Effect of Zirconia on Pd–Pt Supported SBA-15 Catalysts for the Oxidation of Methane

Abstract

:1. Introduction

2. Results and Discussions

2.1. SEM-EDX and FAA

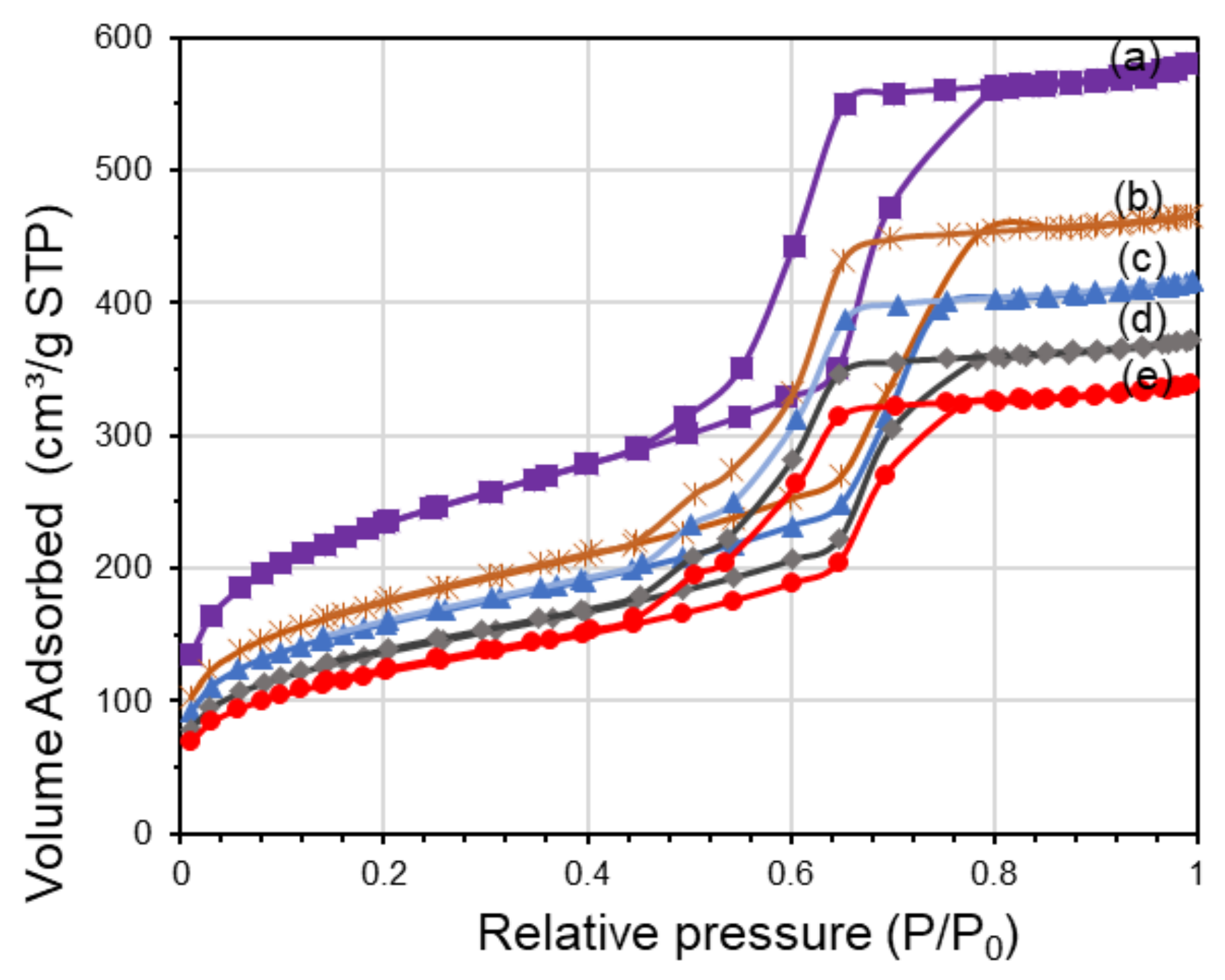

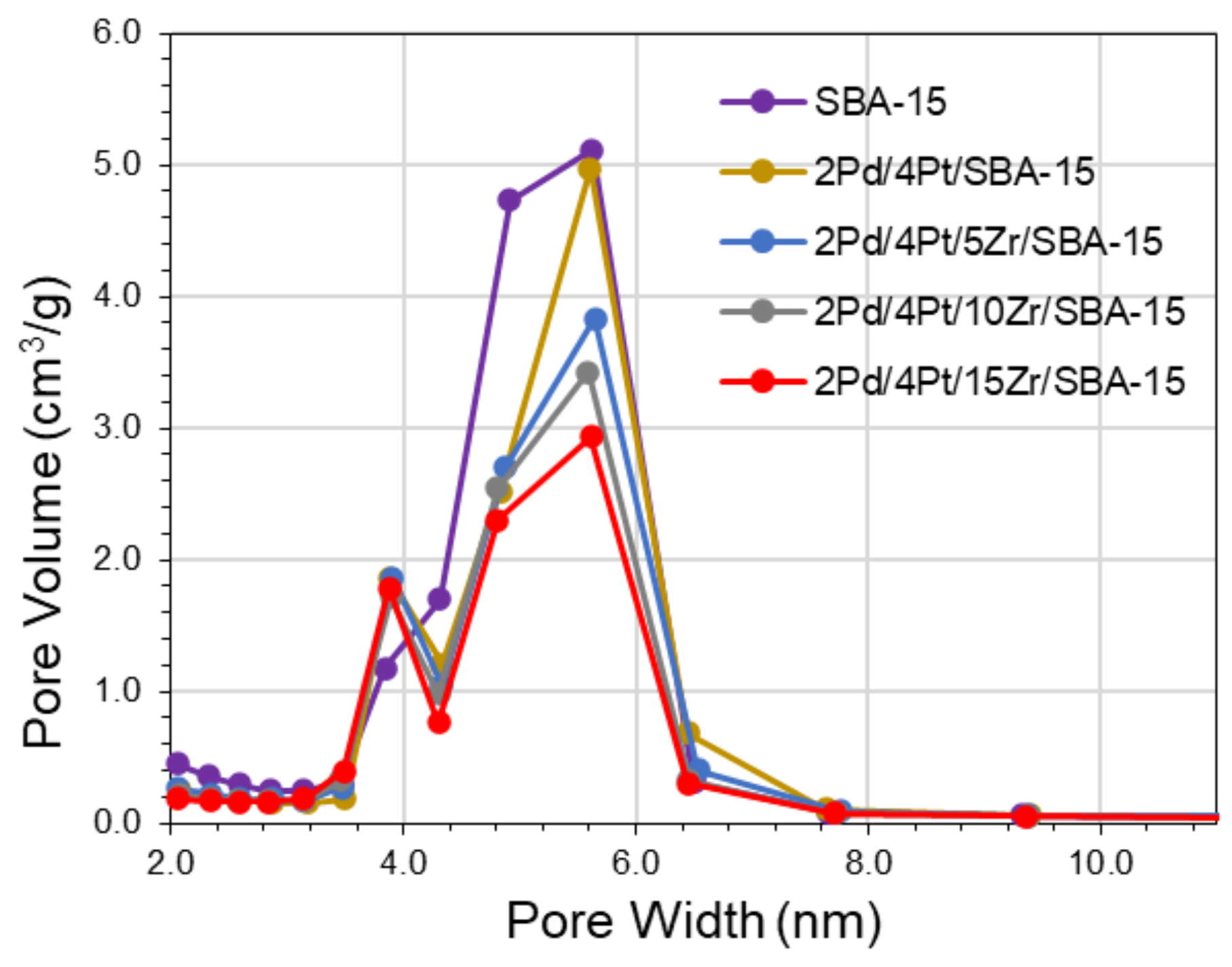

2.2. Textural Characterization

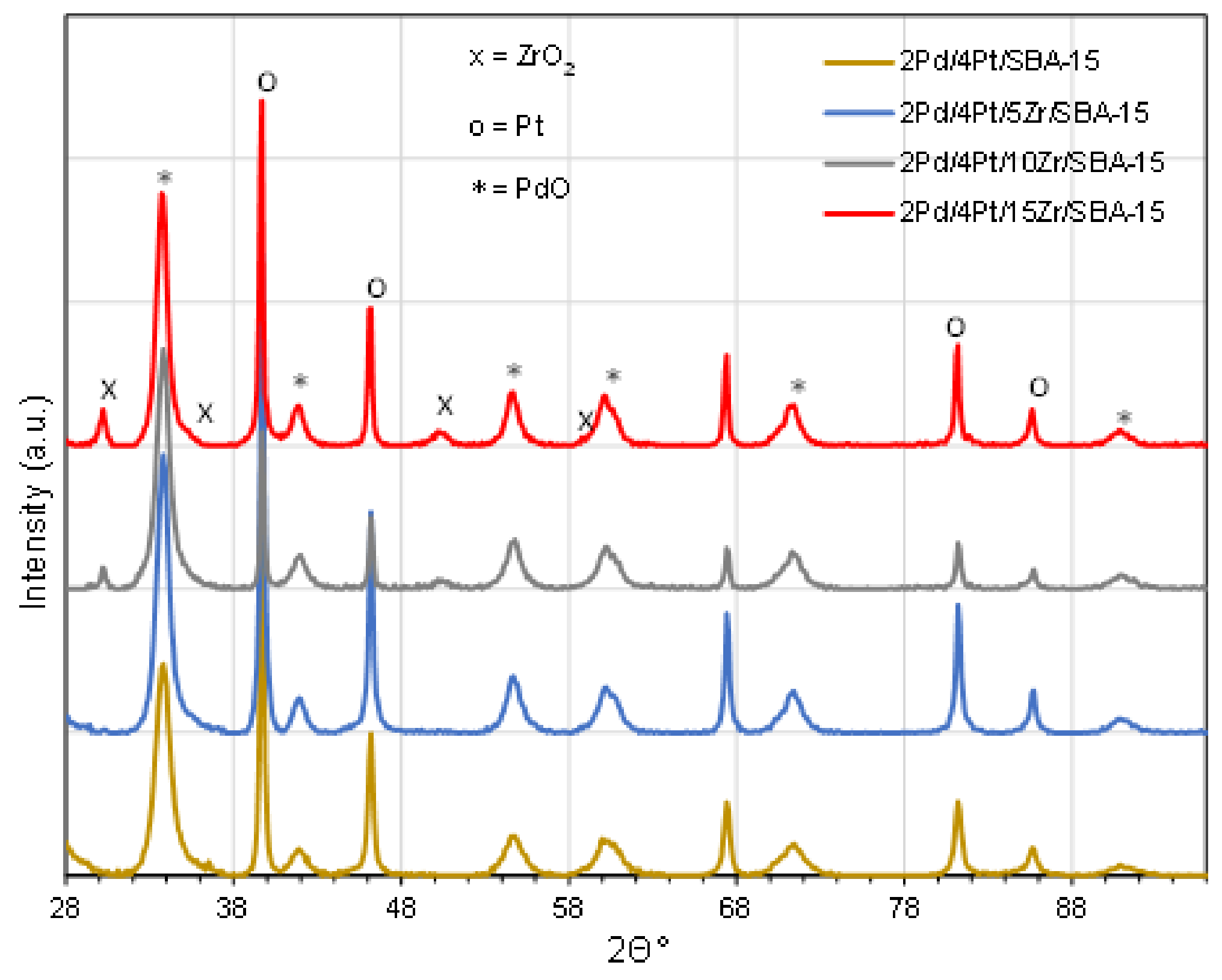

2.3. XRD Analysis

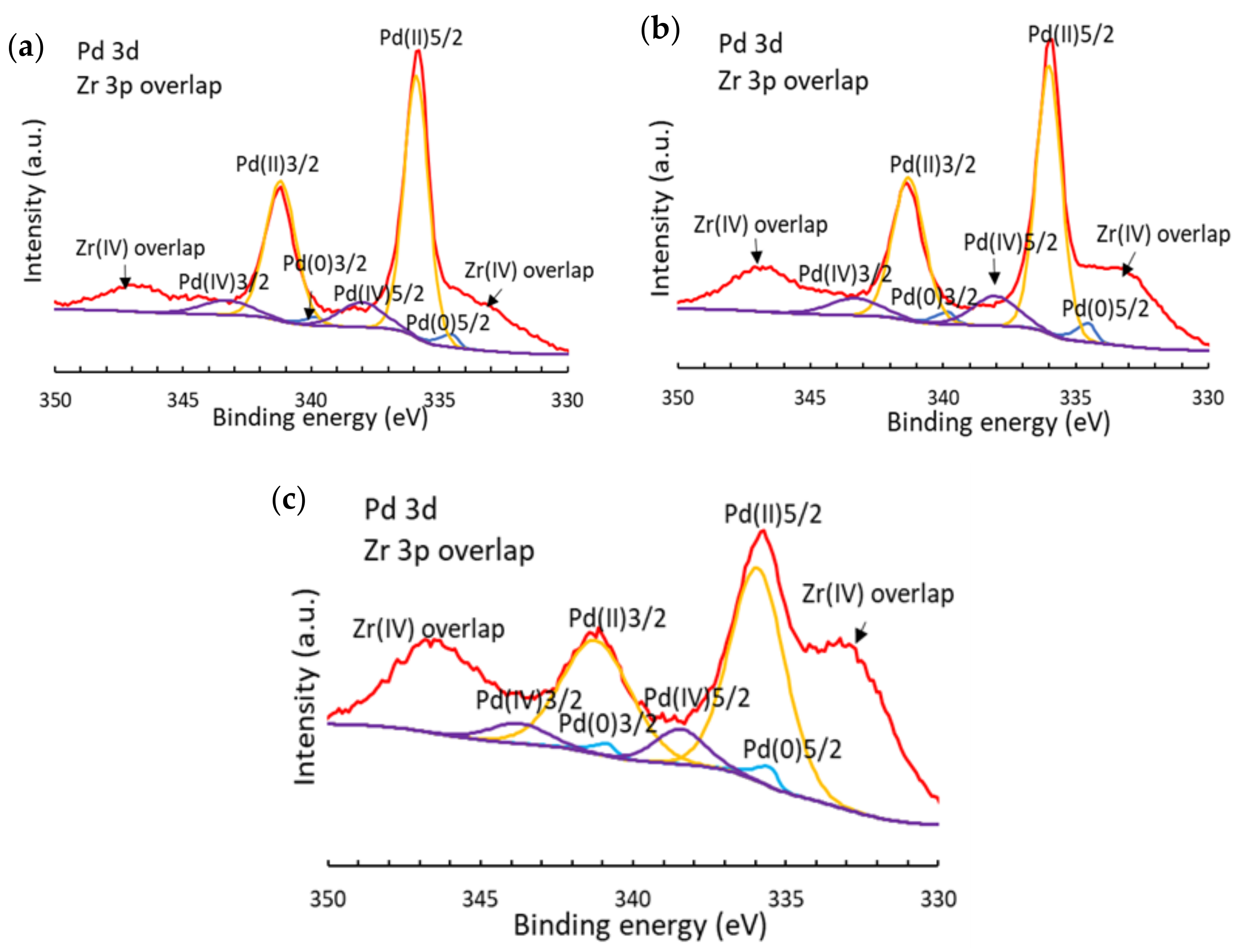

