Numerical Simulation to Determine the Effect of Topological Entropy on the Effective Transport Coefficient of Unidirectional Composites

Abstract

:1. Introduction

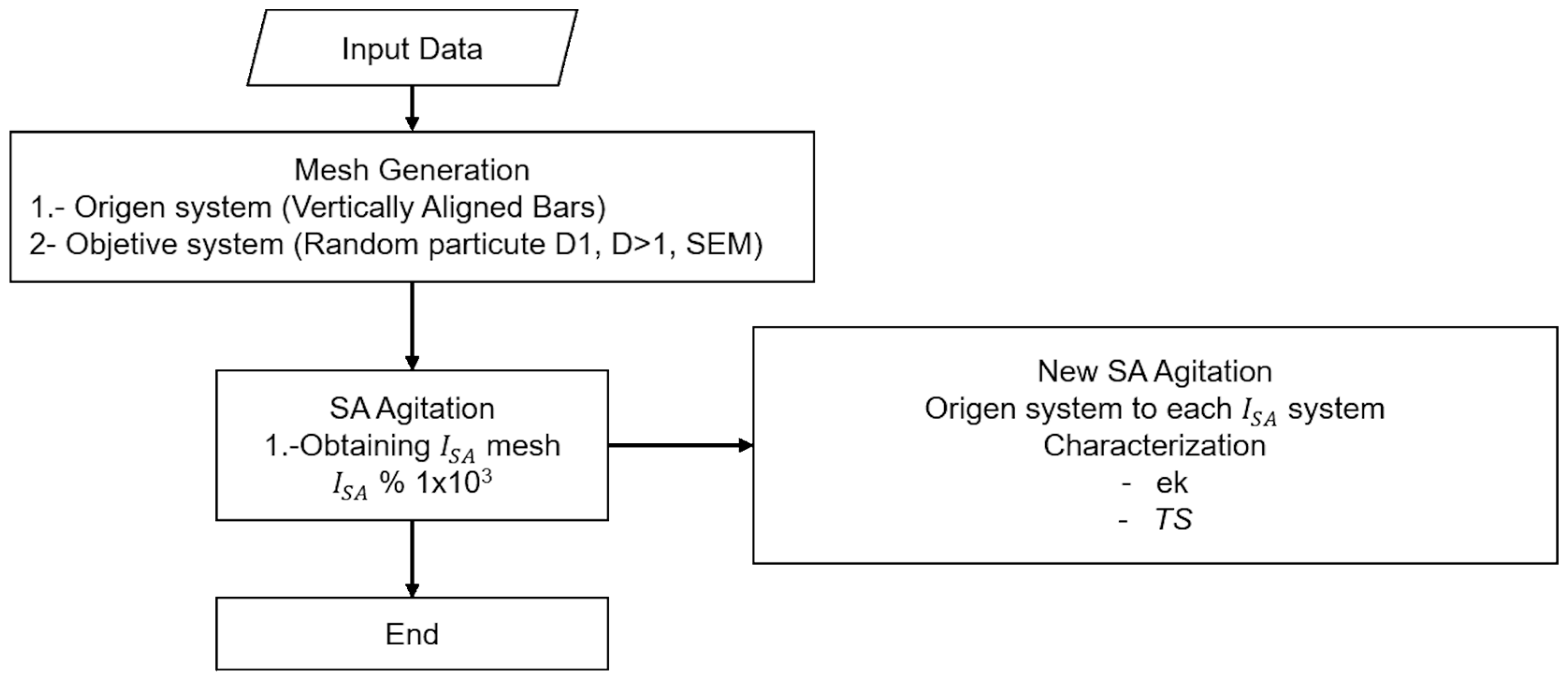

2. Materials and Methods

2.1. Transport Effective Coefficient

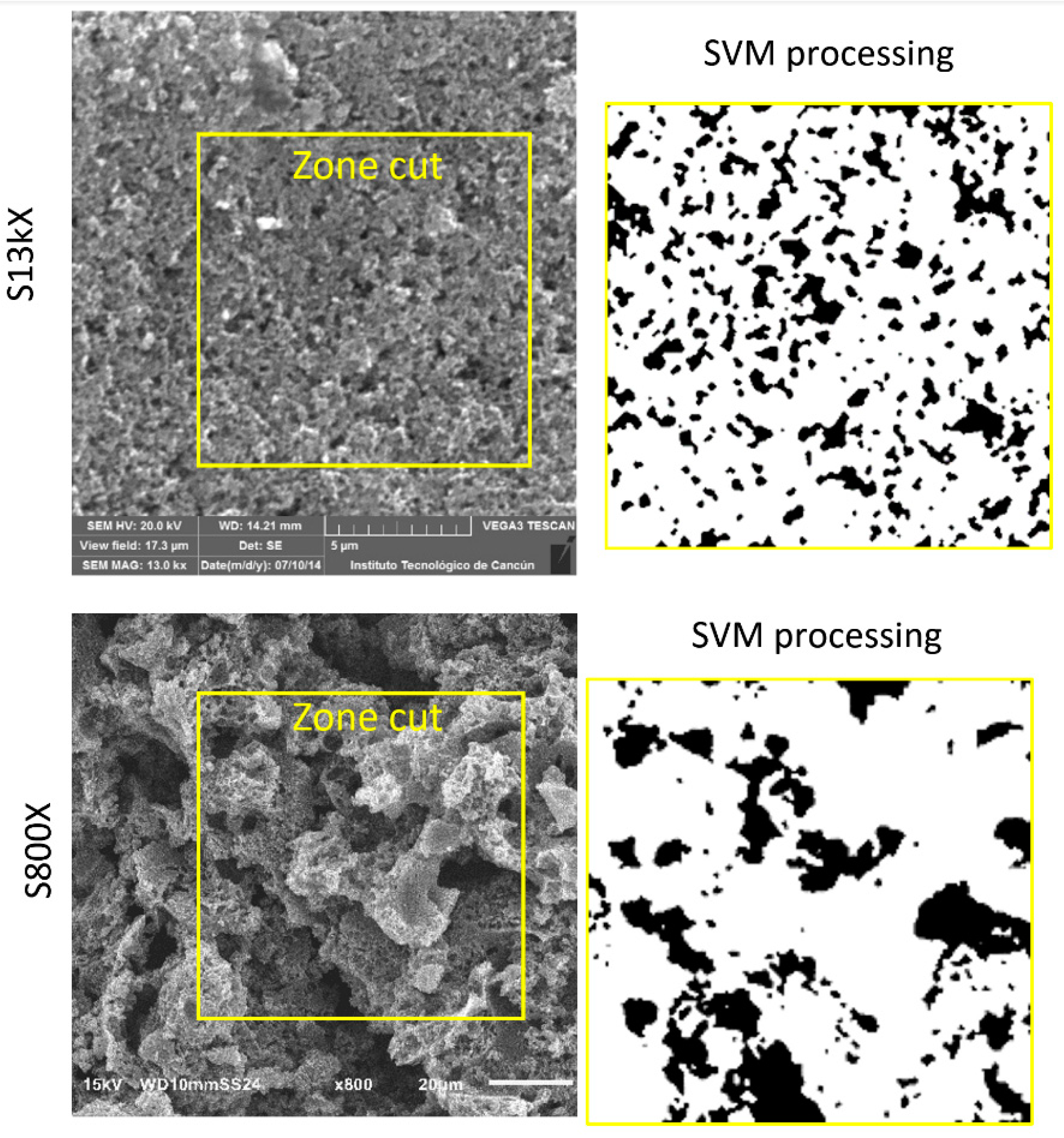

2.2. Microstructure Reconstruction

2.3. Topological Entropy

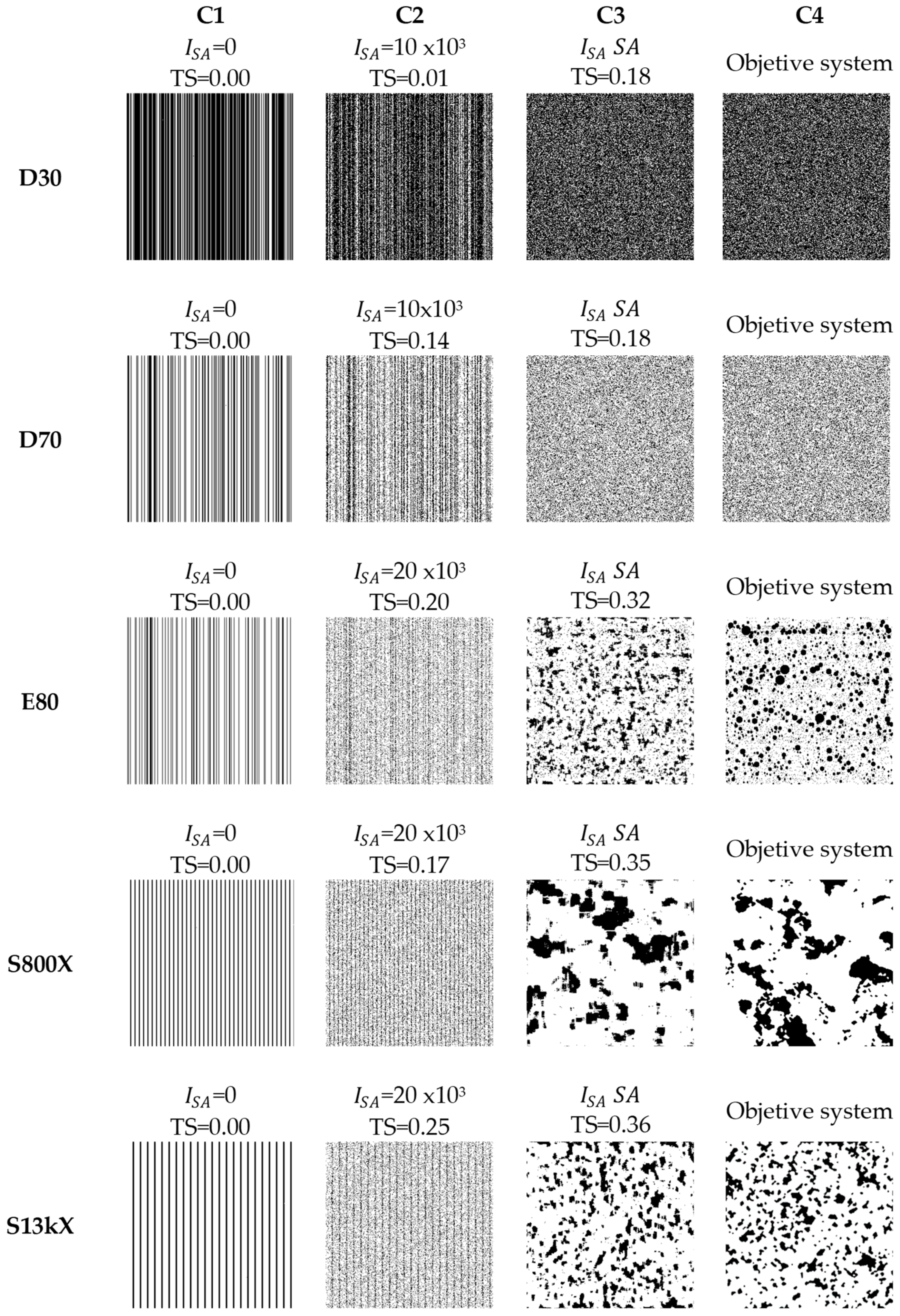

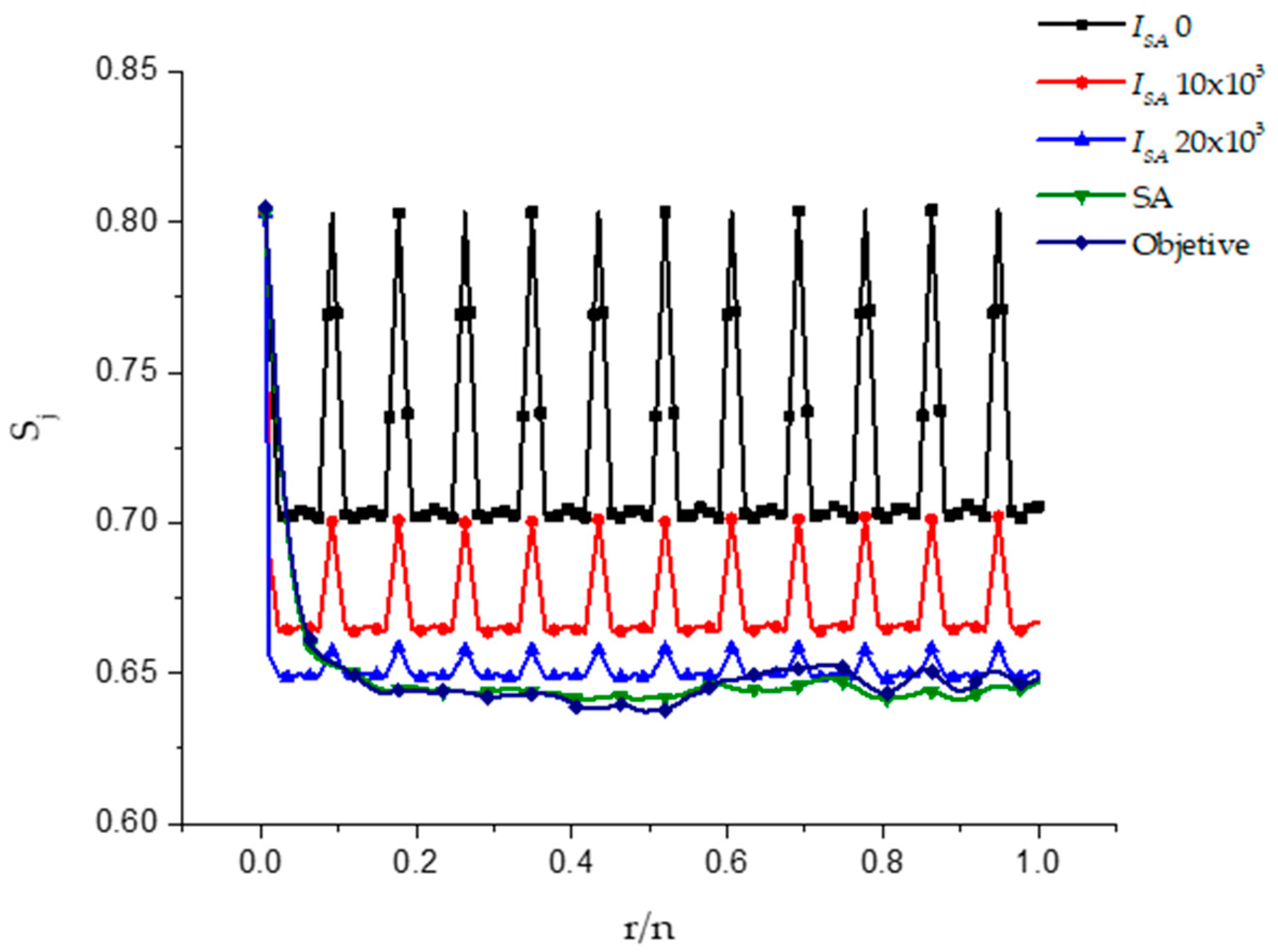

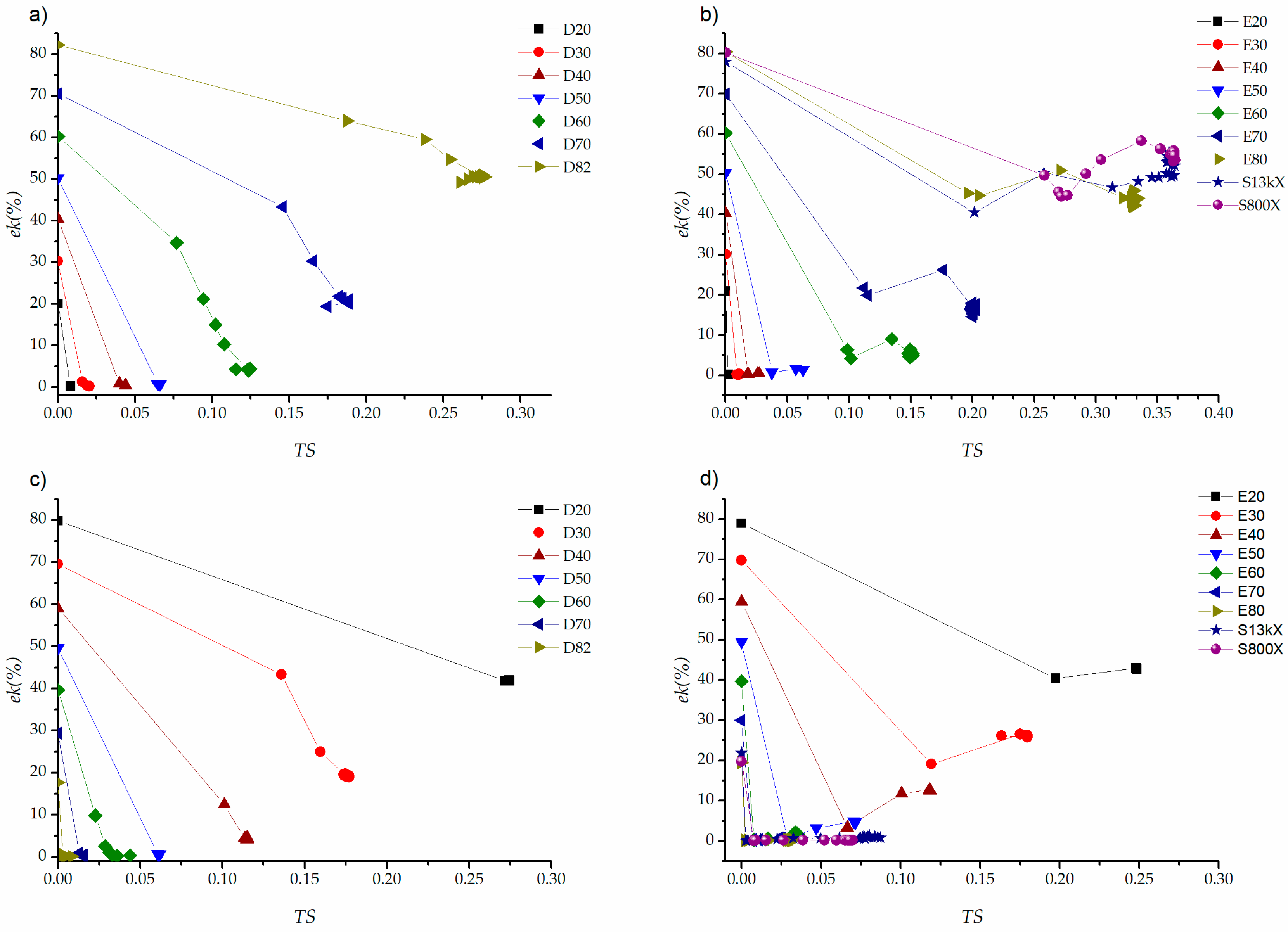

3. Results and Discussion

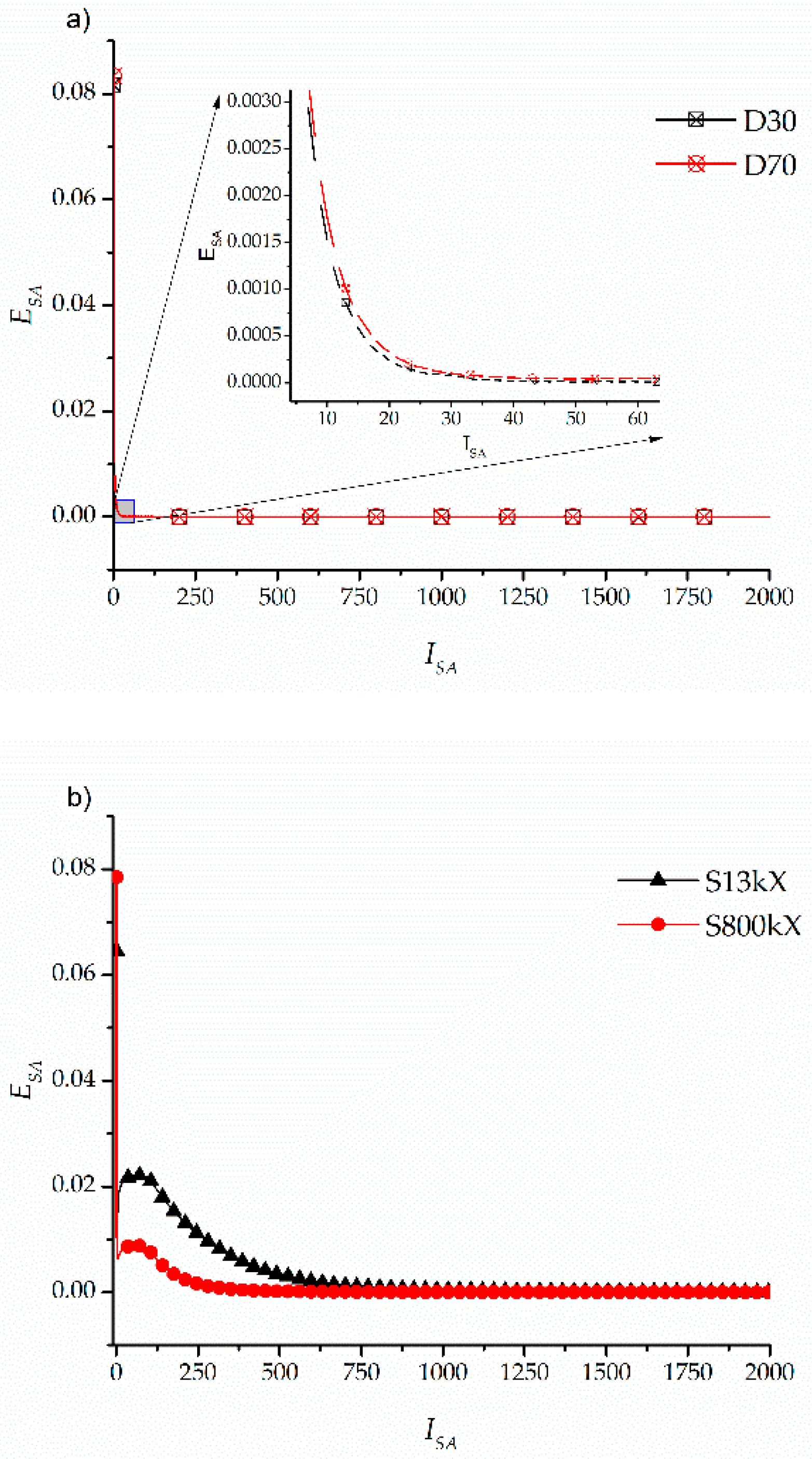

3.1. Reconstruction Process

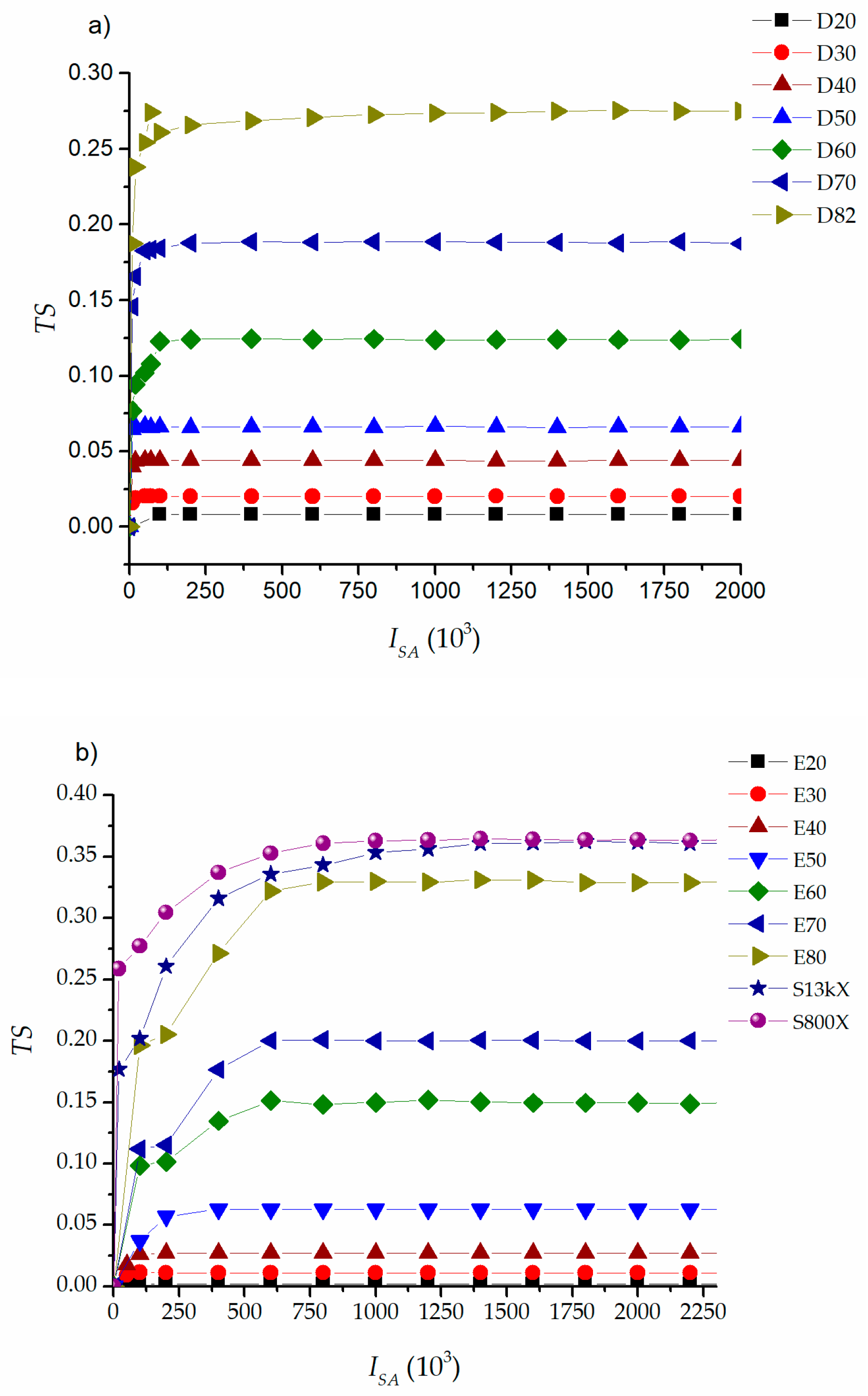

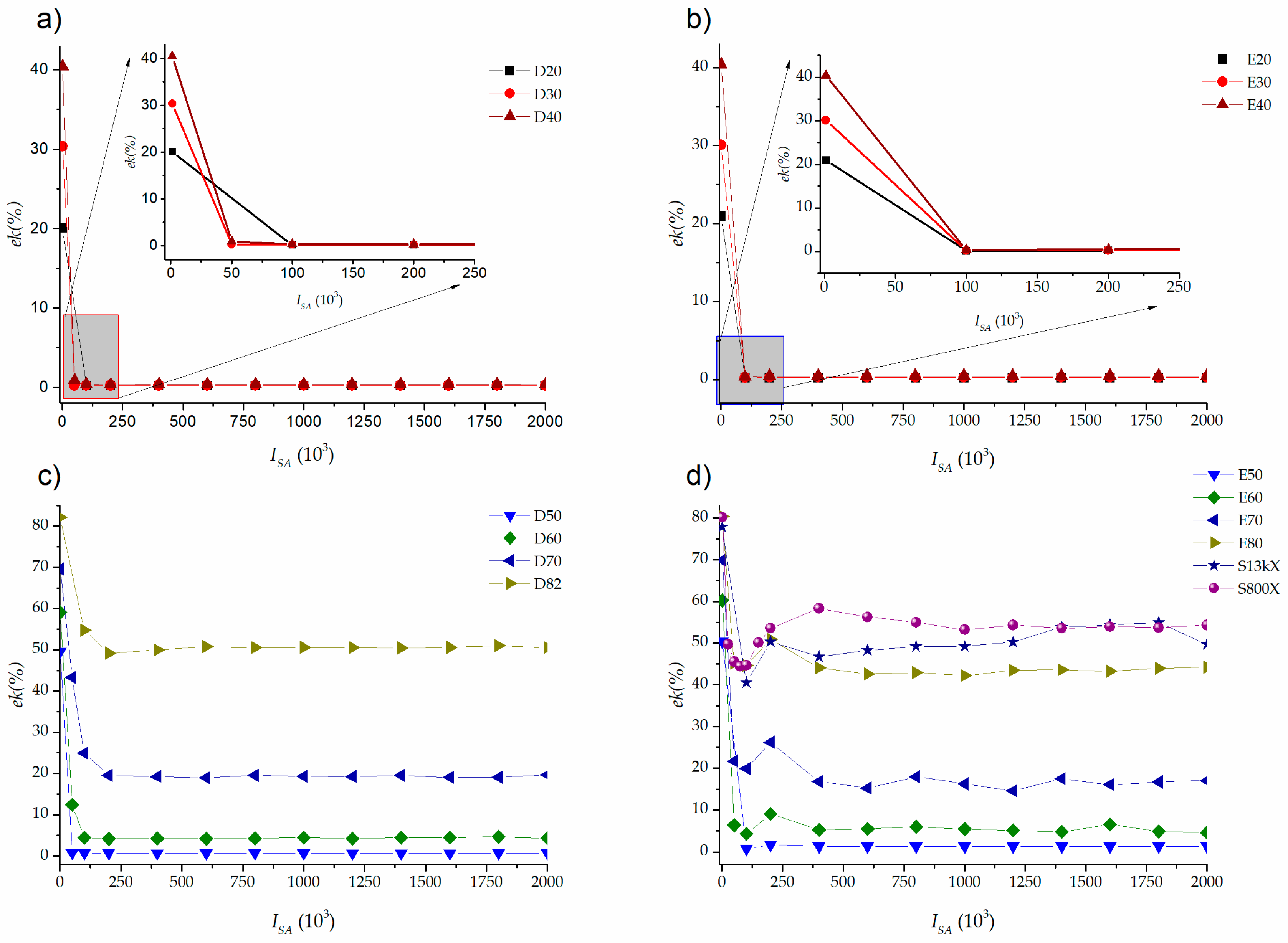

