Effect of Necklace-Type Distribution of SiC Particles on Dry Sliding Wear Behavior of As-Cast AZ91D/SiCp Composites

Abstract

1. Introduction

2. Experimental Details

2.1. Materials Preparation

2.2. Wear Testing

3. Results and Discussion

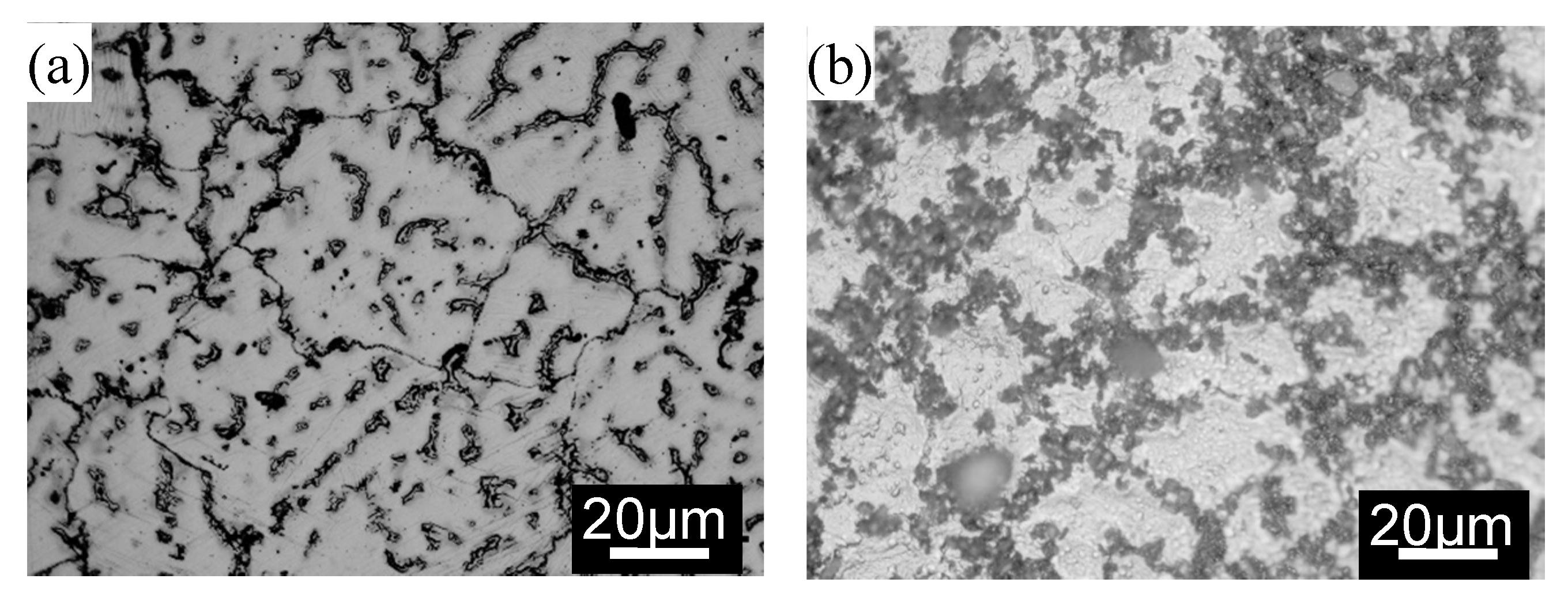

3.1. Microstructure and Mechanical Properties of the Composites

3.2. Effect of Applied Loads on Wear Behavior of the Composites

3.3. Effect of Particle Size on Wear Behavior of the Composites

3.4. Effect of Particle Volume Fraction on Wear Behavior of the Composites

3.5. Wear Mechanisms of the Composites with Necklace-Type Distribution

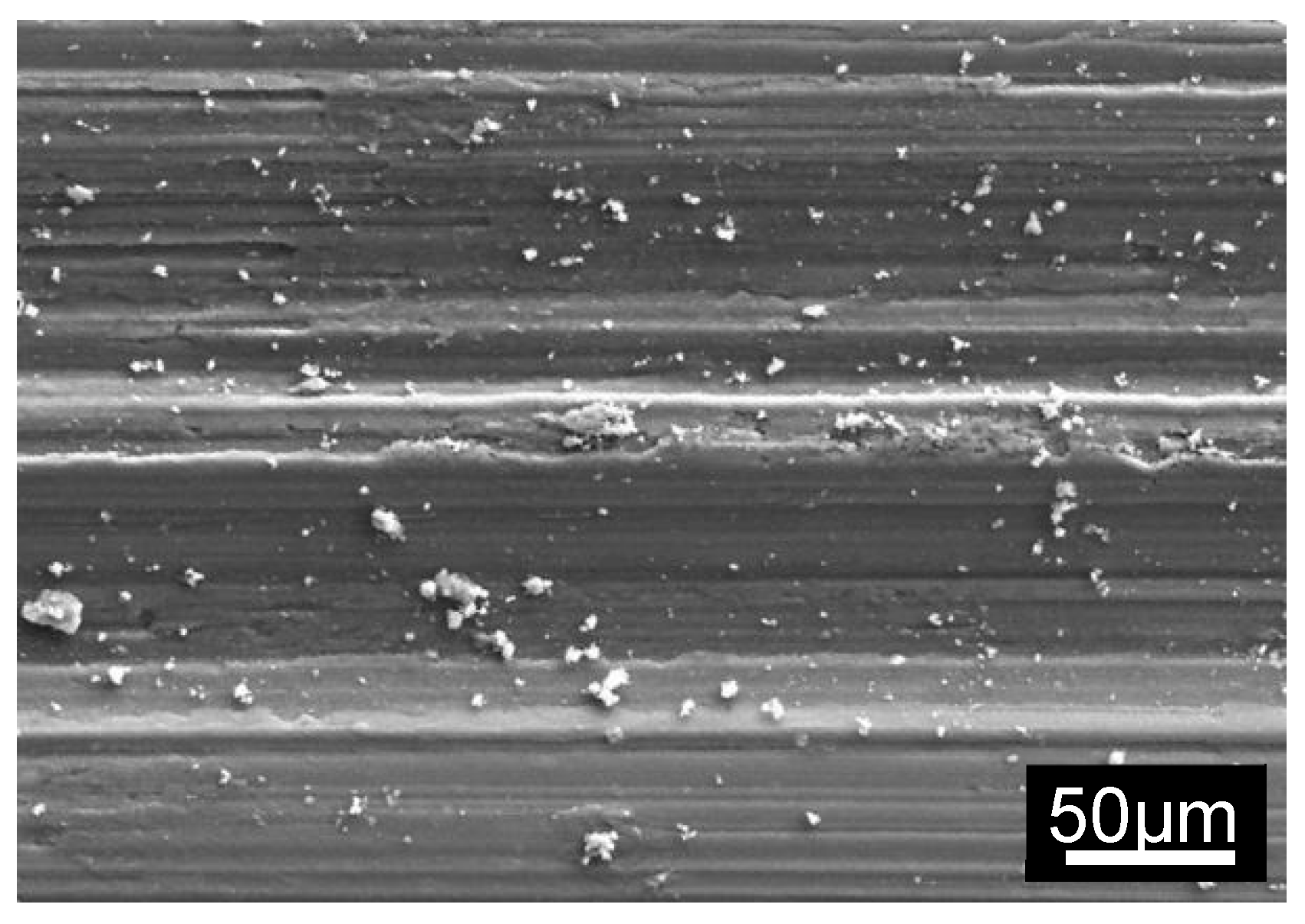

3.5.1. Abrasion

3.5.2. Oxidation

3.5.3. Delamination

3.5.4. Transformation of Wear Mechanisms for the Composites

4. Conclusions

- (1)

- The SiC particles exhibited typical necklace-type distribution in as-cast composites. Finer particle size and higher volume fraction of SiC particles promoted the formation of necklace distribution. At the lower load of 10 N, the presence of SiC particles enhanced the wear resistance of 10 μm 15 vol% composite, whose wear rate was 5.5 × 10−3 mm3/m, much lower than that at high loads of 20 N (11.0 × 10−3 mm3/m) and 30 N (14.0 × 10−3 mm3/m). At higher applied loads, SiC particles were easy to debond from the matrix due to the weak interface bonding caused by necklace-type distribution, and the dominant wear mechanism transformed from abrasion to delamination.

- (2)

- As the sizes of SiC particles increased from 5 to 20 μm, the wear rate of the composites decreased obviously because the necklace-type distribution became less evident. Especially, the 20 μm 15 vol% composite exhibited the optimal wear resistance, as the dominated wear mechanism was converted from delamination to oxidation. Similarly, the necklace-type particle distribution became more evident with the increase of volume fractions of SiC particles, resulting in the higher wear rate of 13.3 × 10−3 mm3/m in the 10 μm 20 vol% composite.

