Numerical Simulation Study on the Front Shape and Thermal Stresses in Growing Multicrystalline Silicon Ingot: Process and Structural Design

Abstract

1. Introduction

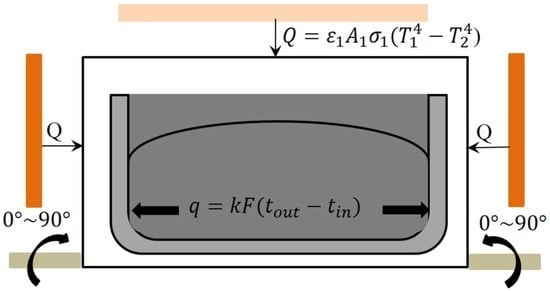

2. Physical Model

3. Effect of Power Ratio on Temperature and Thermal Stress Fields

3.1. Half State

3.2. End State

3.3. Discussion

4. Furnace Structure: The Effect of the Position of the Block under the Side Heater

4.1. Half State

4.2. End State

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fraunhofer Institute for Solar Energy Systems. Photovoltaics Report; Fraunhofer ISE: Freiburg, Germany, 2020. [Google Scholar]

- Li, T.F.; Huang, H.C.; Tsai, H.W.; Lan, A.; Chuck, C.; Lan, C.W. An enhanced cooling design in directional solidification for high quality multi-crystalline solar silicon. J. Cryst. Growth 2012, 340, 202–208. [Google Scholar] [CrossRef]

- Chen, X.J.; Nakano, S.; Liu, L.J.; Kakimoto, K. Study on thermal stress in a silicon ingot during a unidirectional solidification process. J. Cryst. Growth 2008, 310, 4330–4335. [Google Scholar] [CrossRef]

- Lv, G.; Chen, D.; Yang, X.; Ma, W.; Luo, T.; Wei, K.; Zhou, Y.; Zheng, G. Numerical simulation and experimental verification of vacuum directional solidification process for multicrystalline silicon. Vacuum 2015, 116, 96–103. [Google Scholar] [CrossRef]

- Wang, K. Fundations of Materials Engineering, 2nd ed.; Tsinghua University Press: Beijing, China, 2009. [Google Scholar]

- Nguyen, T.H.; Liao, S.H.; Chen, J.C.; Chen, C.H.; Huang, Y.H.; Yang, C.J.; Lin, H.W.; Nguyen, H.B. Effects of the hot zone design during the growth of large size multi-crystalline silicon ingots by the seeded directional solidification process. J. Cryst. Growth 2016, 452, 27–34. [Google Scholar] [CrossRef]

- Chen, L.G.; Dai, B. Optimization of power consumption on silicon directional solidification system by using numerical simulations. J. Cryst. Growth 2012, 354, 86–92. [Google Scholar] [CrossRef]

- Stelian, C. Numerical modeling of carbon distribution and precipitation during directional solidification of photovoltaic silicon. Int. J. Heat Mass Transf. 2019, 145, 118775. [Google Scholar] [CrossRef]

- Cablea, M.; Zaidat, K.; Gagnoud, A.; Nouri, A.; Chichignoud, G.; Delannoy, Y. Multi-crystalline silicon solidification under controlled forced convection. J. Cryst. Growth 2015, 417, 44–50. [Google Scholar] [CrossRef]

- Rao, S.; Chen, X.H.; Zhang, F.; He, L.; Luo, Y.; Xiong, H.; Hu, Y.; Wang, F.; Song, B. Influence of modified bottom insulation on the seeded directional solidification process for high-performance multi-crystalline silicon. Vacuum 2020, 172, 108969. [Google Scholar] [CrossRef]

- Pokland, E.S.A.; Heinze, V.; Meier, D.; Pätzold, O.; Stelter, M. Growth of multicrystalline silicon in a cone-shaped crucible. J. Cryst. Growth 2015, 416, 1–7. [Google Scholar]

- Lin, T.K.; Lin, C.H.; Chen, C.Y. Numerical analysis of steady and transient processes in a directional solidification system. Multi-Scale Multi-Phys. Mech. 2016, 1, 113–125. [Google Scholar] [CrossRef]

- Wu, Z.; Zhong, G.; Zhou, X.; Zhang, Z.; Wang, Z.; Chen, W.; Huang, X. Upgrade of the hot zone for large-size high performance multi-crystalline silicon ingot casting. J. Cryst. Growth 2016, 441, 58–63. [Google Scholar] [CrossRef]

- Srinivasan, M.; Nagarajan, S.G.; Ramasamy, P. Computational Study of Heat Transfer on Molten Silicon during Directional Solidification for Solar Cell Applications. Procedia Eng. 2015, 127, 1250–1255. [Google Scholar] [CrossRef]

- Ma, X.; Zheng, L.; Zhang, H.; Zhao, B.; Wang, C.; Xu, F. Thermal system design and optimization of an industrial silicon directional solidification system. J. Cryst. Growth 2011, 318, 288–292. [Google Scholar] [CrossRef]

