Biodiesel at the Crossroads: A Critical Review

Abstract

:1. Introduction

2. Biodiesel: The Current Renewable Biofuel in CI Diesel Engines

3. Biodiesel-Like Biofuels Which Integrate Glycerol as a Derivative Obtained in the Same Transesterification Process

3.1. Biodiesel-Like Biofuels that Integrate Glycerol as Glycerol Triacetate, Obtained by Interesterification of Oils or Fats

3.2. Biodiesel-Like Biofuels that Integrate the Glycerol as Glycerol Carbonate, Obtained in a Single Process of Interesterification of Oils or Fats

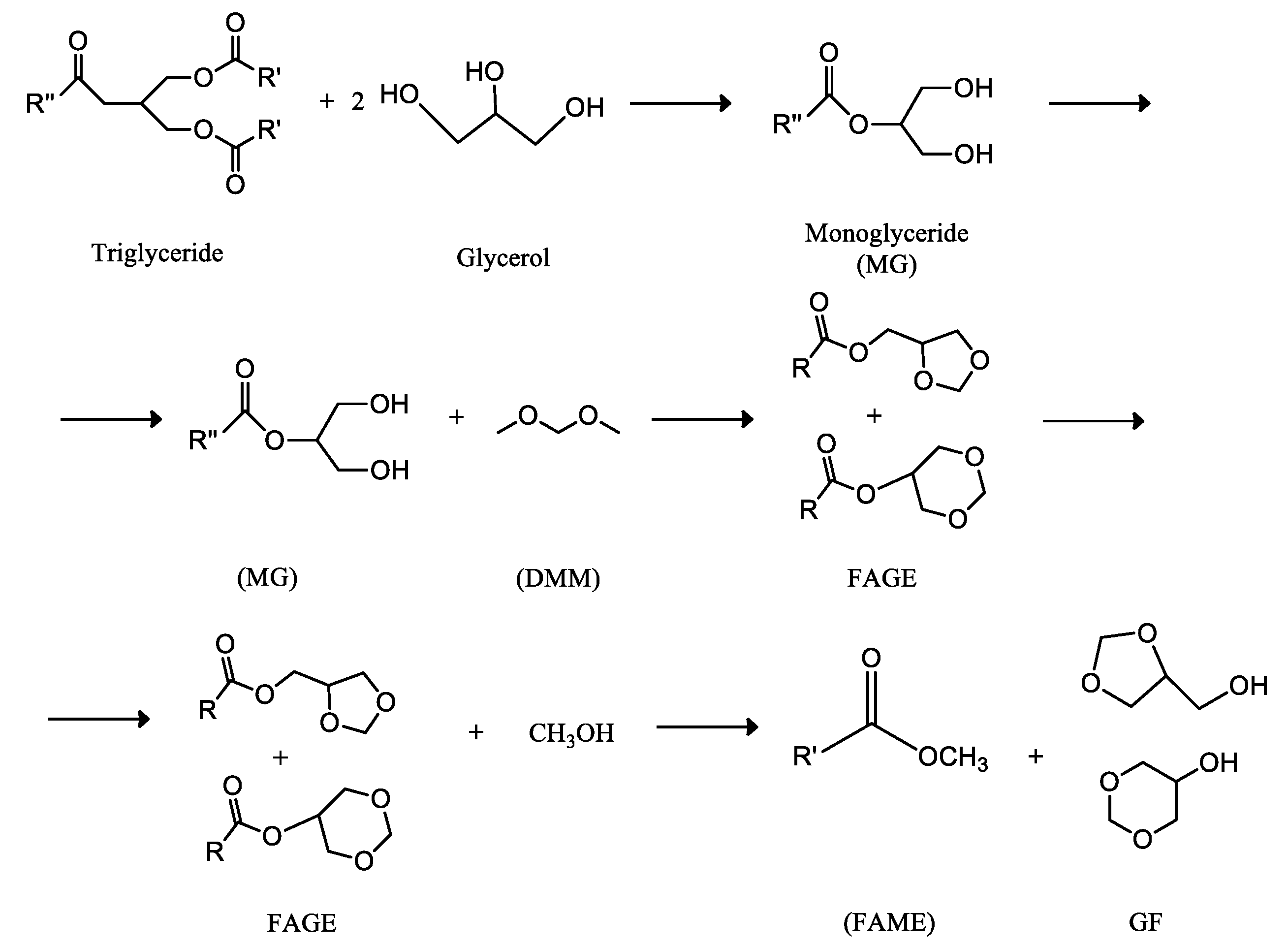

3.3. Biodiesel-Like Biofuels that Integrate Glycerol as Monoglycerides, Obtained in a Selective 1,3-Transesterification Process

4. Fossil Diesel-Like Biofuels: Green Diesel from Hydrotreated Vegetable Oils

5. Blends of Straight Vegetable Oils (SVO) with Less Viscous and Lower Cetane (LVLC) Biofuels

6. Summary, Conclusions, Challenges, and Research Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| GHG | greenhouse gas emissions |

| CI | compression ignition engines |

| SVO | straight vegetable oils |

| LVLC | less viscous and lower cetane fuels |

| FAME | fatty acids methyl esters, components of conventional biodiesel |

| FAEE | fatty acids ethyl esters, components of conventional biodiesel |

| DMC | dimethyl carbonate |

| FAGCs | fatty acid glycerol carbonate esters |

| GDC | glycerol dicarbonate |

| GC | glycerol carbonate |

| PPL | pig pancreatic lipase |

| MG | monoglycerides or monoacylglycerols |

| DG | diacylglycerols |

| TG | triacylglycerols or triglycerides |

| THC | total hydrocarbons |

| CO | carbon monoxide |

| PM | particulate maters |

| HAP | hazardous air pollutants emissions |

| DEC | diethyl carbonate |

| DMM | Dimethoxymethane |

| GF | formal glycerol |

| DEE | diethyl ether |

| DIGLYME | diethylene glycol dimethyl ether |

References

- Obergassel, W.; Arens, C.; Hermwille, L.; Kreibich, N.; Mersmann, F.; Ott, H.E.; Wang-Helmreich, H. Phoenix from the Ashes—An Analysis of the Paris Agreement to the United Nations Framework Convention on Climate Change; Wuppertal Institute for Climate, Environment and Energy: Wuppertal, Germany, 2016. [Google Scholar]

- Oberthü, S. Where to go from Paris? The European Union in climate geopolitics. Glob. Aff. 2016, 2, 119–130. [Google Scholar] [CrossRef]

- Delucchi, M.A.; Jacobson, M.Z. Meeting the world’s energy needs entirely with wind, water, and solar power. Bull. At. Sci. 2013, 69, 30–40. [Google Scholar] [CrossRef]

- Arutyunov, V.S.; Lisichkin, G.V. Energy resources of the 21st century: Problems and forecasts. Can renewable energy sources replace fossil fuels? Russ. Chem. Rev. 2017, 86, 777–804. [Google Scholar] [CrossRef]

- Sen, B.; Ercan, T.; Tatari, O. Does a battery-electric truck make a difference?—Life cycle emissions, costs, and externality analysis of alternative fuel-powered Class 8 heavy-duty trucks in the United States. J. Clean. Prod. 2017, 141, 110–121. [Google Scholar] [CrossRef]

- Nair, S.; Paulose, H. Emergence of green business models: The case of algae biofuel for aviation. Energy Policy 2014, 65, 175–184. [Google Scholar] [CrossRef]

- Noh, H.M.; Benito, A.; Alonso, G. Study of the current incentive rules and mechanisms to promote biofuel use in the EU and their possible application to the civil aviation sector. Transp. Res. Part. D Transp. Environ. 2016, 46, 298–316. [Google Scholar] [CrossRef] [Green Version]

- Winnes, H.; Styhre, L.; Fridell, E. Reducing GHG emissions from ships in port areas. Res. Transp. Bus. Manag. 2015, 17, 73–82. [Google Scholar] [CrossRef] [Green Version]

- Levidow, L. EU criteria for sustainable biofuels: Accounting for carbon, depoliticising plunder. Geoforum 2013, 44, 211–223. [Google Scholar] [CrossRef]

- Creutzig, F.; Jochem, P.; Edelenbosch, O.Y.; Mattauch, L.; van Vuuren, D.P.; McCollum, D.; Minx, J. Transport: A roadblock to climate change mitigation? Science 2015, 350, 911–912. [Google Scholar] [CrossRef] [Green Version]

- Abas, N.; Kalair, A.; Khan, N. Review of fossil fuels and future energy technologies. Futures 2015, 69, 31–49. [Google Scholar] [CrossRef]

- Fulton, L.M.; Lynd, L.R.; Körner, A.; Greene, N.; Tonachel, L.R. The need for biofuels as part of a low carbon energy future. Biofuels Bioprod. Biorefin. 2015, 9, 476–483. [Google Scholar] [CrossRef]

- Fontana, G.; Galloni, E. Variable valve timing for fuel economy improvement in a small spark-ignition engine. Appl. Energy 2009, 86, 96–105. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef] [Green Version]

- Zhoua, D.; Yanga, W.; Lia, J.; Taya, K.L.; Choua, S.K.; Kraftb, M. Efficient Combustion Modelling in RCCI Engine with Detailed Chemistry. Energy Procedia 2017, 105, 1582–1587. [Google Scholar] [CrossRef]

- Petrovi, G.S.; Madi, M.J.; Markovi, D.S.; Mili, P.D.; Stefanovi, G.M. Multiple criteria decision making of alternative fuels for waste collection vehicles in southeast region of Serbia. Therm. Sci. 2016, 20 (Suppl. 5), S1585–S1598. [Google Scholar] [CrossRef] [Green Version]

- Ridjan, I.; Mathiesen, B.V.; Connolly, D.; Dui, N. The feasibility of synthetic fuels in renewable energy systems. Energy 2013, 57, 76–84. [Google Scholar] [CrossRef] [Green Version]

- Dafnomilisa, I.; Hoefnagelsb, R.; Pratamab, Y.W.; Schotta, D.L.; Lodewijksa, G.; Jungingerb, M. Review of solid and liquid biofuel demand and supply in Northwest Europe towards 2030—A comparison of national and regional projections. Renew. Sustain. Energy Rev. 2017, 78, 31–45. [Google Scholar] [CrossRef] [Green Version]

- Nogueira, L.A.H. Does biodiesel make sense? Energy 2011, 36, 3659–3666. [Google Scholar] [CrossRef]

- Rocha, M.H.; Capaz, R.S.; Lora, E.E.S.; Nogueira, L.A.H.; Leme, M.M.V.; Renó, M.L.G.; Olmo, O.A. Life cycle assessment (LCA) for biofuels in Brazilian conditions: A meta-analysis. Renew. Sustain. Energy Rev. 2014, 37, 435–459. [Google Scholar] [CrossRef]

- Bindraban, P.S.; Bulte, E.H.; Conijn, S.G. Can large-scale biofuels production be sustainable by 2020? Agric. Syst. 2009, 101, 197–199. [Google Scholar] [CrossRef]

- Demirbas, A. Biofuels securing the planet’s future energy needs. Energy Convers. Manag. 2009, 50, 2239–2249. [Google Scholar] [CrossRef]

- Kumbar, V.; Dostal, P. Temperature dependence density and kinematic viscosity of petrol, bioethanol and their blends. Pak. J. Agric. Sci. 2014, 51, 175–179. [Google Scholar]

- Demirbas, A. Future Energy Sources. In Waste Energy for Life Cycle Assessment; Springer: Cham, Switzerland, 2016; pp. 33–70. [Google Scholar]

- Mythili1, R.; Venkatachalam, P.; Subramanian, P.; Uma, D. Production characterization and efficiency of biodiesel: A review. Int. J. Energy Res. 2014, 38, 1233–1259. [Google Scholar] [CrossRef]

- Siraj, S.; Kale, R.; Deshmukh, S. Effects of Thermal, Physical, and Chemical Properties of Biodiesel and Diesel Blends. Am. J. Mech. Ind. Eng. 2017, 2, 24–31. [Google Scholar] [CrossRef]

- Poonam Singh Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Luque, R.; Herrero-Davila, L.; Campelo, J.M.; Clark, J.H.; Hidalgo, J.M.; Luna, D.; Marinas, J.M.; Romero, A.A. Biofuels: A technological perspective. Energy Environ. Sci 2008, 1, 513–596. [Google Scholar] [CrossRef]

