Fabrication of In(P)As Quantum Dots by Interdiffusion of P and As on InP(311)B Substrate

Abstract

1. Introduction

2. Experiments

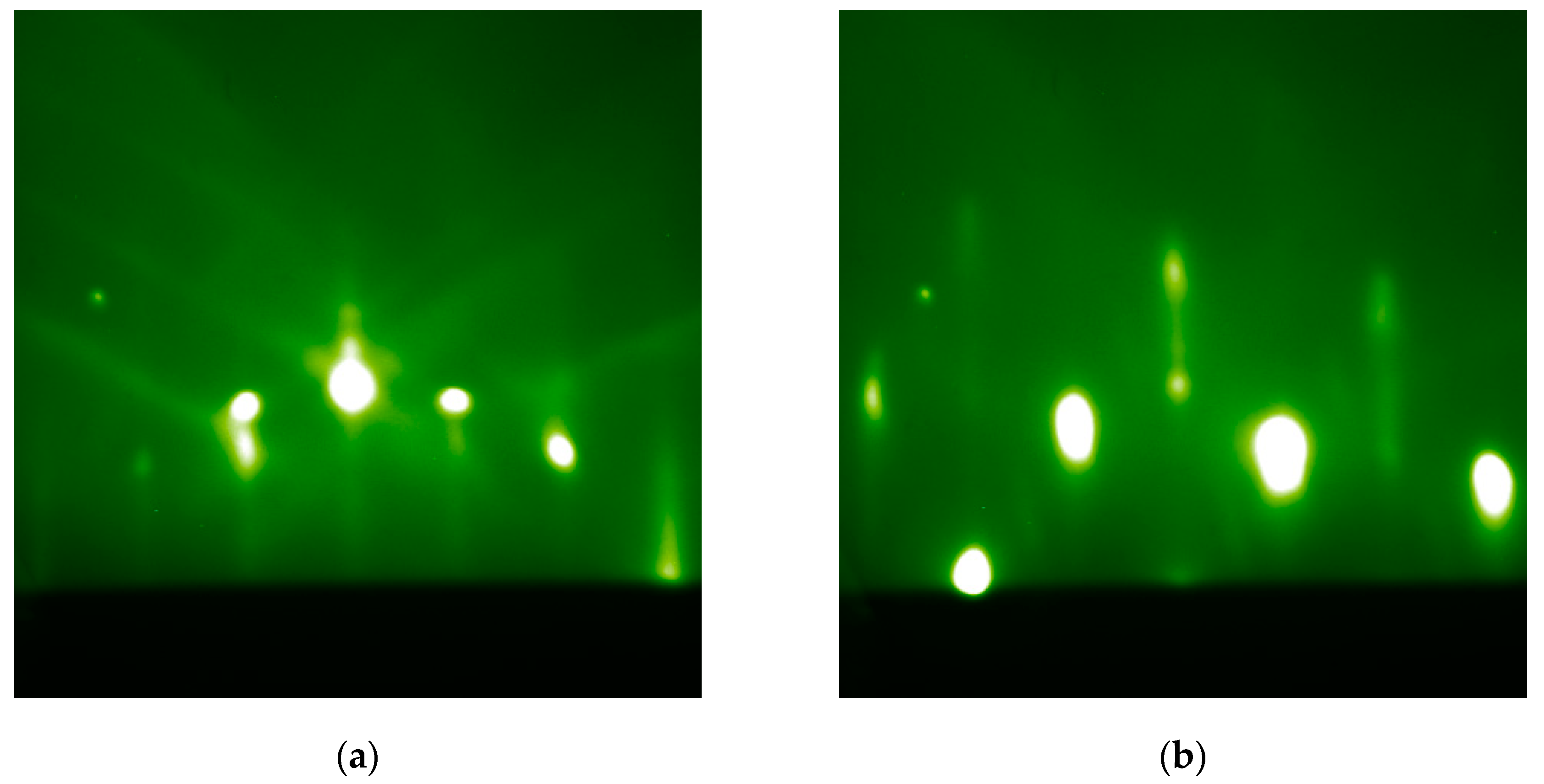

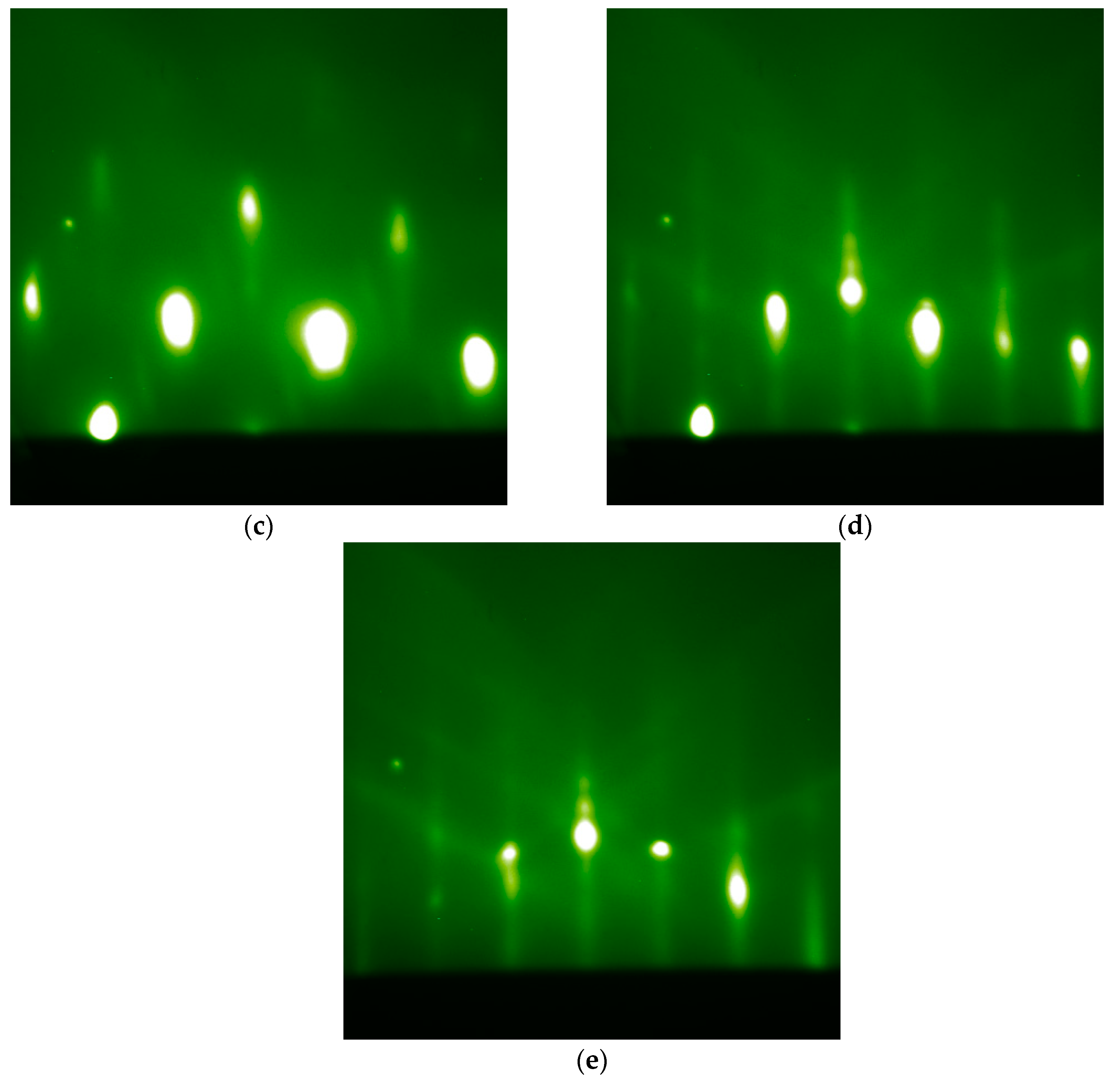

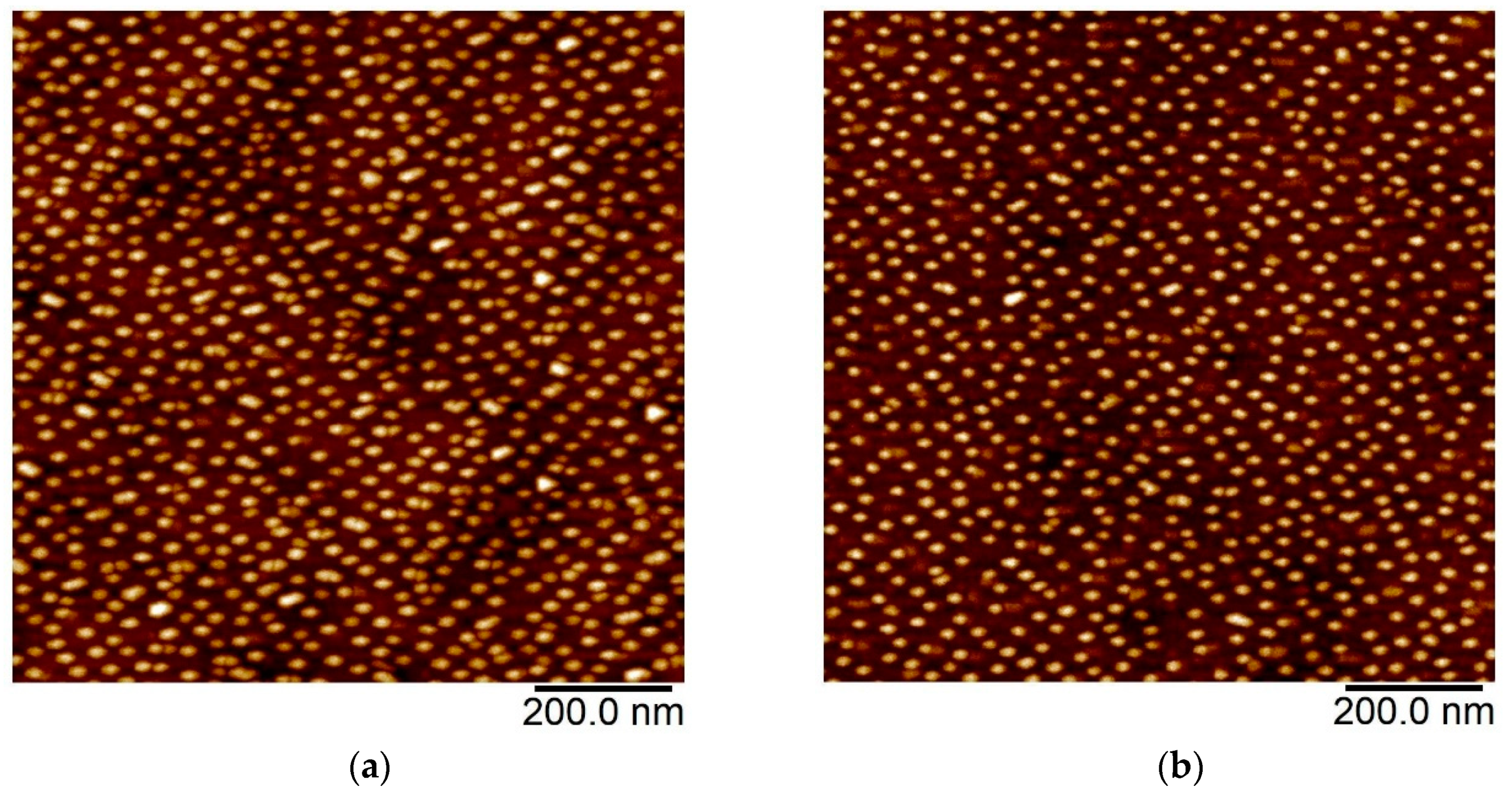