- Trempa, C.R.M.; Jung, T.; Friedrich, J.; Müller, G. Modeling of incorporation of O, N, C and formation of related precipitates during directional solidification of silicon under consideration of variable processing parameters. J. Cryst. Growth 2010, 312, 878–885. [Google Scholar] [CrossRef]

- Yu, Q.; Liu, L.; Li, Z.; Shao, Y. Parameter study of traveling magnetic field for control of melt convection in directional solidification of crystalline silicon ingots. Int. J. Heat Fluid Flow 2018, 71, 55–67. [Google Scholar] [CrossRef]

- Li, Z.; Qi, X.; Liu, L.; Zhou, G. Numerical study of melt flow under the influence of heater-generating magnetic field during directional solidification of silicon ingots. J. Cryst. Growth 2018, 484, 78–85. [Google Scholar] [CrossRef]

- Kesavan, V.; Srinivasan, M.; Ramasamy, P. Numerical investigation of Directional Solidification process for improving multi-crystalline silicon ingot quality for photovoltaic applications. Mater. Lett. 2019, 241, 180–183. [Google Scholar] [CrossRef]

- Wu, B.; Stoddard, N.; Ma, R.H.; Clark, R. Bulk multicrystalline silicon growth for photovoltaic (PV) application. J. Cryst. Growth 2008, 310, 2178–2184. [Google Scholar] [CrossRef]

- Xie, G.; Lv, G.; Wang, Y.; Ma, W.; Yang, X.; Lei, Y. The influence of Marangoni effect on the growth quality of multi-crystalline silicon during the vacuum directional solidification process. Mater. Sci. Semicond. Process. 2019, 91, 124–132. [Google Scholar] [CrossRef]

- Karuppasamya, P.; Srinivasana, M.; Aravintha, K.; Ramasamya, P. Numerical Modelling on Modified Directional Solidification Process of Multi-crystalline Silicon Growth for Photovoltaic Applications. Mater. Today Proc. 2018, 5, 23014–23021. [Google Scholar] [CrossRef]

| Silicon | Value | Value | |

| Liquid specific heat capacity (J/kg∙K) | 710 | Liquid thermal conductivity (W/m∙K) | 22 |

| Solid specific heat capacity (J/kg∙K) | 1000 | Solid thermal conductivity (W/m∙K) | 64 |

| Emissivity (W/m∙K) | 0.3 | Latent heat of fusion (J/kg) | 1.587 × 106 |

| Density of solid (kg/m3) | 2330 | Stress coefficient c11/c22/c33 | 1.653 × 1011 |

| Density of liquid in 1600 K (kg/m3) | 2520 | Stress coefficient c12/c13/c23 | 6.393 × 1010 |

| Phase change temperature (K) | 1687 | Stress coefficient c44 | 7.962 × 1010 |

| Crucible | Value | Value | |

| Specific heat capacity (J/kg∙K) | 740 | Thermal conductivity (W/m∙K) | 4.8 |

| Emissivity (W/m∙K) | 0.8 | ||

| Heater/graphite/cooler plate | Value | Value | |

| Specific heat capacity (J/kg∙K) | 740 | Thermal conductivity (W/m∙K) | 80 |

| Emissivity (W/m∙K) | 0.8 | ||

| Insulator | Value | ||

| Specific heat capacity (J/kg∙K) | 846 | Thermal conductivity (W/m∙K) | 0.4 |

| Emissivity (W/m∙K) | 0.8 |

| No. | Heating Power and Ratio * | Insulation Rising Velocity (m/s) |

|---|---|---|

| Case a | 26:26 kW, (1:1) | 2 × 10−6 |

| Case b | 17.3:34.7 kW, (1:2) | |

| Case c | 13:39 kW, (1:3) | |

| Case d | 10.4:41.6 kW, (1:4) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Liu, G.; Zhang, L.; Wang, G.; Hou, Y.; Li, Y. Numerical Simulation Study on the Front Shape and Thermal Stresses in Growing Multicrystalline Silicon Ingot: Process and Structural Design. Crystals 2020, 10, 1053. https://doi.org/10.3390/cryst10111053

Chen C, Liu G, Zhang L, Wang G, Hou Y, Li Y. Numerical Simulation Study on the Front Shape and Thermal Stresses in Growing Multicrystalline Silicon Ingot: Process and Structural Design. Crystals. 2020; 10(11):1053. https://doi.org/10.3390/cryst10111053

Chicago/Turabian StyleChen, Chengmin, Guangxia Liu, Lei Zhang, Guodong Wang, Yanjin Hou, and Yan Li. 2020. "Numerical Simulation Study on the Front Shape and Thermal Stresses in Growing Multicrystalline Silicon Ingot: Process and Structural Design" Crystals 10, no. 11: 1053. https://doi.org/10.3390/cryst10111053

APA StyleChen, C., Liu, G., Zhang, L., Wang, G., Hou, Y., & Li, Y. (2020). Numerical Simulation Study on the Front Shape and Thermal Stresses in Growing Multicrystalline Silicon Ingot: Process and Structural Design. Crystals, 10(11), 1053. https://doi.org/10.3390/cryst10111053