- Abdulkareem-Alsultan, G.; Asikin-Mijan, N.; Lee, H.V.; Rashid, U.; Islam, A.; Taufiq-Yap, Y.H. A Review on Thermal Conversion of Plant Oil (Edible and Inedible) into Green Fuel Using Carbon-Based Nanocatalyst. Catalysts 2019, 9, 350. [Google Scholar] [CrossRef] [Green Version]

- Calero, J.; Luna, D.; Sancho, E.D.; Luna, C.; Bautista, F.M.; Romero, A.A.; Posadillo, A.; Berbel, J.; Verdugo-Escamilla, C. An overview on glycerol-free processes for the production of renewable liquid biofuels, applicable in diesel engines. Renew. Sustain. Energy Rev. 2015, 42, 1437–1452. [Google Scholar] [CrossRef]

- Mat, S.C.; Idroas, M.Y.; Teoh, Y.H.; Hamid, M.F. An Investigation of Viscosities, Calorific Values and Densities of Binary Biofuel Blends. In Proceedings of the MATEC Web of Conferences (ICME’17), Langkawi, Malaysis, 22–23 July 2017. [Google Scholar]

- Prakash, T.; Geo, V.E.; Martin, L.J.; Nagalingam, B. Evaluation of pine oil blending to improve the combustion of high viscous (castor oil) biofuel compared to castor oil biodiesel in a CI engine. Heat Mass Transf. 2019, 55, 1491–1501. [Google Scholar] [CrossRef]

- Von Stein, J. The International Law and Politics of Climate Change Ratification of the United Nations Framework Convention and the Kyoto Protocol. J. Confl. Resolut. 2008, 52, 243–268. [Google Scholar] [CrossRef]

- Knothe, G.; Van Gerpen, J.; Krahl, J. (Eds.) The Biodiesel Handbook, 2nd ed.; AOCS Press: Champaign, IL, USA, 2015. [Google Scholar]

- Knothe, G.; Razon, L.F. Biodiesel fuels. Prog. Energy Combust. Sci. 2017, 58, 36–59. [Google Scholar] [CrossRef]

- Nda-Umar, U.I.; Ramli, I.; Taufiq-Yap, Y.H.; Muhamad, E.N. An Overview of Recent Research in the Conversion of Glycerol into Biofuels, Fuel Additives and other Bio-Based Chemicals. Rev. Catal. 2019, 9, 15. [Google Scholar] [CrossRef] [Green Version]

- Quispe, C.A.; Coronado, C.J.; Carvalho, J.A., Jr. Glycerol: Production, consumption, prices, characterization and new trends in combustion. Renew. Sustain. Energy Rev. 2013, 27, 475–493. [Google Scholar] [CrossRef]

- Smirnov, A.A.; Selishcheva, S.A.; Yakovlev, V.A. Acetalization Catalysts for Synthesis of Valuable Oxygenated Fuel Additives from Glycerol. Catalysts 2018, 8, 595. [Google Scholar] [CrossRef] [Green Version]

- Anuar, M.R.; Abdullah, A.Z. Challenges in biodiesel industry with regards to feedstock, environmental, social and sustainability issues: A critical review. Renew. Sustain. Energy Rev. 2016, 58, 208–223. [Google Scholar] [CrossRef]

- Atadashi, I.M.; Aroua, M.K.; Abdul Aziz, A.R.; Sulaiman, N.M.N. The effects of water on biodiesel production and refining technologies: A review. Renew. Sustain. Energy Rev. 2012, 16, 3456–3470. [Google Scholar] [CrossRef]

- Garcia-Gomes, M.; Queiroz-Santos, D.; Carlos de Morais, L.; Pasquini, D. Purification of biodiesel by dry washing, employing starch and cellulose as natural adsorbents. Fuel 2015, 155, 1–6. [Google Scholar] [CrossRef]

- Squissato, A.L.; Fernandes, D.V.; Sousa, R.M.F.; Cunha, R.R.; Serqueira, D.S.; Richter, E.M.; Pasquini, P.; Muñoz, R.A.A. Eucalyptus pulp as an adsorbent for biodiesel purification. Cellulose 2015, 22, 1263–1274. [Google Scholar] [CrossRef]

- Rahmat, N.; Abdullah, A.Z.; Mohamed, A.R. Recent progress on innovative and potential technologies for glycerol transformation into fuel additives: A critical review. Renew. Sustain. Energy Rev. 2010, 14, 987–1000. [Google Scholar] [CrossRef]

- Oha, P.P.; Lau, H.L.N.; Chen, J.; Chong, M.F.; Choo, Y.M. A review on conventional technologies and emerging process intensification (PI) methods for biodiesel production. Renew. Sustain. Energy Rev. 2012, 16, 5131–5145. [Google Scholar] [CrossRef]

- Santori, G.; Di Nicola, G.; Moglie, M.; Polonara, F. A review analyzing the industrial biodiesel production practice starting from vegetable oil refining. Appl. Energy 2012, 92, 109–132. [Google Scholar] [CrossRef] [Green Version]

- Demirbas, A. Importance of biodiesel as transportation fuel. Energy Policy 2007, 35, 4661–4670. [Google Scholar] [CrossRef]

- Estevez, R.; Aguado-Deblas, L.; Luna, D.; Bautista, F.M. An Overview of the Production of Oxygenated Fuel Additives by Glycerol Etherification, Either with Isobutene or tert-Butyl Alcohol, over Heterogeneous Catalysts. Energies 2019, 12, 2364. [Google Scholar] [CrossRef] [Green Version]

- Drozdzynska, A.; Leja, K.; Czaczyk, K. Biotechnological production of 1,3-propanediol from crude glycerol. Biotechnol. J. Biotechnol. Comput. Biol. Bionanotechnol. 2011, 92, 92–100. [Google Scholar]

- Posada, J.A.; Orrego, C.E.; Cardona, C.A. Biodiesel production: Biotechnological approach. Int. Rev. Chem. Eng. 2009, 1, 571–580. [Google Scholar]

- Khang, D.S.; Tan, R.R.; Uy, O.M.; Michael Angelo, B.; Promentilla, M.G.B.; Tuan, P.-D.; Abe, N.; Razon, L.F. A design of experiments approach to the sensitivity analysis of the life cycle cost of biodiesel. Clean Technol. Environ. Policy 2018, 20, 573–580. [Google Scholar] [CrossRef]

- Calero, J.; Luna, D.; Sancho, E.D.; Luna, C.; Posadillo, A.; Bautista, F.M.; Romero, A.A.; Berbel, J.; Verdugo, C. Technological challenges for the production of biodiesel in arid lands. J. Arid Environ. 2014, 102, 127–138. [Google Scholar] [CrossRef]

- Vasudevan, P.T.; Briggs, M. Biodiesel production—Current state of the art and challenges. J. Ind. Microbiol. Biotechnol. 2008, 35, 421–430. [Google Scholar] [CrossRef]

- Okoye, B.P.U.; Hameed, H. Review on recent progress in catalytic carboxylation anda cetylation of glycerol as a byproduct of biodiesel production. Renew. Sustain. Energy Rev. 2016, 53, 558–574. [Google Scholar] [CrossRef]

- Uthoff, S.; Bröker, D.; Steinbüchel, A. Current state and perspectives of producing biodiesel-like compounds by biotechnology. Microb. Biotechnol. 2009, 2, 551–565. [Google Scholar] [CrossRef] [Green Version]

- Kijenski, J.; Lipkowski, A.; Walisiewicz-Niedbalska, W.; Gwardiak, H.; Rożyczki, K.; Pawlak, I. A Biofuel for Compression-Ignition Engines and a Method for Preparing the Biofuel. European Patent EP1580255, 26 March 2004. [Google Scholar]

- Ryms, M.; Lewandowski, W.M.; Januszewicz, K.; Klugmann-Radziemska, E.; Ciunel, K.K. Methods of liquid biofuel production-the biodiesel example. Proc. ECOpole 2013, 7, 511–516. [Google Scholar] [CrossRef]

- Kijenski, J. Biorefineries: From biofuels to the chemicalization of agricultural products. Pol. J. Chem. Technol. 2007, 9, 42–45. [Google Scholar] [CrossRef] [Green Version]

- Casas, A.; Ramos, M.J.; Pérez, A. Product Separation after Chemical Interesterification of Vegetable Oils with Methyl Acetate. Part II: Liquid–Liquid Equilibrium. Ind. Eng. Chem. Res. 2012, 51, 10201–10206. [Google Scholar] [CrossRef]

- Casas, A.; Ramos, M.J.; Pérez, A. Kinetics of chemical interesterification of sunflower oil with methyl acetate for biodiesel and triacetin production. Chem. Eng. J. 2011, 171, 1324–1332. [Google Scholar] [CrossRef]

- Casas, A.; Ramos, M.J.; Perez, A. New trends in biodiesel production: Chemical interesterification of sunflower oil with methyl acetate. Biomass Bioenergy 2011, 35, 1702–1709. [Google Scholar] [CrossRef]

- Casas, A.; Ramos, M.J.; Pérez, A. Methanol-enhanced chemical interesterification of sunflower oil with methyl acetate. Fuel 2013, 106, 869–872. [Google Scholar] [CrossRef]

- Visioli, L.J.; Trentini, C.P.; Castilhos, F.; Silva, C. Esters production in continuous reactor from macauba pulp oil using methyl acetate in pressurized conditions. J. Supercrit. Fluids 2018, 140, 238–247. [Google Scholar] [CrossRef]

- Kampars, V.; Abelniece, Z.; Blaua, S. The Unanticipated Catalytic Activity of Lithium tert-Butoxide/THF in the Interesterification of Rapeseed Oil with Methyl Acetate. Hindawi J. Chem. 2019. [Google Scholar] [CrossRef] [Green Version]

- Sile, E.; Kampars, V.; Sustere, Z. Competitive Interesterification-Transesterification of Rapeseed Oil with Methyl Acetate in Presence of Potassium Metoxide Solutions. Eng. Mater. 2018, 762, 158–162. [Google Scholar] [CrossRef]

- Kampars, V.; Abelniece, Z.; Kampare, R. Biofuel via interesterification of rapeseed oil with methyl acetate in presence of potassium t-butoxide/THF. SWS J. Earth Planet. Sci. 2019, 1, 1–10. [Google Scholar] [CrossRef]

- Brondani, L.N.; Simões, S.S.; Celante, D.; Castilhos, F. Kinetic Modeling of Supercritical Interesterification with Heterogeneous Catalyst to Produce Methyl Esters Considering Degradation Effects. Ind. Eng. Chem. Res. 2019, 58, 816–827. [Google Scholar] [CrossRef]

- Sustere, Z.; Murnieks, R.; Kampars, V. Chemical interesterification of rapeseed oil with methyl, ethyl, propyl and isopropyl acetates and fuel properties of obtained mixtures. Fuel Process. Technol. 2016, 149, 320–325. [Google Scholar] [CrossRef]

- Singh, D.S.; Tat, T.K. Optimization of biodiesel production via methyl acetate reaction from cerbera odollam. Adv. Energy Res. 2016, 4, 325–337. [Google Scholar] [CrossRef]

- Ribeiro, J.S.; Celante, D.; Simoe, S.S.; Bassac, M.M.; Silva, C.; Castilhos, F. Efficiency of heterogeneous catalysts in interesterification reaction from macaw oil (Acrocomia aculeata) and methyl acetate. Fuel 2017, 200, 499–505. [Google Scholar] [CrossRef]

- Māliņš, K.; Kampars, V.; Kampare, R.; Sustere, Z.; Arenta, A. Production of Biodiesel and Triacetin by Interesterification of Rapeseed Oil. Key Eng. Mater. 2018, 762, 129–133. [Google Scholar] [CrossRef]

- Simões, S.S.; Ribeiro, J.S.; Celante, D.; Brondani, L.N.; Castilhos, F. Heterogeneous catalyst screening for fatty acid methyl esters production through interesterification reaction. Renew. Energy 2020, 146, 719–726. [Google Scholar] [CrossRef]

- Tian, Y.; Xiang, J.; Verni, C.C.; Soh, L. Fatty acid methyl ester production via ferric sulfate catalyzed interesterification. Biomass Bioenergy 2018, 115, 82–87. [Google Scholar] [CrossRef]

- Ribeiro, J.S.; Celante, D.; Brondani, L.N.; Trojahn, D.O.; Silva, C.; Castilhos, F. Synthesis of methyl esters and triacetin from macaw oil (Acrocomia aculeata) and methyl acetate over γ-alumina. Ind. Crops Prod. 2018, 124, 84–90. [Google Scholar] [CrossRef]

