The Effects of Catalyst Support and Temperature on the Hydrotreating of Waste Cooking Oil (WCO) over CoMo Sulfided Catalysts

Abstract

:1. Introduction

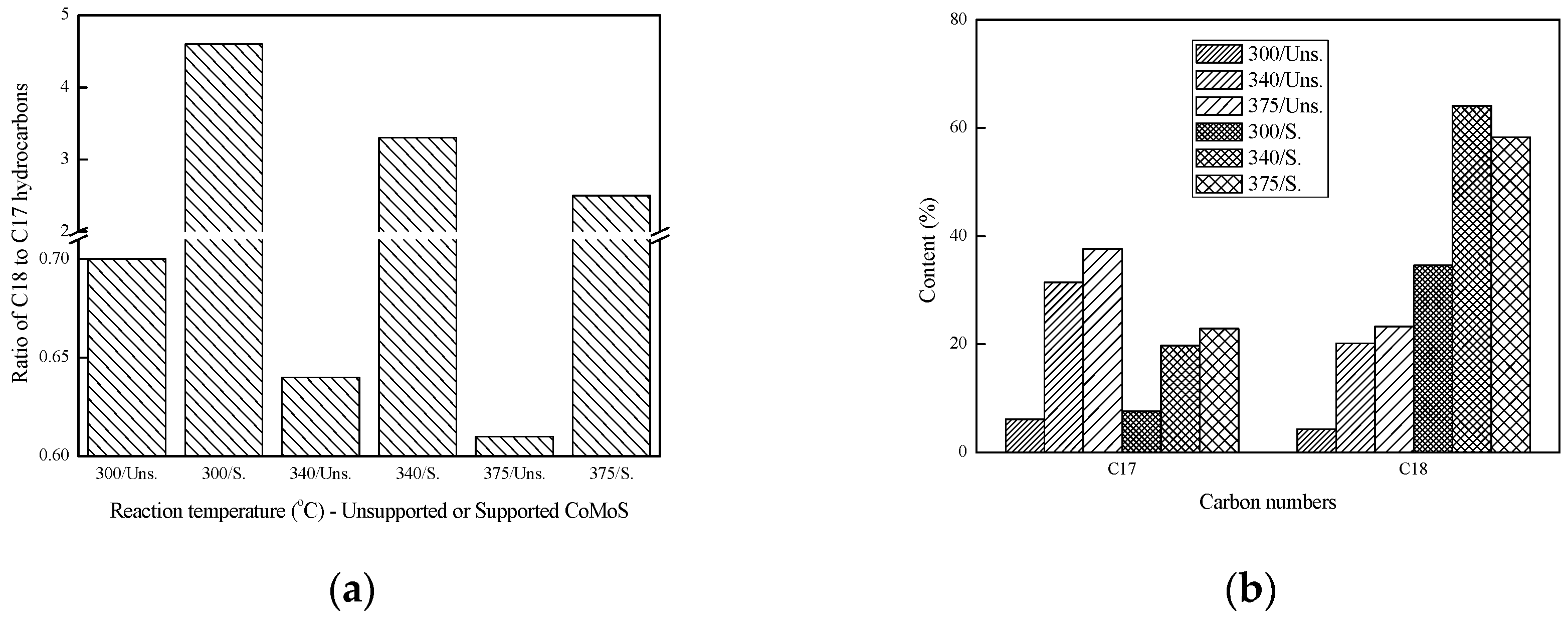

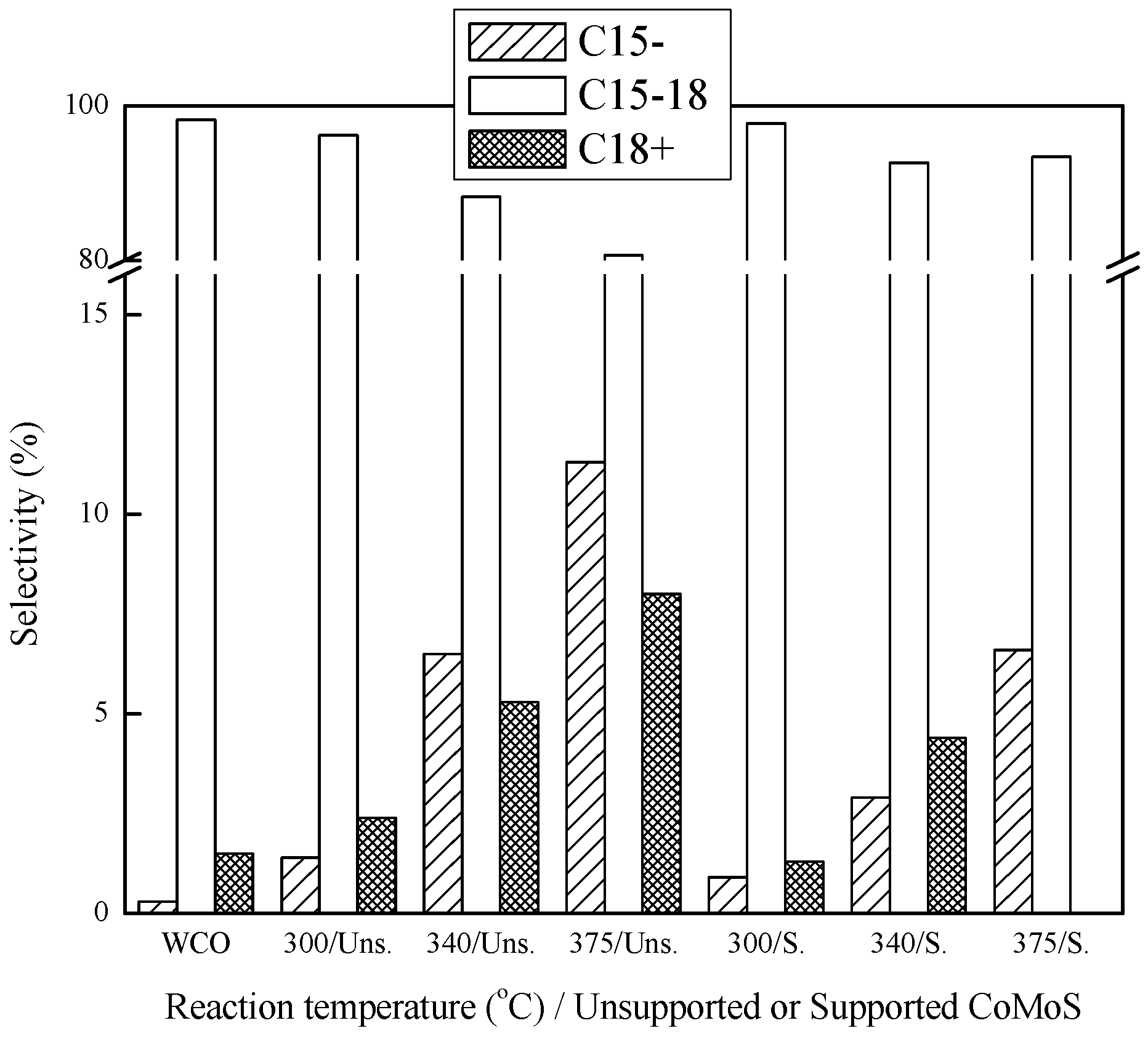

2. Results and Discussion

2.1. Catalyst Characterization

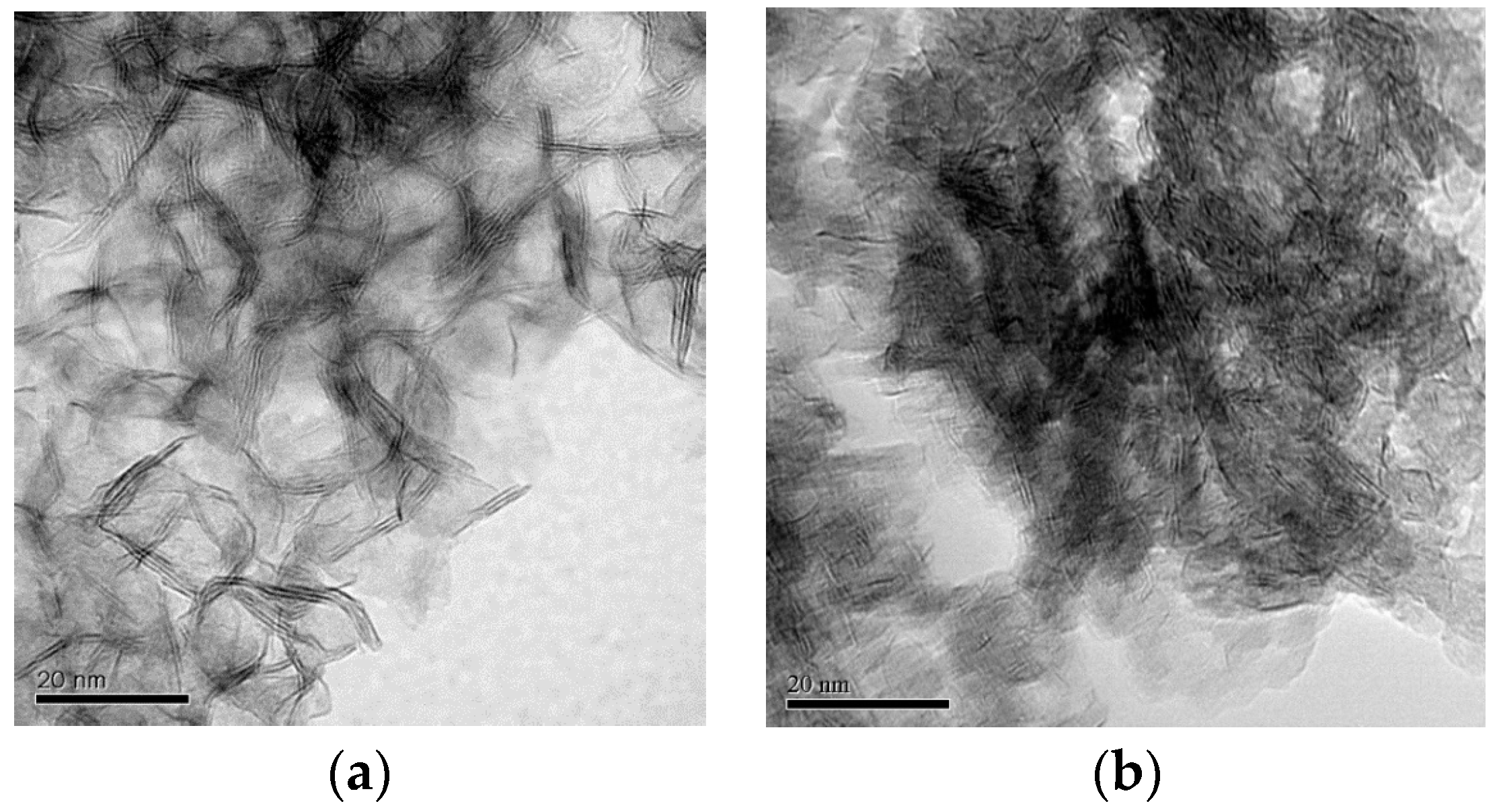

2.1.1. Catalyst Morphology and Basic Properties

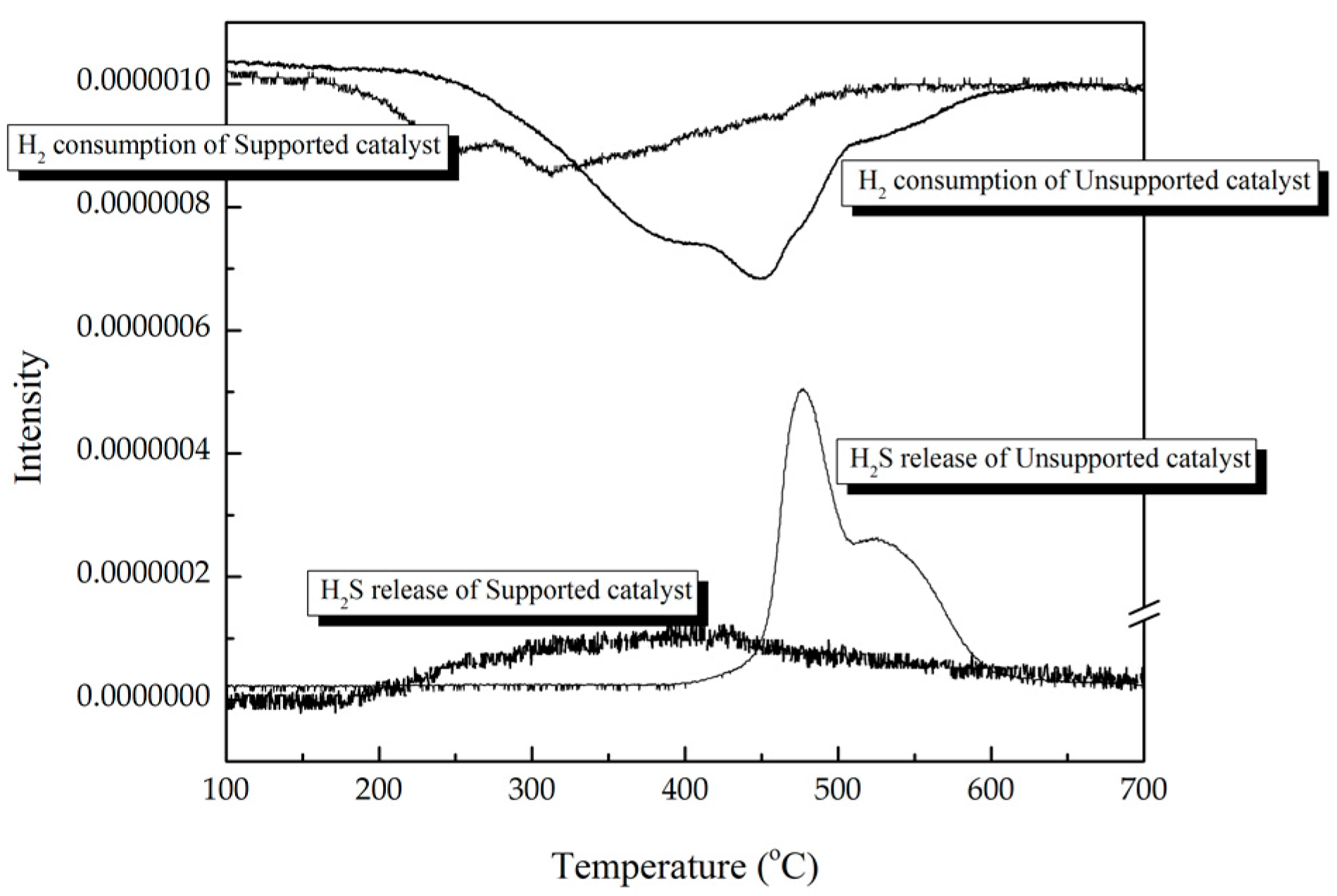

2.1.2. Active Site Distribution

2.2. Liquid Products

Compositions of Feed and Liquid Products

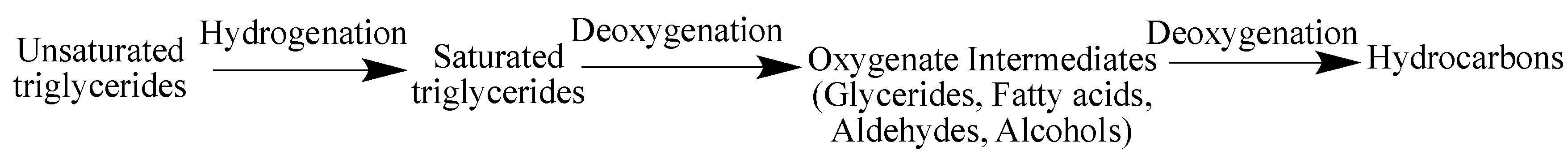

3. Reaction Route Discussion

