The Synthesis, Characteristics, and Application of Hierarchical Porous Materials in Carbon Dioxide Reduction Reactions

Abstract

:1. Introduction

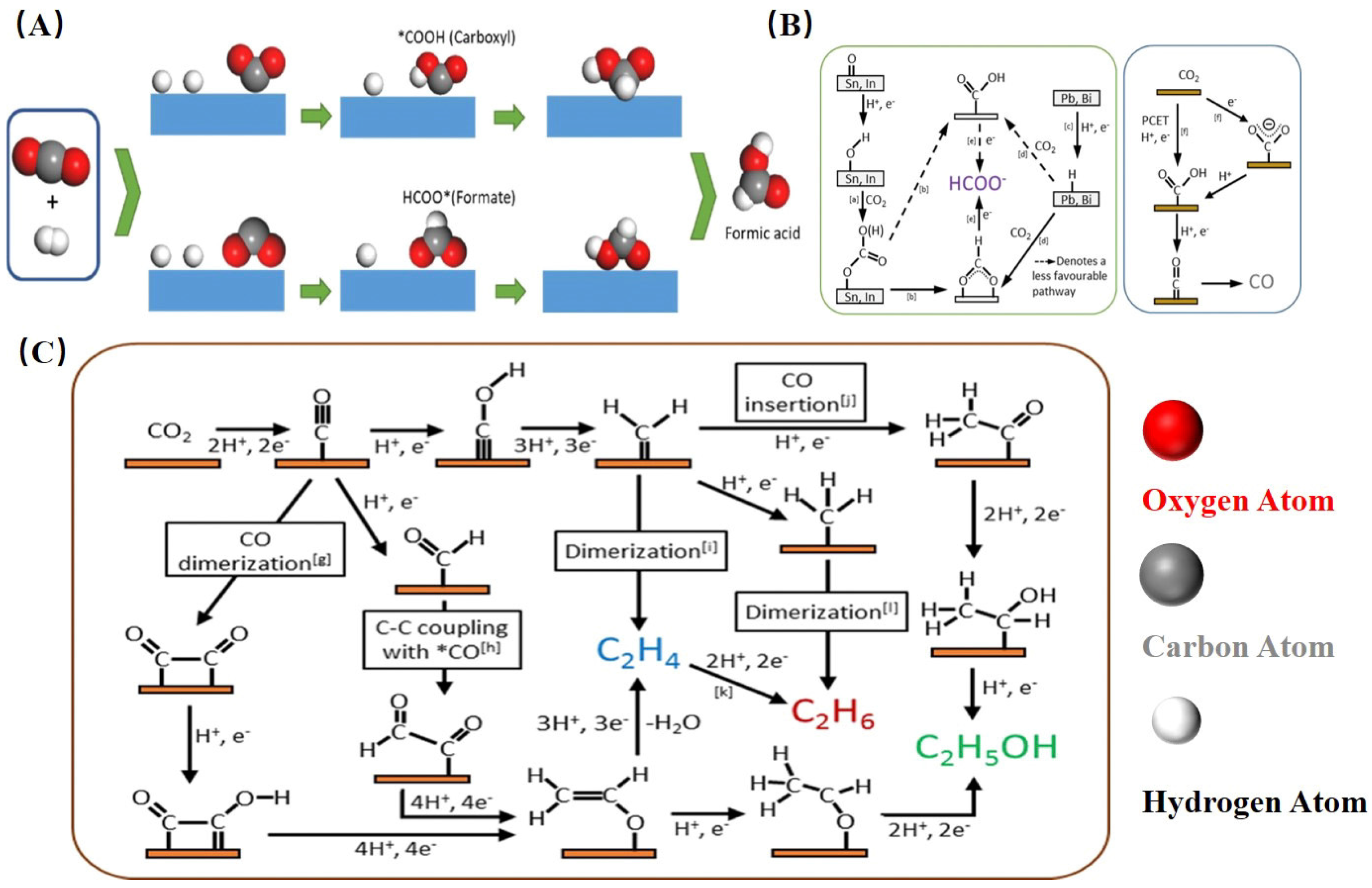

2. Mechanism of CO2 Reduction Reaction

3. Synthesis Methods of Hierarchical Porous Materials

3.1. Basic Methods

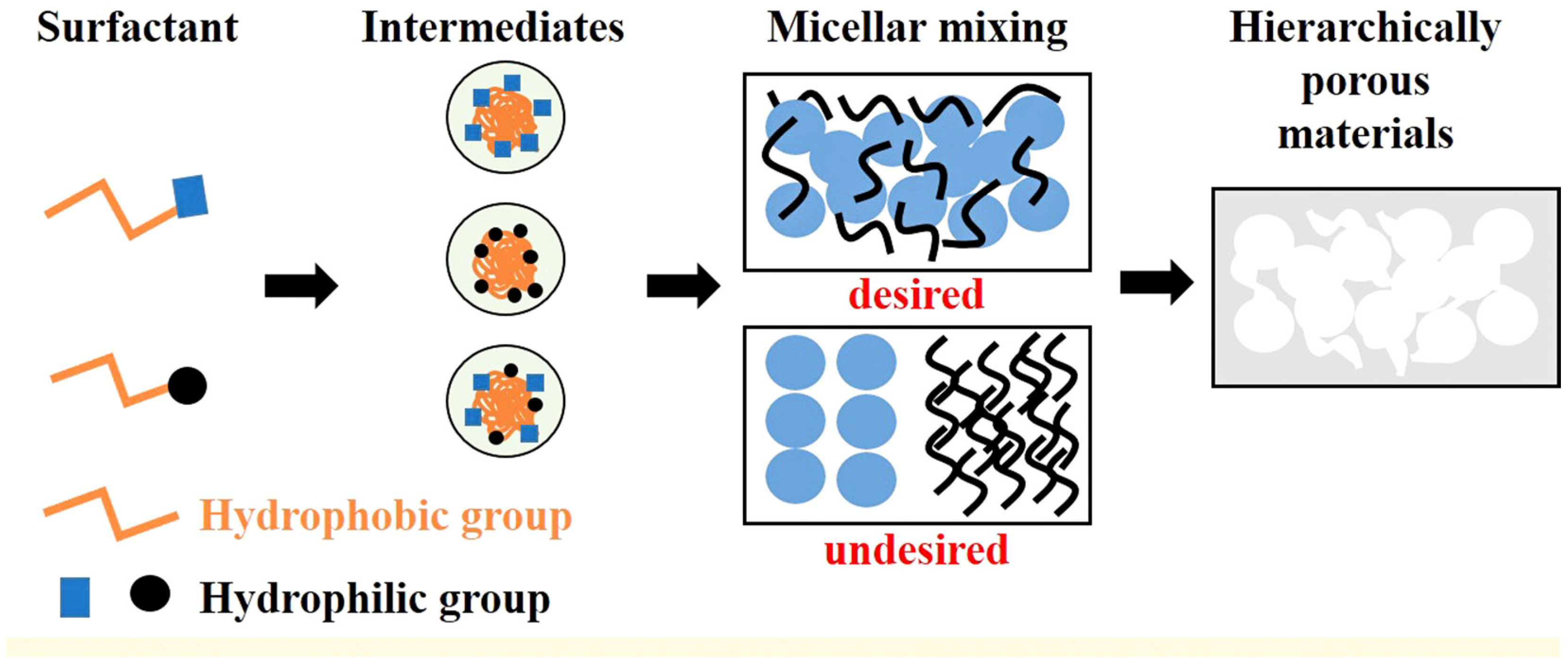

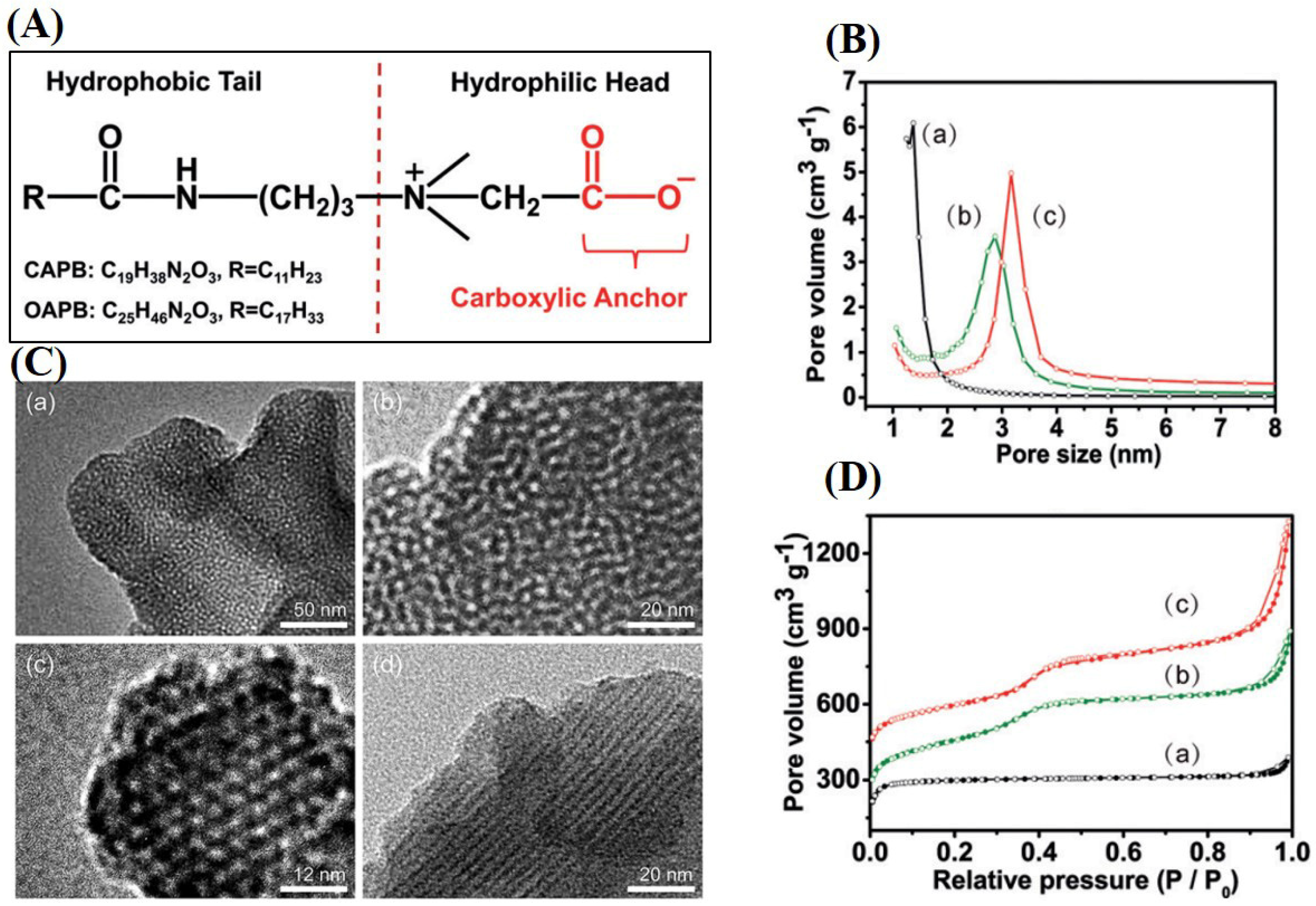

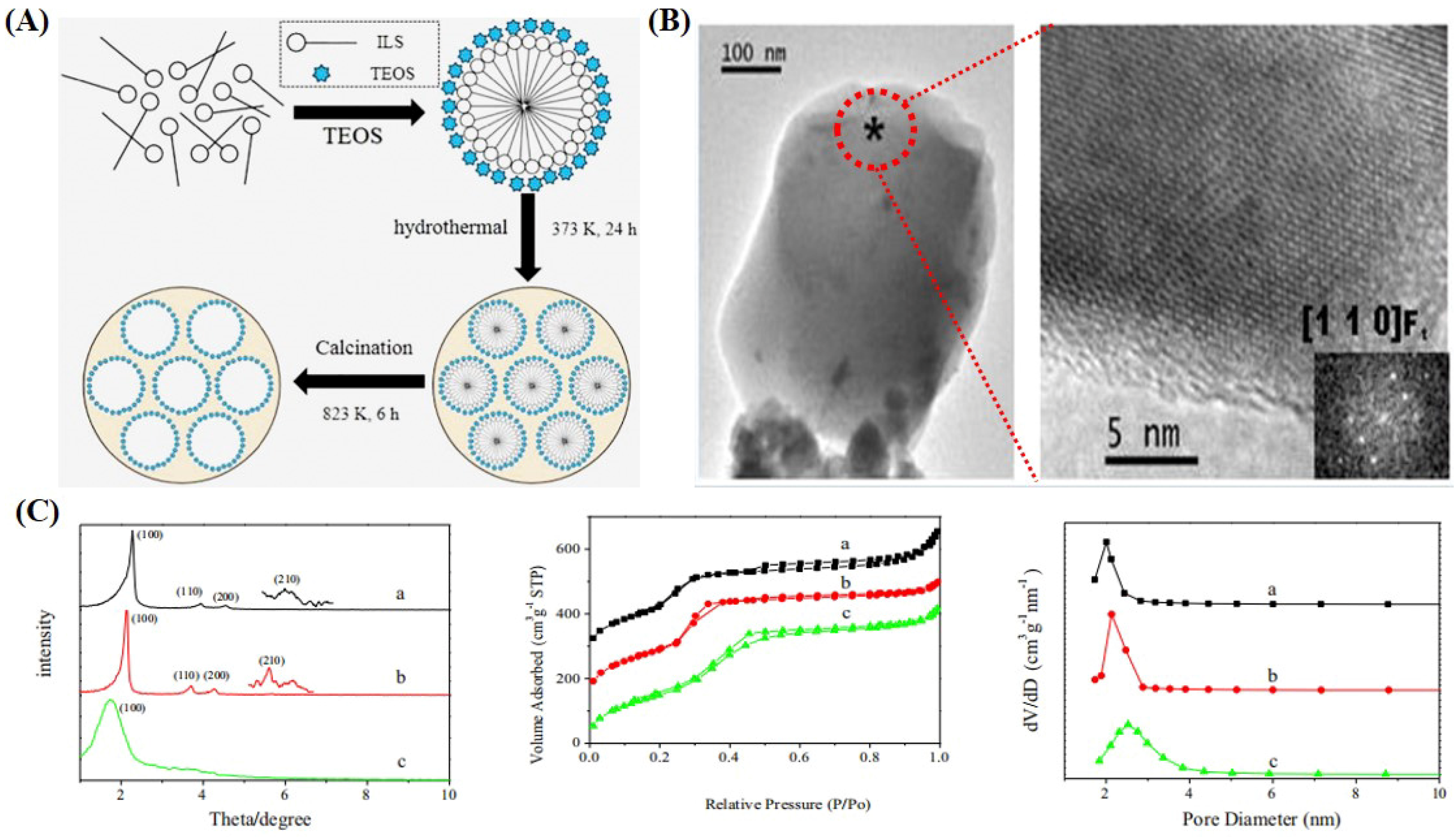

3.1.1. Surfactant Templating

3.1.2. Replication

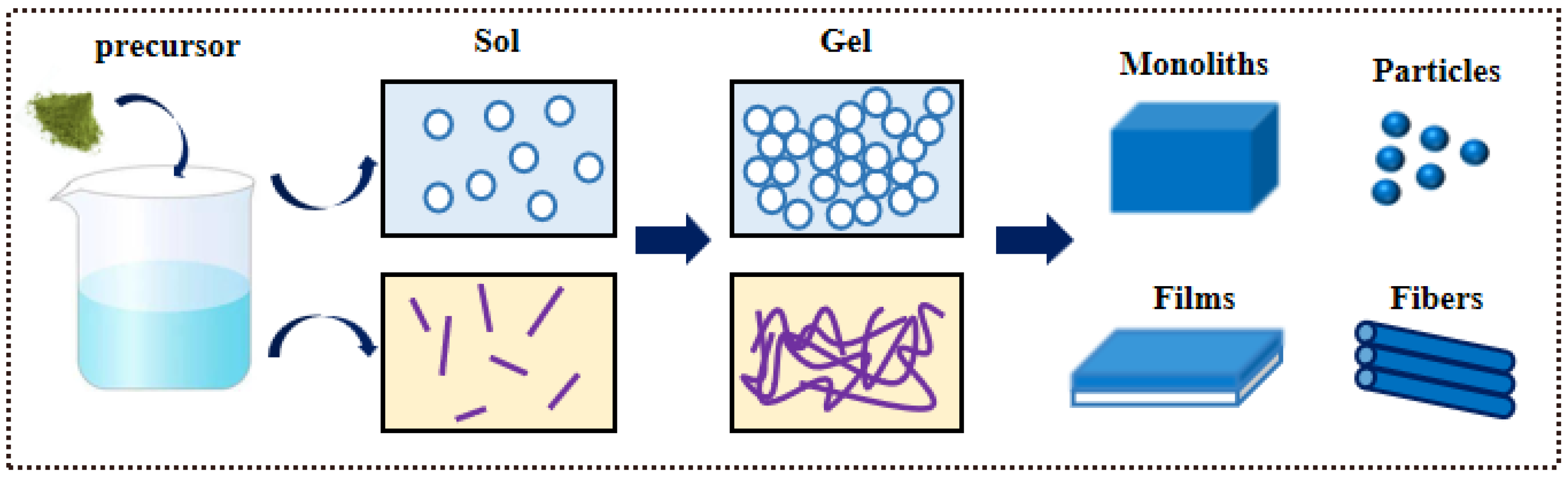

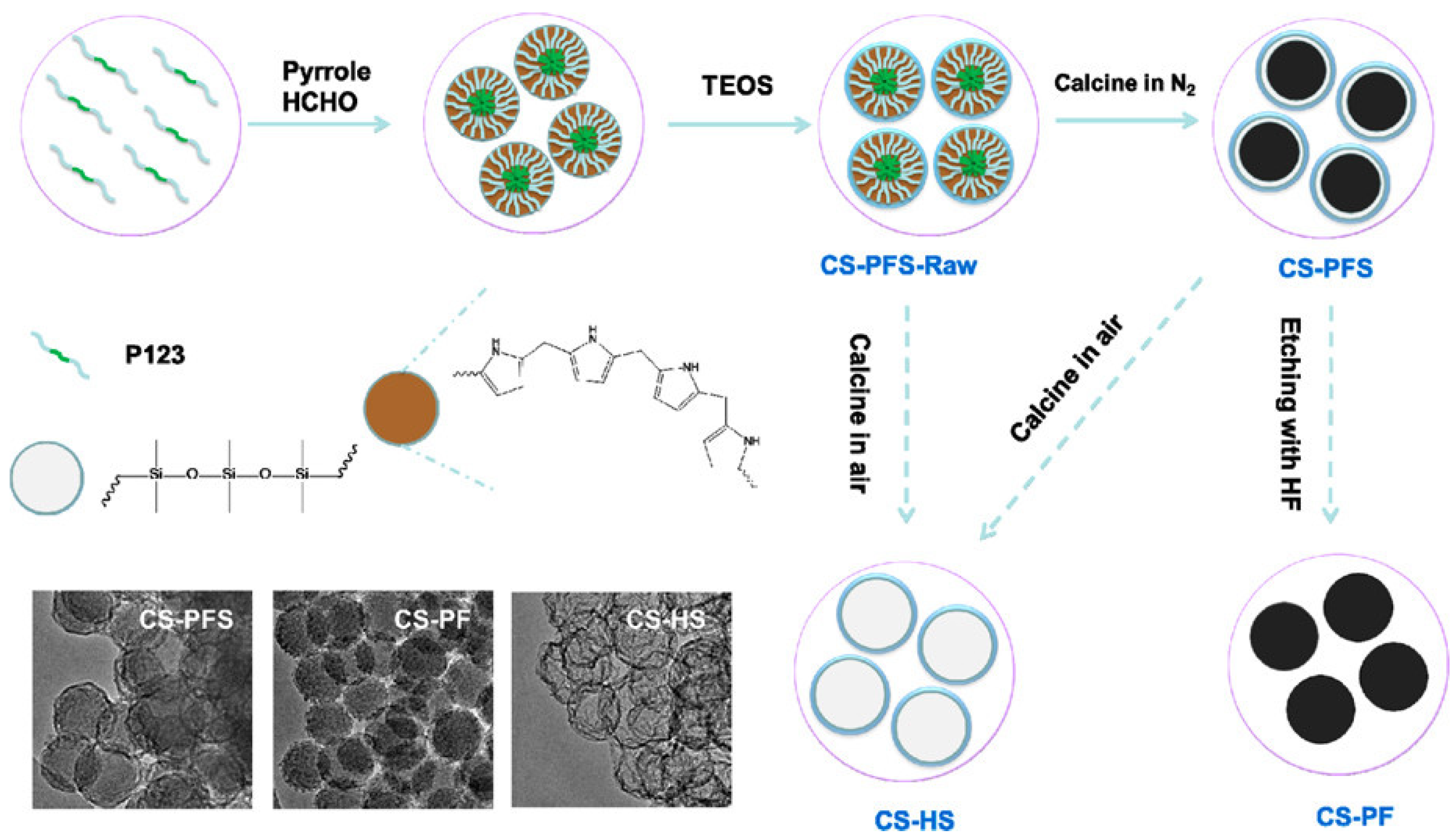

3.1.3. Sol–Gel

3.2. Chemical Technology

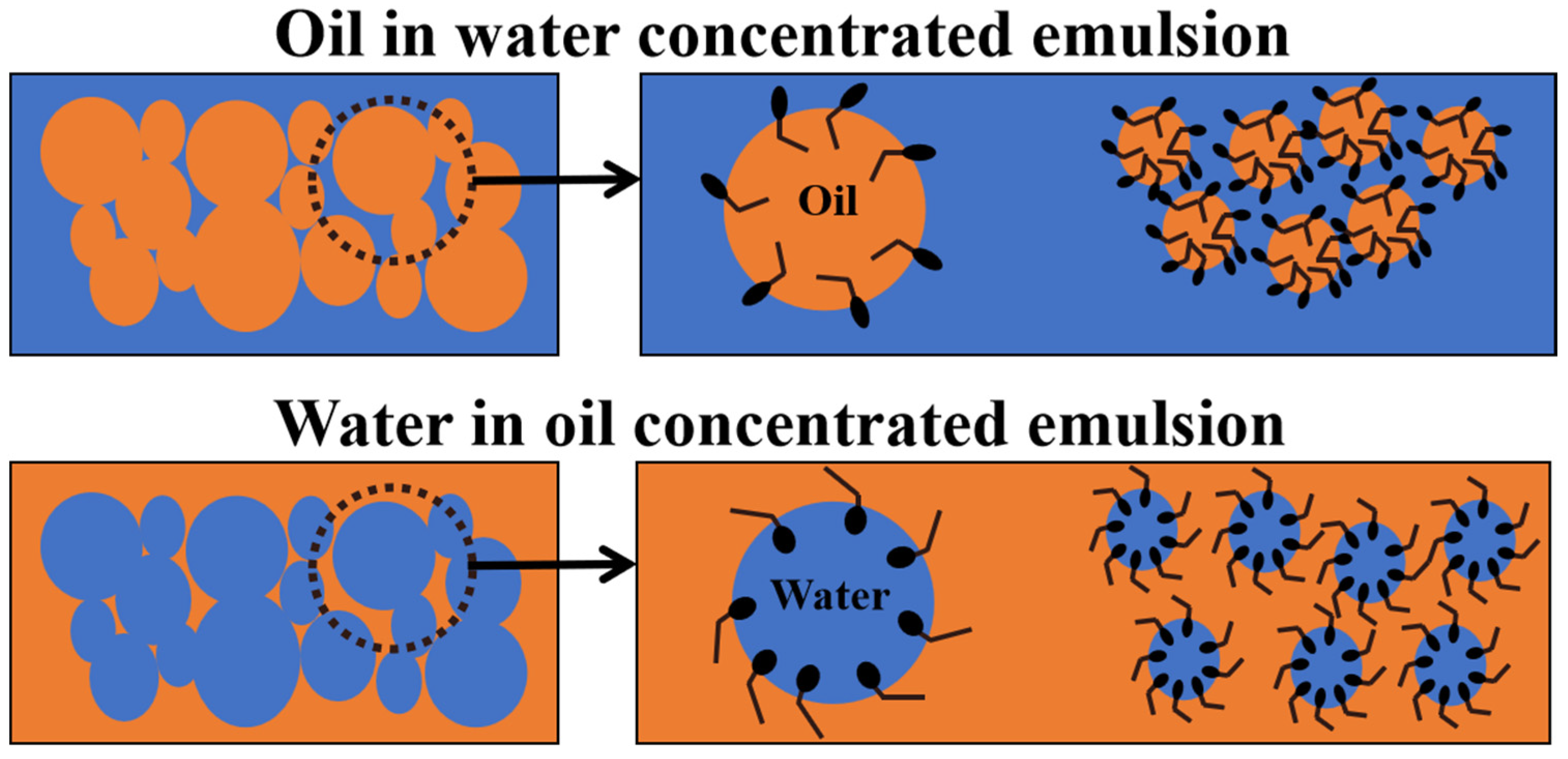

3.2.1. Emulsion Templating

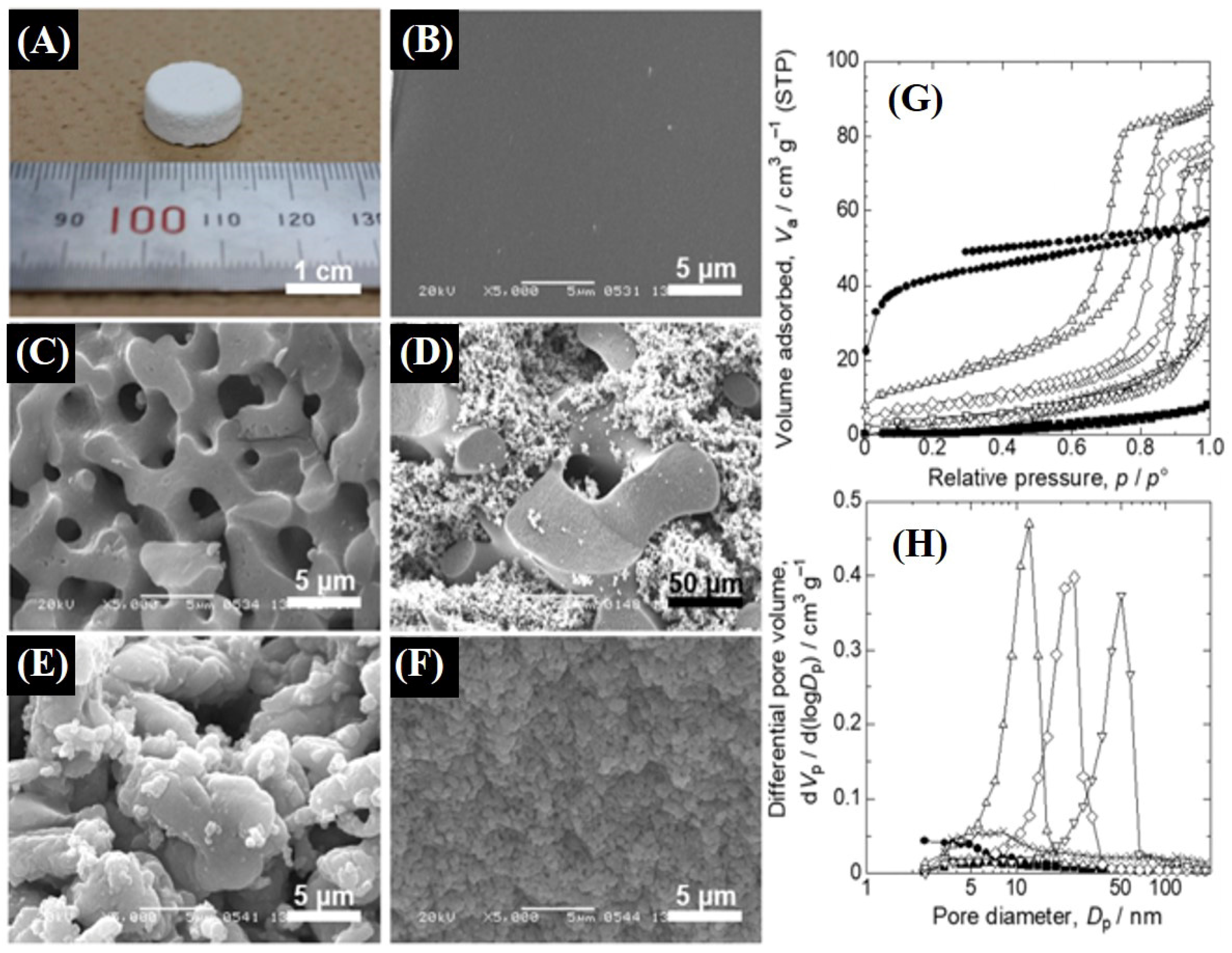

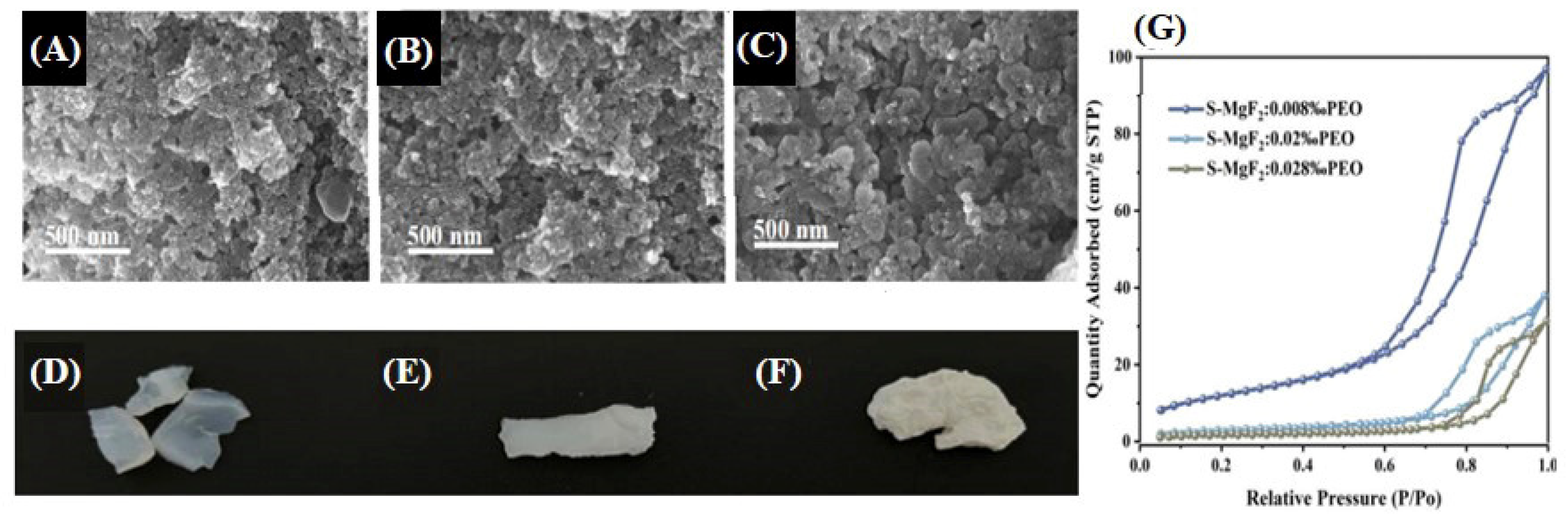

3.2.2. Phase Separation

3.2.3. Zeolitization Process

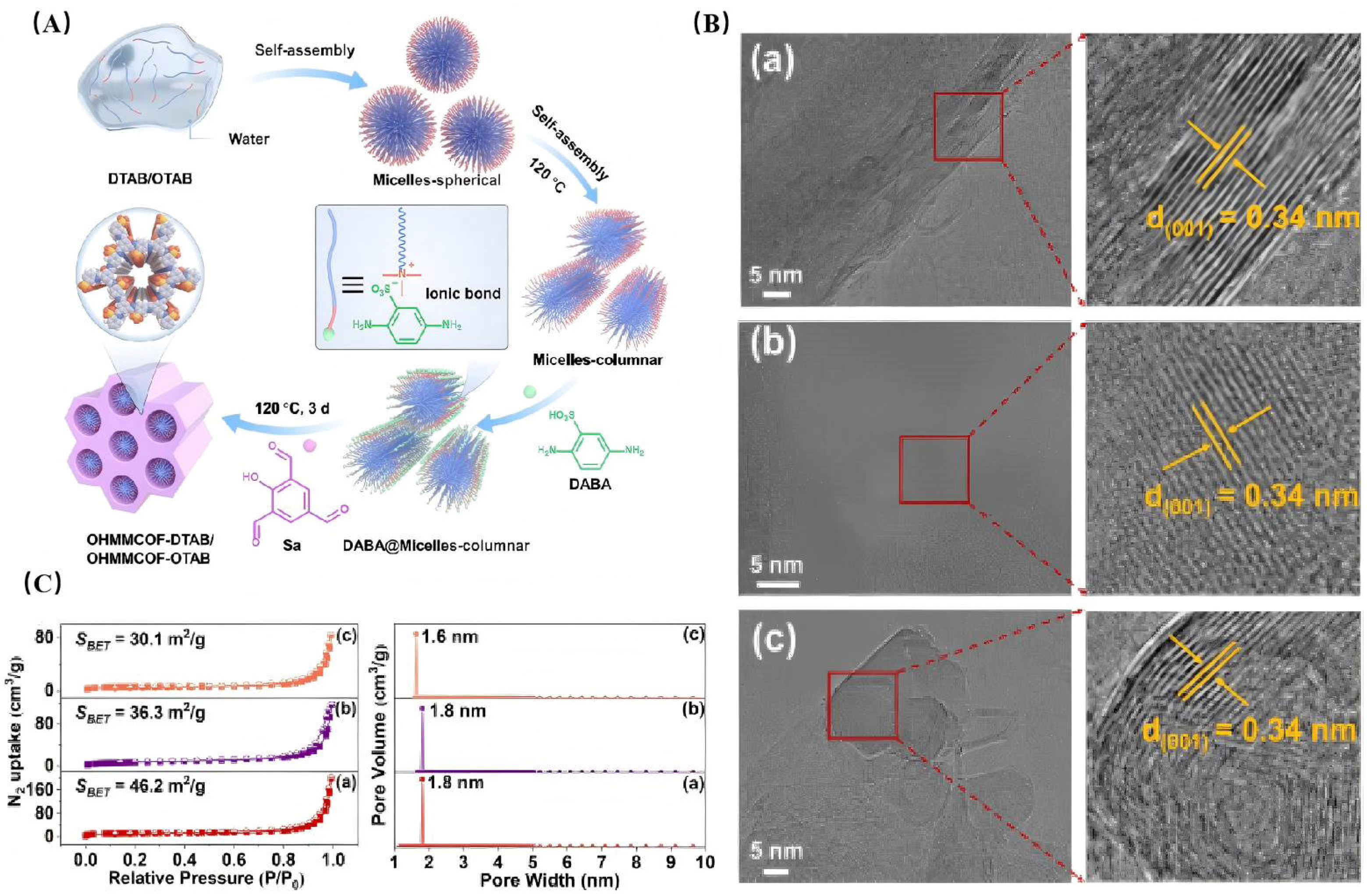

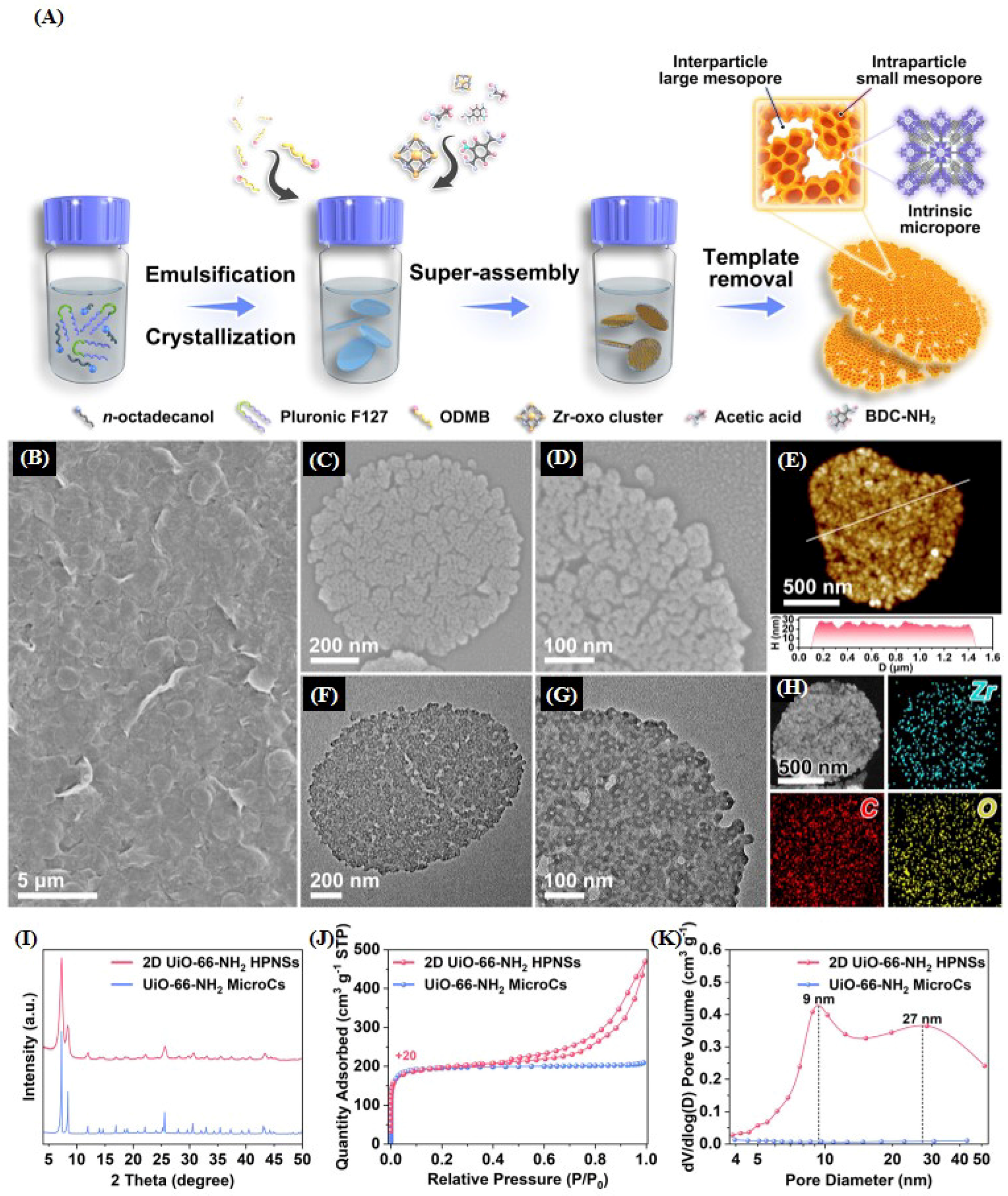

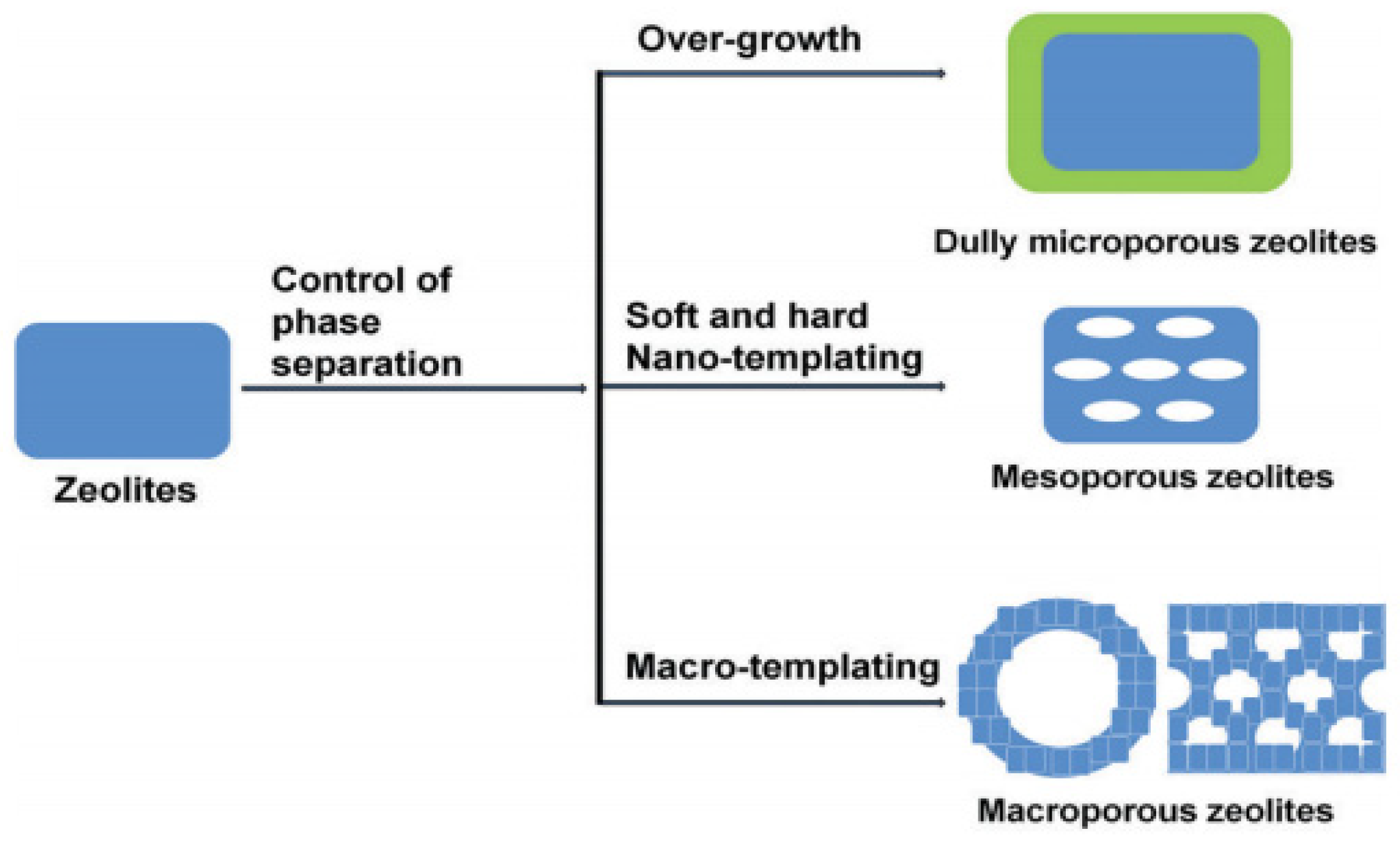

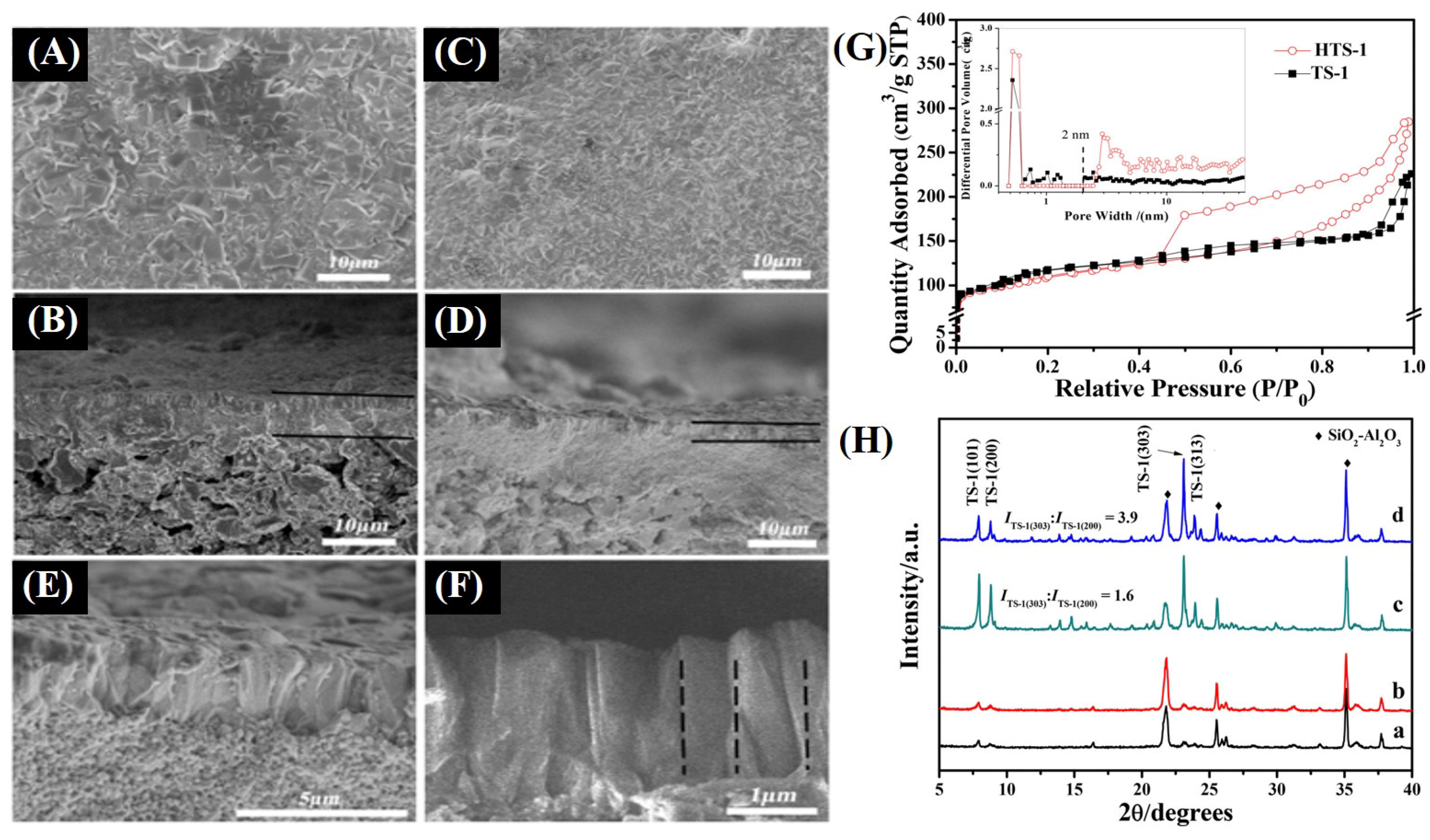

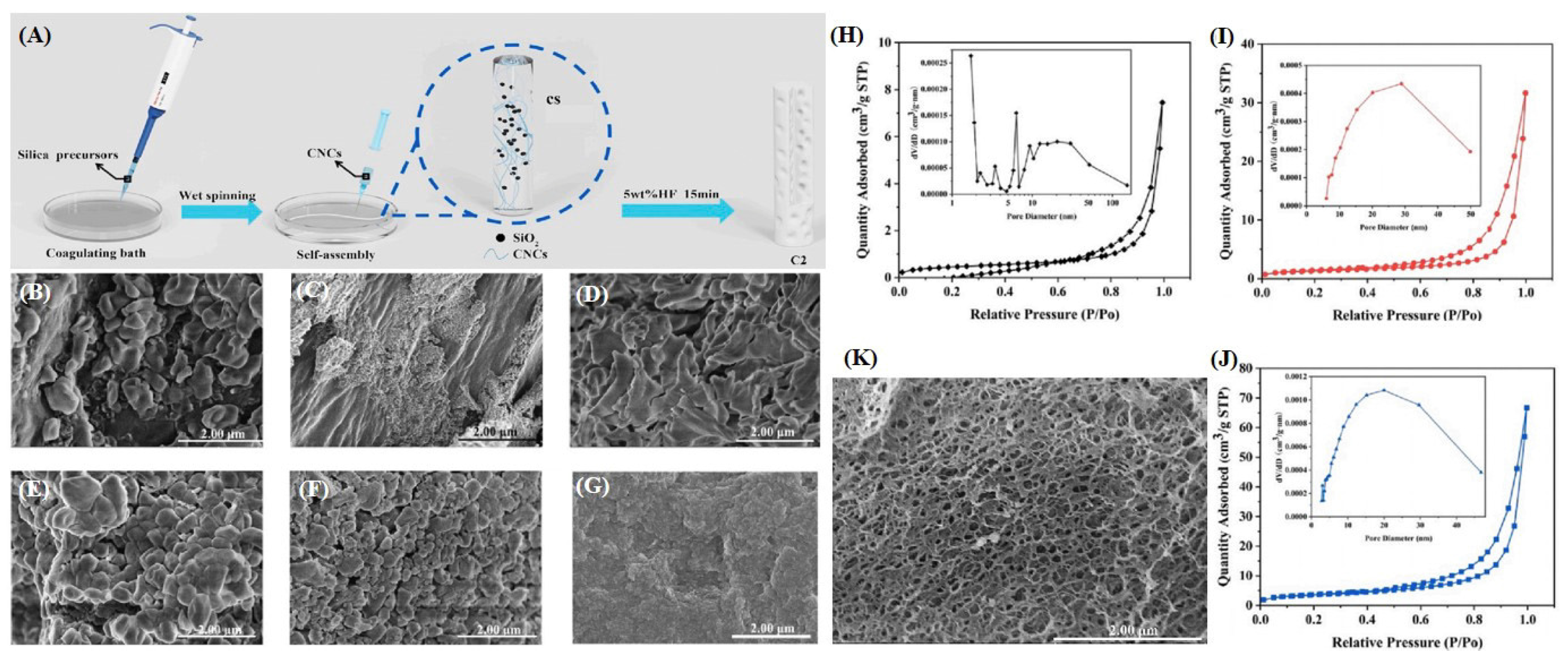

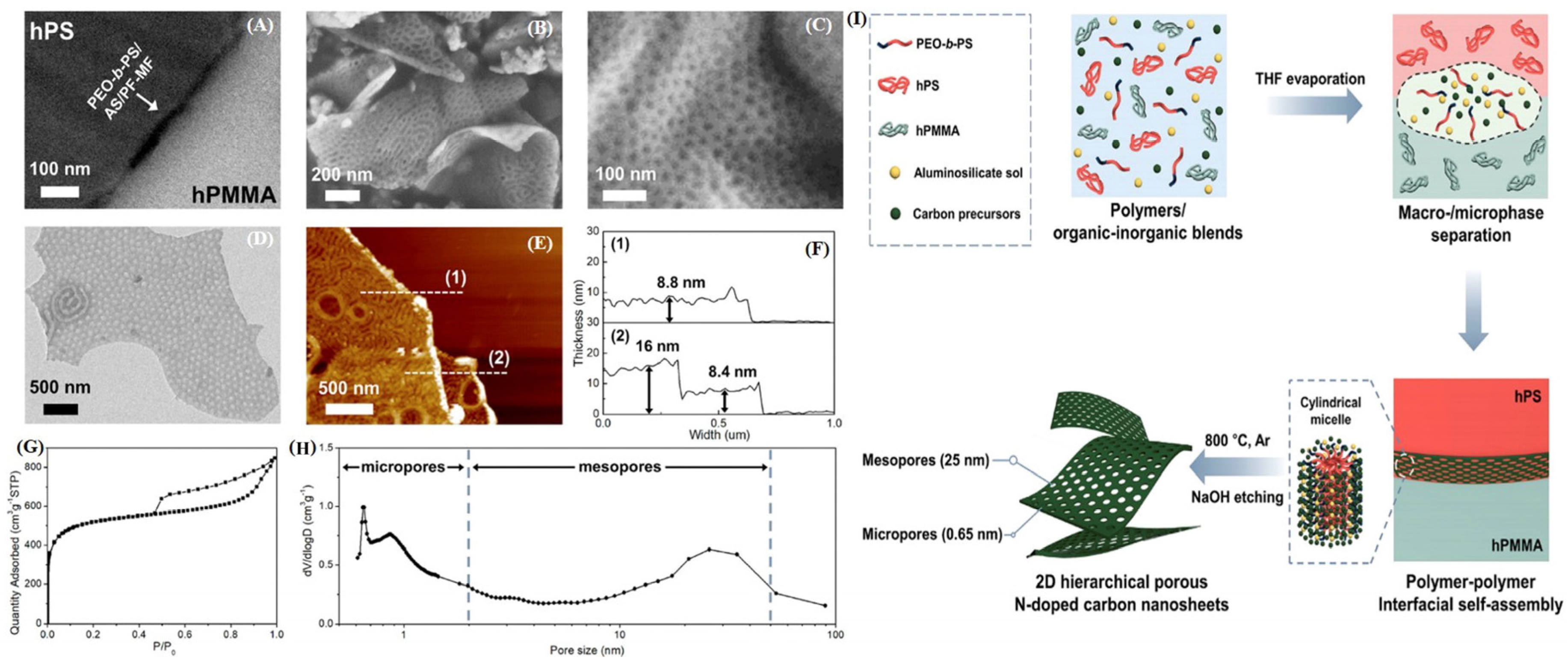

3.2.4. Self-Assembly

3.3. Physical–Chemical Methods

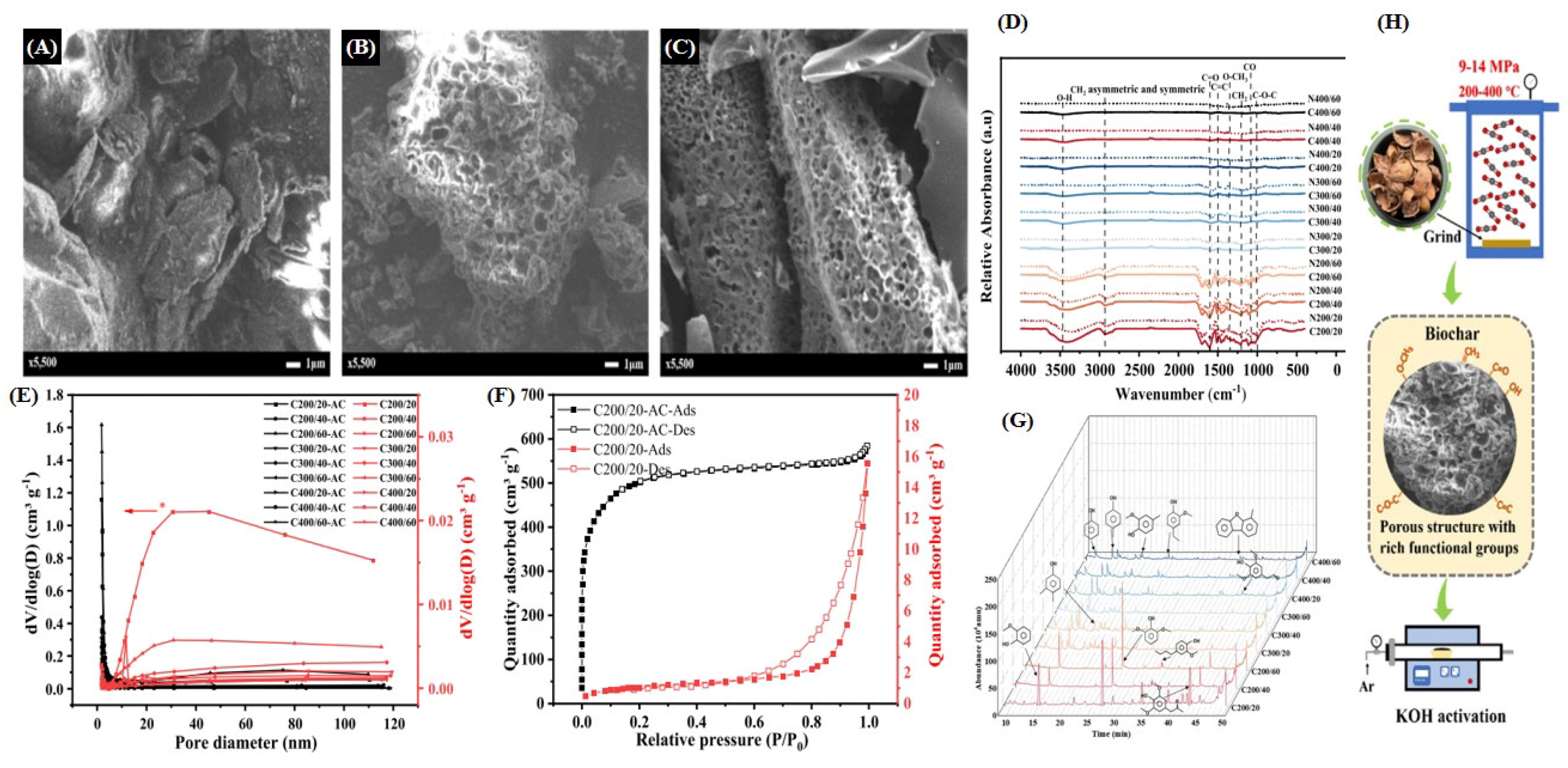

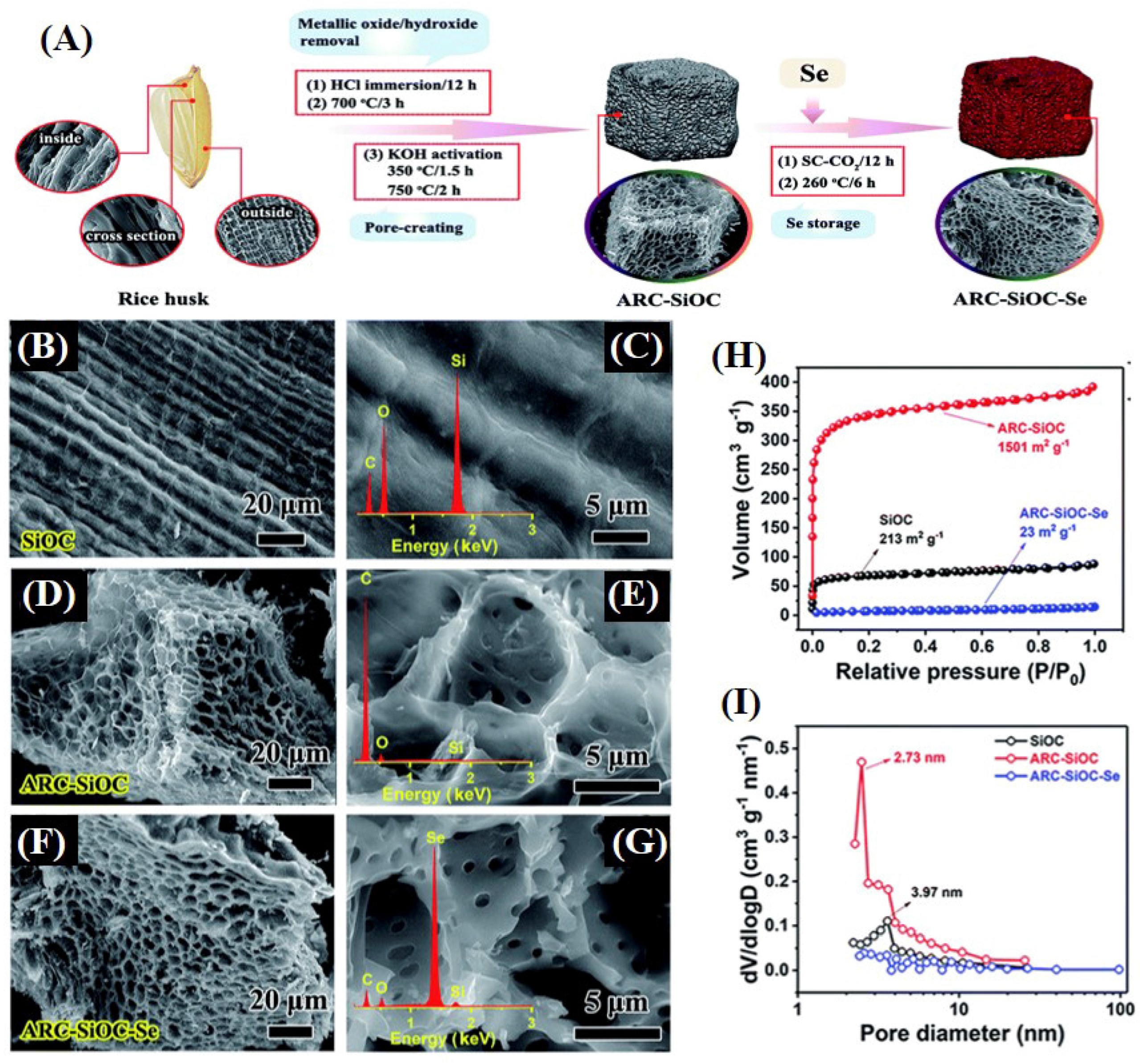

3.3.1. Supercritical Fluids

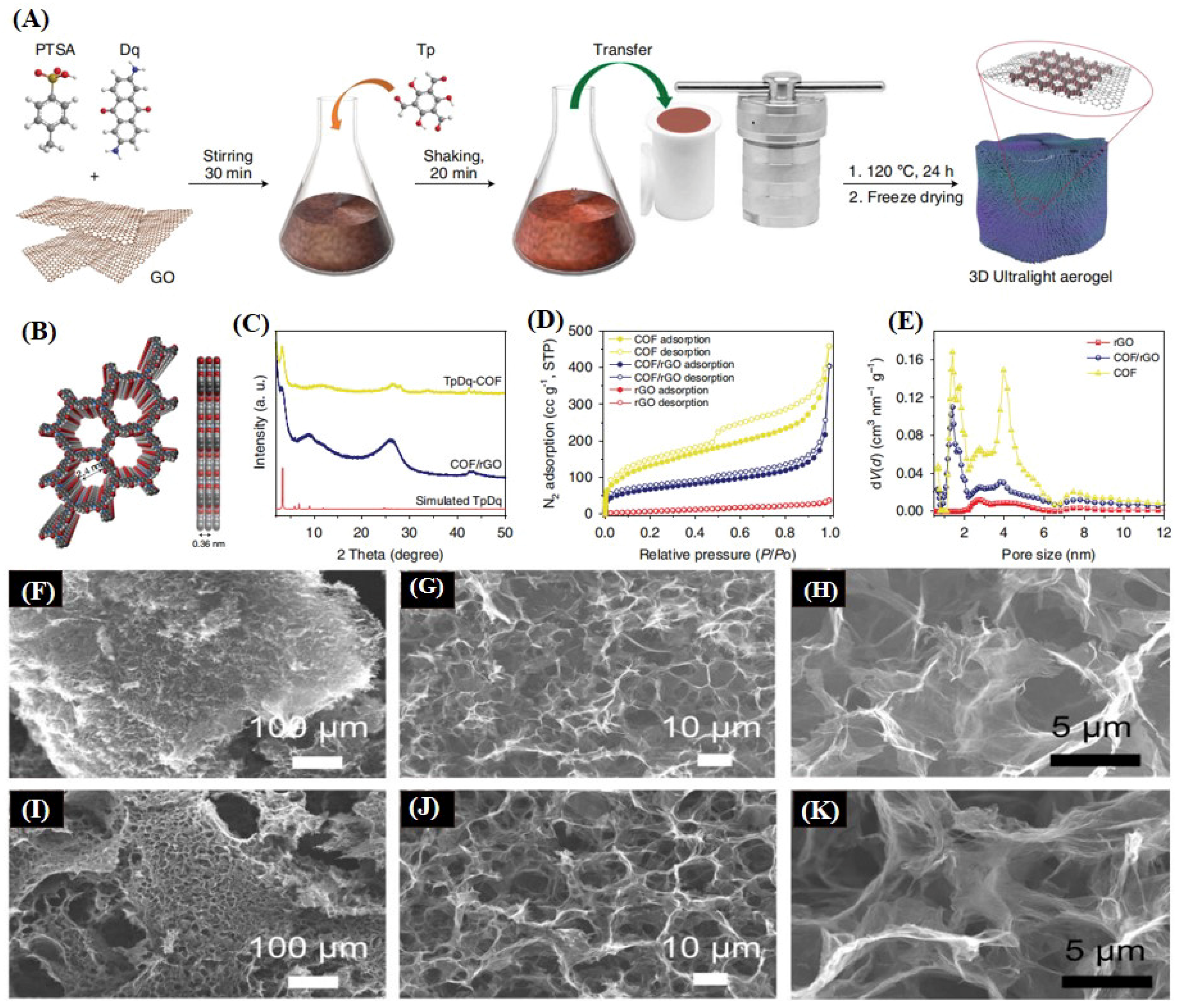

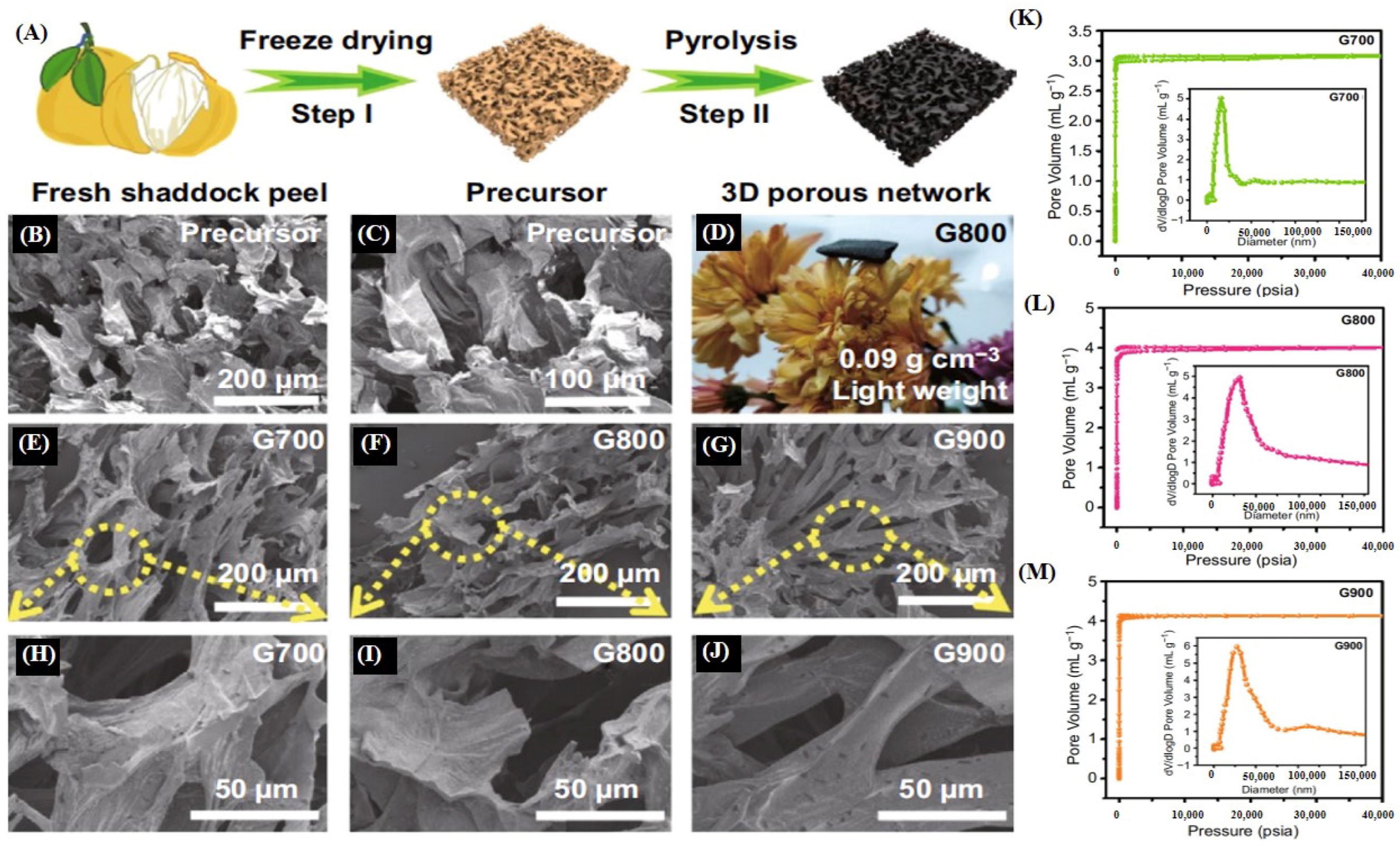

3.3.2. Freeze-Drying

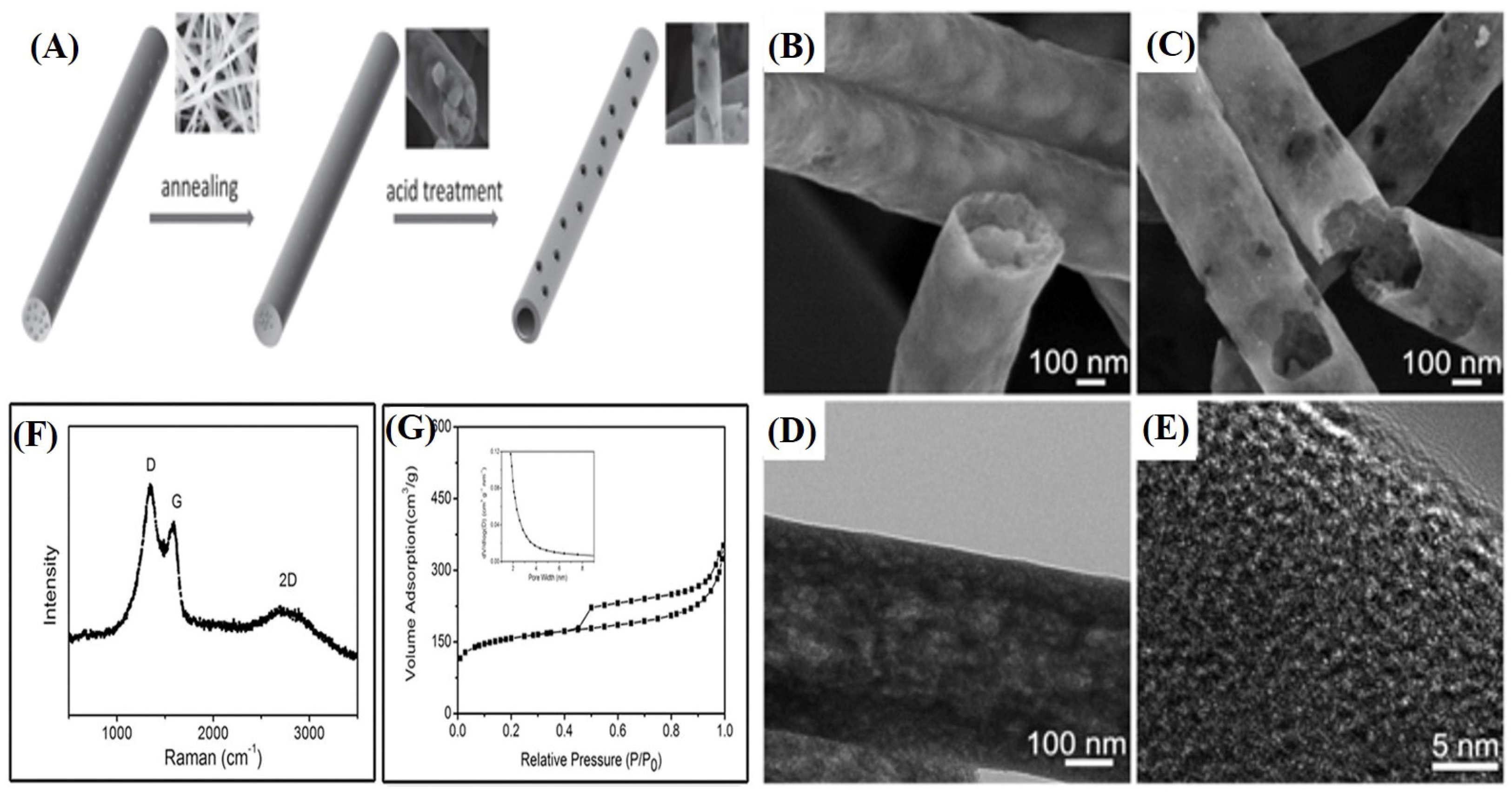

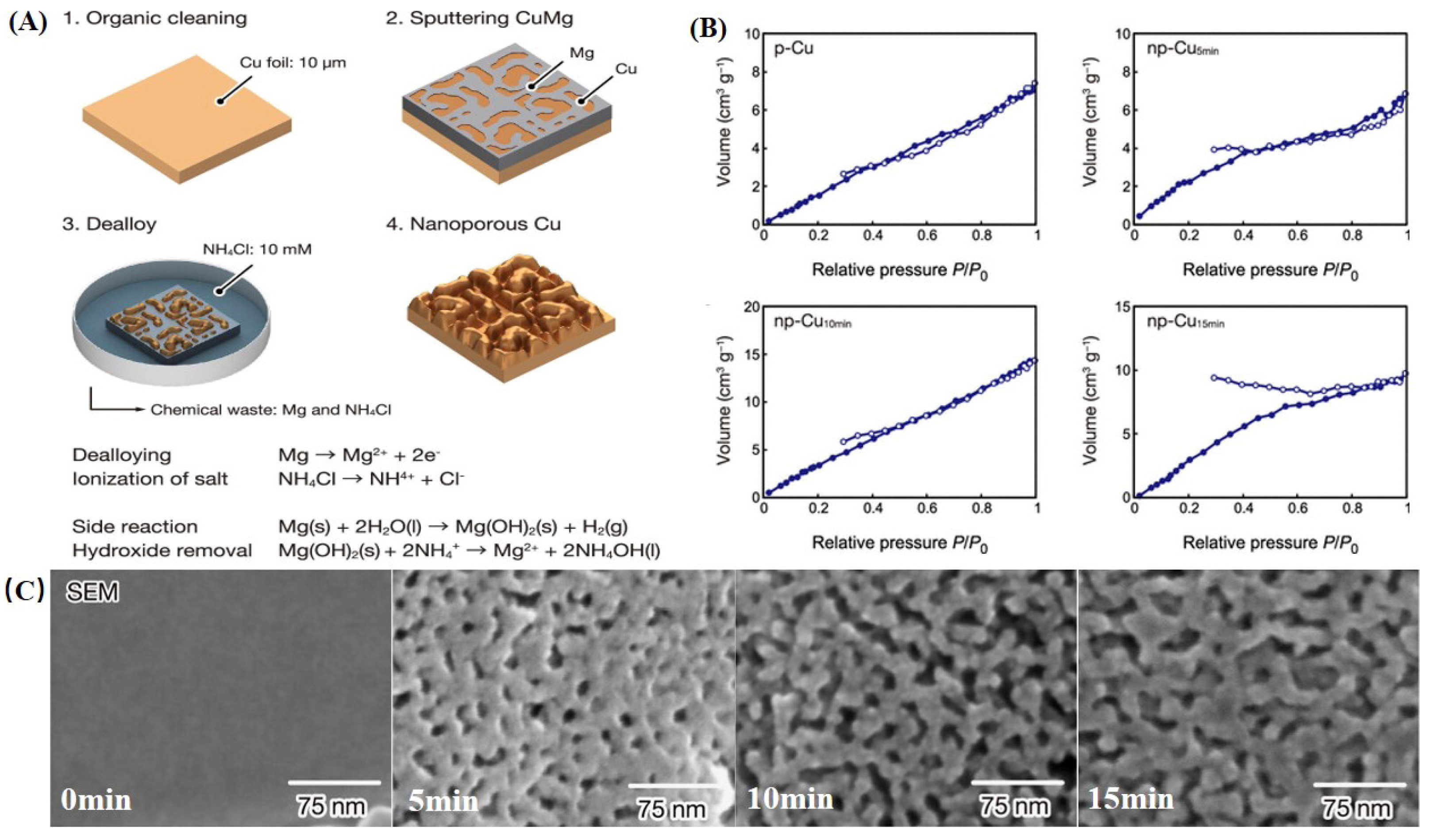

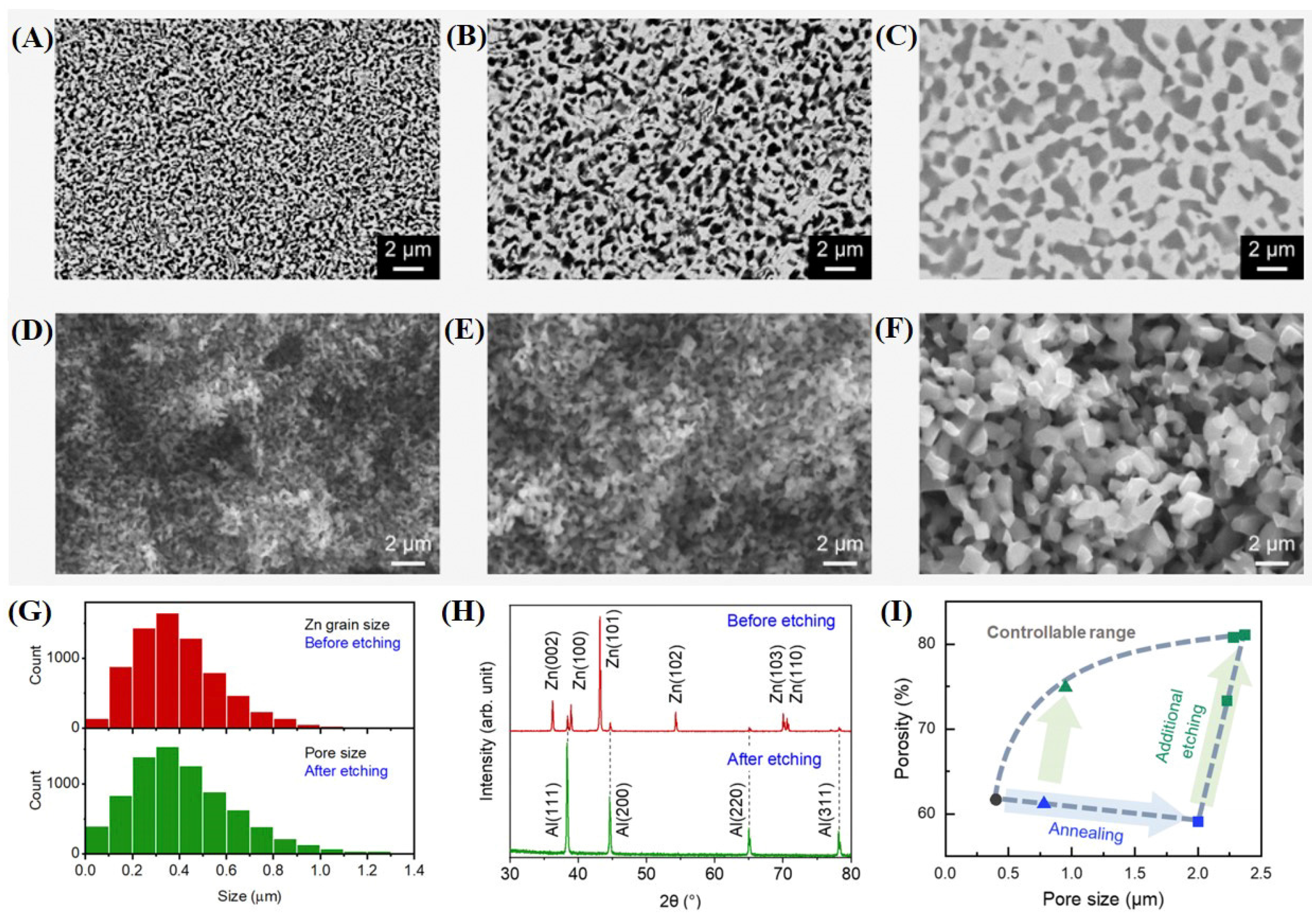

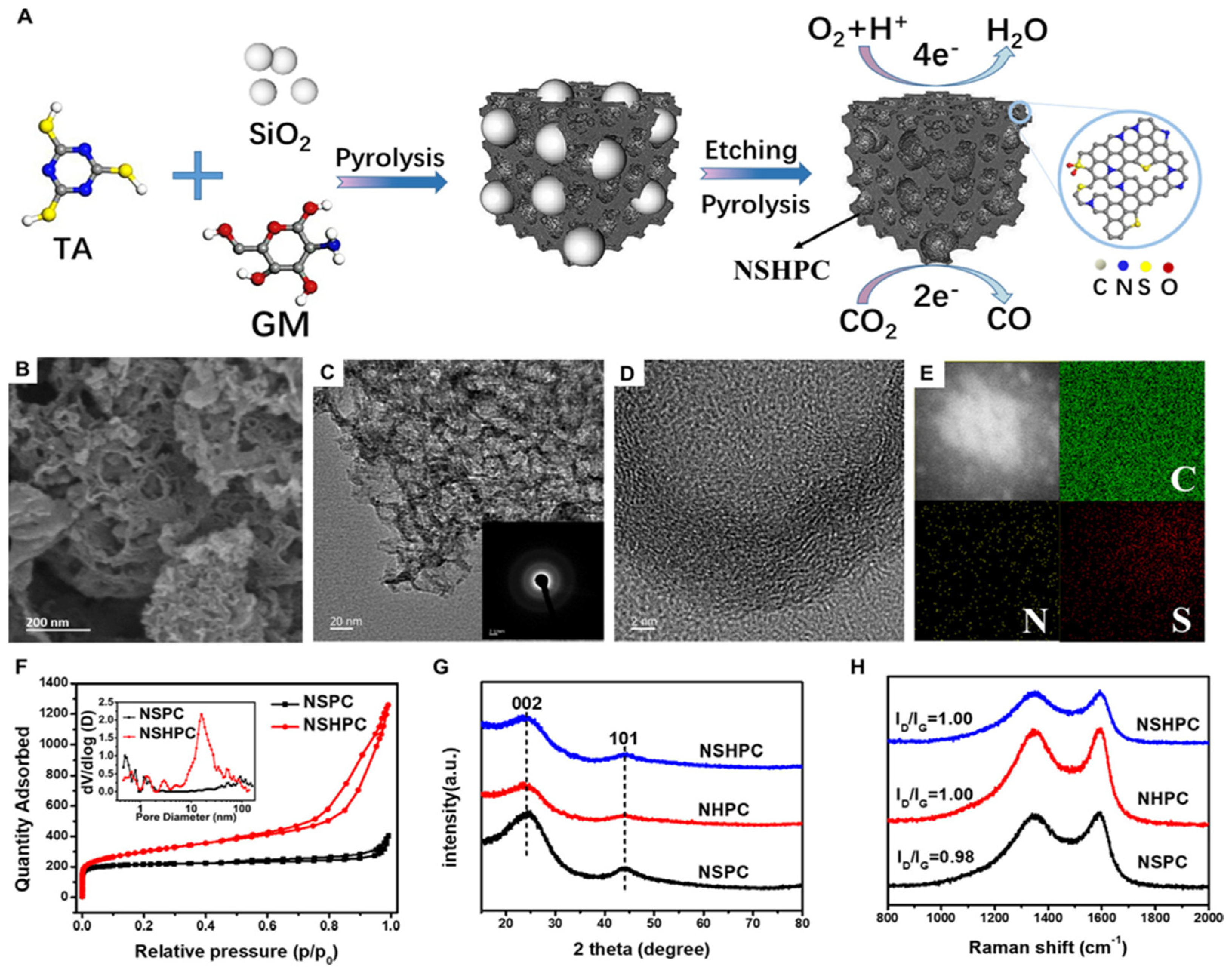

3.3.3. Selective Leaching

4. Application of Hierarchical Porous Materials in CO2RRs

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, X.; Li, X.; Chen, D.; Cui, H.; Ge, Q. Overestimated climate warming and climate variability due to spatially homogeneous CO2 in climate modeling over the Northern Hemisphere since the mid-19th century. Sci. Rep. 2019, 9, 17426. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Meireles, C.I.R.; Pinto Gomes, C.J.; Almeida Ribeiro, N.M.C. Forest Contribution to Climate Change Mitigation: Management Oriented to Carbon Capture and Storage. Climate 2020, 8, 21. [Google Scholar] [CrossRef]

