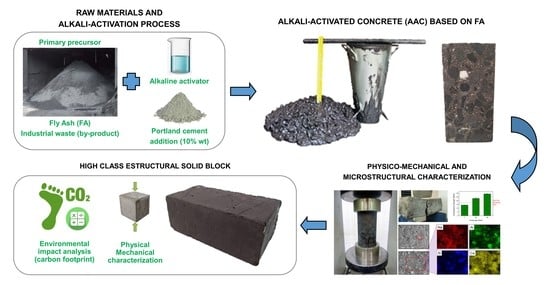

Alkali-Activated Hybrid Concrete Based on Fly Ash and Its Application in the Production of High-Class Structural Blocks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methodology

2.2.1. Design and Obtaining of Mixtures

2.2.2. Instrumental Techniques

- Chemical composition. It was determined by X-ray fluorescence (XRF) using a Phillips PANalytical MagiX PRO PW 2440 spectrometer (Tollerton, United Kingdom) equipped with a rhodium tube, whose maximum power is 4 kW.

- Particle size and distribution. These properties were evaluated by the Laser Granulometry technique (ISO 13320 standard) in a Mastersizer 2000 (Malvern Instrument, UK) equipment coupled to a Hydro 2000MU dispersion unit, using distilled water as dispersion medium.

- Mineralogical and morphological characteristics. X-ray diffraction (XRD) and scanning electron microscopy (SEM) techniques were used. XRD and SEM were performed on a PANalytical X’Pert MRD X-ray diffractometer with Cu k-α radiation, where the diffraction angle 2θ was varied between 10 and 60° with increments of 0.020°, and a JEOL JSM-6490LV microscope with an acceleration voltage of 20 kV. The specimens were examined in low vacuum mode. An Oxford Instruments INCAPentaFETx3 X-ray spectrometer (energy-dispersive X-ray spectroscopy, EDS) was attached to the microscope. For the SEM test on the samples of 90% FA–10% OPC concrete after 28 days of curing, a 1 cm3 sample was extracted from the concrete, which was subsequently encapsulated in epoxy resin and finally the observation surface was polished. DRX information processing was performed using the X´pert HighScore Plus software package, version 2.2.5.

- Heat of reaction and setting time of the pastes. The heat of reaction and heat evolution were evaluated using an I-Cal 8000 isothermal calorimeter (Calmetrix) at a temperature of 25 °C (ASTM C1702), and the setting time was determined with a Vicat apparatus (Humboldt) following the procedure of ASTM C191 (method B).

- The physical properties of density, absorption and porosity of the hybrid concrete and the solid concrete blocks were determined according to the ASTM C642 standard.

- Mechanical properties. The compressive strength of each paste was measured using an INSTRON 3369 universal machine (50 kN capacity) at a test speed of 1 mm/min. The compressive strengths of the mortars (ASTM C109), hybrid concrete (ASTM C39) and solid concrete blocks (ASTM C140) were determined in an ELE International hydraulic press, with 1000 kN capacity. The diameter of the concrete cylinders was 76.2 mm and the dimension (height × width × length) of the solid blocks was 80 mm × 100 mm × 200 mm. The flexural strength or modulus of rupture of the hybrid concrete was determined by a 3-bearing flexural test (ASTM C293) using beams of 300 mm × 75 mm × 75 mm (length × width × height). This test was carried out on a Tinius Olsen H50KS universal machine with a capacity of 50 kN at a loading speed of 1 mm/min.

