Effect of Scan Length on Densification and Crystallographic Texture Formation of Pure Chromium Fabricated by Laser Powder Bed Fusion

Abstract

:1. Introduction

- The effect of energy density on densification of pure W showed an increase in bulk density up to 97% with increasing the energy density, while micro cracks and defects still existed due to the residual stress [21].

- Preheating the build platform to reduce the temperature gradient in the as-built component has been among the most commonly used methods. It was reported that preheating reduced residual stress by 46% and increased density by 2.9%, while considering that preheat can reach higher than the DBTT to improve ductility of the build part [22].

- The remelting of the processed layer during LPBF improved the surface quality and microstructure, achieving 98.4% relative density regarding the recovery of cracks with a subsequent scan [23].

- The scan strategy affects the heat distribution and ultimately the defect location and distribution. Generally, an island scan strategy is suggested to avoid the accumulation of defects by homogenizing the residual stress distribution by dividing the scan area into small islands, resulting in a reduction in scan length [24].

- Therefore, LPBF fabrication with short scan length to decrease the defects and cracks showed reduced residual stress due to short time intervals between tracks and layers, uniform thermal distribution, small thermal gradient, and overall high ambient temperature during processing [25].

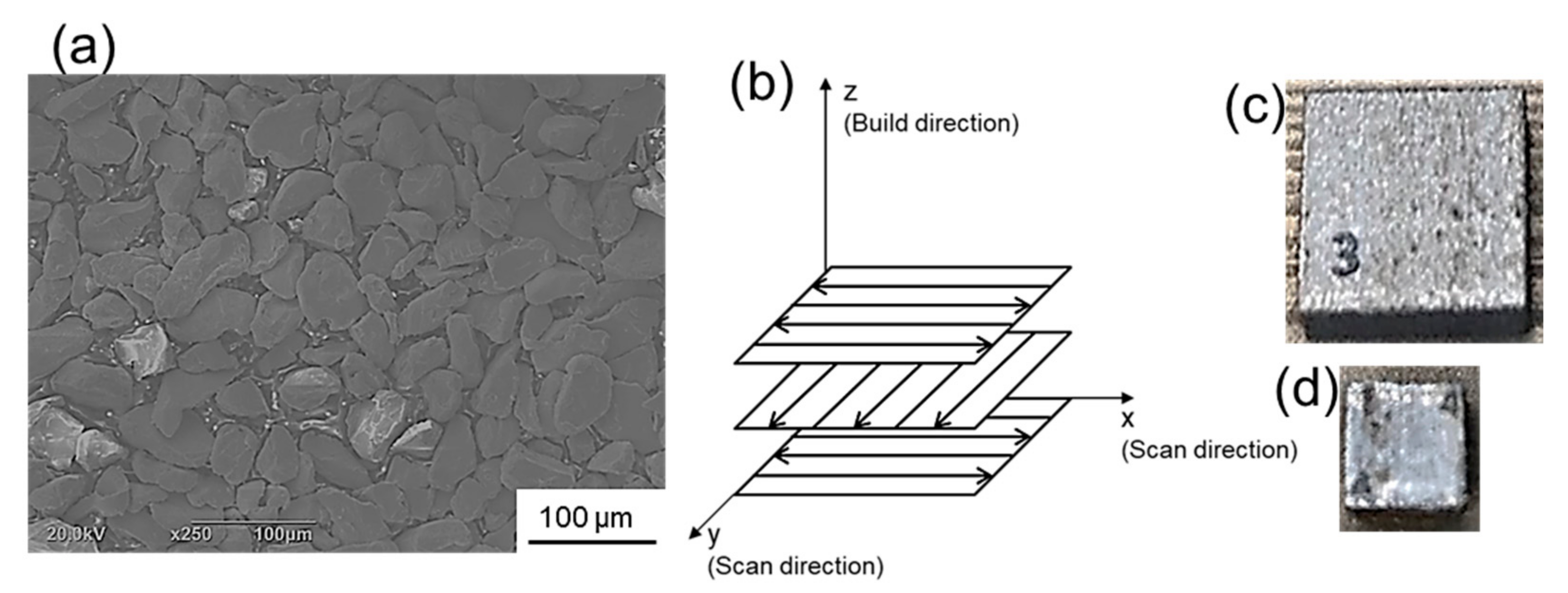

2. Materials and Methods

3. Results and Discussion

3.1. LPBF Processing and Densification

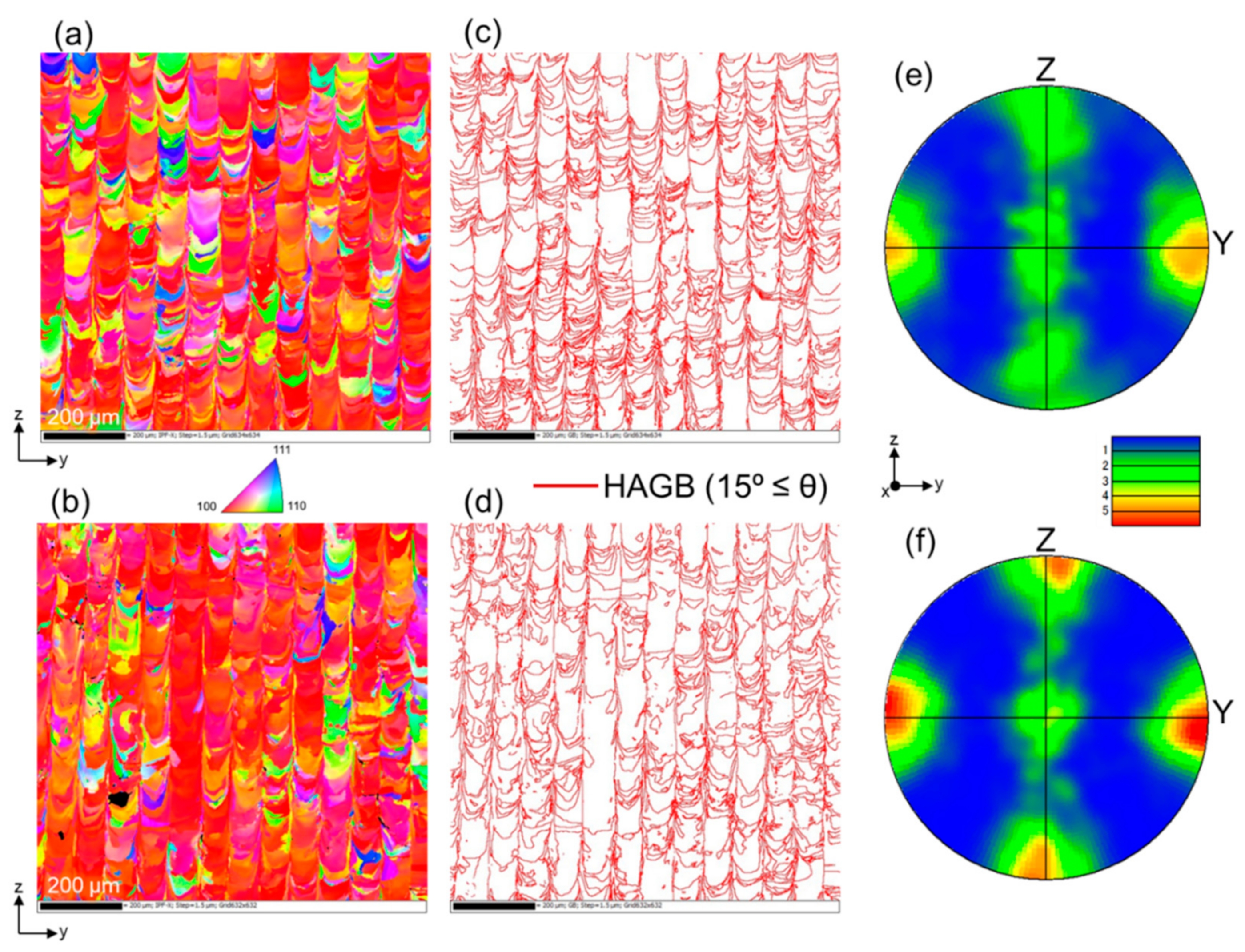

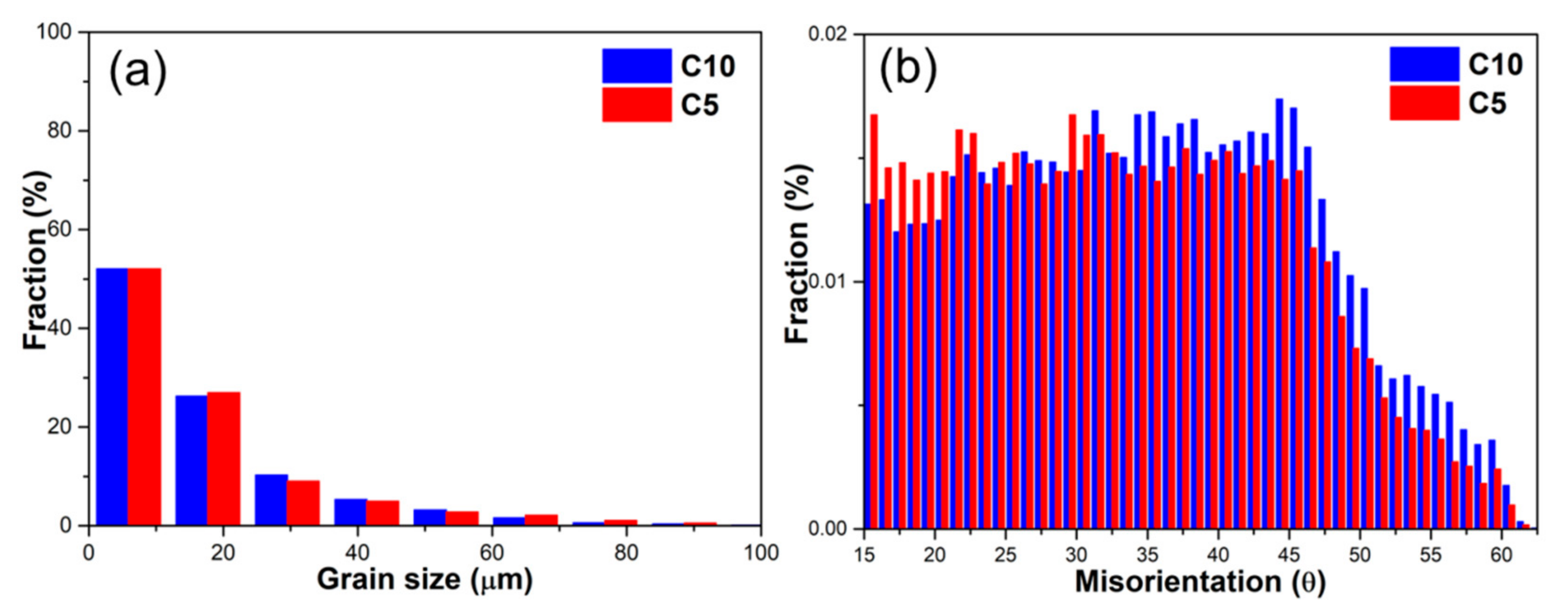

3.2. Microstructure and Crystallographic Texture

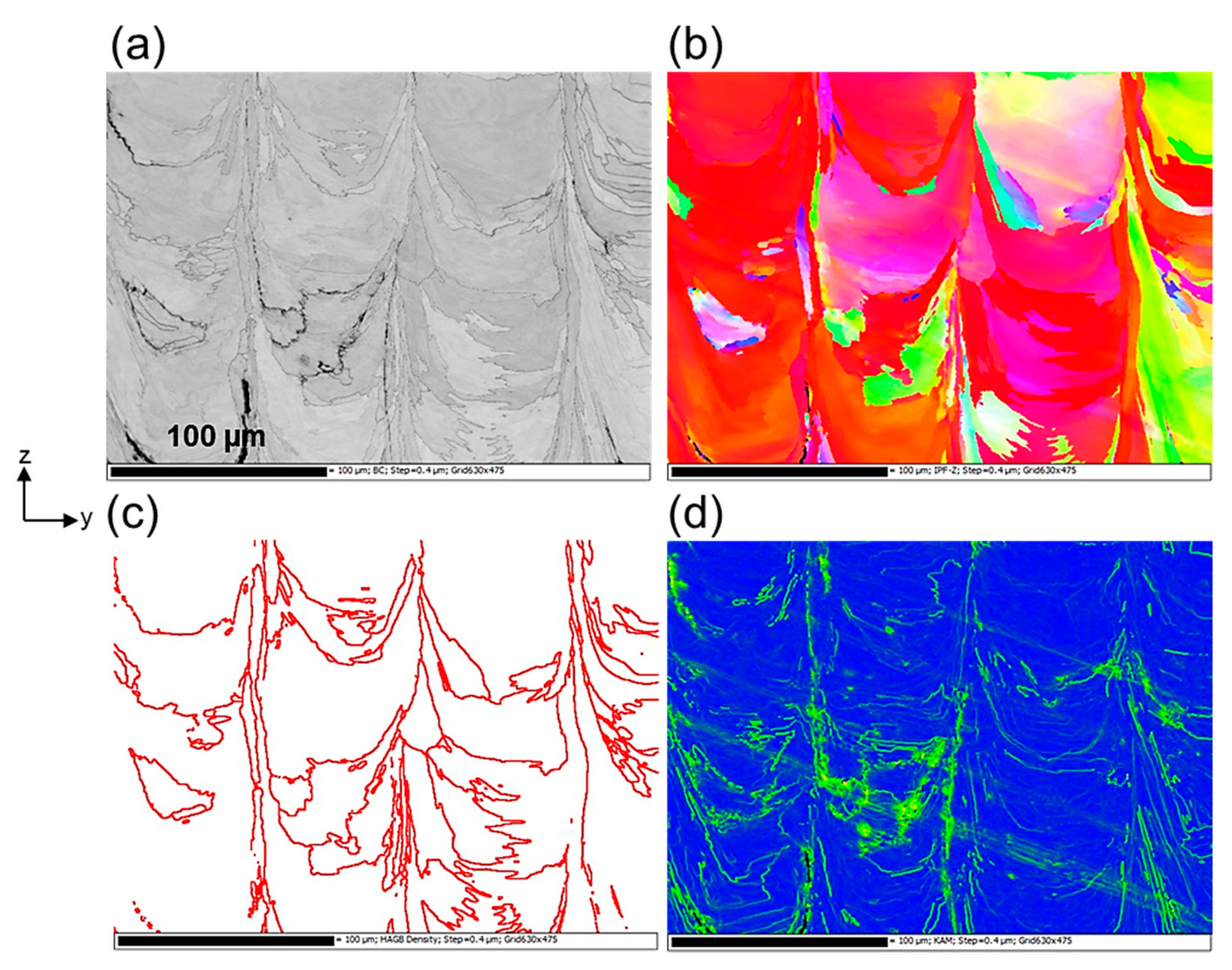