3.1. Deoxygenation

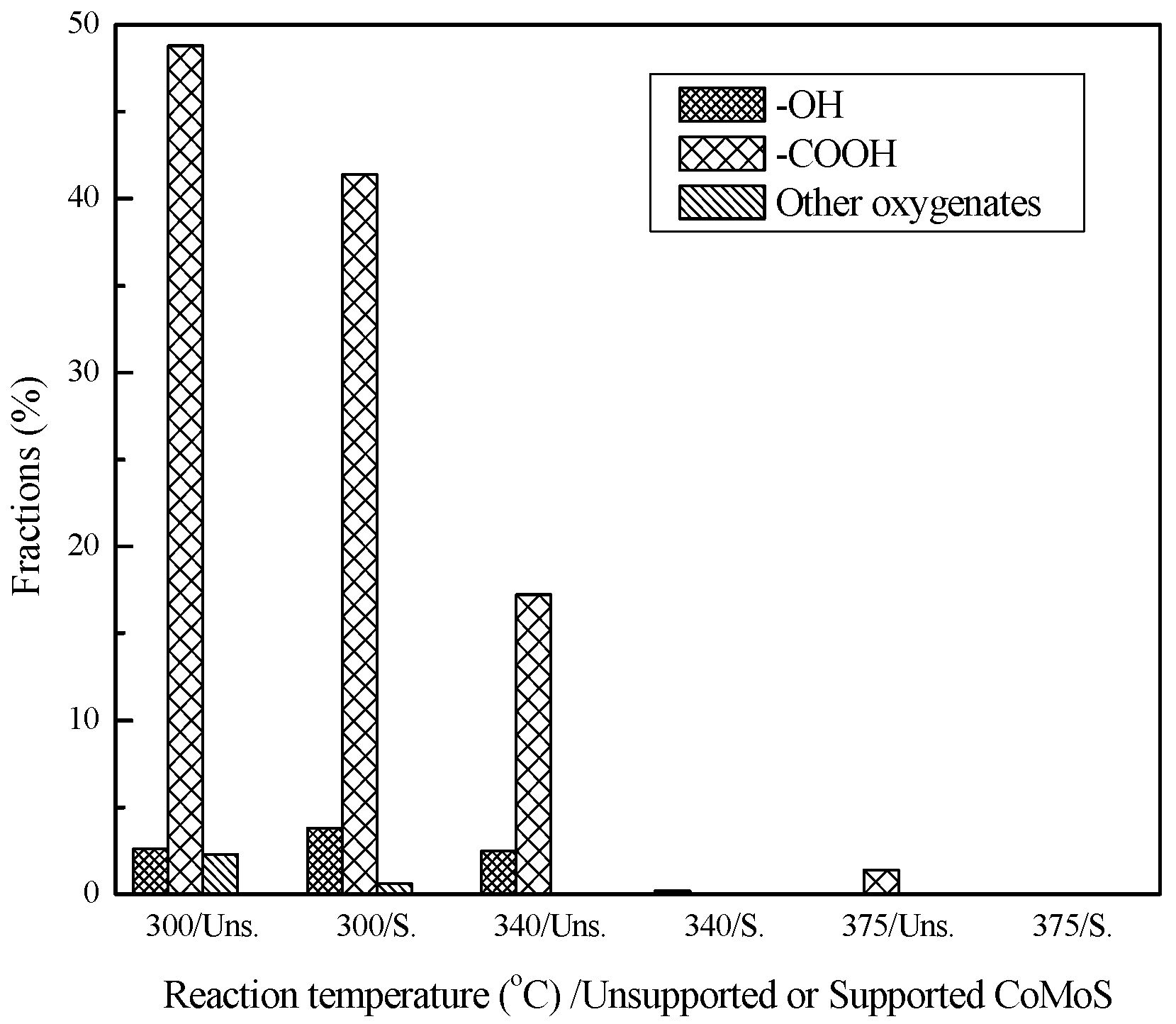

3.1.1. Types of Oxygen Containing Compounds

3.1.2. HDO vs. HDCO

3.2. Hydrocracking (C–C Cracking) and Polymerization (C–C Chain Growth)

3.3. Hydrogenation (C=C Saturation) and Dehydrogenation (C–H Disassociation)

4. Experimental

4.1. Catalyst Preparation and Evaluation

4.2. Catalyst Characterization

4.3. Product Analysis

4.4. Calculations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| WCO | waste cooking oil. |

| CoMoS | sulfided Cobalt and Molybdenum. |