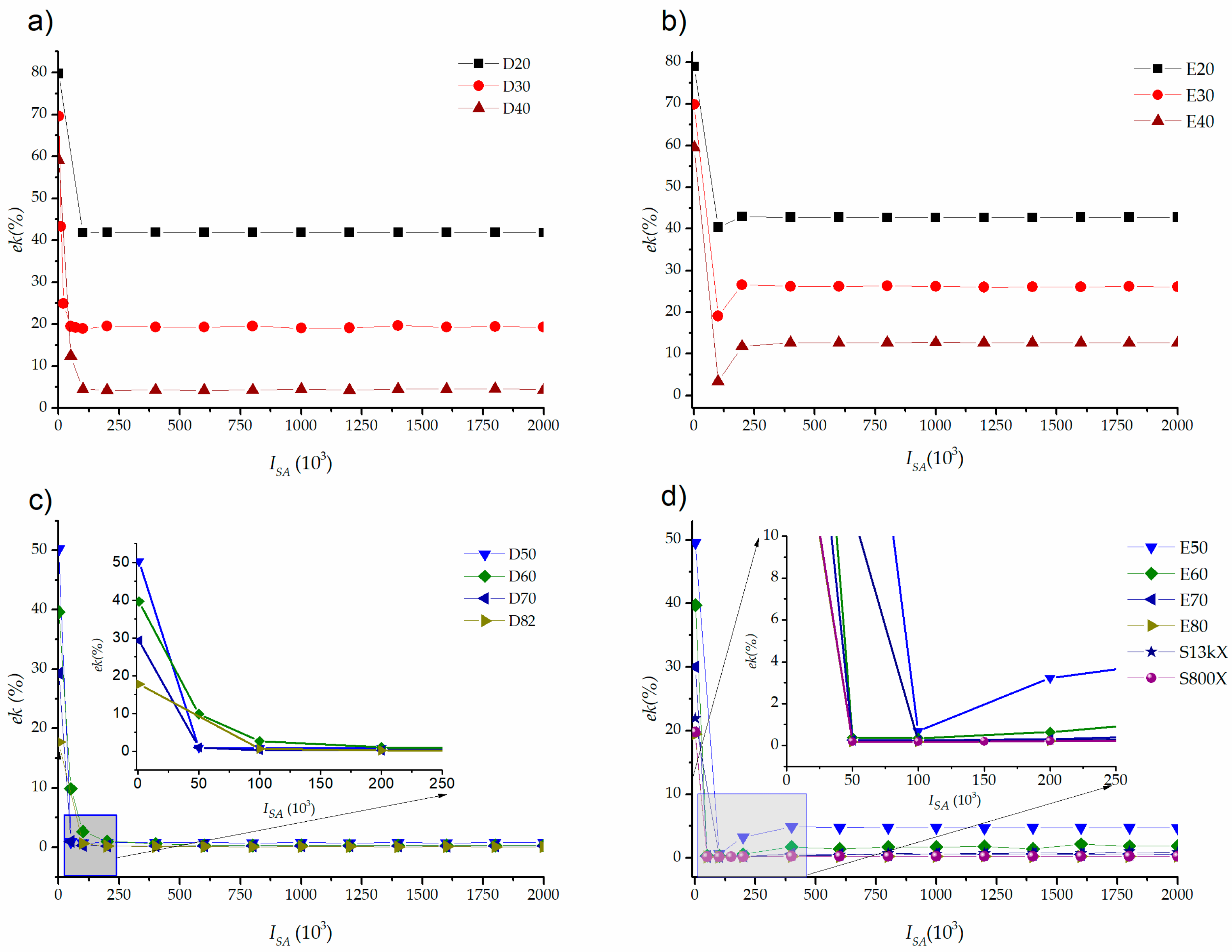

3.2. Effective Transport Coefficient

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, M.C.; Lou, C.W.; Lin, J.Y.; Lin, T.A.; Lin, J.H. Mechanical property evaluations of flexible laminated composites reinforced by high-performance Kevlar filaments: Tensile strength, peel load, and static puncture resistance. Compos. Part B Eng. 2019, 166, 139–147. [Google Scholar] [CrossRef]

- Huang, Z.H.; Zhou, Y.J.; Nguyen, T.T. Study of nickel matrix composite coatings deposited from electroless plating bath loaded with TiB2, ZrB2 and TiC particles for improved wear and corrosion resistance. Surf. Coat. Technol. 2019, 364, 323–329. [Google Scholar] [CrossRef]

