A Recyclable Co-Fe Bimetallic Immobilized Cellulose Hydrogel Bead (CoFeO@CHB) to Boost Singlet Oxygen Evolution for Tetracycline Degradation

Abstract

:1. Introduction

2. Results and Discussions

2.1. Optimization of the Synthesis

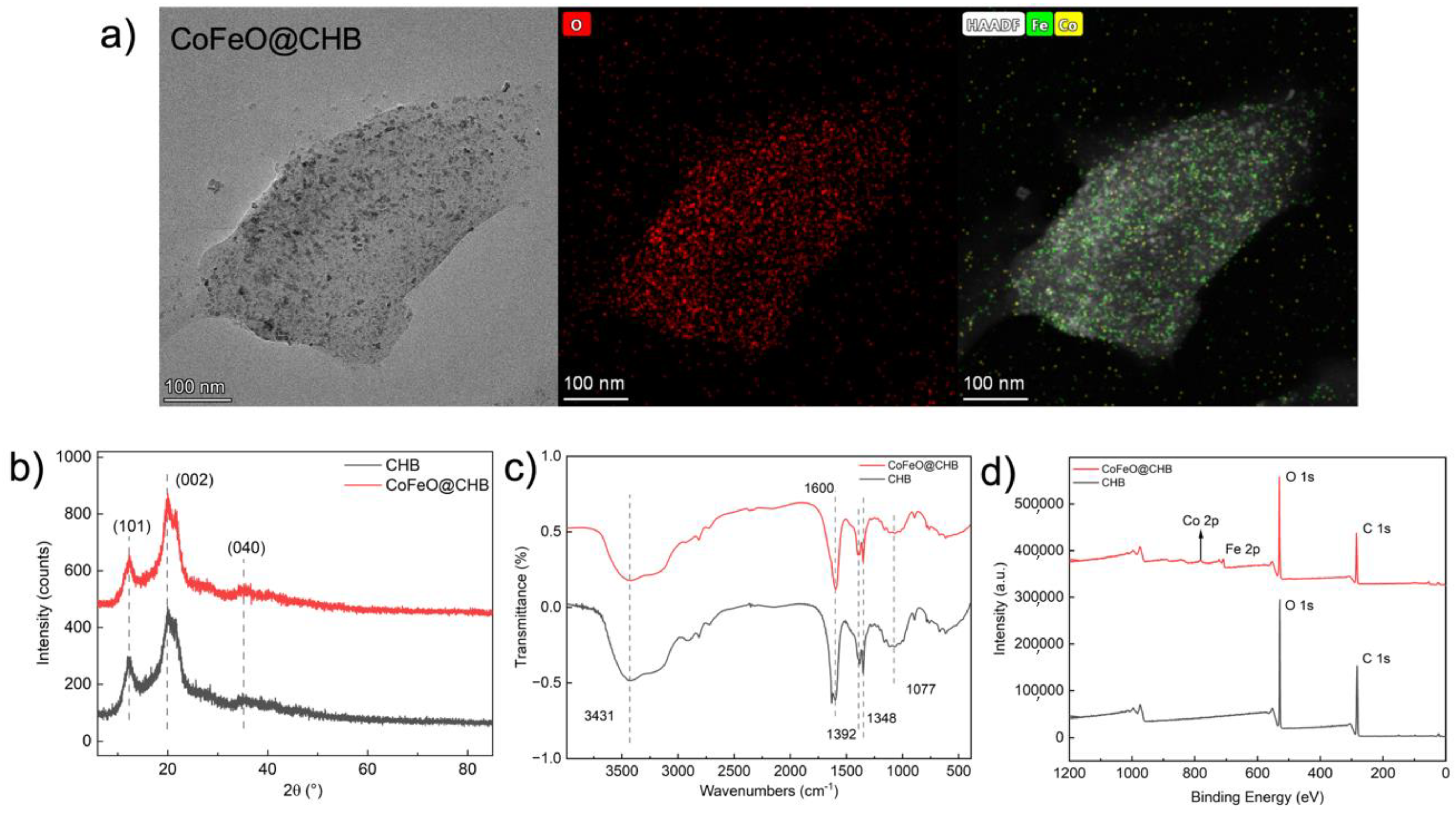

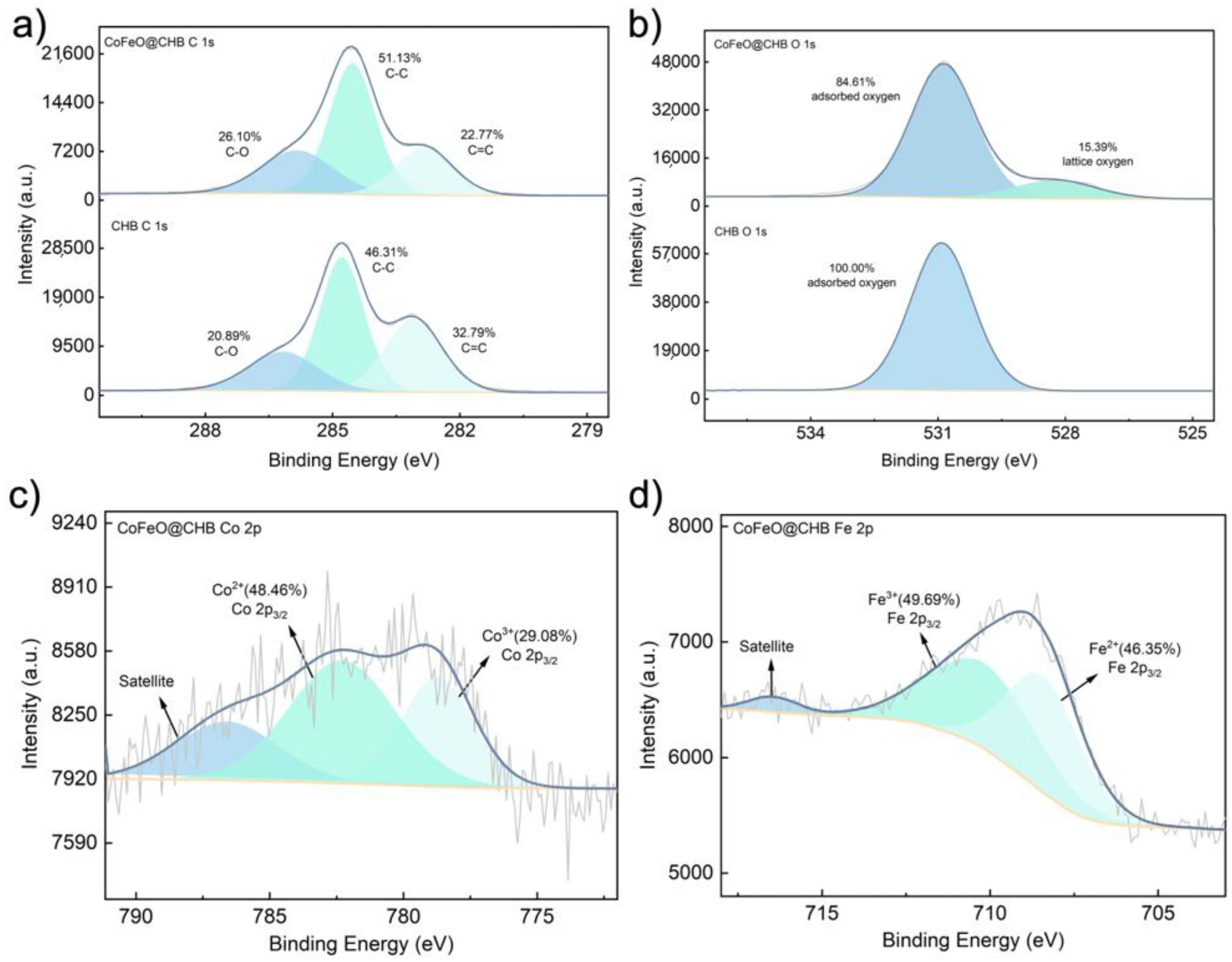

2.2. Characterizations of CoFeO@CHB

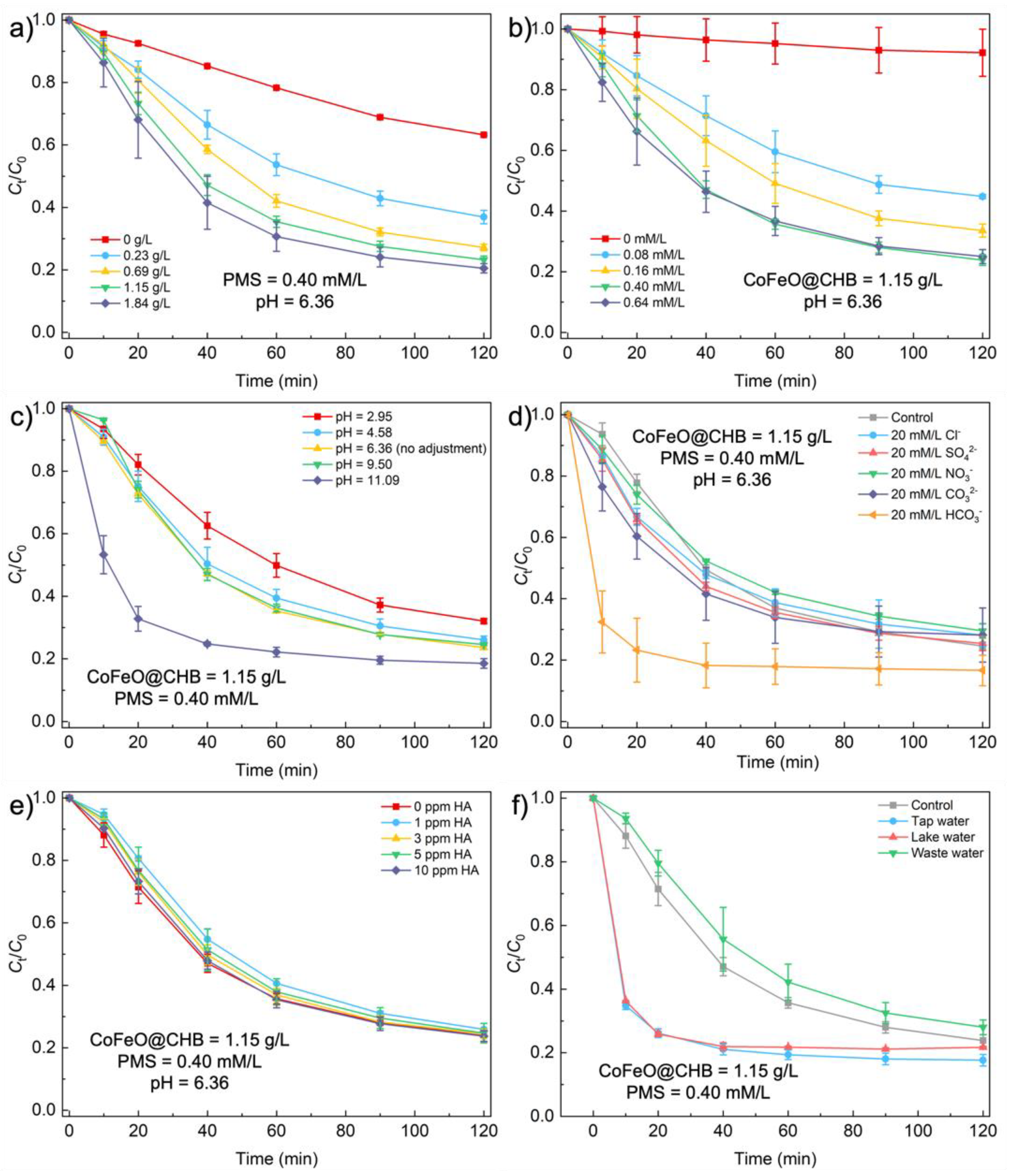

2.3. Catalytic Performance Evaluation

2.4. Identification of Reactive Oxygen Species (ROS)