| HDO | hydrodeoxygenation. In the HDO reaction, oxygen is removed in the form of water by adding hydrogen into oxygen-containing compounds. |

| HDCO | hydrodecarbonylation and decarboxylation. |

| DCO | the process in the hydrodecarbonylation reaction, in which oxygen is removed in the form of water and CO. |

| DCO2 | the process in the hydrodecarboxylation reaction, in which oxygen is removed in the form of CO2. |

| SAPO-11 | a medium-pore silicoaluminophosphate molecular sieve with tunable acidity. |

| A/B catalyst | A stands for the active metal of the catalyst, B stands for the support of the catalyst. For example, CoMoS/SiO2 means that the active metal of the catalyst is sulfided Cobalt and Molybdenum, and the support of the catalyst is Silica. |

References

- Bezergianni, S.; Dimitriadis, A.; Kalogianni, A.; Pilavachi, P.A. Hydrotreating of waste cooking oil for biodiesel production. Part I: Effect of temperature on product yields and heteroatom removal. Bioresour. Technol. 2010, 101, 6651–6656. [Google Scholar] [CrossRef] [PubMed]

- Bezergianni, S.; Dimitriadis, A.; Kalogianni, A.; Knudsen, K.G. Toward Hydrotreating of Waste Cooking Oil for Biodiesel Production. Effect of Pressure, H2/Oil Ratio, and Liquid Hourly Space Velocity. Ind. Eng. Chem. Res. 2011, 50, 3874–3879. [Google Scholar] [CrossRef]

- Veriansyah, B.; Han, J.Y.; Kim, S.K.; Hong, S.-A.; Kim, Y.J.; Lim, J.S.; Shu, Y.-W.; Oh, S.-G.; Kim, J. Production of renewable diesel by hydroprocessing of soybean oil: Effect of catalysts. Fuel 2012, 94, 578–585. [Google Scholar] [CrossRef]

- Sankaranarayanan, T.M.; Banu, M.; Pandurangan, A.; Sivasanker, S. Hydroprocessing of sunflower oil–gas oil blends over sulfided Ni–Mo–Al–zeolite beta composites. Bioresour. Technol. 2011, 102, 10717–10723. [Google Scholar] [CrossRef] [PubMed]

