A State-of-the-Art Review on Suitability of Granite Dust as a Sustainable Additive for Geotechnical Applications

Abstract

1. Introduction

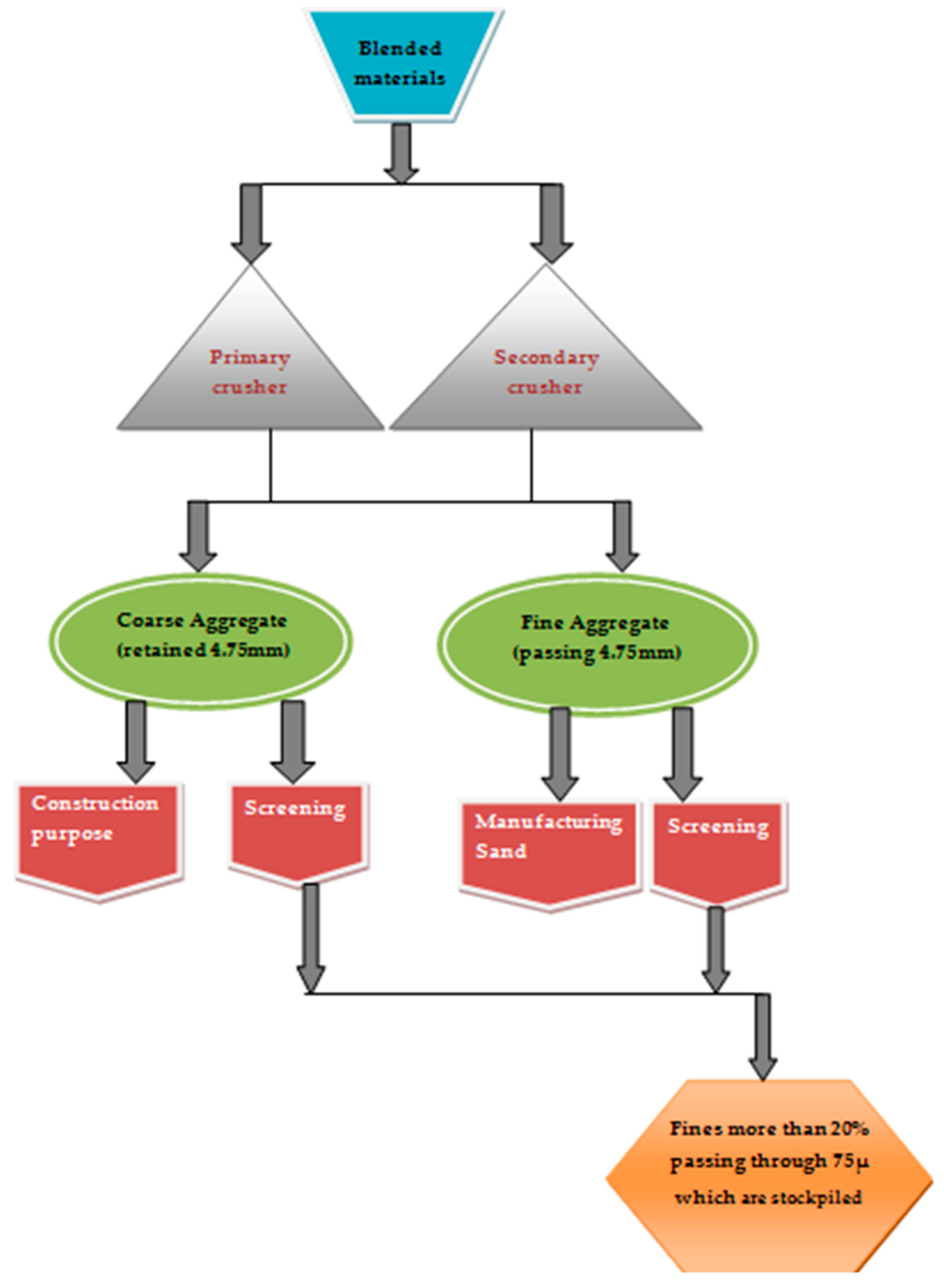

2. Physical and Chemical Properties of Granite Dust

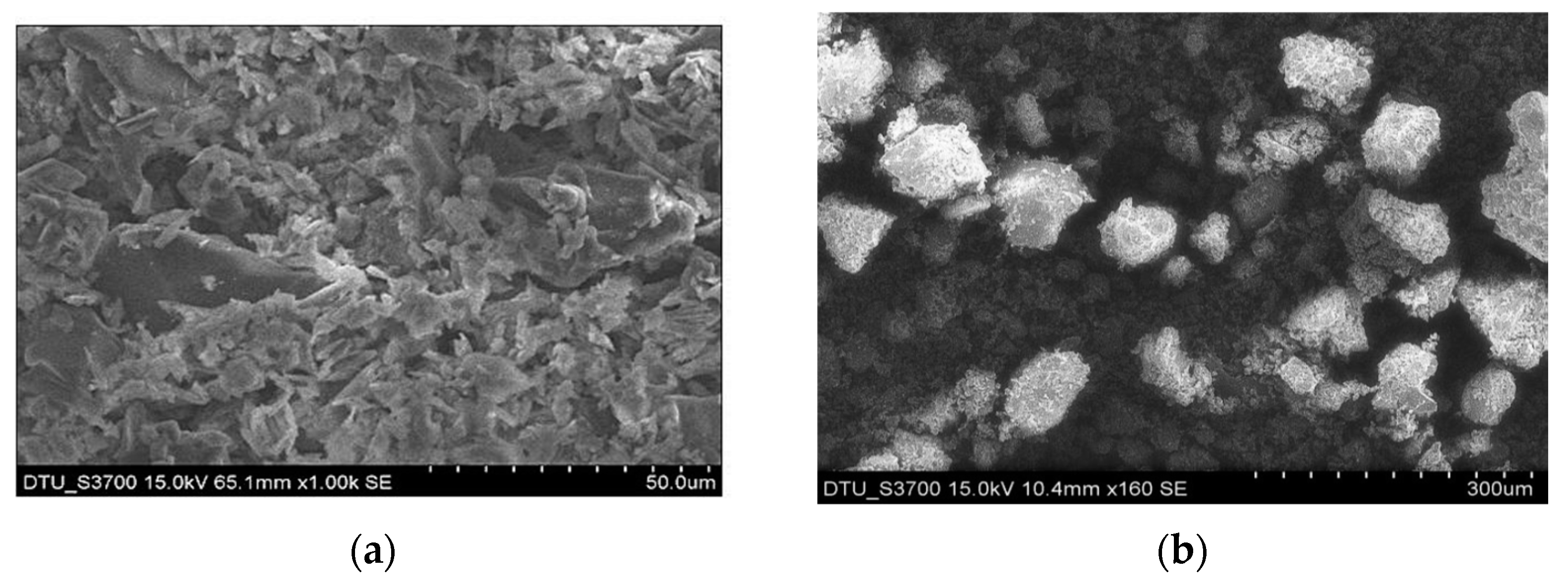

2.1. Morphology and Mineralogy of Granite Dust

2.2. Granite Dust and Composition

3. Granite Dust as a Sustainable Material

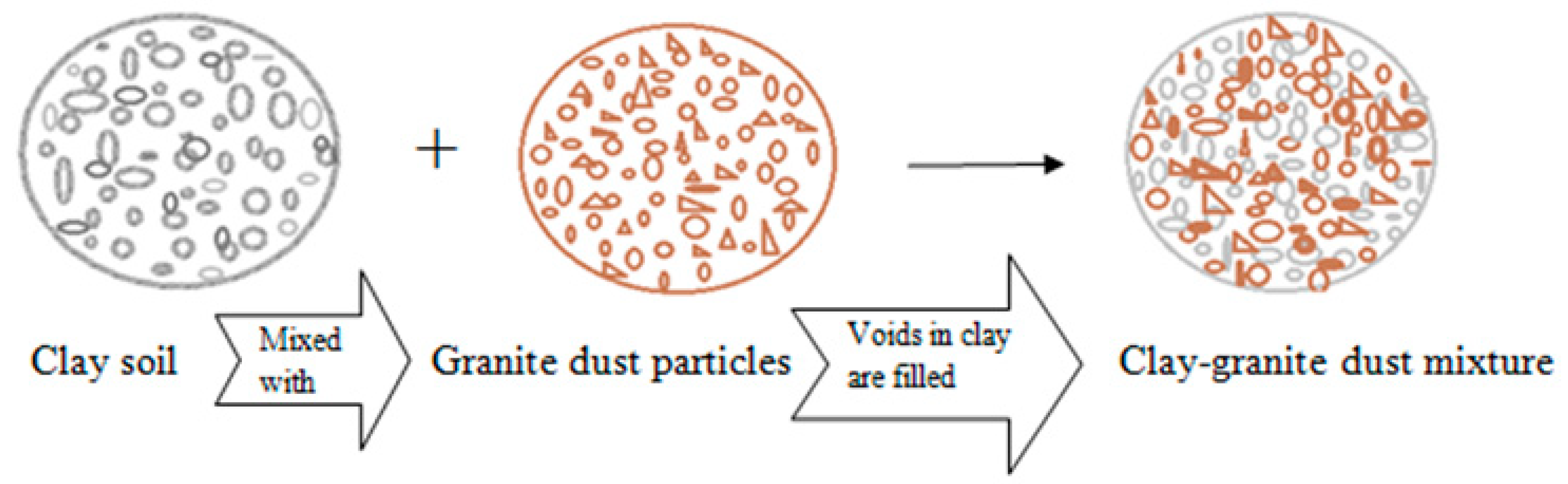

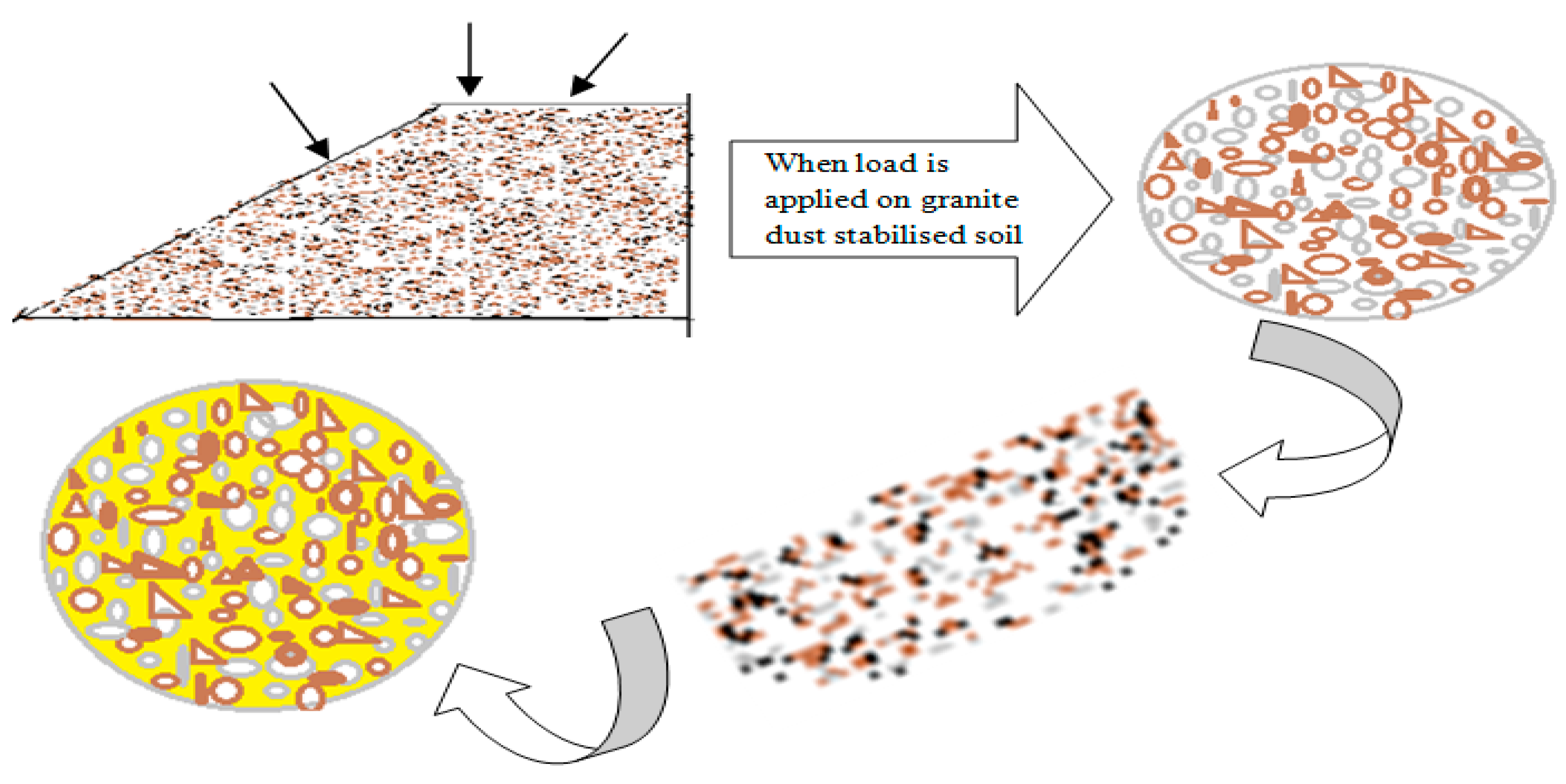

4. Effect of Granite Dust Addition on the Geotechnical Properties

4.1. Atterberg Limits

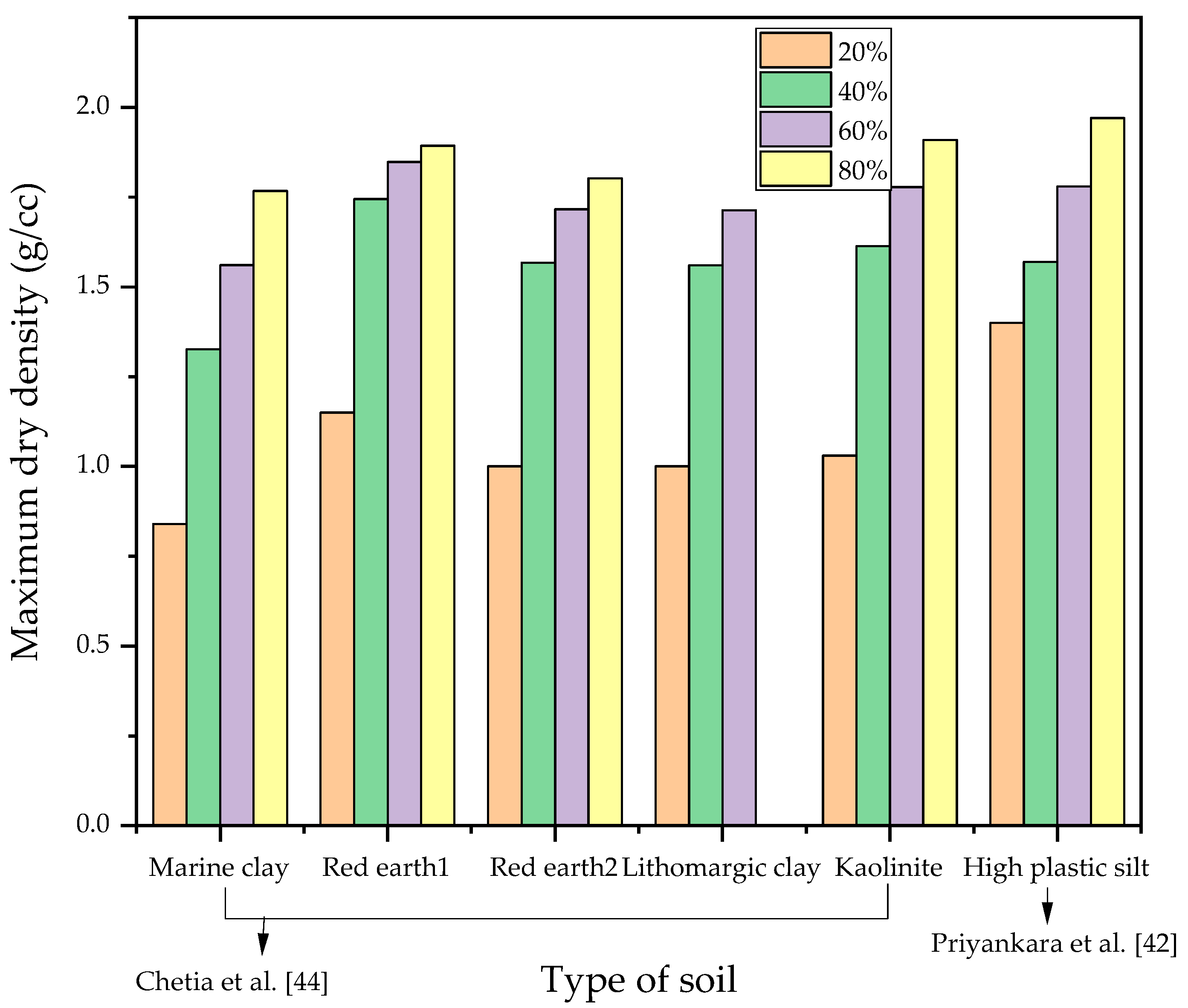

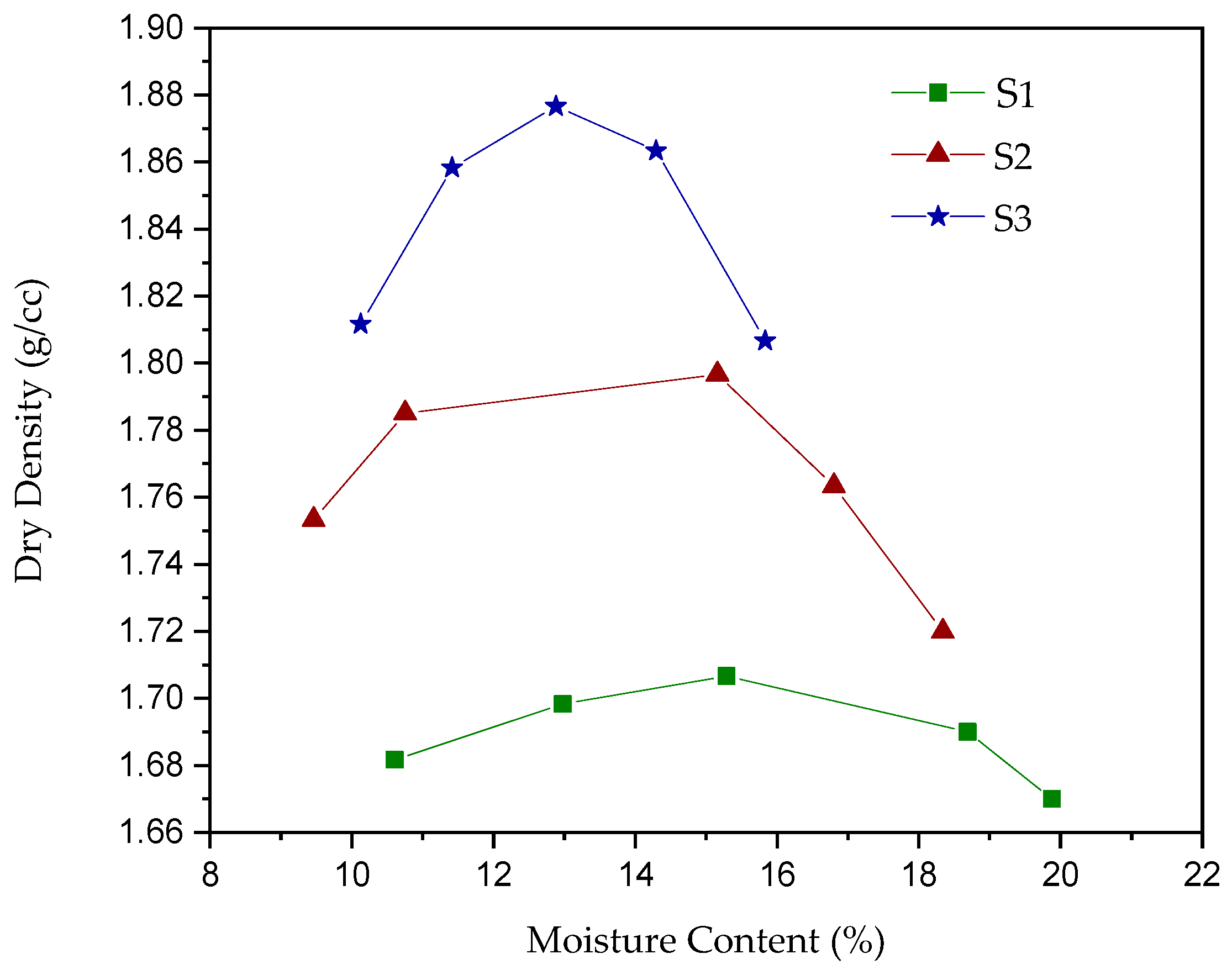

4.2. Compaction Attributes