- Gupta, A.R.; Yadav, S.V.; Rathod, V.K. Enhancement in biodiesel production using waste cooking oil and calcium diglyceroxide as a heterogeneous catalyst in presence of ultrasound. Fuel 2015, 158, 800–806. [Google Scholar] [CrossRef]

- Galia, A.; Centineo, A.; Saracco, G.; Schiavo, B.; Scialdone, O. Interesterification of rapeseed oil catalyzed by tin octoate. Biomass Bioenergy 2014, 67, 193–200. [Google Scholar] [CrossRef]

- Man, I.C.; Soriga, S.G.; Parvulescu, V. Theoretical aspects of methyl acetate and methanol activation on MgO(100) and (501) catalyst surfaces with application in FAME production. Appl. Surf. Sci. 2017, 392, 920–928. [Google Scholar] [CrossRef]

- Man, I.C.; Soriga, S.G.; Parvulescu, V. Effect of Ca and Sr in MgO(100) on the activation of methanol and methyl acetate. Catal. Today 2018, 306, 207–214. [Google Scholar] [CrossRef]

- Alves, M.A.L.; Pinheiro, N.S.C.; Brondani, L.N.; Celante, D.; Ketzer, F.; Castilhos, F. Assessment of niobium phosphate as heterogeneous catalyst in esterification with methyl acetate. Chem. Technol. Biotechnol. 2019, 94, 3172–3179. [Google Scholar] [CrossRef]

- Komintarachat, C.; Tongroon, M.; Chuepeng, S. Biofuel Synthesis from Waste Cooking Oils and Ethyl Acetate via Interesterification under CaO Catalyst from Waste Eggshells. In Proceedings of the 2018 Third International Conference on Engineering Science and Innovative Technology (ESIT), North Bangkok, Thailand, 19–22 April 2018. [Google Scholar]

- Casas, A.; Ramos, M.J.; Pérez, A. Adsorption equilibrium and kinetics of methyl acetate/methanol and methyl acetate/water mixtures on zeolite 5A. Chem. Eng. J. 2013, 220, 337–342. [Google Scholar] [CrossRef]

- Demirbas, A. Comparison of transesterification methods for production of biodiesel from vegetable oils and fats. Energy Convers. Manag. 2008, 49, 125–130. [Google Scholar] [CrossRef]

- Xu, Y.; Du, W.; Liu, D.; Zeng, J. A novel enzymatic route for biodiesel production from renewable oils in a solvent-free medium. Biotechnol. Lett. 2003, 25, 1239–1241. [Google Scholar] [CrossRef]

- Xu, Y.; Du, W.; Liu, D. Study on the kinetics of enzymatic interesterification of triglycerides for biodiesel production with methyl acetate as the acyl acceptor. J. Mol. Catal. B Enzym. 2005, 32, 241–245. [Google Scholar] [CrossRef]

- Du, W.; Xu, Y.; Liu, D.; Zeng, J. Comparative study on lipase-catalyzed transformation of soybean oil for biodiesel production with different acyl acceptors. J. Mol. Catal. B Enzym. 2004, 30, 125–129. [Google Scholar] [CrossRef]

- Orçaire, O.; Buisson, P.; Pierre, A.C. Application of silica aerogel encapsulated lipases in the synthesis of biodiesel by transesterification reactions. J. Mol. Catal. B Enzym. 2006, 42, 106–113. [Google Scholar] [CrossRef]

- Usai, E.M.; Gualdi, E.; Solinas, V.; Battistel, E. Simultaneous enzymatic synthesis of FAME and triacetyl glycerol from triglycerides and methyl acetate. Bioresour. Technol. 2010, 101, 7707–7712. [Google Scholar] [CrossRef]

- Huang, Y.; Yan, Y. Lipase-Catalyzed Biodiesel Production with Methyl Acetate as Acyl Acceptor. Z. Nat. C 2008, 63, 297–302. [Google Scholar] [CrossRef] [PubMed]

- Ognjanovic, N.; Bezbradica, D.; Knezevic-Jugovic, Z. Enzymatic conversion of sunflower oil to biodiesel in a solvent-free system: Process optimization and the immobilized system stability. Bioresour. Technol. 2009, 100, 5146–5154. [Google Scholar] [CrossRef] [PubMed]

- Talukder, M.M.R.; Das, P.; Fang, T.S.; Wu, J.C. Enhanced enzymatic transesterification of palm oil to biodiesel. Biochem. Eng. J. 2011, 55, 119–122. [Google Scholar] [CrossRef]

- Vasudevan, P.T.; Fu, B. Environmentally Sustainable Biofuels: Advances in Biodiesel Research. Waste Biomass Valorization 2010, 1, 47–63. [Google Scholar] [CrossRef]

- Razack, S.A.; Duraiarasan, S. Response surface methodology assisted biodiesel production from waste cooking oil using encapsulated mixed enzyme. Waste Manag. 2016, 47, 98–104. [Google Scholar] [CrossRef]

- Surendhiran, D.; Sirajunnisa, A.R.; Vijay, M. An alternative method for production of microalgal biodiesel using novel Bacillus lipase. 3 Biotech. 2015, 5, 715–725. [Google Scholar] [CrossRef] [Green Version]

- Marx, S. Glycerol-free biodiesel production through transesterification: A review. Fuel Process. Technol. 2016, 151, 139–147. [Google Scholar] [CrossRef]

- Norjannah, B.; Ong, H.C.; Masjuki, H.H.; Juan, J.C.; Chong, W.T. Enzymatic transesterification for biodiesel production: A comprehensive review. RSC Adv. 2016, 6, 60034–60055. [Google Scholar] [CrossRef]

- Van Dammea, S.; Brama, S.; Contino, F. Comparison of biodiesel production scenarios with coproduction of triacetin according to energy and GHG missions. Energy Procedia 2014, 61, 1852–1859. [Google Scholar] [CrossRef] [Green Version]

- Karmee, S.K. Lipase Catalyzed Synthesis of Fatty Acid Methyl Esters from Crude Pongamia Oil. Energy Sources Part A Recovery Util. Environ. Eff. 2015, 37, 536–542. [Google Scholar] [CrossRef]

- Ognjanović, N.D.; Šaponjić, S.V.; Bezbradica, D.I.; Knežević, Z.D. Lipase-catalyzed biodiesel synthesis with different acyl acceptors. APTEFF 2008, 39, 161–169. [Google Scholar] [CrossRef]

- Nguyen, H.C.; Liang, S.H.; Chen, S.S.; Su, C.H.; Lin, I.H.; Chien, C.C. Enzymatic production of biodiesel from insect fat using methyl acetate as an acyl acceptor: Optimization by using response surface methodology. Energy Convers. Manag. 2018, 158, 168–175. [Google Scholar] [CrossRef]

- Alavijeh, R.S.; Tabandeh, F.; Tavakoli, O.; Karkhane, A.; Shariati, P. Enzymatic Production of Biodiesel from Microalgal Oil using Ethyl Acetate as an Acyl Acceptor. J. Oleo Sci. 2015, 64, 69–74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruzich, N.I.; Bassi, A.S. Investigation of Enzymatic Biodiesel Production using Ionic Liquid as a Co-solvent. Can. J. Chem. Eng. 2010, 68, 277–284. [Google Scholar] [CrossRef]

- Ruzich, N.I.; Bassi, A.S. Proposed kinetic mechanism of biodiesel production through lipase catalysed interesterification with a methyl acetate acyl acceptor and ionic liquid [BMIM][PF6] co-solvent. Can. J. Chem. Eng. 2011, 89, 166–170. [Google Scholar] [CrossRef]

- Muhammada, N.; Elsheikh, Y.A.; Mutalib, M.I.A.; Bazmi, A.A.; Khan, R.A.; Khan, H.; Rafiq, S.; Man, Z.; Khan, I. An overview of the role of ionic liquids in biodiesel reactions. J. Ind. Eng. Chem. 2015, 21, 1–10. [Google Scholar] [CrossRef]

- Andreani, L.; Rocha, J.D. Use of ionic liquids in biodiesel production: A review. Braz. J. Chem. Eng. 2012, 29, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Saka, S.; Isayama, Y. A new process for catalyst-free production of biodiesel using supercritical methyl acetate. Fuel 2009, 88, 1307–1313. [Google Scholar] [CrossRef] [Green Version]

- Tan, K.T.; Lee, K.T.; Mohamed, A.R. A glycerol-free process to produce biodiesel by supercritical methyl acetate technology: An optimization study via Response Surface Methodology. Bioresour. Technol. 2010, 101, 965–969. [Google Scholar] [CrossRef]

- Campanelli, P.; Banchero, M.; Manna, L. Synthesis of biodiesel from edible, non-edible and waste cooking oils via supercritical methyl acetate transesterification. Fuel 2010, 89, 3675–3682. [Google Scholar] [CrossRef]

- Niza, N.M.; Tan, K.; Ahmad, Z.; Lee, K.T. Comparison and optimisation of biodiesel production from Jatropha curcas oil using supercritical methyl acetate and methanol. Chem. Pap. 2011, 65, 721–729. [Google Scholar] [CrossRef]

- Niza, N.M.; Tan, K.T.; Lee, K.T.; Ahmad, Z. Biodiesel production by non-catalytic supercritical methyl acetate: Thermal stability study. Appl. Energy 2013, 101, 198–202. [Google Scholar] [CrossRef]

- Goembira, F.; Matsuura, K.; Saka, S. Biodiesel production from rapeseed oil by various supercritical carboxylate esters. Fuel 2012, 97, 373–378. [Google Scholar] [CrossRef] [Green Version]

- Bernal, M.; Lozano, P.; García-Verdugo, E.; Burguete, M.I.; Sánchez-Gómez, G.; López-López, G.; Pucheault, M.; Vaultier, M.; Luis, S.V. Supercritical Synthesis of Biodiesel. Review. Molecules 2012, 17, 8696–8719. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lourinho, G.; Brito, P. Advanced biodiesel production technologies: Novel developments. Rev. Environ. Sci. Biotechnol. 2015, 14, 287–316. [Google Scholar] [CrossRef]

- Komintarachat, C.; Sawangkeaw, R.; Ngamprasertsith, S. Continuous production of palm biofuel under supercritical ethyl acetate. Energy Convers. Manag. 2015, 93, 332–338. [Google Scholar] [CrossRef]

- Goembira, F.; Saka, S. Advanced supercritical Methyl acetate method for biodiesel production from Pongamia pinnata oil. Renew. Energy 2015, 83, 1245–1249. [Google Scholar] [CrossRef]

- Hoang, D.; Bensaid, S.; Saracco, G. Supercritical fluid technology in biodiesel production. Green Process. Synth. 2013, 2, 407–425. [Google Scholar] [CrossRef]

- Farobie, O.; Matsumura, Y. State of the art of biodiesel production under supercritical conditions. Prog. Energy Combust. Sci. 2017, 63, 173–203. [Google Scholar] [CrossRef]

- Patil, P.D.; Reddy, H.; Muppaneni, T.; Deng, S. Biodiesel fuel production from algal lipids using supercritical methyl acetate (glycerin-free) technology. Fuel 2017, 195, 201–207. [Google Scholar] [CrossRef] [Green Version]

- Sootchiewcharn, N.; Attanatho, L.; Reubroycharoen, P. Biodiesel Production from Refined Palm Oil using Supercritical Ethyl Acetate in A Microreactor. Energy Procedia 2015, 79, 697–703. [Google Scholar] [CrossRef] [Green Version]

- Lamba, N.; Gupta, K.; Modak, J.M.; Madras, G. Biodiesel synthesis from Calophyllum inophyllum oil with different supercritical fluids. Bioresour. Technol. 2017, 241, 767–774. [Google Scholar] [CrossRef] [PubMed]

- Maddikeri, G.L.; Pandit, A.B.; Gogate, P.R. Ultrasound assisted interesterification of waste cooking oil and methyl acetate for biodiesel and triacetin production. Fuel Process. Technol. 2013, 116, 241–249. [Google Scholar] [CrossRef]

- Tavares, G.R.; Gonzalves, J.E.; dos Santos, W.D.; da Silvad, C. Enzymatic interesterification of crambe oil assisted by ultrasound. Ind. Crops Prod. 2017, 97, 218–223. [Google Scholar] [CrossRef]

- Subhedar, P.B.; Gogate, P.R. Ultrasound assisted intensification of biodiesel production using enzymatic interesterification. Ultrason. Sonochem. 2016, 29, 67–75. [Google Scholar] [CrossRef]