- Guzman, A.; Torres, J.E.; Prada, L.P.; Nuñez, M.L. Hydroprocessing of crude palm oil at pilot plant scale. Catal. Today 2010, 156, 38–43. [Google Scholar] [CrossRef]

- Kubička, D.; Šimáček, P.; Žilková, N. Transformation of Vegetable Oils into Hydrocarbons over Mesoporous-Alumina-Supported CoMo Catalysts. Top. Catal. 2009, 52, 161–168. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, L.; Li, G.; Rogers, K.; Lin, H.; Seers, P.; Ledan, T.; Ng, S.; Zheng, Y. Application of uniform design experimental method in waste cooking oil (WCO) co-hydroprocessing parameter optimization and reaction route investigation. Fuel 2017, 210, 390–397. [Google Scholar] [CrossRef]

- Wang, H.; Li, G.; Rogers, K.; Lin, H.; Zheng, Y.; Ng, S. Hydrotreating of waste cooking oil over supported CoMoS catalyst—Catalyst deactivation mechanism study. Mol. Catal. 2017, 443, 228–240. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, H.; Zheng, Y. The role of cobalt and nickel in deoxygenation of vegetable oils. Appl. Catal. B Environ. 2014, 160, 415–422. [Google Scholar] [CrossRef]

- Bui, V.N.; Laurenti, D.; Afanasiev, P.; Geantet, C. Hydrodeoxygenation of guaiacol with CoMo catalysts. Part I: Promoting effect of cobalt on HDO selectivity and activity. Appl. Catal. B Environ. 2011, 101, 239–245. [Google Scholar] [CrossRef]

- Shimada, H. Morphology and orientation of MoS2 clusters on Al2O3 and TiO2 supports and their effect on catalytic performance. Catal. Today 2003, 86, 17–29. [Google Scholar] [CrossRef]

- Qiherima; Li, H.; Yuan, H.; Zhang, Y.; Xu, G. Effect of Alumina Support on the Formation of the Active Phase of Selective Hydrodesulfurization Catalysts Co-Mo/Al2O3. Chin. J. Catal. 2011, 32, 240–249. [Google Scholar] [CrossRef]

- Sakashita, Y.; Araki, Y.; Shimada, H. Effects of surface orientation of alumina supports on the catalytic functionality of molybdenum sulfide catalysts. Appl. Catal. A Gen. 2001, 215, 101–110. [Google Scholar] [CrossRef]

- Rana, M.S.; Ancheyta, J.; Maity, S.K.; Rayo, P. Maya crude hydrodemetallization and hydrodesulfurization catalysts: An effect of TiO2 incorporation in Al2O3. Catal. Today 2005, 109, 61–68. [Google Scholar] [CrossRef]

- De la Puente, G.; Gil, A.; Pis, J.J.; Grange, P. Effects of Support Surface Chemistry in Hydrodeoxygenation Reactions over CoMo/Activated Carbon Sulfided Catalysts. Langmuir 1999, 15, 5800–5806. [Google Scholar] [CrossRef]

- Centeno, A.; Laurent, E.; Delmon, B. Influence of the Support of CoMo Sulfide Catalysts and of the Addition of Potassium and Platinum on the Catalytic Performances for the Hydrodeoxygenation of Carbonyl, Carboxyl, and Guaiacol-Type Molecules. J. Catal. 1995, 154, 288–298. [Google Scholar] [CrossRef] [Green Version]

- Kubicka, D.; Horacek, J.; Setnicka, M.; Bulanek, R.; Zukal, A.; Kubickova, I. Effect of support-active phase interactions on the catalyst activity and selectivity in deoxygenation of triglycerides. Appl. Catal. B Environ. 2014, 145, 101–107. [Google Scholar] [CrossRef]

- Wang, H.; Yan, S.; Salley, S.; Ng, K. Support effects on hydrotreating of soybean oil over NiMo carbide catalyst. Fuel 2013, 111, 81–87. [Google Scholar] [CrossRef]

- Bui, V.N.; Laurenti, D.; Delichère, P.; Geantet, C. Hydrodeoxygenation of guaiacol: Part II: Support effect for CoMoS catalysts on HDO activity and selectivity. Appl. Catal. B Environ. 2011, 101, 246–255. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Q.; Zhang, X.; Wang, L. Effect of support on the NiMo phase and its catalytic hydrodeoxygenation of triglycerides. Fuel 2015, 159, 430–435. [Google Scholar] [CrossRef]