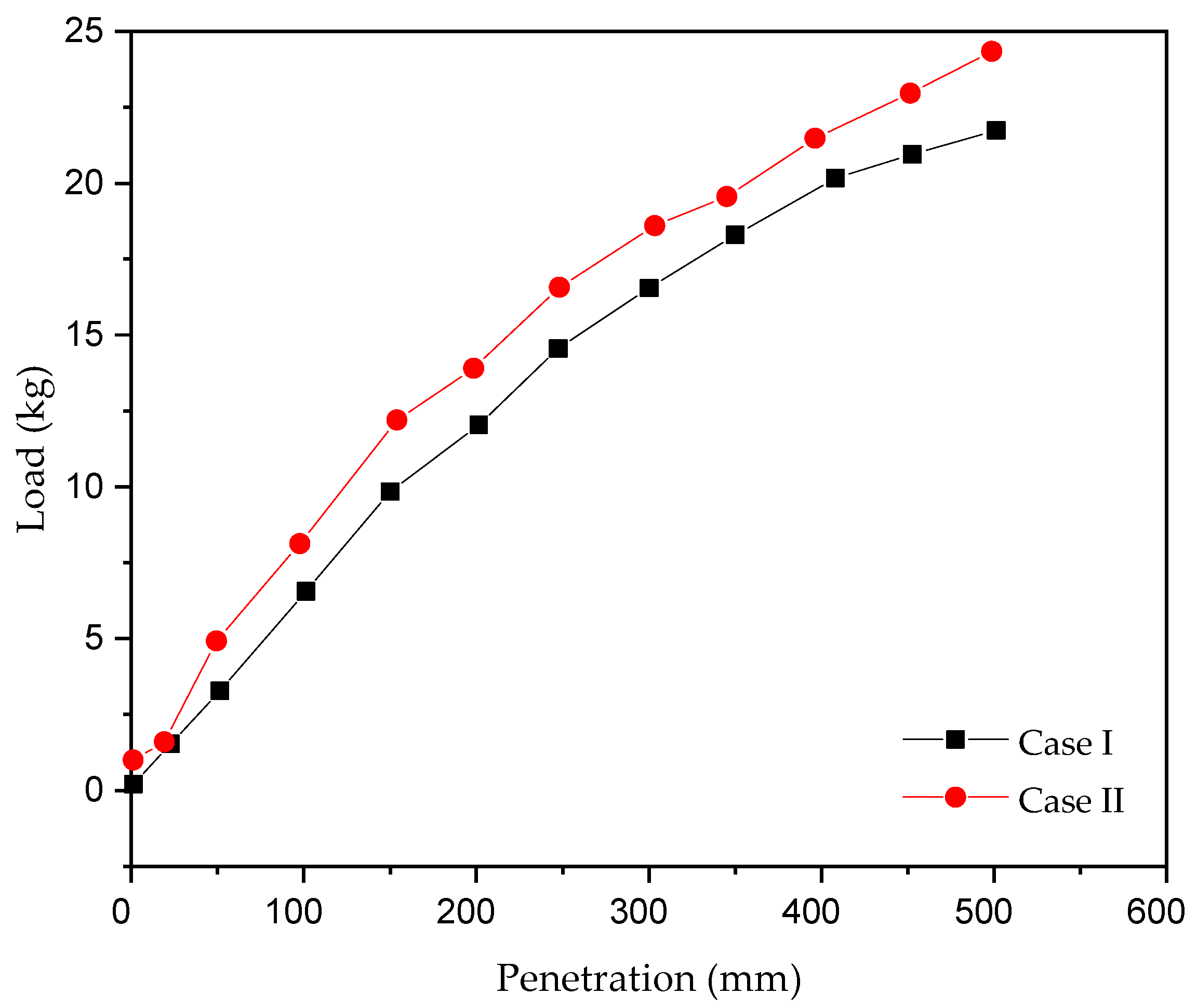

4.3. California Bearing Ratio

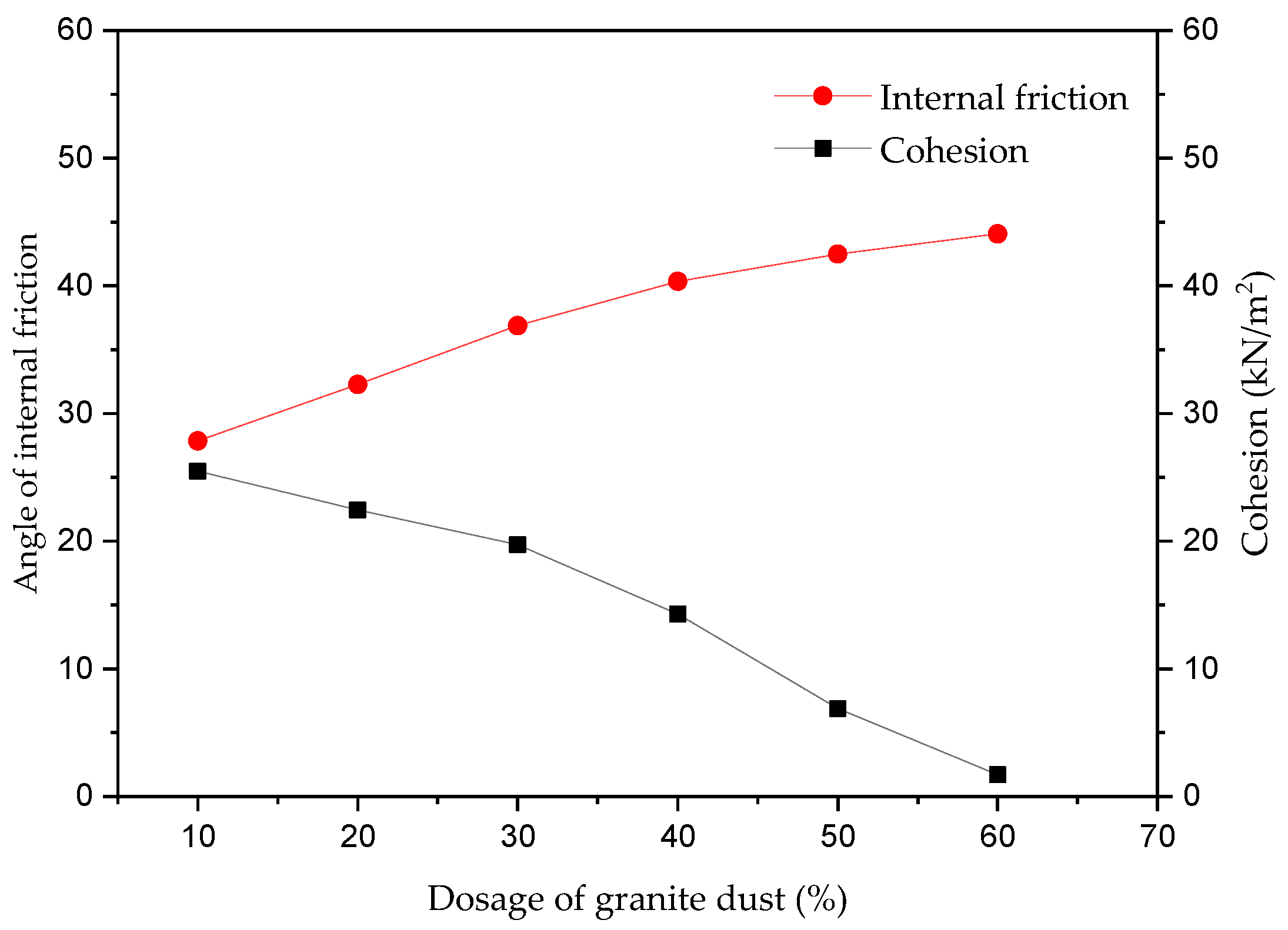

4.4. Shear Strength

4.5. UCS and Permeability

5. Granite Dust as a Substitute for Sand

6. Alternate Treatment Methods

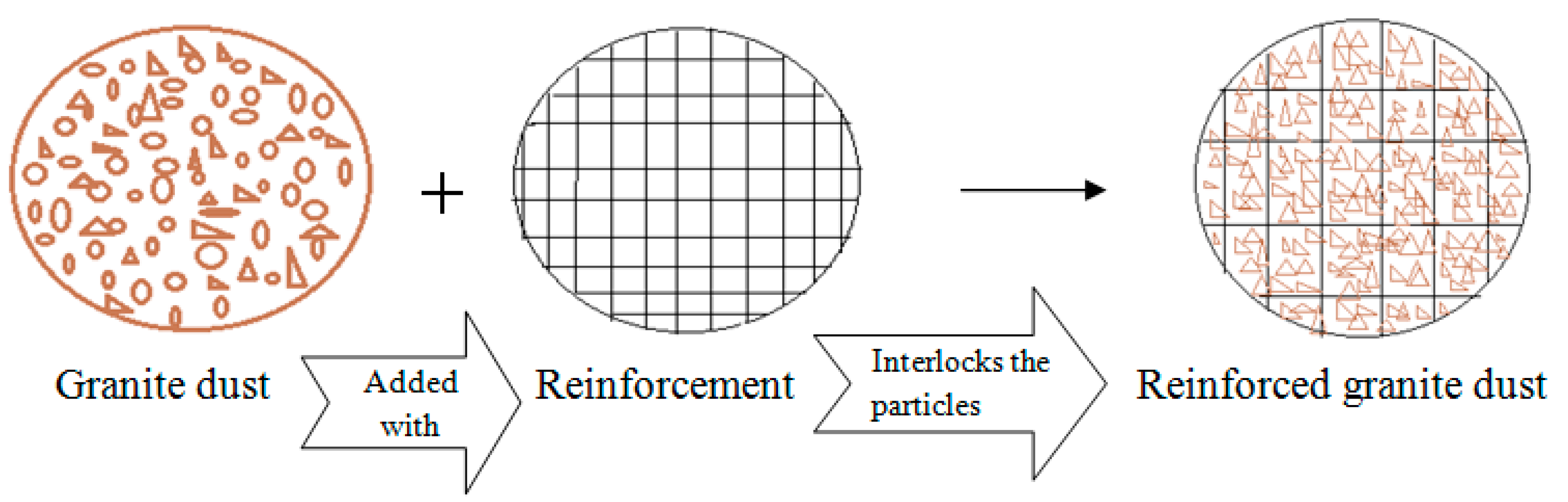

Reinforced Granite Dust

7. Effect of Granite Dust and Stabilizer(s) on Geotechnical Behavior

Importance of the Stabilizer

8. Practical Applications of Granite Dust

9. Conclusions

- This significant improvement in Atterberg limits and Compaction characteristics is attributed to the increase in the coarser fraction and specific gravity, followed by a decrease in the water absorption capacity of the soil.

