Correlation Analysis of Heat Curing and Compressive Strength of Carbon Nanotube–Cement Mortar Composites at Sub-Zero Temperatures

Abstract

:1. Introduction

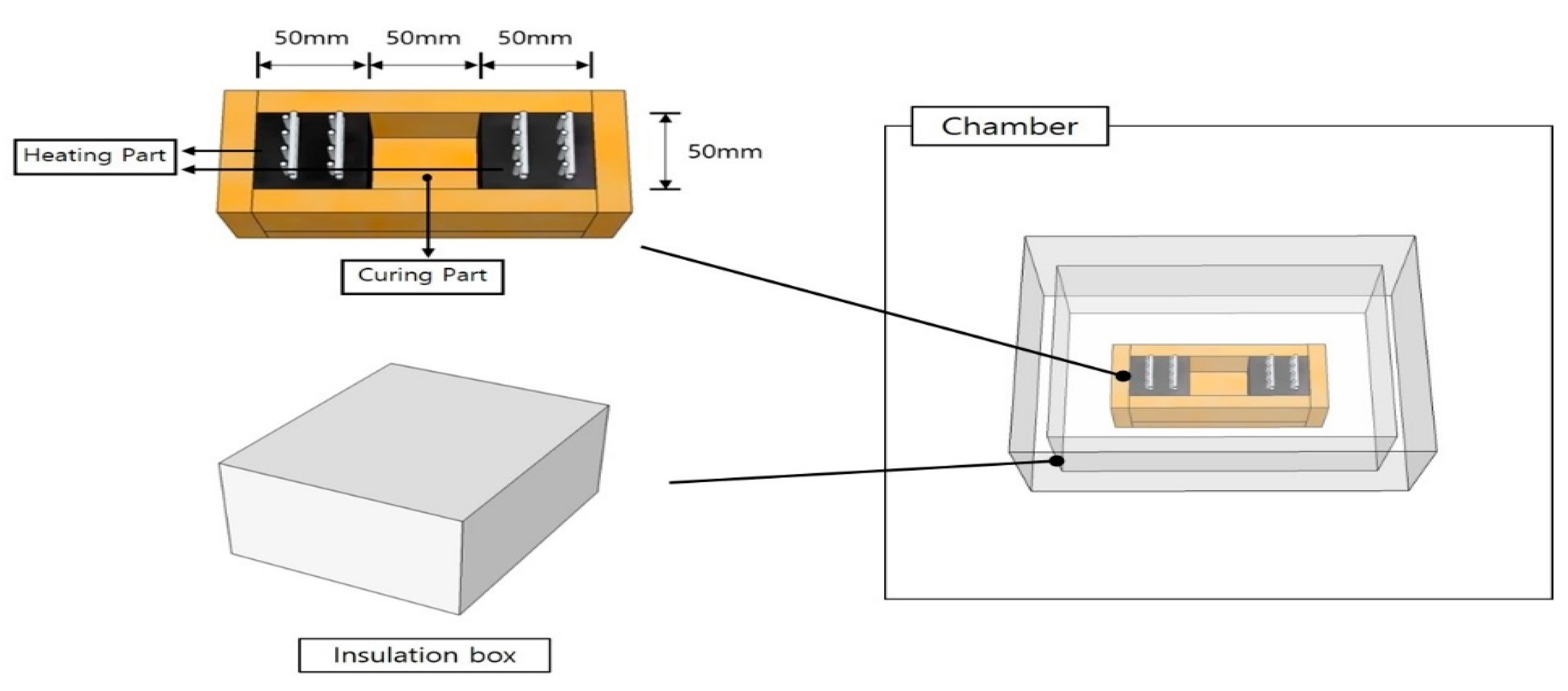

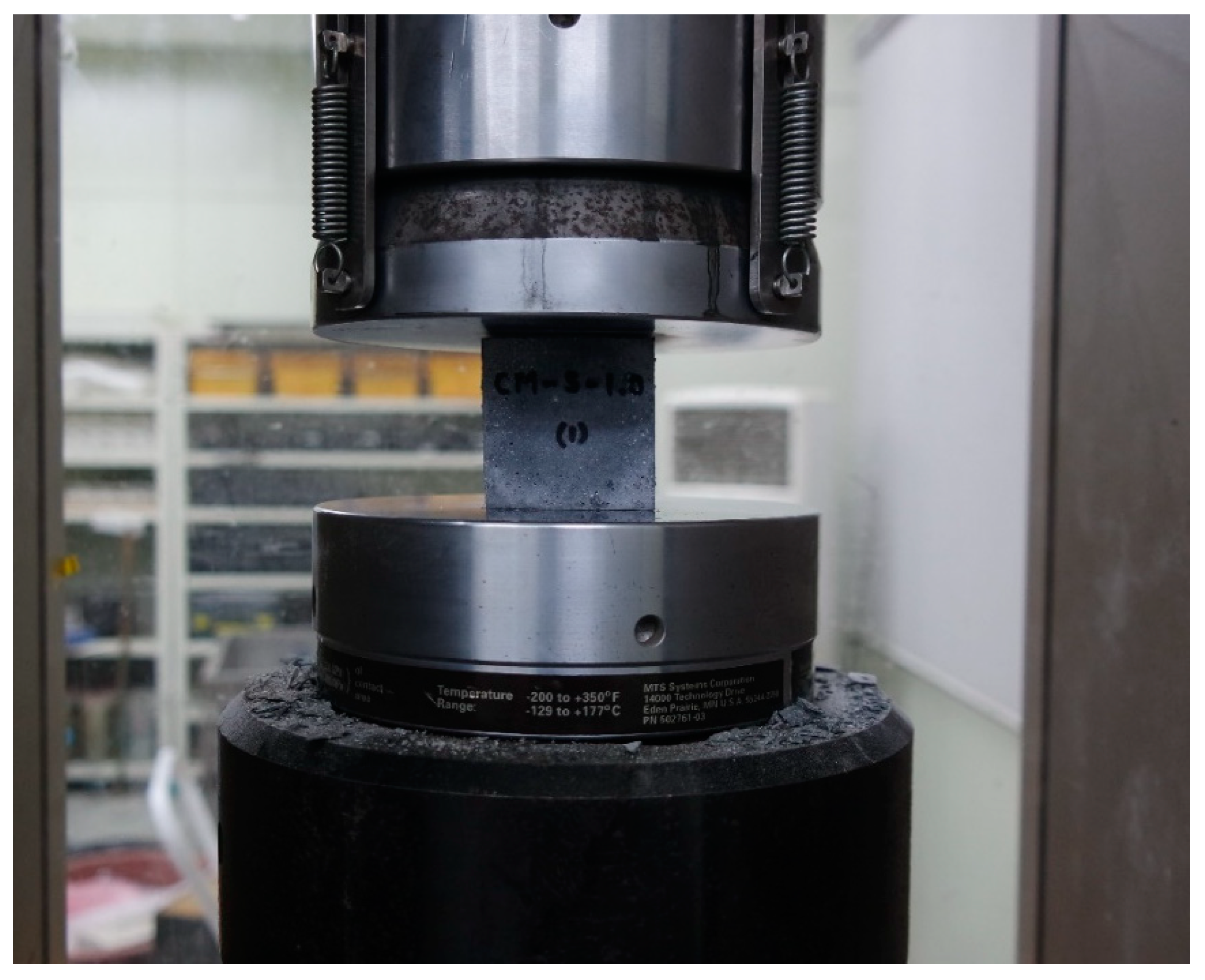

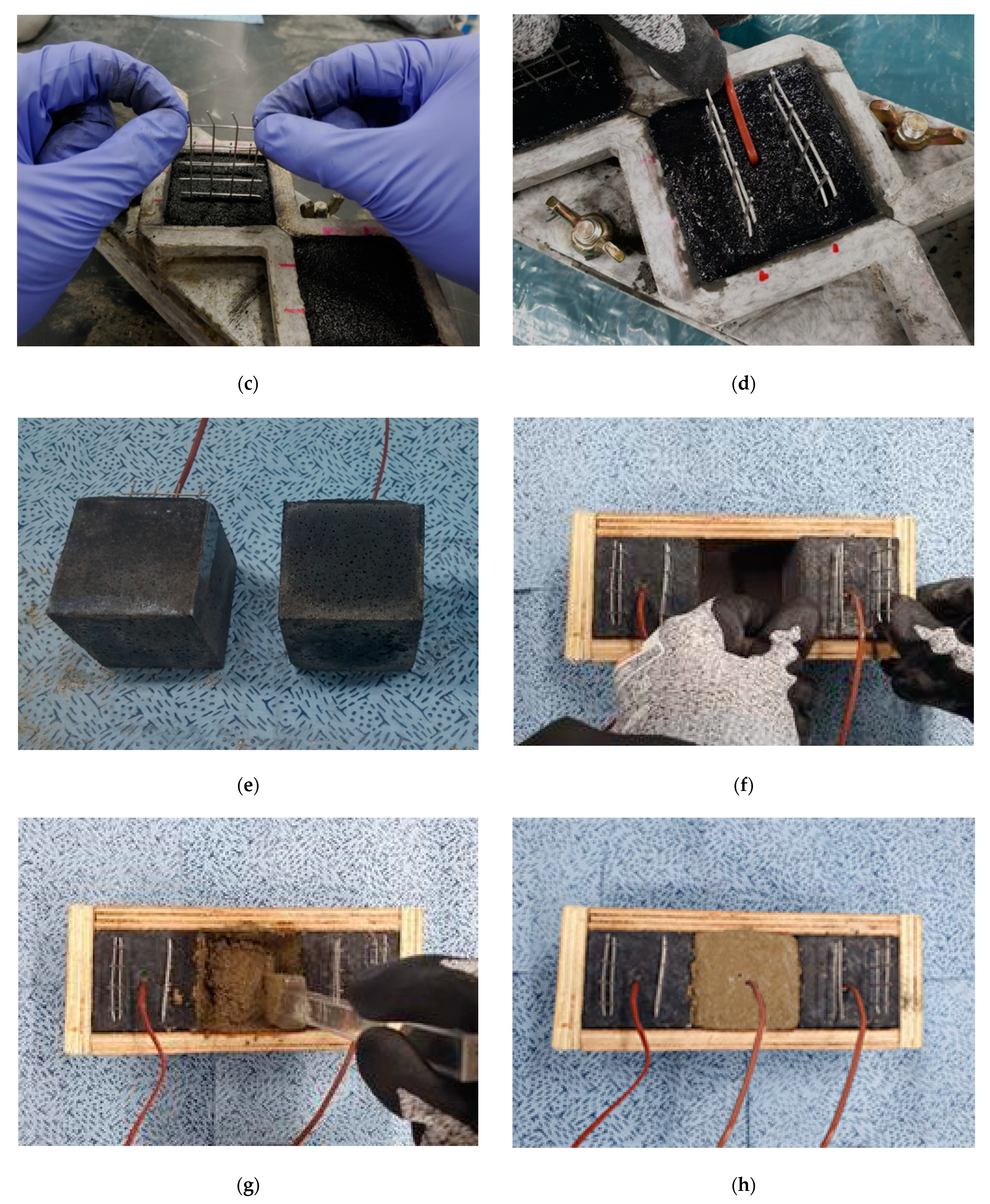

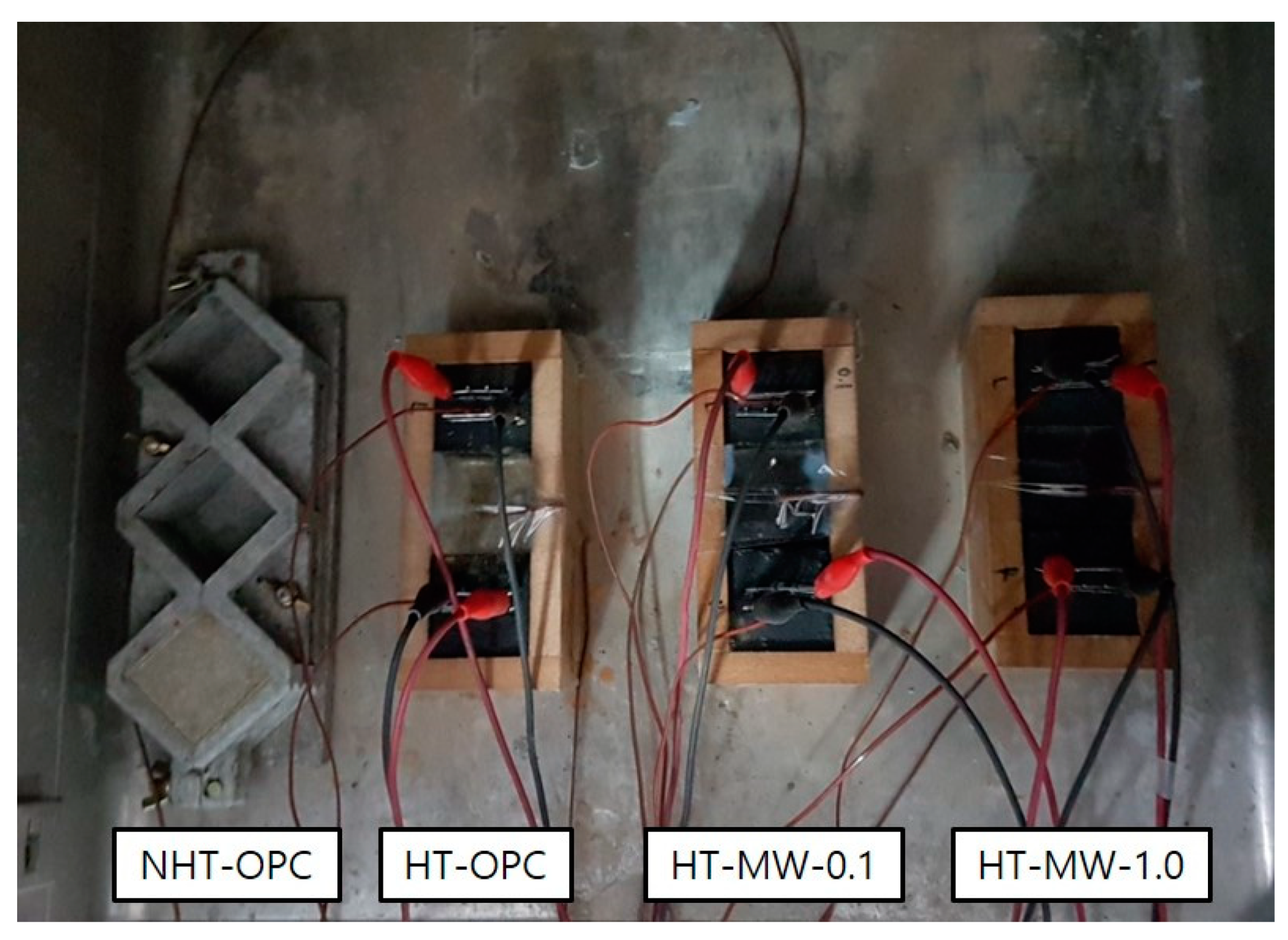

2. Experimental Methods

