Dibenzothiophene Hydrodesulfurization over P-CoMo on Sol-Gel Alumina Modified by La Addition. Effect of Rare-Earth Content

Abstract

:1. Introduction

2. Results and Discussion

2.1. N2 Physisorption

2.2. Thermal Analyses (Thermogravimetric and Differential Thermal Analyses, TG and DTA)

2.3. X-ray Difracction (XRD)

2.4. Chemical Analysis (Scanning Electron Microscopy-Energy Dispersive Spectroscopy (SEM-EDS)

2.5. Surface Bascity (CO2-Adsorption Studied In IR Region, CO2-FTIR)

2.6. Raman Spectroscopy

2.7. UV-Vis Spectroscopy

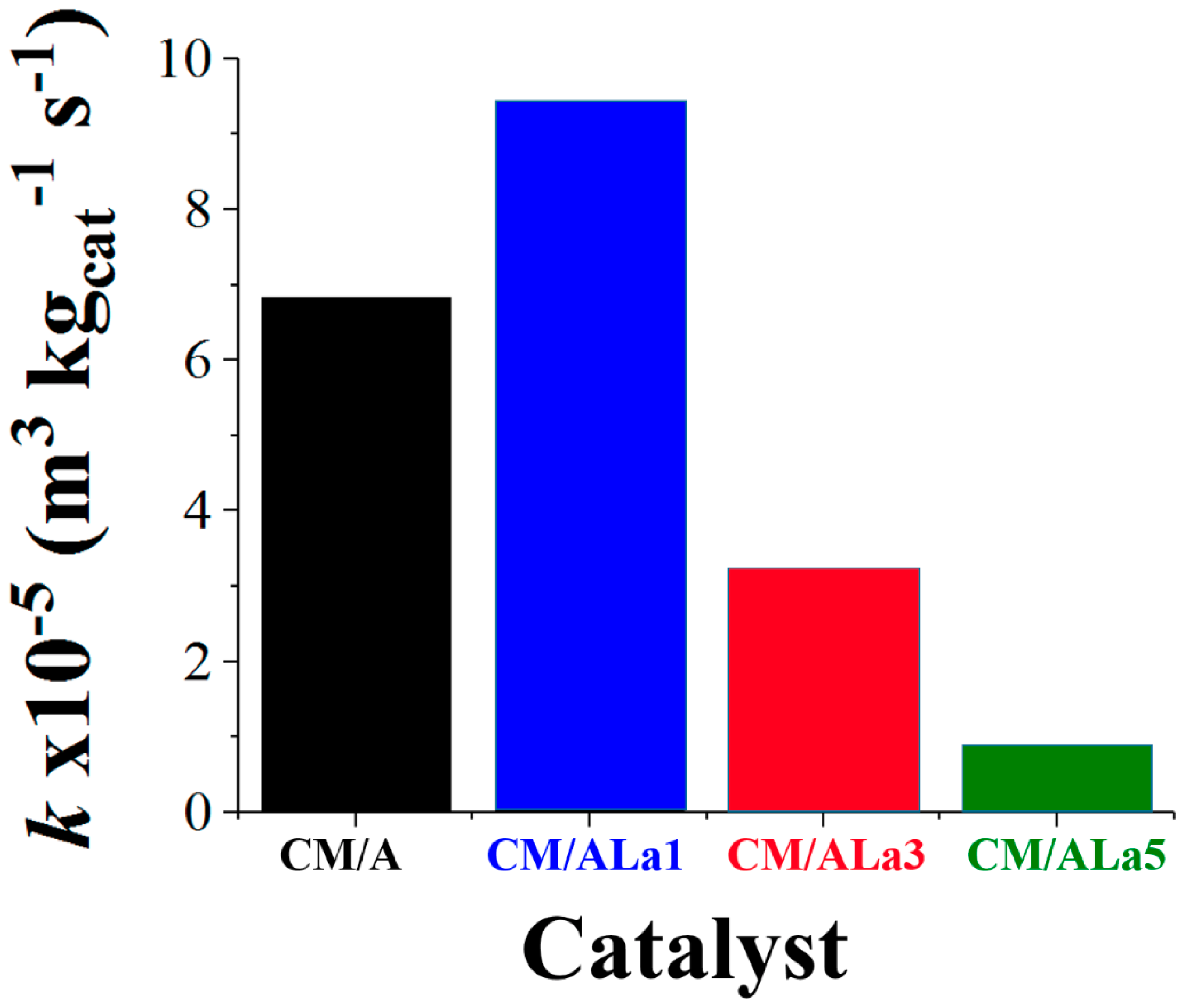

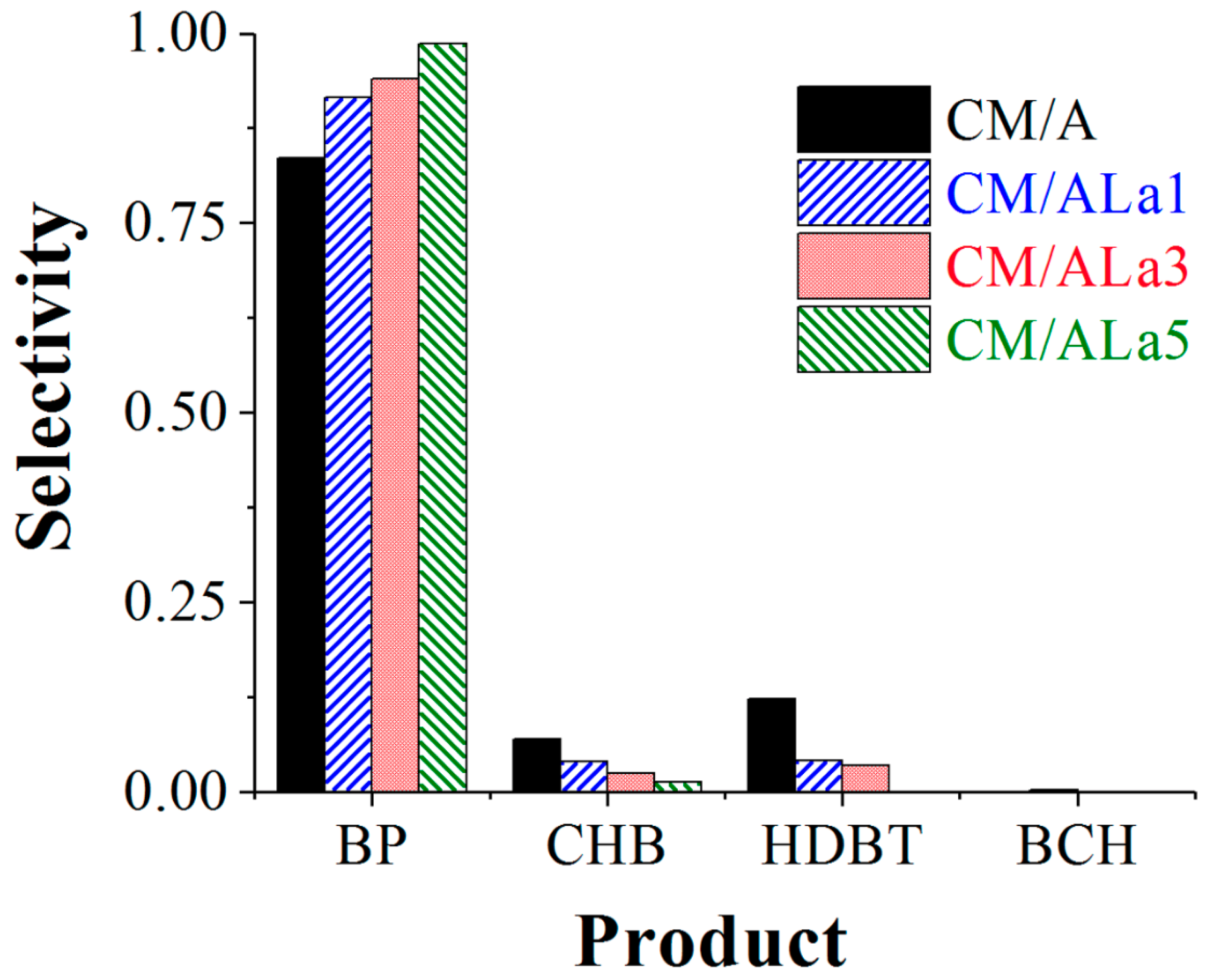

2.8. HDS Reaction Test

3. Experimental

3.1. Materials Synthesis

3.2. Materials Characterization

3.3. HDS Reaction Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, J.; Guo, Y.; Huang, T.; Fan, Y. Hexamethonium bromide-assisted synthesis of CoMo/graphene catalysts for selective hydrodesulfurization. Appl. Catal. B Environ. 2019, 244, 385–395. [Google Scholar] [CrossRef]