- The interfacial friction of cohesive soil increased and cohesion value decreased due to the presence of coarser particles that fills the voids in clays, thereby increasing the friction component between the soil particles.

- Soaked CBR values are increased due to the improvement in corresponding Maximum dry density and Shear strength.

- A small amount of additive (calcium-based stabilizers) (<10%) with granite dust enhances the engineering properties of cohesive soils by causing net reduction in the pore volume, assisting in the rapid formation of ettringite, and substantially enhancing the tensile strength.

- Granite dust is a highly recommended material as a replacement of sand in concrete and geotechnical applications due to its chemical composition and interfacial friction angle.

- To explore the particle size effect of granite dust on the strength characteristics of the soil.

- Dynamic studies on the granite dust stabilized soil can be explored for future rail and roadway applications.

- The stability of embankments and long-term durability of highways constructed with granite dust amended soils may be carried out.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Almajed, A.; Lateef, M.A.; Moghal, A.A.B.; Lemboye, K.K. State-of-the-Art Review of the Applicability and Challenges of Microbial-Induced Calcite Precipitation (MICP) and Enzyme-Induced Calcite Precipitation (EICP) Techniques for Geotechnical and Geoenvironmental Applications. Crystals 2021, 11, 370. [Google Scholar] [CrossRef]

- Moghal, A.A.B. State-of-the-Art Review on the Role of Fly Ashes in Geotechnical and Geo environmental Applications. J. Mater. Civ. Eng. 2017, 29, 04017072. [Google Scholar] [CrossRef]

- Moghal, A.A.B. Geotechnical and physico-chemical characterization of low lime fly ashes. Adv. Mater. Sci. Eng. 2013, 2013, 1. Available online: https://www.hindawi.com/journals/amse/2013/674306 (accessed on 1 July 2021). [CrossRef]

- Ashfaq, M.; Lal, M.H.; Moghal, A.A.B.; Murthy, V.R. Carbon Footprint Analysis of Coal Gangue in Geotechnical Engineering Applications. Indian Geotech. J. 2019, 50, 646–654. [Google Scholar] [CrossRef]