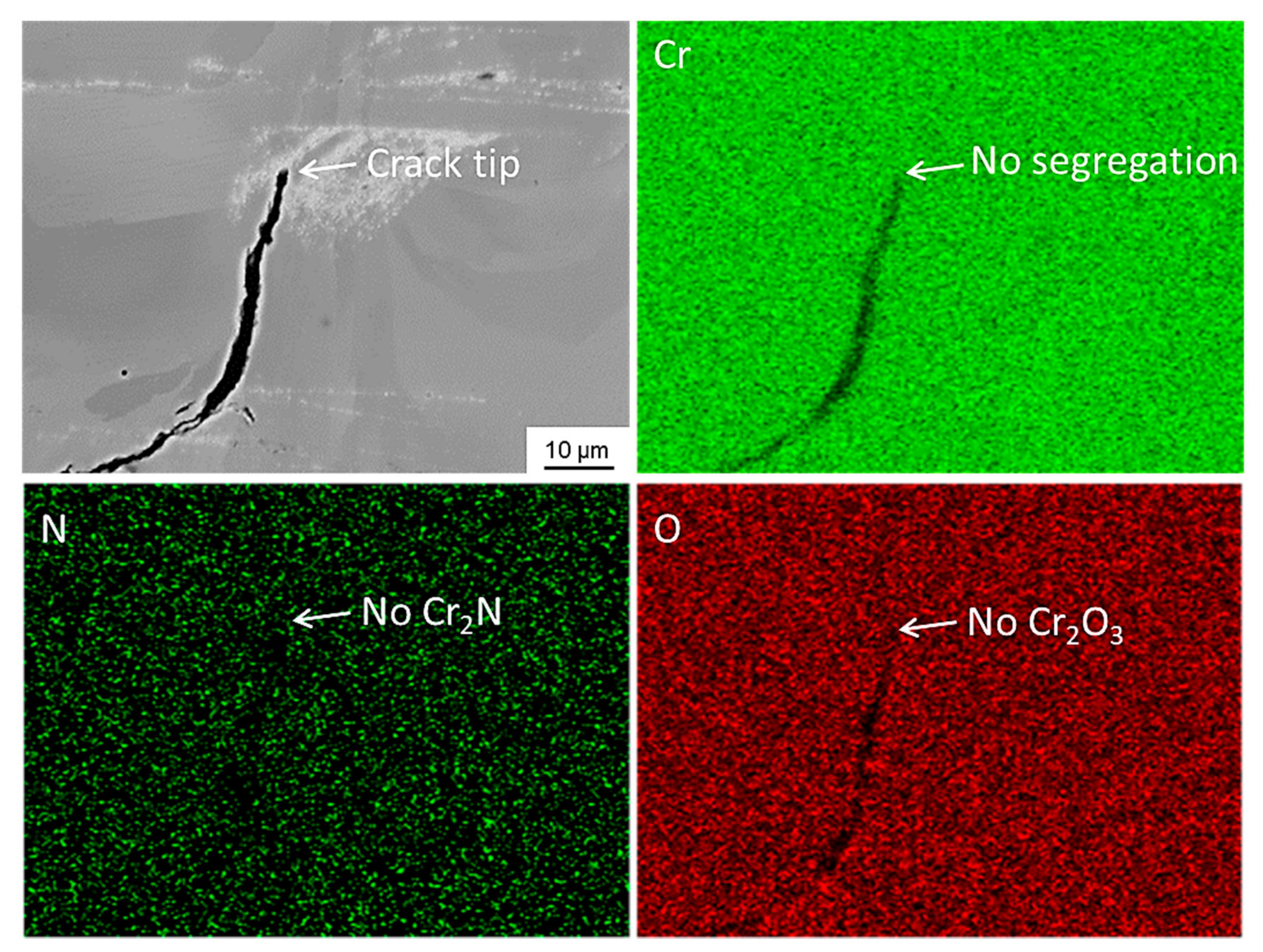

3.3. Crack Formation and Hardness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Klopp, W.D. Recent developments in chromium and chromium alloys. JOM 1969, 21, 23–32. [Google Scholar] [CrossRef] [Green Version]

- Medvedeva, N.I.; Gornostyrev, Y.N.; Freeman, A.J. Carbon stabilized A15 Cr3Re precipitates and ductility enhancement of Cr-based alloys. Acta Mater. 2002, 50, 2471–2476. [Google Scholar] [CrossRef]

- Gu, Y.F.; Ro, Y.; Harada, H. Tensile properties of chromium alloyed with silver. Metall. Mater. Trans. A 2004, 35, 3329–3331. [Google Scholar] [CrossRef]

- Wilms, G.R.; Rea, T.W. Atmospheric contamination of chromium and its effect on mechanical properties. J. Less Common Met. 1959, 1, 152–156. [Google Scholar] [CrossRef]

- Henderson, F.; Quaass, S.T.; Wain, H.L. The fabrication of chromium and some dilute chromium-base alloys. J. Inst. Metals. 1954, 83, 4400440. [Google Scholar]

- Wang, P.; Lib, X.; Jianga, Y.; Nai, M.L.S.; Ding, J.; Wei, J. Electron beam melted heterogeneously porous microlattices for metallic bone applications: Design and investigations of boundary and edge effects. Addit. Manuf. 2020, 36, 101566. [Google Scholar] [CrossRef]