- Yang, L.; Peng, C.; Fang, X.; Cheng, Z.; Zhou, Z. Hierarchically macro-mesoporous Ni-Mo/Al2O3 catalysts for hydrodesulfurization of dibenzothiophene. Catal. Commun. 2019, 121, 68–72. [Google Scholar] [CrossRef]

- Zhang, C.; Brorson, M.; Li, P.; Liu, X.; Liu, T.; Jiang, Z.; Li, C. CoMo/Al2O3 catalysts prepared by tailoring the surface properties of alumina for highly selective hydrodesulfurization of FCC gasoline. Appl. Catal. A Gen. 2019, 570, 84–95. [Google Scholar] [CrossRef]

- Mey, D.; Brunet, S.; Canaff, C.; Maugé, F.; Bouchy, C.; Diehl, F. HDS of a model FCC gasoline over a sulfided CoMo/Al2O3 catalyst: Effect of the addition of potassium. J. Catal. 2004, 227, 436–447. [Google Scholar] [CrossRef]

- Klimova, T.; Solís Casados, D.; Ramírez, J. New selective Mo and NiMo HDS catalysts supported on Al2O3-MgO(x) mixed oxides. Catal. Today 1998, 43, 135–146. [Google Scholar] [CrossRef]

- Lu, J.; Luo, Y.; He, D.; Xu, Z.; He, S.; Xie, D.; Mei, Y. An exploration into potassium (K) containing MoS2 active phases and its transformation process over MoS2 based materials for producing methanethiol. Catal. Today 2019. [Google Scholar] [CrossRef]

- Alphonse, P.; Faure, B. Thermal stabilization of alumina modified by lanthanum. Microporous Mesoporous Mater. 2014, 196, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Lu, J.; Hao, H.; Zhang, L.; Xu, Z.; Zhong, L.; Zhao, Y.; He, D.; Liu, J.; Chen, D.; Pu, H.; et al. The investigation of the role of basic lanthanum (La) species on the improvement of catalytic activity and stability of HZSM-5 material for eliminating methanethiol-(CH3SH). Appl. Catal. B Environ. 2018, 237, 185–197. [Google Scholar] [CrossRef]

- Garbarino, G.; Vijayakumar, R.P.P.; Riani, P.; Finocchio, E.; Busca, G. Ethanol and diethyl ether catalytic conversion over commercial alumina and lanthanum-doped alumina: Reaction paths, catalyst structure and coking. Appl. Catal. B Environ. 2018, 236, 490–500. [Google Scholar] [CrossRef]

- Garbarino, G.; Wang, C.; Valsamakis, I.; Chitsazan, S.; Riani, P.; Finocchio, E.; Flytzani-Stephanopoulos, M.; Busca, G. Acido-basicity of lanthana/alumina catalysts and their activity in ethanol conversion. Appl. Catal. B Environ. 2017, 200, 458–468. [Google Scholar] [CrossRef]

- Garbarino, G.; Wang, C.; Cavattoni, T.; Finocchio, E.; Riani, P.; Flytzani-Stephanopoulos, M.; Busca, G. A study of Ni/La-Al2O3 catalysts: A competitive system for CO2 methanation. Appl. Catal. B Environ. 2018. [Google Scholar] [CrossRef]

- He, D.; Zhao, Y.; Yang, S.; Mei, Y.; Yu, J.; Liu, J.; Chen, D.; He, S.; Luo, Y. Enhancement of catalytic performance and resistance to carbonaceous deposit of lanthanum (La) doped HZSM-5 catalysts for decomposition of methyl mercaptan. Chem. Eng. J. 2018, 336, 579–586. [Google Scholar] [CrossRef]

- Cui, J.-W.; Massoth, F.E.; Topsøe, N.Y. Studies of Molybdena-Alumina Catalysts XVIII. Lanthanum-Modified Supports. J. Catal. 1992, 136, 361–377. [Google Scholar]

- Blanchard, P.; Payen, E.; Grimblot, J.; Le Bihan, L.; Poulet, O.; Loutaty, R. Preparation of Co-Mo-based hydrodesulphurization catalysts: Characterizations of deposited species on lanthanum modified γ-alumina. J. Mol. Catal. A Chem. 1998, 135, 143–153. [Google Scholar] [CrossRef]

- Afanasiev, P.; Bezverkhyy, I. Ternary transition metals sulfides in hydrotreating catalysis. Appl. Catal. A Gen. 2007, 322, 129–141. [Google Scholar] [CrossRef]