3. Experimental Results

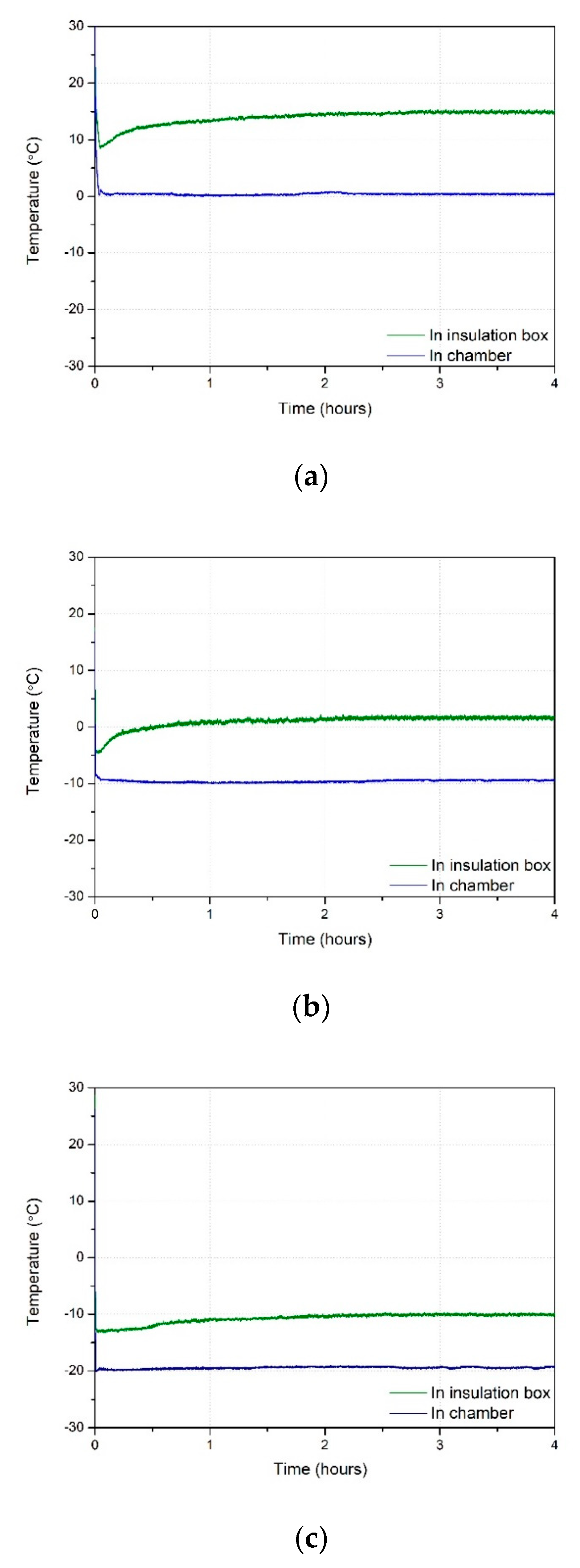

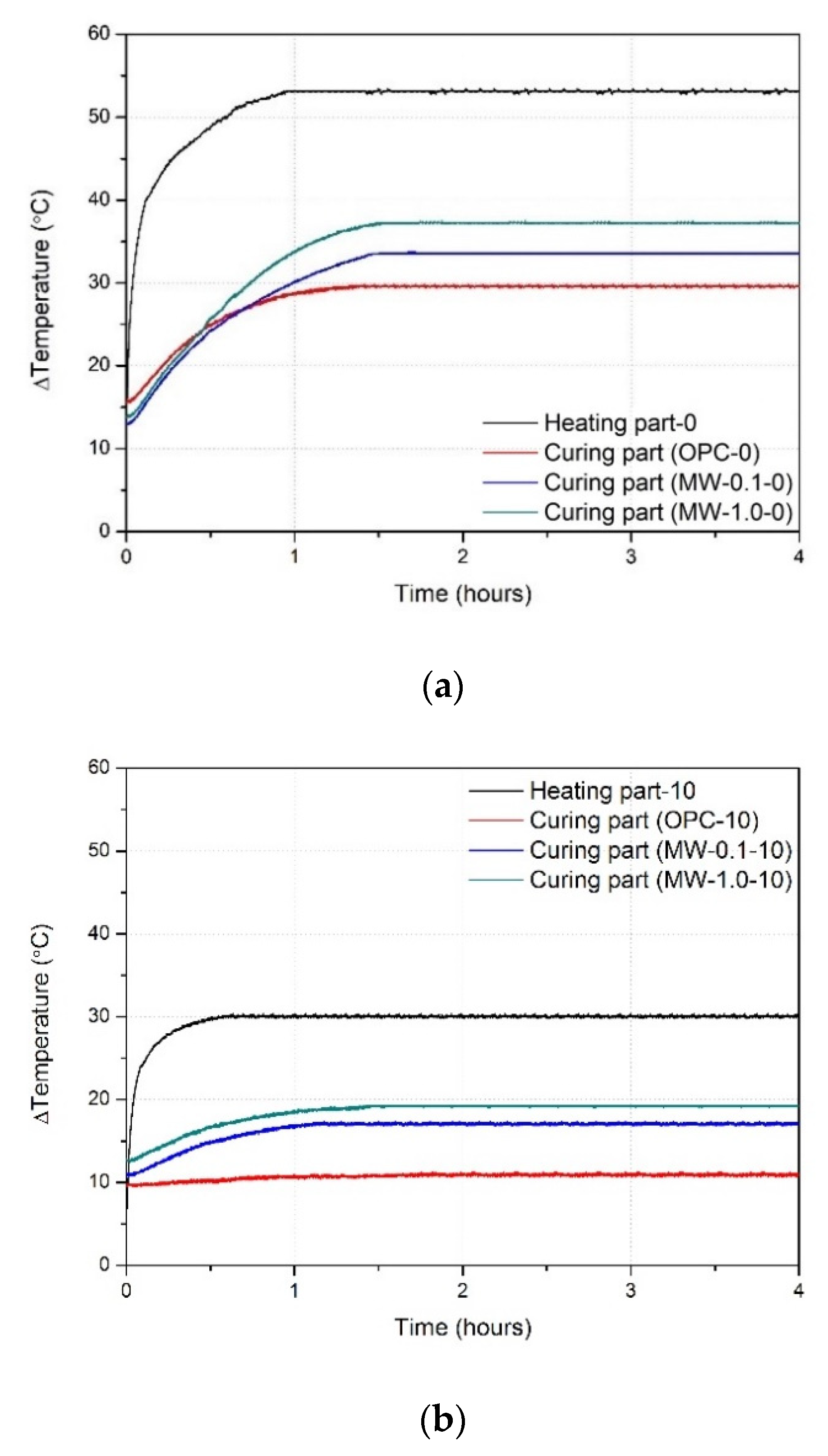

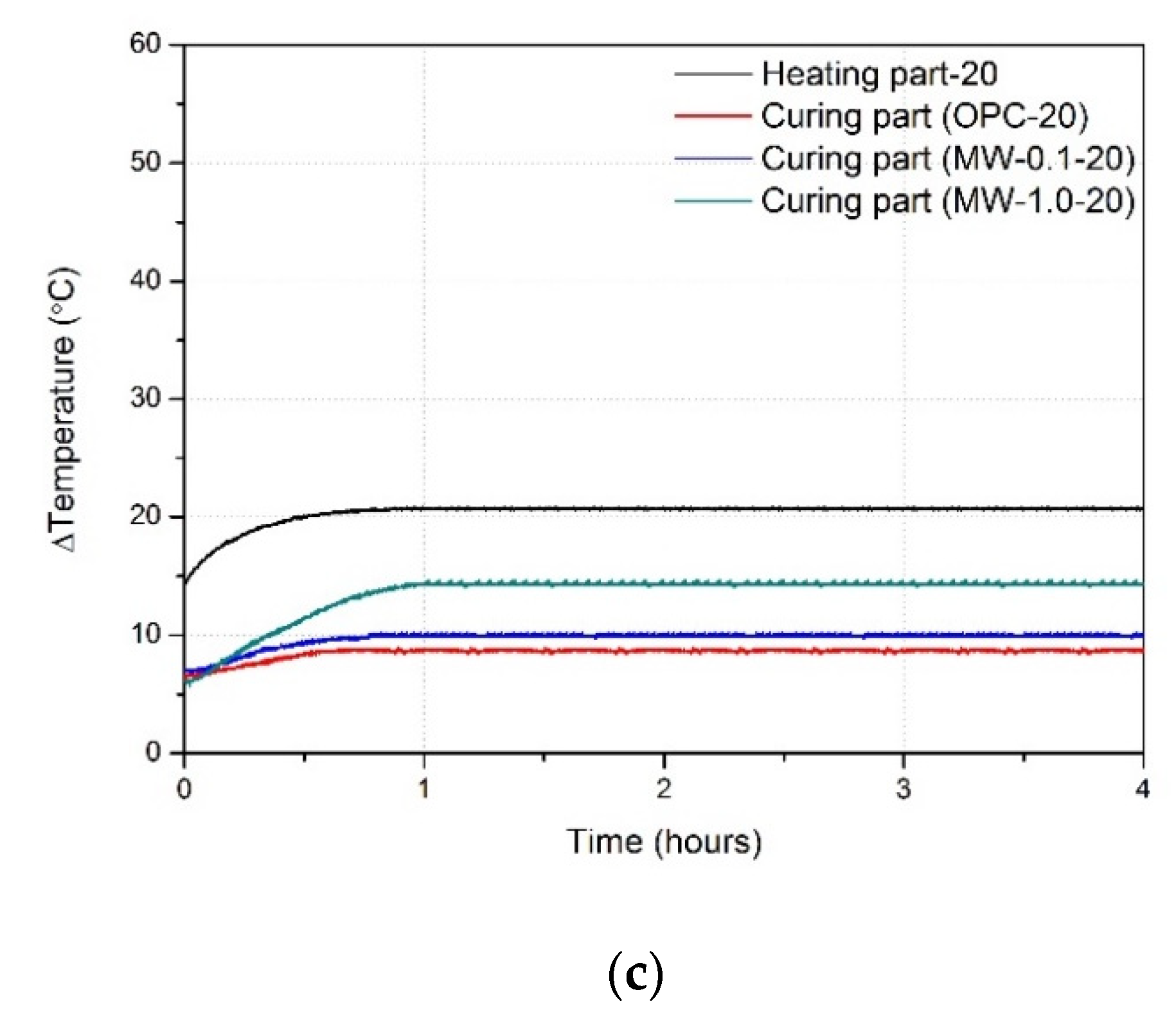

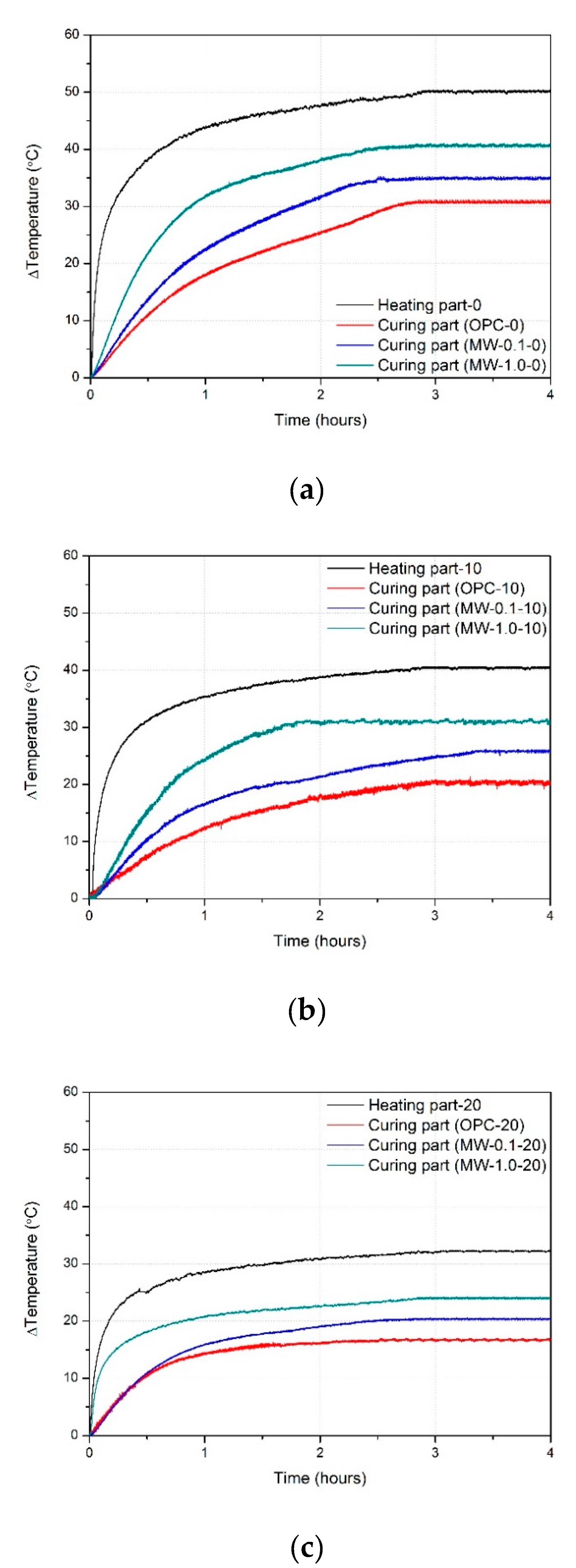

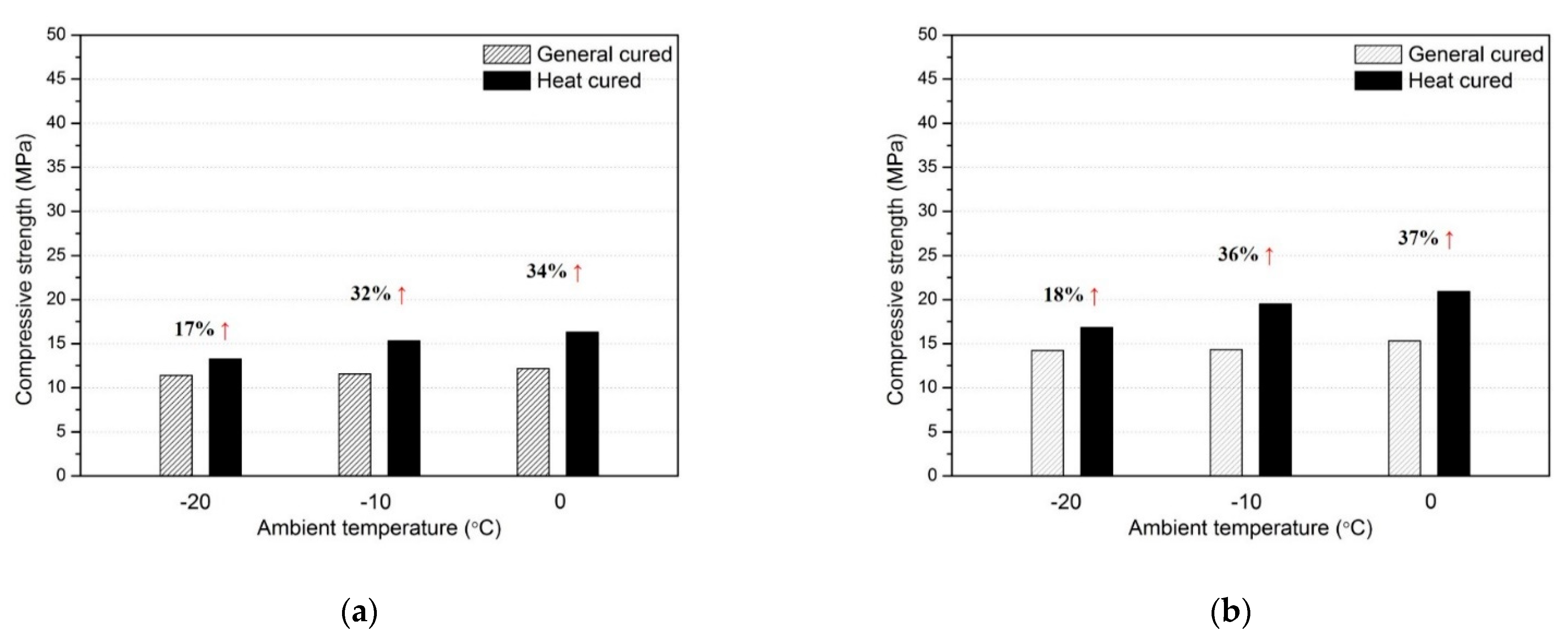

3.1. Results of Heat Curing Experiment

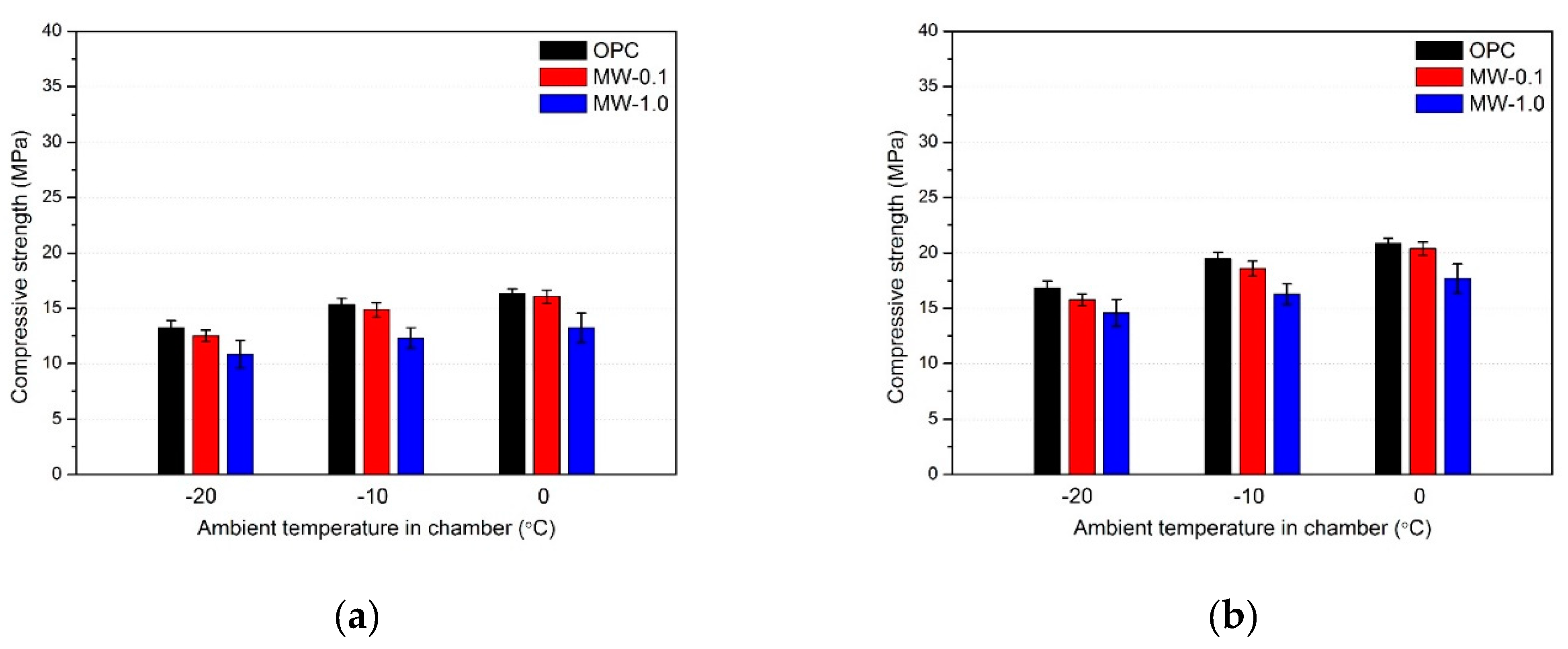

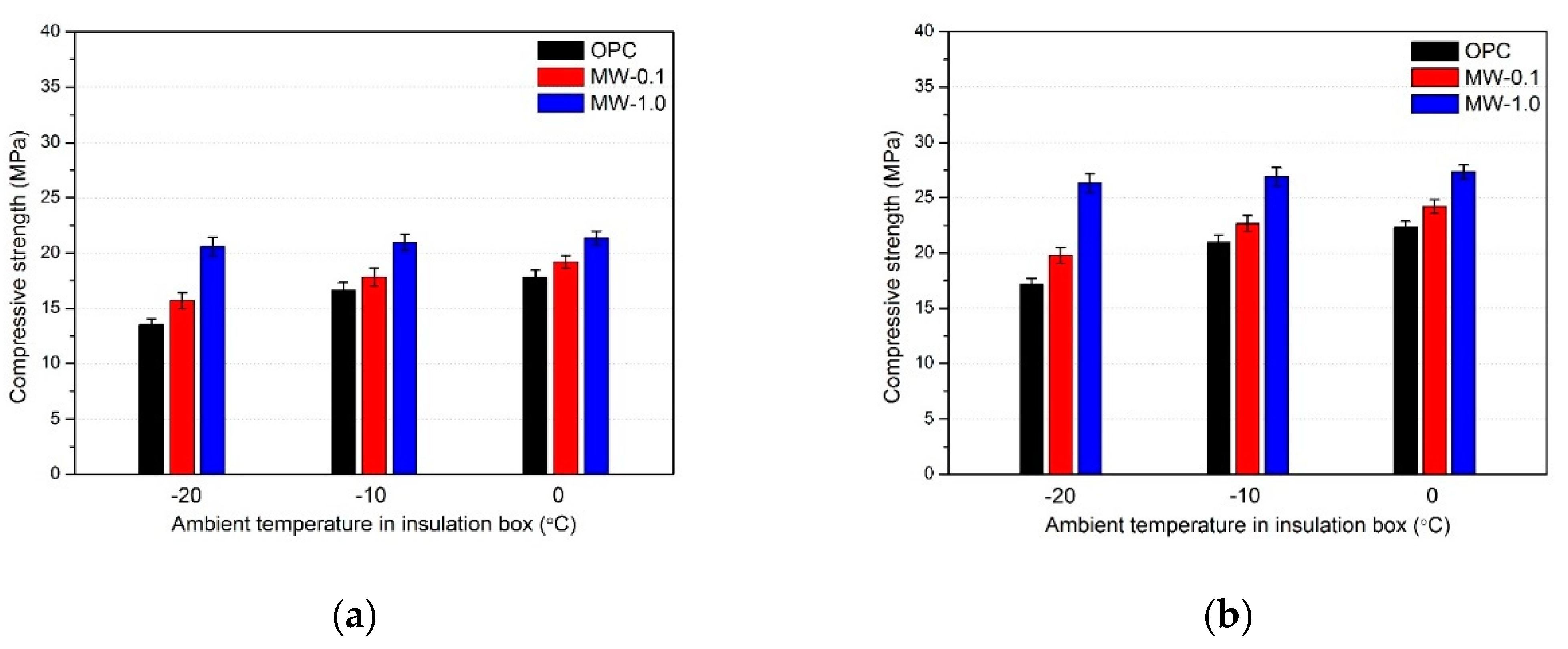

