Intelligent Algorithms Enable Photocatalyst Design and Performance Prediction

Abstract

1. Introduction

2. The Processes of Intelligent Algorithms Design Photocatalysts or Predict the Photocatalytic Activity

3. Neural Network Model

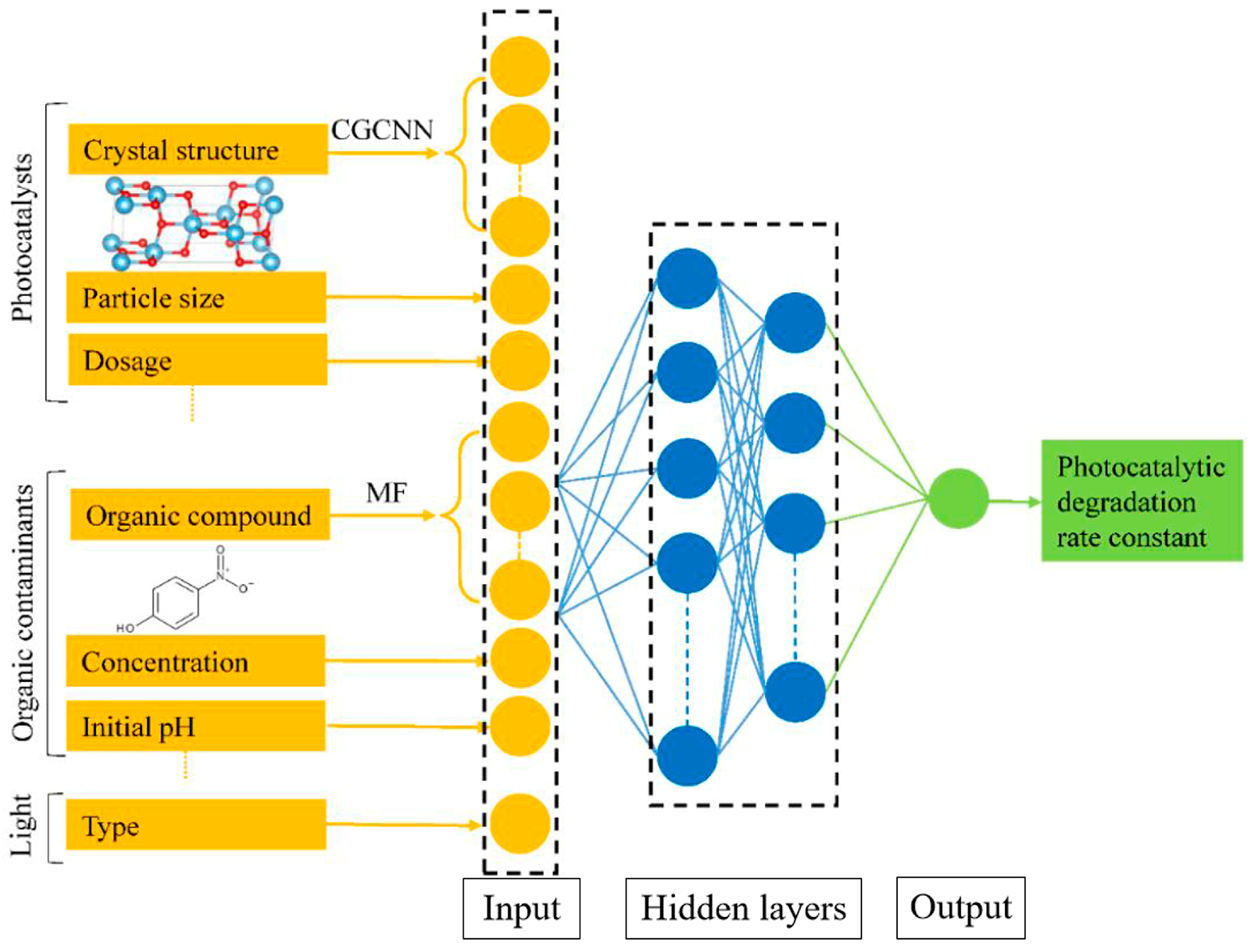

3.1. Neural Network Model Suitable for Photocatalyst Development

3.2. BP Neural Network Model

3.3. Limitations of Neural Network Models

4. Intelligent Algorithm Optimization of Neural Network Model

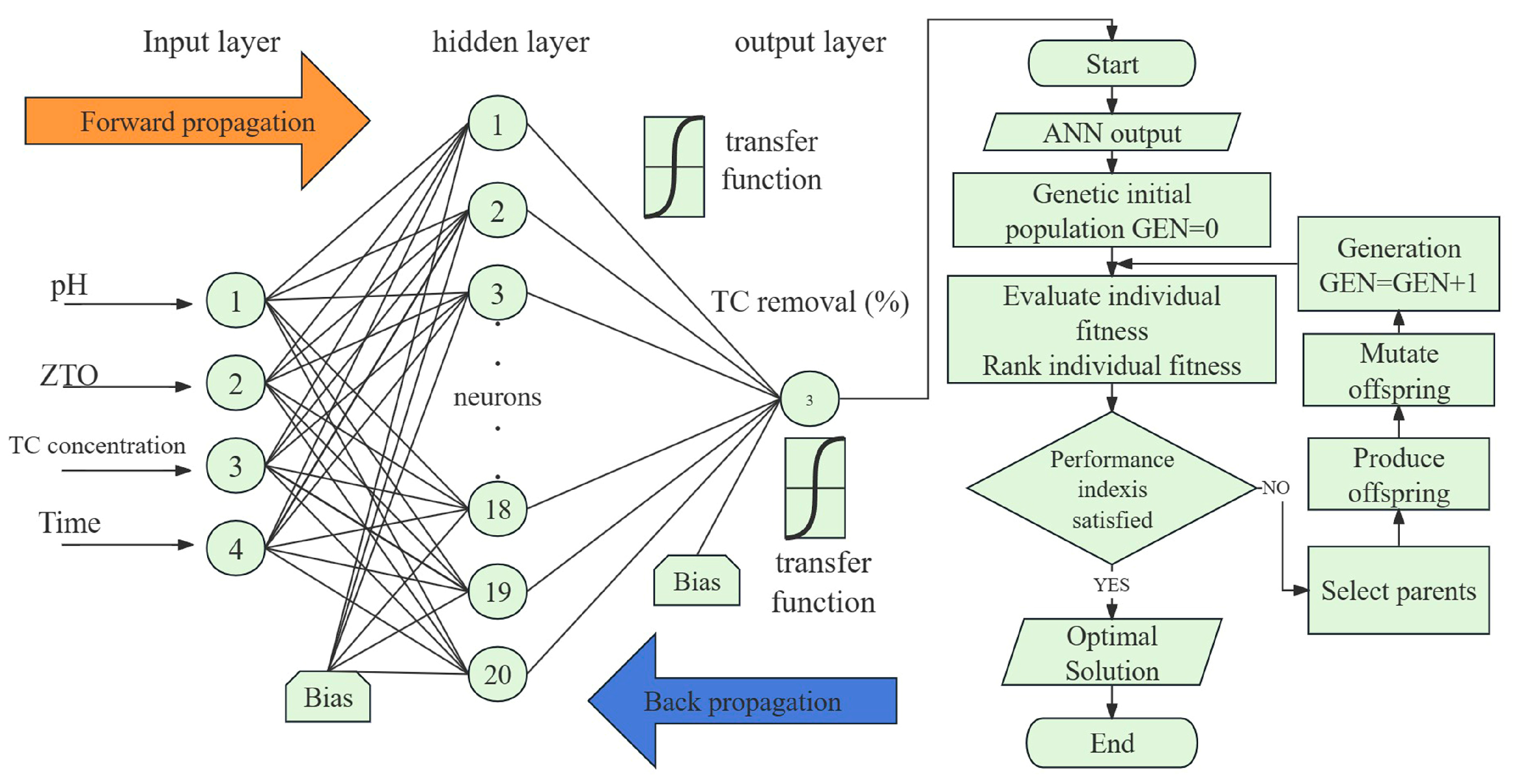

4.1. Neural Network Model Optimized by Genetic Algorithm

4.2. Neural Network Model Optimized by Whale Algorithm

4.3. Neural Network Model Optimized by Sparrow Search Algorithm

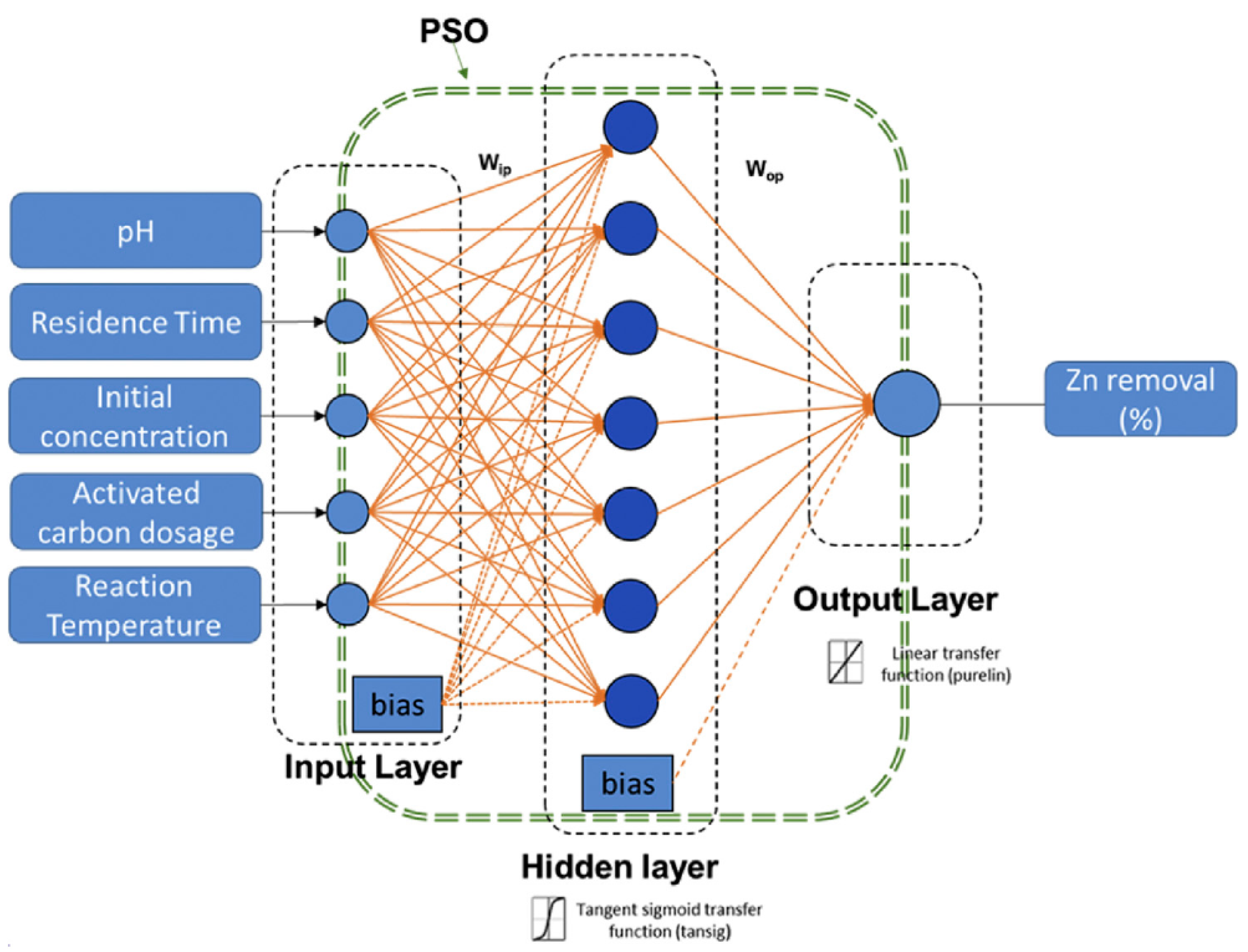

4.4. Neural Network Model Optimized by Particle Swarm Algorithm

5. Practical Application in the Field of Photocatalysis

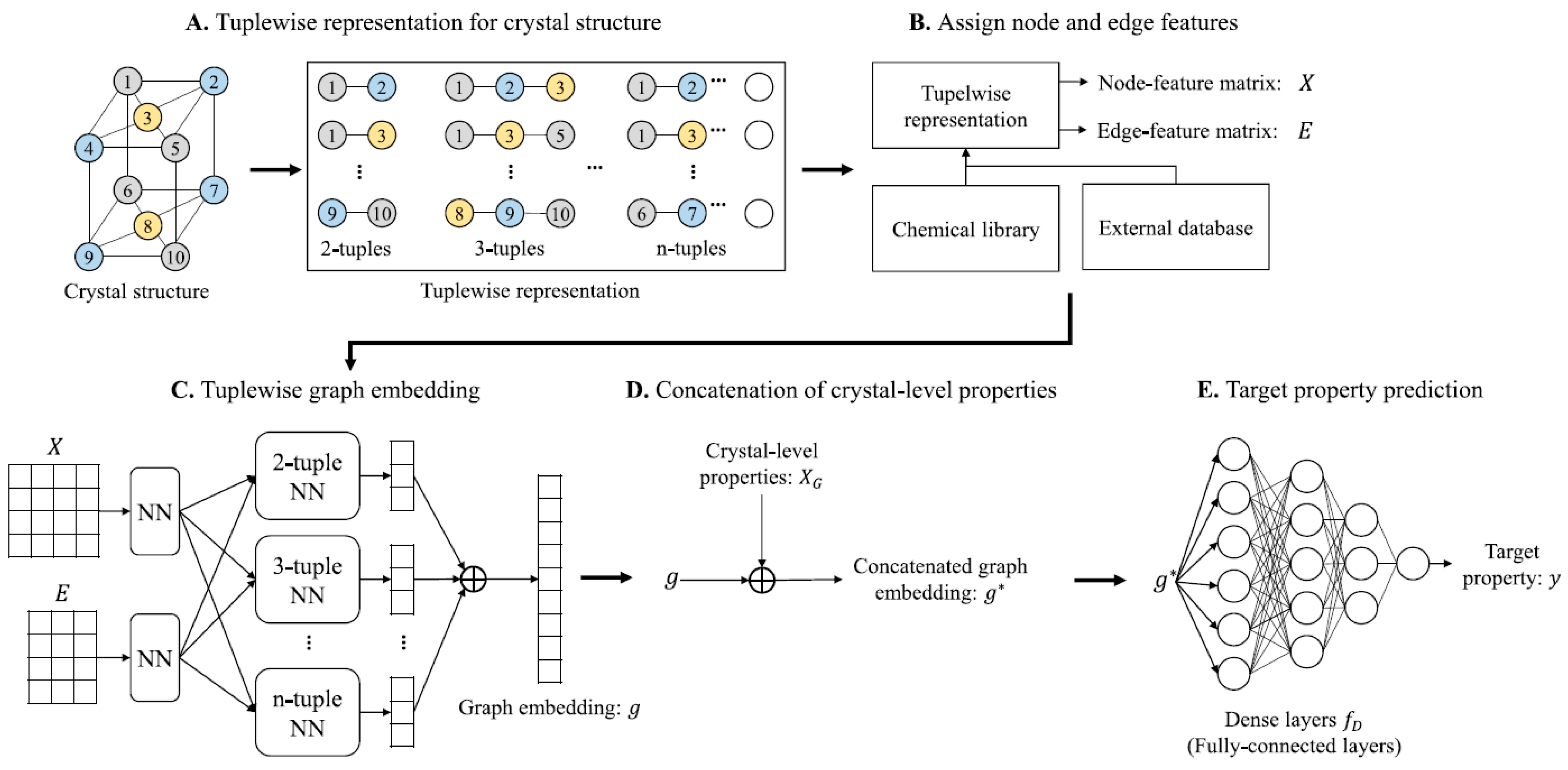

5.1. Intelligent Algorithm Combined with DFT Calculation to Develop New Photocatalyst

5.2. The Intelligent Algorithm Optimally Calculates the Degradation Percentage of Photocatalyst

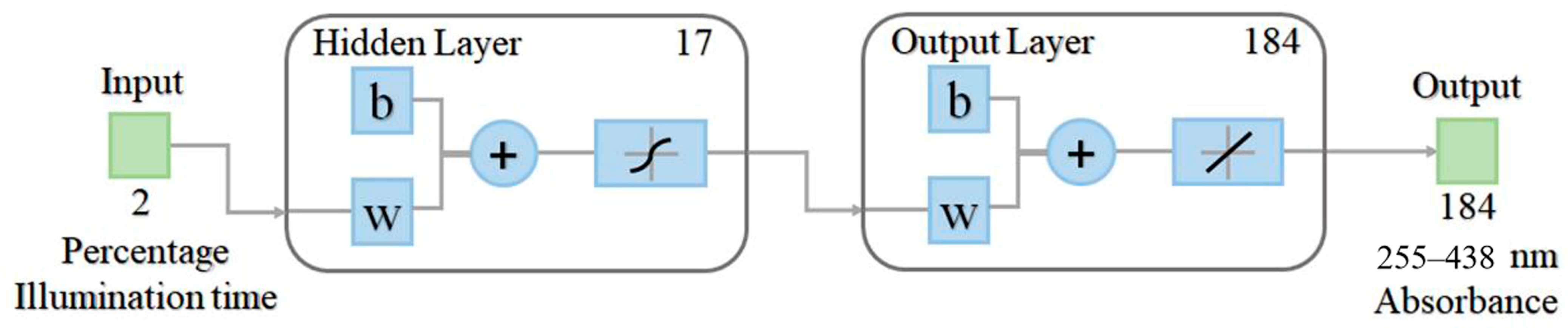

5.3. The Intelligent Algorithm Optimizes the Absorbance Curve and Then Predicts the Photocatalytic Activity of the Photocatalyst

6. Conclusions and Prospect

6.1. Conclusions

6.2. Prospect

- (1)

- The development of many intelligent algorithms is still ongoing. These newly discovered intelligent algorithms can be applied in photocatalysis to expand their use in interdisciplinary fields and promote the development of photocatalysis technology. In particular, combining and matching the algorithm model with experimental data, theoretical calculation data, and data from other databases to make it suitable for the calculation, training, and prediction of the model can also promote the improvement of the model and trigger the development of new models.

- (2)

