High-Durability Concrete with Supplementary Cementitious Admixtures Used in Corrosive Environments

Abstract

1. Introduction

2. Materials and Test Methods

2.1. Materials

2.2. Mix Proportion

2.3. Test Method

3. Results and Discussion

3.1. Compressive Strength

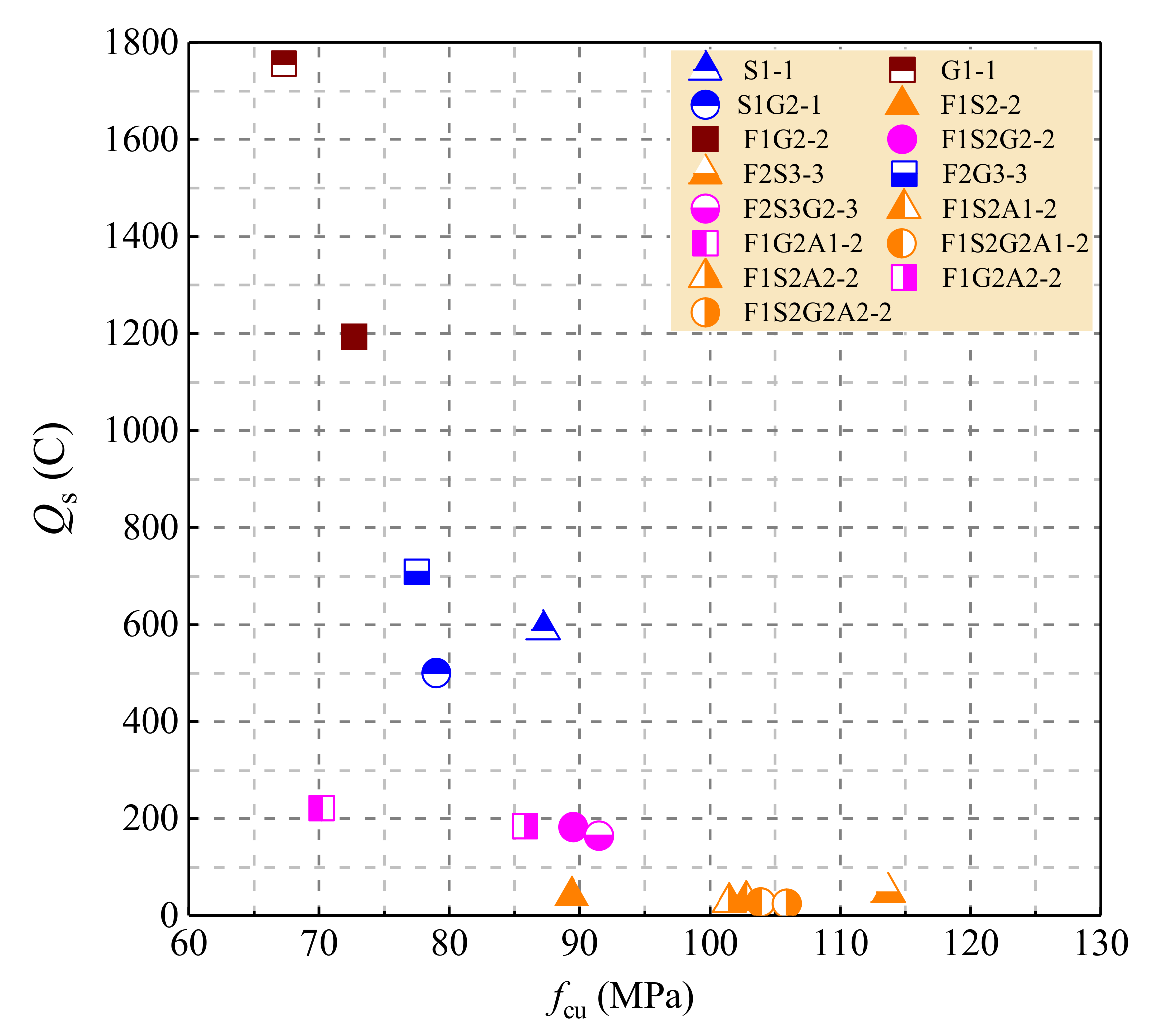

3.2. Chloride Resistance

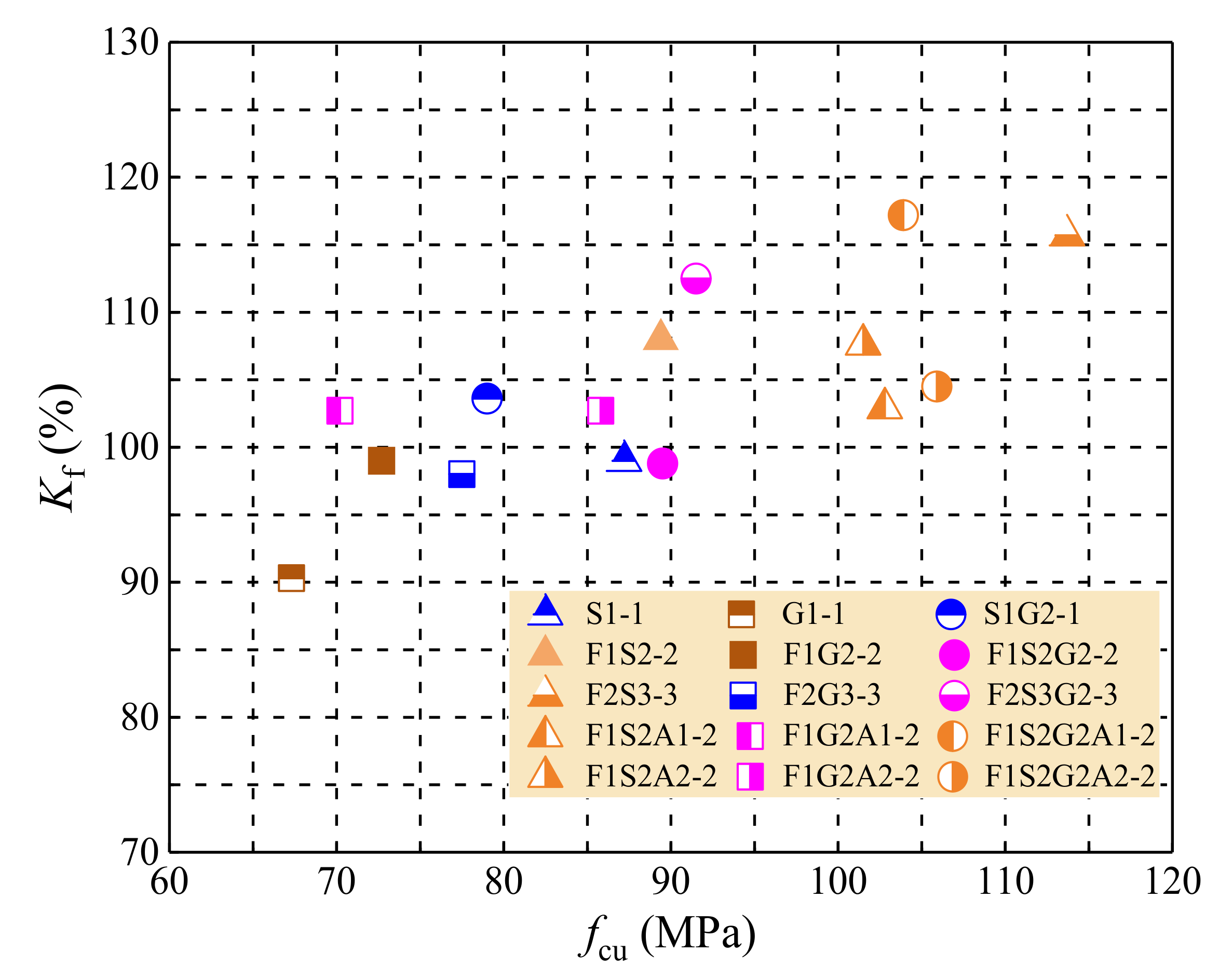

3.3. Sulfate Resistance

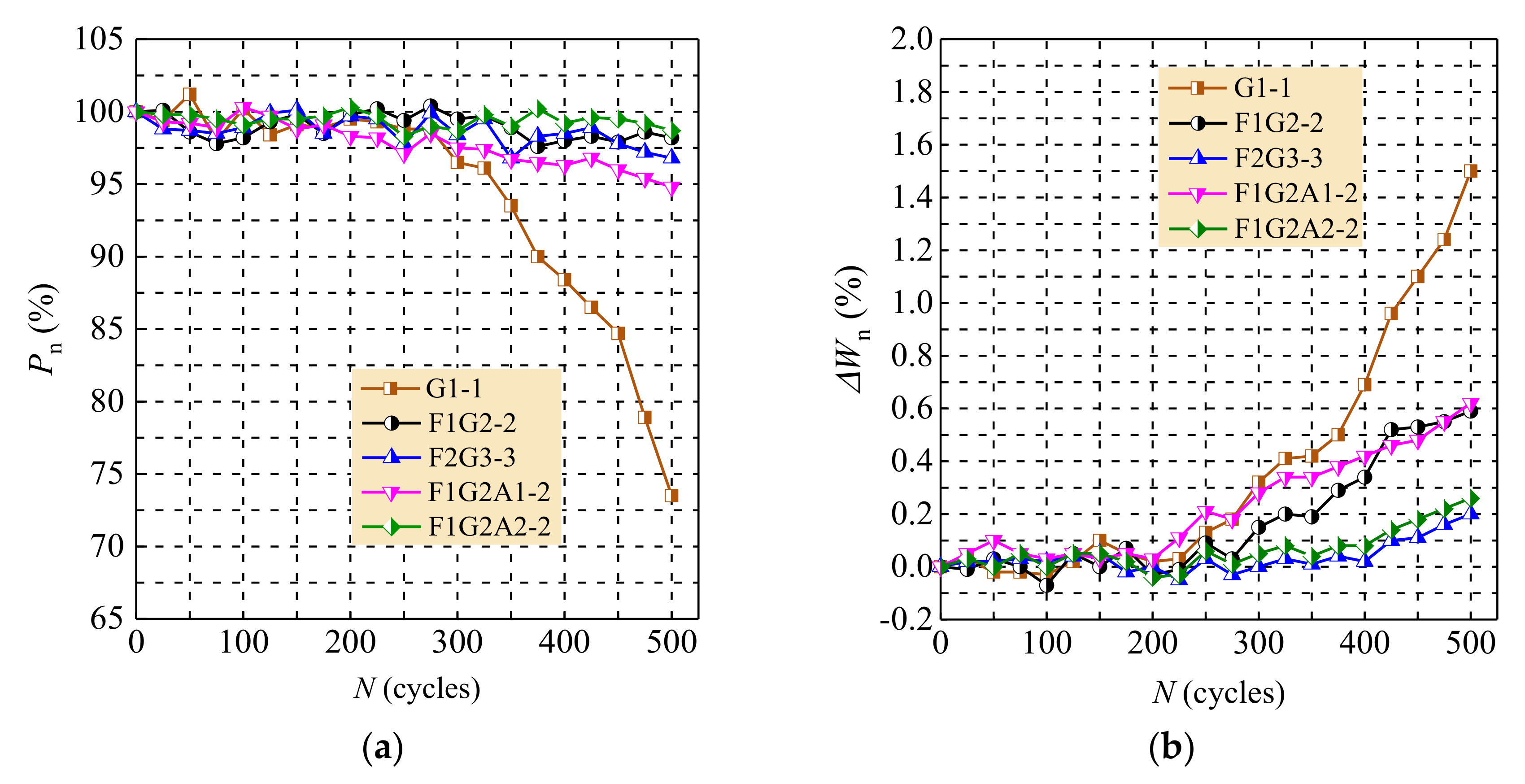

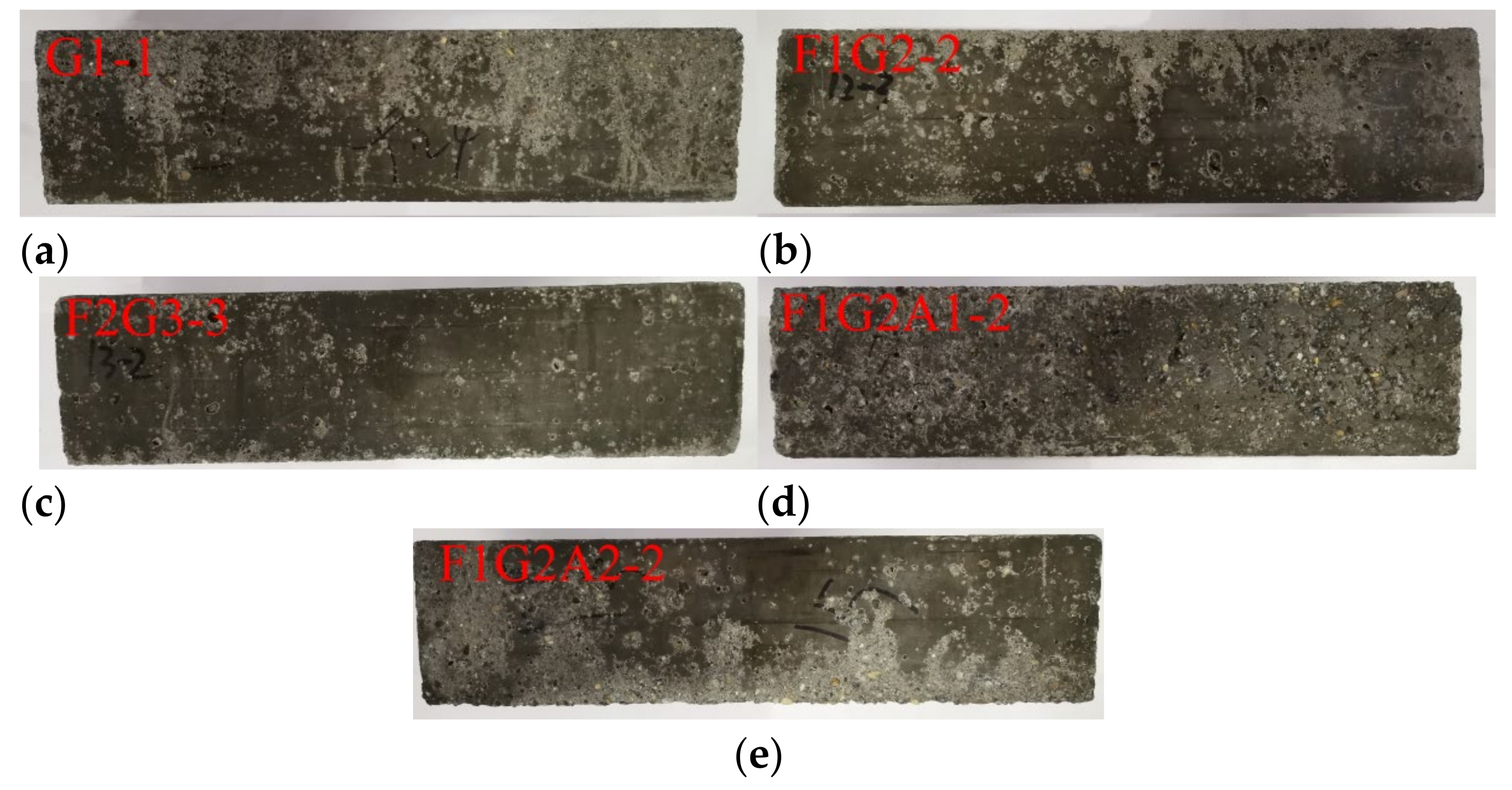

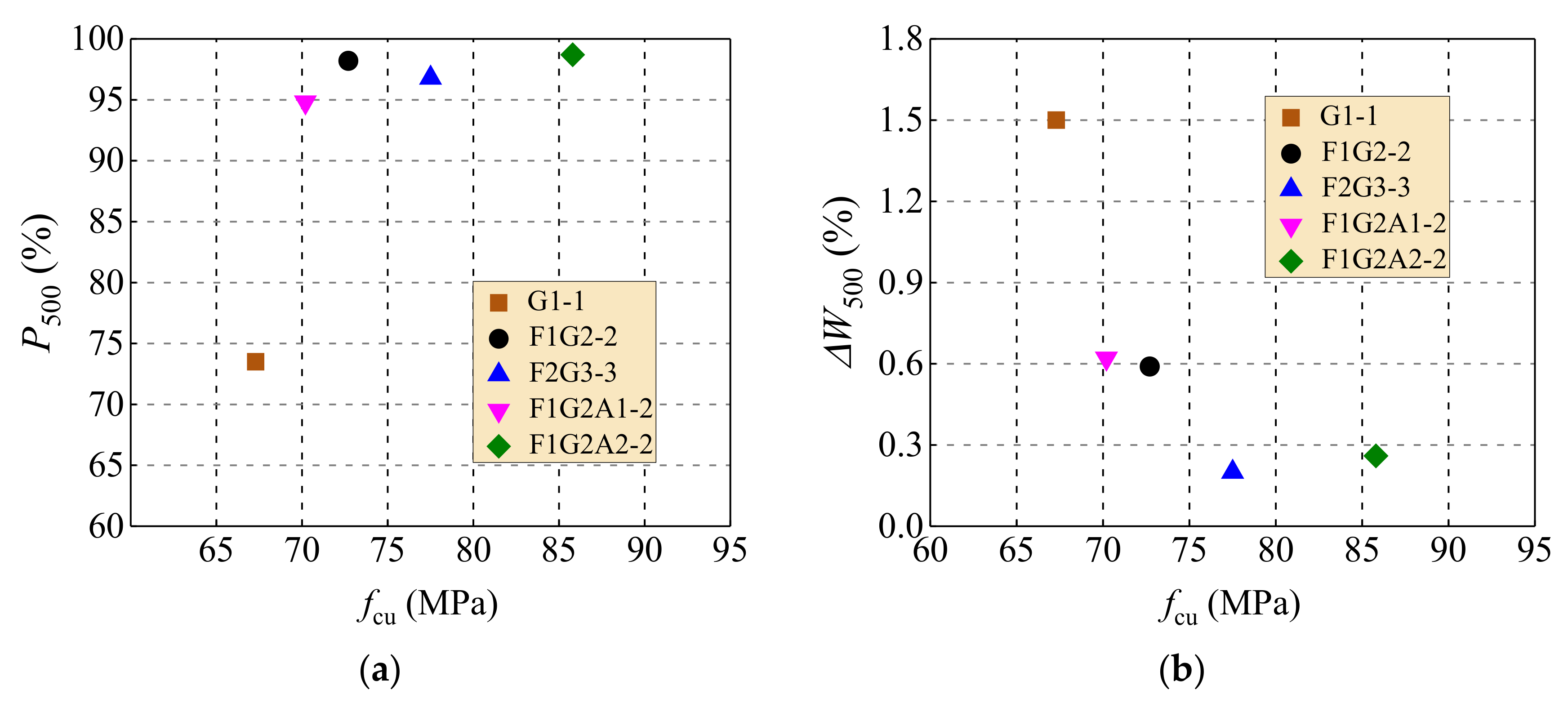

3.4. Frost Resistance

4. Conclusions

- Due to the difference of chemical composition, fineness, and pozzolanic activity, the supplementary cementitious admixtures