The Effect of Thermocycling and Surface Treatments on the Surface Roughness and Microhardness of Three Heat-Pressed Ceramics Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimens Preparation

2.2. Surface Roughness Measurements

2.3. Artificial Aging of the Samples Using Thermocycling

2.4. Scanning Electron Microscopy (SEM)

2.5. Atomic Force Microscopy (AFM) Nano Surface Characterization

2.6. Microhardness Testing (VH)

2.7. Methods of Statistical Analysis

3. Results

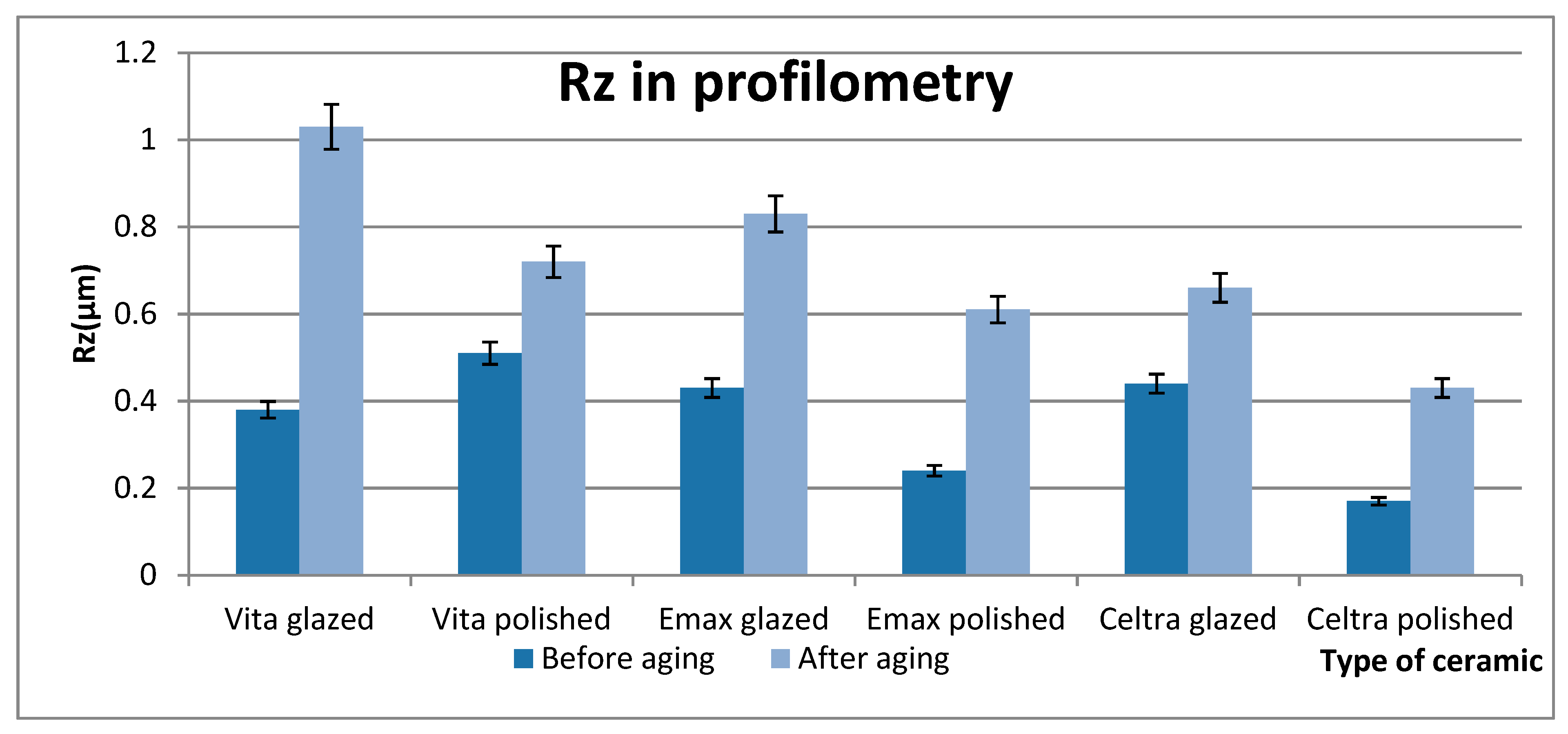

3.1. Micro Surface Roughness in Profilometry

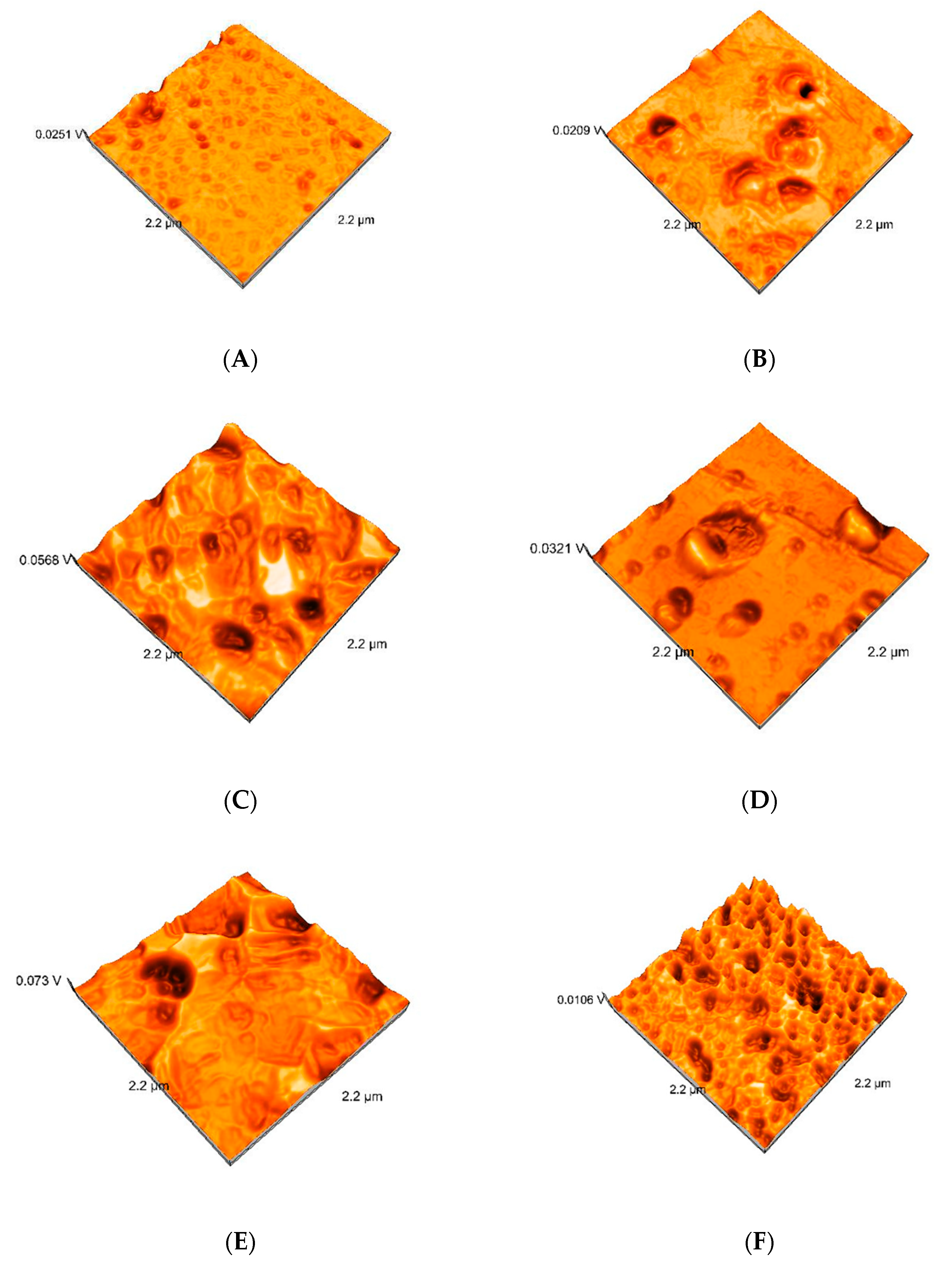

3.2. Test Carried Out by Atomic Force Microscope

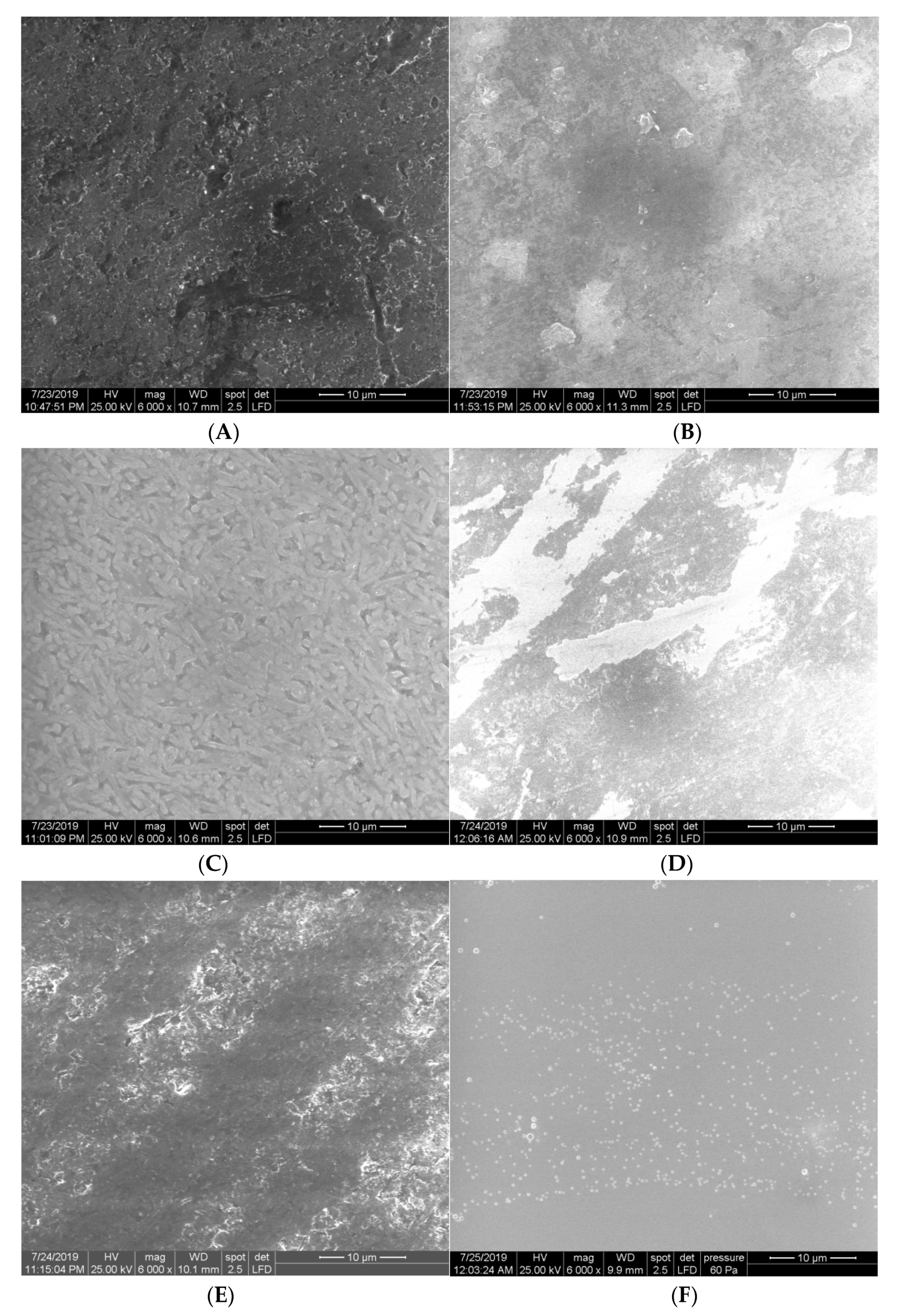

3.3. Analysis with Scanning Electron Microscopy

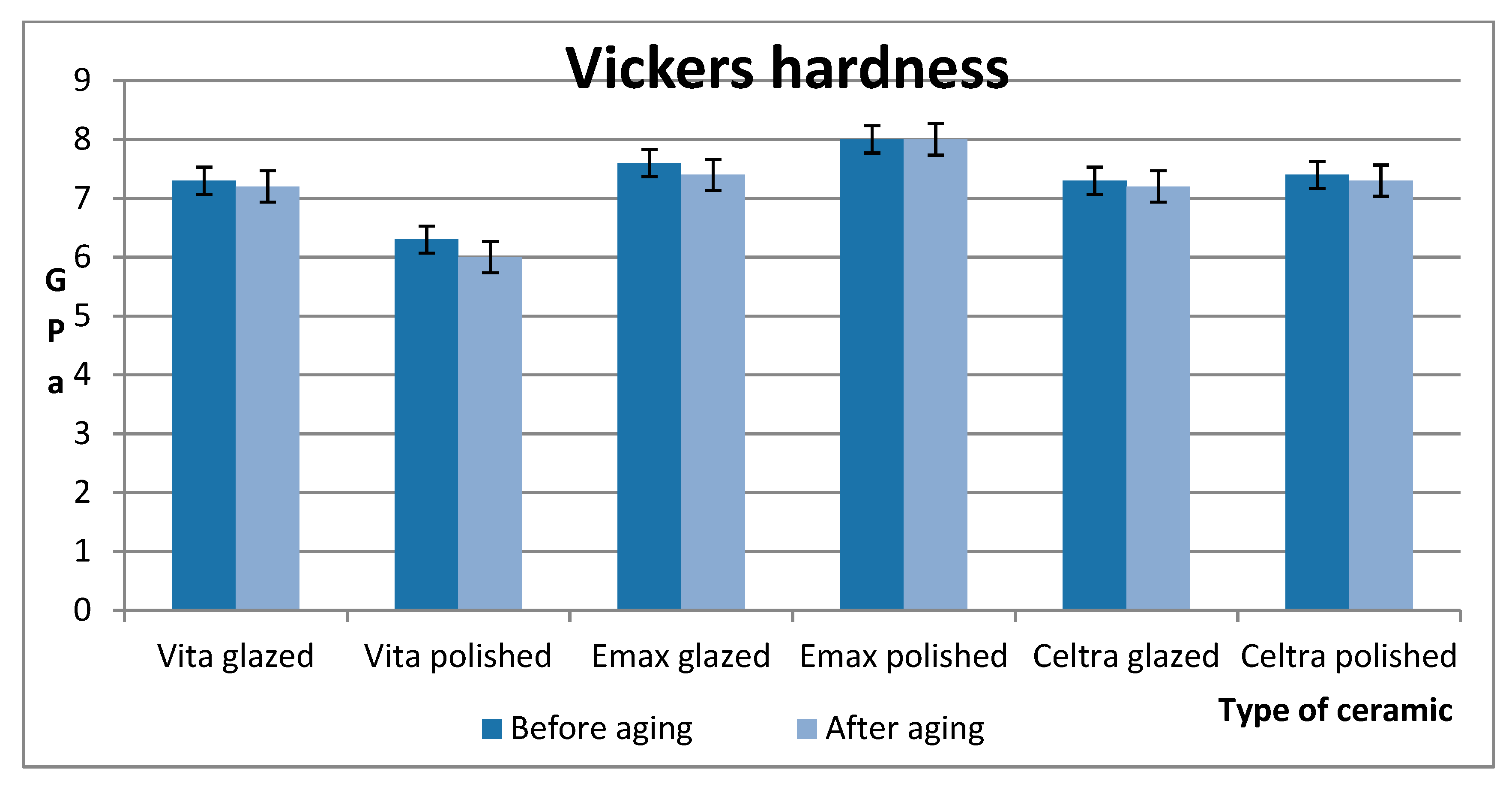

3.4. Microhardness Testing

3.5. Statistical Analysis

4. Discussion

5. Within the Limitations of This Study, Some Conclusions Can Be Drawn:

- The tested ceramic systems behaved differently to the aging and surface treatments.