- It is difficult for a single algorithmic model to meet the requirements of calculation, training, and prediction, so it is necessary to combine a variety of algorithmic models to make use of the advantages of these algorithms to better predict the photocatalytic performance of photocatalysts. The integration of multiple models requires relatively difficult technology, which limits the application of intelligent algorithms in the field of photocatalysis to a certain extent.

- (3)

- Most neural network models have multiple inputs and only one output, but research on multiple input and multiple output models is relatively rare. The application of a neural network model optimized by an intelligent algorithm in the field of photocatalysis is a technical challenge.

- (4)

- Explore the development of new intelligent algorithms for training and predicting the photocatalytic performance of photocatalysts. The development of intelligent algorithms suitable for the prediction of the photocatalytic performance of different photocatalysts will promote the development of photocatalytic technology, shorten the time required to develop new photocatalysts, and save costs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, C.M.; Jaffari, Z.H.; Abbas, A.; Chowdhury, M.F.; Cho, K.H. Machine learning analysis to interpret the effect of the photocatalytic reaction rate constant (k) of semiconductor-based photocatalysts on dye removal. J. Hazard. Mater. 2024, 465, 132995. [Google Scholar] [CrossRef]

- Jaffari, Z.H.; Abbas, A.; Umer, M.; Kim, E.S.; Cho, K.H. Crystal graph convolution neural networks for fast and accurate prediction of adsorption ability of Nb2 CTx towards Pb (ii) and Cd (ii) ions. J. Mater. Chem. A 2023, 11, 9009–9018. [Google Scholar] [CrossRef]

