Magnetic Phase Transition, Elastic and Thermodynamic Properties of L12-(Ni,Cu)3(Al,Fe,Cr) in 3d High-Entropy Alloys

Abstract

:1. Introduction

2. Computational Details

3. Results and Discussion

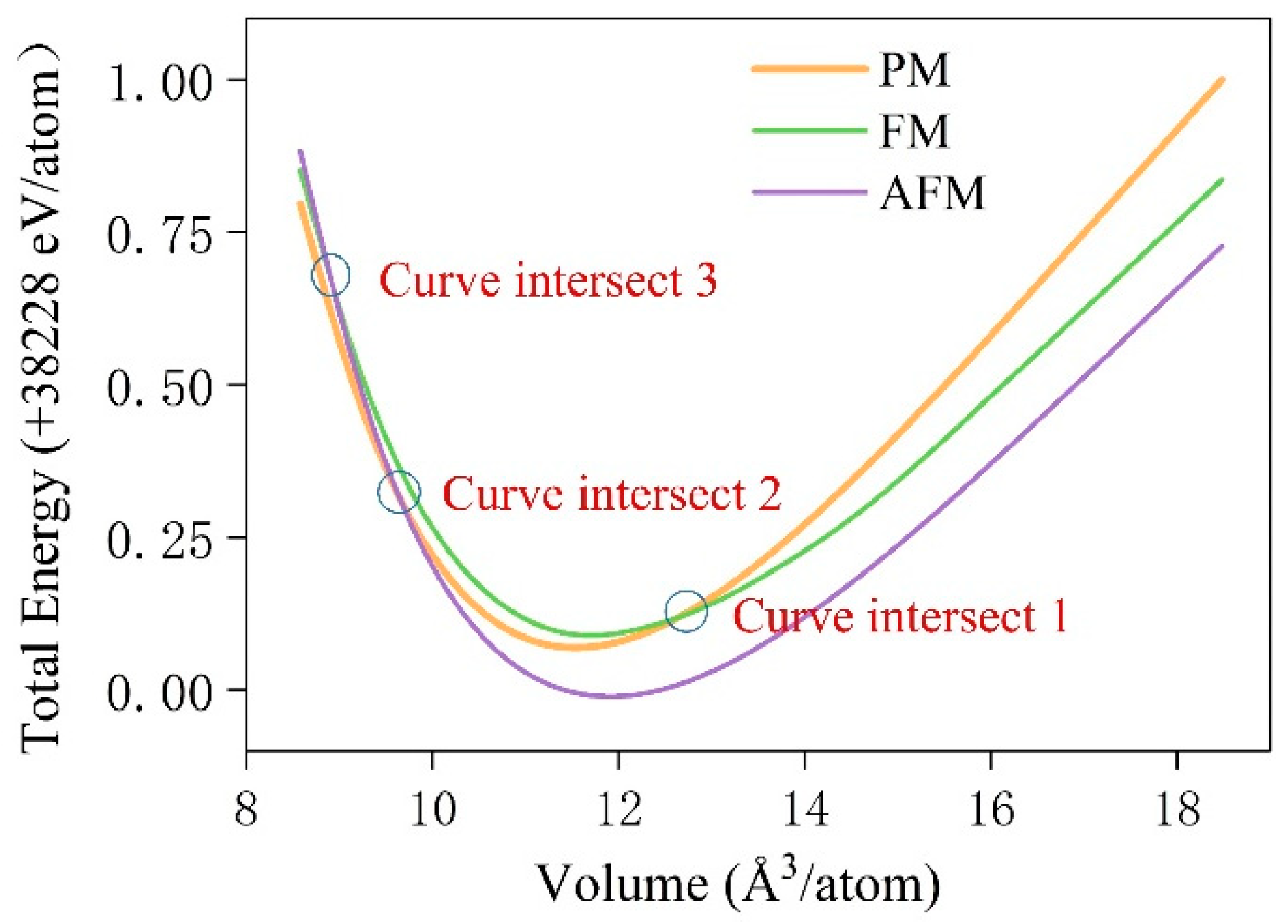

3.1. Phase Stability

3.2. Elastic Properties

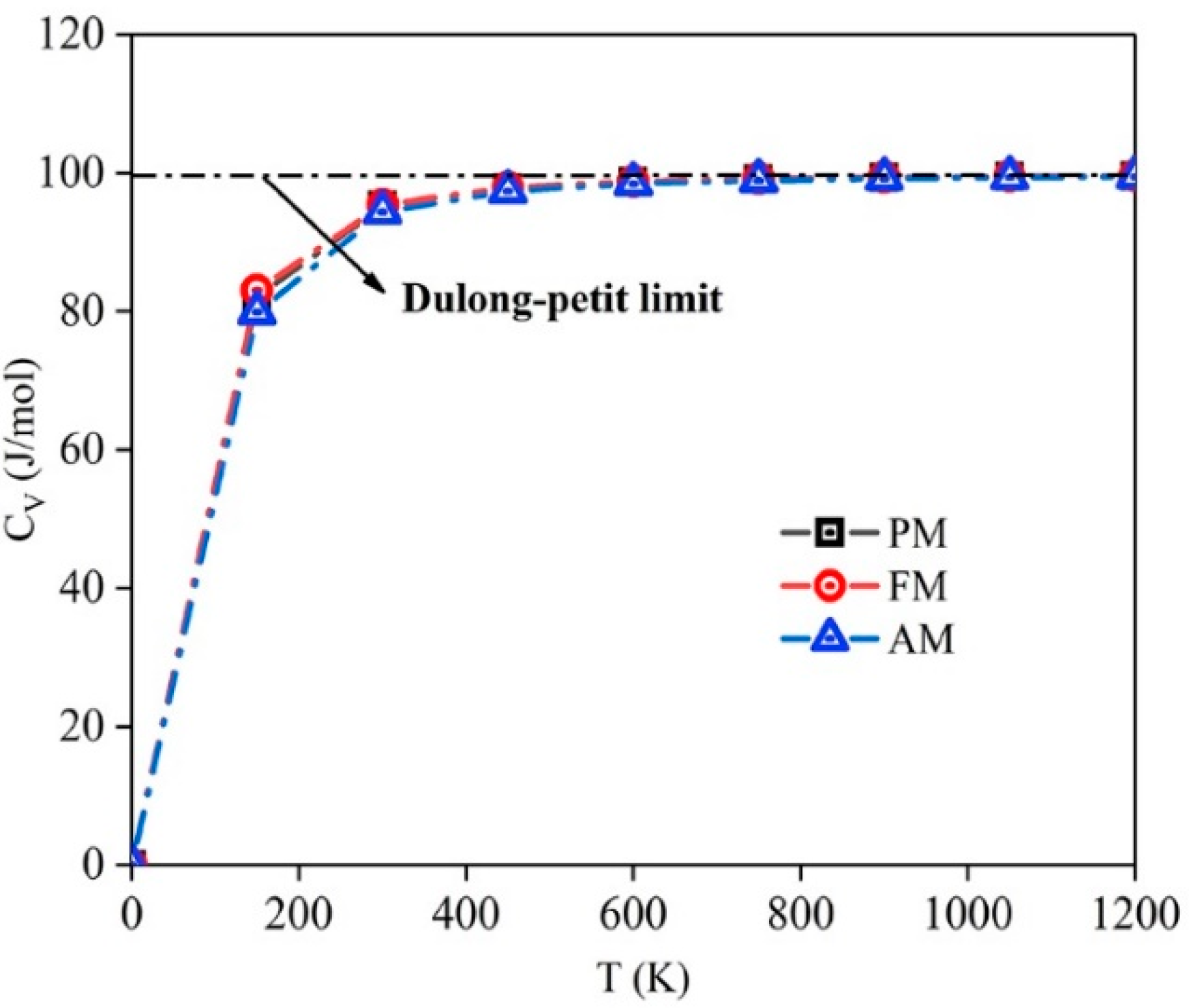

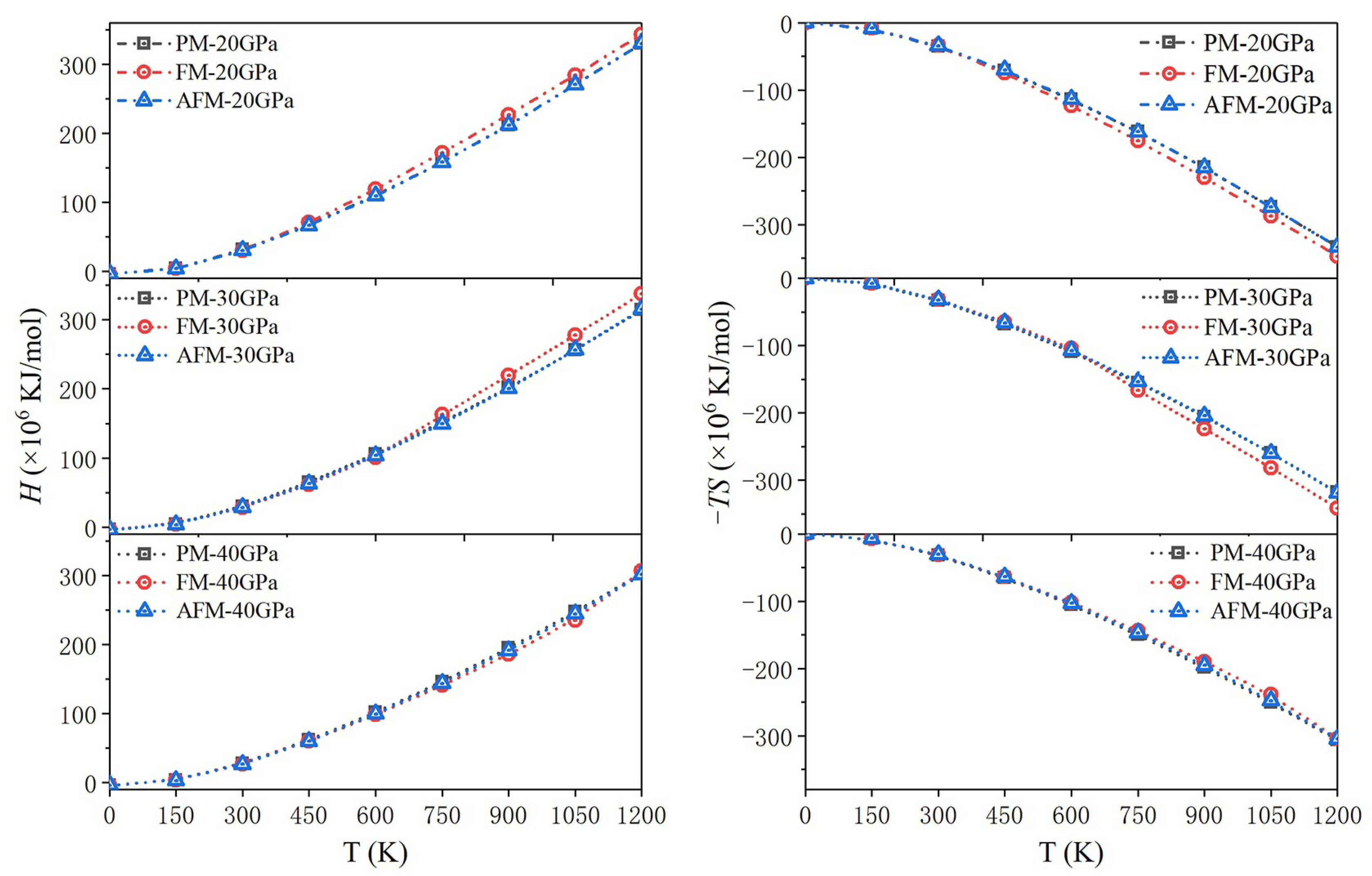

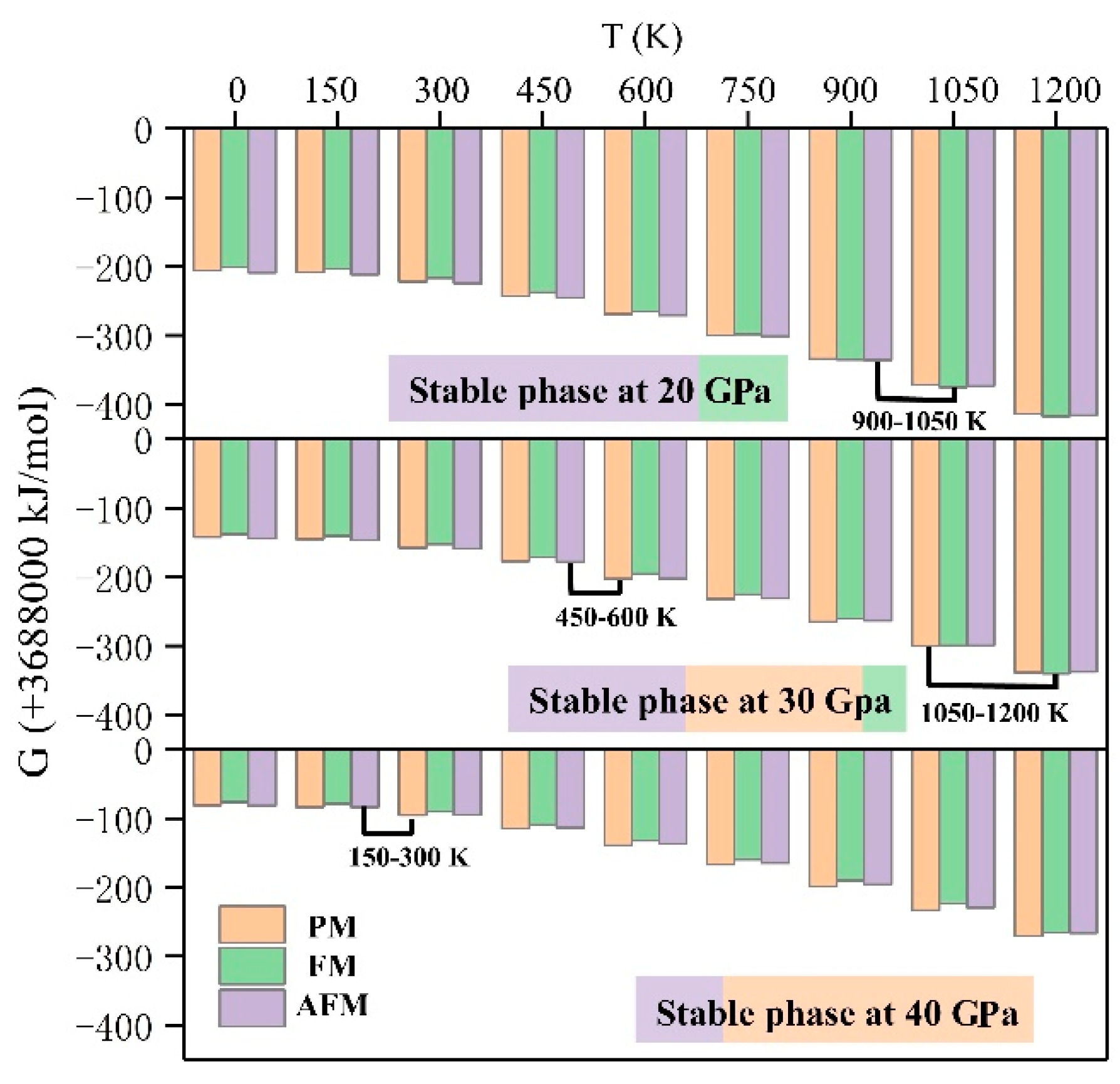

3.3. Thermodynamic Properties and Magnetic Phase Transition