- Surface treatments had a significant impact on the microhardness and surface characteristics. The glazed groups were reported with higher surface roughness and lower microhardness when compared to the polished groups before and after thermocycling.

- The measuring roughness techniques determine the scale-dependent values for the Ra(Sa) and Rz(Sq) parameters.

- Thermocycling almost doubled the surface roughness for all the tested samples. Microhardness decreased only for the Celtra glazed samples.

- Nano-roughness increased the values for Vita and slightly for Emax. Thermocycling had little effect on Emax ceramic but a more significant impact on Celtra Press ceramic.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rashid, H. The effect of surface roughness on ceramics used in dentistry: A review of the literature. Eur. J. Dent. 2014, 8, 571–579. [Google Scholar] [CrossRef]

- Moffa, J.P. Porcelain materials. Adv. Dent. Res. 1988, 2, 3–6, 8–11. [Google Scholar] [CrossRef] [PubMed]

- Al-Shammery, H.A.; Bubb, N.L.; Youngson, C.C.; Fasbinder, D.J.; Wood, D.J. The use of confocal microscopy to assess surface roughness of two milled CAD-CAM ceramics following two polishing techniques. Dent. Mater. 2007, 23, 736–741. [Google Scholar] [PubMed]

- Quirynen, M.; Bollen, C.M. The influence of surface roughness and surface-free energy on supra-and subgingival plaque formation in man. A review of the literature. J. Clin. Periodontol. 1995, 22, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Quirynen, M.; Marechal, M.; Busscher, H.J.; Weerkamp, A.H.; Darius, P.L.; van Steenberghe, D. The influence of surface free energy and surface roughness on early plaque formation. An in vivo study in man. J. Clin. Periodontol. 1990, 17, 138–144. [Google Scholar] [CrossRef] [PubMed]

- Madhuri, A.S.; Ashu, B.; Zeba, J.; Nishat, S.; Anika, D. Tooth Polishing: The Current Status. J. Indian Soc. Periodontol. 2015, 19, 375–380. [Google Scholar]

- Al-Wahadni, A.; Martin, D.M. Glazing and Finishing Dental Porcelain: A Literature Review. J.-Can. Dent. Assoc. 1998, 64, 580–583. Available online: http://www.cda-adc.ca/jcda/vol-64/issue-8/580.html (accessed on 29 February 2020).

- McLean, J.W. The Science and Art of Dental Ceramics; Quintessence Publishing: Berlin, Germany, 1979; ISBN 978-0-93138-604-6. [Google Scholar]

- Wiley, M.G. Effects of porcelain on occluding surface of restored teeth. J. Prosthet. Dent. 1989, 61, 133–137. [Google Scholar] [CrossRef]

- Patterson, C.J.; McLundie, A.C.; Stirrups, D.R.; Taylor, W.G. Refinishing of porcelain by using a refinishing kit. J. Prosthet. Dent. 1991, 65, 383–388. [Google Scholar] [CrossRef]

- Patterson, C.J.; McLundie, A.C.; Stirrups, D.R.; Taylor, W.G. Efficacy of a porcelain refinishing system in restoring surface finish after grinding with fine and extra-fine diamond burs. J. Prosthet. Dent. 1992, 68, 402–406. [Google Scholar] [CrossRef]