- Friedlingstein, P.; Jones, M.W.; O’Sullivan, M.; Andrew, R.M.; Bakker, D.C.E.; Hauck, J.; Le Quéré, C.; Peters, G.P.; Peters, W.; Pongratz, J.; et al. Global Carbon Budget 2021. Earth Syst. Sci. Data 2022, 14, 1917–2005. [Google Scholar] [CrossRef]

- Hasan, S.Z.; Ahmad, K.N.; Isahak, W.N.R.W.; Pudukudy, M.; Masdar, M.S.; Jahim, J.M. Synthesis, Characterisation and Catalytic Activity of NiO supported Al2O3 for CO2 Hydrogenation to Carboxylic Acids: Influence of Catalyst Structure. IOP Conf. Ser. Earth Environ. Sci. 2019, 268, 012079. [Google Scholar] [CrossRef]

- Zhou, J.; Yu, Z.; Ma, L.; Zhu, X.; Jin, S.; Du, J.; Cheng, X.; Ke, S.; Xie, G.; Cheng, Y.-B.; et al. Pure Ammonia-Fueled Roller Kiln for the Production of Ceramic Tiles: A First Demonstration. Energy Fuels 2024, 38, 22593–22604. [Google Scholar] [CrossRef]

- Moritz, M.; Schönfisch, M.; Schulte, S. Estimating global production and supply costs for green hydrogen and hydrogen-based green energy commodities. Int. J. Hydrogen Energy 2023, 48, 9139–9154. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, Z. Carbon Capture, Utilization and Storage (CCUS). Appl. Energy 2019, 235, 1289–1299. [Google Scholar] [CrossRef]

- Tan, X.; Sun, X.; Han, B. Ionic liquid-based electrolytes for CO2 electroreduction and CO2 electroorganic transformation. Natl. Sci. Rev. 2022, 9, nwab022. [Google Scholar] [CrossRef]

- Kumaravel, V.; Bartlett, J.; Pillai, S.C. Photoelectrochemical Conversion of Carbon Dioxide (CO2) into Fuels and Value-Added Products. ACS Energy Lett. 2020, 5, 486–519. [Google Scholar] [CrossRef]

- Sun, K.; Fan, Z.; Ye, J.; Yan, J.; Ge, Q.; Li, Y.; He, W.; Yang, W.; Liu, C.-j. Hydrogenation of CO2 to methanol over In2O3 catalyst. J. CO2 Util. 2015, 12, 1–6. [Google Scholar] [CrossRef]

- Yang, D.; Zhu, Q.; Han, B. Electroreduction of CO2 in Ionic Liquid-Based Electrolytes. Innovation 2020, 1, 100016. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-K.; Liu, J.; Zhang, L.; Dong, L.-Z.; Li, S.-L.; Kan, Y.-H.; Li, D.-S.; Lan, Y.-Q. Monometallic Catalytic Models Hosted in Stable Metal–Organic Frameworks for Tunable CO2 Photoreduction. ACS Catal. 2019, 9, 1726–1732. [Google Scholar] [CrossRef]