- Plocher, J.; Panesar, A. Review on design and structural optimisation in additive manufacturing: Towards next-generation lightweight structures. Mater. Des. 2019, 183, 108164. [Google Scholar] [CrossRef]

- Ishimoto, T.; Ozasa, R.; Nakano, K.; Weinmann, M.; Schnitter, C.; Stenzel, M.; Matsugaki, A.; Nagase, T.; Matsuzaka, T.; Todai, M. Development of TiNbTaZrMo bio–high entropy alloy (BioHEA) super–solid solution by selective laser melting, and its improved mechanical property and biocompatibility. Scr. Mater. 2021, in press. [Google Scholar] [CrossRef]

- Wang, P.; Li, X.; Luo, S.; Nai, M.L.S.; Ding, J.; Wei, J. Additively manufactured heterogeneously porous metallic bone with biostructural functions and bone-like mechanical properties. J. Mater. Sci. Technol. 2021, 62, 173–179. [Google Scholar] [CrossRef]

- Tancogne-Dejean, T.; Spierings, A.B.; Mohr, D. Additively-manufactured metallic micro-lattice materials for high specific energy absorption under static and dynamic loading. Acta Mater. 2016, 116, 14–28. [Google Scholar] [CrossRef]

- Wang, P.; Song, J.; Nai, M.L.S.; Wei, J. Experimental analysis of additively manufactured component and design guidelines for lightweight structures: A case study using electron beam melting. Addit. Manuf. 2020, 33, 101088. [Google Scholar] [CrossRef]

- Field, A.C.; Carter, L.N.; Adkins, N.J.E.; Attallah, M.M.; Gorley, M.J.; Strangwood, M. The effect of powder characteristics on build quality of high-purity tungsten produced via laser powder bed fusion (LPBF). Metal. Mater. Trans. A 2020, 51, 1367–1378. [Google Scholar] [CrossRef] [Green Version]

- Hu, Z.; Zhao, Y.; Guan, K.; Wang, Z.; Ma, Z. Pure tungsten and oxide dispersion strengthened tungsten manufactured by selective laser melting: Microstructure and cracking mechanism. Addit. Manuf. 2020, 36, 101579. [Google Scholar] [CrossRef]

- Hagihara, K.; Nakano, T.; Suzuki, M.; Ishimoto, T.; Sun, S.H. Successful additive manufacturing of MoSi2 including crystallographic texture and shape control. J. Alloy Compd. 2017, 696, 67–72. [Google Scholar] [CrossRef] [Green Version]

- Gokcekaya, O.; Hayashi, N.; Ishimoto, T.; Ueda, K.; Narushima, T.; Nakano, T. Crystallographic orientation control of pure chromium via laser powder-bed fusion and improved high temperature oxidation resistance. Addit. Manuf. 2020. [Google Scholar] [CrossRef]

- Yin, B.; Ma, H.; Wang, J.; Fang, K.; Zhao, H.; Liu, Y. Effect of CaF2 addition on macro/microstructures and mechanical properties of wire and arc additive manufactured Ti-6Al-4V components. Mater. Lett. 2017, 190, 64–66. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Otis, R.A.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; Liu, Z.-K.; Beese, A.M. Additive manufacturing of a functionally graded material from Ti-6Al-4V to Invar: Experimental characterization and thermodynamic calculations. Acta Mater. 2017, 127, 133–142. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect formation mechanisms in selective laser melting: A review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef] [Green Version]

- Sims, C.T. The case for chromium. JOM 1963, 15, 127–132. [Google Scholar] [CrossRef]

- Wang, D.Z.; Li, K.L.; Yu, C.F.; Ma, J.; Liu, W.; Shen, Z.J. Cracking behavior in additively manufactured pure tungsten. Acta Metall. Sin. 2019, 32, 127–135. [Google Scholar] [CrossRef] [Green Version]

- Sidambe, A.T.; Tian, Y.; Prangnell, P.B.; Fox, P. Effect of processing parameters on the densification, microstructure and crystallographic texture during the laser powder bed fusion of pure tungsten. Int. J. Refract. Met. Hard Mater. 2019, 78, 254–263. [Google Scholar] [CrossRef]

