Structure and Phase Transition Features of Monoclinic and Tetragonal Phases in U–Mo Alloys

Abstract

1. Introduction

2. Computational Method

3. Results

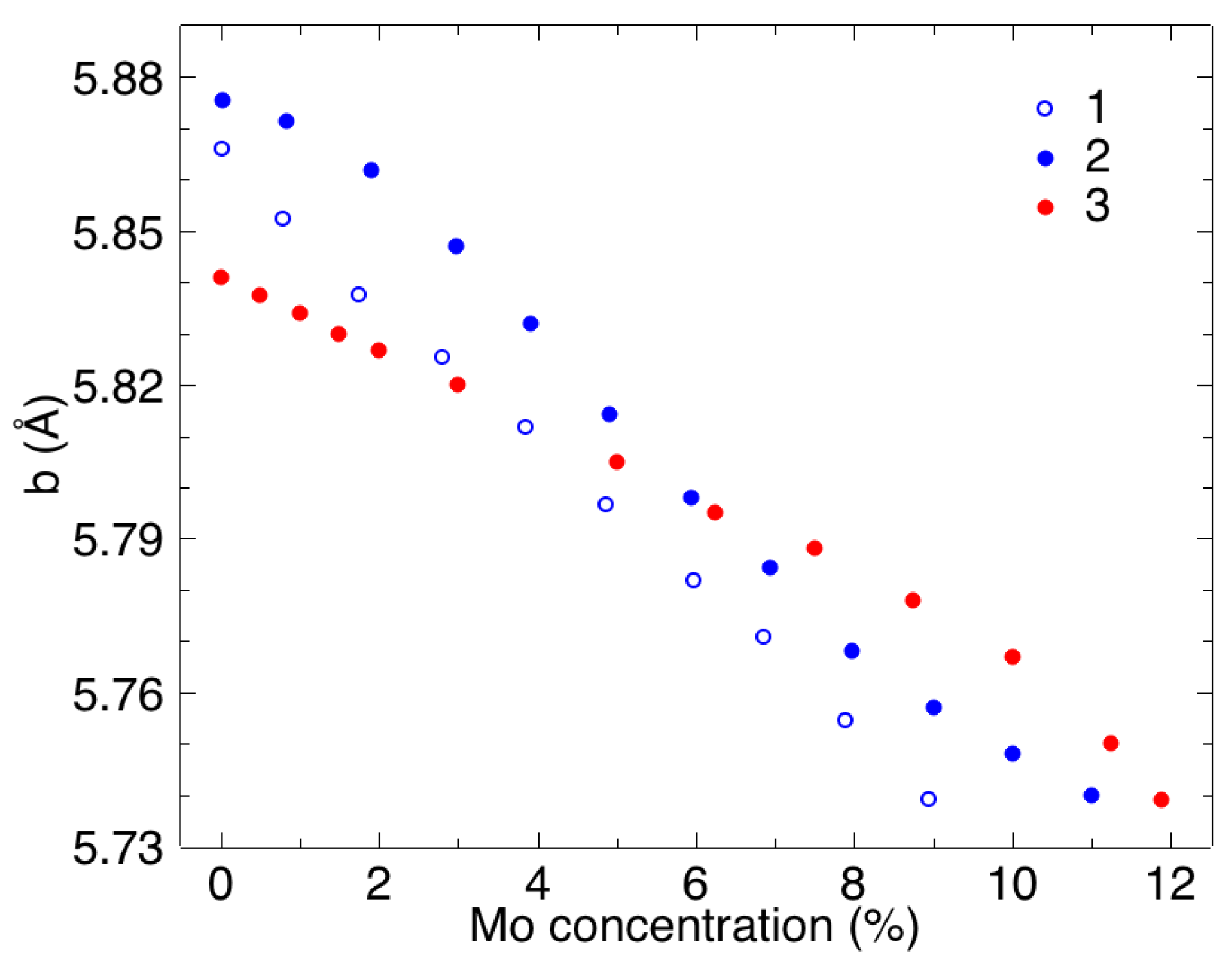

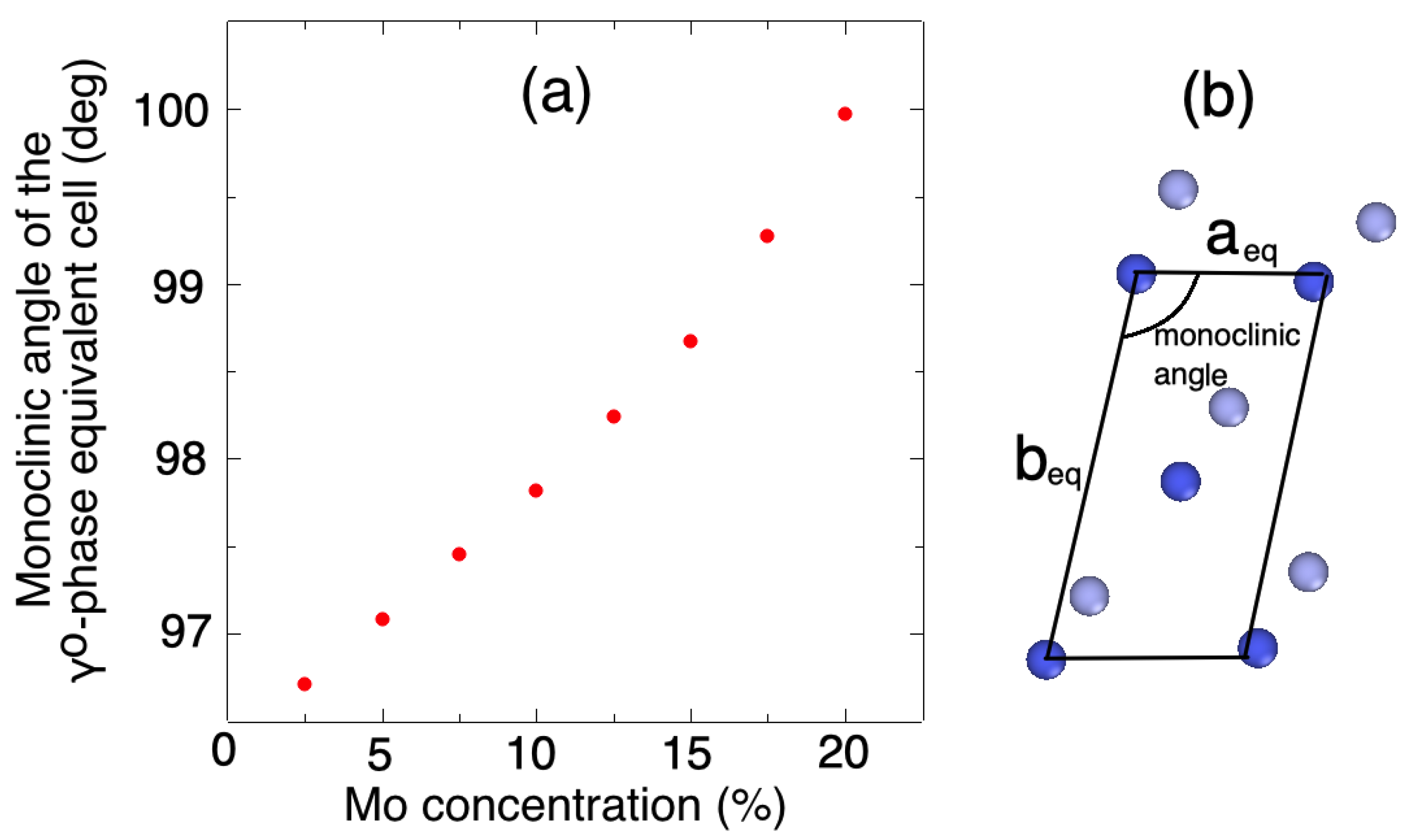

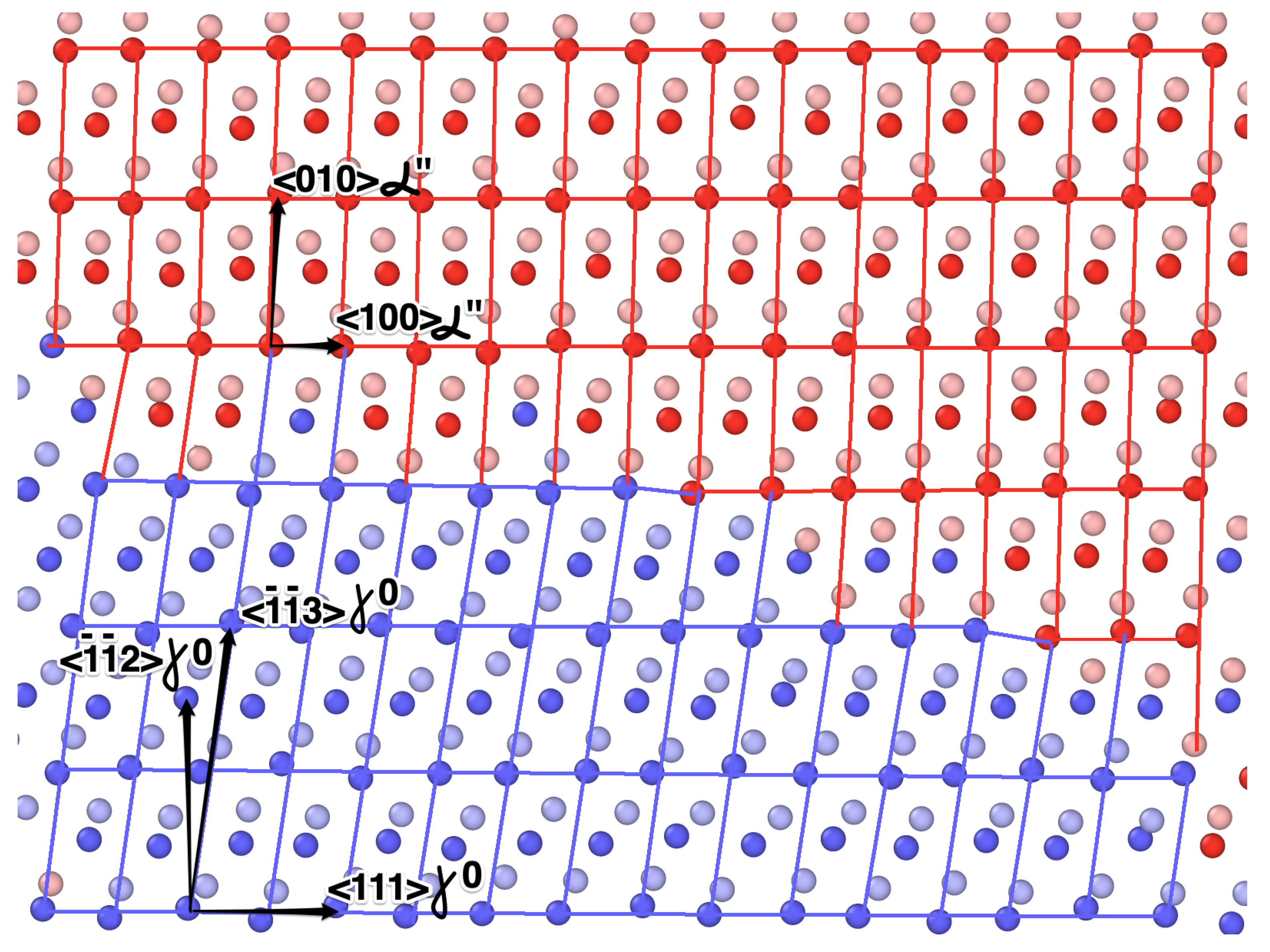

3.1. -Like Phases in U–Mo Alloy

3.2. Mechanical Properties of U–Mo Alloy

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kalashnikov, V.; Titova, V.; Sergeev, G.I.; Samoilov, A. Uranium-molybdenum alloys in reactor construction. At. Energy 1959, 5, 1315–1325. [Google Scholar] [CrossRef]