3. Results and Analysis

3.1. Characterization of Hybrid Cement

3.1.1. Optimization of Alkaline Activator Content

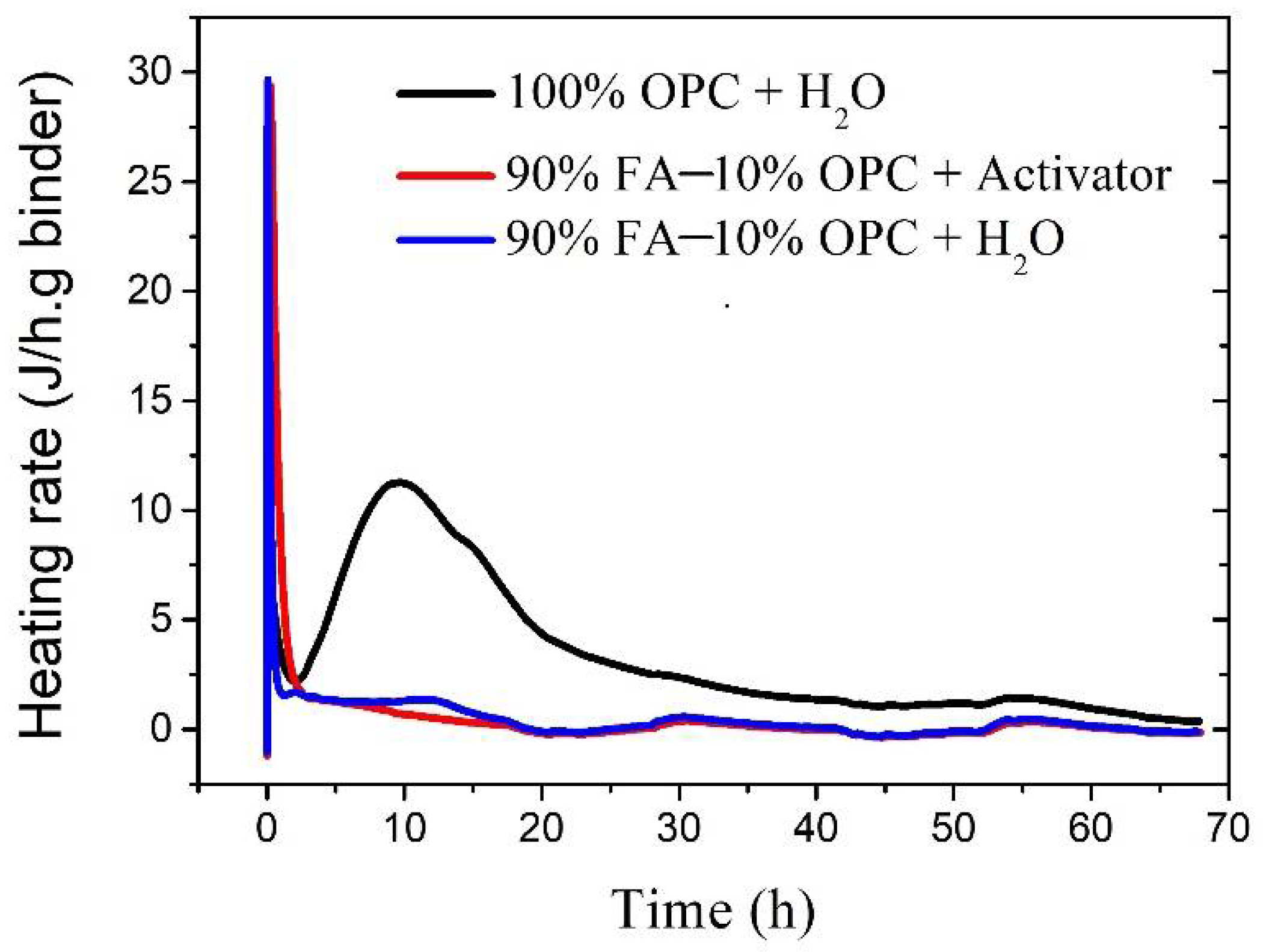

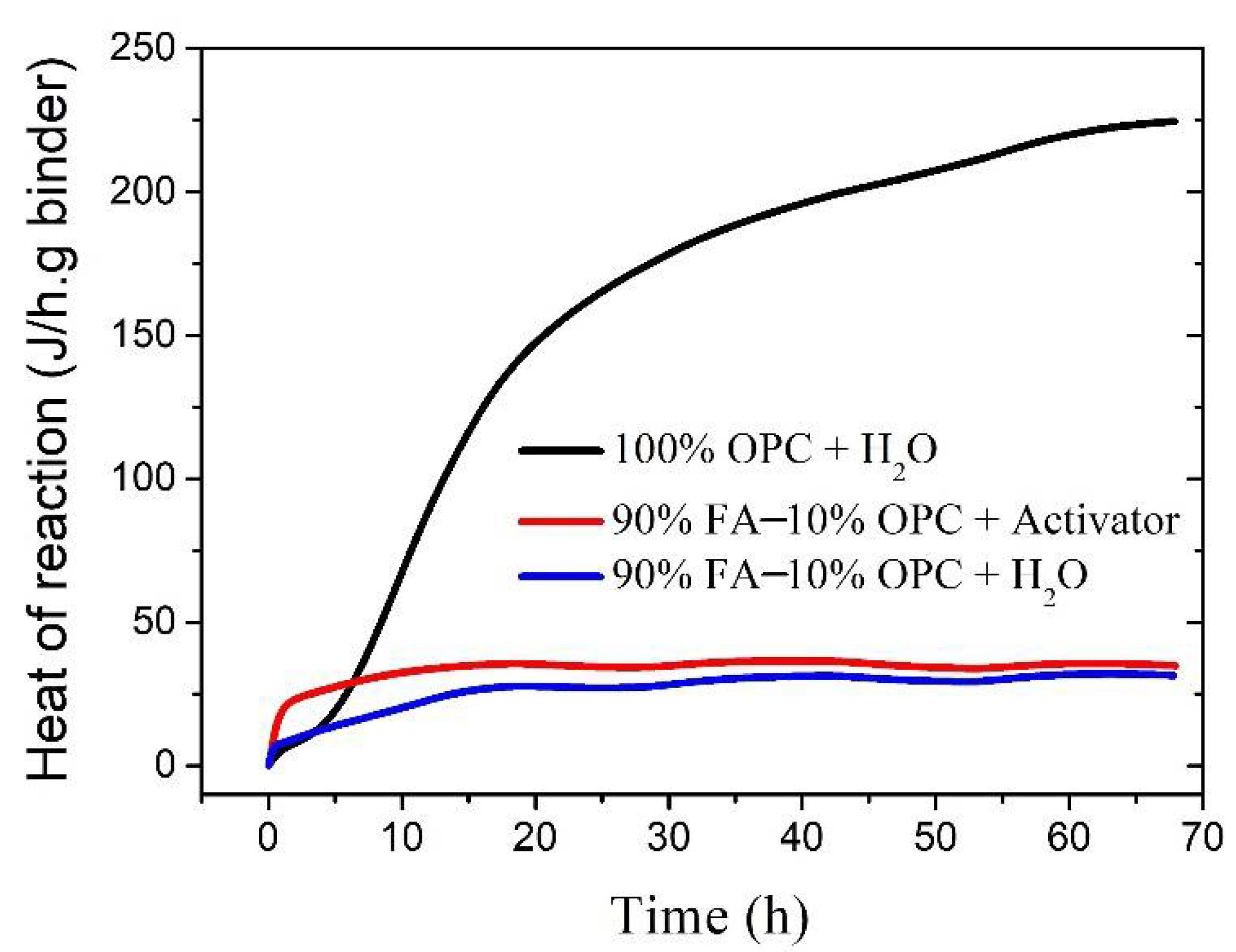

3.1.2. Reaction Kinetics of the Hybrid Cement

3.1.3. Compressive Strength and Classification of the Hybrid Cement

3.2. Physico-Mechanical and Microstructural Characterization of Hybrid Concrete

3.2.1. Physical-Mechanical Characterization

3.2.2. Microstructural Analysis of Hybrid Concrete

3.3. Production of Solid Blocks from the Hybrid Concrete

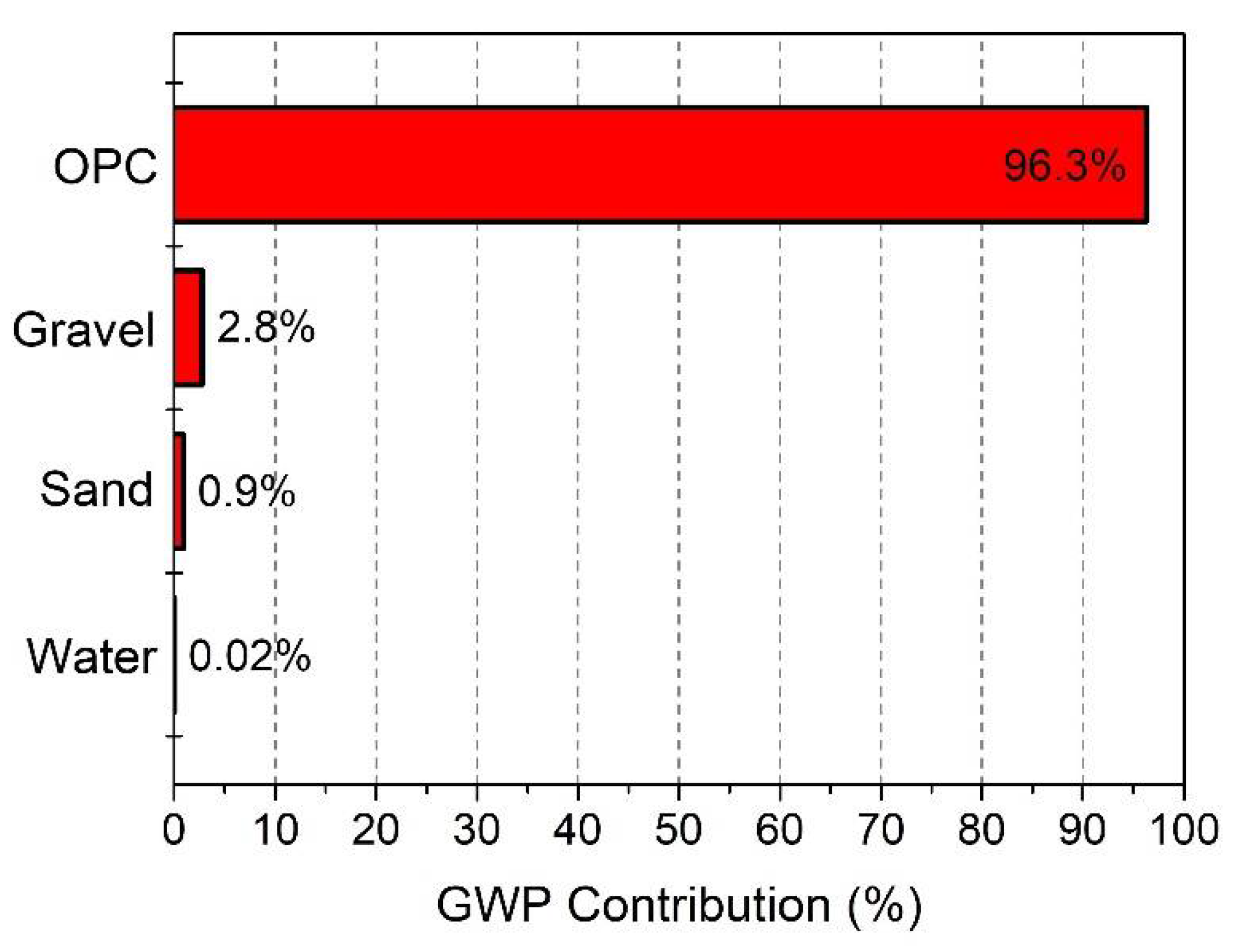

3.4. Analysis of the Life Cycle of the Hybrid Concrete: Global Warning Potential

4. Conclusions

- The addition of 10% OPC to the hybrid cement allowed the curing and development of strengths at room temperature (~25 °C). This aspect is considered an advantage from a technological point of view since no additional hydro-thermal curing processes are necessary. The optimization of this percentage of OPC addition was carried out taking into account the compressive strength reached at 28 days (31.56 MPa) and the initial setting time (93.5 min), achieving a balance between mechanical strength and workability of the material.

- The results of the setting time test indicated that the addition of OPC has a catalytic effect on the reaction kinetics of the hybrid cement, proportionally accelerating the hardening of the mixture.

- The 85% decrease in the total heat of reaction of the hybrid cement (90% FA–10% OPC) compared to a 100% OPC–based paste represents one of the main advantages from the point of view of application. The hybrid cement, in fact, complies with the specifications of ASTM C1157 (equivalent to NTC 121) to be classified as a low reaction heat cement (type LH), taking into account the properties of compressive strength, setting time, and heat of hydration (cement hybrid: 34.85 kJ/kg vs. 200 kJ/kg specified by ASTM).