- Ashfaq, M.; Heeralal, M.; Moghal, A.A.B. Characterization studies on coal gangue for sustainable geotechnics. Innov. Infrastruct. Solut. 2020, 5, 1–12. [Google Scholar] [CrossRef]

- Behnood, A. Soil and clay stabilization with calcium- and non-calcium-based additives: A state-of-the-art review of challenges, approaches and techniques. Transp. Geotech. 2018, 17, 14–32. [Google Scholar] [CrossRef]

- Dash, S.K.; Hussain, M. Lime stabilization of soils: Reappraisal. J. Mater. Civ. Eng. 2012, 24, 707–714. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Kareem Obaid, A.A.; Al-Refeai, T.O.; Al-Shamrani, M.A. Compressibility and durability characteristics of lime treated expansive semiarid soils. J. Test. Eval. 2014, 43. [Google Scholar] [CrossRef]

- Osinubi, K.J.; Nwaiwu, C.M. Compaction delay effects on properties of lime-treated soil. J. Mater. Civ. Eng. 2006, 18, 250–258. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Ashfaq, M.; Al-Al-Obaid, A.A.K.H.; Abbas, M.F.; Al-Mahbashi, A.M.; Shaker, A.A. Compaction delay and its effect on the geotechnical properties of lime treated semi-arid soils. Road Mater. Pavement Des. 2020, 22, 2626–2640. [Google Scholar] [CrossRef]

- Ali, H.; Mohamed, M. The effects of compaction delay and environmental temperature on the mechanical and hydraulic properties of lime-stabilized extremely high plastic clays. Appl. Clay Sci. 2017, 150, 333–341. [Google Scholar] [CrossRef]

- Al-Aghbari, M.Y.; Mohamedzein, Y.E.-A.; Taha, R. Stabilisation of desert sands using cement and cement dust. Proc. Inst. Civ. Eng. -Ground Improv. 2009, 162, 145–151. [Google Scholar] [CrossRef]

- Consoli, N.C.; Montardo, J.P.; Prietto, P.D.M.; Pasa, G.S. Engineering behavior of a sand reinforced with plastic waste. J. Geotech. Geoenviron. Eng. 2002, 128, 462–472. [Google Scholar] [CrossRef]

- Chen, Q.; Indraratna, B.; Carter, J.; Rujikiatkamjorn, C. A theoretical and experimental study on the behaviour of lignosulfonate-treated sandy silt. Comput. Geotech. 2014, 61, 316–327. [Google Scholar] [CrossRef]

- Cheng, Q.; Zhang, J.; Zhou, N.; Guo, Y.; Pan, S. Experimental study on unconfined compression strength of polypropylene fiber reinforced composite cemented clay. Crystals 2020, 10, 247. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Vydehi, K.V. State-of-the-art Review on Efficacy of Xanthan Gum and Guar Gum Inclusion on the Engineering Behavior of Soils. Innov. Infrastruct. Solut. 2021, 6, 1–14. [Google Scholar] [CrossRef]

- Ashfaq, M.; Heera Lal, M.; Moghal, A.A.B. Static and Dynamic Leaching Studies on Coal Gangue. In Sustainable Environmental Geotechnics 2020; Lecture Notes in Civil Engineering; Reddy, K.R., Agnihotri, A.K., Yukselen-Aksoy, Y., Dubey, B.K., Bansal, A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 261–270. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Lateef, M.A.; Mohammed, S.A.S.; Ahmad, M.; Usman, A.R.A.; Almajed, A. Heavy Metal Immobilization Studies and Enhancement in Geotechnical Properties of Cohesive Soils by EICP Technique. Appl. Sci. 2020, 10, 7568. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Lateef, M.A.; Mohammed, S.A.S.; Lemboye, K.K.; Chittoori, B.C.S.; Abdullah Almajed, A. Efficacy of Enzymatically Induced Calcium Carbonate Precipitation in the Retention of Heavy Metal Ions. Sustainability 2020, 12, 7019. [Google Scholar] [CrossRef]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Hirata, A. Optimization of enzyme-mediated calcite precipitation as a soil-improvement technique: The effect of aragonite and gypsum on the mechanical properties of treated sand. Crystals 2017, 7, 59. [Google Scholar] [CrossRef]

- David Suits, L.; Sheahan, T.; Soosan, T.; Sridharan, A.; Jose, B.; Abraham, B. Utilization of quarry dust to improve the geotechnical properties of soils in highway construction. Geotech. Test. J. 2005, 28, 11768. [Google Scholar] [CrossRef]

- Sridharan, A.; Soosan, T.G.; Jose, B.T.; Abraham, B.M. Shear strength studies on soil-quarry dust mixtures. Geotech. Geol. Eng. 2006, 24, 1163–1179. [Google Scholar] [CrossRef]

- Birch, W.; Datson, H. Reducing the Environmental Effects of Aggregate Quarrying: Dust, Noise & Vibration. 2008. Available online: https://miningandblasting.files.wordpress.com/2009/09/blast_dust_and_noise_control.pdf (accessed on 5 November 2021).

- Saghafi, B.; Al Nageim, H.; Atherton, W. Mechanical behavior of a new base material containing high volumes of limestone waste dust, PFA, and APC residues. J. Mater. Civ. Eng. 2013, 25, 450–461. [Google Scholar] [CrossRef]

- Kumar, D.S.; Hudson, W.R. Use of Quarry Fines for Engineering and Environmental Applications. Natl. Stone Assoc. 1992. Available online: https://library.ctr.utexas.edu/digitized/iacreports/1992_specrsrch_natlstoneassoc.pdf (accessed on 1 October 2021).

- Kumrawat, N.; Ahirwar, S.K. Performance analysis of black cotton soil treated with calcium carbide residue and stone dust. Int. J. Eng. Res. Sci. Technol. 2014, 3. Available online: http://www.ijerst.com/currentissue.php (accessed on 15 July 2021).

- Antonov, G.I.; Nedosvitii, V.P.; Semenenko, O.M.; Kulik, A.S.; Gerashchuk, Y.D.; I’chenko, N.V.; Poltavets, L.K. Use of dolomite dust for manufacturing stabilized dolomite refractories. Refract. Ind. Ceram. 1997, 38, 238–243. [Google Scholar] [CrossRef]

- Brooks, R.; Udoeyo, F.F.; Takkalapelli, K.V. Geotechnical properties of problem soils stabilized with fly ash and limestone dust in Philadelphia. J. Mater. Civ. Eng. 2011, 23, 711–716. [Google Scholar] [CrossRef]

- Nweke, O.M.; Okogbue, C.O. The potential of cement stabilized shale quarry dust for possible use as road foundation material. Int. J. Geo-Eng. 2017, 8, 29. [Google Scholar] [CrossRef]

- Haldar, M.K.; Das, S.K. Effect of substitution of sand stone dust for quartz and clay in triaxial porcelain composition. Bull. Mater. Sci. 2012, 35, 897–904. [Google Scholar] [CrossRef]