- (3)

- Wear results showed that large particle size and low volume fraction of SiC particles could contribute to the improvement of wear resistance. The necklace-type distribution of SiC particles in as-cast composites are detrimental to enhancement of wear resistance, which should be avoided as it facilitated the operation of delamination during wear. Thus, subsequent plastic processing or modified casting methods are encouraged to promote the distribution of SiC particles and further improve the wear resistance.

Author Contributions

Funding

Conflicts of Interest

References

- Yin, S.Q.; Duan, W.C.; Liu, W.H.; Wu, L.; Yu, J.M.; Zhao, Z.L.; Liu, M.; Wang, P.; Cui, J.Z.; Zhang, Z.Q. Influence of specific second phases on corrosion behaviors of Mg-Zn-Gd-Zr alloys. Corros. Sci. 2020, 166, 108419. [Google Scholar] [CrossRef]

- Zhong, F.; Wu, H.J.; Jiao, Y.L.; Wu, R.Z.; Zhang, J.H.; Hou, L.G.; Zhang, M.L. Effect of Y and Ce on the microstructure, mechanical properties and anisotropy of as-rolled Mg-8Li-1Al alloy. J. Mater. Sci. Technol. 2020, 39, 124–134. [Google Scholar] [CrossRef]

- Liu, H.; Huang, H.; Sun, J.P.; Wang, C.; Bai, J.; Ma, A.B.; Chen, X.H. Microstructure and mechanical properties of Mg–RE–TM cast alloys containing long period stacking ordered phases: A Review. Acta Metall. Sin. (Engl. Lett.) 2019, 32, 269–285. [Google Scholar] [CrossRef]

- Tie, D.; Zhang, B.Y.; Yan, L.F.; Guan, R.G.; Ji, Z.S.; Liu, H.F.; Zhang, D.L.; Liu, D.B.; Chen, M.F. Rheological solidification behavior and mechanical properties of AZ91-Sn alloys. Crystals 2019, 9, 641. [Google Scholar] [CrossRef]

- Liu, H.; Ju, J.; Yang, X.W.; Yan, J.L.; Song, D.; Jiang, J.H.; Ma, A.B. A two-step dynamic recrystallization induced by LPSO phases and its impact on mechanical property of severe plastic deformation processed Mg97Y2Zn1 alloy. J. Alloys Compd. 2017, 704, 509–517. [Google Scholar] [CrossRef]

- Liu, H.; Huang, H.; Wang, C.; Sun, J.P.; Bai, J.; Xue, F.; Ma, A.B.; Chen, X.B. Recent advances in LPSO-containing wrought magnesium alloys: Relationships between processing, microstructure, and mechanical properties. JOM 2019, 71, 3314–3327. [Google Scholar] [CrossRef]

- He, B.; Hu, Y.B.; Zhao, T.S.; Yao, Q.S.; Pan, F.S. Microstructure and mechanical properties of aged and hot rolled AZ80 magnesium alloy sheets. Crystals 2019, 9, 239. [Google Scholar] [CrossRef]

- Wang, B.J.; Xu, D.K.; Wang, S.D.; Sheng, L.Y.; Zeng, R.C.; Han, E.H. Influence of solution treatment on the corrosion fatigue behavior of an as-forged Mg-Zn-Y-Zr alloy. Inter. J. Fatigue 2019, 120, 46–55. [Google Scholar] [CrossRef]

- Huang, H.; Liu, H.; Wang, C.; Sun, J.P.; Bai, J.; Xue, F.; Jiang, J.H.; Ma, A.B. Potential of multi-pass ECAP on improving the mechanical properties of a high-calcium-content Mg-Al-Ca-Mn alloy. J. Magnes. Alloys 2019, 7, 617–627. [Google Scholar] [CrossRef]

- Song, J.F.; She, J.; Chen, D.L.; Pan, F.S. Latest research advances on magnesium and magnesium alloys worldwide. J. Magnes. Alloys 2020, 8, 1–41. [Google Scholar] [CrossRef]

- Liu, W.Q.; Hu, X.S.; Wang, X.J.; Wu, K.; Zheng, M.Y. Evolution of microstructure, texture and mechanical properties of SiC/AZ31 nanocomposite during hot rolling process. Mater. Des. 2016, 93, 194–202. [Google Scholar] [CrossRef]

