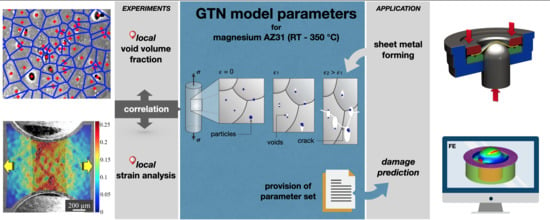

GTN Model-Based Material Parameters of AZ31 Magnesium Sheet at Various Temperatures by Means of SEM In-Situ Testing

Abstract

:1. Introduction

2. Materials and Experimental Procedure

3. Results and Discussion

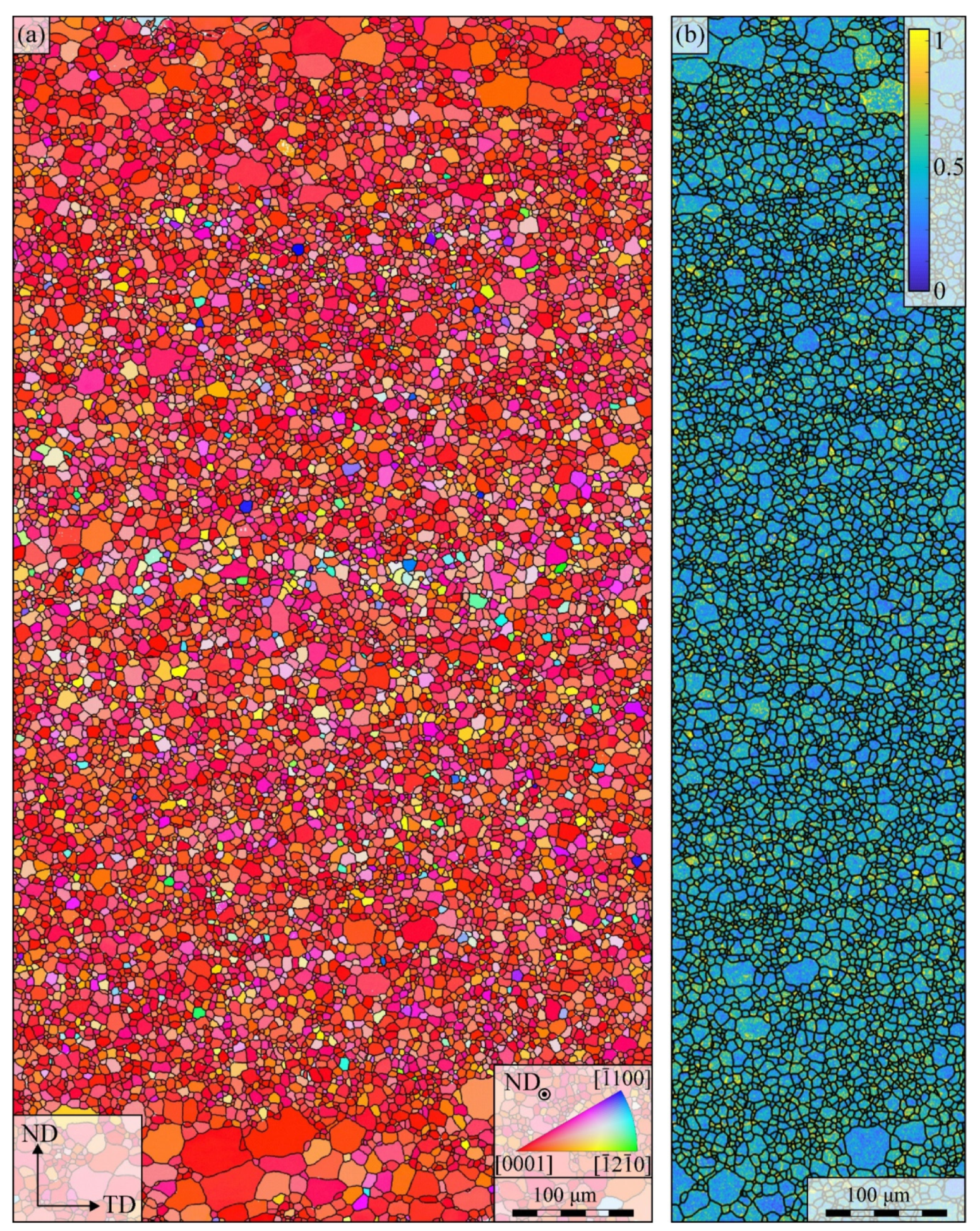

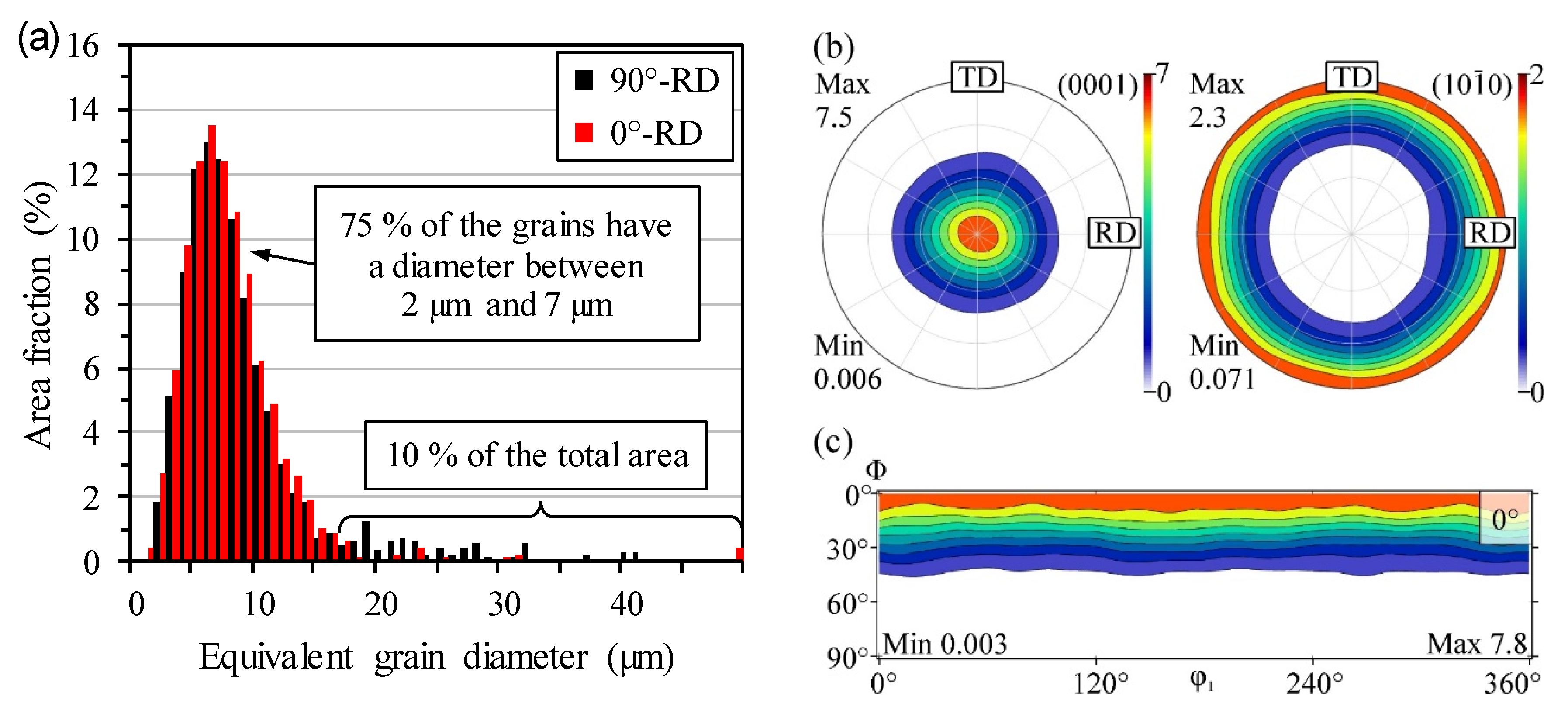

3.1. Materials Characterization

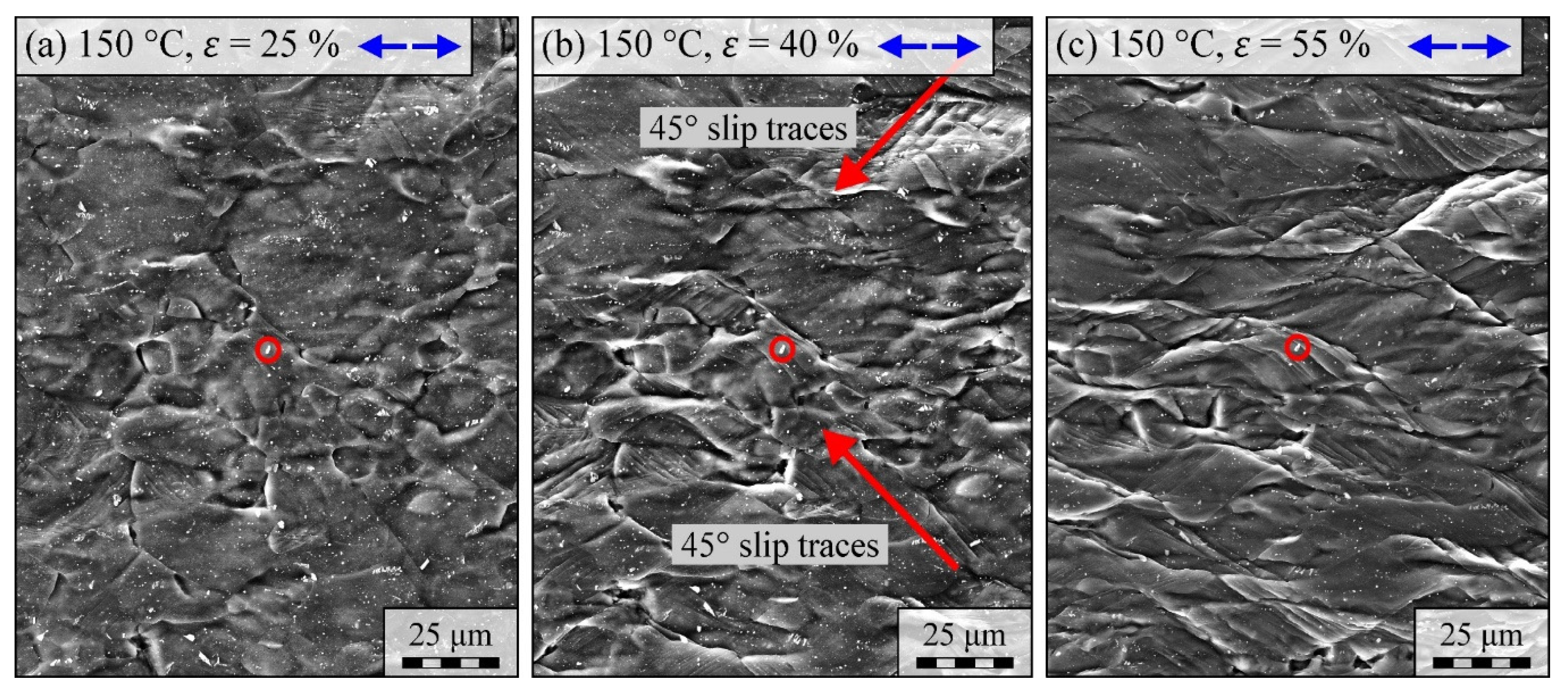

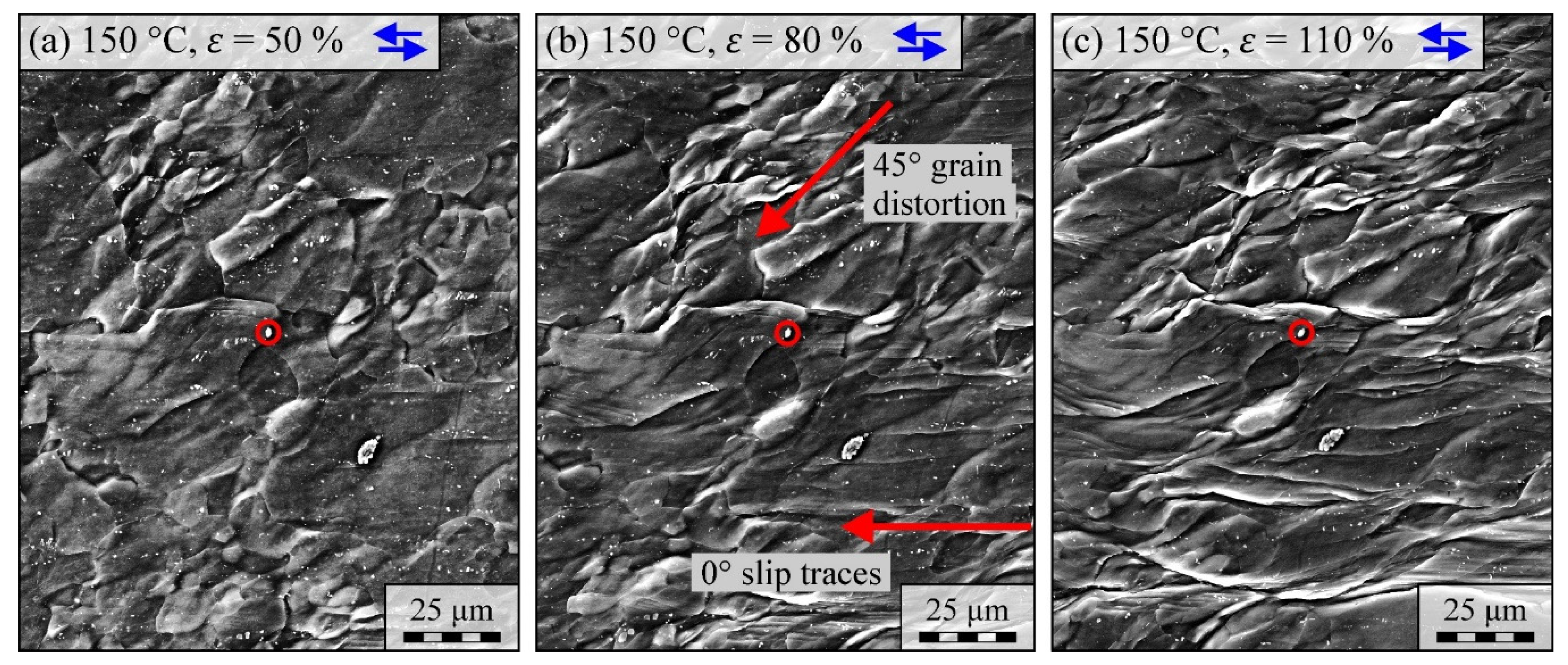

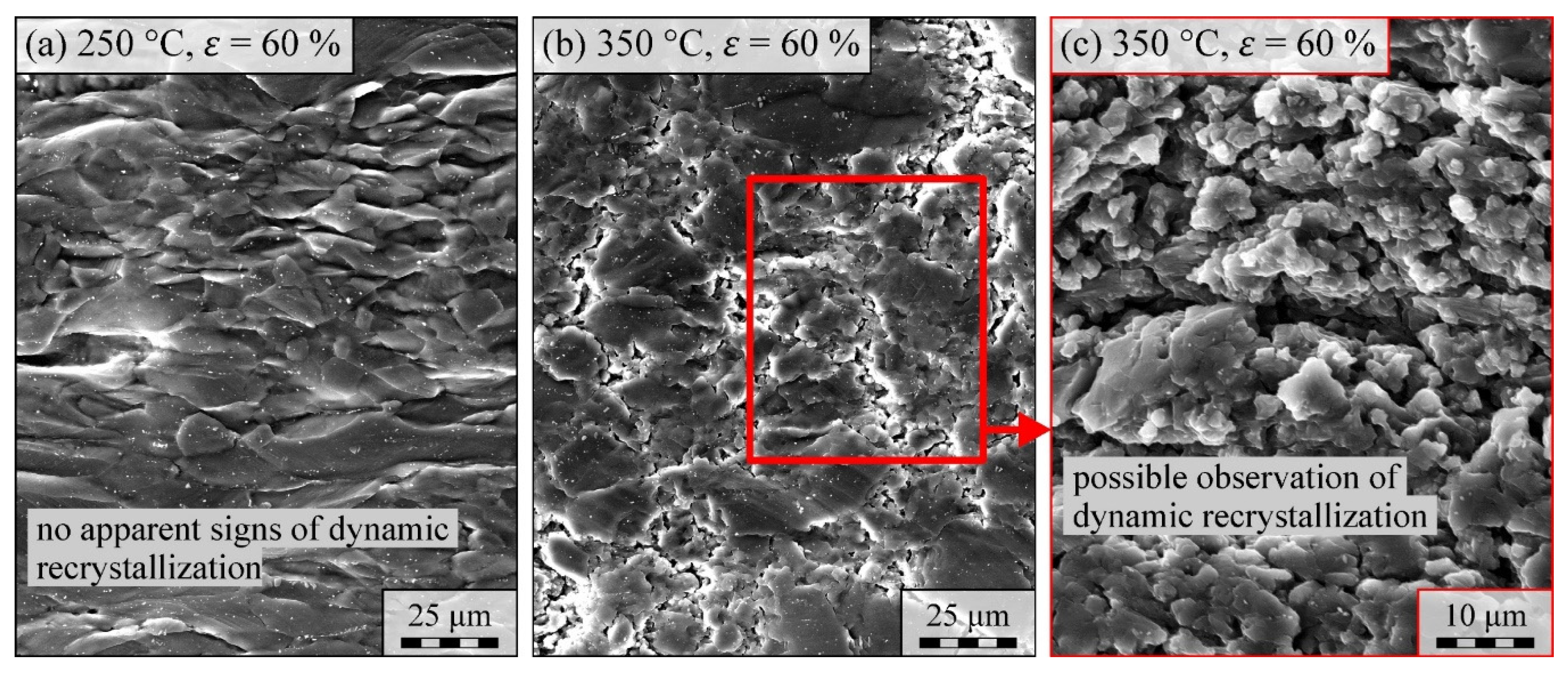

3.2. Deformation Mechanisms

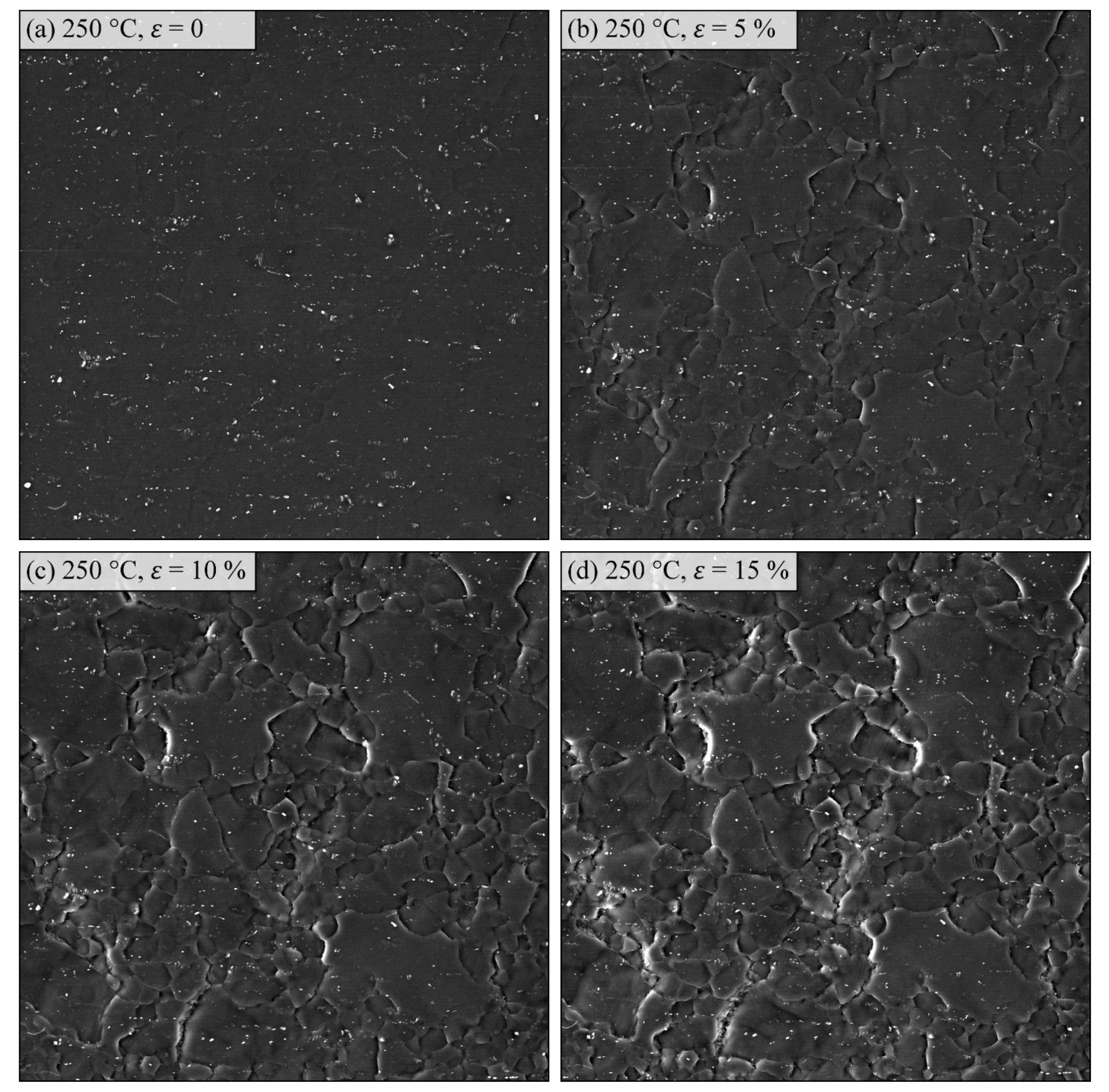