- Chen, C.; Sun, X.; Yan, X.; Wu, Y.; Liu, H.; Zhu, Q.; Bediako, B.B.A.; Han, B. Boosting CO2 Electroreduction on N,P-Co-doped Carbon Aerogels. Angew. Chem. Int. Ed. 2020, 59, 11123–11129. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Ma, J.; Kang, X.; Sun, X.; Liu, H.; Hu, J.; Liu, Z.; Han, B. Efficient Reduction of CO2 into Formic Acid on a Lead or Tin Electrode using an Ionic Liquid Catholyte Mixture. Angew. Chem. Int. Ed. 2016, 55, 9012–9016. [Google Scholar] [CrossRef] [PubMed]

- Hepburn, C.; Adlen, E.; Beddington, J.; Carter, E.A.; Fuss, S.; Mac Dowell, N.; Minx, J.C.; Smith, P.; Williams, C.K. The technological and economic prospects for CO2 utilization and removal. Nature 2019, 575, 87–97. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.-H. Hierarchically porous materials and green chemistry—An interview with Ming-Yuan He. Natl. Sci. Rev. 2020, 7, 1759–1761. [Google Scholar] [CrossRef]

- Sun, K.; Cheng, T.; Wu, L.; Hu, Y.; Zhou, J.; Maclennan, A.; Jiang, Z.; Gao, Y.; Goddard, W.A.; Wang, Z. Ultrahigh Mass Activity for Carbon Dioxide Reduction Enabled by Gold–Iron Core–Shell Nanoparticles. J. Am. Chem. Soc. 2017, 139, 15608–15611. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, H.; Lin, R.; Ai, Y.; Lan, K.; Duan, L.; Chen, W.; Duan, X.; Ma, B.; Wang, C.; et al. Remodeling nanodroplets into hierarchical mesoporous silica nanoreactors with multiple chambers. Nat. Commun. 2022, 13, 6136. [Google Scholar] [CrossRef]

- Latif, M.N.; Wan Isahak, W.N.R.; Samsuri, A.; Hasan, S.Z.; Manan, W.N.; Yaakob, Z. Recent Advances in the Technologies and Catalytic Processes of Ethanol Production. Catalysts 2023, 13, 1093. [Google Scholar] [CrossRef]

- Wu, Q.; Gao, J.; Feng, J.; Liu, Q.; Zhou, Y.; Zhang, S.; Nie, M.; Liu, Y.; Zhao, J.; Liu, F.; et al. A CO2 adsorption dominated carbon defect-based electrocatalyst for efficient carbon dioxide reduction. J. Mater. Chem. A 2020, 8, 1205–1211. [Google Scholar] [CrossRef]

- Wang, R.; Zhao, J.; Fang, Q.; Qiu, S. Advancements and applications of three-dimensional covalent organic frameworks. Chem. Synth. 2024, 4, 29. [Google Scholar] [CrossRef]

- Ting, L.R.L.; Yeo, B.S. Recent advances in understanding mechanisms for the electrochemical reduction of carbon dioxide. Curr. Opin. Electrochem. 2018, 8, 126–134. [Google Scholar] [CrossRef]