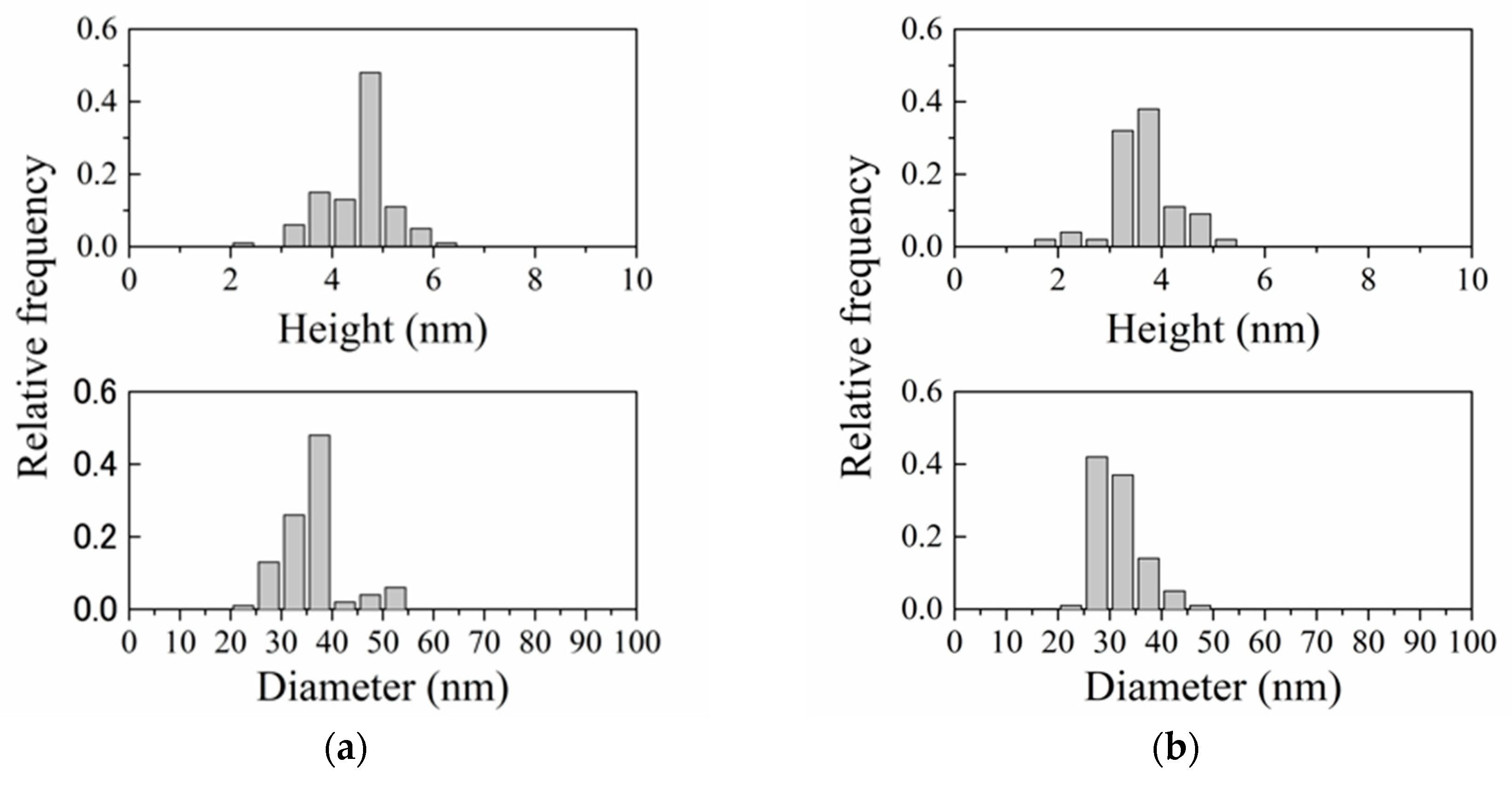

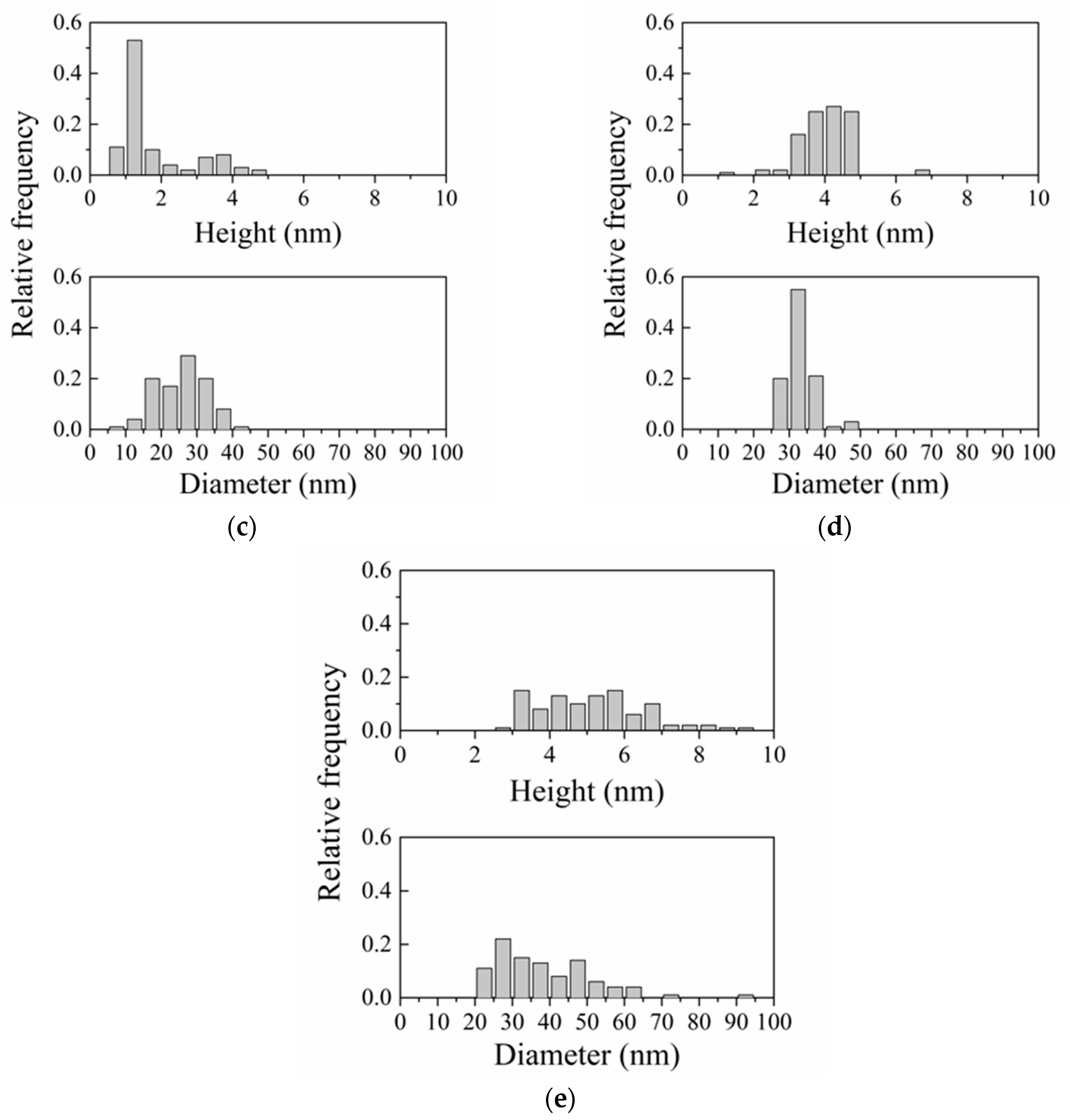

3. Results and Discussion

4. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arakawa, Y.; Sakaki, H. Multidimensional quantum well laser and temperature dependence of its threshold current. Appl. Phys. Lett. 1982, 40, 939–941. [Google Scholar] [CrossRef]