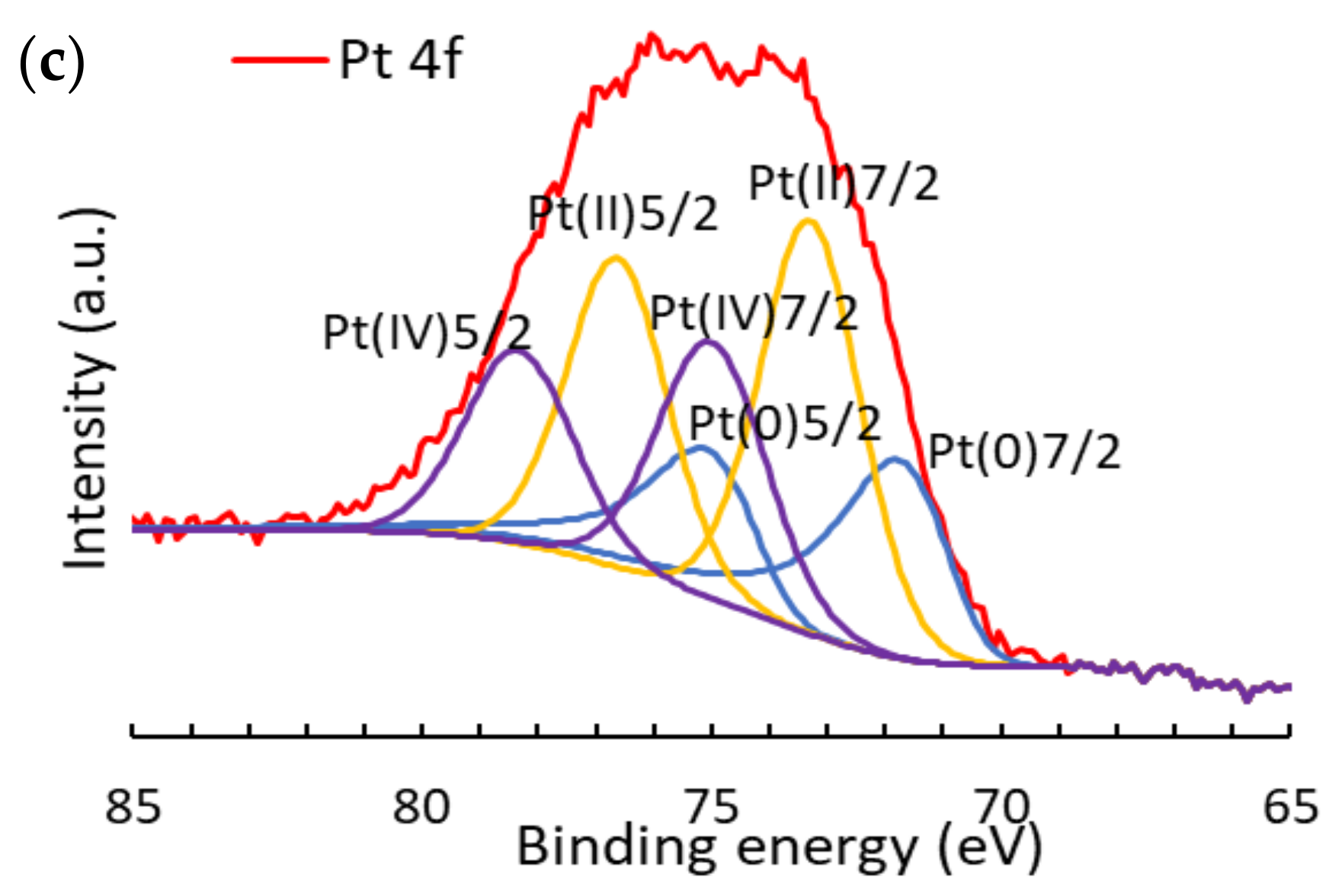

2.4. XPS Analysis

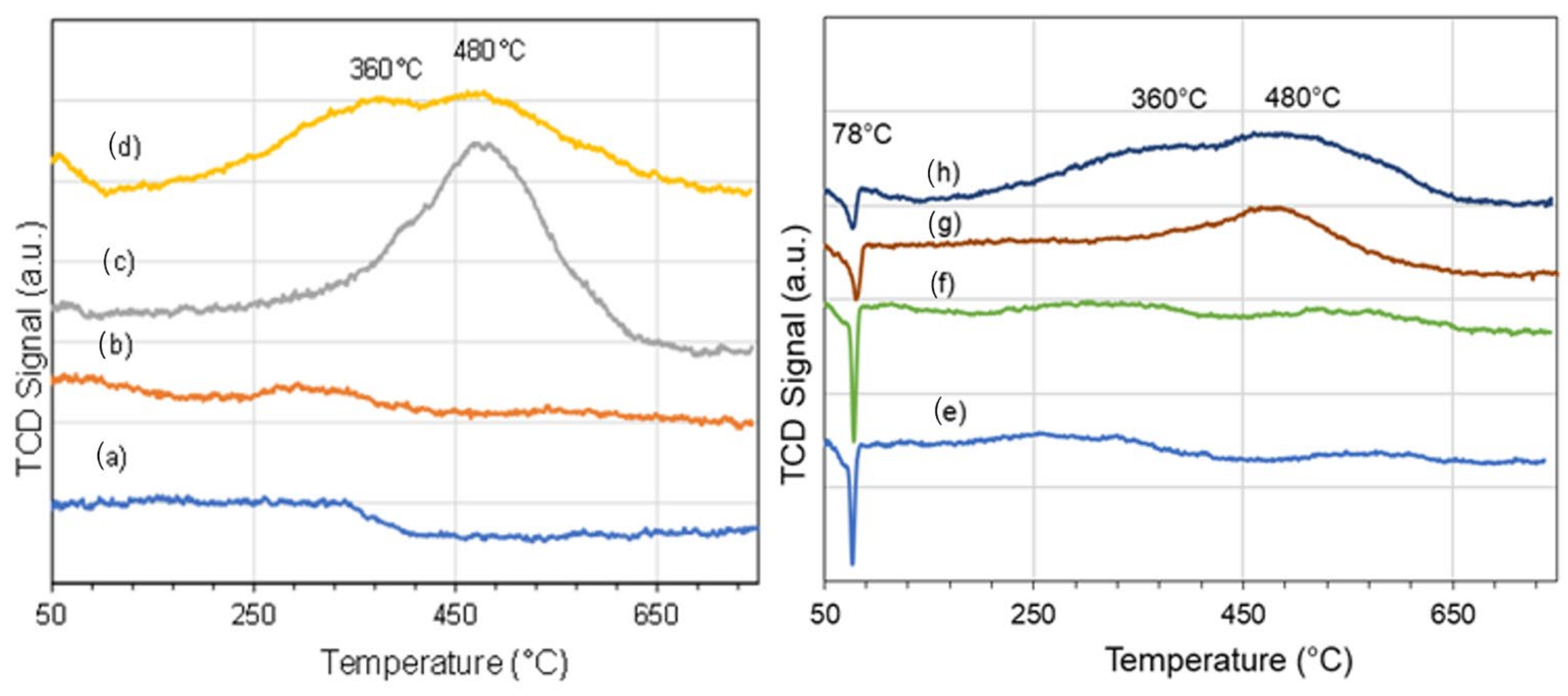

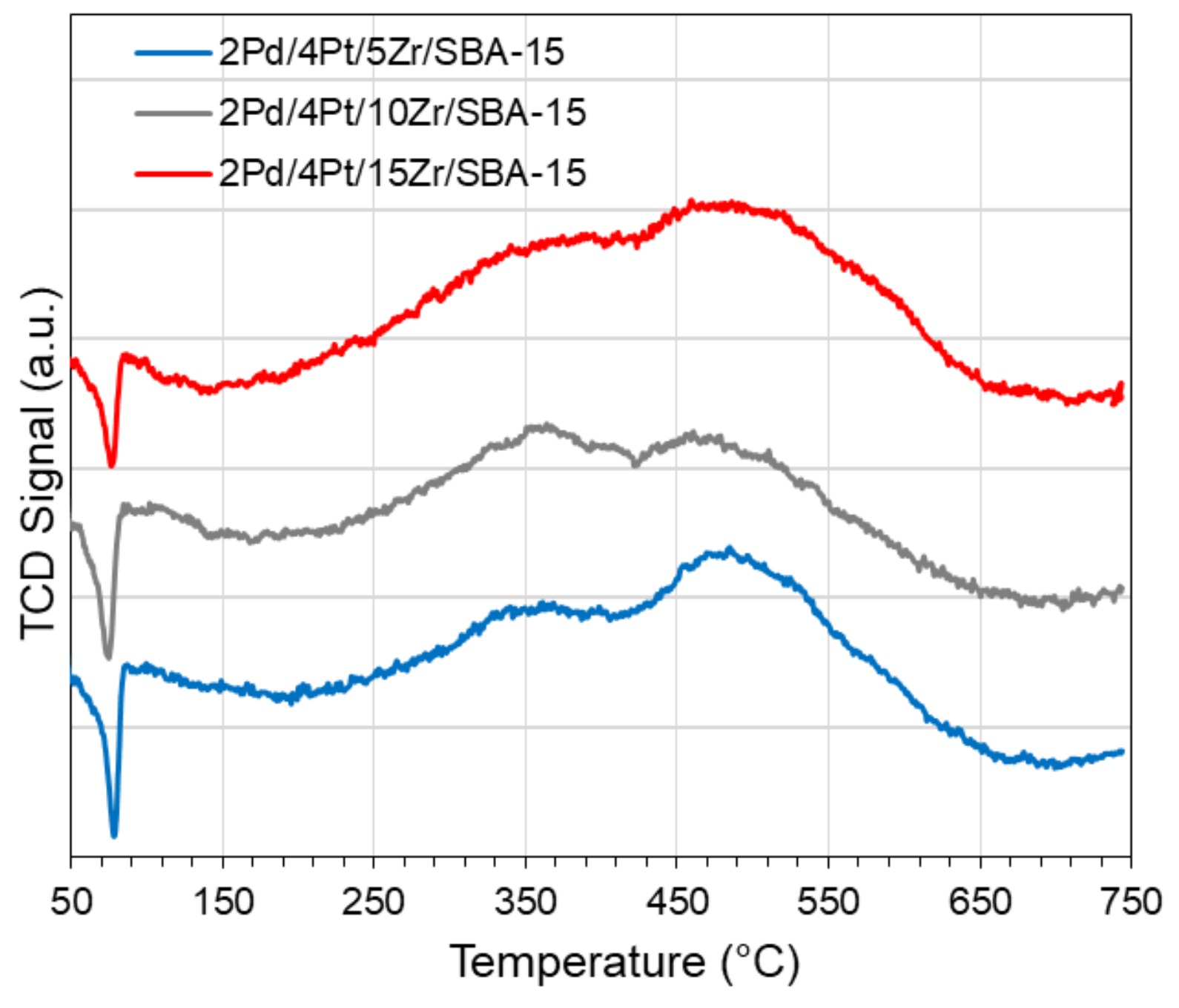

2.5. TPR Characterization

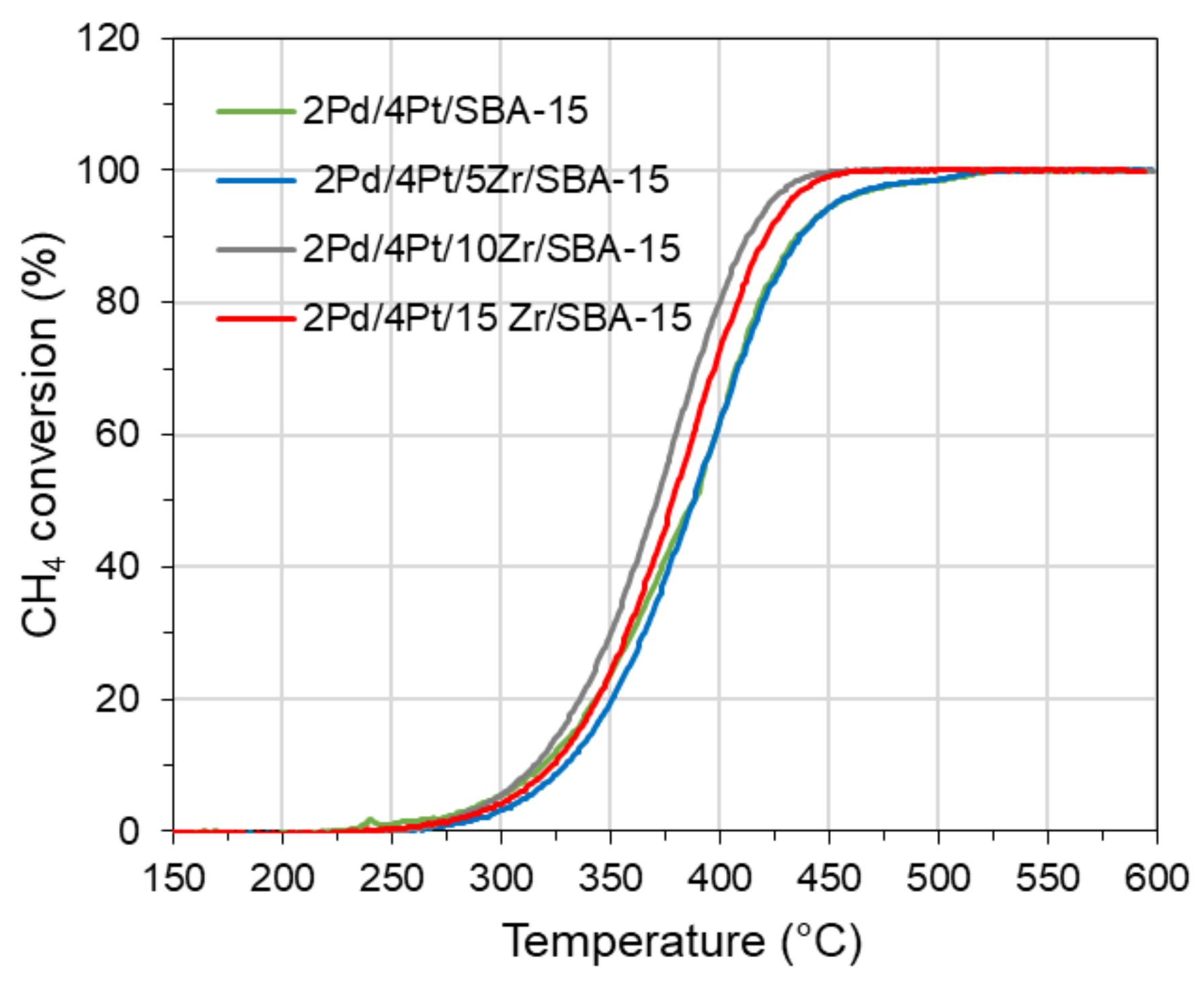

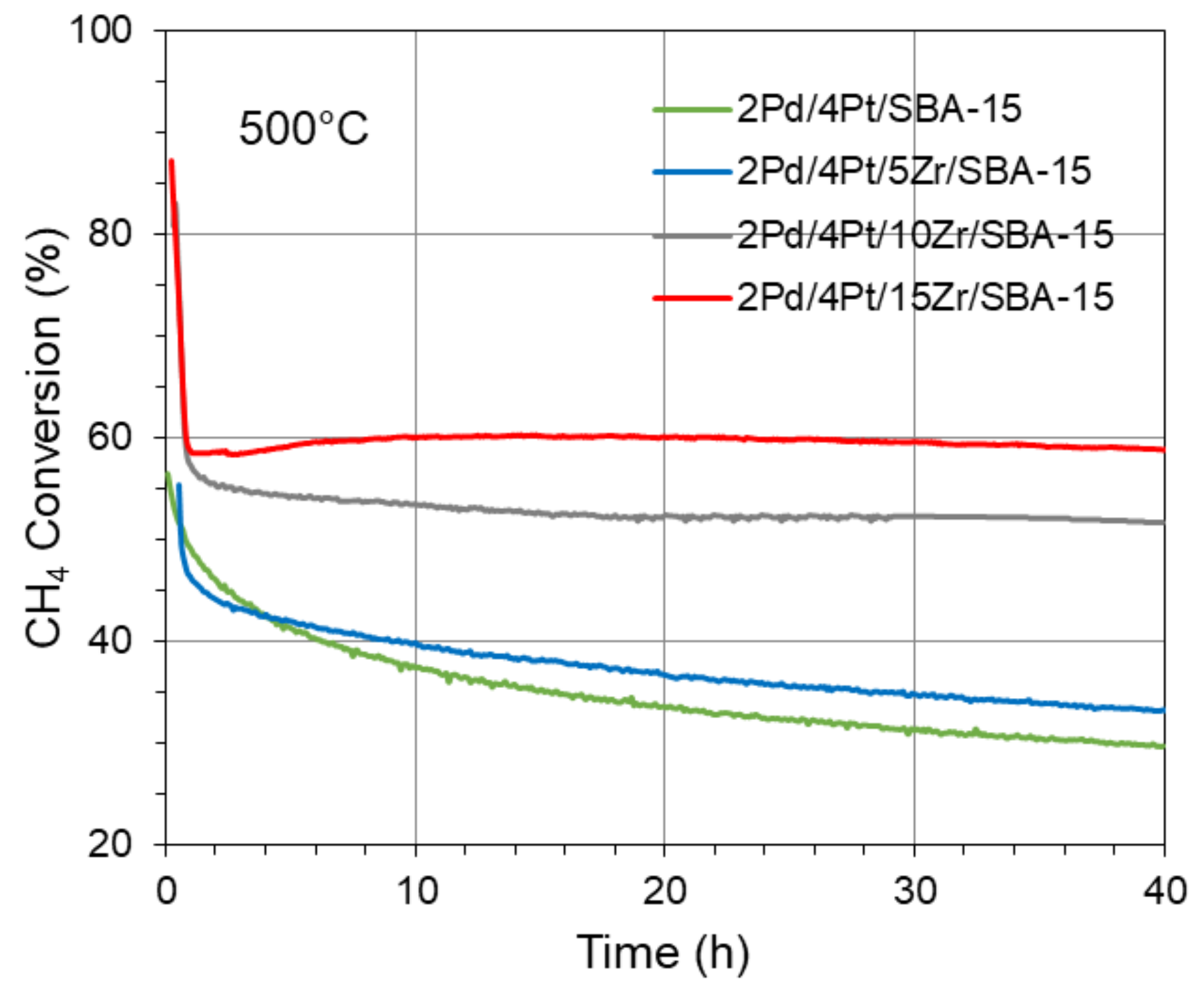

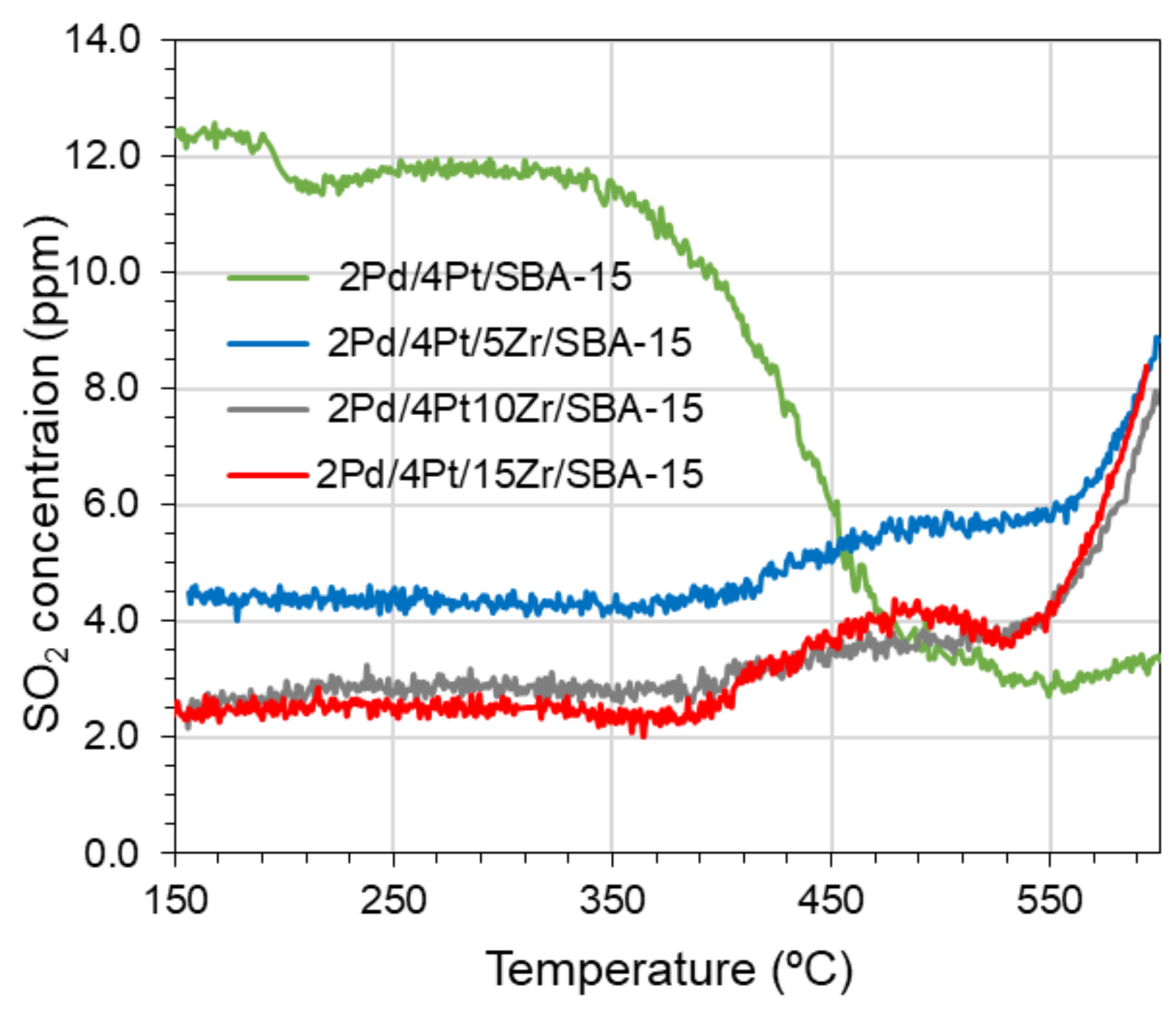

2.6. Catalytic Activity Tests

3. Materials and Methods

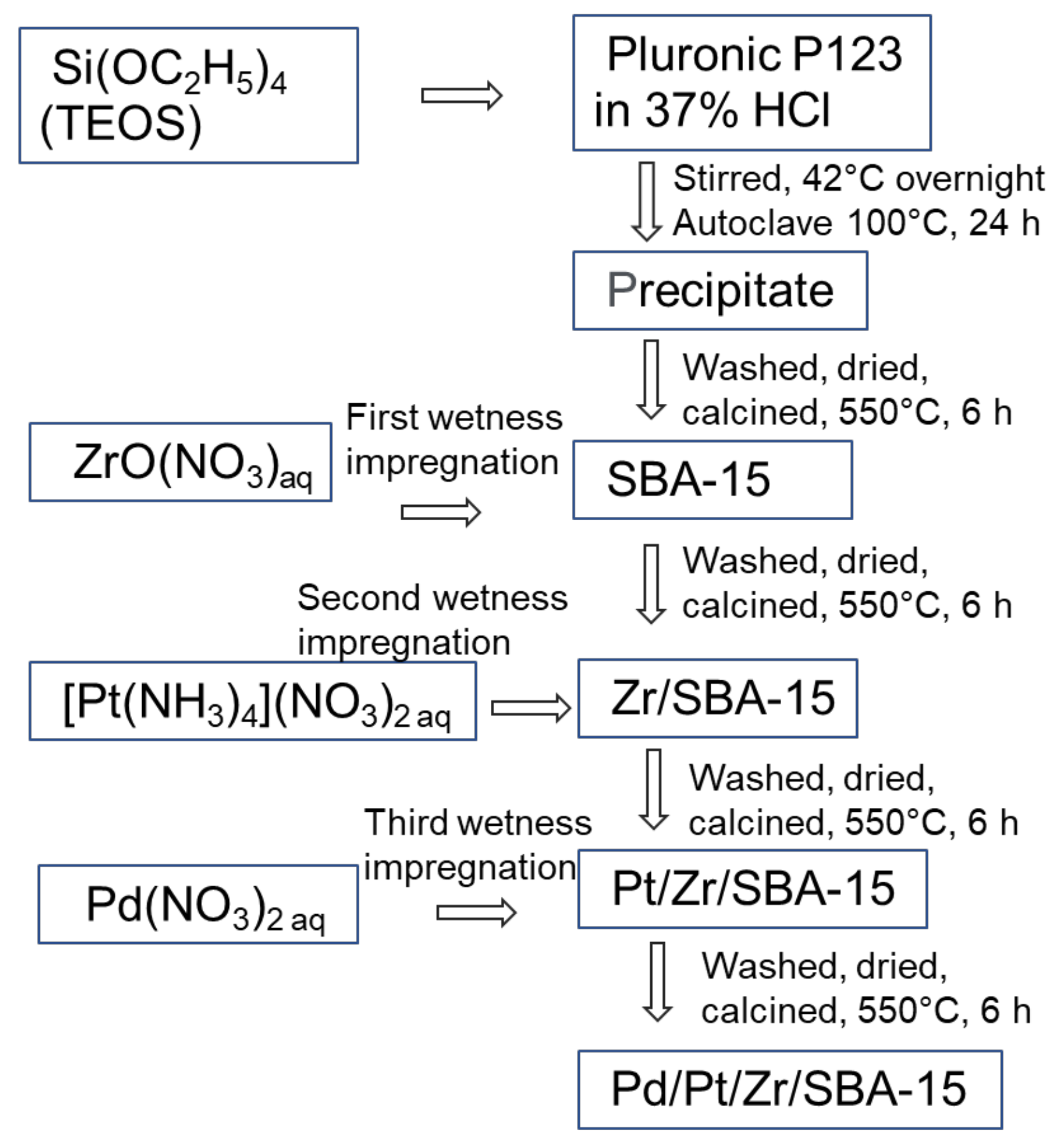