- Gong, S.; Shinozaki, A.; Qian, W. Role of Support in Hydrotreatment of Jatropha Oil over Sulfided NiMo Catalysts. Ind. Eng. Chem. Res. 2012, 51, 13953–13960. [Google Scholar] [CrossRef]

- Krár, M.; Kovács, S.; Kalló, D.; Hancsók, J. Fuel purpose hydrotreating of sunflower oil on CoMo/Al2O3 catalyst. Bioresour. Technol. 2010, 101, 9287–9293. [Google Scholar] [CrossRef] [PubMed]

- Bezergianni, S.; Dimitriadis, A.; Sfetsas, T.; Kalogianni, A. Hydrotreating of waste cooking oil for biodiesel production. Part II: Effect of temperature on hydrocarbon composition. Bioresour. Technol. 2010, 101, 7658–7660. [Google Scholar] [CrossRef] [PubMed]

- Toba, M.; Abe, Y.; Kuramochi, H.; Osako, M.; Mochizuki, T.; Yoshimura, Y. Hydrodeoxygenation of waste vegetable oil over sulfide catalysts. Catal. Today 2011, 164, 533–537. [Google Scholar] [CrossRef]

- Calais, C.; Matsubayashi, N.; Geantet, C.; Yoshimura, Y.; Shimada, H.; Nishijima, A.; Lacroix, M.; Breysse, M. Crystallite Size Determination of Highly Dispersed Unsupported MoS2 Catalysts. J. Catal. 1998, 174, 130–141. [Google Scholar] [CrossRef]

- Pu, J.; Nishikado, K.; Wang, N.; Nguyen, T.T.; Maki, T.; Qian, E.W. Core-shell nickel catalysts for the steam reforming of acetic acid. Appl. Catal. B Environ. 2018, 224, 69–79. [Google Scholar] [CrossRef]

- Chen, N.; Gong, S.; Qian, E.W. Effect of reduction temperature of NiMoO3−x/SAPO-11 on its catalytic activity in hydrodeoxygenation of methyl laurate. Appl. Catal. B Environ. 2015, 174, 253–263. [Google Scholar] [CrossRef]

- Šimáček, P.; Kubička, D.; Šebor, G.; Pospíšil, M. Hydroprocessed rapeseed oil as a source of hydrocarbon-based biodiesel. Fuel 2009, 88, 456–460. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, H.; Wang, W.; Zheng, Y.; Hu, P. Hydroprocessing of waste cooking oil over a dispersed nano catalyst: Kinetics study and temperature effect. Appl. Catal. B Environ. 2014, 150, 238–248. [Google Scholar] [CrossRef]

- Pu, J.; Luo, Y.; Wang, N.; Bao, H.; Wang, X.; Qian, E.W. Ceria-promoted Ni@Al2O3 core-shell catalyst for steam reforming of acetic acid with enhanced activity and coke resistance. Int. J. Hydrogen Energy 2018, 43, 3142–3153. [Google Scholar] [CrossRef]

- Pu, J.; Toyoda, T.; Qian, E.W. Evaluation of Reactivities of Various Compounds in Steam Reforming over RuNi/BaOAl2O3 Catalyst. Energy Fuels 2018, 32, 1804–1811. [Google Scholar] [CrossRef]

- Donnis, B.; Egeberg, R.G.; Blom, P.; Knudsen, K.G. Hydroprocessing of Bio-Oils and Oxygenates to Hydrocarbons. Understanding the Reaction Routes. Top. Catal. 2009, 52, 229–240. [Google Scholar]

- Huber, G.W.; O’Connor, P.; Corma, A. Processing biomass in conventional oil refineries: Production of high quality diesel by hydrotreating vegetable oils in heavy vacuum oil mixtures. Appl. Catal. A Gen. 2007, 329, 120–129. [Google Scholar] [CrossRef]

- Gusmão, J.; Brodzki, D.; Djéga-Mariadassou, G.; Frety, R. Utilization of vegetable oils as an alternative source for diesel-type fuel: Hydrocracking on reduced Ni/SiO2 and sulphided Ni-Mo/γ-Al2O3. Catal. Today 1989, 5, 533–544. [Google Scholar] [CrossRef]

- Ryymin, E.-M.; Honkela, M.L.; Viljava, T.-R.; Krause, A.O.I. Competitive reactions and mechanisms in the simultaneous HDO of phenol and methyl heptanoate over sulphided NiMo/γ-Al2O3. Appl. Catal. A Gen. 2010, 389, 114–121. [Google Scholar] [CrossRef]