- Escobar, J.; Barrera, M.C.; Solís-Casados, D.A.; Santes, V.; Sánchez-Valente, J.; Terrazas, J.E. Hidrodesulfuración de dibenzotiofeno sobre CoMo/Al2O3-La sol-gel. Effecto del contenido de tierra rara. In Proceedings of the Livro de atas XXVI Congresso Ibero-americano de Catálise (CICAT 2018), Coimbra, Portugal, 9–14 September 2018; Gomes, H., Silva, A., Machado, B., Ribeiro, F., Fonseca, I., Faria, J., Pereira, M., Rocha, R., Eds.; Abstract number: P-IR21. Sociedade Portuguesa de Química: Coimbra, Portugal, 2018; pp. 1070–1075. [Google Scholar]

- Leofanti, G.; Padovan, M.; Tozzola, G.; Venturelli, B. Surface area and pore texture of catalysts. Catal. Today 1998, 41, 207–219. [Google Scholar] [CrossRef]

- Dicks, A.L.; Ensell, R.L.; Phillips, T.R.; Szczepura, A.K.; Thorley, M.; Williams, A.; Wragg, R.D. A study of relationships between pore size distribution, hydrogen chemisorption, and activity of hydrodesulphurisation catalysts. J. Catal. 1981, 72, 266–273. [Google Scholar] [CrossRef]

- Gurvich, L. Physico-chemical attractive force. J. Russ. Phys. Chem. Soc. 1915, 47, 805–827. [Google Scholar]

- Ou, E.; Zhou, J.; Mao, S.; Wang, J.; Xia, F.; Min, L. Highly efficient removal of phosphate by lanthanum-doped mesoporous SiO2. Colloid Surf. A 2007, 308, 47–53. [Google Scholar] [CrossRef]

- Zhang, L.; Wan, L.; Chang, N.; Liu, J.; Duan, C.; Zhou, Q.; Li, X.; Wang, X. Removal of phosphate from water by activated carbon fiber loaded with lanthanum oxide. J. Hazard. Mater. 2011, 190, 848–855. [Google Scholar] [CrossRef]

- Kaluža, L.; Gulková, D.; Vít, Z.; Zdražil, M. High-activity MgO-supported CoMo hydrodesulfurization catalysts prepared by non-aqueous impregnation. Appl. Catal. B Environ. 2015, 162, 430–436. [Google Scholar] [CrossRef]

- Escobar, J.; De Los Reyes, J.A.; Viveros, T. Influence of the Synthesis Additive on the Textural and Structural Characteristics of Sol-Gel Al2O3-TiO2. Ind. Eng. Chem. Res. 2000, 39, 666–672. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Dave, P.N. Review on Thermal Decomposition of Ammonium Nitrate. J. Energ. Mater. 2013, 31, 1–26. [Google Scholar] [CrossRef]

- Barrera, A.; Fuentes, S.; Viniegra, M.; Avalos-Borja, M.; Bogdanchikova, N.; Campa-Molina, J. Structural properties of Al2O3-La2O3 binary oxides prepared by sol-gel. Mater. Res. Bull. 2007, 42, 640–648. [Google Scholar] [CrossRef]

- Escobar, J.; Barrera, M.C.; De Los Reyes, J.A.; Cortés, M.A.; Santes, V.; Gómez, E.; Pacheco, J.G. Effect of Mo and Co loading in HDS catalysts supported on solvo-thermally treated ZrO2-TiO2 mixed oxide. Catal. Today 2008, 133–135, 282–291. [Google Scholar] [CrossRef]

- Hattori, H. Heterogeneous Basic Catalysis. Chem. Rev. 1995, 95, 537–558. [Google Scholar] [CrossRef]

- Bálsamo, N.; Mendieta, S.; Heredia, A.; Crivello, M. Nanoclays as dispersing precursors of La and Ce oxide catalysts to produce high-valued derivatives of biodiesel by-product. Mol. Catal. 2019. [Google Scholar] [CrossRef]

- Bernal, S.; Díaz, J.A.; García, J.R.; Rodríguez-Izquierdo, J.M. Study of some aspects of the reactivity of La2O3 with CO2 and H2O. J. Mater. Sci. 1985, 20, 537–541. [Google Scholar] [CrossRef]

- Morterra, C.; Ghiotti, G.; Boccuzzi, F.; Coluccia, S. An infrared spectroscopic investigation of the surface properties of magnesium aluminate spinel. J. Catal. 1978, 51, 299–313. [Google Scholar] [CrossRef]