- Malý, M.; Höller, C.; Skalon, M.; Meier, B.; Koutný, D.; Pichler, R.; Sommitsch, C.; Paloušek, D. Effect of process parameters and high-temperature preheating on residual stress and relative density of Ti6Al4V processed by selective laser melting. Materials 2019, 12, 930. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiong, Z.; Zhang, P.; Tan, C.; Dong, D.; Ma, W.; Yu, K. Selective laser melting and remelting of pure tungsten. Adv. Eng. Mater. 2020, 22, 1901352. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Yang, Y.; Dou, W.; Deng, S.; Wang, Z.; Li, S. The effect of a scanning strategy on the residual stress of 316L steel parts fabricated by Selective Laser Melting (SLM). Materials 2018, 11, 1821. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Phutela, C.; Aboulkhair, N.T.; Tuck, C.J.; Ashcroft, I. The effects of feature sizes in selectively laser melted Ti-6Al-4V parts on the validity of optimised process parameters. Materials 2019, 13, 117. [Google Scholar] [CrossRef] [Green Version]

- Cheng, B.; Shrestha, S.; Chou, K. Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit. Manuf. 2016, 12, 240–251. [Google Scholar] [CrossRef]

- Sun, S.-H.; Hagihara, K.; Nakano, T. Effect of scanning strategy on texture formation in Ni-25 at.%Mo alloys fabricated by selective laser melting. Mater. Des. 2018, 140, 307–316. [Google Scholar] [CrossRef]

- Fang, Z.-C.; Wu, Z.-L.; Huang, C.-G.; Wu, C.-W. Review on residual stress in selective laser melting additive manufacturing of alloy parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- Li, C.; Fu, C.H.; Guo, Y.B.; Fang, F.Z. A multiscale modeling approach for fast prediction of part distortion in selective laser melting. J. Mater. Process. Technol. 2016, 229, 703–712. [Google Scholar] [CrossRef]

- Zhou, W.; Zhu, G.; Wang, R.; Yang, C.; Tian, Y.; Zhang, L.; Dong, A.; Wang, D.; Shu, D.; Sun, B. Inhibition of cracking by grain boundary modification in a non-weldable nickel-based superalloy processed by laser powder bed fusion. Mater. Sci. Eng. A 2020, 791, 139745. [Google Scholar] [CrossRef]

- Wang, Y.C.; Lei, L.M.; Shi, L.; Wan, H.Y.; Liang, F.; Zhang, G.P. Scanning strategy dependent tensile properties of selective laser melted GH4169. Mater. Sci. Eng. A 2020, 788, 139616. [Google Scholar] [CrossRef]

- Ishimoto, T.; Hagihara, K.; Hisamoto, K.; Sun, S.-H.; Nakano, T. Crystallographic texture control of beta-type Ti–15Mo–5Zr–3Al alloy by selective laser melting for the development of novel implants with a biocompatible low Young’s modulus. Scr. Mater. 2017, 132, 34–38. [Google Scholar] [CrossRef]

- Sun, S.-H.; Ishimoto, T.; Hagihara, K.; Tsutsumi, Y.; Hanawa, T.; Nakano, T. Excellent mechanical and corrosion properties of austenitic stainless steel with a unique crystallographic lamellar microstructure via selective laser melting. Scr. Mater. 2019, 159, 89–93. [Google Scholar] [CrossRef]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An experimental investigation into additive manufacturing-induced residual stresses in 316L stainless steel. Metall. Mater. Trans. A 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Dubrovinskaia, N.A.; Dubrovinsky, L.S.; Saxena, S.K.; Sundman, B. Thermal expansion of Chromium (Cr) to melting temperature. Calphad 1997, 21, 497–508. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Xu, L.; Xu, J.; Ren, X.; Chen, X. Cracking mechanism and susceptibility of laser melting deposited Inconel 738 superalloy. Mater. Des. 2019, 183, 108105. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Z.; Li, K.; Ma, J.; Liu, W.; Shen, Z. Cracking in laser additively manufactured W: Initiation mechanism and a suppression approach by alloying. Mater. Des. 2019, 162, 384–393. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Gouge, M.; Irwin, J.; Michaleris, P. Thermomechanical model development and in situ experimental validation of the Laser Powder-Bed Fusion process. Addit. Manuf. 2017, 16, 73–80. [Google Scholar] [CrossRef]