- Shoji, H.; Mukai, K.; Ohtsuka, N.; Sugawara, M.; Uchida, T.; Ishikawa, H. Lasing at three-dimensionally quantum-confined sublevel of self-organized In/sub 0.5/Ga/sub 0.5/As quantum dots by current injection. IEEE Photon. Technol. Lett. 1995, 7, 1385–1387. [Google Scholar] [CrossRef]

- Akiyama, T.; Kuwatsuka, H.; Simoyama, T.; Nakata, Y.; Mukai, K.; Sugawara, M.; Wada, O.; Ishikawa, H. Nonlinear gain dynamics in quantum-dot optical amplifiers and its application to optical communication devices. IEEE J. Quantum Electron. 2001, 37, 1059–1065. [Google Scholar] [CrossRef]

- Sugawara, M.; Hatori, N.; Ishida, M.; Ebe, H.; Arakawa, Y.; Akiyama, T.; Otsubo, K.; Yamamoto, T.; Nakata, Y. Recent progress in self-assembled quantum-dot optical devices for optical telecommunication: Temperature-insensitive 10 Gb s−1 directly modulated lasers and 40 Gb s−1 signal-regenerative amplifiers. J. Phys. D 2005, 38, 2126–2134. [Google Scholar] [CrossRef]

- Huber, D.; Reindl, M.; Aberl, J.; Rastelli, A.; Trotta, R. Semiconductor quantum dots as an ideal source of polarization-entangled photon pairs on-demand: A review. J. Opt. 2018, 20, 073002. [Google Scholar] [CrossRef]

- Goldstein, L.; Glas, F.; Marzin, J.Y.; Charasse, M.N.; le Roux, G. Growth by molecular beam epitaxy and characterization of InAs/GaAs strained-layer superlattices. Appl. Phys. Lett. 1985, 47, 1099–1101. [Google Scholar] [CrossRef]

- Shchukin, V.A.; Ledentsov, N.N.; Kop’ev, P.S.; Bimberg, D. Spontaneous ordering of arrays of coherent strained islands. Phys. Rev. Lett. 1995, 75, 2968–2971. [Google Scholar] [CrossRef]

- Solomon, G.S.; Trezza, J.A.; Harris, J.S. Substrate temperature and monolayer coverage effects on epitaxial ordering of InAs and InGaAs islands on GaAs. Appl. Phys. Lett. 1995, 66, 991–993. [Google Scholar] [CrossRef]

- Lei, W.; Tan, H.H.; Jagadish, C. Formation and shape control of InAsSb/InP (001) nanostructures. Appl. Phys. Lett. 2009, 95, 013108. [Google Scholar] [CrossRef]

- Lei, W.; Tan, H.H.; Jagadish, C. Effect of matrix material on the morphology and optical properties of InP-based InAsSb nanostructures. Appl. Phys. Lett. 2009, 95, 143124. [Google Scholar] [CrossRef]

- Lei, W.; Chen, Y.H.; Wang, Y.L.; Huang, X.Q.; Zhao, C.; Liu, J.Q.; Xu, B.; Jin, P.; Zeng, Y.P.; Wang, Z.G. Optical properties of self-assembled InAs/InAlAs/InP quantum wires with different InAs deposited thickness. J. Cryst. Growth 2006, 286, 23–27. [Google Scholar] [CrossRef]

- Koguchi, N.; Takahashi, S.; Chikyow, T. New MBE growth method for InSb quantum-well boxes. J. Cryst. Growth 1991, 111, 688–692. [Google Scholar] [CrossRef]

- Mano, T.; Mitsuishi, K.; Nakayama, Y.; Noda, T.; Sakoda, K. Structural properties of GaAs nanostructures formed by a supply of intense As4 flux in droplet epitaxy. Appl. Surf. Sci. 2008, 254, 7770–7773. [Google Scholar] [CrossRef]

