Engineered Layer-Stacked Interfaces Inside Aurivillius-Type Layered Oxides Enables Superior Ferroelectric Property

Abstract

:1. Introduction

2. Experimental Process

3. Results and Discussion

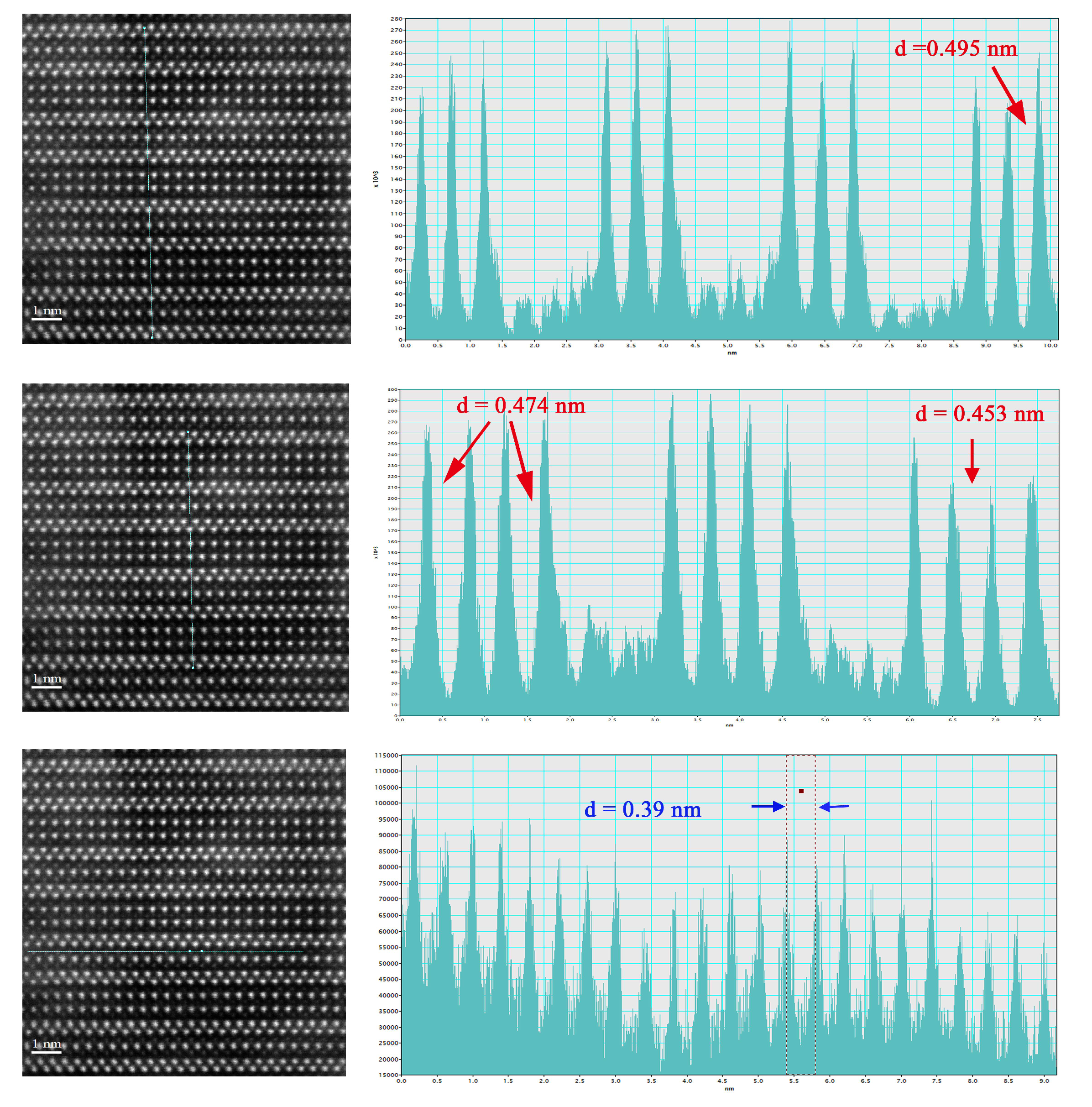

3.1. Crystal Phase and Mixed-Layer Structure

3.2. Insight from Raman and XPS Spectra

3.3. Ferroelectric and Dielectric Properties

3.4. Correlations Between Structures and Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hwang, H.Y.; Lwasa, Y.; Kawasaki, M.; Keimer, B.; Nagaosa, N.; Tokura, Y. Emergent phenomena at oxide interfaces. Nat. Mater. 2012, 11, 103–113. [Google Scholar]