- Bokhari, A.; Suzana Yusup, S.; Chuah, L.F.; Klemeš, J.J.; Asif, S.; Ali, B.; Akbar, M.M.; Kamil, R.N.M. Pilot scale intensification of rubber seed (Hevea brasiliensis) oil via chemical interesterification using hydrodynamic cavitation technology. Bioresour. Technol. 2017, 242, 272–282. [Google Scholar] [CrossRef]

- Kashyap, S.S.; Gogate, P.R.; Joshi, S.M. Ultrasound assisted synthesis of biodiesel from karanja oil by interesterification: Intensification studies and optimization using RSM. Ultrason. Sonochem. 2019, 50, 36–45. [Google Scholar] [CrossRef]

- Sustere, Z.; Kampars, V. Chemical Interesterification of the Rapeseed Oil with Methyl Acetate in the Presence of Potassium tert-Butoxide in tert-Butanol. Int. J. Eng. Technol. Res. 2015, 3, 226–232. [Google Scholar]

- Kovalenko, G.A.; Perminova, L.V.; Beklemishev, A.B.; Yakovleva, E.Y.; Pykhtina, M.B. Heterogeneous biocatalytic processes of vegetable oil interesterification to biodiesel. Catal. Ind. 2015, 7, 73–81. [Google Scholar] [CrossRef]

- Valdis, K.; Zane, S.; Ruta, K. Biofuel via interesterification of rapeseed oil with methyl acetate in presence of potassium t-butoxide/THF. Min. Ecol. Manag. 2018, 18, 163–170. [Google Scholar] [CrossRef]

- Aldo, M.; Medeiros, A.M.; Santos, E.R.M.; Azevedo, S.H.G.; Jesus, A.A.; Oliveira, H.N.M.; Sousa, E.M.B.D. Chemical interesterification of cotton oil with methyl acetate assisted by ultrasound for biodiesel production. Braz. J. Chem. Eng. 2018, 35, 1005–1018. [Google Scholar] [CrossRef] [Green Version]

- Ketzer, F.; Celante, D.; de Castilhos, F. Catalytic performance and ultrasonic-assisted impregnation effects on WO3/USY zeolites in esterification of oleic acid with methyl acetate. Microporous Mesoporous Mater. 2020, 291, 109704. [Google Scholar] [CrossRef]

- Kashyap, S.S.; Gogate, P.R.; Joshi, S.M. Ultrasound assisted intensified production of biodiesel from sustainable source as karanja oil using interesterification based on heterogeneous catalyst (γ-alumina). Chem. Eng. Process. Process. Intensif. 2019, 136, 11–16. [Google Scholar] [CrossRef]

- Poppe, J.K.; Matte, C.R.; Fernandez-Lafuente, R.; Rodrigues, R.C.; Ayub, M.A.Z. Transesterification of Waste Frying Oil and Soybean Oil by Combi-lipases Under Ultrasound-Assisted Reactions. Appl. Biochem. Biotechnol. 2018, 186, 576–589. [Google Scholar] [CrossRef] [PubMed]

- da Silva, S.B.; Garcia, V.A.S.; Arroyo, P.A.; da Silva, C. Ultrasound-assisted extraction of radish seed oil with methyl acetate for biodiesel production. Can. J. Chem. Eng. 2017, 95, 2142–2147. [Google Scholar] [CrossRef]

- Gusniah, A.; Veny, H.; Hamzah, F. Ultrasonic Assisted Enzymatic Transesterification for Biodiesel Production. Ind. Eng. Chem. Res. 2019, 58, 581–589. [Google Scholar] [CrossRef]

- Pukale, D.D.; Maddikeri, G.L.; Gogate, P.R.; Pandit, A.B.; Pratap, A.P. Ultrasound assisted transesterification of waste cooking oil using heterogeneous solid catalyst. Ultrason. Sonochem. 2015, 22, 278–286. [Google Scholar] [CrossRef]

- Kusumaningtyas, R.D.; Pristiyani, R.; Dewajani, H. A New Route of Biodiesel Production through Chemical Interesterification of Jatropha Oil using Ethyl Acetate. Int. J. ChemTech Res. 2016, 9, 627–634. [Google Scholar]

- Leonardo Interrante, L.; Bensaid, S.; Galletti, C.; Pirone, R.; Schiavo, B.; Scialdone, O.; Galia, A. Interesterification of rapeseed oil catalysed by a low surface area tin (II) oxide heterogeneous catalyst. Fuel Process. Technol. 2018, 177, 336–344. [Google Scholar] [CrossRef]

- Kim, S.J.; Jung, S.M.; Park, Y.C.; Park, K. Lipase catalyzed transesterification of soybean oil using ethyl acetate, an alternative acyl acceptor. Biotechnol. Bioprocess. Eng. 2007, 12, 441–445. [Google Scholar] [CrossRef]

- Chuepeng, S.; Komintarachat, C. Interesterification optimization of waste cooking oil and ethyl acetate over homogeneous catalyst for biofuel production with engine validation. Appl. Energy 2018, 232, 728–739. [Google Scholar] [CrossRef]

- Jeong, G.T.; Park, D.H. Synthesis of Rapeseed Biodiesel Using Short-Chained Alkyl Acetates as Acyl Acceptor. Appl. Biochem. Biotechnol. 2010, 161, 195–208. [Google Scholar] [CrossRef] [PubMed]

- Miesiac, I.; Rogalinski, A.; Jozwiak, P. Transesterification of triglycerides with ethyl acetate. Fuel 2013, 105, 169–175. [Google Scholar] [CrossRef]

- Melero, J.A.; Vicente, G.; Morales, G.; Paniagua, M.; Bustamante, J. Oxygenated compounds derived from glycerol for biodiesel formulation: Influence on EN 14214 quality parameters. Fuel 2010, 89, 2011–2018. [Google Scholar] [CrossRef]

- Gonzalves, V.L.C.; Pinto, B.P.; Silva, J.C.; Mota, C.J.A. Acetylation of glycerol catalyzed by different solid acids. Catal. Today 2008, 133, 673–677. [Google Scholar] [CrossRef]

- Liao, X.; Zhua, Y.; Wang, S.G.; Li, Y. Producing triacetylglycerol with glycerol by two steps: Esterification and acetylation. Fuel Process. Technol. 2009, 90, 988–993. [Google Scholar] [CrossRef]

- Balaraju, M.; Nikhitha, P.; Jagadeeswaraiah, K.; Srilatha, K.; Sai Prasad, P.S.; Lingaiah, N. Acetylation of glycerol to synthesize bioadditives over niobic acid supported tungstophosphoric acid catalysts. Fuel Process. Technol. 2010, 91, 249–253. [Google Scholar] [CrossRef]

- Rezayat, M.; Ghaziaskar, H.S. Continuous synthesis of glycerol acetates in supercritical carbon dioxideusing Amberlyst 15®. Green Chem. 2009, 11, 710–715. [Google Scholar] [CrossRef]

- Galana, M.I.; Bonet., J.; Sire, R.; Reneaume, J.M.; Plesu, A.E. From residual to useful oil: Revalorization of glycerine from the biodiesel synthesis. Bioresour. Technol. 2009, 100, 3775–3778. [Google Scholar] [CrossRef]

- Bonet, J.; Costa, J.; Sire, R.; Reneaume, J.M.; Plesu, A.E.; Plesu, V.; Bozga, G. Revalorization of glycerol: Comestible oil from biodiesel synthesis. Food Bioprod. Process. 2009, 87, 171–178. [Google Scholar] [CrossRef]

- Ferreira, P.; Fonseca, I.M.; Ramos, A.M.; Vital, J.; Castanheiro, J.E. Acetylation of glycerol over heteropolyacids supported on activated carbon. Catal. Commun. 2011, 12, 573–576. [Google Scholar] [CrossRef]

- Dosuna-Rodríguez, I.; Gaigneaux, E.M. Glycerol acetylation catalysed by ion exchange resins. Catal. Today 2012, 195, 14–21. [Google Scholar] [CrossRef]

- Testa, M.L.; La Parola, V.; Liotta, L.F.; Venezia, A.M. Screening of different solid acid catalysts for glycerol acetylation. J. Mol. Catal. A Chem. 2013, 367, 69–76. [Google Scholar] [CrossRef]

- Costa, B.O.D.; Decolattia, H.P.; Legnoverde, M.S.; Querini, C.A. Influence of acidic properties of different solid acid catalysts for glycerol acetylation. Catal. Today 2017, 289, 222–230. [Google Scholar] [CrossRef]

- Huang, M.Y.; Han, X.X.; Hung, C.T.; Lin, J.C.; Wuc, P.H.; Wud, J.C.; Liu, S.B. Heteropolyacid-based ionic liquids as efficient homogeneous catalysts for acetylation of glycerol. J. Catal. 2014, 320, 42–51. [Google Scholar] [CrossRef]

- Khayoon, M.S.; Triwahyono, S.; Hameed, B.H.; Jalil, A.A. Improved production of fuel oxygenates via glycerol acetylation with acetic acid. Chem. Eng. J. 2014, 243, 473–484. [Google Scholar] [CrossRef]

- Betiha, M.A.; Hassan, H.M.A.; El-Sharkawy, E.A.; Al-Sabagh, A.M.; Menoufy, M.F.; Abdelmoniem, H.-E.M. A new approach to polymer-supported phosphotungstic acid: Application for glycerol acetylation using robust sustainable acidic heterogeneous–homogenous catalyst. Appl. Catal. B Environ. 2016, 182, 15–25. [Google Scholar] [CrossRef]

- Sandesh, S.; Manjunathan, P.; Halgeri, A.B.; Shanbhag, G.V. Glycerol acetins: Fuel additive synthesis by acetylation and esterification of glycerol using cesium phosphotungstate catalyst. RSC Adv. 2015, 5, 104354–104362. [Google Scholar] [CrossRef]

- Kong, P.S.; Aroua, M.K.; Daud, W.M.A.W.; Lee, H.V.; Cognet, P.; Peres-Lucchese, Y. Catalytic role of solid acid catalysts in glycerol acetylation for the production of bio-additives: A review. RSC Adv. 2016, 6, 68885–68905. [Google Scholar] [CrossRef]

- Okoye, P.U.; Abdullah, A.Z.; Hameed, B.H. A review on recent developments and progress in the kinetics and deactivation of catalytic acetylation of glycerol—A byproduct of biodiesel. Renew. Sustain. Energy Rev. 2017, 74, 387–401. [Google Scholar] [CrossRef]

- Casas, A.; Ruiz, J.R.; Ramos, M.J.; Perez, A. Effects of triacetin on biodiesel quality. Energy Fuels 2010, 24, 4481–4489. [Google Scholar] [CrossRef]

- Rao, P.V.; Rao, B.V.A. Performance, Emission and Cylinder Vibration studies of DI-Diesel Engine with COME-Triacetin Additive Blends. Int. J. Therm. Technol. 2011, 1, 100–109. [Google Scholar]

- Rao, P.V.; Rao, B.V.A.; Radhakrishna, D. Experimental Analysis of DI Diesel Engine Performance with Triacetin Blend Fuels of Oxygenated Additive and COME Biodiesel. Iran. J. Energy Environ. 2012, 3, 109–117. [Google Scholar] [CrossRef]

- Zare, A.; Bodisco, T.A.; Nabi, M.N.; Hossain, F.M.; Ristovski, Z.D.; Brown, R.J. Engine Performance during Transient and Steady-State Operation with Oxygenated Fuels. Energy Fuels 2017, 31, 7510–7522. [Google Scholar] [CrossRef]

- Zare, A.; Nabi, M.N.; Bodisco, T.A.; Hossain, F.M.; Rahman, M.M.; Ristovski, Z.D.; Brown, R.J. The effect of triacetin as a fuel additive to waste cooking biodiesel on engine performance and exhaust emissions. Fuel 2016, 182, 640–649. [Google Scholar] [CrossRef] [Green Version]

- Mukhopadhyay, P.; Chakraborty, R. Effects of Bioglycerol Based Fuel Additives on Diesel Fuel Property, Engine Performance and Emission Quality: A Review. Energy Procedia 2015, 79, 671–676. [Google Scholar] [CrossRef] [Green Version]

- Hedayat, F.; Stevanovic, S.; Milic, A.; Miljevic, B.; Nabi, M.N.; Zare, A.; Bottle, S.E.; Brown, R.J.; Ristovski, Z.D. Influence of oxygen content of the certain types of biodiesels on particulate oxidative potential. Sci. Total Environ. 2016, 545, 381–388. [Google Scholar] [CrossRef] [Green Version]