3.3. Damage Mechanisms

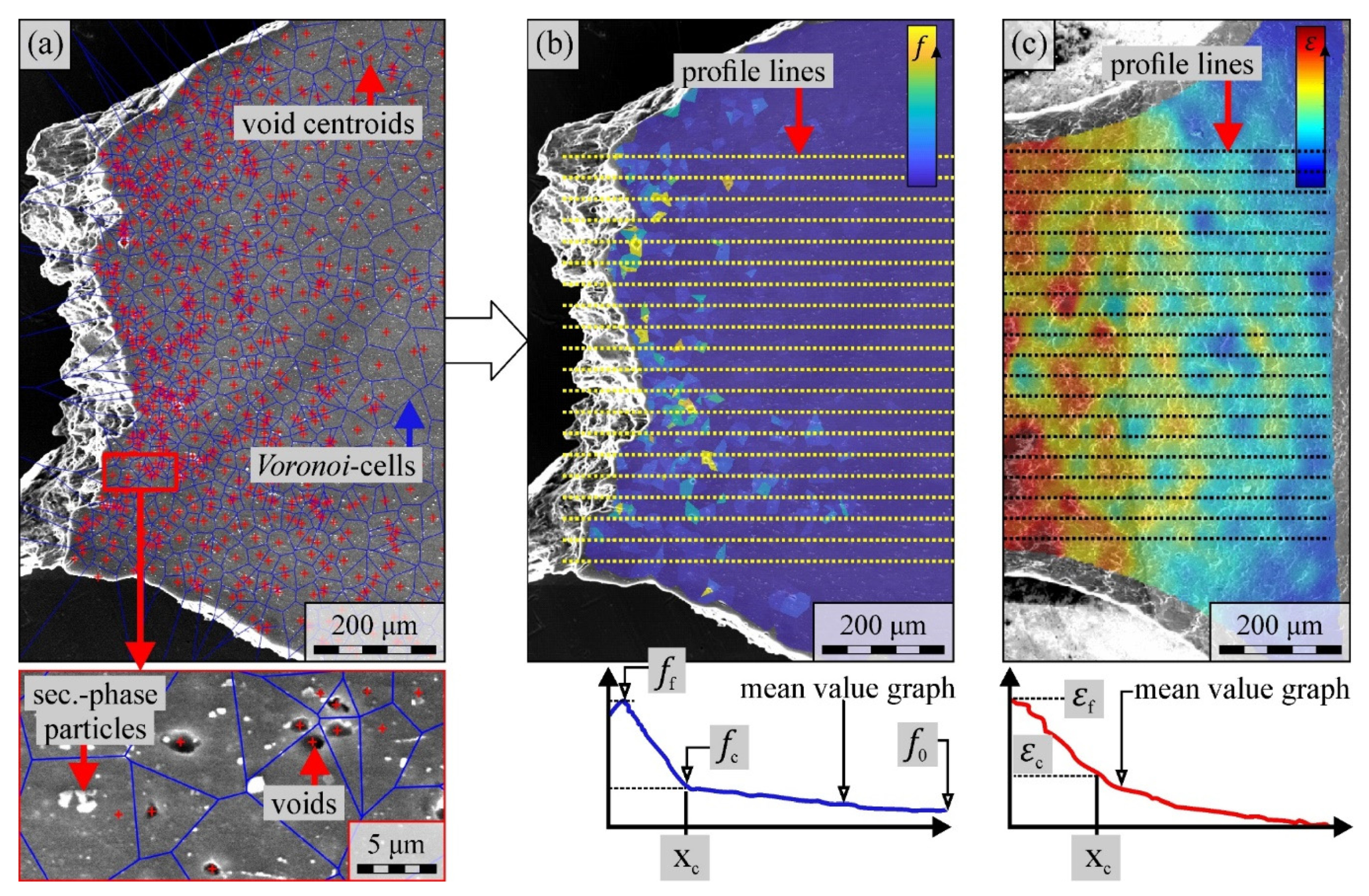

3.3.1. Initial Void Volume Fraction

3.3.2. Void Nucleation

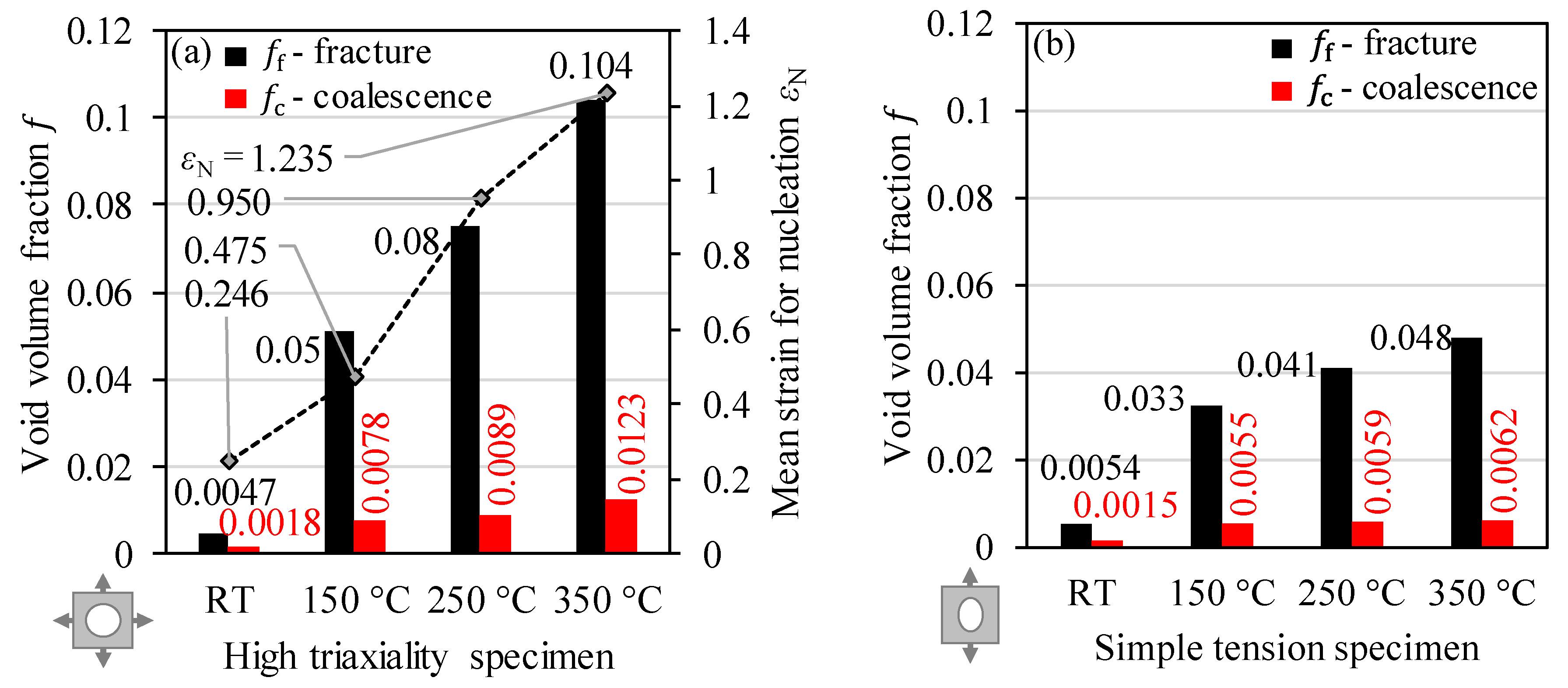

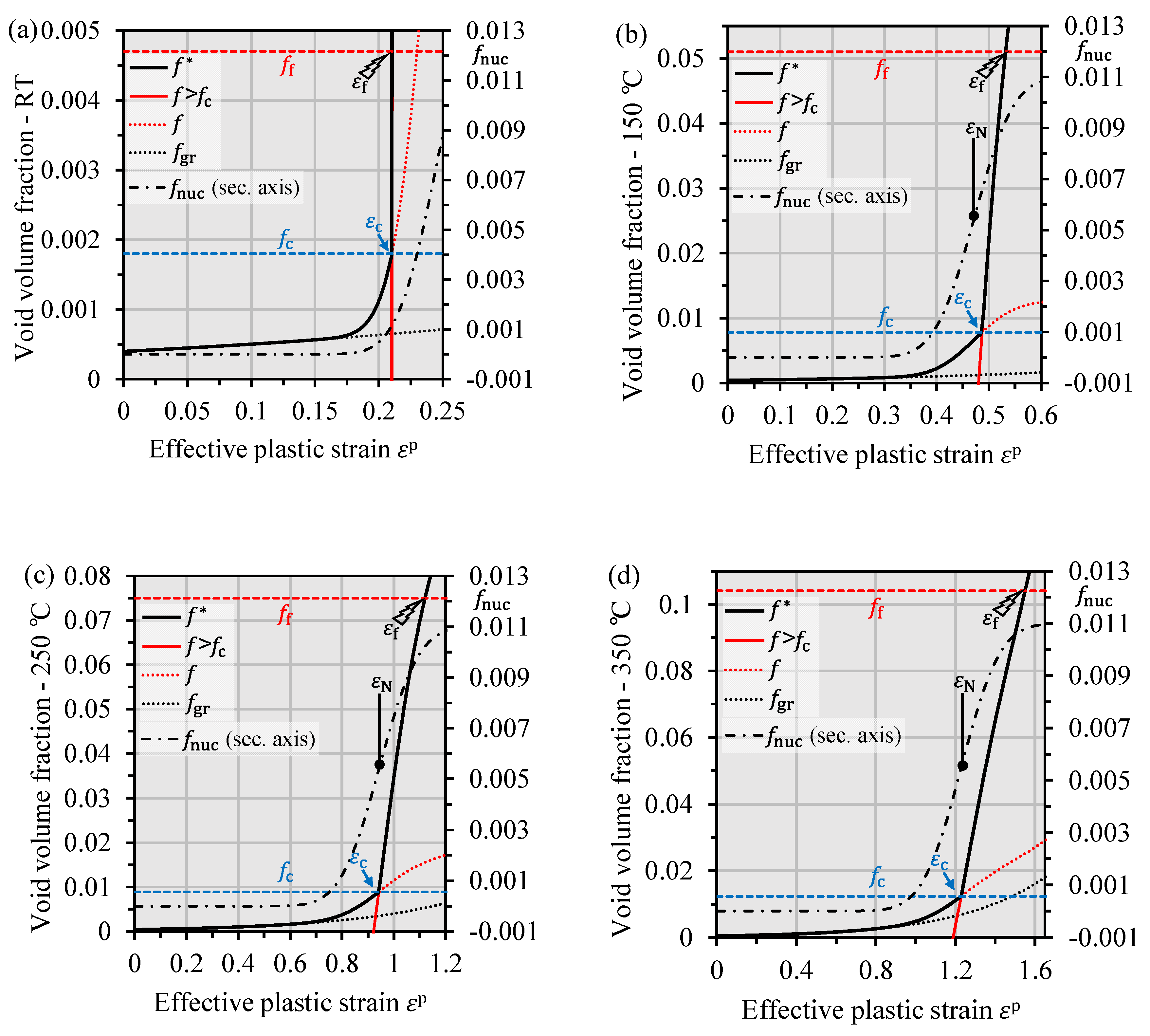

3.3.3. Void Coalescence and Failure

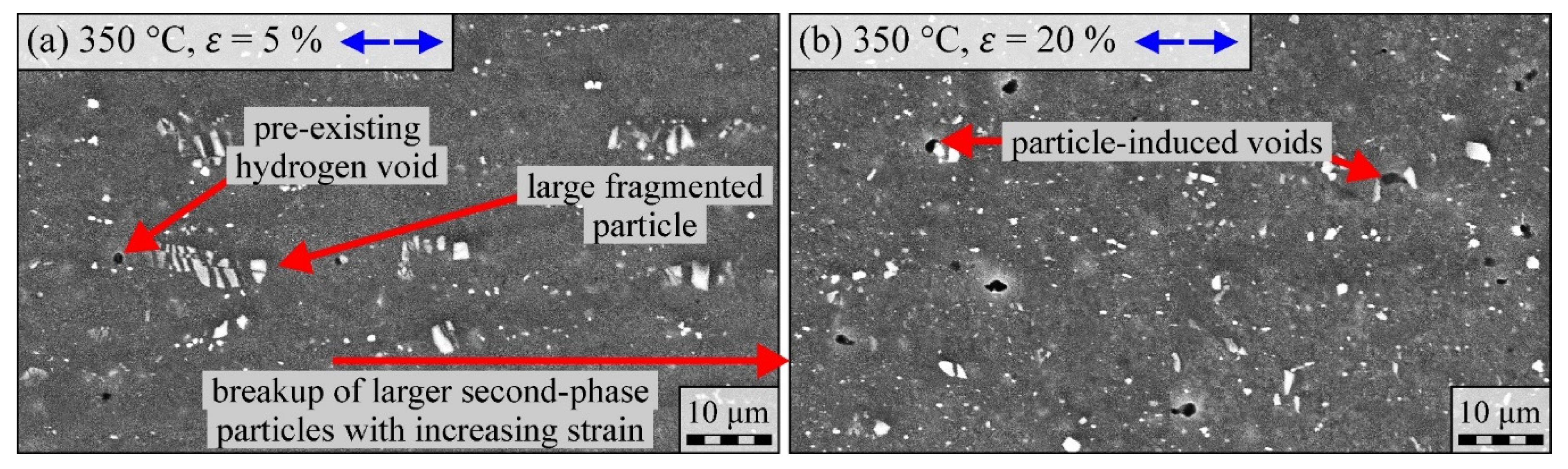

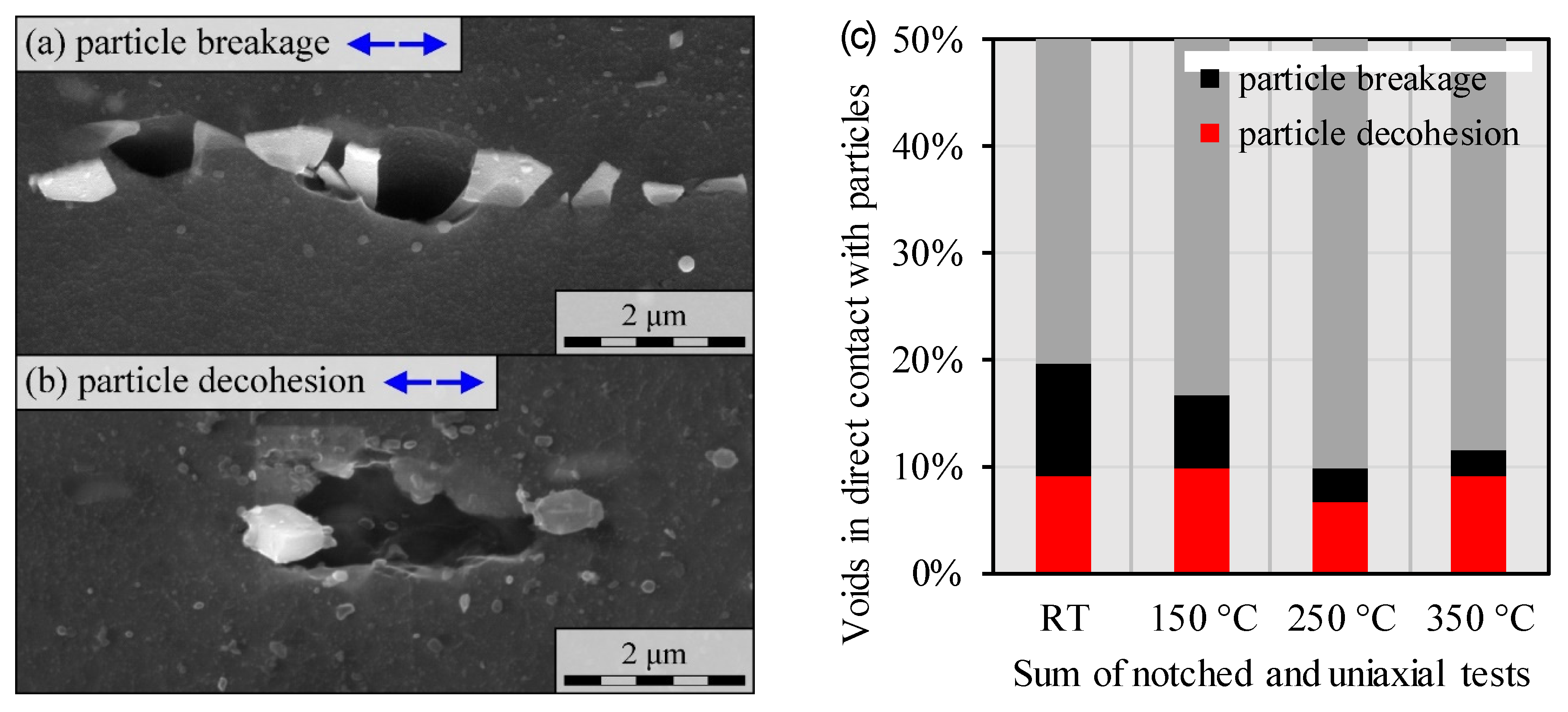

3.3.4. Role of Second Phase Particles

3.3.5. Calibration of Growth Parameters and Normal Distribution

4. Summary and Conclusions

- SEM in-situ images have shown that the specimen surface shows no characteristic signs of ductile damage, but rather allows statements to be made about the deformation mechanisms;