- Shi, H.L.; Wang, X.J.; Zhang, C.L.; Li, C.D.; Ding, C. A novel melt processing for Mg matrix composites reinforced by multiwalled carbon nanotubes. J. Mater. Sci. Technol. 2016, 32, 1303–1308. [Google Scholar] [CrossRef]

- Deng, K.; Li, J.; Xu, F.; Nie, K.; Liang, W. Hot deformation behavior and processing maps of fine-grained SiCp/AZ91 composite. Mater. Des. 2015, 67, 72–81. [Google Scholar] [CrossRef]

- Zhou, S.; Deng, K.; Li, J.; Shang, S.; Liang, W.; Fan, J. Effects of volume ratio on the microstructure and mechanical properties of particle reinforced magnesium matrix composite. Mater. Des. 2014, 63, 672–677. [Google Scholar] [CrossRef]

- Wang, X.J.; Xu, D.K.; Wu, R.Z.; Chen, X.B.; Peng, Q.M.; Jin, L.; Xin, Y.C.; Zhang, Z.Q.; Liu, Y.; Chen, X.H.; et al. What is going on in magnesium alloys? J. Mater. Sci. Technol. 2018, 34, 245–247. [Google Scholar] [CrossRef]

- Deng, K.K.; Wang, C.J.; Nie, K.B.; Wang, X.J. Recent Research on the Deformation Behavior of Particle Reinforced Magnesium Matrix Composite: A Review. Acta Metall. Sin. (Engl. Lett.) 2019, 32, 413–425. [Google Scholar] [CrossRef]

- Luo, A. Processing, microstructure, and mechanical-behavior of cast magnesium metal-matrix composites. Metall. Mater. Trans. A 1995, 26, 2445–2455. [Google Scholar] [CrossRef]

- Zhong, W.M.; L’Espérance, G.; Suéry, M. Effect of thermomechanical processing on the microstructure and mechanical properties of Al-Mg (5083)/SiCp and Al-Mg (5083)/Al2O3 composites. Part 3: Fracture mechanisms of the composites. Mat. Sci. Eng. A 1996, 214, 104–114. [Google Scholar] [CrossRef]

- Wang, X.J.; Wu, K.; Huang, W.X.; Zhang, H.F.; Zheng, M.Y.; Peng, D.L. Study on fracture behavior of particulate reinforced magnesium matrix composite using in situ SEM. Compos. Sci. Technol. 2007, 67, 2253–2260. [Google Scholar] [CrossRef]

- García-Rodríguez, S.; Torres, B.; Maroto, A.; López, A.J.; Otero, E.; Rams, J. Dry sliding wear behavior of globular AZ91 magnesium alloy and AZ91/SiCp composites. Wear 2017, 390–391, 1–10. [Google Scholar] [CrossRef]

- Venkataraman, B.; Sundararajan, G. The sliding wear behaviour of Al-SiC particulate composites-I. Macrobehaviour. Acta Mater. 1996, 44, 451–460. [Google Scholar] [CrossRef]

- Iwai, Y.; Honda, T.; Miyajima, T.; Iwasaki, Y.; Surappa, M.K.; Xu, J.F. Dry sliding wear behavior of Al2O3 fiber reinforced aluminum composites. Compos. Sci. Technol. 2000, 60, 1781–1789. [Google Scholar] [CrossRef]

- Surappa, M.K.; Prasad, S.V.; Rohatgi, P.K. Wear and abrasion of cast Al-alumina particle composites. Wear 1982, 77, 295–302. [Google Scholar] [CrossRef]

- Alpas, A.T.; Embury, J.D. Sliding and abrasive wear behavior of an aluminum (2014)-SiC particle reinforced composite. Scr. Mater. 1990, 24, 931–935. [Google Scholar] [CrossRef]

- Kwok, J.; Lim, S.C. High-speed tribological properties of some Al/SiCp composites: I. Frictional and wear-rate characteristics. Compos. Sci. Technol. 1999, 59, 55–63. [Google Scholar] [CrossRef]

- Kwok, J.; Lim, S.C. High-speed tribological properties of some Al/SiCp composites: II. Wear mechanisms. Compos. Sci. Technol. 1999, 59, 65–75. [Google Scholar] [CrossRef]

- Chung, S.; Hwang, B.H. A microstructural study of the wear behaviour of SiCp/Al composites. Tribol. Int. 1994, 27, 307–314. [Google Scholar] [CrossRef]