- Dong, H.; Xu, F.; Sun, Z.Q.; Wu, X.; Zhang, Q.B.; Zhai, Y.S.; Tan, X.D.; He, L.; Xu, T.; Zhang, Z.; et al. In situ interface engineering for probing the limit of quantum dot photovoltaic devices. Nat. Nanotechnol. 2019, 14, 950–956. [Google Scholar]

- Spaldin, N.A.; Ramesh, R. Advances in magnetoelectric multiferroics. Nat. Mater. 2019, 18, 103–113. [Google Scholar]

- Cao, Y.; Li, W.W.; Liu, Z.; Zhao, Z.Q.; Xiao, Z.Y.; Zi, W.; Cheng, N. Ligand modification of Cu2ZnSnS4 nanoparticles boosts the performance of low temperature paintable carbon electrode based perovskite solar cells to 17.71%. J. Mater. Chem. A 2020, 8, 12080–12088. [Google Scholar]

- Mundy, J.; Brooks, C.; Holtz, M.; Moyer, J.; Das, H.; Rebola, A.; Heron, J.; Clarkson, J.; Disseler, S.; Liu, Z.; et al. Atomically engineered ferroic layers yield a room-temperature magnetoelectric multiferroic. Nature 2016, 537, 523–527. [Google Scholar]

- Anderson, P.W. More is different. Science 1972, 177, 393–396. [Google Scholar]

- Fiebig, M.; Lottermoser, T.; Meier, D.; Trassin, M. The evolution of multiferroics. Nat. Rev. Mater. 2016, 1, 16046. [Google Scholar]

- Gopalan, V.; Engel-Herbert, R. Creative tension in layered crystals. Nat. Mater. 2016, 15, 928–930. [Google Scholar]

- Moure, A. Review and perspectives of Aurivillius structures as a lead-free piezoelectric system. Appl. Sci. 2018, 8, 62. [Google Scholar]

- Chon, U.; Jang, H.M.; Kim, M.G.; Chang, C.H. Layered perovskites with giant spontaneous polarizations for nonvolatile memories. Phys. Rev. Lett. 2002, 89, 087601. [Google Scholar]

- Lisiñska-Czekaj, A.; Czekaj, D.; Gomes, M.; Kuprianov, M. Investigations on the synthesis of Bi3NbTiO9 ceramics. J. Eur. Ceram. Soc. 1999, 19, 969–972. [Google Scholar]

- Lei, Z.; Chen, T.; Li, W.; Liu, M.; Ge, W.; Lu, Y. Cobalt-substituted seven-layer Aurivillius Bi8Fe4Ti3O24 ceramics: Enhanced ferromagnetism and ferroelectricity. Crystals 2017, 7, 76. [Google Scholar]

- Krzhizhanovskaya, M.; Filatov, S.; Gusarov, V.; Paufler, P.; Bubnova, R.; Morozov, M.; Meyer, D.C. Aurivillius phases in the Bi4Ti3O12/BiFeO3 system: Termal behaviour and crystal structure. Z Anorg. Allg. Chem. 2005, 631, 1603–1608. [Google Scholar]

- Sun, S.J.; Huang, Y.; Wang, G.P.; Wang, J.L.; Peng, R.R.; Fu, Z.P.; Zhai, X.F.; Mao, X.Y.; Chen, X.B.; Lu, Y.L. Room-temperature multiferroic responses arising from 1D phase modulation in correlated Aurivillius-type layer structures. J. Phys. D Appl. Phys. 2016, 49, 125005. [Google Scholar]

- Sun, S.J.; Liu, C.H.; Wang, G.P.; Chen, Z.Z.; Chen, T.; Peng, R.R.; Lu, Y.L. Structural and physical properties of mixed-layer Aurivillius-type multiferroics. J. Am. Ceram. Soc. 2016, 99, 3033–3038. [Google Scholar]

- Sun, S.J.; Huang, Y.; Wang, G.P.; Wang, J.L.; Fu, Z.P.; Peng, R.R.; Knize, R.J.; Lu, Y.L. Nanoscale structural modulation and enhanced room-temperature multiferroic properties. Nanoscale 2014, 6, 13494–13500. [Google Scholar]

- Sun, S.J.; Chen, Z.Z.; Wang, G.P.; Geng, X.J.; Xiao, Z.Y.; Sun, Z.Z.; Sun, Z.H.; Peng, R.R.; Lu, Y.L. Nanoscale structural modulation and low-temperature magnetic response in mixed-layer Aurivillius-type oxides. Sci. Rep. 2018, 8, 871. [Google Scholar]

- Wang, G.P.; Chen, Z.Z.; He, H.C.; Meng, D.C.; Yang, H.; Mao, X.Y.; Pan, Q.; Chu, B.J.; Zuo, M.; Sun, Z.H.; et al. Room temperature exchange bias in structure-modulated single-phase multiferroic materials. Chem. Mater. 2018, 30, 6156–6163. [Google Scholar]