3.1. Support and Catalyst Preparation

3.2. Characterization of Catalysts

3.3. Catalyst Activity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tajima, H.; Tsuru, D. Reduction of Methane Slip from Gas Engines by O2 Concentration Control Using Gas Permeation Membrane. In Proceedings of the SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Johnson, J. Methane’s Role in Climate Change. Chem. Eng. News 2014, 92, 10–15. [Google Scholar] [CrossRef]

- He, L.; Fan, Y.; Bellettre, J.; Yue, J.; Luo, L. A Review on Catalytic Methane Combustion at Low Temperatures: Catalysts, Mechanisms, Reaction Conditions and Reactor Designs. Renew. Sustain. Energy Rev. 2020, 119, 109589. [Google Scholar] [CrossRef]

- Gélin, P.; Urfels, L.; Primet, M.; Tena, E. Complete Oxidation of Methane at Low Temperature over Pt and Pd Catalysts for the Abatement of Lean-Burn Natural Gas Fuelled Vehicles Emissions: Influence of Water and Sulphur Containing Compounds. Catal. Today 2003, 83, 45–57. [Google Scholar] [CrossRef]

- Li, Z.; Hoflund, G. A Review on Complete Oxidation of Methane at Low Temperatures. J. Nat. Gas Chem. 2003, 12, 153–160. [Google Scholar]

- Fraga, M.A.; Soares de Souza, E.; Villain, F.; Appel, L.G. Addition of La and Sn to Alumina-Supported Pd Catalysts for Methane Combustion. Appl. Catal. A Gen. 2004, 259, 57–63. [Google Scholar] [CrossRef]

- Yasuda, K.; Masui, T.; Miyamoto, T.; Imanaka, N. Catalytic Combustion of Methane over Pt and PdO-Supported CeO2–ZrO2–Bi2O3/γ-Al2O3 Catalysts. J. Mater. Sci. 2011, 46, 4046–4052. [Google Scholar] [CrossRef]