- Brunet, S.; Mey, D.; Pérot, G.; Bouchy, C.; Diehl, F. On the hydrodesulfurization of FCC gasoline: A review. Appl. Catal. A Gen. 2005, 278, 143–172. [Google Scholar] [CrossRef]

- Şenol, O.İ.; Ryymin, E.M.; Viljava, T.R.; Krause, A.O.I. Reactions of methyl heptanoate hydrodeoxygenation on sulphided catalysts. J. Mol. Catal. A Chem. 2007, 268, 1–8. [Google Scholar] [CrossRef]

- Kubička, D.; Kaluža, L. Deoxygenation of vegetable oils over sulfided Ni, Mo and NiMo catalysts. Appl. Catal. A Gen. 2010, 372, 199–208. [Google Scholar] [CrossRef]

- Boda, L.; Onyestyák, G.; Solt, H.; Lónyi, F.; Valyon, J.; Thernesz, A. Catalytic hydroconversion of tricaprylin and caprylic acid as model reaction for biofuel production from triglycerides. Appl. Catal. A Gen. 2010, 374, 158–169. [Google Scholar] [CrossRef]

- Bezergianni, S.; Dimitriadis, A. Temperature effect on co-hydroprocessing of heavy gas oil–waste cooking oil mixtures for hybrid diesel production. Fuel 2013, 103, 579–584. [Google Scholar] [CrossRef]

- Costa, R.; d’Acampora Zellner, B.; Crupi, M.L.; Fina, M.R.D.; Valentino, M.R.; Dugo, P.; Dugo, G.; Mondello, L. GC–MS, GC–O and enantio–GC investigation of the essential oil of Tarchonanthus camphoratus L. Flavour Fragr. J. 2008, 23, 40–48. [Google Scholar] [CrossRef]

- Wang, H.; Lin, H.; Feng, P.; Han, X.; Zheng, Y. Integration of catalytic cracking and hydrotreating technology for triglyceride deoxygenation. Catal. Today 2017, 291, 172–179. [Google Scholar] [CrossRef]

- Wang, H.; Lin, H.; Zheng, Y.; Ng, S.; Brown, H.; Xia, Y. Kaolin-based catalyst as a triglyceride FCC upgrading catalyst with high deoxygenation, mild cracking, and low dehydrogenation performances. Catal. Today 2019, 319, 164–171. [Google Scholar] [CrossRef]

| Catalysts | Supported Catalyst | Unsupported Catalyst |

|---|---|---|

| Average slab length (nm) | 5.84 | 7.80 |

| Average layer numbers | 2.34 | 2.92 |

| Fraction of edge metal atoms | 0.25 | 0.15 |

| Surface area (m2 g−1) | 150.0 | 82.2 |

| Pore volume (cm3 g−1) | 0.35 | 0.53 |

| Co/Mo (wt%/wt%) | 3.0–4.0/16–20 | 10.3/50.4 |

| Co/(Co + Mo) (atom ratio) | 0.31 | 0.25 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Rogers, K.; Zhang, H.; Li, G.; Pu, J.; Zheng, H.; Lin, H.; Zheng, Y.; Ng, S. The Effects of Catalyst Support and Temperature on the Hydrotreating of Waste Cooking Oil (WCO) over CoMo Sulfided Catalysts. Catalysts 2019, 9, 689. https://doi.org/10.3390/catal9080689

Wang H, Rogers K, Zhang H, Li G, Pu J, Zheng H, Lin H, Zheng Y, Ng S. The Effects of Catalyst Support and Temperature on the Hydrotreating of Waste Cooking Oil (WCO) over CoMo Sulfided Catalysts. Catalysts. 2019; 9(8):689. https://doi.org/10.3390/catal9080689

Chicago/Turabian StyleWang, Hui, Kyle Rogers, Haiping Zhang, Guoliang Li, Jianglong Pu, Haoxuan Zheng, Hongfei Lin, Ying Zheng, and Siauw Ng. 2019. "The Effects of Catalyst Support and Temperature on the Hydrotreating of Waste Cooking Oil (WCO) over CoMo Sulfided Catalysts" Catalysts 9, no. 8: 689. https://doi.org/10.3390/catal9080689

APA StyleWang, H., Rogers, K., Zhang, H., Li, G., Pu, J., Zheng, H., Lin, H., Zheng, Y., & Ng, S. (2019). The Effects of Catalyst Support and Temperature on the Hydrotreating of Waste Cooking Oil (WCO) over CoMo Sulfided Catalysts. Catalysts, 9(8), 689. https://doi.org/10.3390/catal9080689