- Kawamura, T.; Akahane, K.; Okada, Y.; Kawabe, M. Growth Mechanism of Surface Dots Self-Assembled on InP(311)B Substrate. J. Appl. Phys. 1999, 38, L720–L723. [Google Scholar] [CrossRef]

- Nötzel, R.; Temmyo, J.; Tamamura, T. Self-organized growth of strained InGaAs quantum disks. Nature 1994, 369, 131–133. [Google Scholar] [CrossRef]

- Temmyo, J.; Nötzel, R.; Tamamura, T. Semiconductor nanostructures formed by the Turing instability. Appl. Phys. Lett. 1997, 71, 1086–1088. [Google Scholar] [CrossRef]

- Davies, G.J.; Heckingbottom, R.; Ohno, H.; Wood, C.E.C.; Calawa, A.R. Arsenic stabilization of InP substrates for growth of GaxIn1−xAs layers by molecular beam epitaxy. Appl. Phys. Lett. 1980, 37, 290–292. [Google Scholar] [CrossRef]

- Moison, J.M.; Bensoussan, M.; Houzay, F. Epitaxial regrowth of an InAs surface on InP: An example of artificial surfaces. Phys. Rev. B 1986, 34, 2018. [Google Scholar] [CrossRef]

- Akahane, K.; Ohtani, N.; Okada, Y.; Kawabe, M. Fabrication of ultra-high density InAs-stacked quantum dots by strain-controlled growth on InP (3 1 1) B substrate. J. Cryst. Growth 2002, 245, 31–36. [Google Scholar] [CrossRef]

- Akahane, K.; Yamamoto, N.; Kawanishi, T. Fabrication of ultra-high-density InAs quantum dots using the strain-compensation technique. Phys. Status Solidi A 2011, 208, 425–428. [Google Scholar] [CrossRef]

- Akahane, K.; Yamamoto, N. Fabrication of low-density self-assembled InAs quantum dots on InP (311) B substrate by molecular beam epitaxy. J. Cryst. Growth 2013, 378, 450–453. [Google Scholar] [CrossRef]

- Kaizu, T.; Yamaguchi, K. Self size-limiting process of InAs quantum dots grown by molecular beam epitaxy. Jpn. J. Appl. Phys. 2001, 40, 1885. [Google Scholar] [CrossRef]

- Kaizu, T.; Yamaguchi, K. Facet formation of uniform InAs quantum dots by molecular beam epitaxy. Jpn. J. Appl. Phys. 2003, 42, 4166. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Lu, Z.D.; Yang, X.P.; Yuan, Z.L.; Zheng, B.Z.; Xu, J.Z. Carrier relaxation and thermal activation of localized excitons in self-organized InAs multilayers grown on GaAs substrates. Phys. Rev. B 1996, 54, 11528. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akahane, K.; Matsumoto, A.; Umezawa, T.; Yamamoto, N. Fabrication of In(P)As Quantum Dots by Interdiffusion of P and As on InP(311)B Substrate. Crystals 2020, 10, 90. https://doi.org/10.3390/cryst10020090

Akahane K, Matsumoto A, Umezawa T, Yamamoto N. Fabrication of In(P)As Quantum Dots by Interdiffusion of P and As on InP(311)B Substrate. Crystals. 2020; 10(2):90. https://doi.org/10.3390/cryst10020090

Chicago/Turabian StyleAkahane, Kouichi, Atsushi Matsumoto, Toshimasa Umezawa, and Naokatsu Yamamoto. 2020. "Fabrication of In(P)As Quantum Dots by Interdiffusion of P and As on InP(311)B Substrate" Crystals 10, no. 2: 90. https://doi.org/10.3390/cryst10020090

APA StyleAkahane, K., Matsumoto, A., Umezawa, T., & Yamamoto, N. (2020). Fabrication of In(P)As Quantum Dots by Interdiffusion of P and As on InP(311)B Substrate. Crystals, 10(2), 90. https://doi.org/10.3390/cryst10020090