- Faraz, A.; Arif, S. Magnetic-field-induced ferroelectric domain dynamics and in-plane polarization in odd and mixed layered Aurivillius structures. J. Appl. Phys. 2019, 126, 084104. [Google Scholar]

- Keeney, L.; Downing, C.; Schmidt, M.; Pemble, M.E.; Nicolosi, V.; Whatmore, R.W. Direct atomic scale determination of magnetic ion partition in a room temperature multiferroic material. Sci. Rep. 2017, 7, 1737. [Google Scholar]

- Morozov, M.I.; Gusarov, V.V. Synthesis of Am−1Bi2MmO3m+3 compounds in the Bi4Ti3O12–BiFeO3 system. Inorg. Mater. 2002, 38, 723–729. [Google Scholar]

- Arenas, D.J.; Gasparov, L.V.; Qiu, W.; Nino, J.C.; Patterson, C.H.; Tanner, D.B. Raman study of phonon modes in bismuth pyrochlores. Phys. Rev. B 2010, 82, 214302. [Google Scholar]

- Kojima, S.; Imaizumi, R.; Hamazaki, S.; Takashige, M. Raman scattering study of bismuth layer-structure ferroelectrics. Jpn. J. Appl. Phys. 1994, 33, 5559–5564. [Google Scholar]

- Jiang, L.; Ni, S.; Liu, G.; Xu, X. Photocatalytic hydrogen production over Aurivillius compound Bi3TiNbO9 and its modifications by Cr/Nb co-doping. Appl. Catal. B Environ. 2017, 217, 342–352. [Google Scholar]

- Kaspar, T.C.; Ney, A.; Mangham, A.N.; Heald, S.M.; Joly, Y.; Ney, V.; Wilhelm, F.; Rogalev, A.; Yakou, F.; Chambers, S.A. Structure of epitaxial (Fe,N) codoped rutile TiO2 thin films by x-ray absorption. Phys. Rev. B 2012, 86, 3089–3094. [Google Scholar]

- Sun, S.; Zhu, L.; Zhang, B.; Zhang, L.; Li, Y.; Cheng, N.; Yin, X.; Tian, Y.; Li, X.; Lu, Y. Structural modulation enables magneto-dielectric effect and enhanced photoactivity in ferroelectric bismuth iron niobate pyrochlore. J. Mater. Chem. C 2019, 7, 1263–1272. [Google Scholar]

- Liu, C.H.; Chen, Z.Z.; Peng, R.R.; Fu, Z.P.; Zhai, X.F.; Lu, Y.L. The structure and properties of Co substituted Bi7Ti4NbO21 with intergrowth phases. RSC Adv. 2017, 7, 50477. [Google Scholar]

- Shao, C.; Lu, Y.; Wang, D.; Li, Y. Effect of Nd substitution on the microstructure and electrical properties of Bi7Ti4NbO21 piezoceramics. J. Eur. Ceram. Soc. 2012, 32, 3781–3789. [Google Scholar]

- Rehman, F.; Wang, L.; Jin, H.B.; Ahmad, P.; Zhao, Y.J.; Li, J.B. Dielectric relaxation and electrical properties of Sm0.5Bi4.5Ti3FeO15 ceramics. J. Alloy Compd. 2017, 709, 686–691. [Google Scholar]

- Sun, S.J.; Chen, W.J.; Fang, L.; Cheng, N.; Xiao, Z.Y.; Zhao, Z.Q.; Tian, Y.S.; Lu, Y.L. Dielectric relaxation and microwave absorption properties of aurivillius-type multiferroic ceramics. Ceram. Int. 2018, 44, 9942–9949. [Google Scholar]

- Jimenez, B.; Jimenez, R.; Castro, A.; Millan, P.; Pardo, L. Dielectric and mechanoelastic relaxations due to point defects in layered bismuth titanate ceramics. J. Phys. Condens. Matter. 2001, 13, 7315–7326. [Google Scholar]

- Du, H.L.; Shi, X. Strontium-induced ferroelectriclike relaxor behavior in Bi-based pyrochlores. Appl. Phys. Lett. 2010, 97, 052901. [Google Scholar]

- Rojac, T.; Bencan, A.; Malic, B.; Tutuncu, G.; Jones, J.L.; Daniels, J.E.; Damjanovic, D. BiFeO3 ceramics: Processing, electrical, and electromechanical properties. J. Am. Ceram. Soc. 2014, 97, 1993–2011. [Google Scholar]

- Zhou, Z.Y.; Li, Y.C.; Yang, L.H.; Dong, X.L.; Wang, Y.L. Microstructure and electrical properties of textured Bi-Layered Bi3TiNbO9 piezoceramics. Ferroelectrics 2008, 363, 127–133. [Google Scholar]