- Rashtbari, S.; Dehghan, G.; Marefat, A.; Khataee, S.; Khataee, A. Proficient sonophotocatalytic degradation of organic pollutants using Co3O4/TiO2 nanocomposite immobilized on zeolite: Optimization, and artificial neural network modeling. Ultrason. Sonochem. 2024, 102, 106740. [Google Scholar] [CrossRef] [PubMed]

- Ramkumar, G.; Tamilselvi, M.; Jebaseelan, S.S.; Mohanavel, V.; Kamyab, H.; Anitha, G.; Thandaiah, R.P.; Rajasimman, M. Enhanced machine learning for nanomaterial identification of photo thermal hydrogen production. Int. J. Hydrogen Energy 2024, 52, 696–708. [Google Scholar] [CrossRef]

- Chen, X.Y.; Wang, S.F.; Jin, Y.J.; Han, M.J.; Gao, H.J.; Yang, H.; Fang, L.M.; Jagadeesha Angadi, V.; Abd El-Rehim, A.F.; Ali, A.M.; et al. Construction of CeO2/PbFe12O19 Heterojunction Photocatalysts and their Preference for the Photodegradation of -C=O and -CONH2. ChemistrySelect 2023, 8, e202204779. [Google Scholar] [CrossRef]

- Panchal, P.; Sharma, R.; Reddy, A.S.; Nehra, K.; Sharma, A.; Nehra, S.P. Eco-friendly synthesis of Ag-doped ZnO/MgO as a potential photocatalyst for antimicrobial and dye degradation applications. Coordin. Chem. Rev. 2023, 493, 215283. [Google Scholar] [CrossRef]

- Han, Y.; Wang, S.F.; Li, M.Y.; Gao, H.J.; Han, M.J.; Yang, H.; Fang, L.M.; Jagadeesha, V.A.; Abd El-Rehim, A.F.; Ali, A.M.; et al. Strontium-induced phase, energy band and microstructure regulation in Ba1−xSrxTiO3 photocatalysts for boosting visible-light photocatalytic activity. Catal. Sci. Technol. 2023, 13, 2814–2854. [Google Scholar] [CrossRef]

- Faisal, M.; Ahmed, J.; Algethami, J.S.; El-Toni, A.M.; Labis, J.P.; Khan, A.; Harraz, F.A. Au nanoparticles dispersed chitosan/ZnO ternary nanocomposite as a highly efficient and reusable visible light photocatalyst. Mat. Sci. Semicon. Proc. 2023, 167, 107798. [Google Scholar] [CrossRef]

- Yang, H. A short review on heterojunction photocatalysts: Carrier transfer behavior and photocatalytic mechanisms. Mater. Res. Bull. 2021, 142, 111406. [Google Scholar] [CrossRef]