- Di Cosimo, J.I.; Diez, V.K.; Xu, M.; Iglesia, E.; Apesteguia, C.R. Structure and Surface and Catalytic Properties of Mg-Al Basic Oxides. J. Catal. 1998, 78, 499–510. [Google Scholar] [CrossRef]

- Boukha, Z.; Fitian, L.; López-Haro, M.; Mora, M.; Ruiz, J.R.; Jiménez-Sanchidrián, C.; Blanco, G.; Calvino, J.J.; Cifredo, G.A.; Trasobares, S.; et al. Influence of the calcination temperature on the nano-structural properties, surface basicity, and catalytic behavior of alumina-supported lanthana samples. J. Catal. 2010, 272, 121–130. [Google Scholar] [CrossRef]

- Bettman, M.; Chase, R.E.; Otto, K.; Weber, W.H. Dispersion Studies on the System La2O3/γ-A12O3. J. Catal. 1989, 117, 447–454. [Google Scholar] [CrossRef]

- Kraus, H.; Prins, R. Proton NMR Investigations of Surface Hydroxyl Groups on Oxidic Mo-P/γ-Al2O3 Catalysts. J. Catal. 1996, 164, 260–267. [Google Scholar] [CrossRef]

- Ledford, J.S.; Kim, Y.-M.; Houalla, M.; Proctor, A.; Hercules, D.M. Surface Analysis of Lanthanum-modified Cobalt Catalysts. Analyst 1992, 117, 323–327. [Google Scholar] [CrossRef]

- Wachs, I.E. Raman and IR studies of surface metal oxide species on oxide supports: Supported metal oxide catalysts. Catal. Today 1996, 27, 437–455. [Google Scholar] [CrossRef]

- Scheithauer, M.; Knözinger, H.; Vannice, M.A. Raman Spectra of La2O3 Dispersed on γ-Al2O3. J. Catal. 1998, 178, 701–7005. [Google Scholar] [CrossRef]

- Dedov, A.G.; Loktev, A.S.; Moiseev, I.I.; Aboukais, A.; Lamonier, J.F.; Filimonov, I.N. Oxidative coupling of methane catalyzed by rare earth oxides: Unexpected synergistic effect of the oxide mixtures. Appl. Catal. A Gen. 2003, 245, 209–220. [Google Scholar] [CrossRef]

- Chen, J.; Mi, J.; Li, K.; Wang, X.; Dominguez Garcia, E.; Cao, Y.; Jiang, L.; Oliviero, L.; Mauge, F. The role of citric acid in preparing highly active CoMo/Al2O3 catalyst: From aqueous impregnation solution to active site formation. Ind. Eng. Chem. Res. 2017, 56, 14172–14181. [Google Scholar] [CrossRef]

- Nicosia, D.; Prins, R. 31P MAS NMR and Raman study of a Co(Zn)MoP/γ-Al2O3 HDS catalyst precursor containing triethylene glycol. J. Catal. 2005, 234, 414–420. [Google Scholar] [CrossRef]

- Bergwerff, J.A.; Visser, T.; Leliveld, B.R.G.; Rossenaar, B.D.; de Jong, K.P.; Weckhuysen, B.M. Envisaging the physicochemical processes during the preparation of supported catalysts: Raman microscopy on the impregnation of Mo onto Al2O3 extrudates. J. Am. Chem. Soc. 2004, 126, 14548–14556. [Google Scholar] [CrossRef]

- Catita, L.; Quoineaud, A.-A.; Espinat, D.; Pichon, C.; Delpoux, O. Application of magnetic resonance imaging and raman imaging to study the impact of phosphorus in impregnation of hydrotreatment catalysts. Appl. Catal. A Gen. 2017, 547, 164–175. [Google Scholar] [CrossRef]

- Kraus, H.; Prins, R. Composition of impregnation solutions and wet impregnated Mo-P/γ-Al2O3 catalysts as investigated by 31P and 95Mo NMR. J. Catal. 1995, 164, 251–259. [Google Scholar] [CrossRef]

- Vázquez-Garrido, I.; López-Benítez, A.; Berhault, G.; Guevara-Lara, A. Effect of support on the acidity of NiMo/Al2O3-MgO and NiMo/TiO2-Al2O3 catalysts and on the resulting competitive hydrodesulfurization/hydrodenitrogenation reactions. Fuel 2019, 236, 55–64. [Google Scholar] [CrossRef]

- Ishutenko, D.; Nikulshin, P.; Pimerzin, A. Relation between composition and morphology of K(Co)MoS active phase species and their performances in hydrotreating of model FCC gasoline. Catal. Today 2016, 271, 16–27. [Google Scholar] [CrossRef]