3.2. Results of Compressive Strength Test

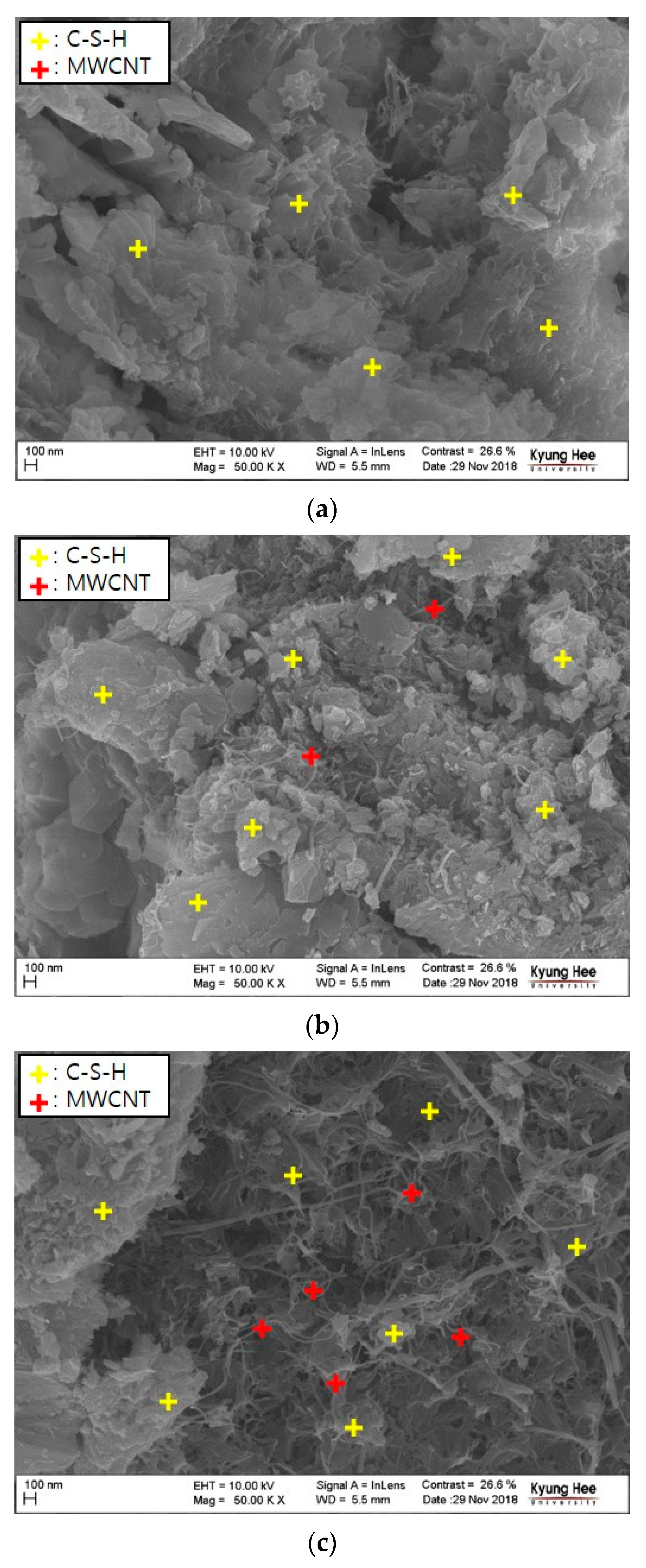

3.3. Results of Microstructure Analysis

4. Conclusions

- The internal temperature change of the MWCNT cementitious mortar composites increased with the increasing ambient temperature and MWCNT content. At higher ambient temperatures, the heating temperature of the heating part of the MWCNT cementitious mortar composite increased, transmitting a large amount of heat to the curing part. Furthermore, owing to the excellent thermal conductivity of MWCNTs, the heat generated in the heating part spread more rapidly to the curing part of the MWCNT cementitious composite compared with the OPC. As the MWCNT content increased, the amount of MWCNTs dispersed inside the cementitious mortar composite increased, and the thermal conductivity of the composite improved.

- The installation of an insulation box increased the maximum temperature change of the curing part of the MWCNT cementitious mortar composite. The insulation box created an environment similar to a closed system, in which heat generated in the heating part circulated, causing the internal temperature to increase. The temperature on the surface of the cementitious mortar composite also increased, which further increased the heating temperature of the heating part of the MWCNT cementitious mortar composite. Consequently, the maximum temperature change in the cementitious composite of the curing part increased.