- Firet, N.J.; Smith, W.A. Probing the Reaction Mechanism of CO2 Electroreduction over Ag Films via Operando Infrared Spectroscopy. ACS Catal. 2016, 7, 606–612. [Google Scholar] [CrossRef]

- Han, N.; Ding, P.; He, L.; Li, Y.; Li, Y. Promises of Main Group Metal–Based Nanostructured Materials for Electrochemical CO2 Reduction to Formate. Adv. Energy Mater. 2019, 10, 1902338. [Google Scholar] [CrossRef]

- Abdinejad, M.; Subramanian, S.; Motlagh, M.K.; Noroozifar, M.; Duangdangchote, S.; Neporozhnii, I.; Ripepi, D.; Pinto, D.; Li, M.; Tang, K.; et al. Insertion of MXene-Based Materials into Cu–Pd 3D Aerogels for Electroreduction of CO2to Formate. Adv. Energy Mater. 2023, 13, 2300402. [Google Scholar] [CrossRef]

- Chen, H.; Liang, X.; Liu, Y.; Ai, X.; Asefa, T.; Zou, X. Active Site Engineering in Porous Electrocatalysts. Adv. Mater. 2020, 32, 2002435. [Google Scholar] [CrossRef]

- Fujiwara, A.; Wang, J.; Hiraide, S.; Götz, A.; Miyahara, M.T.; Hartmann, M.; Apeleo Zubiri, B.; Spiecker, E.; Vogel, N.; Watanabe, S. Fast Gas-Adsorption Kinetics in Supraparticle-Based MOF Packings with Hierarchical Porosity. Adv. Mater. 2023, 35, 2305980. [Google Scholar] [CrossRef]

- Jena, R.; Rahimi, F.A.; Karmakar, S.; Dey, A.; Kalita, D.; Das, T.N.; Maji, T.K. Electron Rich Guest Regulated Enhanced CO2 Reduction in a Multivariate Porous Coordination Polymer. Adv. Funct. Mater. 2024, 34, 2407721. [Google Scholar] [CrossRef]

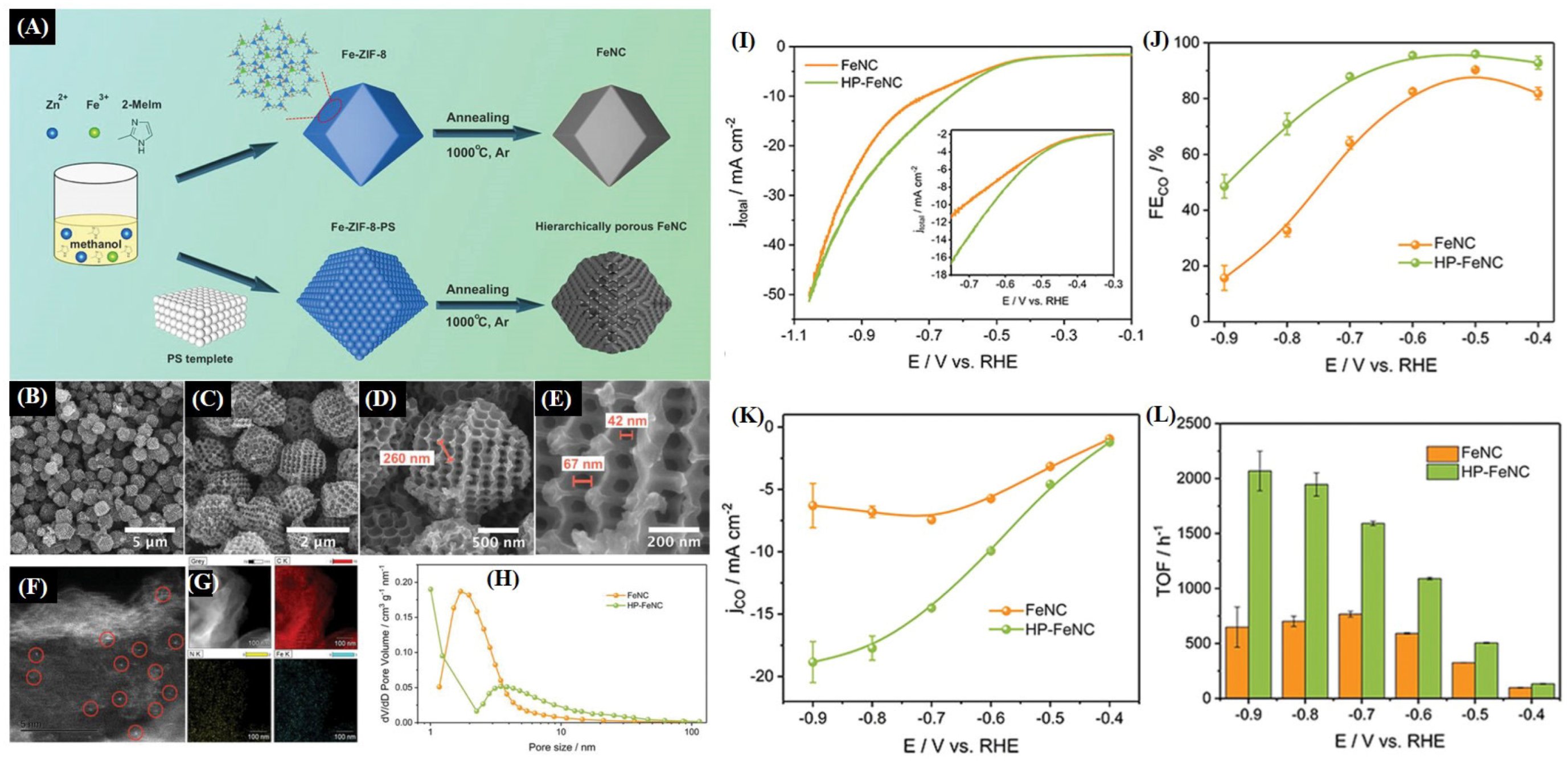

- Jia, C.; Zhao, Y.; Song, S.; Sun, Q.; Meyer, Q.; Liu, S.; Shen, Y.; Zhao, C. Highly Ordered Hierarchical Porous Single-Atom Fe Catalyst with Promoted Mass Transfer for Efficient Electroreduction of CO2. Adv. Energy Mater. 2023, 13, 2302007. [Google Scholar] [CrossRef]

- Li, H.; Niu, J.B.; Tao, L.G.; Tan, M.C.; Low, H.Y. Cascade Reactions for Enhanced CO2 Capture: Concurrent Optimization of Porosity and N-Doping. Adv. Funct. Mater. 2024, 34, 2415441. [Google Scholar] [CrossRef]

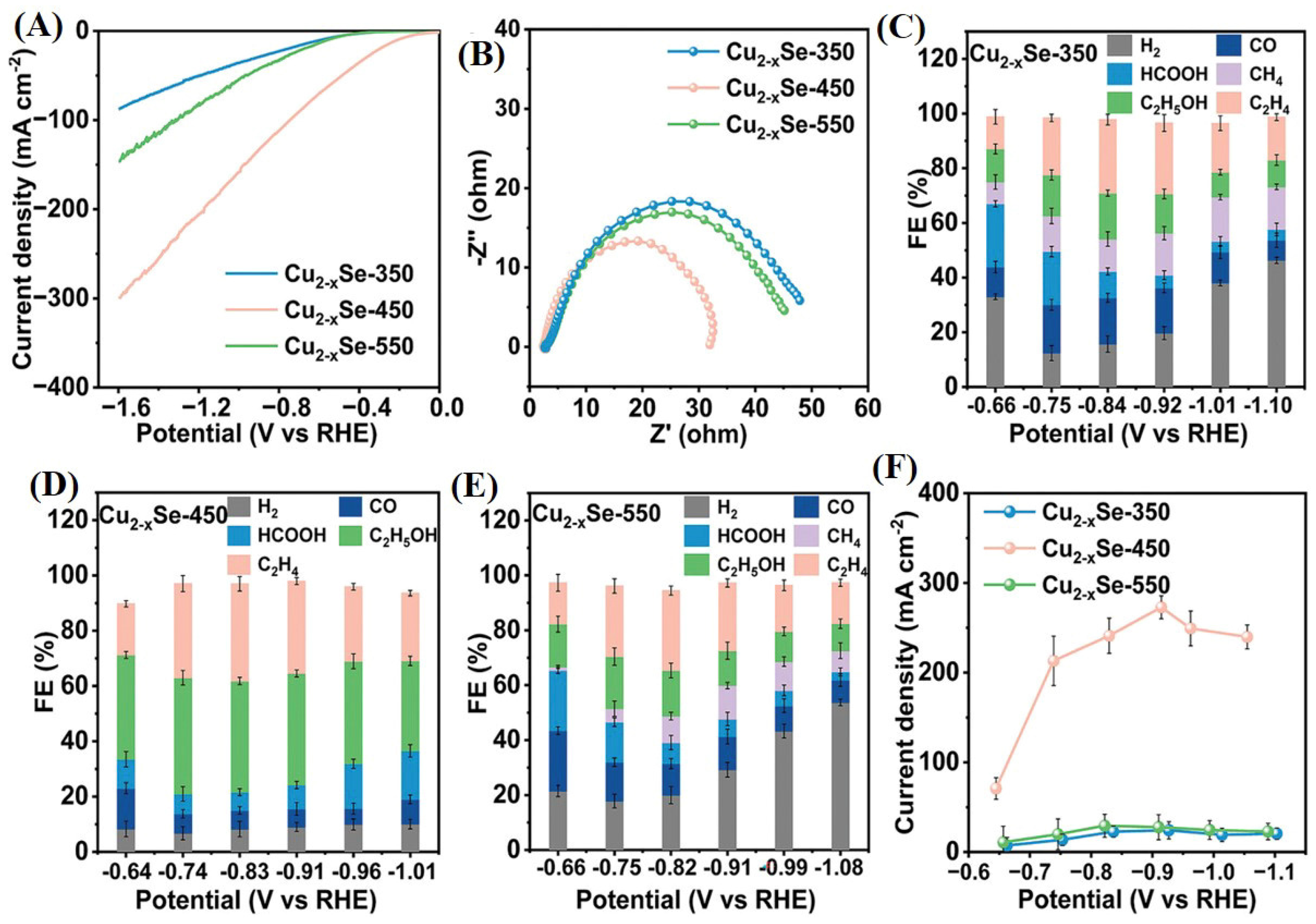

- Li, S.; Yu, J.; Zhang, S.; Qiu, W.; Tang, X.; Lin, Z.; Cai, R.; Fang, Y.; Yang, S.; Cai, X. OperandoReconstruction of Porous Carbon Supported Copper Selenide Promotes the C2Production from CO2RR. Adv. Funct. Mater. 2023, 34, 2311989. [Google Scholar] [CrossRef]