- Solís-Casados, D.A.; Escobar-Alarcón, L.; Klimova, T.; Escobar-Aguilar, J.; Rodríguez-Castellón, E.; Cecilia, J.A.; Morales-Ramírez, C. Catalytic performance of CoMo/Al2O3-MgO-Li(x) formulations in DBT hydrodesulfurization. Catal. Today 2016, 271, 35–44. [Google Scholar] [CrossRef]

- Sheik Saleem, S.; Aruldhas, G. Raman and Infrared Spectra of Lanthanum Molybdate. J. Solid State Chem. 1982, 42, 158–162. [Google Scholar] [CrossRef]

- Frank, C.J.; Redd, D.C.B.; Gansler, T.S.; McCreery, R.L. Characterization of Human Breast Biopsy with Near-IR Raman Spectroscopy Specimens. Anal. Chem. 1994, 66, 319–326. [Google Scholar] [CrossRef]

- Ramírez, J.; Macías, G.; Cedeño, L.; Gutiérrez-Alejandre, A.; Cuevas, R.; Castillo, P. The role of titania in supported Mo, CoMo, NiMo, and NiW hydrodesulfurization catalysts: Analysis of past and new evidences. Catal. Today 2004, 98, 19–30. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; Zhao, L.; Lyu, Y.; Xu, L.; Rood, M.J.; Wei, L.; Liu, Z.; Yan, Z. Effect of lanthanum species on the physicochemical properties of La/SAPO-11 molecular sieve. J. Catal. 2017, 347, 170–184. [Google Scholar] [CrossRef]

- Torres-Mancera, P.; Ramírez, J.; Cuevas, R.; Gutiérrez-Alejandre, A.; Murrieta, F.; Luna, R. Hydrodesulfurization of 4,6-DMDBT on NiMo and CoMo catalysts supported on B2O3-Al2O3. Catal. Today 2005, 107–108, 551–558. [Google Scholar] [CrossRef]

- Weber, R.S. Effect of local structure on the UV-visible absorption edges of molybdenum oxide clusters and supported molybdenum oxides. J. Catal. 1995, 151, 470–474. [Google Scholar] [CrossRef]

- Sreedhara, M.B.; Ramakrishna Matte, H.S.S.; Govindaraj, A.; Rao, C.N.R. Synthesis, Characterization, and Properties of Few-Layer MoO3. Chem. Asian J. 2013, 8, 2430–2435. [Google Scholar] [CrossRef] [PubMed]

- Makshina, E.V.; Zhilinskaya, E.A.; Siffert, S.; Mazo, G.N.; Aboukaïs, A.; Grünert, W.; Romanovsky, B.V. Nanostructured lanthanum cobaltate: Oxidation and coordination states of Co atoms. J. Exp. Nanosci. 2009, 5, 427–437. [Google Scholar] [CrossRef]

- Xie, L.L.; Gao, Q.M.; Li, Q.H. Nanoporous metal phosphate CoVSB-1 catalyst for oxidation of styrene with H2O2. In From Zeolites to Porous MOF Materials—The 40th Anniversary of International Zeolite Conference. Proceedings of the 15th International Zeolite Conference, Beijing, China, 12–17 August 2007; Xu, R., Gao, Z., Chen, J., Yan, W., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2007; pp. 1338–1343. [Google Scholar]

- Martin, C.; Martin, I.; Rives, V.; Malet, P. Changes in the Struture of TiO2-supported Molybdena Induced by Na-doping. J. Catal. 1994, 147, 465–475. [Google Scholar] [CrossRef]

- Topsøe, N.Y.; Topsøe, H. FTIR Studies of Mo/Al2O3-Based Catalysts: II. Evidence for the Presence of SH Groups and Their Role in Acidity and Activity. J. Catal. 1993, 139, 641–651. [Google Scholar] [CrossRef]

- Morales, A.; Ramírez de Agudelo, M.M. Promoter Role of Octahedral Co (and Ni) in Modified Co(Ni)Mo-Al2O3 Catalysts for Hydrodesulfurization Reactions. Appl. Catal. 1986, 23, 23–34. [Google Scholar] [CrossRef]

- Solís-Casados, D.; Escobar, J.; García Orozco, I.; Klimova, T. Effect of Potassium Content on the Performance of CoMo/Al2O3-MgOK2O(x) Catalysts in Hydrodesulfurization of Dibenzothiophene. Ind. Eng. Chem. Res. 2011, 50, 2755–2761. [Google Scholar] [CrossRef]