- Brewer, J.D.; Garlapo, D.A.; Chipps, E.A.; Tedesco, L.A. Clinical discrimination between auto glazed and polished porcelain surfaces. J. Prosthet. Dent. 1990, 64, 631–634. [Google Scholar] [CrossRef]

- Porojan, L.; Savencu, C.; Porojan, S. Application of heat-pressed ceramics for single-tooth restorations. Rev. Chim. 2016, 1, 123–126. [Google Scholar]

- Vasiliu, R.D.; Porojan, S.; Porojan, L. The influence of oral environment on the optical properties of heat-pressed ceramics. Mater. Plast. 2019, 56, 271–276. [Google Scholar] [CrossRef]

- Dallas, M.; Sipahi, C.; Beydemir, B. Effects of six surface treatment methods on the surface roughness of a low-fusing and an ultra low-fusing feldspathic ceramic material. J. Prosthodont. 2009, 18, 217–222. [Google Scholar]

- Bazant, Z. Mechanics of distributed cracking. Appl. Mech. Rev. 1986, 39, 675–705. [Google Scholar] [CrossRef]

- Irwin, G. Analysis of stresses and strains near the end of a crack transversing a plate. J. Appl. Mech. 1957, 24, 361–364. [Google Scholar]

- Porojan, L.; Topală, F. Failure analysis of various monolithic posterior aesthetic dental crowns using the finite element method. J. Phys. Conf. Ser. 2017, 885, 012003. [Google Scholar] [CrossRef]

- Kukiattrakoon, B.; Junpoom, P. Vicker’s microhardness and energy dispersive X-ray analysis of fluoride leucite fluorapatite ceramics clinically immersed in acid agents. J. Oral Sci. 2009, 51, 443–450. [Google Scholar] [CrossRef] [Green Version]

- Vasiliu, R.D.; Uţu, I.D.; Porojan, L. Evaluation of different pH solutions on the mechanical behavior of two hot pressed dental ceramics. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012012. [Google Scholar] [CrossRef]

- Porojan, L.; Porojan, S.; Rusu, L.; Boloş, A.; Savencu, C. Experimental analyses for the mechanical behavior of pressed all-ceramic molar crowns with anatomical design. MATEC Web Conf. 2017, 108, 02001. [Google Scholar] [CrossRef] [Green Version]

- Ritter, R.G. Multifunctional uses of a novel ceramic-lithium disilicate. J. Esthet. Restor. Dent. 2010, 22, 332–341. [Google Scholar] [CrossRef]

- Pieger, S.; Salman, A.; Bidra, A.S. Clinical outcomes of lithium disilicate single crowns and partial fixed dental prostheses: A systematic review. J. Prosthet. Dent. 2014, 112, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Borges, G.A.; Caldas, D.; Taskonak, B.; Yan, J.; CorrerSobrinho, L.; Oliveira, W.J. Fracture loads of all-ceramic crowns under wet and dry fatigue conditions. J. Prosthodont. 2009, 18, 649–655. [Google Scholar] [CrossRef] [PubMed]

- Celik Koycy, B.; Imirzaliouglu, P. Heat transfer and thermal stress analysis of a mandibular molar restored by different indirect restorations using a three-dimensional finite element method. J. Prosthodont. 2015, 26, 460–473. [Google Scholar] [CrossRef]

- Hamza, T.A.; Alameldin, A.A.; Elkouedi, A.Y.; Wee, A.G. Effect of artificial accelerated aging on surface roughness and color stability of different ceramic restorations. Stomatol. Dis. Sci. 2017, 1, 8–13. [Google Scholar] [CrossRef] [Green Version]

- Dos Santos, P.H.; Catalan, A.; Albuquerque Guedes, A.P.; Umeda Suzuki, T.Y.; de Lima Godas, A.G.; Fraga Briso, A.L.; Bedran-Russo, A.K. Effect of thermocycling on the roughness of nanofilm, microfilm, and micro-hybrid composites. Acta Odontol. Scand. 2015, 73, 176–181. [Google Scholar] [CrossRef]

- Vasiliu, R.D.; Porojan, S.D.; Birdeanu, M.I.; Porojan, L. Effect of thermocycling, surface treatments and microstructure on the optical properties and roughness of CAD-CAM and heat-pressed glass-ceramics. Materials 2020, 13, 381. [Google Scholar] [CrossRef] [Green Version]

- Moressi, A.L.; D’Amario, M.; Capogreco, M.; Gatto, R.; Marzo, G. Thermal cycling for restorative materials does a standardised protocol exist in laboratory testing? A literature review. J. Mech. Behav. Biomed. Mater. 2014, 29, 295–308. [Google Scholar] [CrossRef]

- Palmer, D.S.; Barco, M.T.; Billy, E.J. Temperature extremes produced orally by hot and cold liquids. J. Prosthet. Dent. 1992, 67, 325–327. [Google Scholar] [CrossRef]

- Moressi, A.L.; D’Amario, M.; Monaco, A. Effect of critical thermal cycling on the flexural strength of resin composites. J. Oral Sci. 2015, 57, 137–143. [Google Scholar] [CrossRef] [Green Version]