- Li, S.; Zhang, H.; Li, S.; Wang, J.; Wang, Q.; Cheng, Z. Advances in hierarchically porous materials: Fundamentals, preparation and applications. Renew. Sustain. Energy Rev. 2024, 202, 114641. [Google Scholar] [CrossRef]

- Ni, W.; Xue, Y.; Zang, X.; Li, C.; Wang, H.; Yang, Z.; Yan, Y.-M. Fluorine Doped Cagelike Carbon Electrocatalyst: An Insight into the Structure-Enhanced CO Selectivity for CO2 Reduction at High Overpotential. ACS Nano 2020, 14, 2014–2023. [Google Scholar] [CrossRef]

- Ni, Y.; Hu, R.; Cheng, Z.; Meng, F.; Sun, F. An Ice-Dissolving-Crosslinking Method for Efficient and Large-Scale Preparation of Polyelectrolyte Monoliths with Ultra-Stability in Aqueous Environments. Adv. Funct. Mater. 2024, 34, 2407268. [Google Scholar] [CrossRef]

- Sam, D.K.; Li, H.; Xu, Y.-T.; Cao, Y. Advances in porous carbon materials for a sustainable future: A review. Adv. Colloid Interface Sci. 2024, 333, 103279. [Google Scholar] [CrossRef] [PubMed]

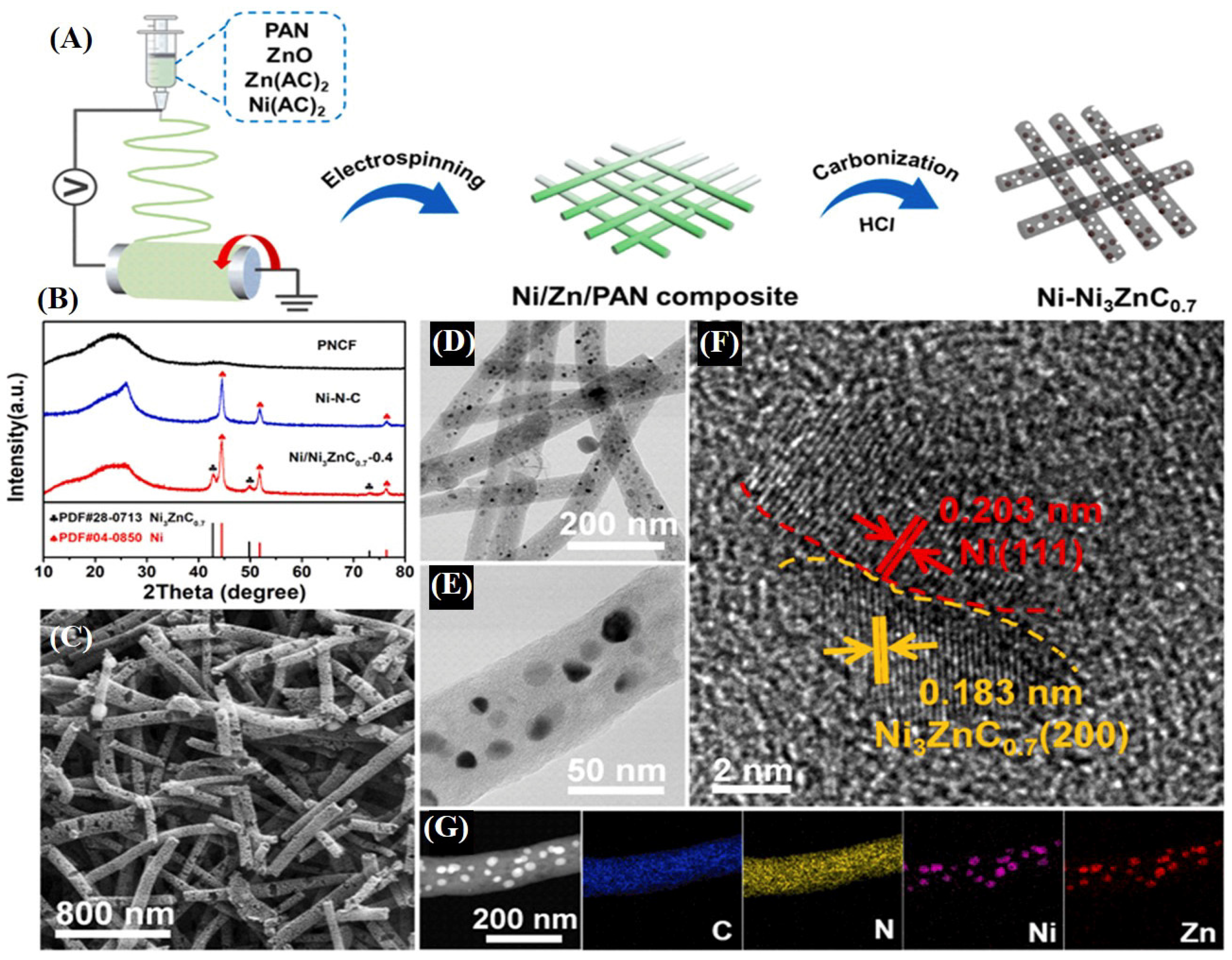

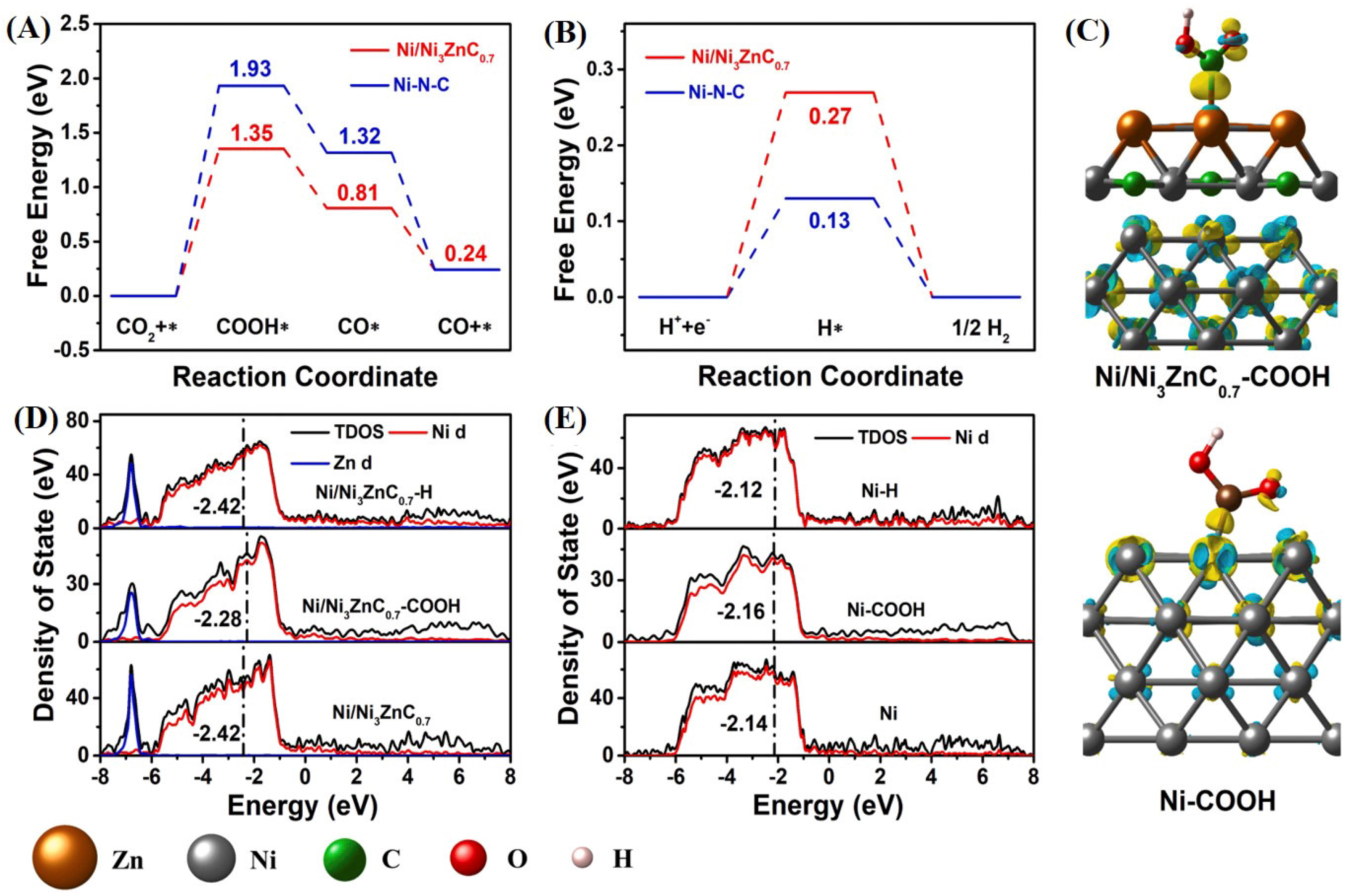

- Wei, X.; Xiao, S.; Wu, R.; Zhu, Z.; Zhao, L.; Li, Z.; Wang, J.; Chen, J.S.; Wei, Z. Activating COOH* intermediate by Ni/Ni3ZnC0.7 heterostructure in porous N-doped carbon nanofibers for boosting CO2 electroreduction. Appl. Catal. B Environ. 2022, 302, 120861. [Google Scholar] [CrossRef]

- Zhao, D.; Li, X.; Zhang, K.; Guo, J.; Huang, X.; Wang, G. Recent advances in thermocatalytic hydrogenation of unsaturated organic compounds with Metal-Organic Frameworks-based materials: Construction strategies and related mechanisms. Coord. Chem. Rev. 2023, 487, 215159. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, L.; Kang, Y.; Shen, C.-H.; Liu, X.; Jiang, D.; Fu, L.; Guselnikova, O.; Huang, L.; Song, X.; et al. Nanoengineering Multilength-Scale Porous Hierarchy in Mesoporous Metal–Organic Framework Single Crystals. ACS Nano 2024, 18, 22404–22414. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Wang, C.; Han, N.; Liu, M.; Zheng, R.; Chen, L.-H.; Zhong, J.; Su, B.-L. Two-dimensional hierarchically porous C3N4 for photocatalysis: Perspective and challenges. Chem. Synth. 2024, 4, 59. [Google Scholar] [CrossRef]

- Li, W.; Wang, D.; Wang, Y.; Shi, Z.; Liu, J.; Zhang, L.; Xue, D.; Liu, Y. Biological metal–organic frameworks for natural gas purification and MTO product separation. Chem. Synth. 2024, 4, 22. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Y.; Wang, S.; Fu, Y.; Li, X.; Zeng, J.; Zhang, W.; Ma, H. Fluorinated porous organic frameworks for C2F6/CF4 gases separation. Chem. Synth. 2024, 4, 48. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Jiang, L.; Han, Q.; Wang, Q.; Jia, J.; Zhu, G. Post-modified porous aromatic frameworks for carbon dioxide capture. Chem. Synth. 2024, 4, 40. [Google Scholar] [CrossRef]

- Sun, M.-H.; Zhou, J.; Hu, Z.-Y.; Chen, L.-H.; Li, L.-Y.; Wang, Y.-D.; Xie, Z.-K.; Turner, S.; Van Tendeloo, G.; Hasan, T.; et al. Hierarchical Zeolite Single-Crystal Reactor for Excellent Catalytic Efficiency. Matter 2020, 3, 1226–1245. [Google Scholar] [CrossRef]

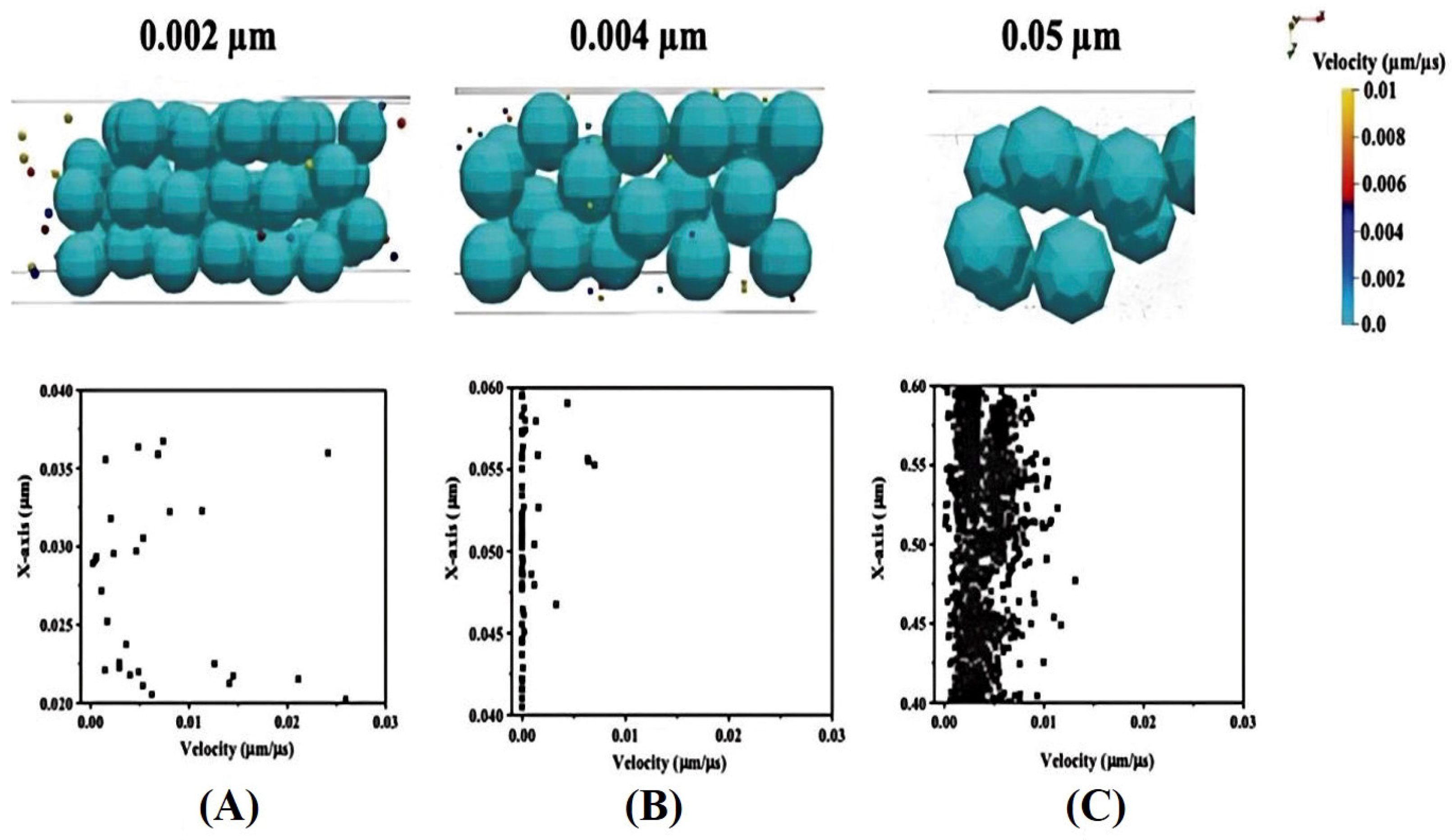

- Sun, M.-H.; Gao, S.-S.; Hu, Z.-Y.; Barakat, T.; Liu, Z.; Yu, S.; Lyu, J.-M.; Li, Y.; Xu, S.-T.; Chen, L.-H.; et al. Boosting molecular diffusion following the generalized Murray’s Law by constructing hierarchical zeolites for maximized catalytic activity. Natl. Sci. Rev. 2022, 9, nwac236. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Li, H.; Yu, J.; Ye, M.; Liu, Z. Quantitative principle of shape-selective catalysis for a rational screening of zeolites for methanol-to-hydrocarbons. AIChE J. 2022, 69, e17881. [Google Scholar] [CrossRef]

- Hu, N.; Li, X.-Y.; Liu, S.-M.; Wang, Z.; He, X.-K.; Hou, Y.-X.; Wang, Y.-X.; Deng, Z.; Chen, L.-H.; Su, B.-L. Enhanced stability of highly-dispersed copper catalyst supported by hierarchically porous carbon for long term selective hydrogenation. Chin. J. Catal. 2020, 41, 1081–1090. [Google Scholar] [CrossRef]

- Mohan, S.; Honnappa, B.; Augustin, A.; Shanmugam, M.; Chuaicham, C.; Sasaki, K.; Ramasamy, B.; Sekar, K. A Critical Study of Cu2O: Synthesis and Its Application in CO2 Reduction by Photochemical and Electrochemical Approaches. Catalysts 2022, 12, 445. [Google Scholar] [CrossRef]

- Mendoza-Castro, M.J.; Serrano, E.; Linares, N.; García-Martínez, J. Surfactant-Templated Zeolites: From Thermodynamics to Direct Observation. Adv. Mater. Interfaces 2020, 8, 2001388. [Google Scholar] [CrossRef]

- Zhao, S.; Li, H.; Zhang, W.; Wang, B.; Yang, X.; Peng, Y.; Zhang, Y.; Li, Z. Insight into Crystallization Features of MOR Zeolite Synthesized via Ice-Templating Method. Catalysts 2022, 12, 301. [Google Scholar] [CrossRef]

- Fang, R.; Xia, Y.; Liang, C.; He, X.; Huang, H.; Gan, Y.; Zhang, J.; Tao, X.; Zhang, W. Supercritical CO2-assisted synthesis of 3D porous SiOC/Se cathode for ultrahigh areal capacity and long cycle life Li–Se batteries. J. Mater. Chem. A 2018, 6, 24773–24782. [Google Scholar] [CrossRef]

- He, N.; Zou, Y.; Chen, C.; Tan, M.; Zhang, Y.; Li, X.; Jia, Z.; Zhang, J.; Long, H.; Peng, H.; et al. Constructing ordered and tunable extrinsic porosity in covalent organic frameworks via water-mediated soft-template strategy. Nat. Commun. 2024, 15, 3896. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, C.; Bai, Y.; Li, Q.; Yang, X. Synthesis of mesoporous silica with ionic liquid surfactant as template. Mater. Lett. 2021, 291, 129556. [Google Scholar] [CrossRef]

- Li, C.; Hu, Z.; Jiang, G.; Zhang, Y.; Wu, Z. 3D Carbon Microspheres with a Maze-Like Structure and Large Mesopore Tunnels Built from Rapid Aerosol-Confined Coherent Salt/Surfactant Templating. Small 2023, 20, 2305316. [Google Scholar] [CrossRef]

- Feng, A.; Mi, L.; Yu, Y.; Cao, Y.; Yu, Y.; Song, L. Development of intracrystalline mesoporosity in NH4HF2-etched NaY zeolites by surfactant-templating and its effect on toluene adsorption. Chem. Eng. J. 2020, 390, 124529. [Google Scholar] [CrossRef]

- Hasanvandian, F.; Zehtab Salmasi, M.; Moradi, M.; Farshineh Saei, S.; Kakavandi, B.; Rahman Setayesh, S. Enhanced spatially coupling heterojunction assembled from CuCo2S4 yolk-shell hollow sphere capsulated by Bi-modified TiO2 for highly efficient CO2 photoreduction. Chem. Eng. J. 2022, 444, 136493. [Google Scholar] [CrossRef]

- Lv, H.; Mao, Y.; Yao, H.; Ma, H.; Han, C.; Yang, Y.Y.; Qiao, Z.A.; Liu, B. Ir-Doped CuPd Single-Crystalline Mesoporous Nanotetrahedrons for Ethylene Glycol Oxidation Electrocatalysis: Enhanced Selective Cleavage of C-C Bond. Angew. Chem. Int. Ed. 2024, 63, 2400281. [Google Scholar] [CrossRef] [PubMed]

- Qiu, P.; Yang, J.; Jiang, W.; Wang, L.; Fan, Y.; Luo, W. Interfacial engineering of core-shell structured mesoporous architectures from single-micelle building blocks. Nano Today 2020, 35, 100940. [Google Scholar] [CrossRef]

- Sun, L.; Lv, H.; Feng, J.; Guselnikova, O.; Wang, Y.; Yamauchi, Y.; Liu, B. Noble-Metal-Based Hollow Mesoporous Nanoparticles: Synthesis Strategies and Applications. Adv. Mater. 2022, 34, 2201954. [Google Scholar] [CrossRef] [PubMed]

- Vu, H.-T.; Harth, F.M.; Goepel, M.; Linares, N.; García-Martínez, J.; Gläser, R. Enhanced activity of a bifunctional Pt/zeolite Y catalyst with an intracrystalline hierarchical pore system in the aqueous-phase hydrogenation of levulinic acid. Chem. Eng. J. 2022, 430, 132763. [Google Scholar] [CrossRef]

- Li, K.; Yang, J.; Gu, J. Hierarchically Porous MOFs Synthesized by Soft-Template Strategies. Acc. Chem. Res. 2022, 55, 2235–2247. [Google Scholar] [CrossRef]

- Suresh, A.; Rowan, S.J.; Liu, C. Macroscale Fabrication of Lightweight and Strong Porous Carbon Foams through Template-Coating Pair Design. Adv. Mater. 2023, 35, 2206416. [Google Scholar] [CrossRef]

- Wu, B.; Meng, Y.; Peng, C.; Yang, J.; Xing, S.; Wu, N.; Yin, C.; Yang, J.; Bai, S.; Tiwari, M.K. Porous bulk superhydrophobic nanocomposites for extreme environments. Matter 2023, 6, 1992–2004. [Google Scholar] [CrossRef]

- Liu, R.-L.; Ji, W.-J.; He, T.; Zhang, Z.-Q.; Zhang, J.; Dang, F.-Q. Fabrication of nitrogen-doped hierarchically porous carbons through a hybrid dual-template route for CO2 capture and haemoperfusion. Carbon 2014, 76, 84–95. [Google Scholar] [CrossRef]