- Rachel, C.; Senra, M.; Soh, L. Cold Flow Properties of Fatty Acid Methyl Ester Blends with and without Triacetin. Energy Fuels 2016, 30, 7400–7409. [Google Scholar] [CrossRef]

- Lacerda, C.V.; Carvalho, M.J.S.; Ratton, A.R.; Soares, I.P.; Borgesa, L.E.P. Synthesis of Triacetin and Evaluation on Motor. J. Braz. Chem. Soc. 2015, 26, 1625–1631. [Google Scholar] [CrossRef]

- Zare, A.; Bodisco, T.; Nabi, M.N.; Farhad, H.M.; Rahman, M.M.; Stuart, D.; Ristovski, Z.; Brown, R.J. Impact of Triacetin as an oxygenated fuel additive to waste cooking biodiesel: Transient engine performance and exhaust emissions. In Proceedings of the Australian Combustion Symposium, Melbourne, Australia, 7–9 December 2015. [Google Scholar]

- Rao, P.V.; Rao, B.V.A. Performance and emission characteristics of diesel engine with COME-Triacetin additive blends as fuel. Int. J. Energy Environ. 2012, 3, 629–638. [Google Scholar]

- Rao, P.V. Role of Triacetin additive in the performance of single cylinder D I diesel engine with COME biodiesel. Int. J. Adv. Eng. Res. Sci. 2018, 5, 253–260. [Google Scholar] [CrossRef] [Green Version]

- Meisam Tabatabaei, M.; Aghbashlo, M.; Najafi, B.; Hosseinzadeh-Bandbafha, H.; Ardabili, S.F.; Akbarian, E.; Khalife, E.; Mohammadi, P.; Rastegari, H.; Ghaziaskar, H.S. Environmental impact assessment of the mechanical shaft work produced in a diesel engine running on diesel/biodiesel blends containing glycerol-derived triacetin. J. Clean. Prod. 2019, 223, 466–486. [Google Scholar] [CrossRef]

- Rao, P.V.; Rao, B.V.A. Heat release rate, performance and vibration analysis of diesel engine operating with biodiesel-triacetin additive blend fuels. Int. J. Automob. Eng. Res. Dev. 2018, 8, 11–22. [Google Scholar]

- Zare, A.; Bodisco, T.A.; Nabi, M.N.; Hossain, F.M.; Rahman, M.M.; Ristovski, Z.D.; Brown, R.J. The influence of oxygenated fuels on transient and steady-state engine emissions. Energy 2017, 121, 841–853. [Google Scholar] [CrossRef] [Green Version]

- Panda, K.; Sastry, G.R.K.S.; Rai, R.N. Experimental analysis of performance and emission on DI diesel engine fueled with diesel-palm kernel methyl ester-triacetin blends: A Taguchi fuzzy-based optimization. Environ. Sci. Pollut. Res. 2018, 25, 22035–22051. [Google Scholar] [CrossRef]

- Sakdasri, W.; Ngamprasertsith, S.; Daengsanun, S.; Sawangkeaw, R. Lipid-based biofuel synthesized from palm-olein oil by supercritical ethyl acetate in fixed-bed reactor. Energy Convers. Manag. 2019, 182, 215–223. [Google Scholar] [CrossRef]

- Lapuerta, M.; González-García, I.; Céspedes, I.; Estévez, C.; Bayarri, N. Improvement of cold flow properties of a new biofuel derived from glycerol. Fuel 2019, 242, 794–803. [Google Scholar] [CrossRef]

- Żółtowski, A.; Grzelak, P.L. Emissions from engines fuelled with biofuels. J. Kones Powertrain Transp. 2018, 25, 533–539. [Google Scholar] [CrossRef]

- Ang, G.T.; Tan, K.T.; Lee, K.T. Recent development and economic analysis of glycerol-free processes via supercritical fluid transesterification for biodiesel production. Renew. Sustain. Energy Rev. 2014, 31, 61–70. [Google Scholar] [CrossRef]

- Kralisch, D.; Staffel, C.; Ott, D.; Bensaid, S.; Saracco, G.; Bellantonic, P.; Loebd, P. Process design accompanying life cycle management and risk analysis as a decision support tool for sustainable biodiesel production. Green Chem. 2013, 15, 463–477. [Google Scholar] [CrossRef]

- Yusof, Z. An overview of current issues on fabrication, application and metallic corrosion of biodiesel. J. Petrochem. Eng. Dep. 2015, 2, 25–55. [Google Scholar]

- Li, Y.; Zhao, X.; Wang, Y. Synthesis of dimethyl carbonate from methanol, propylene oxide and carbon dioxide over KOH/4A molecular sieve catalyst. Appl. Catal. A 2005, 279, 205–208. [Google Scholar] [CrossRef]

- Choi, J.C.; He, L.N.; Yasuda, H.; Sakakura, T. Selective and high yield synthesis of dimethyl carbonate directly from carbon dioxide and methanol. Green Chem. 2002, 4, 230–234. [Google Scholar] [CrossRef]

- Teng, W.K.; Ngoh, G.C.; Yusoff, R.; Aroua, M.K. A review on the performance of glycerol carbonate production via catalytic transesterification: Effects of influencing parameters. Energy Convers. Manag. 2014, 88, 484–497. [Google Scholar] [CrossRef]

- Tudorache, M.; Negoi, A.; Tudora, B.; Parvulescu, V.I. Environmental-friendly strategy for biocatalytic conversion of waste glycerol to glycerol carbonate. Appl. Catal. B Environ. 2014, 146, 274–278. [Google Scholar] [CrossRef]

- Tudorache, M.; Nae, A.; Coman, S.; Parvulescu, V.I. Strategy of cross-linked enzyme aggregates ontomagnetic particles adapted to the green design of biocatalytic synthesis of glycerol carbonate. RSC Adv. 2013, 3, 4052–4058. [Google Scholar] [CrossRef]

- Lanjekar, K.; Rathod, V.K. Utilization of glycerol for the production of glycerol carbonate through greener route. J. Environ. Chem. Eng. 2013, 1, 1231–1236. [Google Scholar] [CrossRef]

- Ji, Y. Review. Recent Development of Heterogeneous Catalysis in the Transesterification of Glycerol to Glycerol Carbonate. Catalysts 2019, 9, 581. [Google Scholar] [CrossRef] [Green Version]

- Algoufi, Y.T.; Kabir, G.; Hameed, B.H. Synthesis of glycerol carbonate from biodiesel by-product glycerol over calcined dolomite. J. Taiwan Inst. Chem. Eng. 2017, 70, 179–187. [Google Scholar] [CrossRef]

- Algoufi, Y.T.; Akpan, U.G.; Kabir, G.; Asif, B.M.; Hameed, H. Upgrading of glycerol from biodiesel synthesis with dimethyl carbonate on reusable Sr–Al mixed oxide catalysts. Energy Convers. Manag. 2017, 138, 183–189. [Google Scholar] [CrossRef]

- Parameswaram, G.; Srinivas, M.; Babu, B.H.; Prasad, P.S.S.; Lingaiah, N. Transesterification of glycerol with dimethyl carbonate for the synthesis of glycerol carbonate over Mg/Zr/Sr mixed oxide base catalysts. Catal. Sci. Technol. 2013, 3, 3242–3249. [Google Scholar] [CrossRef]

- Okoye, P.U.; Abdullah, A.Z.; Hameed, B.H. Stabilized ladle furnace steel slag for glycerol carbonate synthesis via glycerol transesterification reaction with dimethyl carbonate. Energy Convers. Manag. 2017, 133, 477–485. [Google Scholar] [CrossRef]

- Okoye, P.U.; Abdullah, A.Z.; Hameed, B.H. Glycerol carbonate synthesis from glycerol and dimethyl carbonate using trisodium phosphate. J. Taiwan Inst. Chem. Eng. 2016, 68, 51–58. [Google Scholar] [CrossRef]

- Wang, S.; Hao, P.; Li, S.; Zhang, A.; Guan, Y.; Zhang, L. Synthesis of glycerol carbonate from glycerol and dimethyl carbonate catalyzed by calcined silicates. Appl. Catal. A Gen. 2017, 542, 174–181. [Google Scholar] [CrossRef]

- Wan, Y.; Lei, Y.; Lan, G.; Liu, D.; Li, G.; Bai, R. Synthesis of glycerol carbonate from glycerol and dimethyl carbonate over DABCO embedded porous organic polymer as a bifunctional and robust catalyst. Appl. Catal. A Gen. 2018, 562, 267–275. [Google Scholar] [CrossRef]

- Fabbri, D.; Bevoni, V.; Notari, M.; Rivetti, F. Properties of a potential biofuel obtained from soybean oil by transmethylation with dimethyl carbonate. Fuel 2007, 86, 690–697. [Google Scholar] [CrossRef]

- Notari, M.; Rivetti, F. Use of a Mixture of Esters of Fatty Acids as Fuel or Solvent. Patent No. WO2004/052874, 24 March 2004. [Google Scholar]

- Islam, M.R.; Kurle, Y.M.; Gossage, J.L.; Benson, T.J. Kinetics of Triazabicyclodecene-Catalyzed Canola Oil Conversion to Glycerol-free Biofuel Using Dimethyl Carbonate. Energy Fuels 2013, 27, 1564–1569. [Google Scholar] [CrossRef]

- Zhang, L.; Sheng, B.; Xin, Z.; Liu, Q.; Sun, S. Kinetics of transesterification of palm oil and dimethyl carbonate for biodiesel production at the catalysis of homogeneous base catalyst. Bioresour. Technol. 2010, 101, 8144–8150. [Google Scholar] [CrossRef]

- Celante, D.; Schenkel, J.V.D.; Castilhos, F. Biodiesel production from soybean oil and dimethyl carbonate catalyzed by potassium methoxide. Fuel 2018, 212, 101–107. [Google Scholar] [CrossRef]

- Dawodu, F.A.; Ayodele, O.O.; Xin, J.; Zhang, S. Dimethyl carbonate mediated production of biodiesel at different reaction temperatures. Renew. Energy 2014, 68, 581–587. [Google Scholar] [CrossRef]

- Panchal, B.M.; Deshmukh, S.A.; Sharma, M.R. Kinetic and effective production of DMC-Sm-BioDs from Sapindus mukorossi seed kernel powder using dimethyl carbonate with KOH–Folch mixture solution as a catalyst. Biofuels 2015, 6, 305–312. [Google Scholar] [CrossRef]

- Kai, T.; Mak, G.L.; Wada, S.; Nakazato, T.; Takanashi, H.; Uemura, Y. Production of biodiesel fuel from canola oil with dimethyl carbonate using an active sodium methoxide catalyst prepared by crystallization. Bioresour. Technol. 2014, 163, 360–363. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Syamsuddin, Y.; Murat, M.N.; Hameed, B.H. Transesterification of Jatropha oil with dimethyl carbonate to produce fatty acid methyl ester over reusable Ca–La–Al mixed-oxide catalyst. Energy Convers. Manag. 2015, 106, 1356–1361. [Google Scholar] [CrossRef]

- Panchal, B.M.; Deshmukh, S.A.; Sharma, M.R. Biodiesel from Thevetia peruviana Seed Oil with Dimethyl Carbonate Using as an Active Catalyst Potassium-Methoxide. Sains Malays. 2016, 45, 1461–1468. [Google Scholar]

- Al-Saadi, L.S.; Eze, V.C.; Harvey, A.P. Experimental Determination of Optimal Conditions for Reactive Coupling of Biodiesel Production With in situ Glycerol Carbonate Formation in a Triglyceride Transesterification Process. Front. Chem. 2018, 6, 625. [Google Scholar] [CrossRef] [PubMed]

- Rathore, V.; Tyagi, S.; Newalkar, B.; Badoni, R.P. Jatropha and Karanja oil derived DMC–biodiesel synthesis: A kinetics study. Fuel 2015, 140, 597–608. [Google Scholar] [CrossRef]

- Lee, J.; Jung, J.M.; Oh, J.I.; Ok, Y.S.; Lee, S.R.; Kwon, E.E. Evaluating the effectiveness of various biochars as porous media for biodiesel synthesis via pseudo-catalytic transesterification. Bioresour. Technol. 2017, 231, 59–64. [Google Scholar] [CrossRef]

- Tang, Y.; Cheng, Q.; CaO, H.; Zhang, L.; Zhang, J.; Li, H. Coupling transesterifications for no-glycerol biodiesel production catalyzed by calcium oxide. C. R. Chim. 2015, 18, 1328–1334. [Google Scholar] [CrossRef]

