwal, N.; Kiely, C.J.; Hutchings, G.J. Role of the Support in Gold-Containing Nanoparticles as Heterogeneous Catalysts. Chem. Rev. 2020, 120, 3890–3938. [Google Scholar] [CrossRef]

- Monti, E.; Ventimiglia, A.; Soto, C.A.G.; Martelli, F.; Rodríguez-Aguado, E.; Cecilia, J.A.; Maireles-Torres, P.; Ospitali, F.; Tabanelli, T.; Albonetti, S.; et al. Oxidative condensation/esterification of furfural with ethanol using preformed Au colloidal nanoparticles. Impact of stabilizer and heat treatment protocols on catalytic activity and stability. Mol. Catal. 2022, 528, 112438. [Google Scholar] [CrossRef]

- Wojcieszak, R.; Ferraz, C.; Sha, J.; Houda, S.; Rossi, L.; Paul, S. Advances in Base-Free Oxidation of Bio-Based Compounds on Supported Gold Catalysts. Catalysts 2017, 7, 352. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, Y.; Chen, Y.; Wang, F.; Cao, Y.; Guan, W.; Li, X. Crystal Faces-Tailored Oxygen Vacancy in Au/CeO2 Catalysts for Efficient Oxidation of HMF to FDCA. ChemSusChem 2021, 15, e202101983. [Google Scholar] [CrossRef]

- Zhao, D.; Sheng, G.; Hu, J.; Chen, C.; Wang, X. The adsorption of Pb (II) on Mg2Al layered double hydroxide. Chem. Eng. J. 2011, 171, 167–174. [Google Scholar] [CrossRef]

| Entry | Substrate | Solvent | Conv. | (di)Ester | Monoester | Monoacetal | Monoester-Monoacetal | (di)Acetal |

|---|---|---|---|---|---|---|---|---|

| entry 1 | FF 1 | methanol | 100.00 | 97.23 | / | / | / | 2.77 |

| entry 2 | BzH 2 | methanol | 100.00 | 99.01 | / | / | / | 0.99 |

| entry 3 | DFF | methanol | 100.00 | 97.78 | / | / | / | 2.22 |

| entry 4 | DFF | ethanol | 100.00 | 54.61 | 12.89 | 6.47 | 24.45 | 1.57 |

| entry 5 | DFF | n-butanol | 94.02 | 6.65 | 3.76 | 82.59 | 6.99 | / |

| entry 6 | DFF | 1-pentanol | 59.24 | / | 2.60 | 34.56 | 62.84 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, T.; Liu, X.; Tang, J.; Liu, C.; Huang, J. Effect of Support on Oxidative Esterification of 2,5-Furandiformaldehyde to Dimethyl Furan-2,5-dicarboxylate. Catalysts 2023, 13, 1430. https://doi.org/10.3390/catal13111430

Ge T, Liu X, Tang J, Liu C, Huang J. Effect of Support on Oxidative Esterification of 2,5-Furandiformaldehyde to Dimethyl Furan-2,5-dicarboxylate. Catalysts. 2023; 13(11):1430. https://doi.org/10.3390/catal13111430

Chicago/Turabian StyleGe, Tingting, Xiaorui Liu, Jie Tang, Chao Liu, and Jiahui Huang. 2023. "Effect of Support on Oxidative Esterification of 2,5-Furandiformaldehyde to Dimethyl Furan-2,5-dicarboxylate" Catalysts 13, no. 11: 1430. https://doi.org/10.3390/catal13111430

APA StyleGe, T., Liu, X., Tang, J., Liu, C., & Huang, J. (2023). Effect of Support on Oxidative Esterification of 2,5-Furandiformaldehyde to Dimethyl Furan-2,5-dicarboxylate. Catalysts, 13(11), 1430. https://doi.org/10.3390/catal13111430