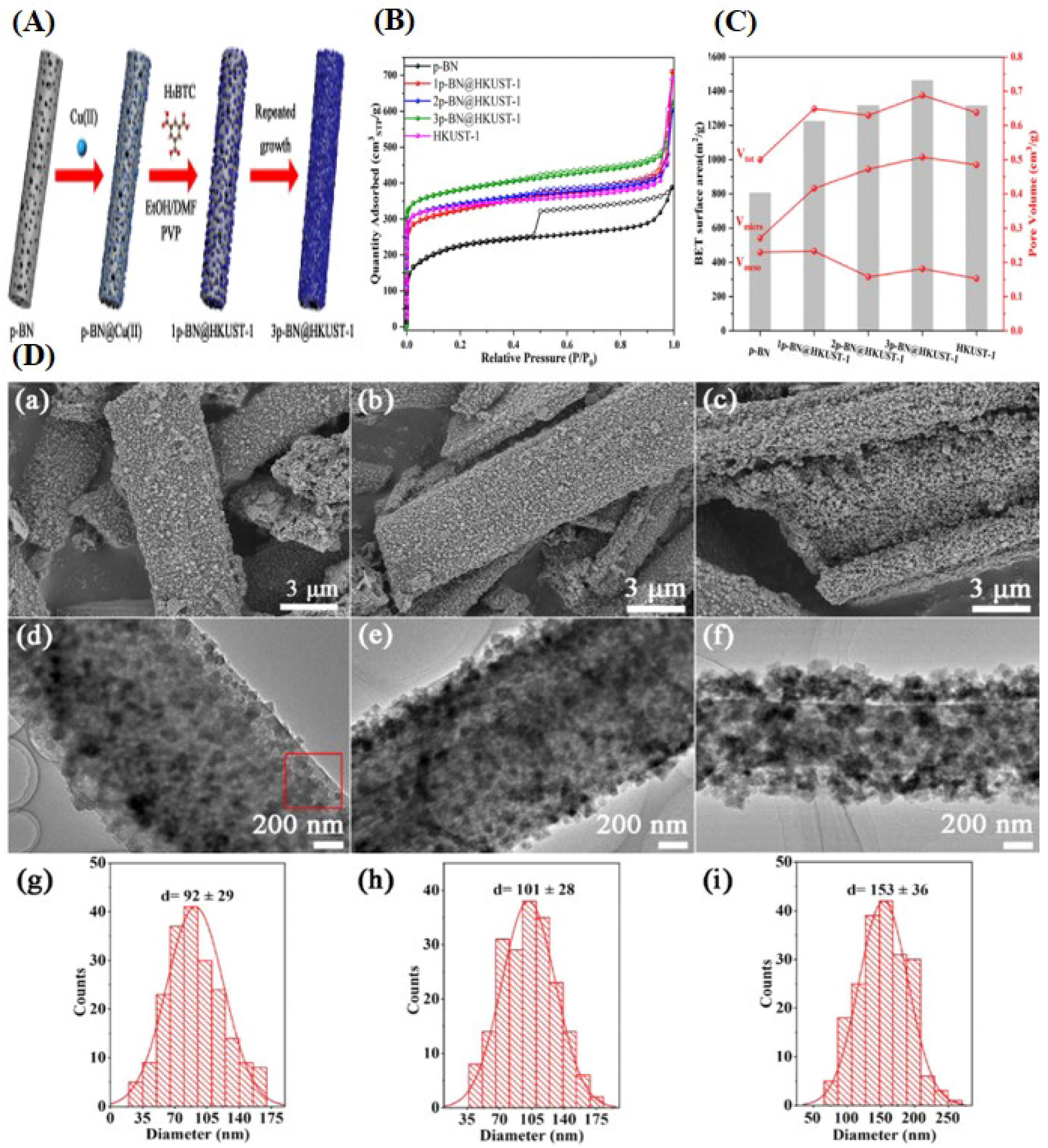

- Jia, J.; Wang, Y.; Feng, Y.; Hu, G.; Lin, J.; Huang, Y.; Zhang, Y.; Liu, Z.; Tang, C.; Yu, C. Hierarchically Porous Boron Nitride/HKUST-1 Hybrid Materials: Synthesis, CO2 Adsorption Capacity, and CO2/N2 and CO2/CH4 Selectivity. Ind. Eng. Chem. Res. 2021, 60, 2463–2471. [Google Scholar] [CrossRef]

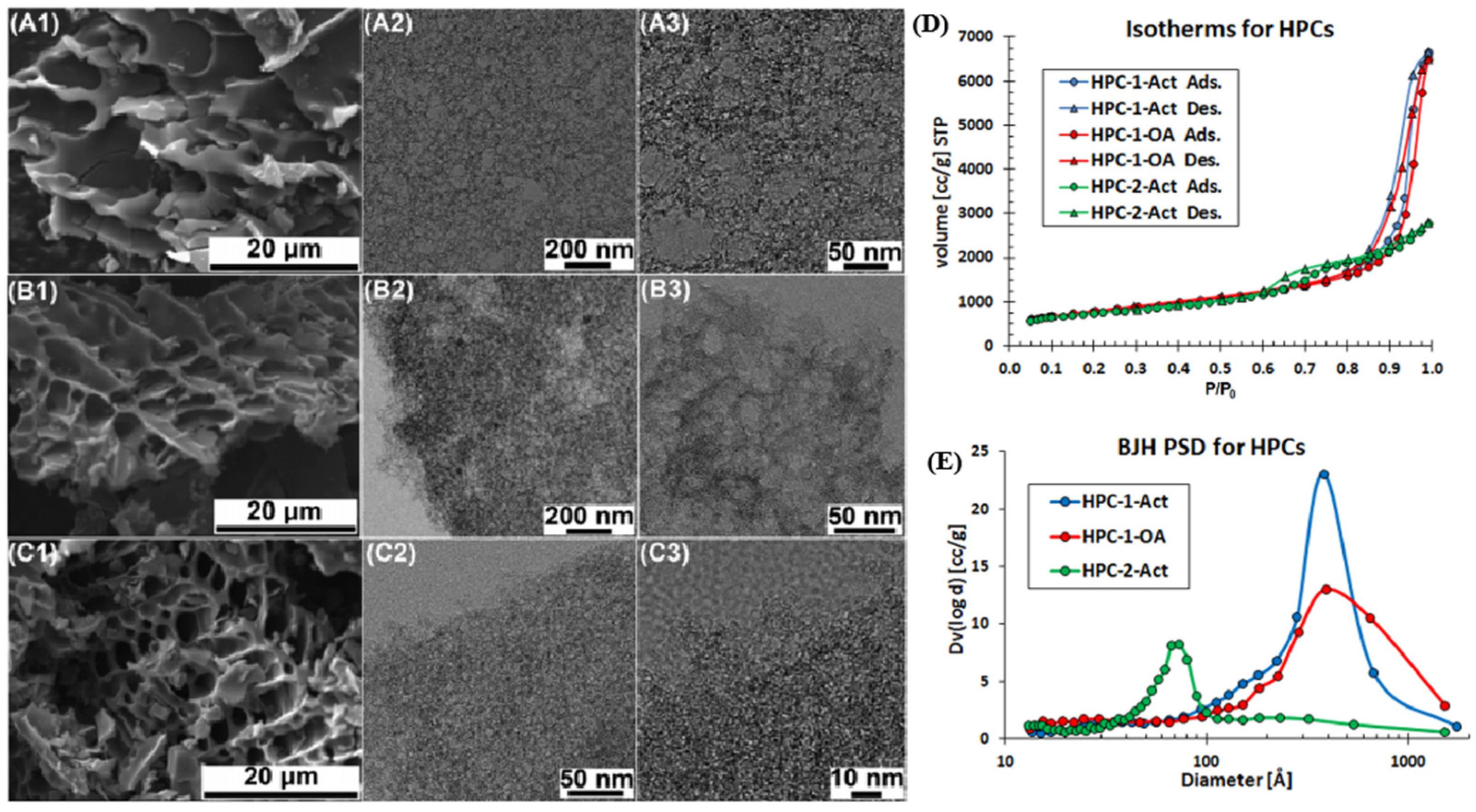

- Estevez, L.; Barpaga, D.; Zheng, J.; Sabale, S.; Patel, R.L.; Zhang, J.-G.; McGrail, B.P.; Motkuri, R.K. Hierarchically Porous Carbon Materials for CO2 Capture: The Role of Pore Structure. Ind. Eng. Chem. Res. 2018, 57, 1262–1268. [Google Scholar] [CrossRef]

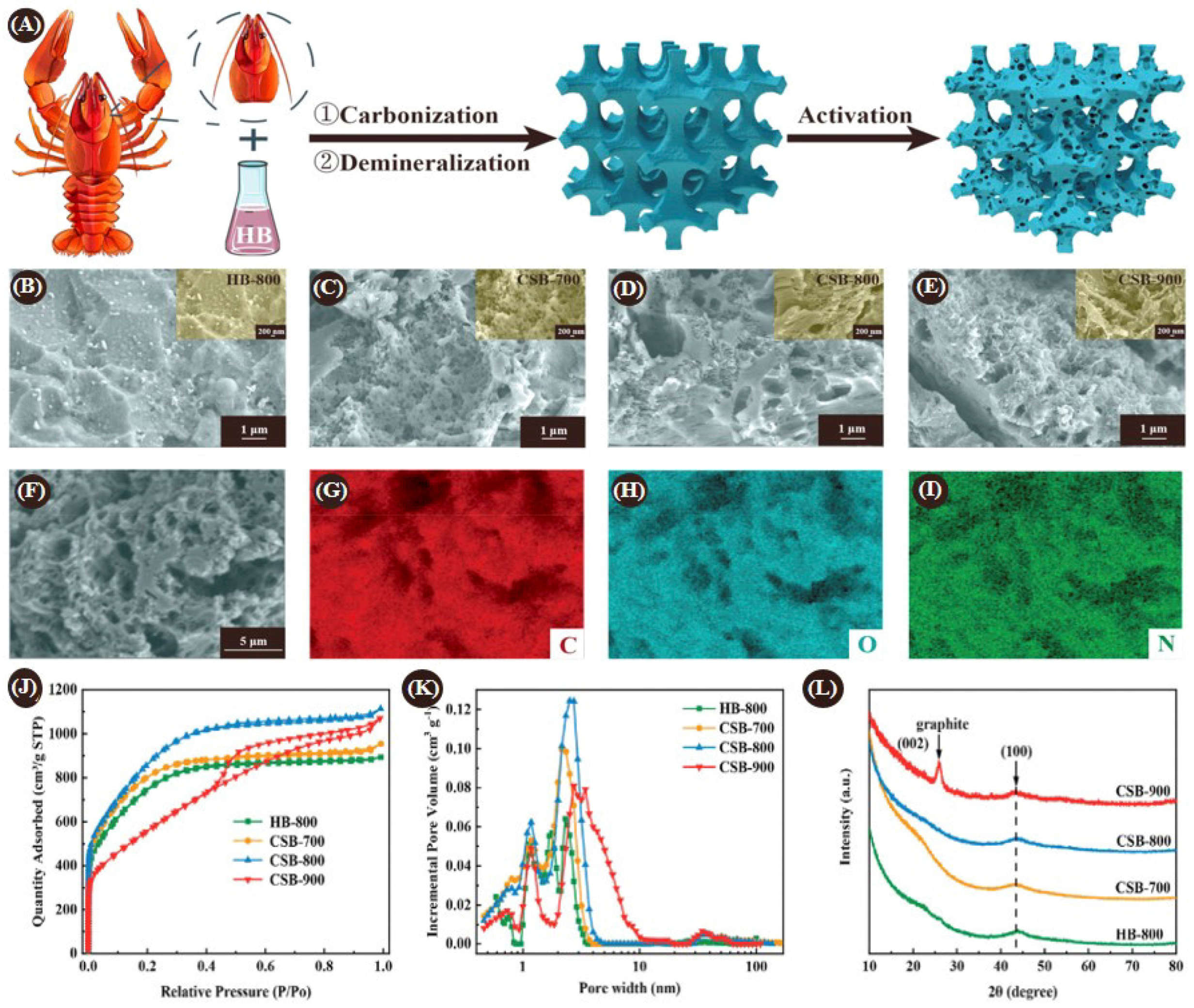

- Luo, Z.; Lin, N.; Sun, M.; Wang, Y.; Zhu, X. Synthesis of 3D-interconnected hierarchical porous carbon from heavy fraction of bio-oil using crayfish shell as the biological template for high-performance supercapacitors. Carbon 2021, 173, 910–917. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, S.; Cui, Z.; Li, Z.; Wu, S.; Xu, W.; Ba, T.; Liang, Y.; Jiang, H. Solvent-free one-step green synthesis of MXenes by “gas-phase selective etching”. Energy Storage Mater. 2024, 70, 103503. [Google Scholar] [CrossRef]

- Li, R.; Wang, L.; Zhou, P.; Lin, J.; Liu, Z.; Chen, J.; Zhao, D.; Huang, X.; Tao, Z.; Wang, G. Electronic state, abundance and microenvironment modulation of Ru nanoclusters within hierarchically porous UiO-66(Ce) for efficient hydrogenation of dicyclopentadiene. Chin. J. Catal. 2024, 56, 150–165. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Z.; Liu, Y.; Zhang, K.; Luo, S.; Li, W.; Liu, S. Worm-like ordered mesoporous carbon from liquefied wood: Morphological manipulation by varying hydrothermal temperature. Aggregate 2024, 5, e570. [Google Scholar] [CrossRef]

- Min, S.; Chang, H.; Tao, H.; Wang, F. A porous carbon membrane with abundant intrinsic carbon defects as an integrated gas-diffusion electrode for CO2 electroreduction. J. Mater. Chem. A 2023, 11, 15643–15650. [Google Scholar] [CrossRef]

- Song, G.; Li, C.; Wang, T.; Lim, K.H.; Hu, F.; Cheng, S.; Hondo, E.; Liu, S.; Kawi, S. Hierarchical Hollow Carbon Particles with Encapsulation of Carbon Nanotubes for High Performance Supercapacitors. Small 2023, 20, 2305517. [Google Scholar] [CrossRef]

- Taniguchi, Y.; Kokuryo, S.; Takada, R.; Yang, X.; Miyake, K.; Uchida, Y.; Nishiyama, N. Synthesis of N-doped carbon with a high concentration of pyridinic N using a zeolite template method with pyridine as the deposition source. Carbon 2024, 223, 118961. [Google Scholar] [CrossRef]

- Xie, L.; Jin, Z.; Dai, Z.; Chang, Y.; Jiang, X.; Wang, H. Porous carbons synthesized by templating approach from fluid precursors and their applications in environment and energy storage: A review. Carbon 2020, 170, 100–118. [Google Scholar] [CrossRef]

- Yang, Y.; Lou, J.; Zhao, Y.; Wei, J.; Zhou, Y.; Zhang, C.; Wu, M.; Zhang, Y.; Wang, Q.; Wang, L.; et al. Ice-templating co-assembly of dual-MOF superstructures derived 2D carbon nanobelts as efficient electrocatalysts. Chem. Eng. J. 2023, 477, 146900. [Google Scholar] [CrossRef]

- Sakka, S. Birth of the sol–gel method: Early history. J. Sol-Gel Sci. Technol. 2021, 102, 478–481. [Google Scholar] [CrossRef]

- Xiao, P.-W.; Zhao, L.; Sui, Z.-Y.; Han, B.-H. Synthesis of Core–Shell Structured Porous Nitrogen-Doped Carbon@Silica Material via a Sol–Gel Method. Langmuir 2017, 33, 6038–6045. [Google Scholar] [CrossRef] [PubMed]

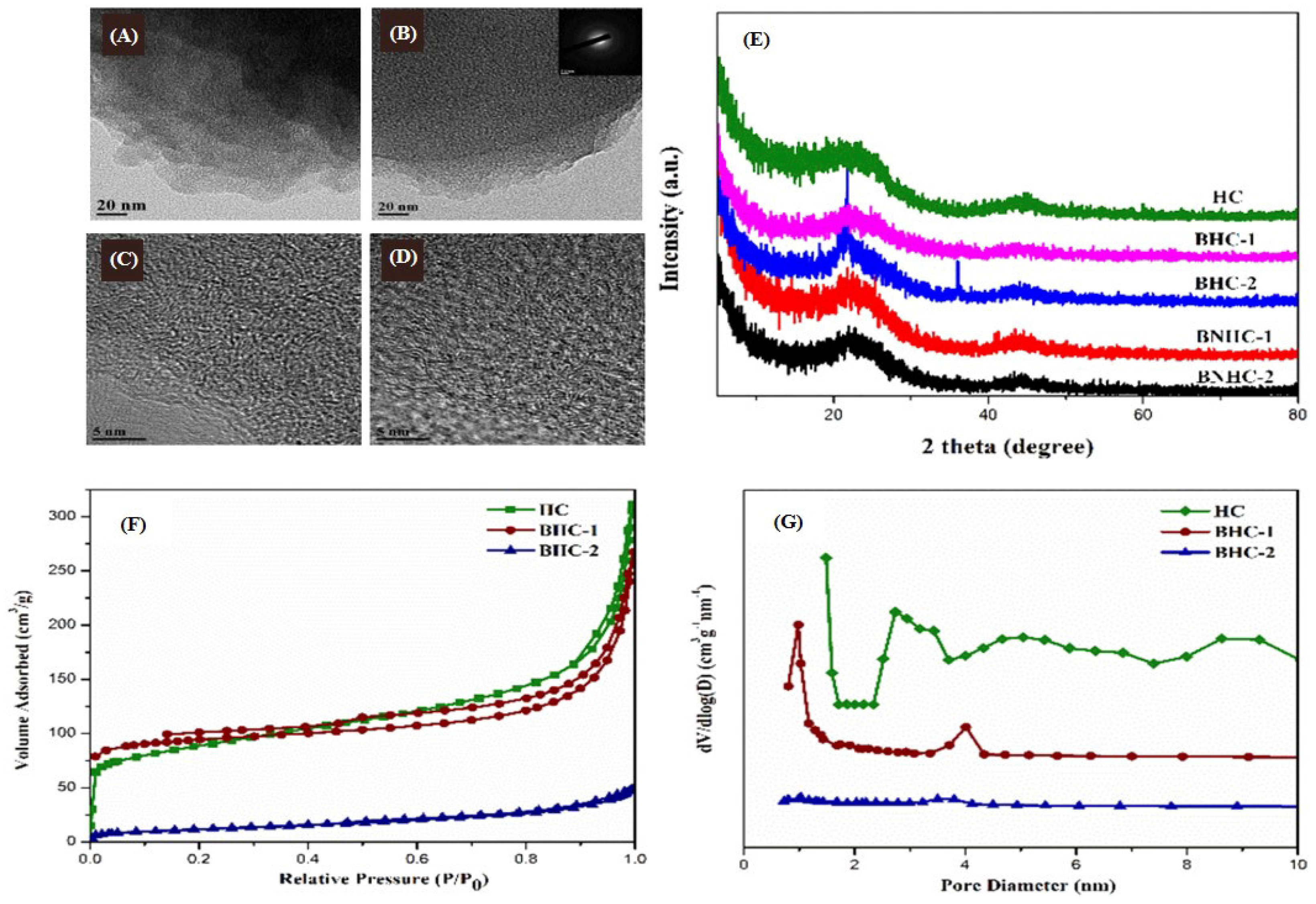

- Li, J.; Zhang, W.; Bao, A. Design of Hierarchically Structured Porous Boron/Nitrogen-Codoped Carbon Materials with Excellent Performance for CO2 Capture. Ind. Eng. Chem. Res. 2021, 60, 2710–2718. [Google Scholar] [CrossRef]

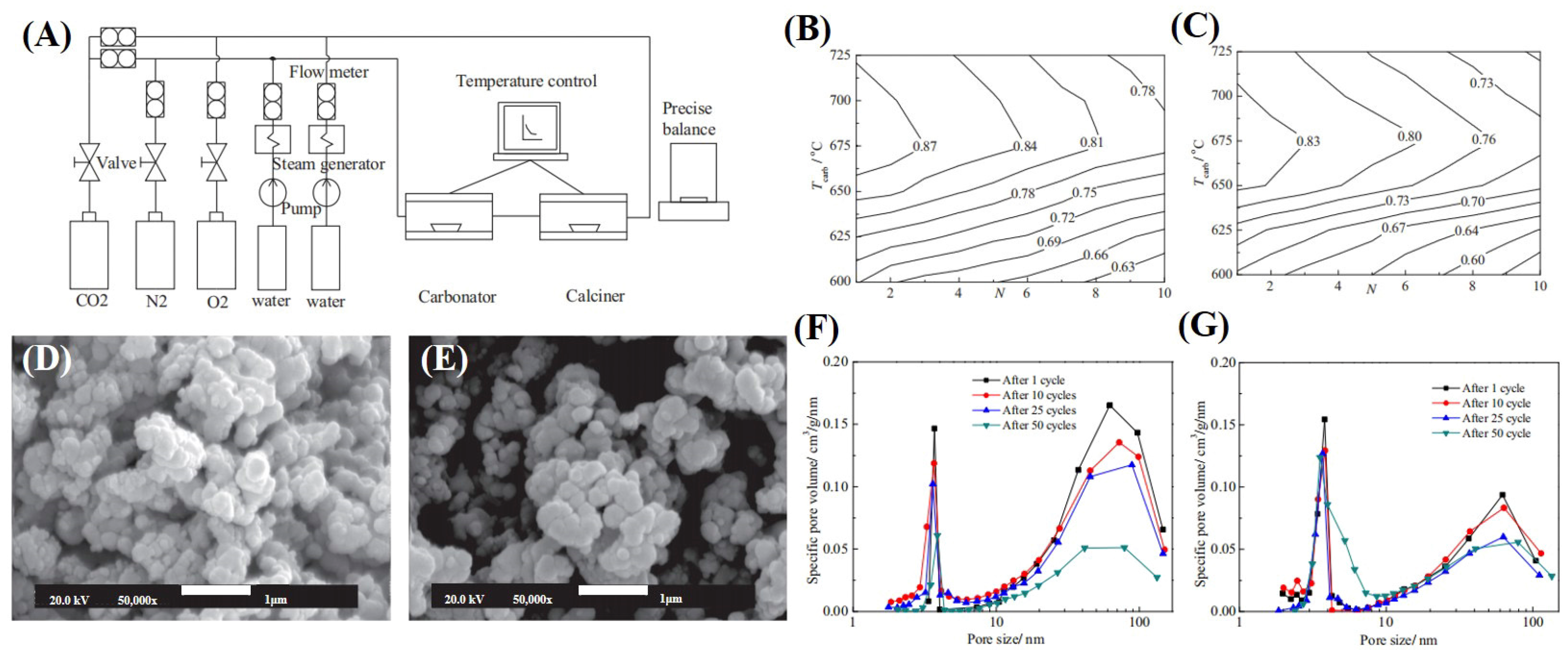

- Chen, H.; Zhang, P.; Duan, Y.; Zhao, C. CO2 capture of calcium based sorbents developed by sol–gel technique in the presence of steam. Chem. Eng. J. 2016, 295, 218–226. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, H.; Zheng, Y.; Chen, Y.; Ma, M.; Wang, X.; Wang, L.; Zeng, D.; Shi, J. A facile in situ hydrophobic layer protected selective etching strategy for the synchronous synthesis/modification of hollow or rattle-type silica nanoconstructs. J. Mater. Chem. 2012, 22, 12553–12561. [Google Scholar] [CrossRef]

- Carrington, M.E.; Rampal, N.; Madden, D.G.; O’Nolan, D.; Casati, N.P.M.; Divitini, G.; Martín-Illán, J.Á.; Tricarico, M.; Cepitis, R.; Çamur, C.; et al. Sol-gel processing of a covalent organic framework for the generation of hierarchically porous monolithic adsorbents. Chem 2022, 8, 2961–2977. [Google Scholar] [CrossRef]

- Fijneman, A.J.; Högblom, J.; Palmlöf, M.; de With, G.; Persson, M.; Friedrich, H. Multiscale Colloidal Assembly of Silica Nanoparticles into Microspheres with Tunable Mesopores. Adv. Funct. Mater. 2020, 30, 2002725. [Google Scholar] [CrossRef]

- Lori, O.; Zion, N.; Honig, H.C.; Elbaz, L. 3D Metal Carbide Aerogel Network as a Stable Catalyst for the Hydrogen Evolution Reaction. ACS Catal. 2021, 11, 13707–13713. [Google Scholar] [CrossRef]

- Luo, Y.; Li, K.; Hu, Y.; Chen, T.; Wang, Q.; Hu, J.; Feng, J.; Feng, J. TiN as Radical Scavenger in Fe-N-C Aerogel Oxygen Reduction Catalyst for Durable Fuel Cell. Small 2024, 20, 2309822. [Google Scholar] [CrossRef] [PubMed]

- Lv, C.; Huang, K.; Fan, Y.; Xu, J.; Lian, C.; Jiang, H.; Zhang, Y.; Ma, C.; Qiao, W.; Wang, J.; et al. Electrocatalytic reduction of carbon dioxide in confined microspace utilizing single nickel atom decorated nitrogen-doped carbon nanospheres. Nano Energy 2023, 111, 108384. [Google Scholar] [CrossRef]

- Martín-Illán, J.Á.; Rodríguez-San-Miguel, D.; Castillo, O.; Beobide, G.; Perez-Carvajal, J.; Imaz, I.; Maspoch, D.; Zamora, F. Macroscopic Ultralight Aerogel Monoliths of Imine-based Covalent Organic Frameworks. Angew. Chem. Int. Ed. 2021, 60, 13969–13977. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.K.; Lin, S.C.; Yan, J.; Zhao, C.Y. Improved durability in thermochemical energy storage using Ti/Al/Mg Co-doped Calcium-based composites with hierarchical Meso/Micro pore structures. Chem. Eng. J. 2022, 450, 138142. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Li, B.; Han, P.; Qi, G.; Gao, D.; Wei, Z.; Tao, S. Facile synthesis of hierarchically porous carbon monolith without templating agent for various applications in energy and catalysis. Carbon 2024, 230, 119645. [Google Scholar] [CrossRef]

- Wu, C.; Huang, H.; Jin, X.; Yan, X.; Wang, H.; Pan, Y.; Zhang, X.; Hong, C. Water-assisted synthesis of phenolic aerogel with superior compression and thermal insulation performance enabled by thick-united nano-structure. Chem. Eng. J. 2023, 464, 142805. [Google Scholar] [CrossRef]