- Sato, A.; Mehrabian, R. Aluminum matrix composites: Fabrication and properties. Met. Trans. B 1976, 7, 443–451. [Google Scholar] [CrossRef]

- Sannino, A.P.; Rack, H.J. Tribological investigation of 2009 Al-20 vol.% SiCp/17-4 PH Part I: Composite performance. Wear 1996, 197, 151–159. [Google Scholar] [CrossRef]

- Skolianos, S.; Kattamis, T.Z. Tribological properties of SiCp-reinforced Al-4.5% Cu-1.5% Mg alloy composites. Mat. Sci. Eng. A 1993, 163, 107–113. [Google Scholar] [CrossRef]

- Das, S.; Das, S.; Das, K. Abrasive wear of zircon sand and alumina reinforced Al-4.5 wt%Cu alloy matrix composites-A comparative study. Compos. Sci. Technol. 2007, 67, 746–751. [Google Scholar] [CrossRef]

- Lim, C.Y.H.; Lim, S.C.; Gupta, A. Wear behaviour of SiCp-reinforced magnesium matrix composites. Wear 2003, 255, 629–637. [Google Scholar] [CrossRef]

- Alpas, A.T.; Zhang, J. Effect of SiC particulate reinforcement on the dry sliding wear of aluminum silicon alloys (A356). Wear 1992, 155, 83–104. [Google Scholar] [CrossRef]

- Alpas, A.T.; Zhang, J. Wear rate transitions in cast aluminum-silicon alloys reinforced with SiC particles. Scr. Metall. Mater. 1992, 26, 505–509. [Google Scholar] [CrossRef]

- Hokkirigawa, K.; Kato, K. An experimental and theoretical investigation of plowing, cutting and wedge formation during abrasive wear. Tribol. Int. 1988, 21, 51–57. [Google Scholar] [CrossRef]

- Maruschak, P.O.; Konovalenko, I.V.; Vuherer, T.; Panin, S.V.; Berto, F.; Danyliuk, I.M.; Menou, A. Analysis and automated fatigue damage evaluation of a 17Mn1Si pipeline steel. Procedia Struct. Integr. 2016, 2, 1928–1935. [Google Scholar] [CrossRef]

- Suh, N.P. The delamination theory of wear. Wear 1973, 25, 111–124. [Google Scholar] [CrossRef]

- Suh, N.P. An overview of the delamination theory of wear. Wear 1977, 44, 1–16. [Google Scholar] [CrossRef]

- Taltavull, C.; Torres, B.; López, A.J.; Rams, J. Dry sliding wear behavior of AM60B magnesium alloy. Wear 2013, 301, 615–625. [Google Scholar] [CrossRef]

- Karamis, M.B.; Cerit, A.A.; Selcuk, B.; Nair, F. The effects of different ceramics size and volume fraction on wear behavior of Al matrix composites (for automobile cam material). Wear 2012, 289, 73–81. [Google Scholar] [CrossRef]

- Yilmaz, O.; Buytoz, S. Abrasive wear of Al2O3-reinforced aluminium-based MMCs. Compos. Sci. Technol. 2001, 61, 2381–2392. [Google Scholar] [CrossRef]

- Gul, F.; Acilar, M. Effect of the reinforcement volume fraction on the dry sliding wear behaviour of Al-10Si/SiCp composites produced by vacuum infiltration technique. Compos. Sci. Technol. 2004, 64, 1959–1970. [Google Scholar] [CrossRef]

- Ma, T.J.; Yamaura, H.; Koss, D.A.; Voigt, R.C. Dry sliding wear behavior of cast SiC-reinforced Al MMCs. Mat. Sci. Eng. A 2003, 360, 116–125. [Google Scholar] [CrossRef]

- Tjong, S.C.; Wu, S.Q.; Liao, H.C. Wear behaviour of an Al-12% Si alloy reinforced with a low volume fraction of SiC particles. Compos. Sci. Technol. 1997, 57, 1551–1558. [Google Scholar] [CrossRef]

- Iwai, Y.; Yoneda, H.; Honda, T. Sliding wear behavior of SiC whisker-reinforced aluminum composite. Wear 1995, 181, 594–602. [Google Scholar] [CrossRef]

- Misra, A.; Finnie, I. A classification of three-body abrasive wear and design of a new tester. Wear 1980, 60, 111–121. [Google Scholar] [CrossRef]