- Gale, M.S.; Darvell, B.W. Thermal cycling procedures for laboratory testing of dental restorations. J. Dent. 1999, 66, 1336–1339. [Google Scholar] [CrossRef]

- Caleb, B.; Hailee, R.; Abdallah, A. Mechanical properties of resin-ceramic CAD-CAM materials after accelerated aging. J. Prosthet. Dent. 2018, 119, 954–958. [Google Scholar]

- Sasipin, L.; Hidekazu, T.; Maho, S.; Naohiko, I. Mechanical properties of composite resin blocks for CAD/CAM. Dent. Mater. J. 2014, 33, 705–710. [Google Scholar]

- Kamolporn, W.; Viritpon, S.; Kanchana, N.M.; Pasutha, T. Improving shear bond strength between feldspathic porcelain and zirconia substructure with lithium disilicate glass-ceramic liner. Dent. Mater. J. 2015, 34, 302–309. [Google Scholar]

- Nesrin, S.; Pinar, G.; Volkan, T.; Gokhan, A.; Deniz, S. Evaluation of five CAD/CAM materials by microstructural characterization and mechanical tests: A comparative in vitro study. BMC Oral Health 2018, 18, 5. [Google Scholar] [CrossRef] [Green Version]

- Gülce, M.S.; Gülce, A. Effects of different glaze treatments on the optical properties and roughness of lithium disilicate ceramics. Cumhur. Dental. J. 2019, 22, 48–55. [Google Scholar]

- Gürdal, I.; Atay, A.; Eichberger, M.; Cal, E.; Üsümez, A.; Stawarczyk, B. Color change of CAD-CAM materials and composite resin cements after thermocycling. J. Prosthet. Dent. 2018, 120, 546–552. [Google Scholar] [CrossRef]

- Luo, X.; Ren, D.; Nick, S. Effect of etching time and resin bond on theflexural strength of IPS e.max Press glass ceramic. Dent. Mater. 2014, 30, e330–e336. [Google Scholar]

- Abu-Izze, F.O.; Dal Piva, A.M.; Bottino, M.A.; Valandro, L.F.; Melo, R.M. The influence of ceramic re-pressing on surface properties, bond strength, and color stability of leucite ceramic. J. Adhes. Dent. 2018, 20, 389–395. [Google Scholar]

- Alp, G.; Subasi, M.G.; Johnston, W.M.; Yilmaz, B. Effect of surface treatments and coffee thermocycling on the color and translucency of CAD-CAM monolithic glass-ceramic. J. Prosthet. Dent. 2018. [Google Scholar] [CrossRef]

- Kelly, J.R.; Tesk, J.A.; Sorensen, J.A. Failure of all-ceramic fixed partial dentures in vitro and in vivo: Analysis and modeling. J. Dent. Res. 1995, 74, 1253–1258. [Google Scholar] [CrossRef]

- Oliveira-Junior, O.B.; Buso, L.; Fujiy, F.H.; Lombardo, G.H.; Campos, F.; Sarmento, H.R.; Souza, R.O. Influence of polishing procedures on the surface roughness of dental ceramics made by different techniques. Gen. Dent. 2013, 61, e4–e8. [Google Scholar] [PubMed]

- Valian, A.; Moravej-Salehi, E. Surface treatment of feldspathic porcelain: Scanning electron microscopy analysis. J. Adv. Prosthodont. 2014, 6, 387–394. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Donald, A.M. The use of environmental scanning electron microscopy for imaging wet and insulating materials. Nat. Mater. 2003, 2, 511–516. [Google Scholar] [CrossRef] [PubMed]

- Camacho, G.B.; Vinha, D.; Panzeri, H.; Nonaka, T.; Gonçalves, M. Surface roughness of a dental ceramic after polishing with different vehicles and diamond pastes. Braz. Dent. J. 2006, 17, 191–194. [Google Scholar] [CrossRef] [Green Version]

- Tholt, B.; Miranda-Júnior, W.G.; Prioli, R.; Thompson, J.; Oda, M. Surface roughness in ceramics with different finishing techniques using atomic force microscope and profilometry. Oper. Dent. 2006, 31, 442–449. [Google Scholar] [CrossRef] [Green Version]

- Sasahara, R.M.C.; Ribeiro, F.D.C.; Cesar, P.F.; Yoshimura, H.N. Influence of the finishing technique on surface roughness of dental porcelain with different microstructure. Oper. Dent. 2006, 31, 577–583. [Google Scholar] [CrossRef]

- Boaventura, J.M.; Nishida, R.; Elossais, A.A.; Lima, D.M.; Reis, J.M.; Campos, E.A.; de Andrade, M.F. Effect finishing and polishing procedures on the surface roughness of IPS Empress 2 ceramic. Acta Odontol. Scand. 2013, 71, 438–443. [Google Scholar] [CrossRef]