- Panchal, B.M.; Kalaji, H.M. Synthesis and use of a catalyst in the production of biodiesel from Pongamia Pinnata seed oil with dimethyl carbonate. Int. J. Green Energy 2017, 14, 624–631. [Google Scholar] [CrossRef]

- Tang, Y.; Yan, T.; Shen, B.; Li, H.; Jeje, A. nthesis of no-glycerol biodiesel through transesterification catalyzed by CaO from different precursors. Can. J. Chem. Eng. 2016, 94, 1466–1471. [Google Scholar] [CrossRef]

- Tang, Y.; Ren, H.; Chang, F.; Gu, X.; Zhang, J. Nano KF/Al2O3 particles as an efficient catalyst for no-glycerol biodiesel production by coupling transesterification. RSC Adv. 2017, 7, 5694–5700. [Google Scholar] [CrossRef] [Green Version]

- Panchal, B.; Shenjun, Q.; Jinxi, W.; Kai, B.; Chang, T. Biodiesel Synthesis with Iron Oxide Nano-Catalyst Catalyzed Pongamia Pinnata Seed Oil and Dimethyl Carbonate. Am. J. Energy Eng. 2018, 6, 21–28. [Google Scholar] [CrossRef]

- Ali, N.A.M.; Aziz, N. Optimization of DMC Transesterification Based Biodiesel Production. Adv. Mater. Res. 2015, 1113, 370–375. [Google Scholar] [CrossRef]

- Dhawan, M.S.; Yadav, G.D. Insight into a catalytic process for simultaneous production of biodiesel and glycerol carbonate from triglycerides. Catal. Today 2018, 309, 161–171. [Google Scholar] [CrossRef]

- Syamsuddin, Y.; Hameed, B.H. Synthesis of glycerol free-fatty acid methyl esters from Jatropha oil over Ca–La mixed-oxide catalyst. J. Taiwan Inst. Chem. Eng. 2016, 58, 181–188. [Google Scholar] [CrossRef]

- Syamsuddin, Y.; Murat, M.N.; Hameed, B.H. Synthesis of fatty acid methyl ester from the transesterification of high- and low-acid-content crude palm oil (Elaeis guineensis) and karanj oil (Pongamia pinnata) over a calcium–lanthanum–aluminum mixed-oxides catalyst. Bioresour. Technol. 2016, 214, 248–252. [Google Scholar] [CrossRef] [PubMed]

- Panchal, B.; Kalaji, H.M.; Deshmukh, S.; Sharma, M.; Strobel, W.R. Synthesis of Methyl Esters from Silk Cotton Tree Seed Kernel Oil Using Dimethyl Carbonate and KOH Catalysis. Eur. J. Sustain. Dev. Res. 2018, 2, 20. [Google Scholar] [CrossRef]

- Ilham, Z.; Saka, S. Dimethyl carbonate as potential reactant in non-catalytic biodiesel production by supercritical method. Bioresour. Technol. 2009, 100, 1793–1796. [Google Scholar] [CrossRef] [Green Version]

- Ilham, Z.; Saka, S. Production of biodiesel with glycerol carbonate by non-catalytic supercritical dimethyl carbonate. Lipid Technol. 2011, 23, 10–13. [Google Scholar] [CrossRef]

- Tan, K.T.; Lee, K.T. A review on supercritical fluids (SCF) technology in sustainable biodiesel production: Potential and challenges. Renew. Sustain. Energy Rev. 2011, 15, 2452–2456. [Google Scholar] [CrossRef]

- Ilham, Z.; Saka, S. Optimization of supercritical dimethyl carbonate method for biodiesel production. Fuel 2012, 97, 670–677. [Google Scholar] [CrossRef] [Green Version]

- Ilham, Z.; Saka, S. Two-step supercritical dimethyl carbonate method for biodiesel production from Jatropha curcas oil. Bioresour. Technol. 2010, 101, 2735–2740. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tan, K.T.; Lee, K.T.; Mohamed, A.R. Optimization of supercritical dimethyl carbonate (SCDMC) technology for the production of biodiesel and value-added glycerol carbonate. Fuel 2010, 89, 3833–3839. [Google Scholar] [CrossRef]

- Ilham, Z.; Saka, S. Esterification of glycerol from biodiesel production to glycerol carbonate in non-catalytic supercritical dimethyl. SpringerPlus 2016, 5, 923. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rathore, V.; Tyagi, S.; Newalkar, B.; Badoni, R.P. Glycerin-Free Synthesis of Jatropha and Pongamia Biodiesel in Supercritical Dimethyl and Diethyl Carbonate. Ind. Eng. Chem. Res. 2014, 53, 10525–10533. [Google Scholar] [CrossRef]

- Seong, P.J.; Jeon, B.W.; Lee, M.; Cho, D.H.; Kim, D.K.; Jung, K.S.; Kim, S.W.; Han, S.O.; Kim, Y.H.; Park, C. Enzymatic coproduction of biodiesel and glycerol carbonate from soybean oil and dimethyl carbonate. Enzym. Microb. Technol. 2011, 48, 505–509. [Google Scholar] [CrossRef]

- Su, E.; You, P.; Wei, D. In situ lipase-catalyzed reactive extraction of oilseeds with short-chained dialkyl carbonates for biodiesel production. Bioresour. Technol. 2009, 100, 5813–5817. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, S.; Xin, Z.; Sheng, B.; Liu, Q. Synthesis and component confirmation of biodiesel from palm oil and dimethyl carbonate catalyzed by immobilized-lipase in solvent-free system. Fuel 2010, 89, 3960–3965. [Google Scholar] [CrossRef]

- Min, J.Y.; Lee, E.Y. Lipase-catalyzed simultaneous biosynthesis of biodiesel and glycerol carbonate from corn oil in dimethyl carbonate. Biotechnol. Lett. 2011, 33, 1789–1796. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, L.; Meng, X.; Xin, Z. Kinetic study on lipase catalyzed trans-esterification of palm oil and dimethyl carbonate for biodiesel production. J. Renew. Sustain. Energy 2013, 5, 033127. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, X. Enzymatic synthesis of fatty acid ethyl esters by utilizing camellia oil soapstocks and diethyl carbonate. Bioresour. Technol. 2011, 102, 10173–10179. [Google Scholar] [CrossRef] [PubMed]

- Su, E.; Du, L.; Gong, X.; Wang, P. Lipase-Catalyzed Irreversible Transesterification of Jatropha Curcas L. Seed Oil to Fatty Acid Esters: An Optimization Study. J. Am. Oil Chem. Soc. 2011, 88, 793–800. [Google Scholar] [CrossRef]

- Su, E.Z.; Zhang, M.J.; Zhang, J.G.; Gao, J.F.; Wei, D.Z. Lipase-catalyzed irreversible transesterification of vegetable oils for fatty acid methyl esters production with dimethyl carbonate as the acyl acceptor. Biochem. Eng. J. 2007, 36, 167–173. [Google Scholar] [CrossRef]

- Goa, A.R.; Lee, Y.; Kim, Y.H.; Park, S.; Choi, J.; Lee, J.; Han, S.O.; Kim, S.W.; Park, C. Enzymatic coproduction of biodiesel and glycerol carbonate from soybean oil in solvent-free system. Enzym. Microb. Technol. 2013, 53, 154–158. [Google Scholar] [CrossRef] [PubMed]

- Gharat, N.; Rathod, V.K. Ultrasound assisted enzyme catalyzed transesterification of waste cooking oil with dimethyl carbonate. Ultrason. Sonochem. 2013, 20, 900–905. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.; Lee, Y.; Kim, D.; Han, S.O.; Kim, S.W.; Lee, J.; Kim, Y.H.; Park, C. Enzymatic production of glycerol carbonate from by-product after biodiesel manufacturing process. Enzym. Microb. Technol. 2012, 51, 143–147. [Google Scholar] [CrossRef]

- Gharat, N.; Rathod, V.K. Enzyme catalyzed transesterification of waste cooking oil with dimethyl carbonate. J. Mol. Catal. B Enzym. 2013, 88, 36–40. [Google Scholar] [CrossRef]

- Panadare, D.C.; Rathod, V.K. Microwave assisted enzymatic synthesis of biodiesel with waste cooking oil and dimethyl carbonate. J. Mol. Catal. B Enzym. 2016, 133, S518–S524. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, O.K.; Kim, C.H.; Seo, J.W.; Oh, B.R.; Lee, E.Y. Lipase-catalyzed in-situ biosynthesis of glycerol-free biodiesel from heterotrophic microalgae, Aurantiochytrium sp. KRS101 biomass. Bioresour. Technol. 2016, 211, 472–477. [Google Scholar] [CrossRef]

- Jo, Y.J.; Lee, O.K.; Lee, E.Y. Dimethyl carbonate-mediated lipid extraction and lipase-catalyzed in situ transesterification for simultaneous preparation of fatty acid methyl esters and glycerol carbonate from Chlorella sp. KR-1 biomass. Bioresour. Technol. 2014, 158, 105–110. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, E.Y. Simultaneous Production of Transformer Insulating Oil and Value-Added Glycerol Carbonates from Soybean Oil by Lipase-Catalyzed Transesterification in Dimethyl Carbonate. Energies 2018, 11, 82. [Google Scholar] [CrossRef] [Green Version]

- Leão, R.A.C.; Souza, S.P.; Nogueira, D.O.; Silva, G.M.A.; Silva, M.V.; Gutarra, M.L.E.; Miranda, L.S.M.; Castro, A.M.; Junior, I.I.; Souza, R.O.M.A. Consecutive lipase immobilization and glycerol carbonate production under continuous-flow conditions. Catal. Sci. Technol. 2016, 6, 4743–4748. [Google Scholar] [CrossRef]

- Ishak, Z.H.; Sairi, N.A.; Alias, Y.; Aroua, M.K.T.; Yusoff, R. A review of ionic liquids as catalysts for transesterification reactions of biodiesel and glycerol carbonate production. Catal. Rev. Sci. Eng. 2017, 59, 44–93. [Google Scholar] [CrossRef]

- Fan, P.; Wang, J.; Xing, S.; Yang, L.; Yang, G.; Fu, J.; Miao, C.; Lv, P. Synthesis of Glycerol-Free Biodiesel with Dimethyl Carbonate over Sulfonated Imidazolium Ionic Liquid. Energy Fuels 2017, 31, 4090–4095. [Google Scholar] [CrossRef]

- Jung, J.M.; Oh, J.I.; Kwon, D.K.; Park, Y.K.; Zhang, M.; Lee, J.; Kwon, E.E. Synthesis of fatty acid methyl esters via non-catalytic transesterification of avocado oil with dimethyl carbonate. Energy Convers. Manag. 2019, 195, 1–6. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, E.Y. Environmentally-Benign Dimethyl Carbonate-Mediated Production of Chemicals and Biofuels from Renewable Bio-Oil. Review. Energies 2017, 10, 1790. [Google Scholar] [CrossRef] [Green Version]

- Pyo, S.H.; Park, J.H.; Chang, T.S.; Hatti-Kaul, R. Dimethyl carbonate as a Green Chemical. Curr. Opin. Green Sustain. Chem. 2017, 5, 61–66. [Google Scholar] [CrossRef]

- Fiorani, G.; Perosa, A.; Selva, M. Dimethyl carbonate: A versatile reagent for a sustainable valorization of renewables. Green Chem. 2018, 20, 288–322. [Google Scholar] [CrossRef]

- Szőri1, M.; Giri, B.R.; Wang, Z.; Dawood, A.E.; Viskolcz, B.; Farooq, A. Glycerol Carbonate as Fuel Additive for Sustainable Future. Sustain. Energy Fuels 2018, 2, 2171–2178. [Google Scholar] [CrossRef] [Green Version]

- Sonnati, M.O.; Amigoni, S.; de Givenchy, P.T.; Darmanin, T.; Choulet, O.; Guittard, F. Glycerol carbonate as a versatile building block for tomorrow: Synthesis, reactivity, properties and applications. Green Chem. 2013, 15, 283–306. [Google Scholar] [CrossRef]

- Rounce, P.; Tsolakis, A.; Leung, P.; York, A.P.E. A Comparison of Diesel and Biodiesel Emissions Using Dimethyl Carbonate as an Oxygenated Additive. Energy Fuels 2010, 24, 4812–4819. [Google Scholar] [CrossRef]

- Kumar, R.; Saravanan, S. Partially premixed low temperature combustion using dimethyl carbonate (DMC) in a DI diesel engine for favorable smoke/NOx emissions. Fuel 2016, 180, 396–406. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Balasubramanian, R. Efects of oxygenated fuel blends on carbonaceous particulate composition and particle size distributions from a stationary diesel engine. Fuel 2015, 141, 1–8. [Google Scholar] [CrossRef]