- The compressive strength of the hybrid concrete (23.16 MPa at 28 days) exceeds the minimum limit established by ACI 318 for classification as a structural concrete. Furthermore, the modulus of rupture (5.32 MPa) represented 23% of the compressive strength.

- The application of the hybrid concrete in the manufacture of solid block type masonry elements was validated. These blocks are commonly used in the construction of one and two-level houses, under the construction and design method of confined masonry walls. The compressive strength of the blocks at 28 days (21.9 MPa) exceeds the minimum mechanical performance limit established by NTC 4026 (13 MPa) to be classified as high-class structural blocks. The compressive strength specified in ASTM C1790 is reached at 90 days of curing.

- The carbon footprint (GWP) allowed the hybrid concrete to be classified as an environmentally sustainable alternative to conventional 100% OPC-based concrete, with a 35% decrease compared to the GWP of conventional concrete (OPC). Sodium silicate meanwhile was observed to be the largest contributor to CO2 emissions associated with the hybrid concrete, representing a contribution of 67% of total emissions. The need to validate the use of alternative activators to the industrial ones in the search to further reduce their carbon footprint is highlighted.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mukherjee, A.B.; Zevenhoven, R.; Bhattacharya, P.; Sajwan, K.S.; Kikuchi, R. Mercury flow via coal and coal utilization by-products: A global perspective. Resour. Conserv. Recycl. 2008, 52, 571–591. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Van Deventer, J.S.J.; Provis, J.L.; Duxson, P. Technical and commercial progress in the adoption of geopolymer cement. Miner. Eng. 2012, 29, 89–104. [Google Scholar] [CrossRef]

- Palomo, A.; Alonso, S.; Fernandez-Jiménez, A.; Sobrados, I.; Sanz, J. Alkaline Activation of Fly Ashes: NMR Study of the Reaction Products. J. Am. Ceram. Soc. 2004, 87, 1141–1145. [Google Scholar] [CrossRef]

- Shi, C.; Fernandez-Jiménez, A.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Donatello, S.; Fernández-Jiménez, A.; Palomo, A. Hydration of hybrid alkaline cement containing a very large proportion of fly ash: A descriptive model. Materials 2016, 9, 605. [Google Scholar] [CrossRef] [Green Version]

- Donatello, S.; Fernández-Jimenez, A.; Palomo, A. Very high volume fly ash cements. Early age hydration study using Na2SO4 as an activator. J. Am. Ceram. Soc. 2013, 96, 900–906. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A. Variation in hybrid cements over time. Alkaline activation of fly ash-portland cement blends. Cem. Concr. Res. 2013, 52, 112–122. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A.; MacPhee, D.E. Compatibility studies between N-A-S-H and C-A-S-H gels. Study in the ternary diagram Na2O-CaO-Al2O3-SiO2-H2O. Cem. Concr. Res. 2011, 41, 923–931. [Google Scholar] [CrossRef]

- Mejía, J.M.; Rodríguez, E.; Mejía de Gutiérrez, R.; Gallego, N. Preparation and characterization of a hybrid alkaline binder based on a fly ash with no commercial value. J. Clean. Prod. 2015, 104, 346–352. [Google Scholar] [CrossRef]

- Valencia Saavedra, W.G.; Mejía de Gutiérrez, R. Performance of geopolymer concrete composed of fly ash after exposure to elevated temperatures. Constr. Build. Mater. 2017, 154, 229–235. [Google Scholar] [CrossRef]

- Puertas, F.; Martínez-Ramírez, S.; Alonso, S.; Vázquez, T. Alkali-activated fly ash/slag cements: Strength behaviour and hydration products. Cem. Concr. Res. 2000, 30, 1625–1632. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Fernandez-Jimenez, A.; Palomo, A. Hydration kinetics in hybrid binders: Early reaction stages. Cem. Concr. Compos. 2013, 39, 82–92. [Google Scholar] [CrossRef]

- Suwan, T.; Fan, M. Influence of OPC replacement and manufacturing procedures on the properties of self-cured geopolymer. Constr. Build. Mater. 2014, 73, 551–561. [Google Scholar] [CrossRef]

- Rangan, B.V. Engineering properties of geopolymer concrete. In Geopolymers; Provis, J.L., van Deventer, J.S.J., Eds.; Woodhead Publishing: Cambridge, UK, 2009; pp. 211–226. [Google Scholar] [CrossRef]