- The results of the compressive strength test under sub-zero temperatures showed that the heat-cured cementitious mortar composite of the curing part with an insulation box had a higher compressive strength than the OPC in the curing part. As the ambient temperature increased, the compressive strength of the cementitious mortar composite of the curing part improved by up to 47%. Inside the insulation box, the internal temperature of the cementitious composite of the heat-cured curing part was maintained at 8 °C or higher, thus preventing the freezing of moisture. Consequently, as the ambient temperature increased, the heating temperature of the MWCNT cementitious mortar composite of the heating part increased, which improved the compressive strength of the cementitious mortar composite of the curing part.

- When the insulation box was not installed in the heat curing experiment, the compressive strength of the cementitious composite of the curing part decreased with the increasing MWCNT content. In contrast, when the insulation box was installed in the heat curing experiment, the compressive strength of the cementitious composite of the curing part increased by up to 52.9% with the increasing MWCNT content. The MWCNTs not only increased the load transfer efficiency by interconnecting the cement hydrates but also improved the compressive strength of the MWCNT cementitious mortar composites by filling the micropores. The installation of the insulation box created a closed system, and the increased temperature inside the box improved the strength of the MWCNTs. Therefore, it is essential to use an insulation box when using MWCNT cementitious mortar composites for heat curing.

- The FE-SEM images of the internal microstructure of the MWCNT cementitious mortar composites confirmed the network connections between the MWCNTs and cement hydrates inside the cementitious composites. The thermal conductivity of the cementitious composites improved, because the high thermal conductivity of the MWCNTs interconnected the cement hydrates. Furthermore, the MWCNTs improved the compressive strength by promoting the formation of C–S–H and filling the micropores inside the cementitious mortar composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Li, H. Experimental investigation on the ice/snow melting performance of CNFP & MWCNT/cement-based deicing system. In Proceedings of the 6th International Workshop on Advanced Smart Materials and Smart Structures Technology, Dalian, China, 25–26 July 2011; pp. 25–26. [Google Scholar]

- Won, J.P.; Kim, C.K.; Lee, S.J.; Lee, J.H.; Kim, R.W. Thermal characteristics of a conductive cement-based composite for a snow-melting heated pavement system. Compos. Struct. 2014, 118, 106–111. [Google Scholar] [CrossRef]

- Kim, G.M.; Naeem, F.; Kim, H.K.; Lee, H.K. Heating and heat-dependent mechanical characteristics of CNT-embedded cementitious composites. Compos. Struct. 2016, 136, 162–170. [Google Scholar] [CrossRef]

- Lee, H.; Song, Y.M.; Loh, K.J.; Chung, W. Thermal response characterization and comparison of carbon nanotube-enhanced cementitious composites. Compos. Struct. 2018, 202, 1042–1050. [Google Scholar] [CrossRef] [Green Version]

- Al-Khaiat, H.; Haque, M.N. Effect of initial curing on early strength and physical properties of a lightweight concrete. Cem. Concr. Res. 1998, 28, 859–866. [Google Scholar] [CrossRef]

- Sukumar, B.; Nagamani, K.; Raghavan, R.S. Evaluation of strength at early ages of self-compacting concrete with high volume fly ash. Constr. Build. Mater. 2008, 122, 394–1401. [Google Scholar] [CrossRef]

- Assi, L.N.; Deaver, E.E.; ElBatanouny, M.K.; Ziehl, P. Investigation of early compressive strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 807–815. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Zhao, X. Properties of concrete incorporating fly ash and ground granulated blast-furnace slag. Cem. Concr. Compos. 2003, 25, 293–299. [Google Scholar] [CrossRef]

- Kim, J.K.; Moon, Y.H.; Eo, S.H. Compressive strength development of concrete with different curing time and temperature. Cem. Concr. Res. 1998, 28, 1761–1773. [Google Scholar] [CrossRef]

- Lura, P.; van Breugel, K.; Maruyama, I. Effect of curing temperature and type of cement on early-age shrinkage of high-performance concrete. Cem. Concr. Res. 2001, 31, 1867–1872. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Husem, M.; Gozutok, S. The effects of low temperature curing on the compressive strength of ordinary and high performance concrete. Constr. Build. Mater. 2005, 19, 49–53. [Google Scholar] [CrossRef]

- Chaipanich, A.; Nochaiya, T.; Wongkeo, W.; Torkittikul, P. Compressive strength and microstructure of carbon nanotubes–fly ash cement composites. Mater. Sci. Eng. A 2010, 527, 1063–1067. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N.; Emon, M.; Bashar, A. Effect of carbon nanotube size on compressive strengths of nanotube reinforced cementitious composites. J. Mater. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 436, 1239–1245. [Google Scholar] [CrossRef]

- Al-Rub, R.K.A.; Ashour, A.I.; Tyson, B.M. On the aspect ratio effect of multi-walled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Al-Nuaimi, N.; Al-Rub, R.K.A.; Senouci, A.; Bani-Hani, K.A. Effect of mixing duration on flexural strength of multi walled carbon nanotubes cementitious composites. Constr. Build. Mater. 2016, 126, 586–598. [Google Scholar] [CrossRef]

- Tyson, B.M.; Abu Al-Rub, R.K.; Yazdanbakhsh, A.; Grasley, Z. Carbon nanotubes and carbon nanofibers for enhancing the mechanical properties of nanocomposite cementitious materials. J. Mater. Civ. Eng. 2011, 23, 1028–1035. [Google Scholar] [CrossRef]

- Lee, H.; Park, S.; Cho, S.; Chung, W. Correlation analysis of heating performance and electrical energy of multi-walled carbon nanotubes cementitious composites at sub-zero temperatures. Compos. Struct. 2020, 238, 111977. [Google Scholar] [CrossRef]

- Lee, H.; Park, S.; Park, S.; Chung, W. Enhanced Detection Systems of Filling Rates Using Carbon Nanotube Cement Grout. Nanomaterials 2020, 10, 10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gomis, J.; Galao, O.; Gomis, V.; Zornoza, E.; Garcés, P. Self-heating and deicing conductive cement: Experimental study and modeling. Constr. Build. Mater. 2015, 75, 442–449. [Google Scholar] [CrossRef]

- Tawfik, T.A.; Abd El-Aziz, M.A.; Abd El-Aleem, S.; Serag Faried, A. Influence of nanoparticles on mechanical and nondestructive properties of high-performance concrete. J. Chin. Adv. Mater. Soc. 2018, 6, 409–433. [Google Scholar] [CrossRef]

- Cha, S.W.; Song, C.; Cho, Y.H.; Choi, S. Piezoresistive properties of CNT reinforced cementitious composites. Mater. Res. Innov. 2014, 18 (Suppl. 2), S2-716. [Google Scholar] [CrossRef]

- Liew, K.M.; Kai, M.F.; Zhang, L.W. Mechanical and damping properties of CNT-reinforced cementitious composites. Compos. Struct. 2017, 160, 81–88. [Google Scholar] [CrossRef]

- Han, B.; Zhang, K.; Yu, X.; Kwon, E.; Ou, J. Fabrication of piezoresistive CNT/CNF cementitious composites with superplasticizer as dispersant. J. Mater. Civ. Eng. 2011, 24, 658–665. [Google Scholar] [CrossRef]