- Yang, J.; Jiang, Y.; Karavalakis, G.; Johnson, K.C.; Kumar, S.; Cocker, D.R.; Durbin, T.D. Impacts of dimethyl carbonate blends on gaseous and particulate emissions from a heavy-duty diesel engine. Fuel 2016, 184, 681–688. [Google Scholar] [CrossRef] [Green Version]

- Verma, P.; Stevanovic, S.; Zare, A.; Dwivedi, G.; Van, T.C.; Davidson, M.; Rainey, T.; Brown, R.J.; Ristovski, Z.D. An Overview of the Influence of Biodiesel, Alcohols, and Various Oxygenated Additives on the Particulate Matter Emissions from Diesel Engines. Energies 2019, 12, 1987. [Google Scholar] [CrossRef] [Green Version]

- Kumar, B.R.; Saravanan, S.; Rana, R.; Nagendran, A. Combined effect of injection timing and exhaust gas recirculation (EGR) on performance and emissions of a DI diesel engine fuelled with nextgeneration advanced biofuel-diesel blends using response surface methodology. Energy Convers. Manag. 2016, 123, 470–486. [Google Scholar] [CrossRef]

- Srihari, S.; Thirumalini, S. Investigation on reduction of emission in PCCI-DI engine with biofuel blends. Renew. Energy 2017, 114, 1232–1237. [Google Scholar] [CrossRef]

- Khalife, E.; Tabatabaei, M.; Demirbas, A.; Aghbashlo, M. Impacts of additives on performance and emission characteristics of diesel engines during steady state operation. Prog. Energy Combust. Sci. 2017, 59, 32–78. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, Z.; Miao, H.; Di, Y.; Jiang, D.; Zeng, K.; Liu, B.; Wang, X. Combustion and emissions of a DI diesel engine fuelled with diesel-oxygenate blends. Fuel 2008, 87, 2691–2697. [Google Scholar] [CrossRef]

- Arteconi, A.; Mazzarini, A.; Nicola, G. Emissions from Ethers and Organic Carbonate Fuel Additives: A Review. Water Air Soil Pollut. 2011, 221, 405–423. [Google Scholar] [CrossRef]

- Bruno, T.J.; Arron Wolk, A.; Naydich, A.; Huber, M.L. Composition-explicit Distillation Curves for Mixtures of Diesel Fuel with Dimethyl Carbonate and Diethyl Carbonate. Energy Fuels 2009, 23, 3989–3997. [Google Scholar] [CrossRef]

- Nakamura, H.; Curran, H.J.; Córdoba, A.P.; Pitz, W.J.; Dagaut, P.; Togbé, C.; Sarathy, S.M.; Mehl, M.; Agudelo, J.R.; Bustamante, F. An experimental and modeling study of diethyl carbonate oxidation. Combust. Flame 2015, 162, 1395–1405. [Google Scholar] [CrossRef] [Green Version]

- Shahl, R.; Togbé, C.; Thion, S.; Timothée, R.; Lailliau, M.; Halter, F.; Chauveau, C.; Dayma, G.; Dagaut, P. Burning velocities and jet-stirred reactor oxidation of diethyl carbonate. Proc. Combust. Inst. 2017, 36, 553–560. [Google Scholar] [CrossRef]

- Kozak, M.; Merkisz, J.; Bielaczyc, P.; Szczotka, A. The Influence of Oxygenated Diesel Fuels on a Diesel Vehicle PM/NOx Emission Trade-Off; SAE Technical Paper 2009; SAE International: Detroit, MI, USA, 2009. [Google Scholar] [CrossRef]

- Kozak, M.; Merkisz, J.; Bielaczyc, P.; Szczotka, A. The Influence of Synthetic Oxygenates on Euro IV Diesel Passenger Car Exhaust Emissions—Part 3; SAE Technical Paper 2008; SAE International: Shanghai, China, 2008. [Google Scholar] [CrossRef]

- Wenyu, S.; Can, H.; Tao, T.; Feng, Z.; Wei, L.; Hansen, N.; Bin, Y. Exploring the high-temperature kinetics of diethyl carbonate (DEC) under pyrolysis and flame conditions. Combust. Flame 2017, 181, 71–81. [Google Scholar] [CrossRef] [Green Version]

- Kumaresan, M.; Devaradjane, G. Effect of two-springs split injection on the performance and emission characteristics of diesel-oxygenated blends in a DI diesel engine. Indian J. Eng. Mater. Sci. 2012, 19, 411–416. [Google Scholar]

- Mei, D.; Hielscher, K.; Baar, R. Study on Combustion Process and Emissions of a Single-Cylinder Diesel Engine Fueled with DMC/Diesel Blend. J. Energy Eng. 2014, 140, 04013004. [Google Scholar] [CrossRef]

- Caballero, V.; Bautista, F.M.; Campelo, J.M.; Luna, D.; Marinas, J.M.; Romero, A.A.; Hidalgo, J.M.; Luque, R.; Macario, A.; Giordano, G. Sustainable preparation of a novel glycerol-free biofuel by using pig pancreatic lipase: Partial 1,3-regiospecific alcoholysis of sunflower oil. Process. Biochem. 2009, 44, 334–342. [Google Scholar] [CrossRef]

- Verdugo, C.; Luque, R.; Luna, D.; Hidalgo, J.M.; Posadillo, A.; Sancho, E.; Rodríguez, S.; Ferreira-Días, S.; Bautista, F.M.; Romero, A.A. A comprehensive study of reaction parameters in the enzymatic production of novel biofuels integrating glycerol into their composition. Bioresour. Technol. 2010, 101, 6657–6662. [Google Scholar] [CrossRef]

- Luna, D.; Posadillo, A.; Caballero, V.; Verdugo, C.; Bautista, F.M.; Romero, A.A.; Sancho, E.D.; Luna, C.; Calero, J. New Biofuel Integrating Glycerol into Its Composition Through the Use of Covalent Immobilized Pig Pancreatic Lipase. Inter. J. Mol. Sci. 2012, 13, 10091–10112. [Google Scholar] [CrossRef] [Green Version]

- Luna, C.; Sancho, E.D.; Luna, D.; Caballero, V.; Calero, J.; Posadillo, A.; Verdugo, C.; Bautista, F.M.; Romero, A.A. Biofuel that Keeps Glycerol as Monoglyceride by 1,3-Selective Ethanolysis with Pig Pancreatic Lipase Covalently Immobilized on AlPO4 Support. Energies 2013, 6, 3879–3900. [Google Scholar] [CrossRef] [Green Version]

- Luna, D.; Bautista, F.M.; Caballero, V.; Campelo, J.M.; Marinas, J.M.; Romero, A.A. Method for Producing Biodiesel Using Porcine Pancreatic Lipase as An Enzymatic Catalyst. European Patent EP 2050823A1, 22 April 2009. [Google Scholar]

- Verdugo, C.; Luna, D.; Posadillo, A.; Sancho, E.D.; Rodríguez, S.; Bautista, F.M.; Luque, R.; Marinas, J.M.; Romero, A.A. Production of a new second generation biodiesel with a low cost lipase derived from Thermomyces lanuginosus: Optimization by response surface methodology. Catal. Today 2011, 167, 107–112. [Google Scholar] [CrossRef]

- Luna, C.; Verdugo, C.; Sancho, E.D.; Luna, D.; Calero, J.; Posadillo, A.; Bautista, F.M.; Romero, A.A. Production of a biodiesel-like biofuel without glycerol generation, by using Novozym 435, an immobilized Candida antarctica lipase. Bioresour. Bioprocess. 2014, 1, 11. [Google Scholar] [CrossRef] [Green Version]

- Luna, C.; Verdugo, C.; Sancho, E.D.; Luna, D.; Calero, J.; Posadillo, A.; Bautista, F.M.; Romero, A.A. Biocatalytic behaviour of immobilized Rhizopus oryzae lipase in the 1, 3-selective ethanolysis of sunflower oil to obtain a biofuel similar to biodiesel. Molecules 2014, 19, 11419–11439. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Escobar-Niño, A.; Luna, C.; Luna, D.; Marcos, A.T.; Cánovas, D.; Mellado, E. Selection and Characterization of Biofuel-Producing Environmental Bacteria Isolated from Vegetable Oil Rich Wastes. PLoS ONE 2014, 9, e104063. [Google Scholar] [CrossRef] [Green Version]

- Luna, C.; Verdugo-Escamilla, C.; Sancho, E.D.; Luna, D.; Calero, J.; Posadillo, A.; Bautista, F.M.; Romero, A.A. Achievement of a biofuel-like biodiesel by regioselective transesterification of sunflower oil with mucor miehei lipase. New Biotechnol. 2014, 31, S95. [Google Scholar] [CrossRef]

- Luna, C.; Verdugo-Escamilla, C.; Sancho, E.D.; Luna, D.; Calero, J.; Posadillo, A.; Bautista, F.M.; Romero, A.A. Enzymatic production of biodiesel that avoids glycerol as byproduct, by using immobilized rhizopus oryzae lipase. New Biotechnol. 2014, 31, 594. [Google Scholar] [CrossRef]

- Calero, J.; Verdugo-Escamilla, C.; Luna, D.; Sancho, E.D.; Luna, C.; Posadillo, A.; Bautista, F.M.; Romero, A.A. Selective ethanolysis of sunflower oil with lipozyme rm im, an immobilized rhizomucor miehei lipase, to obtain a biodiesel-like biofuel, which avoids glycerol production through the monoglyceride formation. New Biotechnol. 2014, 31, 596–601. [Google Scholar] [CrossRef]

- Luna, C.; Verdugo-Escamilla, C.; Sancho, E.D.; Luna, D.; Calero, J.; Posadillo, A.; Bautista, F.M.; Romero, A.A. A biofuel similar to biodiesel obtained by using a lipase from rhizopus oryzae, optimized by response surface methodology. Energies 2014, 7, 3383–3399. [Google Scholar] [CrossRef] [Green Version]

- Luna, C.; Sancho, E.D.; Luna, D.; Calero, J.; Verdugo-Escamilla, C.; Posadillo, A.; Bautista, F.M.; Romero, A.A. Production of a biofuel similar to conventional biodiesel that avoids residual glycerol by using lipopan 50BG, a low cost commercial thermomyces lanuginosus lipase. Récents Progrès En Génie Des. Procédés 2014, 106, 641. [Google Scholar] [CrossRef]

- Luna, C.; Luna, D.; Bautista, F.M.; Estevez, R.; Calero, J.; Posadillo, A.; Romero, A.A.; Sancho, E.D. Application of Enzymatic Extracts from a CALB Standard Strain as Biocatalyst within the Context of Conventional Biodiesel Production Optimization. Molecules 2017, 22, 2025. [Google Scholar] [CrossRef] [Green Version]

- Luna, C.; Luna, D.; Bautista, F.M.; Calero, J.; Romero, A.A.; Posadillo, A.; Sancho, E.D.; Estevez, R. Evaluation of Lipases fromWild Microbial Strains as Biocatalysts in Biodiesel Production. Separations 2018, 5, 53. [Google Scholar] [CrossRef] [Green Version]

- Calero, J.; Luna, D.; Luna, C.; Bautista, F.M.; Hurtado, B.; Romero, A.A.; Posadillo, A.; Estevez, R. Rhizomucor miehei Lipase Supported on Inorganic Solids, as Biocatalyst for the Synthesis of Biofuels: Improving the Experimental Conditions by Response Surface Methodology. Energies 2019, 12, 831. [Google Scholar] [CrossRef] [Green Version]

- Calero, J.; Cumplido, G.; Luna, D.; Sancho, E.D.; Luna, C.; Posadillo, A.; Bautista, F.M.; Romero, A.A.; Verdugo-Escamilla, C. Production of a Biofuel that Keeps the Glycerol as a Monoglyceride by Using Supported KF as Heterogeneous Catalyst. Energies 2014, 7, 3764–3780. [Google Scholar] [CrossRef] [Green Version]

- Calero, J.; Luna, D.; Sancho, E.D.; Luna, C.; Bautista, F.M.; Romero, A.A.; Posadillo, A.; Verdugo, C. development of a new biodiesel that integrates glycerol, by using CaO as heterogeneous catalyst, in the partial methanolysis of sunflower oil. Fuel 2014, 7, 94–102. [Google Scholar] [CrossRef]