- Wu, L.; Jiao, D.; Wang, J.; Chen, L.; Cao, F. The role of MgO in the formation of surface active phases of CoMo/Al2O3-MgO catalysts for hydrodesulfurization of dibenzothiophene. Catal. Commun. 2009, 11, 302–305. [Google Scholar] [CrossRef]

- Ge, T.; Zuo, C.; Chen, H.; Muhammad, Y.; Wei, L.; Li, C. Catalytic Activity and Molecular Behavior of Lanthanum Modified CoSx/γ-Al2O3 Catalysts for the Reduction of SO2 to Sulfur in Smelter Off-Gas Using CO-H2 Mixture as Reductant. Ind. Eng. Chem. Res. 2019. [Google Scholar] [CrossRef]

- Escobar, J.; Barrera, M.C.; Santes, V.; Terrazas, J.E. Naphthalene hydrogenation over Mg-doped Pt/Al2O3. Catal. Today 2017, 296, 197–204. [Google Scholar] [CrossRef]

- Houalla, M.; Nag, N.K.; Sapre, A.V.; Broderick, D.H.; Gates, B.C. Hydrodesulfurization of dibenzothiophene catalyzed by sulfided CoO-MoO3/γ-Al2O3: The reaction network. AIChEJ 1978, 24, 1015–1021. [Google Scholar] [CrossRef]

- Hensen, E.J.M.; Kooyman, P.J.; van der Meer, Y.; van der Kraan, A.M.; de Beer, V.H.J.; van Veen, J.A.R.; van Santen, R.A. The relation between morphology and hydrotreating activity for supported MoS2 particles. J. Catal. 2001, 199, 224–235. [Google Scholar] [CrossRef]

- Bataille, F.; Lemberton, J.L.; Michaud, P.; Pérot, G.; Vrinat, M.; Lemaire, M.; Schulz, E.; Breysse, M.; Kasztelan, S. Alkyldibenzothiophenes hydrodesulfurization-promoter effect, reactivity, and reaction mechanism. J. Catal. 2000, 191, 409–422. [Google Scholar] [CrossRef]

- Wu, Z.; Whiffen, V.M.L.; Zhu, W.; Wang, D.; Smith, K.J. Effect of Annealing Temperature on Co-MoS2 Nanosheets for Hydrodesulfurization of Dibenzothiophene. Catal. Lett. 2014, 144, 261–267. [Google Scholar] [CrossRef]

- Kaluža, L.; Gulková, D.; Vít, Z.; Zdražil, M. Effect of support type on the magnitude of synergism and promotion in CoMo sulphide hydrodesulphurisation catalyst. Appl. Catal. A Gen. 2007, 324, 30–35. [Google Scholar] [CrossRef]

- Wu, H.; Duan, A.; Zhao, Z.; Qi, D.; Li, J.; Liu, B.; Jiang, G.; Liu, J.; Wei, Y.; Zhang, X. Preparation of NiMo/KIT-6 hydrodesulfurization catalysts with tunable sulfidation and dispersion degrees of active phase by addition of citric acid as chelating agent. Fuel 2014, 130, 203–210. [Google Scholar] [CrossRef]

- Halachev, T.; Atanasova, P.; Lopez Agudo, A.; Arias, M.G.; Ramirez, J. Activity of P-Ni-W/Al2O3 catalysts with varying phosphorus content in the hydrogenation of naphthalene. Appl. Catal. A Gen. 1996, 136, 161–175. [Google Scholar] [CrossRef]

- Wang, T.; Fan, Y.; Wang, X.; Chou, L.; Lin, H. Selectivity enhancement of CoMoS catalysts supported on tri-modal porous Al2O3 for the hydrodesulfurization of fluid catalytic cracking gasoline. Fuel 2015, 157, 171–176. [Google Scholar] [CrossRef]

- Jaf, Z.N.; Altarawneha, M.; Miran, H.A.; Jiang, Z.T.; Dlugogorski, B.Z. Hydrodesulfurization of Thiophene over γ-Mo2N catalyst. Mol. Catal. 2018, 459, 21–30. [Google Scholar] [CrossRef]

- Fujikawa, T.; Chiyoda, O.; Tsukagoshi, M.; Idei, K.; Takehara, S. Development of a high activity HDS catalyst for diesel fuel: From basic research to commercial experience. Catal. Today 1998, 45, 307–312. [Google Scholar] [CrossRef]