- Near-surface phenomena of slip traces, grain boundary sliding, and dynamic recrystallization could be observed as functions of temperature and stress state;

- For the first time in literature, an experimental method is proposed and validated to determine all GTN model parameters for sheet metal;

- The post-mortem analyses confirm that pre-existing hydrogen voids, particle-induced voids, as well as voids from grain boundary failure or twin-boundary failure were responsible for ductile damage accumulation. Nevertheless, the post-mortem analyses do not provide sufficient insight into the exact statistics of void origin;

- The established GTN model parameters show a linear positive dependence on temperature. Furthermore, this parameterization represents a milestone in the ductile damage modeling of Mg thin sheet, because the large temperature ranges that can occur in sheet metal forming can be simulated;

- The authors conclude that the anisotropic deformation properties can still be modeled as soon as they are considered in the yield stress of the GTN model.

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Cao, T. Models for ductile damage and fracture prediction in cold bulk metal forming processes. Int. J. Mater. Form. 2017, 10, 139–171. [Google Scholar] [CrossRef]

- Wu, Z.; Curtin, W.A. The origins of high hardening and low ductility in magnesium. Nature 2015, 526, 62–67. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- John Neil, C.; Agnew, S. Crystal plasticity-based forming limit prediction for non-cubic metals: Application to Mg alloy AZ31B. Int. J. Plast. 2009, 25, 379–398. [Google Scholar] [CrossRef]

- Barnett, M. Influence of deformation conditions and texture on the high temperature flow stress of magnesium AZ31. J. Light Met. 2001, 1, 167–177. [Google Scholar] [CrossRef]

- Barnett, M. A taylor model based description of the proof stress of magnesium AZ31 during hot working. Metall. Mater. Trans. A 2003, 34, 1799–1806. [Google Scholar] [CrossRef] [Green Version]

- Kim, W.; Lee, B. Factors influencing tensile ductility of ultrafine-grained Mg–3Al–1Zn alloy sheet at elevated temperatures. Mater. Sci. Eng. A 2010, 527, 5984–5989. [Google Scholar] [CrossRef]