- Willems, G.; Lanbrechts, P.; Braem, M.; Vuylsteke Wauters, M.; Vanherlo, G. The surface roughness of enamel to enamel contact areas compred with the intrinsic roughness of dental resin composites. J. Dent. Res. 1991, 70, 1299–1305. [Google Scholar] [CrossRef]

- Jones, C.S.; Billington, R.W.; Pearson, G.I. The in vivo perception of roughnes of restorations. Br. Dent. J. 2004, 196, 42–45. [Google Scholar] [CrossRef] [Green Version]

- Amava Pojares, S.P.; Ritter, A.V. Effect of finishing and polishing on the surface roughness of four ceramic materials after occlusal adjustment. J. Esthet. Restor. Dent. 2016, 28, 382–396. [Google Scholar] [CrossRef]

- Sarac, D.; Sarac, Y.S.; Yuzbasioglu, E. The effect of porcelain polishing systems on the color and surface texture of feldspathic porcelain. J. Prosthet. Dent. 2006, 96, 122–128. [Google Scholar] [CrossRef] [PubMed]

- Ludovichetti, F.S.; Trindade, F.Z.; Werner, A.; Kleverlaan, C.J.; Fonseca, R.G. Wear resistance and abrasiveness of CAD-CAM solid materials. J. Prosthet. Dent. 2008, 120, 318.e1–318.e8. [Google Scholar]

- Druck, C.C.; Pozzobon, J.L.; Callegari, G.L.; Dorneles, L.S.; Valandro, L.F. Adhesion to Y-TZP ceramic: A study of silica nanofilm coating on the surface of Y-TZP. J. Biomed. Mater. Res. B Appl. Biomater. 2015, 103, 143–150. [Google Scholar] [CrossRef] [PubMed]

- Bollen, C.M.; Lambrechts, P.; Qurynen, M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature. Dent. Mater. J. 1887, 13, 258–269. [Google Scholar] [CrossRef]

- Sen, N.; Us, Y.O. Mechanical and optical properties of monolithic CAD-CAM restorative materials. J. Prosthet. Dent. 2018, 119, 593–599. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Liebermann, A.; Eichberger, M.; Güth, J.F. Evaluation of mechanical and optical behavior of current aesthetic dental restorative CAD/CAM composites. J. Mech. Behav. Biomed. Mater. 2015, 55, 1–11. [Google Scholar] [CrossRef]

- Vásquez, V.; Ozcan, M.; Nishioka, R.; Souza, R.; Mesquita, A.; Pavanelli, C. Mechanical and thermal cycling effects on the flexural strength of glass ceramics fused to titanium. Dent. Mater. J. 2008, 27, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Egilmez, F.; Ergun, G.; Cekic-Nagas, I.; Lassila, L.V.J. Does artificial aging affect the mechanical properties of CAD/CAM composite materials? J. Prosthodont. Res. 2018, 62, 65–74. [Google Scholar] [CrossRef]

- Mc, C.J.F.; Carrick, T.E. A statistical approach to the mechanical testing of dental materials. Dent. Mater. 1986, 2, 139–142. [Google Scholar]

- Wang, F.; Chai, Z.; Deng, Z.; Gao, J.; Wang, H.; Chen, J. Effect of heat- pressing temperature and holding time on the microstructure and flexural strength of lithium Disilicate glass-ceramics. PLoS ONE 2015, 10, e0130919. [Google Scholar]

- Bradt, R.C.; Evans, A.G.; Hasselman, D.P.H.; Lange, F.F. Surface flaws, statics, and microcracking. In Fracture Mechanics of Ceramics; Plenunm Press: New York, NY, USA, 1983; pp. 365–386. [Google Scholar]

- Paulo, F.C.; Humberto, N.Y.; Walter, G.; Miranda Júniora Cristina, Y.O. Correlation between fracture toughness and leucite content in dental porcelains. J. Dent. 2005, 33, 721–729. [Google Scholar]

- Carla, C.G.; Paulo, F.C.; Walter, G.M., Jr.; Humberto, N.Y. Slow crack growth and reliability of dental ceramics. Dent. Mater. 2011, 27, 394–406. [Google Scholar]

| Material | Composition | Manufacturer | Translucency/Shade |

|---|---|---|---|

| 1. Vita PM9 (Vita)(heat-pressed feldspathic glass-ceramic) | 50% of Leucite reinforced glass-ceramic (size 10–15 μm). | Vita Zahnfabrick, Bad Säckingen, Germany | HT/A2 |

| 2. IPS Emax Press (Emax) (heat-pressed lithium disilicate ceramic) | Lithium disilicate crystals (approx. 70%), Li2Si2O5 crystals measure 3 to 6 μm in length. | Ivoclar Vivadent, Ellwangen, Germany | HT/A2 |

| 3. Celtra Press (Celtra)(zirconia-reinforced lithium silicate glass-ceramic) | A glass matrix and lithium disilicate crystals 1.5 μm plus nanoscale lithium 10% zirconia (ZrO2) | Dentsply, Hanau, Germany | HT/A2 |