- Han, B.; Chen, H.; Hu, T.; Ye, H.; Xu, L. High electrical conductivity in polydimethylsiloxane composite with tailored graphene foam architecture. J. Mol. Struct. 2020, 1203, 127416. [Google Scholar] [CrossRef]

- Blassiau, S.; Thionnet, A.; Bunsell, A.R. Micromechanisms of load transfer in a unidirectional carbon fibre-reinforced epoxy composite due to fibre failures: Part 3. Multiscale reconstruction of composite behaviour. Compos. Struct. 2008, 83, 312–323. [Google Scholar] [CrossRef]

- Wu, X.; Tang, L.; Zheng, S.; Huang, Y.; Yang, J.; Liu, Z.; Yang, W.; Yang, M. Hierarchical unidirectional graphene aerogel/polyaniline composite for high performance supercapacitors. J. Power Sources 2018, 397, 189–195. [Google Scholar] [CrossRef]

- Mao, N.; Chen, W.; Meng, J.; Li, Y.; Zhang, K.; Qin, X.; Zhang, H.; Zhang, C.; Qiu, Y.; Wang, S. Enhanced electrochemical properties of hierarchically sheath-core aligned carbon nanofibers coated carbon fiber yarn electrode-based supercapacitor via polyaniline nanowire array modification. J. Power Sources 2018, 399, 406–413. [Google Scholar] [CrossRef]

- Wang, X.; Zhai, H.; Qie, B.; Cheng, Q.; Li, A.; Borovilas, J.; Xu, B.; Shi, C.; Jin, T.; Liao, X.; et al. Rechargeable solid-state lithium metal batteries with vertically aligned ceramic