- He, P.; Wang, M.; Fu, S.; Jia, D.; Yan, S.; Yuan, J.; Xu, J.; Wang, P.; Zhou, Y. Effects of Si/Al ratio on the structure and properties of metakaolin based geopolymer. Ceram. Int. 2016, 42, 14416–14422. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Phoo-ngernkham, T.; Hanjitsuwan, S.; Horpibulsuk, S.; Poowancum, A.; Injorhor, B. Effect of calcium-rich compounds on setting time and strength development of alkali-activated fly ash cured at ambient temperature. Case Stud. Constr. Mater. 2018, 9, e00198. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Mejia de Gutierrez, R.; Puertas, F. Study of synergy between a natural volcanic pozzolan and a granulated blast furnace slag in the production of geopolymeric pastes and mortars. Constr. Build. Mater. 2017, 157, 151–160. [Google Scholar] [CrossRef]

- Valencia-Saavedra, W.; Mejía de Gutiérrez, R.; Gordillo, M. Geopolymeric concretes based on fly ash with high unburned content. Constr. Build. Mater. 2018, 165, 697–706. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. La activación alcalina de diferentes aluminosilicatos como una alternativa al Cemento Portland: Cementos activados alcalinamente o geopolímeros. Rev. Ing. Constr. 2017, 32, 5–12. [Google Scholar] [CrossRef] [Green Version]

- Puertas, F.; Palacios, M.; Manzano, H.; Dolado, J.S.; Rico, A.; Rodríguez, J. A model for the C-A-S-H gel formed in alkali-activated slag cements. J. Eur. Ceram. Soc. 2011, 31, 2043–2056. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. 2012, 36, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Lloyd, R.R. Accelerated ageing of geopolymers. In Geopolymers; Provis, J.L., van Deventer, J.S.J., Eds.; Woodhead Publishing: Cambridge, UK, 2009; pp. 139–166. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejía De Gutiérrez, R.; Puertas, F. Alkali-activated binary concrete based on a natural pozzolan: Physical, mechanical and microstructural characterization. Mater. Constr. 2019, 69, 1–5. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Alkaline Activation of Aluminosilicates As an Alternative To Portland Cement: A Review. Rom. J. Mater. 2017, 47, 3–15. [Google Scholar]

- Ouellet-Plamondon, C.; Habert, G. Life cycle assessment (LCA) of alkali-activated cements and concretes. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Pacheco-Torgal, F., LabrinchA, J.A., Chindaprasirt, P., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 663–686. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejía-Arcila, J.; Mejía de Gutiérrez, R.; Martínez, E. Life cycle assessment (LCA) of an alkali-activated binary concrete based on natural volcanic pozzolan: A comparative analysis to OPC concrete. Constr. Build. Mater. 2018, 176, 103–111. [Google Scholar] [CrossRef]

- Salas, D.A.; Ramirez, A.D.; Ulloa, N.; Baykara, H.; Boero, A.J. Life cycle assessment of geopolymer concrete. Constr. Build. Mater. 2018, 190, 170–177. [Google Scholar] [CrossRef]

- Teh, S.H.; Wiedmann, T.; Castel, A.; de Burgh, J. Hybrid life cycle assessment of greenhouse gas emissions from cement, concrete and geopolymer concrete in Australia. J. Clean. Prod. 2017, 152, 312–320. [Google Scholar] [CrossRef] [Green Version]

| Material | SiO2 | Al2O3 | Fe2O3 | K2O | CaO | SO3 | MgO | Na2O | Others | LOI 1 | SiO2/Al2O3 (Molar) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FA | 59.03 | 23.97 | 5.98 | 1.21 | 0.74 | 0.55 | 0.31 | 0.19 | 1.66 | 6.35 | 4.19 |