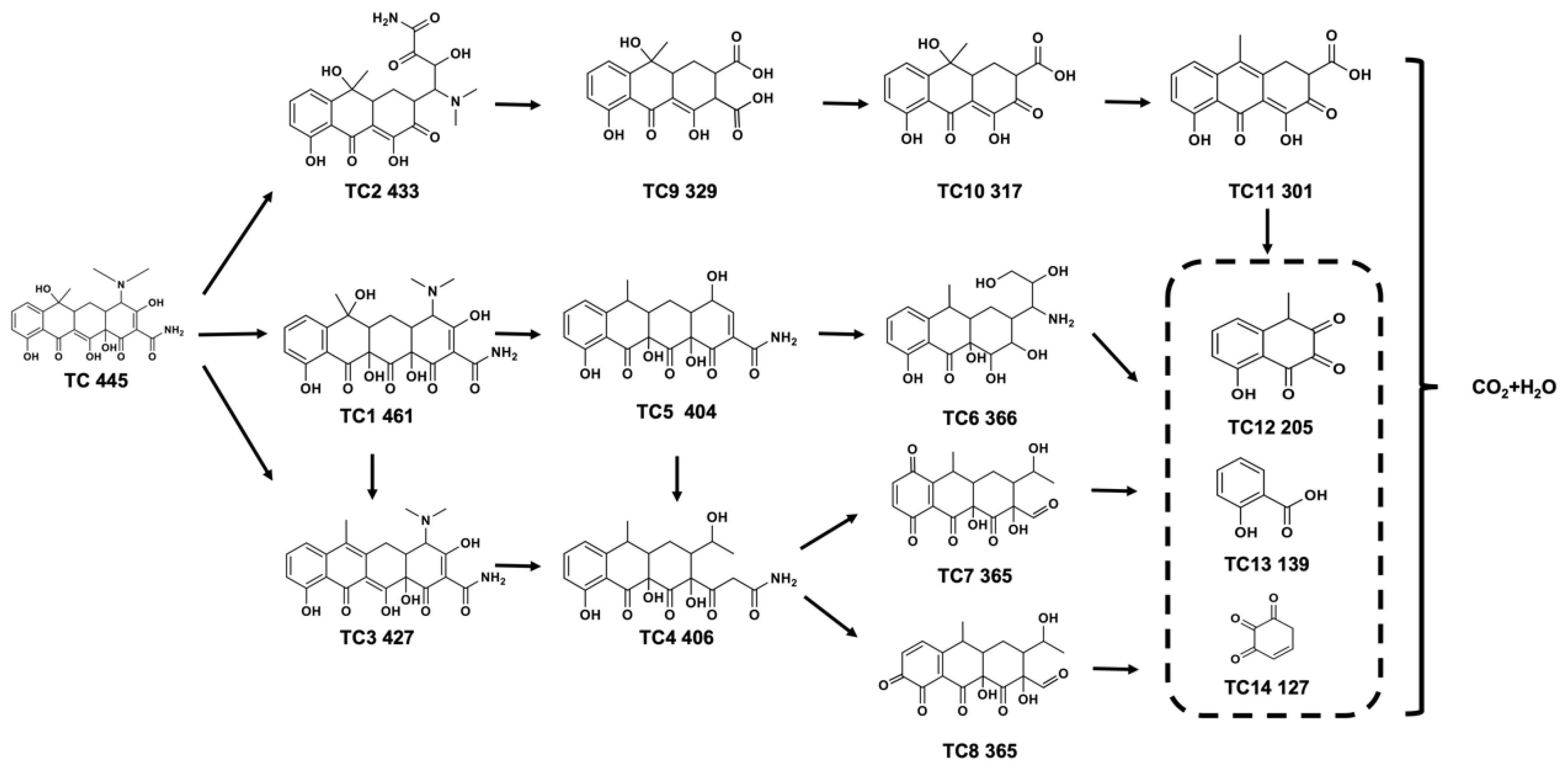

2.5. PMS Activation Mechanism and TC Degradation Pathway

2.6. Long-Term Performance Evaluation in a Continues Filtration Device

3. Experimental Section

3.1. Chemicals and Materials

3.2. Preparation and Characterization of CoFeO@CHB

3.3. Degradation Performance

3.4. Analytic Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Chopra, I.; Roberts, M. Tetracycline Antibiotics: Mode of Action, Applications, Molecular Biology, and Epidemiology of Bacterial Resistance. Microbiol. Mol. Biol. Rev. 2001, 65, 232–260. [Google Scholar] [CrossRef] [Green Version]

- Daghrir, R.; Drogui, P. Tetracycline antibiotics in the environment: A review. Environ. Chem. Lett. 2013, 11, 209–227. [Google Scholar] [CrossRef]

- Grenni, P.; Ancona, V.; Caracciolo, A.B. Ecological effects of antibiotics on natural ecosystems: A review. Microchem. J. 2018, 136, 25–39. [Google Scholar] [CrossRef]

- Leng, Y.; Bao, J.; Chang, G.; Zheng, H.; Li, X.; Du, J.; Snow, D.; Li, X. Biotransformation of tetracycline by a novel bacterial strain Stenotrophomonas maltophilia DT1. J. Hazard. Mater. 2016, 318, 125–133. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baumschlager, A.; Rullan, M.; Khammash, M. Exploiting natural chemical photosensitivity of anhydrotetracycline and tetracycline for dynamic and setpoint chemo-optogenetic control. Nat. Commun. 2020, 11, 3834. [Google Scholar] [CrossRef]