nanoparticle/polymer composite electrolyte. Nano Energy 2019, 60, 205–212. [Google Scholar] [CrossRef]

- Liu, W.; Lee, S.W.; Lin, D.; Shi, F.; Wang, S.; Sendek, A.D.; Cui, Y. Enhancing ionic conductivity in composite polymer electrolytes with well-aligned ceramic nanowires. Nat. Energy 2017, 2, 17035. [Google Scholar] [CrossRef]

- Shin, S.; Liu, J.; Akbar, A.; Um, S. Nanoscale transport characteristics and catalyst utilization of vertically aligned carbon nanotube catalyst layers for fuel cell applications: Comprehensive stochastic modeling of composite morphological structures. J. Catal. 2019, 377, 465–479. [Google Scholar] [CrossRef]

- Mench, M.M. Fuel Cell Engines; John Wiley & Sons: Hoboken, NJ, USA, 2008; ISBN 0471689580. [Google Scholar]

- O’hayre, R.; Cha, S.-W.; Colella, W.; Prinz, F.B. Fuel Cell Fundamentals; John Wiley & Sons: Hoboken, NJ, USA, 2016; ISBN 1119113806. [Google Scholar]

- Chhowalla, M.; Teo, K.B.K.; Ducati, C.; Rupesinghe, N.L.; Amaratunga, G.A.J.; Ferrari, A.C.; Roy, D.; Robertson, J.; Milne, W.I. Growth process conditions of vertically aligned carbon nanotubes using plasma enhanced chemical vapor deposition. J. Appl. Phys. 2001, 90, 5308–5317. [Google Scholar] [CrossRef]

- Jakubinek, M.B.; White, M.A.; Li, G.; Jayasinghe, C.; Cho, W.; Schulz, M.J.; Shanov, V. Thermal and electrical conductivity of tall, vertically aligned carbon nanotube arrays. Carbon N. Y. 2010, 48, 3947–3952. [Google Scholar] [CrossRef]

- Yasuda, S.; Furuya, A.; Uchibori, Y.; Kim, J.; Murakoshi, K. Iron–nitrogen-doped vertically aligned carbon nanotube electrocatalyst for the oxygen reduction reaction. Adv. Funct. Mater. 2016, 26, 738–744. [Google Scholar] [CrossRef]

- Tian, Z.Q.; Lim, S.H.; Poh, C.K.; Tang, Z.; Xia, Z.; Luo, Z.; Shen, P.K.; Chua, D.; Feng, Y.P.; Shen, Z. A highly order-structured membrane electrode assembly with vertically aligned carbon nanotubes for ultra-low Pt loading PEM fuel cells. Adv. Energy Mater. 2011, 1, 1205–1214. [Google Scholar] [CrossRef]