- Landa, A.; Söderlind, P.; Turchi, P. Density-functional study of U–Mo and U–Zr alloys. J. Nucl. Mater. 2011, 414, 132–137. [Google Scholar] [CrossRef]

- Kim, Y.S.; Hofman, G. Fission product induced swelling of U–Mo alloy fuel. J. Nucl. Mater. 2011, 419, 291–301. [Google Scholar] [CrossRef]

- Vatulin, A.; Morozov, A.; Suprun, V.; Petrov, Y.I.; Trifonov, Y.I. Radiation resistance of high-density uranium—molybdenum dispersion fuel for nuclear research reactors. At. Energy 2006, 100, 37–46. [Google Scholar] [CrossRef]

- Rest, J.; Kim, Y.S.; Hofman, G.; Meyer, M.; Hayes, S. U-Mo Fuels Handbook; Argonne Natoinal Laboratory: Lemont, IL, USA, 2009. [Google Scholar]

- Neogy, S.; Saify, M.; Jha, S.; Srivastava, D.; Dey, G. Ageing characteristics of the metastable gamma phase in U–9 wt.% Mo alloy: Experimental observations and thermodynamic validation. Philos. Mag. 2015, 95, 2866–2884. [Google Scholar] [CrossRef]

- Xu, Z.; Joshi, V.; Hu, S.; Paxton, D.; Lavender, C.; Burkes, D. Modeling the homogenization kinetics of as-cast U-10wt% Mo alloys. J. Nucl. Mater. 2016, 471, 154–164. [Google Scholar] [CrossRef]