- Zuber, J.; McJunkin, K.; Fellmann, C.; Dow, E.L.; Taylor, M.J.; Hannon, G.J.; Lowe, S.W. Toolkit for evaluating genes required for proliferation and survival using tetracycline-regulated RNAi. Nat. Biotechnol. 2011, 29, 79–83. [Google Scholar] [CrossRef] [Green Version]

- Fang, H.; Wang, H.; Cai, L.; Yu, Y. Prevalence of Antibiotic Resistance Genes and Bacterial Pathogens in Long-Term Manured Greenhouse Soils as Revealed by Metagenomic Survey. Environ. Sci. Technol. 2015, 49, 1095–1104. [Google Scholar] [CrossRef]

- Priyadarshini, M.; Das, I.; Ghangrekar, M.M.; Blaney, L. Advanced oxidation processes: Performance, advantages, and scale-up of emerging technologies. J. Environ. Manag. 2022, 316, 115295. [Google Scholar] [CrossRef] [PubMed]

- Tian, K.; Hu, L.; Li, L.; Zheng, Q.; Xin, Y.; Zhang, G. Recent advances in persulfate-based advanced oxidation processes for organic wastewater treatment. Chin. Chem. Lett. 2022, 33, 4461–4477. [Google Scholar] [CrossRef]

- Han, S.; Xiao, P. Catalytic degradation of tetracycline using peroxymonosulfate activated by cobalt and iron co-loaded pomelo peel biochar nanocomposite: Characterization, performance and reaction mechanism. Sep. Purif. Technol. 2022, 287, 120533. [Google Scholar] [CrossRef]

- Li, M.; Li, Y.-W.; Yu, P.-F.; Zhao, H.-M.; Xiang, L.; Feng, N.-X.; Li, Q.-K.; He, K.-Y.; Luo, X.; Cai, Q.-Y.; et al. Exploring degradation mechanism of tetracycline via high-effective peroxymonosulfate catalysts of montmorillonite hybridized CoFe composites and safety assessment. Chem. Eng. J. 2022, 427, 130930. [Google Scholar] [CrossRef]

- Bao, Y.; Oh, W.-D.; Lim, T.-T.; Wang, R.; Webster, R.D.; Hu, X. Elucidation of stoichiometric efficiency, radical generation and transformation pathway during catalytic oxidation of sulfamethoxazole via peroxymonosulfate activation. Water Res. 2019, 151, 64–74. [Google Scholar] [CrossRef]

- Kohantorabi, M.; Moussavi, G.; Giannakis, S. A review of the innovations in metal- and carbon-based catalysts explored for heterogeneous peroxymonosulfate (PMS) activation, with focus on radical vs. non-radical degradation pathways of organic contaminants. Chem. Eng. J. 2021, 411, 127957. [Google Scholar] [CrossRef]

- SYe, S.; Zeng, G.; Tan, X.; Wu, H.; Liang, J.; Song, B.; Tang, N.; Zhang, P.; Yang, Y.; Chen, Q.; et al. Nitrogen-doped biochar fiber with graphitization from Boehmeria nivea for promoted peroxymonosulfate activation and non-radical degradation pathways with enhancing electron transfer. Appl. Catal. B Environ. 2020, 269, 118850. [Google Scholar]

- Duan, X.; Sun, H.; Shao, Z.; Wang, S. Nonradical reactions in environmental remediation processes: Uncertainty and challenges. Appl. Catal. B Environ. 2018, 224, 973–982. [Google Scholar] [CrossRef]

- Bokare, A.D.; Choi, W. Singlet-Oxygen Generation in Alkaline Periodate Solution. Environ. Sci. Technol. 2015, 49, 14392–14400. [Google Scholar] [CrossRef]

- Xiao, G.; Xu, T.; Faheem, M.; Xi, Y.; Zhou, T.; Moryani, H.T.; Bao, J.; Du, J. Evolution of Singlet Oxygen by Activating Peroxydisulfate and Peroxymonosulfate: A Review. Int. J. Environ. Res. Public Health 2021, 18, 3344. [Google Scholar] [CrossRef]

- Yao, C.; Qin, Y.; Li, Y.; An, Q.; Xiao, Z.; Wang, C.; Zhai, S. Activation of peroxymonosulfate by cobalt-embedded carbon aerogels: Preparation and singlet oxygen-dominated catalytic degradation insight. Sep. Purif. Technol. 2023, 307, 122728. [Google Scholar] [CrossRef]