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Laplanche, G.; Berglund, S.; Reinhart, C.; Kostka, A.; George, E.P. Phase stability and kinetics of σ-phase precipitation in CrMnFeCoNi high-entropy alloys. Acta Mater. 2018, 161, 338–351. [Google Scholar] [CrossRef]

- Fu, Z.; Chen, W.; Wen, H.; Zhang, D.; Chen, Z.; Zheng, B.; Zhou, Y.; Lavernia, E. Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater. 2016, 107, 59–71. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Zhang, Y.; Wang, Y.L.; Chen, G.L. Solid solution alloys of AlCoCrFeNiTix with excellent room-temperature mechanical properties. Appl. Phys. Lett. 2007, 90, 253–256. [Google Scholar] [CrossRef]

- Shon, Y.; Joshi, S.S.; Katakam, S.; Rajamure, R.S.; Dahotre, N.B. Laser additive synthesis of high entropy alloy coating on aluminum: Corrosion behavior. Mater. Lett. 2015, 142, 122–125. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Miracle, D.B.; Woodward, C.F. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. J. Alloys Compd. 2011, 509, 6043–6048. [Google Scholar] [CrossRef]

- Yong, D.; Lu, Y.; Li, J.; Wang, T.; Li, T. Effects of electro-negativity on the stability of topologically close-packed phase in high entropy alloys. Intermetallics 2014, 52, 105–109. [Google Scholar]

- Gwalani, B.; Soni, V.; Choudhuri, D.; Lee, M.; Hwang, J.Y.; Nam, S.J.; Ryu, H.; Hong, S.H.; Banerjee, R. Stability of ordered L12 and B2 precipitates in face centered cubic based high entropy alloys—Al0.3CoFeCrNi and Al0.3CuFeCrNi2. Scripta Mater. 2016, 123, 130–134. [Google Scholar] [CrossRef]