- Rasouli, K.; Alamdari, A.; Sabbaghi, S. Ultrasonic-assisted synthesis of α-Fe2O3@ TiO2 photocatalyst: Optimization of effective factors in the fabrication of photocatalyst and removal of non-biodegradable cefixime via response surface methodology-central composite design. Sep. Purif. Technol. 2023, 307, 122799. [Google Scholar] [CrossRef]

- He, Z.; Lin, K.; Wong, N.H.; Sunarso, J.; Xia, Y.; Fu, X.; Fu, X.F.; Su, J.B.; Huang, Z.Y.; Wang, Y.; et al. Elucidation of mechanisms, pathways, and toxicity of fabricated Z-scheme KNbO3/ZnIn2S4 hollow core–shell composites for enhanced ciprofloxacin photodegradation. Chem. Eng. J. 2023, 475, 146262. [Google Scholar] [CrossRef]

- Fujishima, A.; Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef]

- Takata, T.; Tanaka, A.; Hara, M.; Kondo, J.N.; Domen, K. Recent progress of photocatalysts for overall water splitting. Catal. Today 1998, 44, 17–26. [Google Scholar] [CrossRef]

- Yang, M.; Ma, G.; Yang, H.; Zhan, X.; Yang, W.; Hou, H. Advanced strategies for promoting the photocatalytic performance of FeVO4 based photocatalysts: A review of recent progress. J. Alloys Compd. 2023, 941, 168995. [Google Scholar] [CrossRef]

- Mutalib, A.A.; Jaafar, N.F. Electrogeneration of active photocatalysts for wastewater remediation: A review. Environ. Chem. Lett. 2023, 21, 981–1003. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Lee, T.; Van Tran, T.; Nguyen, V.H.; Nong, L.X.; Bach, L.G.; Vo, D.V.N. Multicomponent photocatalysts for synergic removal of antibiotics in aqueous media: A review. Environ. Chem. Lett. 2023, 21, 935–980. [Google Scholar] [CrossRef]

- Wang, S.F.; Gao, H.J.; Jin, Y.J.; Chen, X.Y.; Wang, F.; Yang, H.; Fang, L.M.; Chen, X.P.; Tang, S.N.; Li, D.F. Defect engineering in novel broad-band gap hexaaluminate MAl12O19 (M = Ca, Sr, Ba)-Based photocatalysts boosts near ultraviolet and visible light-driven photocatalytic performance. Mater. Today Chem. 2022, 24, 100942. [Google Scholar] [CrossRef]

- Krishnan, A.; Swarnalal, A.; Das, D.; Krishnan, M.; Saji, V.S.; Shibli, S.M.A. A review on transition metal oxides based photocatalysts for degradation of synthetic organic pollutants. J. Environ. Sci. 2023, 139, 389–417. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.F.; Gao, H.J.; Wei, Y.; Li, Y.; Yang, X.; Fang, L.M.; Lei, L. Insight into the optical, color, photoluminescence properties, and photocatalytic activity of the N-O and C-O functional groups decorating spinel type magnesium aluminate. CrystEngComm 2019, 21, 263–277. [Google Scholar] [CrossRef]

- Xian, T.; Sun, X.; Di, L.; Sun, C.; Li, H.; Ma, C.; Yang, H. Enhancing the piezo-photocatalytic tetracycline degradation activity of BiOBr by the decoration of AuPt alloy nanoparaticles: Degradation pathways and mechanism investigation. Appl. Surf. Sci. 2023, 638, 158136. [Google Scholar] [CrossRef]

- Li, H.; Xian, T.; Di, L.; Sun, X.; Sun, C.; Ma, K.; Ma, X.; Dai, J.; Yang, H. Constructing Z-scheme AuAg@δ-Bi2O3/BiOBr multi-heterojunction for efficient photocatalytic removal of dye, antibiotic and heavy metal ions: Performance and mechanism investigation. Opt. Mater. 2023, 136, 113487. [Google Scholar] [CrossRef]

- Xian, T.; Li, H.; Sun, X.; Huo, Y.; Di, L.; Sun, C.; Yang, H. S-scheme In2O3 nanoparticle/BiOBr nanoplate heterojunctions for improved photocatalytic dye degradation and Cr(VI) reduction. ACS Appl. Nano Mater. 2022, 5, 15260–15271. [Google Scholar] [CrossRef]

- Wang, S.F.; Chen, X.Y.; Fang, L.M.; Gao, H.J.; Han, M.J.; Chen, X.P.; Xia, Y.; Xie, L.; Yang, H. Double heterojunction CQDs/CeO2/BaFe12O19 magnetic separation photocatalysts: Construction, structural characterization, dye and POPs removal, and the interrelationships between magnetism and photocatalysis. Nucl. Anal. 2022, 1, 100026. [Google Scholar] [CrossRef]

- Sun, X.; Xu, T.; Xian, T.; Yi, Z.; Liu, G.; Dai, J.; Yang, H. Insight on the enhanced piezo-photocatalytic mechanism of In2O3/BiFeO3 heterojunctions for degradation of tetracycline hydrochloride. Appl. Surf. Sci. 2023, 640, 158408. [Google Scholar] [CrossRef]

- Aghel, B.; Biabani, A. Using solar microreactors and photocatalysts to synthesize biodiesel. Renew. Energ. 2024, 220, 119654. [Google Scholar] [CrossRef]

- Renita, A.A.; Sathish, S.; Kumar, P.S.; Prabu, D.; Manikandan, N.; Iqbal, A.M.; Rajesh, G.; Rangasamy, G. Emerging aspects of metal ions-doped zinc oxide photocatalysts in degradation of organic dyes and pharmaceutical pollutants–A review. J. Environ. Manag. 2023, 344, 118614. [Google Scholar] [CrossRef]

- Sun, X.; Xian, T.; Li, R.; Yang, H. Heterojunction interface field and piezoelectric polarization field cooperatively facilitating photocarrier separation in heterojunction piezo-photocatalysts: Experimental and theoretical characterization. Colloid. Surf. A 2023, 677, 132430. [Google Scholar] [CrossRef]

- Mohanty, U.A.; Sahoo, D.P.; Paramanik, L.; Parida, K.A. critical review on layered double hydroxide (LDH)-derived functional nanomaterials as potential and sustainable photocatalysts. Sustain. Energ. Fuels 2023, 7, 1145–1186. [Google Scholar] [CrossRef]

- Li, J.; Wang, S.; Sun, G.; Gao, H.; Yu, X.; Tang, S.; Zhao, X.; Yi, Z.; Wang, Y.; Wei, Y. Facile preparation of MgAl2O4/CeO2/Mn3O4 heterojunction photocatalyst and enhanced photocatalytic activity. Mater. Today Chem. 2021, 19, 100390. [Google Scholar] [CrossRef]

- Arun, J.; Nachiappan, S.; Rangarajan, G.; Alagappan, R.P.; Gopinath, K.P.; Lichtfouse, E. Synthesis and application of titanium dioxide photocatalysis for energy, decontamination and viral disinfection: A review. Environ. Chem. Lett. 2023, 21, 339–362. [Google Scholar] [CrossRef] [PubMed]

- Qiu, X.; Sun, X.; Ma, J.; Yi, Z.; Liu, G.; Dai, J.; Yang, H. Bi2O2CO3-coating on beverage-derived carbon microspheres to achieve highly-efficient photocatalysts for ciprofloxacin degradation. J. Alloys Compd. 2024, 970, 172608. [Google Scholar] [CrossRef]

- Vosough, M.; Khayati, G.R.; Sharafi, S. A novel nanocomposite for photocatalytic rhodamine B dye removal from wastewater using visible light. Environ. Res. 2024, 249, 118415. [Google Scholar] [CrossRef] [PubMed]