- Bao, Y.; Gupta, N.; Chuah, C.Y.; Chuah, Y.N.; Hu, C.-P.; Hu, X. Highly selective recovery of perfluorooctanoic acid from semiconductor wastewater via adsorption on pH-stimulated poly (dimethyl amino) ethyl methacrylate microgels. Sep. Purif. Technol. 2022, 287, 120479. [Google Scholar] [CrossRef]

- XCheng, X.; Guo, H.; Zhang, Y.; Wu, X.; Liu, Y. Non-photochemical production of singlet oxygen via activation of persulfate by carbon nanotubes. Water Res. 2017, 113, 80–88. [Google Scholar] [CrossRef]

- YGao, Y.; Zhu, Y.; Lyu, L.; Zeng, Q.; Xing, X.; Hu, C. Electronic Structure Modulation of Graphitic Carbon Nitride by Oxygen Doping for Enhanced Catalytic Degradation of Organic Pollutants through Peroxymonosulfate Activation. Environ. Sci. Technol. 2018, 52, 14371–14380. [Google Scholar]

- Qian, J.; Gao, X.; Pan, B. Nanoconfinement-Mediated Water Treatment: From Fundamental to Application. Environ. Sci. Technol. 2020, 54, 8509–8526. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Hedtke, T.; Zhou, X.; Elimelech, M.; Kim, J.-H. Environmental Applications of Engineered Materials with Nanoconfinement. ACS ES&T Eng. 2021, 1, 706–724. [Google Scholar]

- Ristic, M.; Krehula, S.; Reissner, M.; Jean, M.; Hannoyer, B.; Musić, S. Synthesis and properties of precipitated cobalt ferrite nanoparticles. J. Mol. Struct. 2017, 1140, 32–38. [Google Scholar] [CrossRef]

- Chen, C.; Zeng, H.; Yi, M.; Xiao, G.; Xu, S.; Shen, S.; Feng, B. In-situ growth of Ag3PO4 on calcined Zn-Al layered double hydroxides for enhanced photocatalytic degradation of tetracycline under simulated solar light irradiation and toxicity assessment. Appl. Catal. B Environ. 2019, 252, 47–54. [Google Scholar] [CrossRef]

- Bao, Y.; Oh, W.-D.; Lim, T.-T.; Wang, R.; Webster, R.D.; Hu, X. Surface-nucleated heterogeneous growth of zeolitic imidazolate framework—A unique precursor towards catalytic ceramic membranes: Synthesis, characterization and organics degradation. Chem. Eng. J. 2018, 353, 69–79. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Xu, H.; Jiang, N.; Wang, D.; Wang, L.; Song, Y.; Chen, Z.; Ma, J.; Zhang, T. Improving PMS oxidation of organic pollutants by single cobalt atom catalyst through hybrid radical and non-radical pathways. Appl. Catal. B Environ. 2020, 263, 118350. [Google Scholar] [CrossRef]

- El-Sayed, N.S.; El-Aziz, M.A.; Kamel, S.; Turky, G. Synthesis and characterization of polyaniline/tosylcellulose stearate composites as promising semiconducting materials. Synth. Met. 2018, 236, 44–53. [Google Scholar] [CrossRef]

- Pineda, X.; Quintana, G.C.; Herrera, A.P.; Sánchez, J.H. Preparation and characterization of magnetic cellulose fibers modified with cobalt ferrite nanoparticles. Mater. Chem. Phys. 2021, 259, 122778. [Google Scholar] [CrossRef]

- Vinosha, P.A.; Mely, L.A.; Jeronsia, J.E.; Raja, K.; Tamilarsi, D.Q.S.; Fernandez, A.C.; Krishnan, S.; Das, S.J. Investigation of optical, electrical and magnetic properties of cobalt ferrite nanoparticles by naive co-precipitation technique. Optik 2016, 127, 9917–9925. [Google Scholar]

- Li, Z.L.; Ai, J.Z.; Ge, M. A facile approach assembled magnetic CoFe2O4/AgBr composite for dye degradation under visible light. J. Environ. Chem. Eng. 2017, 5, 1394–1403. [Google Scholar] [CrossRef]

- Bao, Y.; Lee, W.J.; Lim, T.-T.; Wang, R.; Hu, X. Pore-functionalized ceramic membrane with isotropically impregnated cobalt oxide for sulfamethoxazole degradation and membrane fouling elimination: Synergistic effect between catalytic oxidation and membrane separation. Appl. Catal. B Environ. 2019, 254, 37–46. [Google Scholar] [CrossRef]