- Liu, S.; Cao, P.; Lin, D.; Tian, F. Stability of L21 (NiM)2TiAl (M = Co, Fe) in high-entropy alloys. J. Alloys Compd. 2018, 764, 650–655. [Google Scholar] [CrossRef]

- Choudhuri, D.; Alam, T.; Borkar, T.; Gwalani, B.; Mantri, A.S.; Srinivasan, S.G.; Gibson, M.A.; Banerjee, R. Formation of a Huesler-like L2 1 phase in a CoCrCuFeNiAlTi high-entropy alloy. Scripta Mater. 2015, 100, 36–39. [Google Scholar] [CrossRef]

- Vitos, L. Total-energy method based on the exact muffin-tin orbitals theory. Phys. Rev. B Condens. Matter 2001, 64, 167–173. [Google Scholar] [CrossRef]

- Vitos, L.; Skriver, H.L.; Johansson, B.; Kollár, J. Application of the exact muffin-tin orbitals theory: The spherical cell approximation. Comput. Mater Sci. 2012, 18, 24–38. [Google Scholar] [CrossRef] [Green Version]

- Vitos, L.; Abrikosov, I.A.; Johansson, B. Anisotropic lattice distortions in random alloys from first-principles theory. Phys. Rev. Lett. 2001, 87, 156401. [Google Scholar] [CrossRef]

- Otero-De-La-Roza, A.; Abbasi-Pérez, D.; Luaña, V. GIBBS2: A new version of the quasiharmonic model code. II. Models for solid-state thermodynamics, features and implementation. Comput. Phys. Commun. 2011, 182, 2232–2248. [Google Scholar] [CrossRef]

- Tian, F.; Delczeg, L.; Chen, N.; Varga, L.K.; Shen, J.; Vitos, J. Structural stability of NiCoFeCrAlx high-entropy alloy from ab initio theory. Phys. Rev. B 2013, 88, 1336–1340. [Google Scholar] [CrossRef]

- Tian, F.; Varga, L.K.; Chen, N.; Shen, J.; Vitos, L. Ab initio design of elastically isotropic TiZrNbMoVx high-entropy alloys. J. Alloys Compd. 2014, 599, 19–25. [Google Scholar] [CrossRef]

- Cao, P.; Ni, X.; Tian, F.; Varga, L.K.; Vitos, L. Ab initio study of Al x MoNbTiV high-entropy alloys. J. Phys. Condens. Matter 2015, 27, 075401. [Google Scholar] [CrossRef]

- Vitos, L. Computational Quantum Mechanics for Materials Engineers; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Perdew, P.J.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [Green Version]

- Korzhavyi, P.A.; Ruban, A.V.; Abrikosov, I.A.; Skriver, H.L. Madelung energy for random metallic alloys in the coherent potential approximation. Phys. Rev. B 1995, 51, 5773–5776. [Google Scholar] [CrossRef] [Green Version]

- Staunton, J.; Gyorffy, B.L.; Pindor, A.J.; Stocks, G.M.; Winter, H. The “disordered local moment” picture of itinerant magnetism at finite temperatures. J. Magn. Magn. Mater. 1984, 45, 15–22. [Google Scholar] [CrossRef]

- Li, X.; Schönecker, S.; Zhao, J.; Johansson, B.; Vitos, L. Elastic properties of Fe–Mn random alloys studied by ab initio calculations. J. Alloys Compd. 2007, 91, 3124–3161. [Google Scholar]

- Tian, F.; Varga, L.K.; Chen, N.; Delczeg, L.; Vitos, L. Ab initio investigation of high-entropy alloys of 3d elements. Phys. Rev. B 2013, 87, 178–187. [Google Scholar] [CrossRef]

- Birch, F. Finite Strain Isotherm and Velocities for Single Crystal and Polycrystalline NaCl at High Pressure and 300 K. J. Geophys. Res. 1978, 83, 1257–1268. [Google Scholar] [CrossRef]

- Mattesini, M.; Ahuja, R.; Johansson, B. Cubic Hf3N4 and Zr3N4: A class of hard materials. Phys. Rev. B 2003, 68, 184108. [Google Scholar] [CrossRef]