- Barrera, A.; Fuentes, S.; Díaz, G.; Gómez-Cortés, A.; Tzompantzi, F.; Molina, J.C. Methane Oxidation over Pd Catalysts Supported on Binary Al2O3–La2O3 Oxides Prepared by the Sol–Gel Method. Fuel 2012, 93, 136–141. [Google Scholar] [CrossRef]

- Ziaei-Azad, H.; Khodadadi, A.; Esmaeilnejad-Ahranjani, P.; Mortazavi, Y. Effects of Pd on Enhancement of Oxidation Activity of LaBO3 (B = Mn, Fe, Co and Ni) Pervoskite Catalysts for Pollution Abatement from Natural Gas Fueled Vehicles. Appl. Catal. B Environ. 2011, 102, 62–70. [Google Scholar] [CrossRef]

- Jiang, D.; Khivantsev, K.; Wang, Y. Low-Temperature Methane Oxidation for Efficient Emission Control in Natural Gas Vehicles: Pd and Beyond. ACS Catal. 2020, 10, 14304–14314. [Google Scholar] [CrossRef]

- Corro, G.; Cano, C.; Fierro, J.L.G. A Study of Pt–Pd/γ-Al2O3 Catalysts for Methane Oxidation Resistant to Deactivation by Sulfur Poisoning. J. Mol. Catal. A Chem. 2010, 315, 35–42. [Google Scholar] [CrossRef]

- Gholami, R.; Alyani, M.; Smith, K. Deactivation of Pd Catalysts by Water during Low Temperature Methane Oxidation Relevant to Natural Gas Vehicle Converters. Catalysts 2015, 5, 561–594. [Google Scholar] [CrossRef]

- Araya, P.; Guerrero, S.; Robertson, J.; Gracia, F.J. Methane Combustion over Pd/SiO2 Catalysts with Different Degrees of Hydrophobicity. Appl. Catal. A Gen. 2005, 283, 225–233. [Google Scholar] [CrossRef]

- Okumura, K.; Shinohara, E.; Niwa, M. Pd Loaded on High Silica Beta Support Active for the Total Oxidation of Diluted Methane in the Presence of Water Vapor. Catal. Today 2006, 117, 577–583. [Google Scholar] [CrossRef]

- Yuranov, I.; Moeckli, P.; Suvorova, E.; Buffat, P.; Kiwi-Minsker, L.; Renken, A. Pd/SiO2 Catalysts: Synthesis of Pd Nanoparticles with the Controlled Size in Mesoporous Silicas. J. Mol. Catal. A Chem. 2003, 192, 239–251. [Google Scholar] [CrossRef]

- Yashnik, S.A.; Chesalov, Y.A.; Ishchenko, A.V.; Kaichev, V.V.; Ismagilov, Z.R. Effect of Pt Addition on Sulfur Dioxide and Water Vapor Tolerance of Pd-Mn-Hexaaluminate Catalysts for High-Temperature Oxidation of Methane. Appl. Catal. B Environ. 2017, 204, 89–106. [Google Scholar] [CrossRef]

- Venezia, A.M.; Di Carlo, G.; Liotta, L.F.; Pantaleo, G.; Kantcheva, M. Effect of Ti(IV) Loading on CH4 Oxidation Activity and SO2 Tolerance of Pd Catalysts Supported on Silica SBA-15 and HMS. Appl. Catal. B Environ. 2011, 106, 529–539. [Google Scholar] [CrossRef]

- Escandón, L.S.; Ordóñez, S.; Vega, A.; Díez, F.V. Sulphur Poisoning of Palladium Catalysts Used for Methane Combustion: Effect of the Support. J. Hazard. Mater. 2008, 153, 742–750. [Google Scholar] [CrossRef]

- Velin, P.; Florén, C.R.; Skoglundh, M.; Raj, A.; Thompsett, D.; Smedler, G.; Carlsson, P.A. Palladium Dispersion Effects on Wet Methane Oxidation Kinetics. Catal. Sci. Technol. 2020, 10, 5460–5469. [Google Scholar] [CrossRef]

- Huang, Z.D.; Bensch, W.; Kienle, L.; Fuentes, S.; Alonso, G.; Ornelas, C. SBA-15 as Support for MoS2 and Co-MoS2 Catalysts Derived from Thiomolybdate Complexes in the Reaction of HDS of DBT. Catal. Lett. 2008, 122, 57–67. [Google Scholar] [CrossRef]

- Gonzalez, G.; Sagarzazu, A.; Cordova, A.; Gomes, M.E.; Salas, J.; Contreras, L.; Noris-Suarez, K.; Lascano, L. Comparative Study of Two Silica Mesoporous Materials (SBA-16 and SBA-15) Modified with a Hydroxyapatite Layer for Clindamycin Controlled Delivery. Microporous Mesoporous Mater. 2018, 256, 251–265. [Google Scholar] [CrossRef]

- Esperanza Adrover, M.; Pedernera, M.; Bonne, M.; Lebeau, B.; Bucalá, V.; Gallo, L. Synthesis and Characterization of Mesoporous SBA-15 and SBA-16 as Carriers to Improve Albendazole Dissolution Rate. Saudi Pharm. J. 2020, 28, 15–24. [Google Scholar] [CrossRef] [PubMed]

- El Hassan, N.; Aouad, S.; Casale, S.; El Zakhem, H.; El Nakat, H. Oxidation of Carbon Black, Propene and Toluene on Highly Reducible Co/SBA-15 Catalysts. Comptes Rendus Chim. 2014, 17, 913–919. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Z.; Wang, J.; Zhong, C.J.; Liu, C.J. Highly Active and Stable Pt–Pd Alloy Catalysts Synthesized by Room-Temperature Electron Reduction for Oxygen Reduction Reaction. Adv. Sci. 2017, 4, 1600486. [Google Scholar] [CrossRef] [PubMed]

- Morlang, A.; Neuhausen, U.; Klementiev, K.V.; Schütze, F.W.; Miehe, G.; Fuess, H.; Lox, E.S. Bimetallic Pt/Pd Diesel Oxidation Catalysts: Structural Characterisation and Catalytic Behaviour. Appl. Catal. B Environ. 2005, 60, 191–199. [Google Scholar] [CrossRef]

- Nagai, Y.; Hirabayashi, T.; Dohmae, K.; Takagi, N.; Minami, T.; Shinjoh, H.; Matsumoto, S. Sintering Inhibition Mechanism of Platinum Supported on Ceria-Based Oxide and Pt-Oxide-Support Interaction. J. Catal. 2006, 242, 103–109. [Google Scholar] [CrossRef]

- Yazawa, Y.; Yoshida, H.; Komai, S.I.; Hattori, T. The Additive Effect on Propane Combustion over Platinum Catalyst: Control of the Oxidation-Resistance of Platinum by the Electronegativity of Additives. Appl. Catal. A Gen. 2002, 233, 113–124. [Google Scholar] [CrossRef]

- Torralba, R.; Corro, G.; Rosales, F.; Bañuelos, F.; Pal, U.; Olivares-Xometl, O.; Guilleminot, E.; Fierro, J.L.G. Total Oxidation of Methane over Sulfur Poisoning Resistant Pt/ZrO2 Catalyst: Effect of Pt2+–Pt4+ and Pt2+–Zr4+ Dipoles at Metal-Support Interface. Catal. Lett. 2021, 151, 1592–1603. [Google Scholar] [CrossRef]