- Kim, W.; Chung, S.; Chung, C.S.; Kum, D. Superplasticity in thin magnesium alloy sheets and deformation mechanism maps for magnesium alloys at elevated temperatures. Acta Mater. 2001, 49, 3337–3345. [Google Scholar] [CrossRef]

- Nemcko, M.; Wilkinson, D. On the damage and fracture of commercially pure magnesium using x-ray microtomography. Mater. Sci. Eng. A 2016, 676, 146–155. [Google Scholar] [CrossRef]

- Ray, A.; Wilkinson, D. The effect of microstructure on damage and fracture in AZ31B and ZEK100 magnesium alloys. Mater. Sci. Eng. A 2016, 658, 33–41. [Google Scholar] [CrossRef]

- Kondori, B.; Benzerga, A. Modeling damage accumulation to fracture in a magnesium-rare earth alloy. Acta Mater. 2017, 124, 225–236. [Google Scholar] [CrossRef] [Green Version]

- Lhuissier, P.; Scheel, M.; Salvo, L.; Di Michiel, M.; Blandin, J. Continuous characterization by X-ray microtomography of damage during high-temperature deformation of magnesium alloy. Scr. Mater. 2013, 69, 85–88. [Google Scholar] [CrossRef]

- Lhuissier, P.; Scheel, M.; Salvo, L.; Boller, E.; Di Michiel, M.; Blandin, J. 4D Damage Characterization during Superplastic Deformation of Magnesium Alloys. MSF 2012, 735, 61–66. [Google Scholar] [CrossRef]

- Rashed, H.M.M.A.; Robson, J.; Bate, P.; Davis, B. Application of X-ray microtomography to analysis of cavitation in AZ61 magnesium alloy during hot deformation. Mater. Sci. Eng. A 2011, 528, 2610–2619. [Google Scholar] [CrossRef]

- Toda, H.; Shamsudin, Z.; Shimizu, K.; Uesugi, K.; Takeuchi, A.; Suzuki, Y.; Nakazawa, M.; Aoki, Y.; Kobayashi, M. Cavitation during high-temperature deformation in Al–Mg alloys. Acta Mater. 2013, 61, 2403–2413. [Google Scholar] [CrossRef]

- Kondori, B.; Benzerga, A. Effect of Stress Triaxiality on the Flow and Fracture of Mg Alloy AZ31. Metall. Mater. Trans. A 2014, 45, 3292–3307. [Google Scholar] [CrossRef]

- Gurson, A. Continuum Theory of Ductile Rupture by Void Nucleation and Growth. J. Eng. Mater. Technol. 1977, 99, 2–15. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. Analysis of the cup-cone fracture in a round tensile bar. Acta Metall. 1984, 32, 157–169. [Google Scholar] [CrossRef]

- Tvergaard, V. Influence of voids on shear band instabilities under plane strain conditions. Int. J. Fract. 1981, 17, 389–407. [Google Scholar] [CrossRef]

- Chu, C.; Needleman, A. Void Nucleation Effects in Biaxially Stretched Sheets. J. Eng. Mater. Technol. 1980, 102, 249. [Google Scholar] [CrossRef]

- Wang, R.; Chen, Z.; Li, Y.; Dong, C. Failure analysis of AZ31 magnesium alloy sheets based on the extended GTN damage model. Int. J. Miner. Metall. Mater. 2013, 20, 1198–1207. [Google Scholar] [CrossRef]

- Zhao, P.; Chen, Z.; Dong, C. Damage and Failure Analysis of AZ31 Alloy Sheet in Warm Stamping Processes. J. Mater. Eng. Perform. 2016, 25, 2702–2710. [Google Scholar] [CrossRef]

- Costa Mattos, H.; Minak, G.; Di Gioacchino, F.; Soldà, A. Modeling the superplastic behavior of Mg alloy sheets under tension using a continuum damage theory. Mater. Des. 2009, 30, 1674–1679. [Google Scholar] [CrossRef]

- Kawalla, R.; Oswald, M.; Schmidt, C.; Ullmann, M.; Vogt, H.-P.; Cuong, N. Development of a strip-rolling technology for Mg alloys based on the twin-roll-casting process. Miner. Met. Mater. Soc. 2008, 177, 182. [Google Scholar]

- Kawalla, R.; Ullmann, M.; Oswald, M.; Schmidt, C. Properties of strips and sheets of magnesium alloy produced by casting-rolling technology. In Proceedings of the 7th International Conference on Magnesium Alloys and Their Applications, Dresden, Germany, 2 January 2007. [Google Scholar]

- Henseler, T.; Ullmann, M.; Kawalla, R.; Berge, F. Influence of the Sheet Manufacturing Process on the Forming Limit Behaviour of Twin-Roll Cast, Rolled and Heat-Treated AZ31. Key Eng. Mater. 2017, 746, 154–160. [Google Scholar] [CrossRef]

- Ullmann, M.; Berge, F.; Neh, K.; Kawalla, R. Development of a rolling technology for twin-roll cast magnesium strip. Metalurgija 2015, 4, 711–714. [Google Scholar]

- Graf, M.; Henseler, T.; Ullmann, M.; Kawalla, R.; Prahl, U.; Awiszus, B. Study on determination of flow behaviour of 6060-aluminium and AZ31-magnesium thin sheet by means of stacked compression test. IOP Conf. Ser. Mater. Sci. Eng. 2019, 480, 12023. [Google Scholar] [CrossRef]

- Kawalla, R.; Ullmann, M.; Henseler, T.; Prahl, U. Magnesium Twin-Roll Casting Technology for Flat and Long Products-State of the Art and Future. Mater. Sci. Forum 2018, 941, 1431–1436. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX–Free and Open Source Software Toolbox. SSP 2010, 160, 63–68. [Google Scholar] [CrossRef] [Green Version]

- Chiu, S.N.; Stoyan, D.; Kendall, W.S.; Mecke, J. Stochastic Geometry and Its Applications; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Blaber, J.; Adair, B.; Antoniou, A. Ncorr: Open-Source 2D Digital Image Correlation Matlab Software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar] [CrossRef]

- Ullmann, M.; Kittner, K.; Henseler, T.; Stöcker, A.; Prahl, U.; Kawalla, R. Development of new alloy systems and innovative processing technologies for the production of magnesium flat products with excellent property profile. Procedia Manuf. 2019, 27, 203–208. [Google Scholar] [CrossRef]

- Masoumi, M.; Zarandi, F.; Pekguleryuz, M. Microstructure and texture studies on twin-roll cast AZ31 (Mg–3wt.%Al–1wt.%Zn) alloy and the effect of thermomechanical processing. Mater. Sci. Eng. A 2011, 528, 1268–1279. [Google Scholar] [CrossRef]

- Liang, P.; Tarfa, T.; Robinson, J.; Wagner, S.; Ochin, P.; Harmelin, M.; Seifert, H.; Lukas, H. Experimental investigation and thermodynamic calculation of the Al–Mg–Zn system. Thermochim. Acta 1998, 314, 87–110. [Google Scholar] [CrossRef]