- Cheah, C.B.; Lim, J.S.; Ramli, M.B. The mechanical strength and durability properties of ternary blended cementitious composites containing granite quarry dust (GQD) as natural sand replacement. Constr. Build. Mater. 2019, 197, 291–306. [Google Scholar] [CrossRef]

- Jain, A.K.; Jha, A.K.; Shivanshi. Improvement in subgrade soils with marble dust for highway construction: A comparative study. Indian Geotech. J. 2020, 50, 307–317. [Google Scholar] [CrossRef]

- Kandolkar, S.S.; Mandal, J.N. Effect of reinforcement on stress–strain behavior of stone dust. Int. J. Geotech. Eng. 2014, 8, 383–395. [Google Scholar] [CrossRef]

- Chetia, M.; Baruah, M.P.; Sridharan, A. Contemporary Issues in Geoenvironmental Engineering, Sustainable Civil Infrastructures. In Effect of Quarry Dust on Compaction Characteristics of Clay; Singh, D.N., Galaa, A., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 78–100. [Google Scholar] [CrossRef]

- Zafar, M.S.; Javed, U.; Khushnood, R.A.; Nawaz, A.; Zafar, T. Sustainable incorporation of waste granite dust as partial replacement of sand in autoclave aerated concrete. Constr. Build. Mater. 2020, 250, 118878. [Google Scholar] [CrossRef]

- Natasha, K.; Chetia, M. Shear strength of Rock quarry dust and Sand mix. Emerg. Trends Civ. Eng. 2020, 1–13. [Google Scholar] [CrossRef]

- Oyediran, I.A.; Idowu, O.D. Performance Analysis of some Quarry dust treated soils. J. Min. Geol. 2017, 53, 45–53. [Google Scholar]

- Bahoria, B.; Parbat, D.K.; Nagarnaik, P.B.; Waghe, U.P. Effect of replacement of natural sand by quarry dust and waste plastic on compressive & split tensile strength of M20 concrete. In Proceedings of the International Conference on Engineering (NUiCONE 2013), Ahmedabad, India, 28–30 November 2013; Available online: www.sciencedirect.com (accessed on 25 November 2021).

- Etim, R.K.; Ekpo, D.U.; Attah, I.C.; Onyelowe, K.C. Effect of micro sized quarry dust particle on the compaction and strength properties of cement stabilized lateritic soil. Clean. Mater. 2021, 2, 100023. [Google Scholar] [CrossRef]

- Bloodworth, A.J.; Scott, P.W.; McEvoy, F.M. Digging the backyard: Mining and quarrying in the UK and their impact on future land use. Land Use Policy 2009, 26, S317–S325. [Google Scholar] [CrossRef]

- Sanjay, M.; Sindhi, P.R.; Vinay, C.; Ravindra, N.; Vinay, A. Crushed rock sand—An economical and ecological alternative to natural sand to optimize concrete mix. Eng. Mater. Sci. 2016, 8, 345–347. [Google Scholar] [CrossRef]

- Priyankara, N.H.; Wijesooriya, R.M.S.D.; Jayasinghe, S.N.; Wickramasinghe, W.R.M.B.E.; Yapa, S.T.A.J. Suitability of quarry dust in geotechnical applications to improve engineering properties. Eng. J. Inst. Eng. Sri Lanka 2009, 42. [Google Scholar] [CrossRef][Green Version]

- Nwaiwu, C.; Mshelia, S.; Durkwa, J. Compactive effort influence on properties of quarry dust-black cotton soil mixtures. Int. J. Geotech. Eng. 2012, 6, 91–101. [Google Scholar] [CrossRef]

- Chetia, M.; Sridharan, A. A Review on the Influence of Rock Quarry Dust on Geotechnical Properties of Soil. In Geo-Chicago 2016; American Society of Civil Engineers: Reston, VA, USA, 2016; pp. 179–190. [Google Scholar] [CrossRef]

- Song, Y.-S.; Kim, K.-S.; Woo, K.-S. Stability of embankments constructed from soil mixed with stone dust in quarry reclamation. Environ. Earth Sci. 2011, 67, 285–292. [Google Scholar] [CrossRef]

- Nayak, S.; Sarvade, P.G. Effect of cement and quarry dust on shear strength and hydraulic characteristics of Lithomargic clay. Geotech. Geol. Eng. 2012, 30, 419–430. [Google Scholar] [CrossRef]

- Kumar, P.; Chandra, S.; Vishal, R. Comparative study of different sub base materials. J. Mater. Civ. Eng. 2006, 18, 576–580. [Google Scholar] [CrossRef]

- Mohammed, S.; Raman, S.N.; Jain, M.F.M. Utilization of Quarry Waste Fine Aggregate in Concrete Mixes. J. Appl. Sci. Res. 2007, 3, 202–208. [Google Scholar]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U.; Feduik, R.; Rashid, M.F.; Waqas, R.M. Reusing marble and granite dust as cement replacement in cementitious composites: A review on sustainability benefits and critical challenges. J. Build. Eng. 2021, 44, 102600. [Google Scholar] [CrossRef]

- Singh, S.; Nagar, R.; Agarwal, V.; Rana, A.; Tiwari, A. Sustainable Utilization of Granite cutting waste in high strength concrete. J. Clean. Prod. 2016, 116, 223–235. [Google Scholar] [CrossRef]

- Rama, S.R.G.V. Studies on Hexagonal Wire Mesh-Reinforced Crushed Stone Dust. Slovak J. Civ. Eng. 2018, 26, 20–25. [Google Scholar] [CrossRef]

- Beju, Y.Z.; Mandal, J.N. Experimental Investigation of Shear strength behaviour of Stone dust-EPS geofoam Interface. J. Hazard. Toxic Radioact. Waste 2018, 22, 04018033. [Google Scholar] [CrossRef]

- Kandolkar, S.S.; Mandal, J.N. Behavior of reinforced-stone dust walls with backfill at varying relative densities. J. Hazard. Toxic Radioact. Waste 2016, 20, 04015010. [Google Scholar] [CrossRef]

- Dutta, R.K.; Sarda, V.K. CBR behaviour of waste plastic strip-reinforced stone dust/fly ash overlying saturated clay. Turk. J. Eng. Environ. Sci. 2007, 31, 171–182. [Google Scholar]

- Mudgal, A.; Raju, S.; Sahu, A.K. Effect of lime and stone dust in the geotechnical properties of black cotton soil. Int. J. Geomate 2014, 7, 1033–1039. [Google Scholar] [CrossRef]

- Manandhar, S.; Suetsugu, D.; Hara, H.; Hayashi, H. Performance of Waste Quarry By-Products as A Supplementary Recycled Subgrade Material. In Proceedings of the 9th International Symposium on Lowland Technology (ISLT 2014), Saga, Japan, 29 September–1 October 2014; pp. 271–278. [Google Scholar]