- Escobar, J.; Gutiérrez, A.; Barrera, M.C.; Colín, J.A. NiMo/alumina hydrodesulphurization catalyst modified by saccharose: Effect of addition stage of organic modifier. Can. J. Chem. Eng. 2016, 94, 66–74. [Google Scholar] [CrossRef]

- Shalagina, A.E.; Aleshina, G.I.; Startsev, A.N. Hydrogen occluded in sulfide catalysts: Evidence from the temperature programmed heating Technique. React. Kinet. Catal. Lett. 2003, 78, 91–98. [Google Scholar] [CrossRef]

| Sample | SgBET (m2 g−1) | Vp (cm3 g−1) | Dp a (nm) | SgBJHa (m2 g−1) | SgBJHd (m2 g−1) |

|---|---|---|---|---|---|

| A | 308 | 0.45 | 5.9 | 347 | 435 |

| ALa1 | 334 | 0.55 | 6.6 | 403 | 485 |

| ALa3 | 335 | 0.69 | 8.3 | 423 | 504 |

| ALa5 | 326 | 0.60 | 7.3 | 419 | 505 |

| CM/A | 199 | 0.43 | 8.6 | 240 | 277 |

| CM/ALa1 | 135 | 0.26 | 7.8 | 191 | 240 |

| CM/ALa3 | 211 | 0.43 | 8.2 | 252 | 291 |

| CM/ALa5 | 141 | 0.41 | 11.7 | 268 | 323 |

| ALa1 | Wt% | At% |

|---|---|---|

| OK | 49.82 | 63.14 |

| AlK | 48.78 | 36.66 |

| LaL | 1.4 | 0.2 |

| Total | 100 | 100 |

| ALa3 | ||

| OK | 48.55 | 62.75 |

| AlK | 47.91 | 36.72 |

| LaL | 3.54 | 0.53 |

| Total | 100 | 100 |

| ALa5 | ||

| OK | 48.12 | 63.15 |

| AlK | 46.27 | 36.01 |

| LaL | 5.6 | 0.85 |

| Total | 100 | 100 |

| Td (°C) | A | ALa1 | ALa3 | ALa5 | CM/A | CM/ALa1 | CM/ALa3 | CM/ALa5 |

|---|---|---|---|---|---|---|---|---|

| 25 | 71 | 79 | 96 | 108 | 36 | 30 | 42 | 41 |

| 100 | 21 | 32 | 54 | 38 | 27 | 16 | 34 | 31 |

| 200 | 15 | 26 | 44 | 29 | 22 | 7 | 24 | 24 |

| 300 | 14 | 26 | 42 | 29 | 19 | 6 | 22 | 21 |

| 400 | 12 | 26 | 41 | 27 | 15 | 5 | 20 | 21 |

| 500 | 11 | 17 | 33 | 25 | 0 | ND | 13 | 12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Escobar, J.; Barrera, M.C.; Valente, J.S.; Solís-Casados, D.A.; Santes, V.; Terrazas, J.E.; Fouconnier, B.A.R. Dibenzothiophene Hydrodesulfurization over P-CoMo on Sol-Gel Alumina Modified by La Addition. Effect of Rare-Earth Content. Catalysts 2019, 9, 359. https://doi.org/10.3390/catal9040359

Escobar J, Barrera MC, Valente JS, Solís-Casados DA, Santes V, Terrazas JE, Fouconnier BAR. Dibenzothiophene Hydrodesulfurization over P-CoMo on Sol-Gel Alumina Modified by La Addition. Effect of Rare-Earth Content. Catalysts. 2019; 9(4):359. https://doi.org/10.3390/catal9040359

Chicago/Turabian StyleEscobar, José, María C. Barrera, Jaime S. Valente, Dora A. Solís-Casados, Víctor Santes, José E. Terrazas, and Benoit A.R. Fouconnier. 2019. "Dibenzothiophene Hydrodesulfurization over P-CoMo on Sol-Gel Alumina Modified by La Addition. Effect of Rare-Earth Content" Catalysts 9, no. 4: 359. https://doi.org/10.3390/catal9040359

APA StyleEscobar, J., Barrera, M. C., Valente, J. S., Solís-Casados, D. A., Santes, V., Terrazas, J. E., & Fouconnier, B. A. R. (2019). Dibenzothiophene Hydrodesulfurization over P-CoMo on Sol-Gel Alumina Modified by La Addition. Effect of Rare-Earth Content. Catalysts, 9(4), 359. https://doi.org/10.3390/catal9040359