- Zhang, L.; Xia, S.; Zhang, X.; Yao, Y.; Zhang, Y.; Chen, S.; Chen, Y.; Yan, J. Low-Temperature Synthesis of Mesoporous Half-Metallic High-Entropy Spinel Oxide Nanofibers for Photocatalytic CO2 Reduction. ACS Nano 2024, 18, 5322–5334. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Horozov, T.; Bismarck, A. One-pot approach to fabrication of porous polymers from Pickering emulsion templates. Polymer 2022, 261, 125406. [Google Scholar] [CrossRef]

- Wen, Z.; Yang, H.; Lv, M.; Yu, C.; Li, Y. A compressible porous superhydrophobic material constructed by a multi-template high internal phase emulsion method for oil–water separation. RSC Adv. 2023, 13, 25920–25929. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Jeon, J.; Chae, J.; Yuk, S.; Lee, D.-H.; Doo, G.; Lee, D.W.; Hyun, J.; Kwen, J.; Choi, S.Q.; et al. Single-Step Fabrication of a Multiscale Porous Catalyst Layer by the Emulsion Template Method for Low Pt-Loaded Proton Exchange Membrane Fuel Cells. ACS Appl. Energy Mater. 2021, 4, 4012–4020. [Google Scholar] [CrossRef]

- Hang, T.; Zhou, L.; Li, Z.; Zheng, Y.; Yao, Y.; Cao, Y.; Xu, C.; Jiang, S.; Chen, Y.; Zheng, J. Constructing gradient reflection and scattering porous framework in composite aerogels for enhanced microwave absorption. Carbohydrate Polymers 2024, 329. [Google Scholar] [CrossRef]

- Yuan, L.; Li, X.; Ge, L.; Jia, X.; Lei, J.; Mu, C.; Li, D. Emulsion Template Method for the Fabrication of Gelatin-Based Scaffold with a Controllable Pore Structure. ACS Appl. Mater. Interfaces 2018, 11, 269–277. [Google Scholar] [CrossRef] [PubMed]

- Bai, X.; Liu, J.; Xu, Y.; Ma, Y.; Liu, Z.; Pan, J. CO2 Pickering emulsion in water templated hollow porous sorbents for fast and highly selective uranium extraction. Chem. Eng. J. 2020, 387, 124096. [Google Scholar] [CrossRef]

- Liu, S.; Tang, N.; Huang, H.; Zhang, X.; Lu, R.; Li, Y. Green and eco-friendly porous imprinted hydrogels with cellulose nanocrystals-based precise-designed hyperbranched sites for high-accuracy separation and purification of naringin. Chem. Eng. J. 2024, 493, 152821. [Google Scholar] [CrossRef]

- Luo, J.; Dai, Z.; Feng, M.; Chen, X.; Sun, C.; Xu, Y. Hierarchically porous carbon derived from natural Porphyra for excellent electromagnetic wave absorption. J. Mater. Sci. Technol. 2022, 129, 206–214. [Google Scholar] [CrossRef]

- Mudassir, M.A.; Aslam, H.Z.; Ansari, T.M.; Zhang, H.; Hussain, I. Fundamentals and Design-Led Synthesis of Emulsion-Templated Porous Materials for Environmental Applications. Adv. Sci. 2021, 8, 2102540. [Google Scholar] [CrossRef] [PubMed]

- Mudassir, M.A.; Kousar, S.; Ehsan, M.; Usama, M.; Sattar, U.; Aleem, M.; Naheed, I.; Saeed, O.B.; Ahmad, M.; Akbar, H.F.; et al. Emulsion-derived porous carbon-based materials for energy and environmental applications. Renew. Sustain. Energy Rev. 2023, 185, 113594. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Zhu, H.; Li, B.-G.; Zhu, S. In-situ construction of hierarchically porous MOF monoliths using high internal phase emulsion templates. Chem. Eng. J. 2023, 456, 141026. [Google Scholar] [CrossRef]

- Yang, G.; Wu, F.; Wei, Z.; Yang, K.; Zhang, C.; Ma, Y.; Pan, J. Capturing lithium using functional macroporous microspheres with multiple chambers from one-step double emulsion via a tailoring supramolecular route and postsynthetic interface modification. Chem. Eng. J. 2020, 389, 124372. [Google Scholar] [CrossRef]

- Zhao, W.; Jia, H.; Qu, J.; Yang, C.; Wang, Y.; Zhu, J.; Wu, H.; Liu, G. Sol-gel synthesis of TiO2-SiO2 hybrid films with tunable refractive index for broadband antireflective coatings covering the visible range. J. Sol Gel Sci. Technol. 2022, 107, 105–121. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, T.; Zhang, M.; Cao, G. A Phase-Separation Route to Synthesize Porous CNTs with Excellent Stability for Na + Storage. Small 2017, 13, 1604045. [Google Scholar] [CrossRef] [PubMed]

- Sato, Y.; Kanamori, K.; Nakanishi, K. Preparation of Hierarchically Porous Niobium (V) Oxide and Alkaline Niobate Monoliths via Sol–Gel Accompanied by Phase Separation. Chem. Mater. 2023, 35, 5177–5184. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, R.; Xu, Y.; Li, D.; Ge, H. Synthesis of Porous MgF2 Coating by a Sol–Gel Method Accompanied by Phase Separation. Coatings 2023, 13, 1083. [Google Scholar] [CrossRef]

- Jiao, F.; Shaju, K.M.; Bruce, P.G. Synthesis of Nanowire and Mesoporous Low-Temperature LiCoO2 by a Post-Templating Reaction. Angew. Chem. Int. Ed. 2005, 44, 6550–6553. [Google Scholar] [CrossRef] [PubMed]

- Bai, Z.; Jia, K.; Zhang, S.; Lin, G.; Huang, Y.; Liu, X. Surface Segregation-Induced Superwetting Separation Membranes with Hierarchical Surface Structures and Internalized Gel Networks. Adv. Funct. Mater. 2022, 32, 2204612. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Z.; Serna, J.A.; Debastiani, R.; Gomez, J.E.U.; Lu, L.; Yang, W.; Dong, Z.; Levkin, P.A. Enhancing Temperature Responsiveness of PNIPAM Through 3D-Printed Hierarchical Porosity. Adv. Funct. Mater. 2024, 34, 2403794. [Google Scholar] [CrossRef]

- Pradyasti, A.; Kim, H.J.; Hyun, W.J.; Kim, M.H. Cellulose/GO monolith covered with Pd–Pt bimetallic nanocrystals for continuous-flow catalytic reduction of hexavalent chromium. Carbohydr. Polym. 2024, 330, 121837. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.-y.; Zhu, G.-d.; Yi, Z.; Zhou, Y.; Gao, C.-j. Critical contributions of additives on the fabrication of asymmetric isoporous membranes from block copolymers: A review. Chem. Eng. J. 2021, 424, 128912. [Google Scholar] [CrossRef]

- Yin, S.; Song, L.; Xia, S.; Cheng, Y.; Hohn, N.; Chen, W.; Wang, K.; Cao, W.; Hou, S.; Müller-Buschbaum, P. Key Factors for Template-Oriented Porous Titania Synthesis: Solvents and Catalysts. Small Methods 2020, 4, 1900689. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, X.; Che, R.; Li, D.; Zeng, X.; Kong, F.; Shao, L.; Li, X.; Xu, F. 3D cellulose scaffold with gradient pore structure controlled by hydrogen bond competition: Super-strength and multifunctional oil/water separation. Carbohydr. Polym. 2024, 344, 122544. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Su, Y.; Liu, Z.; Fang, Y. Shape-Controlled Synthesis of Covalent Organic Frameworks Enabled by Polymerization-Induced Phase Separation. Small 2022, 19, 2205501. [Google Scholar] [CrossRef]

- Hye Kwon, Y.; Kiang, C.; Benjamin, E.; Crawford, P.; Nair, S.; Bhave, R. Krypton-xenon separation properties of SAPO-34 zeolite materials and membranes. AIChE J. 2016, 63, 761–769. [Google Scholar] [CrossRef]

- Yang, X.-Y.; Chen, L.-H.; Li, Y.; Rooke, J.C.; Sanchez, C.; Su, B.-L. Hierarchically porous materials: Synthesis strategies and structure design. Chem. Soc. Rev. 2017, 46, 481–558. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ge, P.; Zhang, Y.; Zhang, B.; Yao, Z.; Wang, Z.; Li, X.; Hu, M. Highly Oriented Thin Membrane Fabrication with Hierarchically Porous Zeolite Seed. Cryst. Growth Des. 2018, 18, 4544–4554. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, S.; Zhang, X.; Chen, S.; Wang, L.; Zhang, C.; Gao, S.; Yu, D.; Fan, X.; Cheng, Y.; et al. Research progress on the preparation of transition metal-modified zeolite catalysts and their catalytic performance for the purification of engine exhausts. J. Mater. Chem. A 2024, 12, 16293–16328. [Google Scholar] [CrossRef]

- Choi, O.; Veetil, K.A.; Park, C.H.; Kim, H.; Kim, T.-H. Fabrication of a high-performance MOF-COP-based porous hollow fiber membrane for carbon dioxide separation. Chem. Eng. J. 2024, 497, 154746. [Google Scholar] [CrossRef]

- Kweon, S.; Cho, Y.; Park, J.S.; Ryu, J.; Yoo, C.G.; Min, H.-K.; Park, M.B. A nickel silicate MFI-type zeolite catalyst prepared by interzeolite transformation: Tailoring the catalytic active sites for glucose conversion. J. Mater. Chem. A 2024, 12, 20894–20909. [Google Scholar] [CrossRef]

- Lee, S.; Park, Y.; Choi, M. Cooperative Interplay of Micropores/Mesopores of Hierarchical Zeolite in Chemical Production. ACS Catal. 2024, 14, 2031–2048. [Google Scholar] [CrossRef]

- Lee, S.; Thuan Khiet Nguyen, T.; Kweon, S.; Park, M.B. Nickel silicate CHA-type zeolite prepared by interzeolite transformation and its catalytic activity in dry reforming of methane. Chem. Eng. J. 2024, 498, 155602. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, X.; Muhammad, F.; Zhang, J. Preparation of hierarchically porous zeolite templated carbon from fly ash with investigation into the adsorption behavior towards volatile organic compound. J. Environ. Chem. Eng. 2024, 12, 112254. [Google Scholar] [CrossRef]

- Lu, J.; Xu, Z.; Yue, Y.; Bao, X.; Lin, M.; Zhu, H. Pt-Zn clusters encapsulated in hierarchical MFI zeolite for efficient propane dehydrogenation. Chem. Eng. J. 2024, 484, 149369. [Google Scholar] [CrossRef]

- Xu, W.; Chen, Y.; Niederberger, M.; Tervoort, E.; Mei, J.; Peng, D.L. Self-Assembled Preparation of Porous Nickel Phosphide Superparticles with Tunable Phase and Porosity for Efficient Hydrogen Evolution. Small 2024, 20, 2309435. [Google Scholar] [CrossRef] [PubMed]

- Xue, W.-L.; Kolodzeiski, P.; Aucharova, H.; Vasa, S.; Koutsianos, A.; Pallach, R.; Song, J.; Frentzel-Beyme, L.; Linser, R.; Henke, S. Highly porous metal-organic framework liquids and glasses via a solvent-assisted linker exchange strategy of ZIF-8. Nat. Commun. 2024, 15, 4420. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, Y.; Zu, Y.; Yan, K.; Luo, Y.; Xing, E.; Qin, Y.; Mei, Y.; Shu, X. Disassembly-reassembly-phosphating strategy to fabricate hydrothermally-stable hierarchical P@ZSM-5 zeolite for efficient methanol-to-propylene. Chem. Eng. J. 2024, 497, 154755. [Google Scholar] [CrossRef]

- Sheng, N.; Xu, H.; Liu, X.; Chu, Y.; Han, S.; Meng, X.; Liu, Y.; Liu, C.; Xiao, F.-S. Self-formation of hierarchical SAPO-11 molecular sieves as an efficient hydroisomerization support. Catal. Today 2020, 350, 165–170. [Google Scholar] [CrossRef]

- Zhang, X.; Cheng, Y.; Wang, S.; Fang, C.; Chen, J.; Li, M.; Zhao, W. Self-assembly of porous cellulose fibers and the incorporation of graphene carbon quantum dots for stable luminescence. Carbohydr. Polym. 2023, 314, 120928. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Ju, M.; Lee, J.; Hwang, J.; Lee, J. Polymer Interfacial Self-Assembly Guided Two-Dimensional Engineering of Hierarchically Porous Carbon Nanosheets. J. Am. Chem. Soc. 2020, 142, 9250–9257. [Google Scholar] [CrossRef]

- Chang, H.; Liu, X.; Zhao, S.; Liu, Z.; Lv, R.; Zhang, Q.; Yi, T.F. Self-Assembled 3D N/P/S-Tridoped Carbon Nanoflower with Highly Branched Carbon Nanotubes as Efficient Bifunctional Oxygen Electrocatalyst Toward High-Performance Rechargeable Zn-Air Batteries. Adv. Funct. Mater. 2023, 34, 2313491. [Google Scholar] [CrossRef]

- Guo, Y.; de Vasconcelos, L.S.; Manohar, N.; Geng, J.; Johnston, K.P.; Yu, G. Highly Elastic Interconnected Porous Hydrogels through Self-Assembled Templating for Solar Water Purification. Angew. Chem. Int. Ed. 2021, 61, 2114074. [Google Scholar] [CrossRef]

- Li, C.; Li, Q.; Kaneti, Y.V.; Hou, D.; Yamauchi, Y.; Mai, Y. Self-assembly of block copolymers towards mesoporous materials for energy storage and conversion systems. Chem. Soc. Rev. 2020, 49, 4681–4736. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Hudson, Z.M. Macro-/mesoporous Metal–Organic Frameworks Templated by Amphiphilic Block Copolymers Enable Enhanced Uptake of Large Molecules. Adv. Funct. Mater. 2023, 33, 2214262. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, Z.; Li, M.; Li, J.; Zhuang, W.; Yang, X.; Wu, S.; Zhang, J. Construction of Single Ni Atom-Immobilized ZIF-8 with Ordered Hierarchical Pore Structures for Selective CO2 Photoreduction. ACS Catal. 2023, 13, 6630–6640. [Google Scholar] [CrossRef]

- Su, X.; Sun, Y.; Jin, L.; Zhang, L.; Yang, Y.; Kerns, P.; Liu, B.; Li, S.; He, J. Hierarchically porous Cu/Zn bimetallic catalysts for highly selective CO2 electroreduction to liquid C2 products. Appl. Catal. B Environ. 2020, 269, 118800. [Google Scholar] [CrossRef]

- Sun, H.; Tang, F.; Bi, Y.; Sun, H.; Huang, L.; Jiang, F.; Chen, L.; Li, J. Hierarchically Porous Cellulose Membrane via Self-Assembly Engineering for Ultra High-Power Thermoelectrical Generation in Natural Convection. Adv. Funct. Mater. 2023, 33, 2307960. [Google Scholar] [CrossRef]

- Tu, S.; Su, H.; Sui, D.; He, Y.; Cheng, M.; Bai, P.; Zhang, C.; Sun, P.; Wang, C.; Jiang, J.; et al. Mesoporous carbon nanomaterials with tunable geometries and porous structures fabricated by a surface-induced assembly strategy. Energy Storage Mater. 2021, 35, 602–609. [Google Scholar] [CrossRef]

- Zhang, T.; Li, T.; Gao, M.; Lu, W.; Chen, Z.; Ong, W.L.; Wong, A.S.W.; Yang, L.; Kawi, S.; Ho, G.W. Ligand Mediated Assembly of CdS Colloids in 3D Porous Metal–Organic Framework Derived Scaffold with Multi-Sites Heterojunctions for Efficient CO2 Photoreduction. Adv. Energy Mater. 2024, 14, 2400388. [Google Scholar] [CrossRef]

- Kapilov-Buchman, K.; Portal, L.; Zhang, Y.; Fechler, N.; Antonietti, M.; Silverstein, M.S. Hierarchically porous carbons from an emulsion-templated, urea-based deep eutectic. J. Mater. Chem. A 2017, 5, 16376–16385. [Google Scholar] [CrossRef]

- Gros, Q.; Duval, J.; West, C.; Lesellier, E. On-line supercritical fluid extraction-supercritical fluid chromatography (SFE-SFC) at a glance: A coupling story. TrAC Trends Anal. Chem. 2021, 144, 116433. [Google Scholar] [CrossRef]

- Zhuang, Z.; Liu, Y.; Wei, W.; Shi, J.; Jin, H. Preparation of biochar adsorption material from walnut shell by supercritical CO2 pretreatment. Biochar 2024, 6, 11. [Google Scholar] [CrossRef]

- Bousige, C.; Levitz, P.; Coasne, B. Bridging scales in disordered porous media by mapping molecular dynamics onto intermittent Brownian motion. Nat. Commun. 2021, 12, 1043. [Google Scholar] [CrossRef] [PubMed]

- Jun, Y.-S.; Hyun, B.G.; Hamidinejad, M.; Habibpour, S.; Yu, A.; Park, C.B. Maintaining electrical conductivity of microcellular MWCNT/TPU composites after deformation. Compos. Part B Eng. 2021, 223, 109113. [Google Scholar] [CrossRef]

- Bai, J.; Chu, J.; Yin, X.; Wang, J.; Tian, W.; Huang, Q.; Jia, Z.; Wu, X.; Guo, H.; Qin, Z. Synthesis of amidoximated polyacrylonitrile nanoparticle/graphene composite hydrogel for selective uranium sorption from saline lake brine. Chem. Eng. J. 2020, 391, 123553. [Google Scholar] [CrossRef]

- Ju, P.; Liu, Q.; Zhang, H.; Chen, R.; Liu, J.; Yu, J.; Liu, P.; Zhang, M.; Wang, J. Hyperbranched topological swollen-layer constructs of multi-active sites polyacrylonitrile (PAN) adsorbent for uranium (VI) extraction from seawater. Chem. Eng. J. 2019, 374, 1204–1213. [Google Scholar] [CrossRef]

- Li, X.-H.; Liu, Y.-W.; Liu, S.-M.; Wang, S.; Xu, L.; Zhang, Z.; Luo, F.; Lu, Y.; Liu, S.-X. A gel-like/freeze-drying strategy to construct hierarchically porous polyoxometalate-based metal–organic framework catalysts. J. Mater. Chem. A 2018, 6, 4678–4685. [Google Scholar] [CrossRef]

- Li, C.; Yang, J.; Pachfule, P.; Li, S.; Ye, M.-Y.; Schmidt, J.; Thomas, A. Ultralight covalent organic framework/graphene aerogels with hierarchical porosity. Nat. Commun. 2020, 11, 4712. [Google Scholar] [CrossRef] [PubMed]

- Gu, W.; Sheng, J.; Huang, Q.; Wang, G.; Chen, J.; Ji, G. Environmentally Friendly and Multifunctional Shaddock Peel-Based Carbon Aerogel for Thermal-Insulation and Microwave Absorption. Nano-Micro Lett. 2021, 13, 102. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Huang, H.; Tai, J.; Wu, X.; Guo, Z.; Shen, X.; Cui, S.; Chen, X. The catalytic activity of reduced graphene aerogel anchored with CoFe2O4 spinel via self-assembly technique for enhanced oxygen evolution reaction. Carbon 2024, 219, 118847. [Google Scholar] [CrossRef]

- Shao, S.; Guo, C.; Wang, H.; Wang, S.; Zhao, T.; Tang, Y.; Liu, J.; Wang, F. Multifunctional graphene/Ti3C2T MXene aerogel inlaid with Ni@TiO2 core-shell microspheres for high-efficiency electromagnetic wave absorption and thermal insulation. Chem. Eng. J. 2024, 488, 150918. [Google Scholar] [CrossRef]

- Song, Y.; Bao, J.; Hu, Y.; Xu, M.; Yang, Z.; Liu, Y.; Yang, Q.; Xiong, C.; Shi, Z. Ultra-porous cellulose nanofibril aerogel films as excellent triboelectric positive materials via direct freeze-drying of dispersion. Nano Energy 2022, 103, 107832. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, Z.; Liu, Y.; Li, Z.; Leng, J. Lightweight carbon nanotube/aramid nanofiber aerogel with superior electromagnetic wave absorption, thermal insulation, and flame resistance. Carbon 2024, 225, 119105. [Google Scholar] [CrossRef]

- Wang, Q.; Li, L.; Tian, Y.; Kong, L.; Cai, G.; Zhang, H.; Zhang, J.; Zuo, W.; Wen, B. Shapeable amino-functionalized sodium alginate aerogel for high-performance adsorption of Cr (VI) and Cd (II): Experimental and theoretical investigations. Chem. Eng. J. 2022, 446, 137430. [Google Scholar] [CrossRef]

- Wang, X.; Yuan, Y.; Sun, X.; Qiang, R.; Xu, Y.; Ma, Y.; Zhang, E.; Li, Y. Lightweight, Flexible, and Thermal Insulating Carbon/SiO2@CNTs Composite Aerogel for High-Efficiency Microwave Absorption. Small 2024, 20, 2311657. [Google Scholar] [CrossRef] [PubMed]

- Xiao, H.; Lv, J.-b.; Tan, W.; He, X.; Chen, M.-h.; Zeng, K.; Hu, J.-h.; Yang, G. Ultrasound-assisted freeze-drying process for polyimide aerogels. Chem. Eng. J. 2022, 450, 138344. [Google Scholar] [CrossRef]

- Yang, T.; Ma, C.; Lin, C.; Wang, J.; Qiao, W.; Ling, L.; Yu, Z.; Zhang, Y. Innovative fabrication of ultrasensitive and durable graphene fiber aerogel for flexible pressure sensors. Carbon 2024, 229, 119484. [Google Scholar] [CrossRef]

- Zhou, J.; Hu, X.; Luo, Z.; Li, X.; Zhang, W.-x.; Deng, Z. Nanocellulose encapsulated nZVI@UiO-66-NH2 aerogel for high-efficiency p-chloronitrobenzene removal with selective reduction. J. Hazard. Mater. 2025, 481, 136520. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.-B.; Joo, W.-H.; Kang, H.-Y.; Lee, J.-C.; Ahn, I.-K.; Kim, J.-Y.; Kim, H.G.; Kim, M.; Nam, D.-H.; Joo, Y.-C. Fabrication of Ni Nanoparticle-Embedded Porous Carbon Nanofibers Through Selective Etching of Selectively Oxidized MgO. Electron. Mater. Lett. 2022, 18, 198–204. [Google Scholar] [CrossRef]

- Miyake, M.; Tanaka, Y.; Ikenoue, T.; Hirato, T. Fabrication of micron-sized three-dimensional porous Al from an Al–Zn monotectoid alloy via selective etching and Al passivation. J. Mater. Sci. 2023, 58, 8169–8177. [Google Scholar] [CrossRef]

- Yamada, S. Nanoporous Cu Prepared through Dealloying by Selectively Etching an Alkaline Metal with Saline. ACS Appl. Nano Mater. 2023, 6, 7229–7233. [Google Scholar] [CrossRef]

- Jeoung, S.; Ju, I.T.; Kim, J.H.; Joo, S.H.; Moon, H.R. Hierarchically porous adamantane-shaped carbon nanoframes. J. Mater. Chem. A 2018, 6, 18906–18911. [Google Scholar] [CrossRef]

- Jung, S.; Lee, J.-R.; Won, Y.; Lee, D.-H.; Park, Y.C.; Bae, Y.-S.; Kim, H. Hierarchical porous carbon beads for selective CO2 capture. J. CO2 Util. 2021, 51, 101659. [Google Scholar] [CrossRef]

- Yun, Y.H.; Kim, K.; Lee, C.; An, B.-S.; Kwon, J.H.; Lee, S.; Kim, M.; Seo, J.; Park, J.H.; Kim, B.-H.; et al. Electrochemical partial reduction of Ni (OH)2 to Ni (OH)2/Ni via coupled oxidation of an interfacing NiAl intermetallic compound for robust hydrogen evolution. J. Energy Chem. 2023, 82, 560–571. [Google Scholar] [CrossRef]

- Zhang, L.-Y.; Li, L.; Li, M.; Liu, Z.-Q.; Wei, X.-Y.; Ma, H.; Cong, X.-S. Catalytic hydrodeoxygenation of lignin enhanced by selectively etching ZSM-5. J. Energy Inst. 2024, 117, 101838. [Google Scholar] [CrossRef]

- Zheng, K.; Benedetti, M.F.; Jain, R.; Guy, B.M.; Pollmann, K.; van Hullebusch, E.D. Selective leaching of indium from spent LCD screens by siderophore desferrioxamine E. J. Hazard. Mater. 2024, 469, 134013. [Google Scholar] [CrossRef] [PubMed]