- Bao, Y.; Lim, T.-T.; Wang, R.; Webster, R.D.; Hu, X. Urea-assisted one-step synthesis of cobalt ferrite impregnated ceramic membrane for sulfamethoxazole degradation via peroxymonosulfate activation. Chem. Eng. J. 2018, 343, 737–747. [Google Scholar] [CrossRef]

- Li, J.; Xu, M.; Yao, G.; Lai, B. Enhancement of the degradation of atrazine through CoFe2O4 activated peroxymonosulfate (PMS) process: Kinetic, degradation intermediates, and toxicity evaluation. Chem. Eng. J. 2018, 348, 1012–1024. [Google Scholar] [CrossRef]

- Grosvenor, A.P.; Kobe, B.A.; Biesinger, M.C.; McIntyre, N.S. Investigation of multiplet splitting of Fe2p XPS spectra and bonding in iron compounds. Surf. Interface Anal. 2004, 36, 1564–1574. [Google Scholar] [CrossRef]

- Tang, W.; Yao, M.; Deng, Y.; Li, X.; Han, N.; Wu, X.; Chen, Y. Decoration of one-dimensional MnO2 with Co3O4 nanoparticles: A heterogeneous interface for remarkably promoting catalytic oxidation activity. Chem. Eng. J. 2016, 306, 709–718. [Google Scholar] [CrossRef]

- Zhou, Y.; Gao, Y.; Jiang, J.; Shen, Y.-M.; Pang, S.-Y.; Wang, Z.; Duan, J.; Guo, Q.; Guan, C.; Ma, J. Transformation of tetracycline antibiotics during water treatment with unactivated peroxymonosulfate. Chem. Eng. J. 2020, 379, 122378. [Google Scholar] [CrossRef]

- Zeng, Z.; Khan, A.; Wang, Z.; Zhao, M.; Mo, W.; Chen, Z. Elimination of atrazine through radical/non-radical combined processes by manganese nano-catalysts/PMS and implications to the structure-performance relationship. Chem. Eng. J. 2020, 397, 125425. [Google Scholar] [CrossRef]

- Shukla, P.; Sun, H.; Wang, S.; Ang, H.M.; Tadé, M.O. Co-SBA-15 for heterogeneous oxidation of phenol with sulfate radical for wastewater treatment. Catal. Today 2011, 175, 380–385. [Google Scholar] [CrossRef]

- Zhang, X.L.; Feng, M.B.; Qu, R.J.; Liu, H.; Wang, L.S.; Wang, Z.Y. Catalytic degradation of diethyl phthalate in aqueous solution by persulfate activated with nano-scaled magnetic CuFe2O4/MWCNTs. Chem. Eng. J. 2016, 301, 1–11. [Google Scholar] [CrossRef]

- Hu, P.; Long, M. Cobalt-catalyzed sulfate radical-based advanced oxidation: A review on heterogeneous catalysts and applications. Appl. Catal. B Environ. 2016, 181, 103–117. [Google Scholar] [CrossRef]

- Oh, W.D.; Dong, Z.L.; Hu, Z.T.; Lim, T.T. A novel quasi-cubic CuFe2O4-Fe2O3 catalyst prepared at low temperature for enhanced oxidation of bisphenol A via peroxymonosulfate activation. J. Mater. Chem. A 2015, 3, 22208–22217. [Google Scholar] [CrossRef]

- Huang, K.-C.; Couttenye, A.R.; Hoag, E.G. Kinetics of heat-assisted persulfate oxidation of methyl tert-butyl ether (MTBE). Chemosphere 2002, 49, 413–420. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Zhang, G.; Liu, H.; Qu, J. Confining Free Radicals in Close Vicinity to Contaminants Enables Ultrafast Fenton-like Processes in the Interspacing of MoS 2 Membranes. Angew. Chem. Int. Ed. 2019, 58, 8134–8138. [Google Scholar] [CrossRef]

- Cao, J.; Lai, L.; Lai, B.; Yao, G.; Chen, X.; Song, L. Degradation of tetracycline by peroxymonosulfate activated with zero-valent iron: Performance, intermediates, toxicity and mechanism. Chem. Eng. J. 2019, 364, 45–56. [Google Scholar] [CrossRef]

- Zhang, T.T.; Zhang, S.Y.; Wu, C.Y.; Zuo, H.R.; Yan, Q.S. Novel La3+/Sm3+ co-doped Bi5O7I with efficient visible-light photocatalytic activity for advanced treatment of wastewater: Internal mechanism, TC degradation pathway, and toxicity analysis. Chemosphere 2023, 313, 137540. [Google Scholar] [CrossRef]