- Taoufik, N.; Janani, F.Z.; Khiar, H.; Sadiq, M.; Abdennouri, M.; Sillanpää, M.; Achak, M.; Barka, N. MgO-La2O3 mixed metal oxides heterostructure catalysts for photodegradation of dyes pollutant: Synthesis, characterization and artificial intelligence modelling. Environ. Sci. Pollut. Res. 2023, 30, 23938–23964. [Google Scholar] [CrossRef]

- Ngulube, K.F.; Abdelhaleem, A.; Fujii, M.; Nasr, M. Synergism of artificial intelligence and techno-economic for sustainable treatment of methylene blue dye-containing wastewater by photocatalysis. Sustainability 2024, 16, 529. [Google Scholar] [CrossRef]

- Malayeri, M.; Nasiri, F.; Haghighat, F.; Lee, C.S. Optimization of photocatalytic oxidation reactor for air purifier design: Application of artificial neural network and genetic algorithm. Chem. Eng. J. 2023, 462, 142186. [Google Scholar] [CrossRef]

- Kanthasamy, R.; Ali, I.; Ayodele, B.V.; Maddah, H.A. Bio-hydrogen production from the photocatalytic conversion of wastewater: Parametric analysis and data-driven modelling using nonlinear autoregressive with exogeneous input and back-propagated multilayer perceptron neural networks. Fuel 2023, 344, 128026. [Google Scholar] [CrossRef]

- Liu, H.; Wang, S.F.; Gao, H.J.; Yang, H.; Wang, F.; Chen, X.; Fang, L.M.; Tang, S.N.; Yi, Z.; Li, D.F. A simple polyacrylamide gel route for the synthesis of MgAl2O4 nanoparticles with different metal sources as an efficient adsorbent: Neural network algorithm simulation, equilibrium, kinetics and thermodynamic studies. Sep. Purif. Technol. 2022, 281, 119855. [Google Scholar] [CrossRef]

- Al-Abidy, M.; Al-Nayili, A. Enhancement of photocatalytic activities of ZnFe2O4 composite by incorporating halloysite nanotubes for effective elimination of aqueous organic pollutants. Environ. Monit. Assess. 2023, 195, 190. [Google Scholar] [CrossRef]

- Xu, M.; Xu, M.; Miao, X. Deep machine learning unravels the structural origin of mid-gap states in chalcogenide glass for high-density memory integration. InfoMat 2022, 4, e12315. [Google Scholar] [CrossRef]

- Gurunathan, R.; Choudhary, K.; Tavazza, F. Rapid prediction of phonon structure and properties using the atomistic line graph neural network (ALIGNN). Phys. Rev. Mater. 2023, 7, 023803. [Google Scholar] [CrossRef]

- Xie, Y.; Sattari, K.; Zhang, C.; Lin, J. Toward autonomous laboratories: Convergence of artificial intelligence and experimental automation. Prog. Mater. Sci. 2023, 132, 101043. [Google Scholar] [CrossRef]

- Grazulis, S.; Chateigner, D.; Downs, R.T.; Yokochi, A.F.T.; Quiros, M.; Lutterotti, L. Crystallography Open Database—An open-access collection of crystal structures. J. Appl. Crystallogr. 2009, 42, 726–729. [Google Scholar] [CrossRef]

- Mortazavi, B.; Shahrokhi, M.; Shojaei, F.; Rabczuk, T.; Zhuang, X.; Shapeev, A.V. A first-principles and machine-learning investigation on the electronic, photocatalytic, mechanical and heat conduction properties of nanoporous C5N monolayers. Nanoscale 2022, 14, 4324–4333. [Google Scholar] [CrossRef]

- Mortazavi, B.; Javvaji, B.; Shojaei, F.; Rabczuk, T.; Shapeev, A.V.; Zhuang, X. Exceptional piezoelectricity, high thermal conductivity and stiffness and promising photocatalysis in two-dimensional MoSi2N4 family confirmed by first-principles. Nano Energy 2021, 82, 105716. [Google Scholar] [CrossRef]

- Xu, A.; Chang, H.; Xu, Y.; Li, R.; Li, X.; Zhao, Y. Applying artificial neural networks (ANNs) to solve solid waste-related issues: A critical review. Waste Manag. 2021, 124, 385–402. [Google Scholar] [CrossRef] [PubMed]

- Khataee, A.R.; Fathinia, M.; Zarei, M.; Izadkhah, B.; Joo, S.W. Modeling and optimization of photocatalytic/photoassisted-electro-Fenton like degradation of phenol using a neural network coupled with genetic algorithm. J. Ind. Eng. Chem. 2014, 20, 1852–1860. [Google Scholar] [CrossRef]

- Khataee, A.R. Photocatalytic removal of CI Basic Red 46 on immobilized TiO2 nanoparticles: Artificial neural network modelling. Environ. Technol. 2009, 30, 1155–1168. [Google Scholar] [CrossRef] [PubMed]

- Cowan, J.D. Discussion: McCulloch-Pitts and related neural nets from 1943 to 1989. Bull. Math. Biol. 1990, 52, 73–97. [Google Scholar] [CrossRef]

- Al Haiqi, O.; Nour, A.H.; Ayodele, B.V.; Bargaa, R. Bayesian regularization-trained multi-layer perceptron neural network predictive modelling of phenol degradation using ZnO/Fe2O3 photocatalyst. J. Phys. Conf. Ser. 2020, 1529, 052058. [Google Scholar] [CrossRef]

- Das, L.; Maity, U.; Basu, J.K. The photocatalytic degradation of carbamazepine and prediction by artificial neural networks. Process Saf. Environ. 2014, 92, 888–895. [Google Scholar] [CrossRef]

- Sargolzaei, J.; Hedayati Moghaddam, A.; Nouri, A.; Shayegan, J. Modeling the removal of phenol dyes using a photocatalytic reactor with SnO2/Fe3O4 nanoparticles by intelligent system. J. Disper. Sci. Technol. 2015, 36, 540–548. [Google Scholar] [CrossRef]

- de Oliveira, G.X.; Kuhn, S.; Riella, H.G.; Soares, C.; Padoin, N. Combining computational fluid dynamics, photon fate simulation and machine learning to optimize continuous-flow photocatalytic systems. React. Chem. Eng. 2023, 8, 2119–2133. [Google Scholar] [CrossRef]

- Caliman, F.A.; Curteanu, S.; Betianu, C.; Gavrilescu, M.; Poulios, I. Neural networks and genetic algorithms optimization of the photocatalytic degradation of Alcian Blue 8GX J. Adv. Oxid. Technol. 2008, 11, 316–326. [Google Scholar] [CrossRef]

- Jaffari, Z.H.; Abbas, A.; Lam, S.M.; Park, S.; Chon, K.; Kim, E.S.; Cho, K.H. Machine learning approaches to predict the photocatalytic performance of bismuth ferrite-based materials in the removal of malachite green. J. Hazard. Mater. 2023, 442, 130031. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Hu, J.; Samia, A.; Yu, X. Predicting active sites in photocatalytic degradation process using an interpretable molecular-image combined convolutional neural network. Catalysts 2022, 12, 746. [Google Scholar] [CrossRef]

- Yang, Z.; Li, S.; Li, S.; Yang, J.; Liu, D. A two-step data augmentation method based on generative adversarial network for hardness prediction of high entropy alloy. Comput. Mater. Sci. 2023, 220, 112064. [Google Scholar] [CrossRef]

- Souiyah, M. Computational energy gap estimation for strontium titanate photocatalyst using extreme learning machine method. Cogent Eng. 2023, 10, 2232596. [Google Scholar] [CrossRef]