- Hurtado, B.; Posadillo, A.; Luna, D.; Bautista, F.; Hidalgo, J.; Luna, C.; Calero, J.; Romero, A.; Estevez, R. Synthesis, Performance and Emission Quality Assessment of Ecodiesel from Castor Oil in Diesel/Biofuel/Alcohol Triple Blends in a Diesel Engine. Catalysts 2019, 9, 40. [Google Scholar] [CrossRef] [Green Version]

- Hu, J.; Du, Z.; Li, C.; Min, E. Study on the lubrication properties of biodiesel as fuel lubricity enhancers. Fuel 2005, 84, 1601–1606. [Google Scholar] [CrossRef]

- Hazrat, M.A.; Rasul, M.G.; Khan, M.M.K. Lubricity Improvement of the Ultra-low Sulfur Diesel Fuel with the Biodiesel. Energy Procedia 2015, 75, 111–117. [Google Scholar] [CrossRef] [Green Version]

- Paryanto, I.; Prakoso, T.; Susanto, B.H.; Gozan, M. The Effect of Outdoor Temperature Conditions and Monoglyceride Content on the Precipitate Formation of Biodiesel-Petrodiesel Blended Fuel (BXX). Evergr. Jt. J. Nov. Carbon Resour. Sci. Green Asia Strategy 2019, 6, 59–64. [Google Scholar] [CrossRef]

- Haseeb, A.; Sia, S.; Fazal, M.; Masjuki, H. Effect of temperature on tribological properties of palm biodiesel. Energy 2010, 35, 1460–1464. [Google Scholar] [CrossRef]

- Paryanto, I.; Prakoso, T.; Suyono, E.A.; Gozan, M. Determination of the upper limit of monoglyceride content in biodiesel for B30 implementation based on the measurement of the precipitate in a Biodiesel–Petrodiesel fuel blend (BXX). Fuel 2019, 258, 116104. [Google Scholar] [CrossRef]

- Tongroon, M.; Suebwong, A.; Kananont, M.; Aunchaisri, J.; Chollacoop, N. High quality jatropha biodiesel (H-FAME) and its application in a common rail diesel engine. Renew. Energy 2017, 113, 660–668. [Google Scholar] [CrossRef]

- Coniglio, L.; Bennadji, H.H.; Glaude, P.A.; Herbinet, O.; Billaud, F. Combustion chemical kinetics of biodiesel and related compounds (methyl and ethyl esters): Experiments and modeling—Advances and future refinements. Prog. Energy Combust. Sci. 2013, 39, 340–382. [Google Scholar] [CrossRef] [Green Version]

- Fernando, S.; Hanna, M.; Adhikari, S. Lubricity characteristics of selected vegetable oils, animal fats, and their derivatives. Appl. Eng. Agric. 2007, 23, 5–11. [Google Scholar] [CrossRef]

- Ilves, R.; Kuut, A.; Kuut, K.; Olt, J. Impact of multifunctional biodiesel fuel additive on diesel engine combustion process. Eng. Rural Dev. 2017, 24, 369–377. [Google Scholar] [CrossRef]

- Estévez, C.; Bayarri, N.; Castell, J. Preparation of Fatty Acid Esters of Glycerol Formal and Its Use as Biofuel. Patent WO2008006860, 8 May 2008. [Google Scholar]

- Ferrer, N.B.; Boliart, J.C. Process for Manufacturing Biofuels. Patent US9157039B1, 13 October 2015. [Google Scholar]

- Lapuerta, M.; Rodríguez-Fernández, J.; Estevez, C.; Bayarri, N. Properties of fatty acid glycerol formal ester (FAGE) for use as a component in blends for diesel engines. Biomass Bioenergy 2015, 76, 130–140. [Google Scholar] [CrossRef]

- Lapuerta, M.; Rodríguez-Fernández, J.; García-Contreras, R. Effect of a glycerol-derived advanced biofuel—FAGE (fatty acid formal glycerol ester)–on the emissions of a diesel engine tested under the New European Driving Cycle. Energy 2015, 93, 568–579. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, J.; Hernández, J.; Calle-Asensio, A.; Ramos, A.; Barba, J. Selection of Blends of Diesel Fuel and Advanced Biofuels Based on Their Physical and Thermochemical Properties. Energies 2019, 12, 2034. [Google Scholar] [CrossRef] [Green Version]

- Knothe, G. Biodiesel and renewable diesel: A comparison. Prog. Energy Combust. Sci. 2010, 36, 364–373. [Google Scholar] [CrossRef]

- Chang, C.C.; Wan, S.W. China’s motor fuels from tung oil. Ind. Eng. Chem. 1947, 39, 1543–1548. [Google Scholar] [CrossRef]

- Lapuerta, M.; Villajos, M.; Agudelo, J.M.; Boehman, A.L. Key properties and blending strategies of hydrotreated vegetable oil as biofuel for diesel engines. Fuel Proc. Technol. 2011, 92, 2406–2411. [Google Scholar] [CrossRef]

- Veriansyah, B.; Han, J.Y.; Kim, S.K.; Hong, S.A.; Kim, Y.J.; Lim, J.; Shu, Y.W.; Oh, S.G.; Kim, J. Production of renewable diesel by hydroprocessing of soybean oil: Effect of catalysts. Fuel 2012, 94, 578–585. [Google Scholar] [CrossRef]

- Sotelo-Boyás, R.; Liu, Y.; Minowa, T. Renewable Diesel Production from the Hydrotreating of Rapeseed Oil with Pt/Zeolite and NiMo/Al2O3 Catalysts. Ind. Eng. Chem. Res. 2011, 50, 2791–2799. [Google Scholar] [CrossRef]

- Liu, Y.; Sotelo-Boyás, R.; Murata, K.; Minowa, T.; Sakanishi, K. Hydrotreatment of Vegetable Oils to Produce Bio-Hydrogenated Diesel and Liquefied Petroleum Gas Fuel over Catalysts Containing Sulfided Ni–Mo and Solid Acids. Energy Fuels 2011, 25, 4675–4685. [Google Scholar] [CrossRef]

- Templis, C.; Vonortas, A.; Sebos, I.; Papayannakos, N. Vegetable oil effect on gasoil HDS in their catalytic co-hydroprocessing. Appl. Catal. B Enviton. 2011, 104, 324–329. [Google Scholar] [CrossRef]

- Shi, N.; Liu, Q.; Jiang, T.; Wang, T.; Ma, L.; Zhang, Q.; Zhang, X. Hydrodeoxygenation of vegetable oils to liquid alkane fuels over Ni/HZSM-5 catalysts: Methyl hexadecanoate as the model compound. Catal. Commun. 2012, 20, 80–84. [Google Scholar] [CrossRef]

- Sivasamy, A.; Cheah, K.Y.; Fornasiero, P.; Kemausuor, F.; Zinoviev, S.; Miertus, S. Catalytic Applications in the Production of Biodiesel from Vegetable Oils. Chemsuschem Chem. Sustain. Energy Mater. 2009, 2, 278–300. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, R.; Rana, R.S.; Kumar, R.; Verma, D.; Kumar, R.; Joshi, R.K.; Garg, M.O.; Sinha, A.K. Hydrotreating and hydrocracking catalysts for processing of waste soya-oil and refinery-oil mixtures. Catal. Commun. 2011, 12, 559–562. [Google Scholar] [CrossRef]

- Serrano-Ruiz, J.C.; Ramos-Fernández, E.V.; Sepúlveda-Escribano, A. From biodiesel and bioethanol to liquid hydrocarbon fuels: New hydrotreating and advanced microbial technologies. Energy Environ. Sci. 2012, 5, 5638–5652. [Google Scholar] [CrossRef]

- Gong, S.; Shinozaki, A.; Shi, M.; Qian, E.W. Hydrotreating of Jatropha Oil over Alumina Based Catalysts. Energy Fuels 2012, 26, 2394–2399. [Google Scholar] [CrossRef]

- Šimáček, P.; Kubička, D.; Kubičková, I.; Homola, F.; Pospíšil, M.; Chudoba, J. Premium quality renewable diesel fuel by hydroprocessing of sunflower oil. Fuel 2011, 90, 2473–2479. [Google Scholar] [CrossRef]

- Liu, J.; Liu, C.; Zhou, G.; Shen, S.; Rong, L. Hydrotreatment of Jatropha oil over NiMoLa/Al2O3 catalyst. Green Chem. 2012, 14, 2499–2505. [Google Scholar] [CrossRef]

- Liu, J.; Fan, K.; Tian, W.; Liu, C.; Rong, L. Hydroprocessing of Jatropha oil over NiMoCe/Al2O3 catalyst. Int. J. Hydrogen Energy 2012, 37, 17731–17737. [Google Scholar] [CrossRef]

- Sebos, I.; Matsoukas, A.; Apostolopoulos, V.; Papayannakos, N. Catalytic hydroprocessing of cottonseed oil in petroleum diesel mixtures for production of renewable diesel. Fuel 2009, 88, 145–149. [Google Scholar] [CrossRef]

- Patel, M.; Kumar, A. Production of renewable diesel through the hydroprocessing of lignocellulosic biomass-derived bio-oil: A review. Renew. Sustain. Energy Rev. 2016, 58, 1293–1307. [Google Scholar] [CrossRef]

- Singh, D.; Subramanian, K.A.; Singal, S.K. Emissions and fuel consumption characteristics of a heavy duty diesel engine fueled with Hydroprocessed Renewable Diesel and Biodiesel. Appl. Energy 2015, 155, 440–446. [Google Scholar] [CrossRef]

- Ogunkoya, D.; Roberts, W.L.; Fang, T.; Thapaliya, N. Investigation of the effects of renewable diesel fuels on engine performance, combustion, and emissions. Fuel 2015, 140, 541–554. [Google Scholar] [CrossRef]

- Bezergianni, S.; Dimitriadis, A. Comparison between different types of renewable diesel. Renew. Sustain. Energy Rev. 2013, 21, 110–116. [Google Scholar] [CrossRef]

- Guzman, A.; Torres, J.E.; Prada, L.P.; Nunñez, M.L. Hydroprocessing of crude palm oil at pilot plant scale. Catal. Today 2010, 156, 38–43. [Google Scholar] [CrossRef]

- Fu, J.; Turn, S.Q. Characteristics and Stability of Neat and Blended Hydroprocessed Renewable Diesel. Energy Fuels 2014, 28, 3899–3907. [Google Scholar] [CrossRef]

- Singh, D.; Subramanian, K.A.; Garg, M.O. Comprehensive review of combustion, performance and emissions characteristics of a compression ignition engine fueled with hydroprocessed renewable diesel. Renew. Sustain. Energy Rev. 2018, 81, 2947–2954. [Google Scholar] [CrossRef]

- Cadrazco, M.; Santamaría, A.; Agudelo, J.R. Chemical and nanostructural characteristics of the particulate matter produced by renewable diesel fuel in an automotive diesel engine. Combust. Flame 2019, 203, 130–142. [Google Scholar] [CrossRef]

- Singh, D.; Subramanian, K.A.; Bal, R.; Singh, S.P.; Badola, R. Combustion and emission characteristics of a light duty diesel engine fueled with hydro-processed renewable diesel. Energy 2018, 154, 498–507. [Google Scholar] [CrossRef]

- Srifa, A.; Faungnawakij, K.; Itthibenchapong, V.; Assabumrungrat, S. Roles of monometallic catalysts in hydrodeoxygenation of palm oil to green diesel. Chem. Eng. J. 2015, 278, 249–258. [Google Scholar] [CrossRef]

- Zarchin, R.; Rabaev, M.; Vidruk-Nehemya, R.; Landau, M.V.; Herskowitz, M. Hydroprocessing of soybean oil on nickel-phosphide supported catalysts. Fuel 2015, 139, 684–691. [Google Scholar] [CrossRef]

- Chu, P.L.; Vanderghem, C.; MacLean, H.L.; Saville, B.A. Financial analysis and risk assessment of hydroprocessed renewable jet fuel production from camelina, carinata and used cooking oil. Appl. Energy 2017, 198, 401–409. [Google Scholar] [CrossRef]

- Wang, W.C. Techno-economic analysis of a bio-refinery process for producing Hydro-processed Renewable Jet fuel from Jatropha. Renew. Energy 2016, 95, 63–73. [Google Scholar] [CrossRef]

- Kruger, J.S.; Christensen, E.D.; Dong, T.; Wychen, S.V.; Fioroni, G.M.; Pienkos, P.T.; McCormick, R.L. Bleaching and Hydroprocessing of Algal Biomass-Derived Lipids to Produce Renewable Diesel Fuel. Energy Fuels 2017, 31, 10946–10953. [Google Scholar] [CrossRef]