- Kong, L.B.; Ma, J.; Zhu, W.; Tan, O.K. Preparation of Bi4Ti3O12 ceramics via a high-energy ball milling process. Mater. Lett. 2001, 51, 108–114. [Google Scholar]

- Mao, X.; Sun, H.; Wang, W.; Lu, Y.L.; Chen, X.B. Effects of Co-substitutes on multiferroic properties of Bi5FeTi3O15 ceramics. Solid State Commun. 2012, 152, 483–487. [Google Scholar]

- Wu, Y.Y.; Yao, T.S.; Lu, Y.X.; Zou, B.W.; Mao, X.Y.; Huang, F.Z.; Sun, H.; Chen, X.B. Magnetic, dielectric, and magnetodielectric properties of Bi-layered perovskite Bi4.25Gd0.75Fe0.5Co0.5Ti3O15. J. Mater. Sci. 2017, 52, 7360–7368. [Google Scholar]

- Glazer, A. The classification of tilted octahedra in perovskites. Acta Crystallogr. B 1972, 28, 3384–3392. [Google Scholar]

- Lomanova, N.A.; Morozov, M.I.; Ugolkov, V.L.; Gusarov, V.V. Properties of Aurivillius phases in the Bi4Ti3O12-BiFeO3 system. Inorg. Mater. 2006, 42, 189–195. [Google Scholar]

- He, J.; Borisevich, A.; Kalinin, S.V.; Pennycook, S.J.; Pantelides, S.T. Control of octahedral tilts and magnetic properties of perovskite oxide heterostructures by substrate symmetry. Phys. Rev. Lett. 2010, 105, 227203. [Google Scholar]

- Zhai, X.F.; Long, C.; Liu, Y.; Schleputz, C.M.; Dong, S.; Li, H.; Zhang, X.Q.; Chu, S.Q.; Zheng, L.R.; Zhang, J.; et al. Correlating interfacial octahedral rotations with magnetism in (LaMnO3+δ)N/(SrTiO3)N superlattices. Nat. Commun. 2014, 5, 4283. [Google Scholar]

- Pitcher, M.J.; Mandal, P.; Dyer, M.S.; Alaria, J.; Borisov, P.; Niu, H.; Claridge, J.B.; Rosseinsky, M.J. Tilt engineering of spontaneous polarization and magnetization above 300 K in a bulk layered perovskite. Science 2015, 374, 420–424. [Google Scholar]

| Materials | 2Pr (μC/cm2) | 2Ec (kV/cm) | Applied E (kV/cm) | Curie Temperature (K) | Activation Energy (eV) | Ref. |

|---|---|---|---|---|---|---|

| Bi1.5Sr0.5Ti1.5Nb0.5O7 ceramic (pyrochlore-phase) | 11.4 | 92 | 100 | >473 | 1.75 | [32] |

| BiFeO3 ceramic | 8.9 | 78 | 100 | 1103 | −− | [33] |

| Bi3TiNbO9 textured ceramic (2-layer) | 1−13.6 | 120 | 100 | 1187 | −− | [34] |

| Bi4Ti3O12 oriented ceramic (3-layer) | 4.5–50 | 10−100 | >30 | 948 | 2.3 | [35] |

| Bi5FeTi3O15 ceramic (4-layer) | 9.7 | 202 | 230 | 1013 | 0.67 | [36] |

| Gd0.75Bi4.25Fe0.5Co0.5Ti3O15 ceramic (4-layer) | 10.6 | 200 | 180 | 1072 | 0.84 | [37] |

| Bi11Fe3Ti6O33 ceramic (mixed-layer) | 4.7 | 110 | 130 | 992 | −− | [15] |

| BTNO-21 ceramic (mixed-layer) | 12.8 | 104 | 120 | >1000 | 2.31 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Yin, X. Engineered Layer-Stacked Interfaces Inside Aurivillius-Type Layered Oxides Enables Superior Ferroelectric Property. Crystals 2020, 10, 710. https://doi.org/10.3390/cryst10080710

Sun S, Yin X. Engineered Layer-Stacked Interfaces Inside Aurivillius-Type Layered Oxides Enables Superior Ferroelectric Property. Crystals. 2020; 10(8):710. https://doi.org/10.3390/cryst10080710

Chicago/Turabian StyleSun, Shujie, and Xiaofeng Yin. 2020. "Engineered Layer-Stacked Interfaces Inside Aurivillius-Type Layered Oxides Enables Superior Ferroelectric Property" Crystals 10, no. 8: 710. https://doi.org/10.3390/cryst10080710

APA StyleSun, S., & Yin, X. (2020). Engineered Layer-Stacked Interfaces Inside Aurivillius-Type Layered Oxides Enables Superior Ferroelectric Property. Crystals, 10(8), 710. https://doi.org/10.3390/cryst10080710