- Mahmoodi, N.M.; Abdi, J.; Taghizadeh, M.; Taghizadeh, A.; Hayati, B.; Shekarchi, A.A.; Vossoughi, M. Activated carbon/metal-organic framework nanocomposite: Preparation and photocatalytic dye degradation mathematical modeling from wastewater by least squares support vector machine. J. Environ. Manag. 2019, 233, 660–672. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, Q.; Zhou, C. Photocatalytic degradation of antibiotics by molecular assembly porous carbon nitride: Activity studies and artificial neural networks modeling. Chem. Phys. Lett. 2020, 750, 137479. [Google Scholar] [CrossRef]

- Du, Y.; Li, X.; Cao, L.; Yang, J. One-step solvothermal synthesis of MoS2@Ti cathode for electrochemical reduction of Hg2+ and predicting BP neural network model. Sep. Purif. Technol. 2024, 331, 125654. [Google Scholar] [CrossRef]

- Kıranşan, M.; Khataee, A.; Karaca, S.; Sheydaei, M. Artificial neural network modeling of photocatalytic removal of a disperse dye using synthesized of ZnO nanoparticles on montmorillonite. Spectrochim. Acta A 2015, 140, 465–473. [Google Scholar] [CrossRef]

- Liu, L. Recognition and analysis of motor imagery EEG signal based on improved BP neural network. IEEE Access 2019, 7, 47794–47803. [Google Scholar] [CrossRef]

- Razzaghi, M.; Karimi, A.; Ansari, Z.; Aghdasinia, H. Phenol removal by HRP/GOx/ZSM-5 from aqueous solution: Artificial neural network simulation and genetic algorithms optimization. J. Taiwan Inst. Chem. Eng. 2018, 89, 1–14. [Google Scholar] [CrossRef]

- Tabatabai-Yazdi, F.S.; Pirbazari, A.E.; Saraei, F.E.K.; Gilani, N. Construction of graphene based photocatalysts for photocatalytic degradation of organic pollutant and modeling using artificial intelligence techniques. Phys. B Condens. Matter 2021, 608, 412869. [Google Scholar] [CrossRef]

- Ahmad, W.; Khan, A.; Ali, N.; Khan, S.; Uddin, S.; Malik, S.; Ali, N.; Bilal, H.; Khan, N.; Khan, H.; et al. Photocatalytic degradation of crystal violet dye under sunlight by chitosan-encapsulated ternary metal selenide microspheres. Environ. Sci. Pollut. Res. 2021, 28, 8074–8087. [Google Scholar] [CrossRef]

- Ding, Y.; Sun, Q.; Lin, Y.; Ping, Q.; Peng, N.; Wang, L.; Li, Y. Application of artificial intelligence in (waste) water disinfection: Emphasizing the regulation of disinfection by-products formation and residues prediction. Water Res. 2024, 253, 121267. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Wang, S.; Yu, X.; Li, M.; Gao, H.; Yang, H.; Fang, L.; Zhang, Y.; Ding, J.; Liu, H.; et al. A and B sites doped CaAl12O19: Phase component, energy band, color and photoluminescence tuning, color performance prediction and application for pigments. Spectrochim. Acta A 2024, 304, 123254. [Google Scholar] [CrossRef] [PubMed]

- Smaali, A.; Berkani, M.; Merouane, F.; Vasseghian, Y.; Rahim, N.; Kouachi, M. Photocatalytic-persulfate-oxidation for diclofenac removal from aqueous solutions: Modeling, optimization and biotoxicity test assessment. Chemosphere 2021, 266, 129158. [Google Scholar] [CrossRef] [PubMed]

- Ciğeroğlu, Z.; Küçükyıldız, G.; Erim, B.; Alp, E. Easy preparation of magnetic nanoparticles-rGO-chitosan composite beads: Optimization study on cefixime removal based on RSM and ANN by using Genetic Algorithm Approach. J. Mol. Struct. 2021, 1224, 129182. [Google Scholar] [CrossRef]

- Suditu, G.D.; Secula, M.; Piuleac, C.G.; Curteanu, S.; Poulios, I. Genetic algorithms and neural networks based optimization applied to the wastewater decolorization by photocatalytic reaction. Rev. Chim 2008, 59, 816–825. [Google Scholar] [CrossRef]

- Hassani, A.; Khataee, A.; Fathinia, M.; Karaca, S. Photocatalytic ozonation of ciprofloxacin from aqueous solution using TiO2/MMT nanocomposite: Nonlinear modeling and optimization of the process via artificial neural network integrated genetic algorithm Process. Saf. Environ. 2018, 116, 365–376. [Google Scholar]

- Hou, T.H.; Su, C.H.; Liu, W.L. Parameters optimization of a nano-particle wet milling process using the Taguchi method, response surface method and genetic algorithm. Powder Technol. 2007, 173, 153–162. [Google Scholar] [CrossRef]

- Taherkhania, S.; Karimi, H.; Mohammadi, F.; Darvishmotevallib, M.; Binac, B. Investigation of photocatalytic activity of synthesized zinc stannate for tetracycline antibiotic degradation: Modelling and optimization through RSM, ANN and genetic algorithm Desalin. Water Treat. 2019, 169, 342–352. [Google Scholar] [CrossRef]

- Kakhki, R.M.; Jafarian Shahri, Y.; Mohammadpoor, M. KCl mediated Ag/Co@Fe2O3/C3N4 heterojunction as a highly efficient visible photocatalyst for tetracycline degradation: Application of machine learning. J. Mol. Struct. 2024, 1299, 137139. [Google Scholar] [CrossRef]

- Mohammadzadeh, A.; Ramezani, M.; Ghaedi, A.M. Synthesis and characterization of Fe2O3-ZnO-ZnFe2O4/carbon nanocomposite and its application to removal of bromophenol blue dye using ultrasonic assisted method: Optimization by response surface methodology and genetic algorithm. J. Taiwan Inst. Chem. E. 2016, 59, 275–284. [Google Scholar] [CrossRef]

- Mohammed, N.; Palaniandy, P.; Shaik, F. Pollutants removal from saline water by solar photocatalysis: A review of experimental and theoretical approaches. Int. J. Environ. Anal. Chem. 2021, 103, 4155–4175. [Google Scholar] [CrossRef]

- Rabiee, F.; Mahanpoor, K. Experimental scale photocatalytic oxidation SO2 from simulated flue gas in the presence of Mn/copper slag as a novel nanocatalyst: Optimizations by hybrid box-behnken experimental design and genetic algorithm. Russ. J. Appl. Chem. 2018, 91, 687–700. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The whale optimization algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Abdulsalam, J.; Lawal, A.I.; Ozonoh, M.; Onifade, M.; Bada, S.; Mulopo, J. Optimization of porous carbons for methane adsorption from South African coal wastes. Int. J. Coal Prep. Util. 2023, 43, 264–287. [Google Scholar] [CrossRef]

- Ren, T.; Wang, L.; Chang, C.; Li, X. Machine learning-assisted multiphysics coupling performance optimization in a photocatalytic hydrogen production system Energ. Energ. Convers. Manag. 2020, 216, 112935. [Google Scholar] [CrossRef]

- Li, M.; Wang, S.; Gao, H.; Yin, Z.; Chen, C.; Yang, H.; Fang, L.; Veerabhadrappa, J.A.; Yi, Z.; Li, D. Selective removal of antibiotics over MgAl2O4/C3N4/YMnO3 photocatalysts: Performance prediction and mechanism insight. J. Am. Ceram. Soc. 2023, 106, 2420–2442. [Google Scholar] [CrossRef]

- Xue, J.; Shen, B. A novel swarm intelligence optimization approach: Sparrow search algorithm. Syst. Sci. Control Eng. 2020, 8, 22–34. [Google Scholar] [CrossRef]