- Qian, J.; Zhang, Y.; Chen, Z.; Yu, R.; Ye, Y.; Ma, R.; Li, K.; Wang, L.; Wang, D.; Ni, B.J. Fe/C composite synthesized from MIL-88A(Fe) for peroxymonosulfate activation towards tetracycline degradation: Multiple active sites and non-radical pathway dominated mechanism. J. Environ. Manag. 2023, 344, 118440. [Google Scholar] [CrossRef]

- Hu, Q.; Cao, J.; Yang, Z.; Xiong, W.; Xu, Z.; Song, P.; Jia, M.; Zhang, Y.; Peng, H.; Wu, A. Fabrication of Fe-doped cobalt zeolitic imidazolate framework derived from Co(OH)2 for degradation of tetracycline via peroxymonosulfate activation. Sep. Purif. Technol. 2021, 259, 118059. [Google Scholar] [CrossRef]

- Xie, F.; Zhu, W.; Lin, P.; Zhang, J.; Hao, Z.; Zhang, J.; Huang, T. A bimetallic (Co/Fe) modified nickel foam (NF) anode as the peroxymonosulfate (PMS) activator: Characteristics and mechanism. Sep. Purif. Technol. 2022, 296, 121429. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, J.; Yang, Z.; Xiong, W.; Xu, Z.; Song, P.; Jia, M.; Sun, S.; Zhang, Y.; Li, W. Fabricating iron-cobalt layered double hydroxide derived from metal-organic framework for the activation of peroxymonosulfate towards tetracycline degradation. J. Solid State Chem. 2021, 294, 121857. [Google Scholar] [CrossRef]

- Wei, J.; Han, D.; Bi, J.; Gong, J. Fe-doped ilmenite CoTiO3 for antibiotic removal: Electronic modulation and enhanced activation of peroxymonosulfate. Chem. Eng. J. 2021, 423, 130165. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, M.; Han, F.; Liu, Z.; Zhou, W. Isomorphic substitution of goethite by cobalt: Effects on the pathway and performance of peroxymonosulfate activation. Chem. Eng. J. 2022, 450, 138460. [Google Scholar] [CrossRef]

- Wu, H.; Tan, Z.; Miao, B.; Hu, H.; Hou, S. Hierarchical porous graphite-like carbon nanosheet cooperated with Fe/Fe3C@Fe-N-C nanocomposites toward catalytic oxidation process. J. Environ. Chem. Eng. 2023, 11, 109204. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Zhang, H.; Xu, S.; Du, X.; Zhang, K.; Hu, C.-P.; Zhan, S.; Mi, X.; Oh, W.D.; Hu, X.; et al. A Recyclable Co-Fe Bimetallic Immobilized Cellulose Hydrogel Bead (CoFeO@CHB) to Boost Singlet Oxygen Evolution for Tetracycline Degradation. Catalysts 2023, 13, 1150. https://doi.org/10.3390/catal13081150

Chen X, Zhang H, Xu S, Du X, Zhang K, Hu C-P, Zhan S, Mi X, Oh WD, Hu X, et al. A Recyclable Co-Fe Bimetallic Immobilized Cellulose Hydrogel Bead (CoFeO@CHB) to Boost Singlet Oxygen Evolution for Tetracycline Degradation. Catalysts. 2023; 13(8):1150. https://doi.org/10.3390/catal13081150

Chicago/Turabian StyleChen, Xinying, He Zhang, Shizhe Xu, Xiaoge Du, Kaida Zhang, Chun-Po Hu, Sihui Zhan, Xueyue Mi, Wen Da Oh, Xiao Hu, and et al. 2023. "A Recyclable Co-Fe Bimetallic Immobilized Cellulose Hydrogel Bead (CoFeO@CHB) to Boost Singlet Oxygen Evolution for Tetracycline Degradation" Catalysts 13, no. 8: 1150. https://doi.org/10.3390/catal13081150

APA StyleChen, X., Zhang, H., Xu, S., Du, X., Zhang, K., Hu, C. -P., Zhan, S., Mi, X., Oh, W. D., Hu, X., Pan, Z., & Bao, Y. (2023). A Recyclable Co-Fe Bimetallic Immobilized Cellulose Hydrogel Bead (CoFeO@CHB) to Boost Singlet Oxygen Evolution for Tetracycline Degradation. Catalysts, 13(8), 1150. https://doi.org/10.3390/catal13081150