- Konobeevskii, S.; Pravdyuk, N.; Dubrovin, K.; Levitskii, B.; Panteleev, L.; Golianov, V. An investigation of structural changes caused by neutron irradiation of a uranium molybdenum alloy. J. Nucl. Energy Part B 1959, 9, 75–89. [Google Scholar]

- Hofman, G.L.; Meyer, M.K.; Ray, A.E. Design of high density gamma-phase uranium alloys for LEU dispersion fuel applications. In Proceedings of the International Reduced Enrichment for Research and Test Reactors Conference, Sao Paulo, Brazil, 18–20 October 1998. [Google Scholar]

- Hengstler, R.; Beck, L.; Breitkreutz, H.; Jarousse, C.; Jungwirth, R.; Petry, W.; Schmid, W.; Schneider, J.; Wieschalla, N. Physical properties of monolithic U8wt.%–Mo. J. Nucl. Mater. 2010, 402, 74–80. [Google Scholar] [CrossRef]

- Joshi, V.V.; Nyberg, E.A.; Lavender, C.A.; Paxton, D.; Burkes, D.E. Thermomechanical process optimization of U-10wt% Mo – Part 2: The effect of homogenization on the mechanical properties and microstructure. J. Nucl. Mater. 2015, 465, 710–718. [Google Scholar] [CrossRef]

- Neogy, S.; Saify, M.; Jha, S.; Srivastava, D.; Hussain, M.; Dey, G.; Singh, R. Microstructural study of gamma phase stability in U–9wt.% Mo alloy. J. Nucl. Mater. 2012, 422, 77–85. [Google Scholar] [CrossRef]

- Pedrosa, T.A.; dos Santos, A.M.M.; Lameiras, F.S.; Cetlin, P.R.; Ferraz, W.B. Phase transitions during artificial ageing of segregated as-cast U–Mo alloys. J. Nucl. Mater. 2015, 457, 100–117. [Google Scholar] [CrossRef]

- Tangri, K.; Williams, G. Metastable phases in the uranium molybdenum system and their origin. J. Nucl. Mater. 1961, 4, 226–233. [Google Scholar] [CrossRef]

- Yakel, H.L. Crystal structures of transition phases formed in U–16.60 at.%Nb–5.64 at.%Zr alloys. J. Nucl. Mater. 1969, 33, 286–295. [Google Scholar] [CrossRef]

- Howlett, B. A study of the shear transformations from the gamma-phase in uranium-molybdenum alloys containing 6.0–12.5 at% molybdenum. J. Nucl. Mater. 1970, 35, 278–292. [Google Scholar] [CrossRef]

- Ivanov, O.S.; Badaeva, T.A.; Sofronova, R.M.; Kishenevskiy, V.B.; Kushnir, N.P. Phase Diagrams and Phase Transitions in Uranium Alloys; Nauka: Moscow, Russia, 1972; p. 254. [Google Scholar]

- Chebotarev, N.T.; Utkina, O.N. Crystal structure of γS phase in U-Mo, U-Re and U-Nb alloys. At. Energy 1980, 48, 76–80. [Google Scholar] [CrossRef]

- Lehmann, M.J. Phases monocliniques dans les alliages uranium-molybdene. J. Nucl. Mater. 1961, 4, 218–225. [Google Scholar] [CrossRef]

- Vandermeer, R.; Ogle, J.; Northcutt, W. A phenomenological study of the shape memory effect in polycrystalline uranium-niobium alloys. Metall. Mater. Trans. A 1981, 12, 733–741. [Google Scholar] [CrossRef]

- Tkach, I.; Kim-Ngan, N.T.; Mašková, S.; Dzevenko, M.; Havela, L.; Warren, A.; Stitt, C.; Scott, T. Characterization of cubic γ-phase uranium molybdenum alloys synthesized by ultrafast cooling. J. Alloys Compd. 2012, 534, 101–109. [Google Scholar] [CrossRef]

- Sagaradze, V.V.; Zuev, Y.N.; Bondarchuk, S.V.; Svyatov, I.L.; Shestakov, A.E.; Pecherkina, N.L.; Kabanova, I.G.; Klyukin, M.F. Structural Heredity in the U–6Nb Alloy and Conditions for Its Elimination. Phys. Met. Metallogr. 2013, 114, 299–307. [Google Scholar] [CrossRef]

- Starikov, S.; Kolotova, L.; Kuksin, A.Y.; Smirnova, D.; Tseplyaev, V. Atomistic simulation of cubic and tetragonal phases of U-Mo alloy: Structure and thermodynamic properties. J. Nucl. Mater. 2018, 499, 451–463. [Google Scholar] [CrossRef]