- Vrancken, B.; Cain, V.; Knutsen, R.; Van Humbeeck, J. Residual stress via the contour method in compact tension specimens produced via selective laser melting. Scr. Mater. 2014, 87, 29–32. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.Y.; Li, H.Q.; Qin, C.X.; Zong, R.; Fang, X.Y. The effect of energy density on texture and mechanical anisotropy in selective laser melted Inconel 718. Mater. Des. 2020, 191, 108642. [Google Scholar] [CrossRef]

- Thijs, L.; Montero Sistiaga, M.L.; Wauthle, R.; Xie, Q.; Kruth, J.-P.; Van Humbeeck, J. Strong morphological and crystallographic texture and resulting yield strength anisotropy in selective laser melted tantalum. Acta Mater. 2013, 61, 4657–4668. [Google Scholar] [CrossRef] [Green Version]

- Boes, J.; Röttger, A.; Theisen, W. Microstructure and properties of high-strength C + N austenitic stainless steel processed by laser powder bed fusion. Addit. Manuf. 2020, 32, 101081. [Google Scholar] [CrossRef]

- Sabzi, H.E.; Maeng, S.; Liang, X.; Simonelli, M.; Aboulkhair, N.T.; Rivera-Díaz-del-Castillo, P.E.J. Controlling crack formation and porosity in laser powder bed fusion: Alloy design and process optimisation. Addit. Manuf. 2020, 34, 101360. [Google Scholar] [CrossRef]

| Abbreviation | Linear Energy Density | Feature Size | Scan Length (mm) |

|---|---|---|---|

| C10 | 0.5 | 10 × 10 × 5 | x = 10 mm, y = 10 mm |

| C5 | 0.5 | 5 × 5 × 5 | x = 5 mm, y = 5 mm |

| Relative Density (%) | Optical Density (%) | Crack Density (%) | Average Grain Size (µm) | HAGB Density (%) | Max MUD | |

|---|---|---|---|---|---|---|

| C10 | 95.5 | 96.7 | 2.8 | 17.3 | 27.9 | 4.7 |

| C5 | 97.4 | 97.6 | 1.9 | 17.9 | 24.1 | 6.2 |

| Average Hardness (Hv) | Hardness (Hv) | |||

|---|---|---|---|---|

| Bottom | Center | Top | ||

| C10 | 221 | 223 | 218 | 222 |

| C5 | 203 | 218 | 204 | 187 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gokcekaya, O.; Ishimoto, T.; Todo, T.; Suganuma, R.; Fukushima, R.; Narushima, T.; Nakano, T. Effect of Scan Length on Densification and Crystallographic Texture Formation of Pure Chromium Fabricated by Laser Powder Bed Fusion. Crystals 2021, 11, 9. https://doi.org/10.3390/cryst11010009

Gokcekaya O, Ishimoto T, Todo T, Suganuma R, Fukushima R, Narushima T, Nakano T. Effect of Scan Length on Densification and Crystallographic Texture Formation of Pure Chromium Fabricated by Laser Powder Bed Fusion. Crystals. 2021; 11(1):9. https://doi.org/10.3390/cryst11010009

Chicago/Turabian StyleGokcekaya, Ozkan, Takuya Ishimoto, Tsubasa Todo, Ryoya Suganuma, Ryo Fukushima, Takayuki Narushima, and Takayoshi Nakano. 2021. "Effect of Scan Length on Densification and Crystallographic Texture Formation of Pure Chromium Fabricated by Laser Powder Bed Fusion" Crystals 11, no. 1: 9. https://doi.org/10.3390/cryst11010009

APA StyleGokcekaya, O., Ishimoto, T., Todo, T., Suganuma, R., Fukushima, R., Narushima, T., & Nakano, T. (2021). Effect of Scan Length on Densification and Crystallographic Texture Formation of Pure Chromium Fabricated by Laser Powder Bed Fusion. Crystals, 11(1), 9. https://doi.org/10.3390/cryst11010009