- Murata, S.; Imanishi, M.; Hasegawa, S.; Namba, R. Vertically aligned carbon nanotube electrodes for high current density operating proton exchange membrane fuel cells. J. Power Sources 2014, 253, 104–113. [Google Scholar] [CrossRef]

- Barbosa, R.; Andaverde, J.; Escobar, B.; Cano, U. Stochastic reconstruction and a scaling method to determine effective transport coefficients of a proton exchange membrane fuel cell catalyst layer. J. Power Sources 2011, 196, 1248–1257. [Google Scholar] [CrossRef]

- Torquato, S. Theory of random heterogeneous materials. In Handbook of Materials Modeling; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1333–1357. [Google Scholar]

- Cano-Castillo, U.; Barbosa-Pool, R. Chapter 2: Reconstruction of PEM fuel cell electrodes with micro- and nano-structures. In Micro & Nano-Engineering of Fuel Cells; Xuan, J., Ed.; Taylor and Francis Group, CRC Press: London, UK, 2015. [Google Scholar]

- Garnett, J.C.M. Colours in metal glasses, in metallic films and in metallic solutions.—II. Proc. R. Soc. Lond. A 1905, 76, 370–373. [Google Scholar]

- Bruggeman, D.A.G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. II. Dielektrizitätskonstanten und Leitfähigkeiten von Vielkristallen der nichtregulären Systeme. Ann. Phys. 1936, 417, 645–672. [Google Scholar] [CrossRef]

- Ortegon, J.; Ledesma-Alonso, R.; Barbosa, R.; Castillo, J.V.; Atoche, A.C. Material phase classification by means of Support Vector Machines. Comput. Mater. Sci. 2018, 148, 336–342. [Google Scholar] [CrossRef] [Green Version]

- Ledesma-Alonso, R.; Barbosa, R.; Ortegón, J. Effect of the image resolution on the statistical descriptors of heterogeneous media. Phys. Rev. E 2018, 97, 23304. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez, A.; Barbosa, R.; Rios, A.; Ortegon, J.; Escobar, B.; Gayosso, B.; Couder, C. Effect of An Image Resolution Change on the Effective Transport Coefficient of Heterogeneous Materials. Materials 2019, 12, 3757. [Google Scholar] [CrossRef] [Green Version]

- Earnshaw, J.C.; Robinson, D.J. Inter-cluster scaling in two-dimensional colloidal aggregation. Phys. A Stat. Mech. Its Appl. 1995, 214, 23–51. [Google Scholar] [CrossRef]

- Torquato, S. Random Heterogeneous Materials: Microstructure and Macroscopic Properties; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 16, ISBN 1475763557. [Google Scholar]

- Torquato, S.; Haslach, H.W., Jr. Random heterogeneous materials: Microstructure and macroscopic properties. Appl. Mech. Rev. 2002, 55, B62–B63. [Google Scholar] [CrossRef]

- Bochenek, B.; Pyrz, R. Reconstruction of random microstructures—A stochastic optimization problem. Comput. Mater. Sci. 2004, 31, 93–112. [Google Scholar] [CrossRef]

- Moncho-Jordá, A.; Martınez-López, F.; Hidalgo-Álvarez, R. Simulations of aggregation in 2D. A study of kinetics, structure and topological properties. Phys. A Stat. Mech. Its Appl. 2000, 282, 50–64. [Google Scholar] [CrossRef]

| Name | Φ Matrix | Φ Dispersion | Diameter | Size |

|---|---|---|---|---|

| D20 | 20.10 | 79.80 | 1 | 300 × 300 |

| D30 | 30.33 | 69.55 | 1 | 300 × 300 |

| D40 | 40.25 | 58.91 | 1 | 300 × 300 |

| D50 | 50.27 | 49.61 | 1 | 300 × 300 |

| D60 | 60.24 | 39.64 | 1 | 300 × 300 |

| D70 | 70.55 | 29.34 | 1 | 300 × 300 |

| D82 | 82.18 | 17.71 | 1 | 300 × 300 |

| E20 | 20.81 | 79.19 | Random | 350 × 350 |

| E30 | 30.25 | 69.75 | Random | 350 × 350 |

| E40 | 40.61 | 59.39 | Random | 350 × 350 |

| E50 | 50.50 | 49.50 | Random | 350 × 350 |

| E60 | 60.21 | 39.70 | Random | 350 × 350 |

| E70 | 69.90 | 30.01 | Random | 350 × 350 |

| E80 | 80.16 | 19.75 | Random | 350 × 350 |

| S13kX | 77.88 | 22.03 | SEM | 350 × 350 |

| S800X | 80.16 | 19.75 | SEM | 350 × 350 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pacheco, C.; Barbosa, R.; Rodriguez, A.; Oskam, G.; Ruiz-Gómez, M.; Escobar, B. Numerical Simulation to Determine the Effect of Topological Entropy on the Effective Transport Coefficient of Unidirectional Composites. Crystals 2020, 10, 423. https://doi.org/10.3390/cryst10060423

Pacheco C, Barbosa R, Rodriguez A, Oskam G, Ruiz-Gómez M, Escobar B. Numerical Simulation to Determine the Effect of Topological Entropy on the Effective Transport Coefficient of Unidirectional Composites. Crystals. 2020; 10(6):423. https://doi.org/10.3390/cryst10060423

Chicago/Turabian StylePacheco, Carlos, Romeli Barbosa, Abimael Rodriguez, Gerko Oskam, Miguel Ruiz-Gómez, and Beatriz Escobar. 2020. "Numerical Simulation to Determine the Effect of Topological Entropy on the Effective Transport Coefficient of Unidirectional Composites" Crystals 10, no. 6: 423. https://doi.org/10.3390/cryst10060423