- Cui, X.H.; Wang, S.Q.; Wang, F.; Chen, K.M. Research on oxidation wear mechanism of the cast steels. Wear 2008, 265, 468–476. [Google Scholar] [CrossRef]

- Sullivan, J.L.; Athwal, S.S. Mild wear of a low alloy steel at temperatures up to 500 °C. Tribol. Int. 1983, 16, 123–131. [Google Scholar] [CrossRef]

| 10% | 15% | 20% | |

|---|---|---|---|

| 5 μm | √ | ||

| 10 μm | √ | √ | √ |

| 20 μm | √ |

| Materials | Ultimate Tensile Strength (MPa) | Tensile Yield Strength (MPa) | Elastic Modulus (GPa) | Ductility (% EL) | Hardness (HB) | Density (g/cm3) |

|---|---|---|---|---|---|---|

| AZ91D | 144.3 | 86.3 | 48.8 | 2.3 | 73.2 | 1.801 |

| 5 μm 15%SiCp/Mg | 150.6 | 50.4 | 74.2 | 0.2 | 112.0 | 2.006 |

| 10 μm 10%SiCp/Mg | 151.2 | 109.6 | 53.8 | 1.3 | 76.3 | 1.914 |

| 10 μm 15%SiCp/Mg | 175.4 | 164.4 | 49.3 | 0.6 | 93.8 | 1.997 |

| 10 μm 20%SiCp/Mg | 213.6 | 209.3 | 65.0 | 0.5 | 106.0 | 2.084 |

| 20 μm 15%SiCp/Mg | 179.8 | 150.7 | 69.0 | 0.7 | 84.9 | 1.998 |

| Material | Wear Rate (10−3 mm3/m) | Friction Coefficient | Features | Wear Mechanisms 1 | ||||

|---|---|---|---|---|---|---|---|---|

| Worn Surface | Wear Debris | |||||||

| Grooves | Fine Particles | Sheets | Abr | Oxi | Del | |||

| Matrix | 10.7 | 0.32 | √√ 2 | √√ | √√ | √√ | √√ | √√ |

| 5 μm 15 vol% composite | 12.5 | 0.39 | √ | √ | √√√ | √ | √ | √√√ |

| 10 μm 15 vol% composite (10N) 3 | 5.5 | 0.52 | √√ | √√ | √ | √√ | √√ | √ |

| 10 μm 15 vol% composite | 11.0 | 0.43 | √ | √√ | √√ | √ | √√ | √√ |

| 10 μm 15 vol% composite (30N) | 14.0 | 0.39 | √ | √ | √√√ | √ | √ | √√√ |

| 20 μm 15 vol% composite | 5.0 | 0.59 | √√ | √√√ | √ | √√ | √√√ | √ |

| 10 μm 10 vol% composite | 10.9 | 0.40 | √ | √√ | √√ | √ | √√ | √√ |

| 10 μm 20 vol% composite | 13.3 | 0.44 | √ | √ | √√√ | √ | √ | √√√ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, C.; Lu, N.; Liu, H.; Wang, X.; Hu, X.; Chen, D. Effect of Necklace-Type Distribution of SiC Particles on Dry Sliding Wear Behavior of As-Cast AZ91D/SiCp Composites. Crystals 2020, 10, 296. https://doi.org/10.3390/cryst10040296

Sun C, Lu N, Liu H, Wang X, Hu X, Chen D. Effect of Necklace-Type Distribution of SiC Particles on Dry Sliding Wear Behavior of As-Cast AZ91D/SiCp Composites. Crystals. 2020; 10(4):296. https://doi.org/10.3390/cryst10040296

Chicago/Turabian StyleSun, Chao, Nannan Lu, Huan Liu, Xiaojun Wang, Xiaoshi Hu, and Deqiang Chen. 2020. "Effect of Necklace-Type Distribution of SiC Particles on Dry Sliding Wear Behavior of As-Cast AZ91D/SiCp Composites" Crystals 10, no. 4: 296. https://doi.org/10.3390/cryst10040296

APA StyleSun, C., Lu, N., Liu, H., Wang, X., Hu, X., & Chen, D. (2020). Effect of Necklace-Type Distribution of SiC Particles on Dry Sliding Wear Behavior of As-Cast AZ91D/SiCp Composites. Crystals, 10(4), 296. https://doi.org/10.3390/cryst10040296