| Vita PM9 | Emax Press | Celtra Press | |

|---|---|---|---|

| Starting temperature | 700 °C | 700 °C | 700 °C |

| Hold time | 20 min | 29 min | 30 min |

| Vacuum level | 47 hPa | 47 hPa | 45 hPa |

| Press time | 10 min | 1 min | 3 min |

| Heat rate | 50 °C/min | 60 °C/min | 40 °C/min |

| Press temperature | 1000 °C | 915 °C | 860 °C |

| Press pressure | 3 bar | 3 bar | 3 bar |

| Type of Ceramic | Start Temperature | Closing Time | Heating Rate (°C/min) | Holding Time | Vacuum 1 | Vacuum 2 |

|---|---|---|---|---|---|---|

| Vita PM9 | 500 °C | 1 min | 50 °C/min | 4 min | OFF | OFF |

| IPS Emax Press | 403 °C | 6 min | 50 °C/min | 1 min | 450 °C | 709 °C |

| Celtra Press | 400 °C | 2 min | 55 °C/min | 2 min | OFF | OFF |

| Type of Ceramic | Type of Glaze |

|---|---|

| 1. Vita PM9 | Vita Akzent Plus Glaze LT (Vita Zahnfabrick, Bad Säckingen, Germany) |

| 2. IPS Emax Press | Emax Ceram (Ivoclar Vivadent, Ellwangen, Germany) |

| 3. Celtra Press | Dentsply Universal stain (Dentsply, Hanau, Germany) |

| Surface Treatment | Type of Ceramic | ||

|---|---|---|---|

| Vita | Emax | Celtra | |

| Polish | p < 0.05 | p < 0.001 | p < 0.001 |

| Glazing | p < 0.001 | p < 0.001 | p < 0.001 |

| Surface Treatment | Type of Ceramic | ||

|---|---|---|---|

| Vita | Emax | Celtra | |

| Polish | > 0.05 | < 0.01 | p < 0.01 |

| Glazing | < 0.0001 | p < 0.001 | p < 0.001 |

| Type of Ceramic | Before Aging | After Aging |

|---|---|---|

| Vita glazed | 0.80 ± 0.01 nm | 19.10 ± 0.01 nm |

| Vita polished | 1.00 ± 0.01 nm | 61.10 ± 0.02 nm |

| Emax glazed | 2.50 ± 0.02 nm | 4.80 ± 0.03 nm |

| Emax polished | 23.10 ± 0.03 nm | 33.00 ± 0.05 nm |

| Celtra glazed | 30.00 ± 0.01 nm | 1.10 ± 0.01 nm |

| Celtra polished | 48.00 ± 0.20 nm | 2.70 ± 0.01 nm |

| Type of Ceramic | Before Aging | After Aging |

|---|---|---|

| Vita glazed | 1.50 ± 0.02 nm | 26.10 ± 0.03 nm |

| Vita polished | 1.50 ± 0.01 nm | 76.20 ± 0.04 nm |

| Emax glazed | 4.30 ± 0.03 nm | 6.70 ± 0.02 nm |

| Emax polished | 29.01 ± 0.05 nm | 41.20 ± 0.01 nm |

| Celtra glazed | 35.10 ± 0.03 nm | 1.40 ± 0.02 nm |

| Celtra polished | 54.00 ± 0.06 nm | 3.40 ± 0.01 nm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasiliu, R.-D.; Porojan, S.-D.; Bîrdeanu, M.-I.; Uțu, I.-D.; Porojan, L. The Effect of Thermocycling and Surface Treatments on the Surface Roughness and Microhardness of Three Heat-Pressed Ceramics Systems. Crystals 2020, 10, 160. https://doi.org/10.3390/cryst10030160

Vasiliu R-D, Porojan S-D, Bîrdeanu M-I, Uțu I-D, Porojan L. The Effect of Thermocycling and Surface Treatments on the Surface Roughness and Microhardness of Three Heat-Pressed Ceramics Systems. Crystals. 2020; 10(3):160. https://doi.org/10.3390/cryst10030160

Chicago/Turabian StyleVasiliu, Roxana-Diana, Sorin-Daniel Porojan, Mihaela-Ionela Bîrdeanu, Ion-Dragoș Uțu, and Liliana Porojan. 2020. "The Effect of Thermocycling and Surface Treatments on the Surface Roughness and Microhardness of Three Heat-Pressed Ceramics Systems" Crystals 10, no. 3: 160. https://doi.org/10.3390/cryst10030160

APA StyleVasiliu, R.-D., Porojan, S.-D., Bîrdeanu, M.-I., Uțu, I.-D., & Porojan, L. (2020). The Effect of Thermocycling and Surface Treatments on the Surface Roughness and Microhardness of Three Heat-Pressed Ceramics Systems. Crystals, 10(3), 160. https://doi.org/10.3390/cryst10030160