- Monai, M.; Montini, T.; Melchionna, M.; Duchoň, T.; Kúš, P.; Chen, C.; Tsud, N.; Nasi, L.; Prince, K.C.; Veltruská, K.; et al. The Effect of Sulfur Dioxide on the Activity of Hierarchical Pd-Based Catalysts in Methane Combustion. Appl. Catal. B Environ. 2017, 202, 72–83. [Google Scholar] [CrossRef]

- Rodríguez-Castellón, E.; Mérida-Robles, J.; Díaz, L.; Maireles-Torres, P.; Jones, D.J.; Rozière, J.; Jiménez-López, A. Hydrogenation and Ring Opening of Tetralin on Noble Metal Supported on Zirconium Doped Mesoporous Silica Catalysts. Appl. Catal. A Gen. 2004, 260, 9–18. [Google Scholar] [CrossRef]

- Bhogeswararao, S.; Srinivas, D. Catalytic Conversion of Furfural to Industrial Chemicals over Supported Pt and Pd Catalysts. J. Catal. 2015, 327, 65–77. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, P.; Cao, H.; Bals, S.; Heeres, H.J.; Pescarmona, P.P. Pt/ZrO2 Prepared by Atomic Trapping: An Efficient Catalyst for the Conversion of Glycerol to Lactic Acid with Concomitant Transfer Hydrogenation of Cyclohexene. ACS Catal. 2019, 9, 9953–9963. [Google Scholar] [CrossRef]

- Howeizi, J.; Taghvaei-Ganjali, S.; Malekzadeh, M.; Motiee, F.; Sahebdelfar, S. Effect of the Distribution and Dispersion of Palladium Nanoparticles on the Reducibility and Performance of Pd/Al2O3 Catalyst in Liquid-Phase Hydrogenation of Olefins. React. Kinet. Mech. Catal. 2020, 130, 777–795. [Google Scholar] [CrossRef]

- Radlik, M.; Śrębowata, A.; Juszczyk, W.; Matus, K.; Małolepszy, A.; Karpiński, Z. N-Hexane Conversion on γ-Alumina Supported Palladium–Platinum Catalysts. Adsorption 2019, 25, 843–853. [Google Scholar] [CrossRef]

- Noh, H.; Flanagan, T.B.; Sonoda, T.; Sakamoto, Y. Solubility and Thermodynamics of Hydrogen in Homogeneous f.c.c. PdPt Alloys. J. Alloys Compd. 1995, 228, 164–171. [Google Scholar] [CrossRef]

- Corro, G.; Torralba, R.; Pal, U.; Olivares-Xometl, O.; Fierro, J.L.G. Total Oxidation of Methane over Pt/Cr2O3 Catalyst at Low Temperature: Effect of Pt0–Ptx+ Dipoles at the Metal–Support Interface. J. Phys. Chem. C 2019, 123, 2882–2893. [Google Scholar] [CrossRef]

- Zhao, D.; Huo, Q.; Feng, J.; Chmelka, B.F.; Stucky, G.D. Nonionic Triblock and Star Diblock Copolymer and Oligomeric Sufactant Syntheses of Highly Ordered, Hydrothermally Stable, Mesoporous Silica Structures. J. Am. Chem. Soc. 1998, 120, 6024–6036. [Google Scholar] [CrossRef]

| Nominal wt% | Pd a | Pt a | Zr b |

|---|---|---|---|

| 2Pd/4Pt | 2.0 | 4.2 | NA |

| 2Pd/4Pt/5Zr | 2.1 | 3.3 | 5.4 |

| 2Pd/4Pt/10Zr | 1.9 | 3.2 | 9.3 |

| 2Pd/4Pt/15Zr | 1.9 | 3.1 | 12.0 |

| Catalyst Name | BET Surface Area (SA) (m2/g) | Pore Volume a (cm3/g) | Pore Size b (nm) | Crystallite Size from XRD (nm) | ||

|---|---|---|---|---|---|---|

| Small | Large | PdO | Pt | |||

| SBA-15 | 836 | 0.82 | NA | 5.6 | NA | NA |

| 2Pd/4Pt | 608 | 0.72 | 3.8 | 5.6 | 7.2 | 33.1 |

| 2Pd/4Pt/5Zr | 554 | 0.64 | 3.8 | 5.6 | 9.7 | 37.4 |

| 2Pd/4Pt/10Zr | 483 | 0.59 | 3.8 | 5.6 | 9.3 | 43.9 |

| 2Pd/4Pt/15Zr | 432 | 0.54 | 3.8 | 5.6 | 11.2 | 43.7 |

| Catalyst | Pd 3d (%) a | Pt 4f (%) a | ||||

|---|---|---|---|---|---|---|

| Pd0 | Pd2+ | Pd4+ | Pt0 | Pt2+ | Pt4+ | |

| 2Pd/4Pt/5Zr | 3.6 | 82.4 | 14.0 | 93.8 | 5.8 | 0.38 |

| 2Pd/4Pt/10Zr | 4.8 | 79.7 | 15.6 | 92.3 | 6.8 | ND |

| 2Pd/4Pt/15Zr | 3.5 | 83.9 | 12.6 | 27.3 | 43.6 | 29.1 |

| 2Pd/4Pt/15Zr (aged) | 12.4 | 70.2 | 17.7 | 18.3 | 55.3 | 26.5 |

| Catalyst | Total H2 Consumption (mmol H2/g Catalyst) at TPR Peak Maxima | |

|---|---|---|

| 360 °C | 480 °C | |

| 2Pd/4Pt/5Zr | 0.10 | 0.22 |

| 2Pd/4Pt/10Zr | 0.12 | 0.14 |

| 2Pd/4Pt/15Zr | 0.17 | 0.27 |

| Catalyst Name | T50 (°C) | Difference | |

|---|---|---|---|

| Fresh | Aged | ||

| 2Pd/4Pt | 389 | 583 | 194 |

| 2Pd/4Pt/5Zr | 389 | 502 | 113 |

| 2Pd/4Pt/10Zr | 371 | 492 | 121 |

| 2Pd/4Pt/15Zr | 378 | 481 | 103 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caravaggio, G.; Nossova, L.; Turnbull, M. Effect of Zirconia on Pd–Pt Supported SBA-15 Catalysts for the Oxidation of Methane. Catalysts 2023, 13, 926. https://doi.org/10.3390/catal13060926

Caravaggio G, Nossova L, Turnbull M. Effect of Zirconia on Pd–Pt Supported SBA-15 Catalysts for the Oxidation of Methane. Catalysts. 2023; 13(6):926. https://doi.org/10.3390/catal13060926

Chicago/Turabian StyleCaravaggio, Gianni, Lioudmila Nossova, and Matthew Turnbull. 2023. "Effect of Zirconia on Pd–Pt Supported SBA-15 Catalysts for the Oxidation of Methane" Catalysts 13, no. 6: 926. https://doi.org/10.3390/catal13060926

APA StyleCaravaggio, G., Nossova, L., & Turnbull, M. (2023). Effect of Zirconia on Pd–Pt Supported SBA-15 Catalysts for the Oxidation of Methane. Catalysts, 13(6), 926. https://doi.org/10.3390/catal13060926