- Lee, H.; Kang, D.; Song, Y.M.; Chung, W. Heating experiment of CNT cementitious composites with single-walled and multiwalled carbon nanotubes. J. Nanomater. 2017, 2017, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Han, Y.; Zhang, T. Morphological properties of surface-treated carbon nanotubes in cement-based composites. J. Nanosci. Nanotechnol. 2012, 12, 8415–8419. [Google Scholar] [CrossRef]

- Lu, L.; Ouyang, D.; Xu, W. Mechanical properties and durability of ultra high strength concrete incorporating multi-walled carbon nanotubes. Materials 2016, 9, 419. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Carriço, A.; Bogas, J.A.; Hawreen, A.; Guedes, M. Durability of multi-walled carbon nanotube reinforced concrete. Constr. Build. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Lee, H.; Yu, W.; Loh, K.J.; Chung, W. Self-heating and electrical performance of carbon nanotube-enhanced cement composites. Constr. Build. Mater. 2020, 250, 118838. [Google Scholar] [CrossRef]

- ASTM C 109. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in, or [50-mm] Cube Specimens); ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ISO (International Organisation for Standardisation). ISO 679. Cement–Test Methods–Determination of Strength; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Lee, H.; Jeong, S.; Park, S.; Chung, W. Enhanced mechanical and heating performance of multi-walled carbon nanotube-cement composites fabricated using different mixing methods. Compos. Struct. 2019, 225, 111072. [Google Scholar] [CrossRef]

- Wang, B.; Han, Y.; Liu, S. Effect of highly dispersed carbon nanotubes on the flexural toughness of cement-based composites. Constr. Build. Mater. 2013, 46, 8–12. [Google Scholar] [CrossRef]

- Kim, G.M.; Yang, B.J.; Cho, K.J.; Kim, E.M.; Lee, H.K. Influences of CNT dispersion and pore characteristics on the electrical performance of cementitious composites. Compos. Struct. 2017, 164, 32–42. [Google Scholar] [CrossRef]

- Hu, Y.; Luo, D.; Li, P.; Li, Q.; Sun, G. Fracture toughness enhancement of cement paste with multi-walled carbon nanotubes. Constr. Build. Mater. 2014, 70, 332–338. [Google Scholar] [CrossRef]

- Lee, H.; Kang, D.; Kim, J.; Choi, W.C. Void detection of cementitious grout composite using single-walled and multi-walled carbon nanotubes. Cem. Concr. Compos. 2019, 95, 237–246. [Google Scholar] [CrossRef]

- Lee, H.; Jeong, S.; Cho, S.; Chung, W. Enhanced bonding behavior of multi-walled carbon nanotube cement composites and reinforcing bars. Compos. Struct. 2020, 112201. [Google Scholar] [CrossRef]

- Naqi, A.; Abbas, N.; Zahra, N.; Hussain, A.; Shabbir, S.Q. Effect of multi-walled carbon nanotubes (MWCNTs) on the strength development of cementitious materials. J. Mater. Res. Technol. 2019, 8, 1203–1211. [Google Scholar] [CrossRef]

- Thomas, J.J.; Jennings, H.M.; Chen, J.J. Influence of nucleation seeding on the hydration mechanisms of tricalcium silicate and cement. J. Phys. Chem. C 2009, 113, 4327–4334. [Google Scholar] [CrossRef] [Green Version]

- Morsy, M.S.; Alsayed, S.H.; Aqel, M. Hybrid effect of carbon nanotube and nano-clay on physico-mechanical properties of cement mortar. Constr. Build. Mater. 2011, 25, 145–149. [Google Scholar] [CrossRef]

- Bharj, J.; Singh, S.; Chander, S.; Singh, R. Role of dispersion of multiwalled carbon Nanotubes on compressive strength of cement paste. World Academy of Science, Engineering and Technology. Int. J. Math. Comput. Phys. Electr. Comput. Eng. 2014, 8, 340–343. [Google Scholar]

- Nochaiya, T.; Chaipanich, A. Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl. Surf. Sci. 2011, 257, 1941–1945. [Google Scholar] [CrossRef]

| Specimen Name | MWCNT Content of the Curing Part(wt%) | Ambient Temperature(°C) |

|---|---|---|

| NHT-OPC-0.0-0 | 0.0 | 0 |

| HT-OPC-0.0-0 | 0.0 | |

| HT-MW-0.1-0 | 0.1 | |

| HT-MW-1.0-0 | 1.0 | |

| NHT-OPC-0.0-10 | 0.1 | −10 |

| HT-OPC-0.0-10 | 1.0 | |

| HT-MW-0.1-10 | 0.0 | |

| HT-MW-1.0-10 | 0.1 | |

| NHT-OPC-0.0-20 | 1.0 | −20 |

| HT-OPC-0.0-20 | 0.0 | |

| HT-MW-0.1-20 | 0.1 | |

| HT-MW-1.0-20 | 1.0 |

| Property | Unit | Value |

|---|---|---|

| Maximum temperature | °C | −20 |

| Minimum temperature | °C | 100 |

| Humidity range | % | 30–90 |

| Capacity/volume | 0.28 | |

| Power requirements | V | 200–208 |

| Specimen Name | Compressive Strength (MPa) | |||

|---|---|---|---|---|

| Uninsulated | Insulated | |||

| 7 d | 28 d | 7 d | 28 d | |

| HT-OPC-0.0-0 | 16.31 | 20.87 | 17.83 | 22.30 |

| HT-MW-0.1-0 | 16.05 | 20.38 | 19.21 | 24.2 |

| HT-MW-1.0-0 | 13.24 | 17.68 | 21.36 | 27.35 |

| HT-OPC-0.0-10 | 15.32 | 19.46 | 16.66 | 20.99 |

| HT-MW-0.1-10 | 14.86 | 18.57 | 17.84 | 22.65 |

| HT-MW-1.0-10 | 12.32 | 16.28 | 20.97 | 26.91 |

| HT-OPC-0.0-20 | 13.25 | 16.83 | 13.52 | 17.17 |

| HT-MW-0.1-20 | 12.51 | 15.76 | 15.72 | 19.81 |

| HT-MW-1.0-20 | 10.86 | 14.57 | 20.58 | 26.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Seong, J.; Chung, W. Correlation Analysis of Heat Curing and Compressive Strength of Carbon Nanotube–Cement Mortar Composites at Sub-Zero Temperatures. Crystals 2021, 11, 1182. https://doi.org/10.3390/cryst11101182

Lee H, Seong J, Chung W. Correlation Analysis of Heat Curing and Compressive Strength of Carbon Nanotube–Cement Mortar Composites at Sub-Zero Temperatures. Crystals. 2021; 11(10):1182. https://doi.org/10.3390/cryst11101182

Chicago/Turabian StyleLee, Heeyoung, Jongkyeong Seong, and Wonseok Chung. 2021. "Correlation Analysis of Heat Curing and Compressive Strength of Carbon Nanotube–Cement Mortar Composites at Sub-Zero Temperatures" Crystals 11, no. 10: 1182. https://doi.org/10.3390/cryst11101182

APA StyleLee, H., Seong, J., & Chung, W. (2021). Correlation Analysis of Heat Curing and Compressive Strength of Carbon Nanotube–Cement Mortar Composites at Sub-Zero Temperatures. Crystals, 11(10), 1182. https://doi.org/10.3390/cryst11101182