- Beeler, B.; Deo, C.; Baskes, M.; Okuniewski, M. Atomistic properties of γ uranium. J. Phys. Condens. Matter 2012, 24, 075401. [Google Scholar] [CrossRef] [PubMed]

- Fernández, J.R.; Pascuet, M. On the accurate description of uranium metallic phases: A MEAM interatomic potential approach. Model. Simul. Mater. Sci. Eng. 2014, 22, 055019. [Google Scholar] [CrossRef]

- Moore, A.; Deo, C.; Baskes, M.; Okuniewski, M.; McDowell, D. Understanding the uncertainty of interatomic potentials’ parameters and formalism. Comput. Mater. Sci. 2017, 126, 308–320. [Google Scholar] [CrossRef]

- Ercolessi, F.; Adams, J.B. Interatomic potentials from first-principles calculations: The force-matching method. Europhys. Lett 1994, 26, 583. [Google Scholar] [CrossRef]

- Brommer, P.; Gahler, F. Potfit: Effective potentials from ab initio data. Modell. Simul. Mater. Sci. Eng. 2007, 15, 295. [Google Scholar] [CrossRef]

- Plimpton, S.J. Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 1995, 117, 1. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Lehmann, J.; Hills, R. Proposed nomenclature for phases in uranium alloys. J. Nucl. Mater. 1960, 2. [Google Scholar] [CrossRef]

- Stewart, D.; Williams, G. The structure and occurrence of the metastable monoclinic phase, α′ b, in uranium-molybdenum alloys. J. Nucl. Mater. 1966, 20, 262–268. [Google Scholar] [CrossRef]

- Kaufmann, A.R. Nuclear Reactor Fuel Elements: Metallurgy and Fabrication; Interscience Publishers: Geneva, Switzerland, 1962. [Google Scholar]

- Tangri, K.; Chaudhuri, D. Metastable phases in uranium alloys with high solute solubility in the BCC gamma phase. Part I—the system U-Nb. J. Nucl. Mater. 1965, 15, 278–287. [Google Scholar] [CrossRef]

- Sinha, V.; Hegde, P.; Prasad, G.; Dey, G.; Kamath, H. Phase transformation of metastable cubic γ-phase in U–Mo alloys. J. Alloys Compd. 2010, 506, 253–262. [Google Scholar] [CrossRef]

- Hood, R.Q.; Yang, L.; Moriarty, J.A. Quantum molecular dynamics simulations of uranium at high pressure and temperature. Phys. Rev. B 2008, 78, 024116. [Google Scholar] [CrossRef]

- Soderlind, P. Theory of the crystal structures of cerium and the light actinides. Adv. Phys. 1998, 47, 959–998. [Google Scholar] [CrossRef]

- Hills, R.; Butcher, B.; Howlett, B. The mechanical properties of quenched uranium-molybdenum alloys: Part I: Tensile tests on polycbystalline specimens. J. Nucl. Mater. 1964, 11, 149–162. [Google Scholar] [CrossRef]

- Butcher, B.; Hatt, B. The mechanical properties of quenched uranium-molybdenum alloys: Part II: A preliminary survey of the deformation mechanisms. J. Nucl. Mater. 1964, 11, 163–182. [Google Scholar] [CrossRef]

- Starikov, S.; Kolotova, L. Features of cubic and tetragonal structures of U–Mo alloys: Atomistic simulation. Scr. Mater. 2016, 113, 27–30. [Google Scholar] [CrossRef]

| 5 at.% of Mo | 7.5 at.% of Mo | 10 at.% of Mo | 12.5 at.% of Mo | |

|---|---|---|---|---|

| -phase | 0 | 0.001 | 0.003 | 0.005 |

| -phase | 0.015 | 0.01 | 0.009 | 0.005 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolotova, L.; Gordeev, I. Structure and Phase Transition Features of Monoclinic and Tetragonal Phases in U–Mo Alloys. Crystals 2020, 10, 515. https://doi.org/10.3390/cryst10060515

Kolotova L, Gordeev I. Structure and Phase Transition Features of Monoclinic and Tetragonal Phases in U–Mo Alloys. Crystals. 2020; 10(6):515. https://doi.org/10.3390/cryst10060515

Chicago/Turabian StyleKolotova, Lada, and Ilia Gordeev. 2020. "Structure and Phase Transition Features of Monoclinic and Tetragonal Phases in U–Mo Alloys" Crystals 10, no. 6: 515. https://doi.org/10.3390/cryst10060515

APA StyleKolotova, L., & Gordeev, I. (2020). Structure and Phase Transition Features of Monoclinic and Tetragonal Phases in U–Mo Alloys. Crystals, 10(6), 515. https://doi.org/10.3390/cryst10060515