- Li, H.-Y.; Li, C.; Wang, Y.-Y.; Dong, W.-D.; Zhang, X.-K.; Sun, M.-H.; Li, Y.; Su, B.-L. Pore structure unveiling effect to boost lithium-selenium batteries: Selenium confined in hierarchically porous carbon derived from aluminum based MOFs. Chem. Synth. 2023, 3, 30. [Google Scholar] [CrossRef]

- Liu, S.Y.; Sun, Q.Q.; Hang, P.Y.; Sun, X.H.; Zhou, C.Q.; Han, J.; Guo, R. β-cyclodextrin mediated construction of porous helical nanoribbons from oligoaniline derivatives. Chem. Synth. 2022, 2, 18. [Google Scholar] [CrossRef]

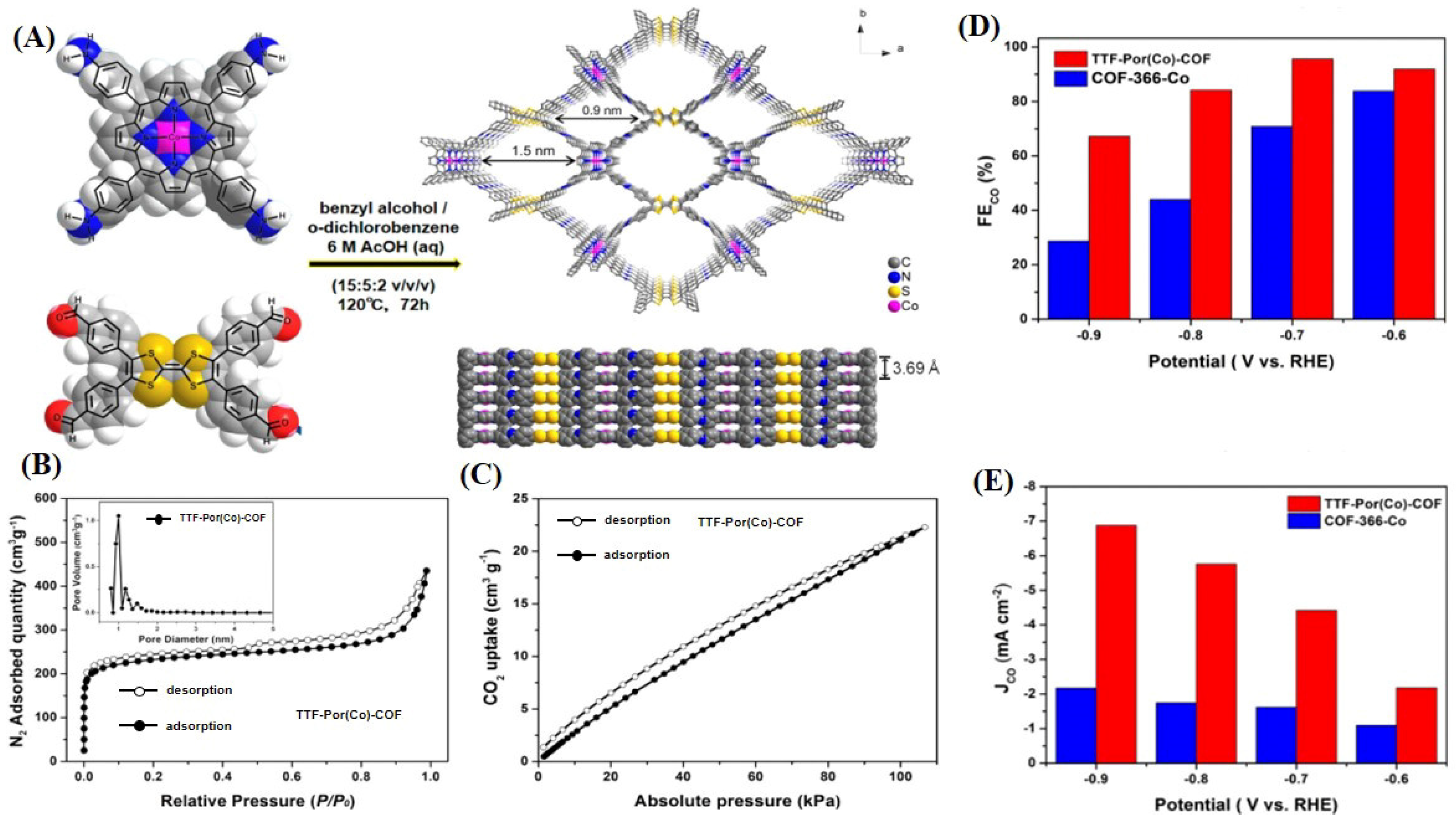

- Wu, Q.-J.; Liang, J.; Huang, Y.-B.; Cao, R. Thermo-, Electro-, and Photocatalytic CO2 Conversion to Value-Added Products over Porous Metal/Covalent Organic Frameworks. Acc. Chem. Res. 2022, 55, 2978–2997. [Google Scholar] [CrossRef] [PubMed]

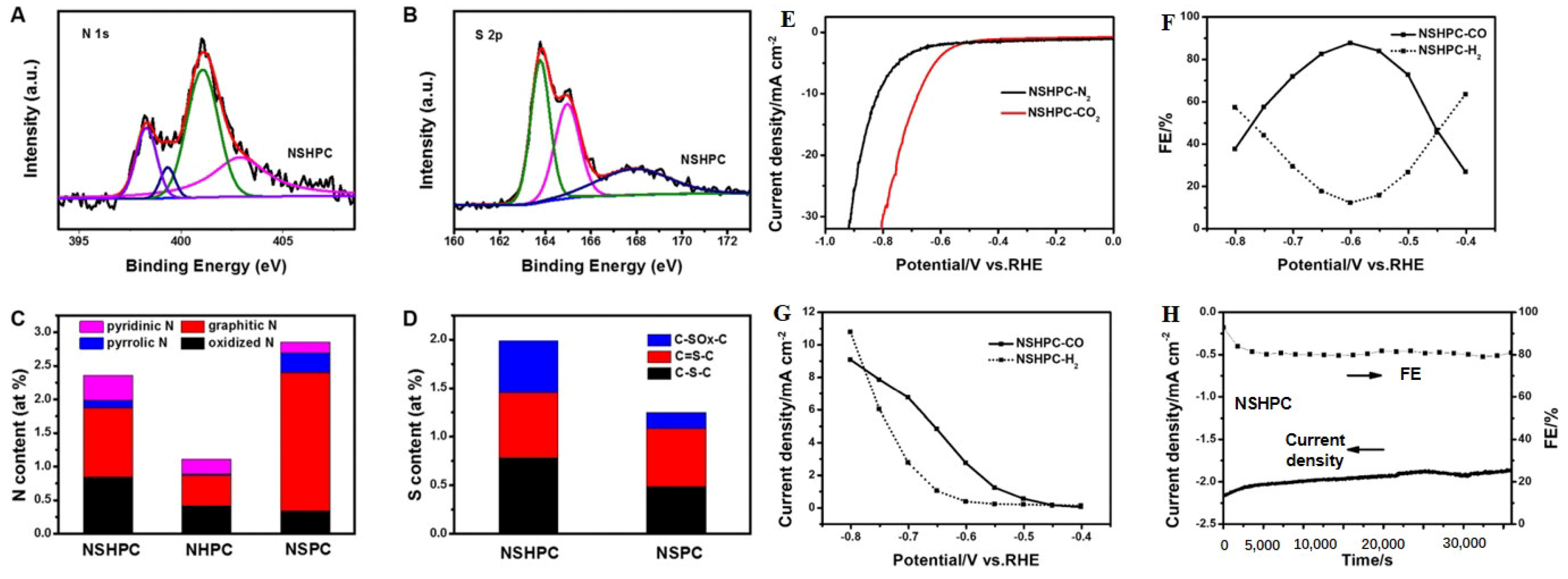

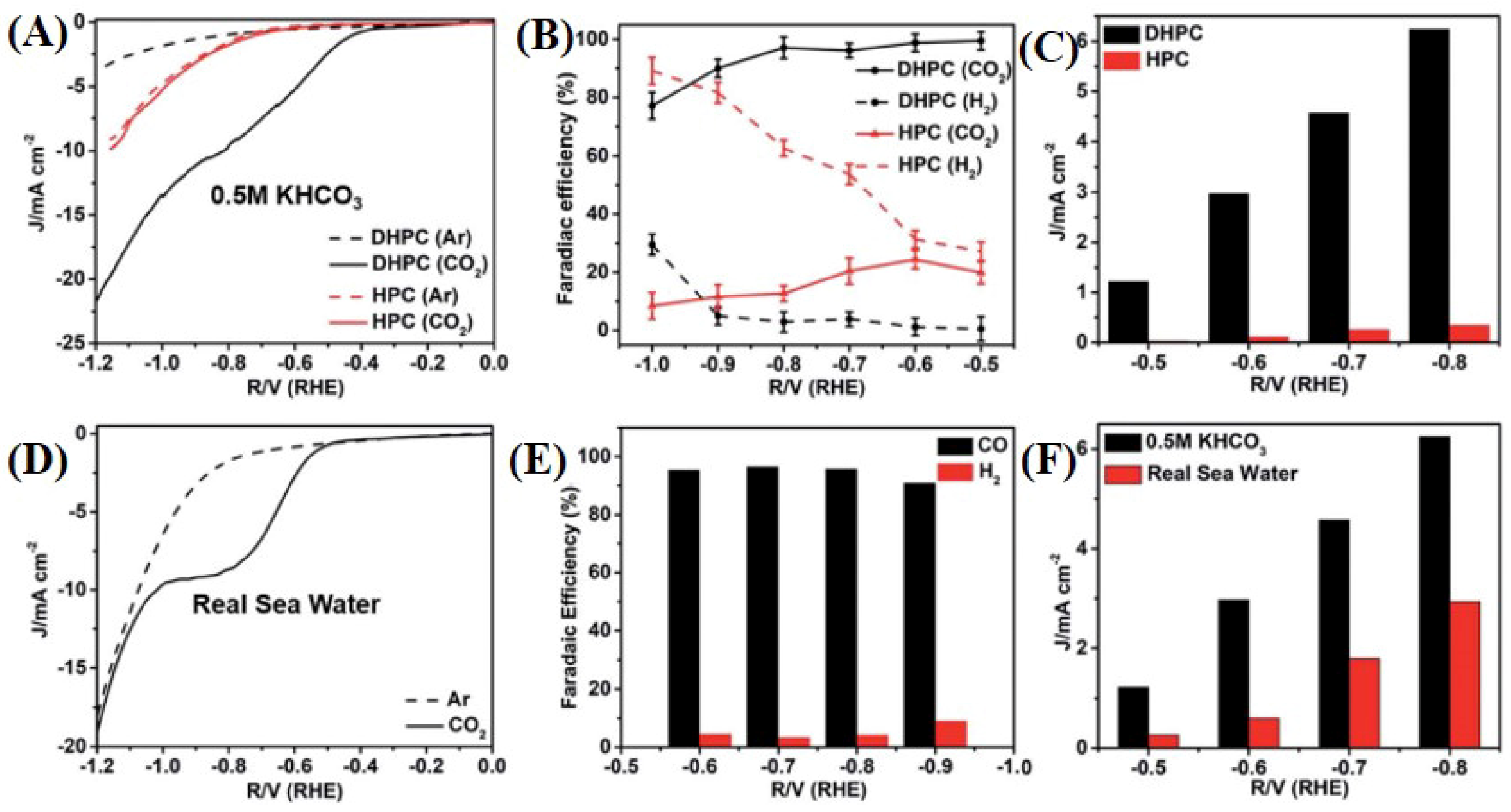

- Li, R.; Liu, F.; Zhang, Y.; Guo, M.; Liu, D. Nitrogen, Sulfur Co-Doped Hierarchically Porous Carbon as a Metal-Free Electrocatalyst for Oxygen Reduction and Carbon Dioxide Reduction Reaction. ACS Appl. Mater. Interfaces 2020, 12, 44578–44587. [Google Scholar] [CrossRef] [PubMed]

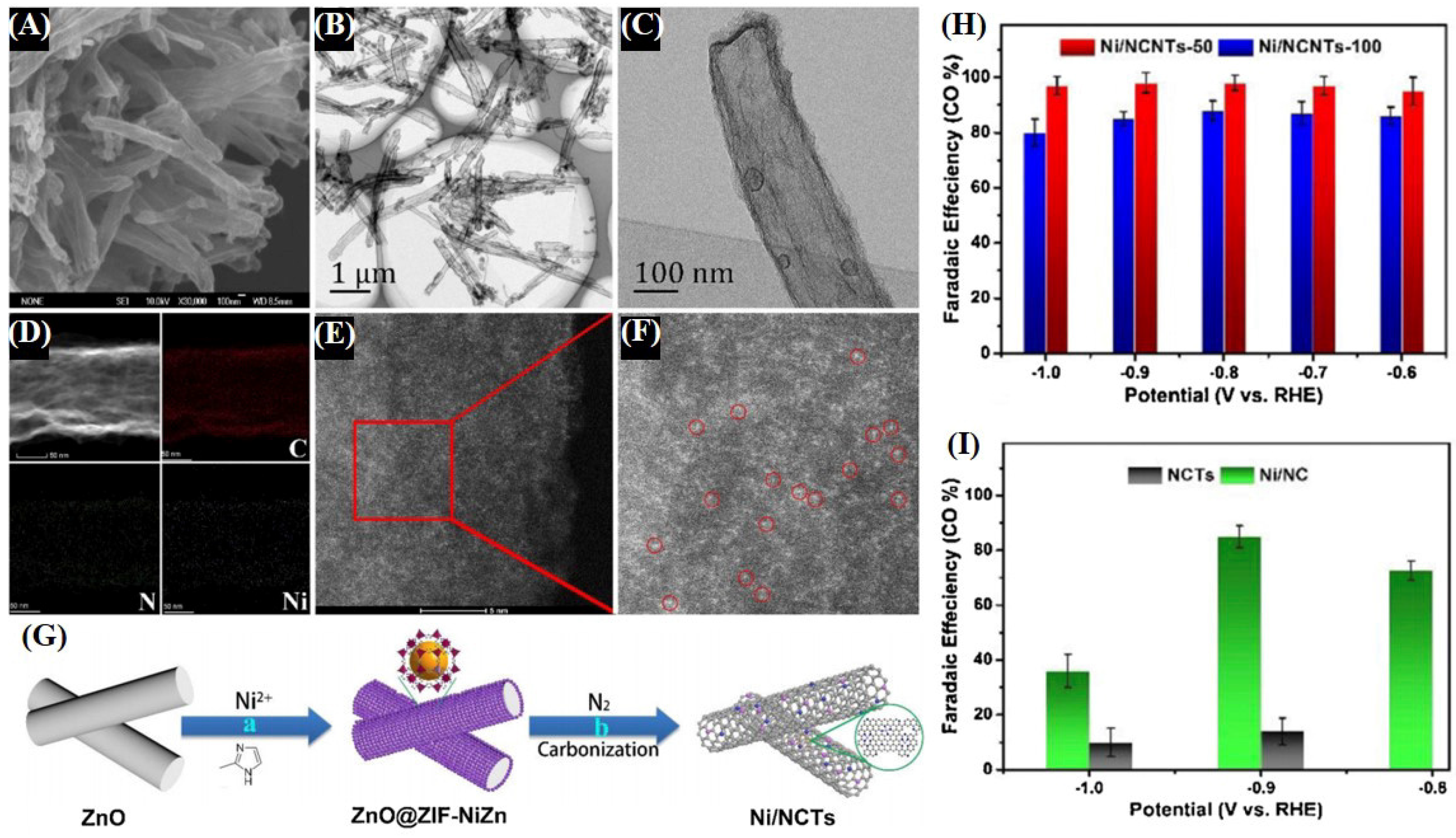

- Hou, Y.; Liang, Y.-L.; Shi, P.-C.; Huang, Y.-B.; Cao, R. Atomically dispersed Ni species on N-doped carbon nanotubes for electroreduction of CO2 with nearly 100% CO selectivity. Appl. Catal. B Environ. 2020, 271, 118929. [Google Scholar] [CrossRef]

- Hou, S.-Z.; Zhang, X.-D.; Yuan, W.-W.; Li, Y.-X.; Gu, Z.-Y. Indium-Based Metal–Organic Framework for High-Performance Electroreduction of CO2 to Formate. Inorg. Chem. 2020, 59, 11298–11304. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, C.; Wang, D.; Yang, C.; Cui, X.; Gao, X.J.; Zhang, Z. A hexacoordinated Bi3+-based ellagate MOF with acid/base resistance boosting carbon dioxide electroreduction to formate. J. Mater. Chem. A 2022, 10, 20018–20023. [Google Scholar] [CrossRef]

- Liu, J.; Yang, D.; Zhou, Y.; Zhang, G.; Xing, G.; Liu, Y.; Ma, Y.; Terasaki, O.; Yang, S.; Chen, L. Tricycloquinazoline-Based 2D Conductive Metal–Organic Frameworks as Promising Electrocatalysts for CO2Reduction. Angew. Chem. Int. Ed. 2021, 60, 14473–14479. [Google Scholar] [CrossRef] [PubMed]

- Shimoni, R.; Shi, Z.; Binyamin, S.; Yang, Y.; Liberman, I.; Ifraemov, R.; Mukhopadhyay, S.; Zhang, L.; Hod, I. Electrostatic Secondary-Sphere Interactions That Facilitate Rapid and Selective Electrocatalytic CO2 Reduction in a Fe-Porphyrin-Based Metal–Organic Framework. Angew. Chem. Int. Ed. 2022, 61, 2206085. [Google Scholar] [CrossRef]

- Zhang, X.-D.; Huang, L.-R.; Wu, J.-X.; Gu, Z.-Y. Enhancing selectivity through decrypting the uncoordinated zirconium sites in MOF electrocatalysts. Chem. Commun. 2021, 57, 5191–5194. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Feng, L.; Pang, J.; Li, J.; Huang, N.; Day, G.S.; Cheng, L.; Drake, H.F.; Wang, Y.; Lollar, C.; et al. Photosensitizer-Anchored 2D MOF Nanosheets as Highly Stable and Accessible Catalysts toward Artemisinin Production. Adv. Sci. 2019, 6, 1802059. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.-L.; Chen, H.-Y.; Han, Y.-X.; Zhao, Z.-H.; Liao, P.-Q.; Chen, X.-M. A Porous π–π Stacking Framework with Dicopper (I) Sites and Adjacent Proton Relays for Electroreduction of CO2 to C2+ Products. J. Am. Chem. Soc. 2022, 144, 13319–13326. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Q.; Qiu, Z.F.; Zhang, X.Y.; Chen, J.Q.; Zhao, Y.; Gong, F.; Sun, W.Y. Tailoring Coordination Microenvironment of Cu (I) in Metal–Organic Frameworks for Enhancing Electroreduction of CO2 to CH4. Adv. Funct. Mater. 2022, 32, 2203677. [Google Scholar] [CrossRef]

- Cui, J.-W.; Yang, J.-H.; Sun, J.-K. Organic cage-based frameworks: From synthesis to applications. Chem. Synth. 2024, 4, 30. [Google Scholar] [CrossRef]

- Chen, J.; Abazari, R.; Adegoke, K.A.; Maxakato, N.W.; Bello, O.S.; Tahir, M.; Tasleem, S.; Sanati, S.; Kirillov, A.M.; Zhou, Y. Metal–organic frameworks and derived materials as photocatalysts for water splitting and carbon dioxide reduction. Coord. Chem. Rev. 2022, 469, 214664. [Google Scholar] [CrossRef]

- Huang, J.-M.; Zhang, X.-D.; Huang, J.-Y.; Zheng, D.-S.; Xu, M.; Gu, Z.-Y. MOF-based materials for electrochemical reduction of carbon dioxide. Coord. Chem. Rev. 2023, 494, 215333. [Google Scholar] [CrossRef]

| Method | Structure | FE (%)/Yield (μmol/g) | Vp (cm3/g) | SBET (m2/g) | Ref. |

|---|---|---|---|---|---|

| Surfactant templating | Meso–micro | - | 0.12 | 46.2 | [51] |

| Surfactant templating | Meso–micro | 42.2 μmol/g | 0.30 | 76.0 | [55] |

| Surfactant templating | Meso–micro | 360.0 μmol/g | 0.05 | 25.0 | [59] |

| Replication | Macro–meso–micro | 81.1% | 0.15 | 270.2 | [60] |

| Replication | Macro–meso–micro | 79% | 0.54 | 888.9 | [70] |

| Replication | Macro–meso–micro | - | 0.25 | 913.0 | [71] |

| Replication | Macro–meso–micro | - | 0.80 | 1175.0 | [74] |

| Sol–gel | Meso–micro | - | 0.99 | 1122 | [80] |

| Sol–gel | Meso–micro | - | 0.35 | 188 | [82] |

| Sol–gel | Meso–micro | 96.6% | 0.92 | 816 | [84] |

| Sol–gel | Macro–meso–micro | 81.1% | - | 269 | [86] |

| Method | Structure | FE (%)/Yield (μmol/g) | Vp (cm3/g) | SBET (m2/g) | Ref. |

|---|---|---|---|---|---|

| Emulsion template | Macro–meso–micro | - | 0.58 | 1145.2 | [97] |

| Emulsion template | Macro–meso–micro | 94% | 0.2 | 961.3 | [100] |

| Phase separation | Macro–meso–micro | - | 0.79 | 889 | [105] |

| Phase separation | Macro–meso–micro | 77% | 0.30 | 675 | [110] |

| Phase separation | Meso–micro | - | 0.02 | 3.7 | [112] |

| Phase separation | Meso–micro | - | 0.60 | 1374 | [113] |

| Zeolitization | Macro–meso–micro | - | 0.1 | 314 | [120] |

| Zeolitization | Meso–micro | - | 0.2 | 855.4 | [125] |

| Zeolitization | Meso–micro | 68% | 0.21 | 269.7 | [126] |

| Self-assembly | Meso–micro | 420 μmol/g | 0.18 | 335.1 | [134] |

| Self-assembly | Meso–micro | 73.9 μmol/g | - | 268.2 | [138] |

| Emulsion template | Macro–meso | 74% | 0.24 | 812 | [139] |

| Method | Structure | FE (%)/Yield (μmol/g) | Vp (cm3/g) | SBET (m2/g) | Ref. |

|---|---|---|---|---|---|

| Supercritical fluid | Macro–meso–micro | 874.1 μmol/g | 0.02 | 43.6 | [142] |

| Supercritical fluid | Macro–meso–micro | - | 0.03 | 32.7 | [143] |

| Supercritical fluid | Meso–micro | 66% | 0.02 | 47 | [85] |

| Freeze-drying | Macro–meso–micro | - | 0.5 | 692 | [156] |

| Freeze-drying | Macro–meso–micro | 58% | 0.62 | 721 | [157] |

| Freeze-drying | Macro–meso–micro | 81% | 0.88 | 942.1 | [93] |

| Freeze-drying | Macro–meso–micro | - | 0.12 | 56.9 | [154] |

| Selective leaching | Macro–micro | - | 1,07 | 1046 | [161] |

| Selective leaching | Macro–meso–micro | 78% | 0.15 | 69.2 | [164] |

| Selective leaching | Macro–meso–micro | 44% | 0.31 | 79 | [165] |

| Selective leaching | Macro–meso–micro | - | 0.42 | 107.3 | [67] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, Z.-L.; Wang, Y.-D.; Wang, Z.; Hong, Y.; Liu, S.-L.; Luo, H.-W.; Liu, X.-L.; Su, B.-L. The Synthesis, Characteristics, and Application of Hierarchical Porous Materials in Carbon Dioxide Reduction Reactions. Catalysts 2024, 14, 936. https://doi.org/10.3390/catal14120936

Guan Z-L, Wang Y-D, Wang Z, Hong Y, Liu S-L, Luo H-W, Liu X-L, Su B-L. The Synthesis, Characteristics, and Application of Hierarchical Porous Materials in Carbon Dioxide Reduction Reactions. Catalysts. 2024; 14(12):936. https://doi.org/10.3390/catal14120936

Chicago/Turabian StyleGuan, Ze-Long, Yi-Da Wang, Zhao Wang, Ying Hong, Shu-Lin Liu, Hao-Wen Luo, Xian-Lin Liu, and Bao-Lian Su. 2024. "The Synthesis, Characteristics, and Application of Hierarchical Porous Materials in Carbon Dioxide Reduction Reactions" Catalysts 14, no. 12: 936. https://doi.org/10.3390/catal14120936

APA StyleGuan, Z.-L., Wang, Y.-D., Wang, Z., Hong, Y., Liu, S.-L., Luo, H.-W., Liu, X.-L., & Su, B.-L. (2024). The Synthesis, Characteristics, and Application of Hierarchical Porous Materials in Carbon Dioxide Reduction Reactions. Catalysts, 14(12), 936. https://doi.org/10.3390/catal14120936