- Liu, R.; Li, G.; Wei, L.; Xu, Y.; Gou, X.; Luo, S.; Yang, X. Spatial prediction of groundwater potentiality using machine learning methods with Grey Wolf and Sparrow Search Algorithms. J. Hydrol. 2022, 610, 127977. [Google Scholar] [CrossRef]

- Liu, J.; Hu, P.; Xue, H.; Pan, X.; Chen, C. Prediction of milk protein content based on improved sparrow search algorithm and optimized back propagation neural network. Spectrosc. Lett. 2022, 55, 229–239. [Google Scholar] [CrossRef]

- An, G.; Jiang, Z.; Chen, L.; Cao, X.; Li, Z.; Zhao, Y.; Sun, H. Ultra short-term wind power forecasting based on sparrow search algorithm optimization deep extreme learning machine. Sustainability 2021, 13, 10453. [Google Scholar] [CrossRef]

- Gharehchopogh, F.S.; Namazi, M.; Ebrahimi, L.; Abdollahzadeh, B. Advances in sparrow search algorithm: A comprehensive survey. Arch. Comput. Method. E. 2023, 30, 427–455. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Liu, S.; Wang, X.; Wu, W. An improved sparrow search algorithm. In Proceedings of the 2020 IEEE Intl Conf on Parallel & Distributed Processing with Applications, Big Data & Cloud Computing, Sustainable Computing & Communications, Social Computing & Networking, Exeter, UK, 17–19 December 2020; pp. 537–543. [Google Scholar]

- Yue, Y.; Cao, L.; Lu, D.; Hu, Z.; Xu, M.; Wang, S.; Li, B.; Ding, H. Review and empirical analysis of sparrow search algorithm. Artif. Intell. Rev. 2023, 56, 10867–10919. [Google Scholar] [CrossRef]

- Yang, F.; Yu, X.; Wang, K.; Liu, Z.; Gao, Z.; Zhang, T.; Niu, J.; Zhao, J.; Yao, B. Photocatalytic degradation of methylene blue over BiVO4/BiPO4/rGO heterojunctions and their artificial neural network model. J. Alloys Compd. 2023, 960, 170716. [Google Scholar] [CrossRef]

- Shi, Y. Particle swarm optimization: Developments, applications and resources. In Proceedings of the 2001 Congress on Evolutionary Computation, Seoul, Republic of Korea, 27–30 May 2001; Volume 1, pp. 81–86. [Google Scholar]

- Dos Santos Coelho, L. A quantum particle swarm optimizer with chaotic mutation operator. Chaos Soliton. Fract. 2008, 37, 1409–1418. [Google Scholar] [CrossRef]

- Owolabi, T.O.; Qahtan, T.F.; Abidemi, O.R.; Saleh, T.A.; Adeyemi, O.W. Bismuth oxychloride photocatalytic wide band gap adjustment through oxygen vacancy regulation using a hybrid intelligent computational method. Mater. Chem. Phys. 2022, 290, 126524. [Google Scholar] [CrossRef]

- Karri, R.R.; Sahu, J.N. Modeling and optimization by particle swarm embedded neural network for adsorption of zinc (II) by palm kernel shell based activated carbon from aqueous environment. J. Environ. Manag. 2018, 206, 178–191. [Google Scholar] [CrossRef]

- Kumar, A.; Upadhyayula, S.; Kodamana, H. A convolutional neural network-based gradient boosting framework for prediction of the band gap of photo-active catalysts. Digit. Chem. Eng. 2023, 8, 100109. [Google Scholar] [CrossRef]

- Wan, Z.; Wang, Q.D.; Liu, D.; Liang, J. Effectively improving the accuracy of PBE functional in calculating the solid band gap via machine learning. Comput. Mater. Sci. 2021, 198, 110699. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X. Machine learning optical band gaps of doped-ZnO films. Optik 2020, 217, 164808. [Google Scholar] [CrossRef]

- Venkatraman, V. The utility of composition-based machine learning models for band gap prediction. Comput. Mater. Sci. 2021, 197, 110637. [Google Scholar] [CrossRef]

- Mattur, M.N.; Nagappan, N.; Rath, S.; Thomas, T. Prediction of nature of band gap of perovskite oxides (ABO3) using a machine learning approach. J. Mater. 2022, 8, 937–948. [Google Scholar]

- Olsthoorn, B.; Geilhufe, R.M.; Borysov, S.S.; Balatsky, A.V. Band gap prediction for large organic crystal structures with machine learning. Adv. Quantum Technol. 2019, 2, 1900023. [Google Scholar] [CrossRef]

- Kauwe, S.K.; Welker, T.; Sparks, T.D. Extracting knowledge from DFT: Experimental band gap predictions through ensemble learning. Integr. Mater. Manuf. Innov. 2020, 9, 213–220. [Google Scholar] [CrossRef]

- Na, G.S.; Jang, S.; Lee, Y.L.; Chang, H. Tuplewise material representation based machine learning for accurate band gap prediction. J. Phys. Chem. A 2020, 124, 10616–10623. [Google Scholar] [CrossRef]

- Han, Y.; Wang, S.F.; Yu, X.; Li, M.Y.; Yi, Z.; Tang, J.; Gao, H.J.; Yang, H.; Fang, L.M.; Syed, A.; et al. Ba0.5Sr0.5TiO3/BaFe12O19 magnetic separation photocatalysts: Structural, optical, microstructure, photocatalytic activity, degradation pathway and mechanism. Ceram. Int. 2023, 49, 37967–37982. [Google Scholar] [CrossRef]

- Wang, S.; Gao, H.; Li, J.; Wang, Y.; Chen, C.; Yu, X.; Tang, S.; Zhao, X.; Sun, G.; Li, D. Comparative study of the photoluminescence performance and photocatalytic activity of CeO2/MgAl2O4 composite materials with an nn heterojunction prepared by one-step synthesis and two-step synthesis methods. J. Phys. Chem. Solid. 2021, 150, 109891. [Google Scholar] [CrossRef]

- Wang, S.F.; Liu, H.; Li, M.; Han, M.J.; Gao, H.J.; Yang, H.; Fang, L.M.; Zhang, H.; Jagadeesha, A.V.; Manjunatha, S.O.; et al. Various carbon-based MgAl2O4 adsorbents and their removal efficiency of CR dye and antibiotics in aqueous media: High selective adsorption capacity, performance prediction and mechanism insight. Ceram. Int. 2023, 49, 26734–26746. [Google Scholar] [CrossRef]

- Sun, X.; Zheng, Z.; Ma, J.; Xian, T.; Liu, G.; Yang, H. Development of ternary Pt/BaTiO3/Bi2O3 heterostructured piezo-photocatalysts for antibiotic degradation. Appl. Surf. Sci. 2024, 653, 159421. [Google Scholar] [CrossRef]

- Mu, W.; Xu, M.; Sun, X.; Liu, G.; Yang, H. Oxygen-vacancy-tunable mesocrystalline ZnO twin “cakes” heterostructured with CdS and Cu nanoparticles for efficiently photodegrading sulfamethoxazole. J. Environ. Chem. Eng. 2024, 12, 112367. [Google Scholar] [CrossRef]

- Gao, H.; Angadi, J.; Wang, S.; Zhou, X.; Yang, H.; Al-Enizi, A.M.; Ubaidullah, M.; Pandit, B.; Dengfeng Li, D.F.; Gupta, M. Designing of Z-Scheme MgFe2O4/Fe2O3 coupled CoCr2O4 heterojunction with high photocatalytic activity for the removal of tetracycline hydrochloride in wastewater. Adv. Sustain. Syst. 2023, 2300533. [Google Scholar] [CrossRef]