- Koike, J.; Ohyama, R.; Kobayashi, T.; Suzuki, M.; Maruyama, K. Grain-Boundary Sliding in AZ31 Magnesium Alloys at Room Temperature to 523 K. Mater. Trans. 2003, 44, 445–451. [Google Scholar] [CrossRef] [Green Version]

- Xia, D.; Huang, G.; Liu, S.; Tang, A.; Gavras, S.; Huang, Y.; Hort, N.; Jiang, B.; Pan, F. Microscopic deformation compatibility during biaxial tension in AZ31 Mg alloy rolled sheet at room temperature. Mater. Sci. Eng. A 2019, 756, 1–10. [Google Scholar] [CrossRef]

- Üçel, İ.; Kapan, E.; Türkoğlu, O.; Aydıner, C. In situ investigation of strain heterogeneity and microstructural shear bands in rolled Magnesium AZ31. Int. J. Plast. 2019, 118, 233–251. [Google Scholar] [CrossRef]

- Wang, F.; Sandlöbes, S.; Diehl, M.; Sharma, L.; Roters, F.; Raabe, D. In situ observation of collective grain-scale mechanics in Mg and Mg–rare earth alloys. Acta Mater. 2014, 80, 77–93. [Google Scholar] [CrossRef]

- Xi, B.; Fang, G.; Xu, S. In-situ analysis of microscopic plastic and failure behaviors of extruded magnesium alloy. Mater. Sci. Eng. A 2019, 749, 148–157. [Google Scholar] [CrossRef]

- Wang, H.; Boehlert, C.; Wang, Q.; Yin, D.; Ding, W. In-situ analysis of the tensile deformation modes and anisotropy of extruded Mg-10Gd-3Y-0.5Zr (wt.%) at elevated temperatures. Int. J. Plast. 2016, 84, 255–276. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.; Molina-Aldareguia, J.; Pérez-Prado, M. EBSD-Assisted Slip Trace Analysis during in Situ SEM Mechanical Testing: Application to Unravel Grain Size Effects on Plasticity of Pure Mg Polycrystals. JOM 2016, 68, 116–126. [Google Scholar] [CrossRef]

- Osovski, S.; Srivastava, A.; Williams, J.; Needleman, A. Grain boundary crack growth in metastable titanium β alloys. Acta Mater. 2015, 82, 167–178. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, X.; Osovski, S.; Srivastava, A. On the micromechanism of inclusion driven ductile fracture and its implications on fracture toughness. J. Mech. Phys. Sol. 2019, 130, 21–34. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Shanthraj, P.; Springer, H.; Raabe, D. Particle-induced damage in Fe–TiB2 high stiffness metal matrix composite steels. Mater. Des. 2018, 160, 557–571. [Google Scholar] [CrossRef]

- Barnett, M. Twinning and the ductility of magnesium alloys. Mater. Sci. Eng. A 2007, 464, 8–16. [Google Scholar] [CrossRef]

- Ulacia, I.; Yi, S.; Hurtado, I. High strain rate formability of AZ31B magnesium alloy sheets. In Magnesium: Proceedings of the 8th International Conference on Magnesium Alloys and Their Applications; Kainer, K.U., Ed.; Wiley-VCH: Weinheim, Germany, 2010; pp. 509–515. [Google Scholar]

- Bieler, T.; Eisenlohr, P.; Roters, F.; Kumar, D.; Mason, D.; Crimp, M.; Raabe, D. The role of heterogeneous deformation on damage nucleation at grain boundaries in single phase metals. Int. J. Plast. 2009, 25, 1655–1683. [Google Scholar] [CrossRef]

- Uthaisangsuk, V.; Prahl, U.; Bleck, W. Micromechanical modelling of damage behaviour of multiphase steels. Comput. Mater. Sci. 2008, 43, 27–35. [Google Scholar] [CrossRef]

- Benzerga, A.; Leblond, J.-B. Ductile fracture by void growth to coalescence. Adv. Appl. Mech. 2010, 169–305. [Google Scholar]

- Nemcko, M.; Li, J.; Wilkinson, D. Effects of void band orientation and crystallographic anisotropy on void growth and coalescence. J. Mech. Phys. Sol. 2016, 95, 270–283. [Google Scholar] [CrossRef]

- Landron, C.; Maire, E.; Adrien, J.; Bouaziz, O. Damage characterization in Dual-Phase steels using X-ray tomography. In Optical Measurements, Modeling, and Metrology; Proulx, T., Ed.; Springer: New York, NY, USA, 2011; Volume 5, pp. 11–18. [Google Scholar]

- Tvergaard, V. Interaction of very small voids with larger voids. Int. J. Solids Struct. 1998, 35, 3989–4000. [Google Scholar] [CrossRef]

- Prahl, U.; Rehbach, W.; Kuckertz, C.; Weichert, D.; Bleck, W. Ductile Damage Prediction on the Basis of Microstructural Observations. KEM 2003, 251–252, 351–356. [Google Scholar] [CrossRef]

- Prahl, U. Schädigung und Versagen Mikrolegierter Feinkornstähle in Experiment und Simulation. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2002. [Google Scholar]

| Al | Zn | Mn | Zr | Cu | Si | Fe | Sn | Ca | Mg |

|---|---|---|---|---|---|---|---|---|---|

| 2.99 | 0.969 | 0.377 | 0.002 | 0.001 | 0.017 | 0.003 | <0.005 | <0.001 | bal. |

| RT | 1.5 | 1 | 2.25 | 0.0004 | 0.011 | 0.0246 | 0.246 | 0.0018 | 0.0047 |

| 150 °C | 0.0594 | 0.475 | 0.0078 | 0.051 | |||||

| 250 °C | 0.1188 | 0.95 | 0.0089 | 0.075 | |||||

| 350 °C | 0.1544 | 1.235 | 0.0123 | 0.104 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Henseler, T.; Osovski, S.; Ullmann, M.; Kawalla, R.; Prahl, U. GTN Model-Based Material Parameters of AZ31 Magnesium Sheet at Various Temperatures by Means of SEM In-Situ Testing. Crystals 2020, 10, 856. https://doi.org/10.3390/cryst10100856

Henseler T, Osovski S, Ullmann M, Kawalla R, Prahl U. GTN Model-Based Material Parameters of AZ31 Magnesium Sheet at Various Temperatures by Means of SEM In-Situ Testing. Crystals. 2020; 10(10):856. https://doi.org/10.3390/cryst10100856

Chicago/Turabian StyleHenseler, Thorsten, Shmuel Osovski, Madlen Ullmann, Rudolf Kawalla, and Ulrich Prahl. 2020. "GTN Model-Based Material Parameters of AZ31 Magnesium Sheet at Various Temperatures by Means of SEM In-Situ Testing" Crystals 10, no. 10: 856. https://doi.org/10.3390/cryst10100856

APA StyleHenseler, T., Osovski, S., Ullmann, M., Kawalla, R., & Prahl, U. (2020). GTN Model-Based Material Parameters of AZ31 Magnesium Sheet at Various Temperatures by Means of SEM In-Situ Testing. Crystals, 10(10), 856. https://doi.org/10.3390/cryst10100856