- Hill, R. The Elastic Behaviour of a Crystalline Aggregate. Proc. Phys. Soc. 1952, 65, 349–354. [Google Scholar] [CrossRef]

- Huang, B.; Duan, Y.H.; Sun, Y.; Peng, M.J.; Chen, S. Electronic structures, mechanical and thermodynamic properties of cubic alkaline-earth hexaborides from first principles calculations. J. Alloys Compd. 2015, 635, 213–224. [Google Scholar] [CrossRef]

- Chouhan, S.S.; Pagare, G.; Rajagopalan, M.; Sanyal, S.P. First principles study of structural, electronic, elastic and thermal properties of YX (X = Cd, In, Au, Hg and Tl) intermetallics. Solid State Sci. 2012, 14, 1004–1011. [Google Scholar] [CrossRef]

- Ivanovskii, A.L. Mechanical and electronic properties of diborides of transition 3d–5d metals from first principles: Toward search of novel ultra-incompressible and superhard materials. Prog. Mater. Sci. 2012, 57, 184–228. [Google Scholar] [CrossRef]

- Teter, D.M. Computational Alchemy: The Search for New Superhard Materials. MRS Bull. 1998, 23, 22–27. [Google Scholar] [CrossRef]

- Wei, Z.; Bao, D.L.; Ping, L.; Duan, Y. Elastic Anisotropies and Thermal Properties of Cubic TMIr (TM = Sc, Y, Lu, Ti, Zr and Hf): A DFT Calculation. Mater. Res. Express 2019, 6, 086574. [Google Scholar]

- Pugh, S.F. XCII. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. Philos. Mag. 2009, 45, 823–843. [Google Scholar] [CrossRef]

- Lu, Z.W.; Zhou, D.W.; Bai, J.P.; Lu, C.; Zhong, Z.G.; Li, G.Q. Theoretical investigation on structural and thermodynamic properties of the intermetallic compound in Mg–Zn–Ag alloy under high pressure and high temperature. J. Alloys Compd. 2013, 550, 406–411. [Google Scholar] [CrossRef]

- Iota, V.; Klepeis, J.H.P.; Yoo, C.S.; Lang, J.; Srajer, G. Electronic structure and magnetism in compressed 3d transition metals. Appl. Phys. Lett. 2007, 90, 1560. [Google Scholar] [CrossRef]

- Tracy, C.L.; Park, S.; Rittman, D.R.; Zinkle, S.J.; Bei, H.; Lang, M.; Ewing, R.C.; Mao, W.L. High pressure synthesis of a hexagonal close-packed phase of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2017, 8, 15634. [Google Scholar] [CrossRef] [Green Version]

| C11 | C12 | C44 | B | G | E | v | G/B | C12−C44 | |

|---|---|---|---|---|---|---|---|---|---|

| PM | 213.7 | 166.4 | 118.3 | 182.2 | 80.5 | 210.4 | 0.308 | 0.44 | 48.1 |

| FM | 187.8 | 141.5 | 118.9 | 156.9 | 85.6 | 206.4 | 0.281 | 0.55 | 22.6 |

| AFM | 193.9 | 148.1 | 128.0 | 163.4 | 86.0 | 219.4 | 0.276 | 0.52 | 20.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Wang, Z.-P.; Huang, G.-H.; Huang, J.-L.; Tang, P.-Y.; Fan, T.-W. Magnetic Phase Transition, Elastic and Thermodynamic Properties of L12-(Ni,Cu)3(Al,Fe,Cr) in 3d High-Entropy Alloys. Crystals 2020, 10, 1102. https://doi.org/10.3390/cryst10121102

Ma L, Wang Z-P, Huang G-H, Huang J-L, Tang P-Y, Fan T-W. Magnetic Phase Transition, Elastic and Thermodynamic Properties of L12-(Ni,Cu)3(Al,Fe,Cr) in 3d High-Entropy Alloys. Crystals. 2020; 10(12):1102. https://doi.org/10.3390/cryst10121102

Chicago/Turabian StyleMa, Li, Zhi-Peng Wang, Guo-Hua Huang, Jin-Li Huang, Ping-Ying Tang, and Tou-Wen Fan. 2020. "Magnetic Phase Transition, Elastic and Thermodynamic Properties of L12-(Ni,Cu)3(Al,Fe,Cr) in 3d High-Entropy Alloys" Crystals 10, no. 12: 1102. https://doi.org/10.3390/cryst10121102