- Han, M.J.; Wang, S.F.; Chen, X.Y.; Liu, H.; Gao, H.J.; Zhao, X.X.; Wang, F.; Yang, H.; Yi, Z.; Fang, L.M. Spinel CuB2O4 (B = Fe, Cr, and Al) oxides for selective adsorption of Congo red and photocatalytic removal of antibiotics. ACS Appl. Nano Mater. 2022, 5, 11194–11207. [Google Scholar] [CrossRef]

- Berkani, M.; Bouchareb, M.K.; Bouhelassa, M.; Kadmi, Y. Photocatalytic degradation of industrial dye in semi-pilot scale prototype solar photoreactor: Optimization and modeling using ANN and RSM based on Box–Wilson approach. Top. Catal. 2020, 63, 964–975. [Google Scholar] [CrossRef]

- Antonopoulou, M.; Papadopoulos, V.; Konstantinou, I. Photocatalytic oxidation of treated municipal wastewaters for the removal of phenolic compounds: Optimization and modeling using response surface methodology (RSM) and artificial neural networks (ANNs). J. Chem. Technol. Biotechnol. 2012, 87, 1385–1395. [Google Scholar] [CrossRef]

- Alsaffar, M.A.; Ghany, M.A.R.A.; Mageed, A.K.; AbdulRazak, A.A.; Ali, J.M.; Sukkar, K.A.; Ayodele, B.V. Effect of textural properties on the degradation of bisphenol from industrial wastewater effluent in a photocatalytic reactor: A modeling approach. Appl. Sci. 2023, 13, 8966. [Google Scholar] [CrossRef]

- Gopalan, A.; Priyadarshini, R.; Titus, A.; Sahoo, S.; Muppala, C.; Ramkumar, G.; Pham, Q.A.; Rubavathy, S.J.; Rajasimman, M.; Hojjati-Najafabadi, A. Deep learning for the encounter of inorganic nanomaterial for efficient photochemical hydrogen production. Int. J. Hydrogen Energ. 2024, 52, 664–673. [Google Scholar] [CrossRef]

- Alyani, S.J.; Pirbazari, A.E.; Khalilsaraei, F.E.; Kolur, N.A.; Gilani, N. Growing Co-doped TiO2 nanosheets on reduced graphene oxide for efficient photocatalytic removal of tetracycline antibiotic from aqueous solution and modeling the process by artificial neural network. J. Alloys Compd. 2019, 799, 169–182. [Google Scholar] [CrossRef]

- Baaloudj, O.; Nasrallah, N.; Kebir, M.; Guedioura, B.; Amrane, A.; Nguyen-Tri, P.; Nanda, S.; Assadi, A.A. Artificial neural network modeling of cefixime photodegradation by synthesized CoBi2O4 nanoparticles. Environ. Sci. Pollut. Res. 2021, 28, 15436–15452. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Bentria, E.T.; Rtimi, S.; Arredouani, A.; Bensmail, H.; El-Mellouhi, F. Accelerating the design of photocatalytic surfaces for antimicrobial application: Machine learning based on a sparse dataset. Catalysts 2021, 11, 1001. [Google Scholar] [CrossRef]

- Han, P.; Shen, X.; Shen, B. A simulation study on NOx reduction efficiency in SCR catalysts utilizing a modern C3-CNN algorithm. Fuel 2024, 363, 130985. [Google Scholar] [CrossRef]

- Zhai, X.; Chen, M. A machine learning-based nano-photocatalyst module for accelerating the design of Bi2WO6/MIL-53 (Al) nanocomposites with enhanced photocatalytic activity. Nanoscale Adv. 2023, 5, 4065–4073. [Google Scholar] [CrossRef] [PubMed]

- Mikolajczyk, A.; Wyrzykowska, E.; Mazierski, P.; Grzyb, T.; Wei, Z.; Kowalska, E.; Caicedo, P.N.A.; Zaleska-Medynska, A.; Puzyn, T.; Nadolna, J. Visible-light photocatalytic activity of rare-earth-metal-doped TiO2: Experimental analysis and machine learning for virtual design. Appl. Catal. B 2024, 346, 123744. [Google Scholar] [CrossRef]

- Yang, Q.; Xu, R.; Wu, P.; He, J.; Liu, C.; Jiang, W. Three-step treatment of real complex, variable high-COD rolling wastewater by rational adjustment of acidification, adsorption, and photocatalysis using big data analysis. Sep. Purif. Technol. 2021, 270, 118865. [Google Scholar] [CrossRef]

- Jiang, Z.; Hu, J.; Tong, M.; Samia, A.C.; Zhang, H.; Yu, X. A novel machine learning model to predict the photo-degradation performance of different photocatalysts on a variety of water contaminants. Catalysts 2021, 11, 1107. [Google Scholar] [CrossRef]

- Hassanien, A.E.; Abouelmagd, L.M.; Mahmoud, A.S.; Darwish, A. An optimized backpropagation neural network models for the prediction of nanomaterials concentration for purification industrial wastewater. Eng. Appl. Artif. Intel. 2023, 126, 107010. [Google Scholar] [CrossRef]

- Wang, S.; Li, M.; Gao, H.; Yin, Z.; Chen, C.; Yang, H.; Fang, L.; Angadi, V.J.; Yi, Z.; Li, D. Construction of CeO2/YMnO3 and CeO2/MgAl2O4/YMnO3 photocatalysts and adsorption of dyes and photocatalytic oxidation of antibiotics: Performance prediction, degradation pathway and mechanism insight. Appl. Surf. Sci. 2023, 608, 154977. [Google Scholar] [CrossRef]

- Fu, X.F.; Tao, J.W.; He, Z.M.; Gao, Y.; Xia, Y.M.; Zhao, Z.Z. Synergy of Z-scheme heterostructure with interfacial S−O bonding in In2S3/BiOBr for efficient tetracycline hydrochloride degradation and Cr(VI) reduction. J. Alloys Compd. 2023, 936, 168202. [Google Scholar] [CrossRef]

- Fu, X.F.; Wang, L.; He, Z.M.; Gao, Y.; Xia, Y.M.; Tao, J.W.; Zhao, Z.Z. Synergetic interfacial charge transfer with Z-scheme heterostructure and S−Mo−S linkage in one-pot synthesized SnIn4S8/MoS2 for efficient photocatalytic activity. J. Solid State Chem. 2023, 319, 23794. [Google Scholar] [CrossRef]

- He, Z.M.; Lin, K.; Wong, N.H.; Sunarso, J.; Xia, Y.M.; Fu, X.F.; Tang, B.; Huang, Z.Y.; Wang, Y.; Yang, H.P. Electron spin-states reconfiguration induced by alternating temperature gradient for boosting photocatalytic hydrogen evolution on hollow core-shell FeS2/CuCo2O4 Z-Scheme heterostructure. Nano Energy 2024, 124, 109483. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Mo, P.; Li, D.; Syed, A. Intelligent Algorithms Enable Photocatalyst Design and Performance Prediction. Catalysts 2024, 14, 217. https://doi.org/10.3390/catal14040217

Wang S, Mo P, Li D, Syed A. Intelligent Algorithms Enable Photocatalyst Design and Performance Prediction. Catalysts. 2024; 14(4):217. https://doi.org/10.3390/catal14040217

Chicago/Turabian StyleWang, Shifa, Peilin Mo, Dengfeng Li, and Asad Syed. 2024. "Intelligent Algorithms Enable Photocatalyst Design and Performance Prediction" Catalysts 14, no. 4: 217. https://doi.org/10.3390/catal14040217

APA StyleWang, S., Mo, P., Li, D., & Syed, A. (2024). Intelligent Algorithms Enable Photocatalyst Design and Performance Prediction. Catalysts, 14(4), 217. https://doi.org/10.3390/catal14040217