- Jemal, A.; Agon, E.C.; Geremew, A. Utilization of crushed stone dust as A stabilizer for sub grade soil: A case study in Jimma town. Int. J. Eng. 2019, 17, 55–63. [Google Scholar]

| Name of Rock Dust | Predominant Constituent | Specific Gravity | Civil Engineering Applications | Reference |

|---|---|---|---|---|

| Dolomite, metamorphic | Calcium magnesium carbonate | 2.84 | Aggregate, ballast, base material | [27] |

| Limestone, sedimentary | Calcium carbonate | 2.7 | Road base and railroad ballast | [28] |

| Shale, sedimentary | Silica | 2.62 | Fills and embankment | [29] |

| Sandstone, sedimentary | Silica | 2.5 | Replacement of natural sand | [30] |

| Granite, igneous | Silica | 2.7 | Filler, subgrade, replacement of natural sand and sub-base | [31] |

| Marble, metamorphic | Dolomite, quartz, and calcite | 2.71 | Filler in concrete production | [32] |

| Location | Petrographic Description | Mineralogy | Reference |

|---|---|---|---|

| Thane, Maharashtra, India | Irregular shaped angular particles | Quartz from XRD | [33] |

| Local quarry in Kedah, Malaysia | Granular, irregular and angular geometry | Quartz, Microcline, Calcium Aluminium Silicate, Kaolinite, Magnesium Sulphate Hydrate from XRD | [31] |

| Quarry dust from local crushing plants, Guwahati, Assam, India | Sub-angular to angular | Quartz and feldspar | [34] |

| Local marble crushing plants, Pakistan | Angular and flaky in shape and bearing rough texture | Quartz, Crystobalite, Zeolite, Wollastonite from XRD | [35] |

| Garchuk quarry, Guwahati, Assam, India | Sub-angular to angular | Quartz, Feldspar, Biotite, Muscovite and others from petrographic analysis from XRD | [36] |

| Element | Composition Range (%) |

|---|---|

| SiO2 | 45–75 |

| Al2O3 | 15–19 |

| CaO | 3–14 |

| Fe2O3 | 6–17 |

| K2O | 3–4.5 |

| MgO | 1–3.6 |

| Na2O | 0–3.7 |

| P2O3 | 0–0.02 |

| TiO2 | 0–2.65 |

| Soil Type | % Granite Dust | Specific Gravity | Liquid Limit (%) | Plastic Limit (%) |

|---|---|---|---|---|

| Red earth | 0 | 2.70 | 40 | 25 |

| 20 | 2.72 | 35 | Non-plastic | |

| 40 | 2.74 | 27 | - | |

| 60 | 2.76 | 25 | - | |

| 80 | 2.78 | 24 | - | |

| Kaolinite | 0 | 2.6 | 55 | 30 |

| 20 | 2.64 | 47 | 19 | |

| 40 | 2.68 | 37 | Non-plastic | |

| 60 | 2.72 | 30 | - | |

| 80 | 2.76 | 26 | - | |

| Sundried marine clay | 0 | 2.62 | 73 | 36 |

| 20 | 2.66 | 57 | 28 | |

| 40 | 2.69 | 44 | 21 | |

| 60 | 2.72 | 35 | Non-plastic | |

| 80 | 2.76 | 27 | - |

| Soil Type | Outcome | Reference |

|---|---|---|

| Red earth | Decreased gradually | [21] |

| Lithomargic clay | Significant decrease of liquid limit and plastic limit | [43] |

| Black cotton soil | Liquid limit is decreased by 42% at 40% addition of granite dust | [44] |

| Soil Type | % Granite Dust | Soaked CBR (%) | Unsoaked CBR (%) |

|---|---|---|---|

| Red earth | 0 | 8.8 | 9.9 |

| 20 | 9.8 | 10.5 | |

| 40 | 10.8 | 12.0 | |

| 60 | 13.0 | 14.3 | |

| 80 | 14.7 | 15.5 | |

| Kaolinite | 0 | 5.2 | 7.8 |

| 20 | 6.7 | 8.8 | |

| 40 | 8.8 | 10.8 | |

| 60 | 18.7 | 20.8 | |

| 80 | 20.8 | 22.8 | |

| Sun-dried marine clay | 0 | 3.8 | 4.7 |

| 20 | 4.3 | 5.2 | |

| 40 | 5.1 | 6.2 | |

| 60 | 8.9 | 9.4 | |

| 80 | 11.2 | 11.8 |

| Soil Type | Outcome | Reference |

|---|---|---|

| Marine clay | Good improvement at less amount of granite dust | [21] |

| Residual soil | Soaked CBR value is comparatively higher than un soaked | [37] |

| Black cotton soil | Significant increase at 50% addition of granite dust | [44] |

| Soil Type | Outcome | Reference |

|---|---|---|

| Black cotton soil with lime and granite dust | Cohesion increased. Good improvement observed in engineering properties | [55] |

| Silty clay with CCR and granite dust | Good chemical bonding appeared. CBR increased | [26] |

| Lithomargic clay with granite dust and cement | Strength and cohesion increased. Pore volume decreased | [46] |

| Kaolinite clay with granite dust/flyash with waste plastic | CBR increased | [54] |

| High plastic silt with cement and granite dust | CBR improved | [42] |

| Granite Dust: Natural Soil | Yangju, Gyeonggi Province | Gongju, South Chungcheong | ||

|---|---|---|---|---|

| C (t/m2) | φ | C(t/m2) | Φ | |

| 100:0 | 0.52 | 30.2 | 0.45 | 29.3 |

| 75:25 | 0.51 | 30.8 | 0.51 | 30.6 |

| 50:50 | 0.48 | 32.1 | 0.48 | 31.5 |

| 25:75 | 0.44 | 33.4 | 0.4 | 34.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amulya, G.; Moghal, A.A.B.; Almajed, A. A State-of-the-Art Review on Suitability of Granite Dust as a Sustainable Additive for Geotechnical Applications. Crystals 2021, 11, 1526. https://doi.org/10.3390/cryst11121526

Amulya G, Moghal AAB, Almajed A. A State-of-the-Art Review on Suitability of Granite Dust as a Sustainable Additive for Geotechnical Applications. Crystals. 2021; 11(12):1526. https://doi.org/10.3390/cryst11121526

Chicago/Turabian StyleAmulya, Gudla, Arif Ali Baig Moghal, and Abdullah Almajed. 2021. "A State-of-the-Art Review on Suitability of Granite Dust as a Sustainable Additive for Geotechnical Applications" Crystals 11, no. 12: 1526. https://doi.org/10.3390/cryst11121526

APA StyleAmulya, G., Moghal, A. A. B., & Almajed, A. (2021). A State-of-the-Art Review on Suitability of Granite Dust as a Sustainable Additive for Geotechnical Applications. Crystals, 11(12), 1526. https://doi.org/10.3390/cryst11121526