| OPC | 17.99 | 3.88 | 4.76 | 0.32 | 62.28 | 4.03 | 1.71 | 0.23 | 0.66 | 4.14 | - |

| Material | Dry Weight | Density | Volume |

|---|---|---|---|

| (kg) | (kg/m3) | (m3) | |

| FA | 360.0 | 2395.8 | 0.150 |

| OPC | 40.0 | 3100.0 | 0.0120 |

| Activator * | 288.8 | 1407.4 | 0.205 |

| Sand | 722.6 | 2570.0 | 0.281 |

| Gravel | 883.2 | 2520.0 | 0.350 |

| Total | 2294.6 | 1.000 |

| Mix (Paste) | Total Heat of Reaction (70 h) (kJ/kg of Paste) |

|---|---|

| 90% FA–10% OPC + H2O | 31.49 |

| 90% FA–10% OPC + Activator | 34.85 |

| 100% OPC + H2O | 224.6 |

| Mix (Paste) | Setting Time (min) | |

|---|---|---|

| Initial | Final | |

| 95% FA + 5% OPC | 293 | 420 |

| 90% FA + 10% OPC | 93 | 200 |

| 80% FA + 20% OPC | 33 | 80 |

| Curing Age | LH Cement (ASTM C1157) | Hybrid Mortar (1:2.75) |

|---|---|---|

| 7 days | 11 MPa | 14.67 MPa |

| 28 days | 21 MPa | 22.68 MPa |

| Physical Properties | |

|---|---|

| Density | 2665 kg/m3 |

| Absorption | 8.69% |

| Porosity | 18.80% |

| Physical Properties | Hybrid Concrete Solid Block | NTC 4026 Specifications | ASTM C1790 Specifications |

|---|---|---|---|

| Density (kg/m3) | 2183 | Greater than 2000 (normal weight) | Greater than 2000 (normal weight) |

| Absorption (%) | 9 | ≤9 | ≤10 |

| Porosity (%) | 19.67 | Not applicable | Not applicable |

| Raw Materials | GWP100 (kg∙CO2∙eq) | Alkali-Activated Hybrid Concrete (90% FA + 10%OPC) | Conventional Concrete (100% OPC) | |||

|---|---|---|---|---|---|---|

| Input Values (kg) | Output Values (kg∙CO2∙eq) | Input Values (kg) | Output Values (kg∙CO2∙eq) | |||

| Primary precursor | FA | 5.26 × 10−3 a | 360 | 1.894 | ||

| OPC | 9.10 × 10−1 b | 40 | 36.39 | 400 | 363.9 | |

| Alkaline activator | NaOH | 1.36 × 100 b | 20.2 | 27.45 | ||

| Na2SiO3 | 7.92 × 10−1 b | 207.8 | 164.7 | |||

| Water | Water | 4.29 × 10−4 b | 60.8 | 0.026 | 256.8 | 0.110 |

| Aggregates | Sand | 4.47 × 10−3 b | 722.6 | 3.22 | 691.74 | 3.09 |

| Gravel | 1.11 × 10−2 b | 883.2 | 9.79 | 845.46 | 9.37 | |

| Total | 243.5 | 377.8 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojas-Duque, O.; Espinosa, L.M.; Robayo-Salazar, R.A.; Mejía de Gutiérrez, R. Alkali-Activated Hybrid Concrete Based on Fly Ash and Its Application in the Production of High-Class Structural Blocks. Crystals 2020, 10, 946. https://doi.org/10.3390/cryst10100946

Rojas-Duque O, Espinosa LM, Robayo-Salazar RA, Mejía de Gutiérrez R. Alkali-Activated Hybrid Concrete Based on Fly Ash and Its Application in the Production of High-Class Structural Blocks. Crystals. 2020; 10(10):946. https://doi.org/10.3390/cryst10100946

Chicago/Turabian StyleRojas-Duque, Oriana, Lina Marcela Espinosa, Rafael A. Robayo-Salazar, and Ruby Mejía de Gutiérrez. 2020. "Alkali-Activated Hybrid Concrete Based on Fly Ash and Its Application in the Production of High-Class Structural Blocks" Crystals 10, no. 10: 946. https://doi.org/10.3390/cryst10100946

APA StyleRojas-Duque, O., Espinosa, L. M., Robayo-Salazar, R. A., & Mejía de Gutiérrez, R. (2020). Alkali-Activated Hybrid Concrete Based on Fly Ash and Its Application in the Production of High-Class Structural Blocks. Crystals, 10(10), 946. https://doi.org/10.3390/cryst10100946