present different effects on the strength and durability of concrete. In general, SF and FA benefit the compressive strength and durability of concrete, and the negative effect of GGBS can be overcome with the hybrid use of SF, FA, and AS. AS benefits the compressive strength and the resistances of concrete to chloride penetration and sulfate corrosion, while showing no obvious effect on the resistance of concrete to frost.

- With the different combinations of the supplementary cementitious admixtures, the concrete can be produced with the compressive strength ranging from 70 MPa to 110 MPa. With the binary use of FA and SF, FA and GGBS, or the ternary use of SF, FA, and GGBS, the compressive strength of concrete increases with the reduction of water to binder ratio. With the admixing of proper content of 7% FA and 8% SF, the concrete can be prepared with compressive strength of about 100 MPa, in which the cement can be replaced by equal weight of 8% GGBS and 10~12% AS.

- Except for the concrete only mixed with GGBS or with GGBS and FA, other concrete can be produced with ideal resistance to chloride penetration. With proper content of FA and SF, the concretes present a superior resistance to chloride penetration of the highest grade over Q-V with the index of total electric flux lower than 500 C specified in the China code, in which the cement can be replaced by equal weight of 8% GGBS and 10~12% AS.

- Except for the concrete only mixed with GGBS or with GGBS and FA, other concretes reaching the highest grade over KS150 withstood the 150 dry–wet cycles of sulfate corrosion specified in the China code. The concretes with the AS appeared to have a superior ability to resist the sulfate corrosion.

- All concretes are at the highest grade over F400 for the resistance to frost, with the relative dynamic elastic modulus no less than 60% and the weight loss rate no larger than 5% specified in the China code, although the concrete admixed only with GGBS appears to have a relatively low resistance.

- The durability is positively related to the compressive strength of concrete with hybrid admixtures. With water to binder ratio of 0.29 and total binders of 500 kg/m3, the highest grades of resistances specified in the China codes to chloride penetration, sulfate corrosion, and frost can be reached for the concrete admixed with 7% FA + 8% SF + 8% GGBS or 7% FA + 8% SF + 8% GGBS + (10~12)% AS, while the compressive strength was about 100 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- China Academy of Railway Sciences. Code for Durability Design on Concrete Structure of Railway; TB 10005-2010; China Railway Publishing House: Beijing, China, 2011. [Google Scholar]

- Qu, F.L.; Liu, G.R.; Zhao, S.B.; Yan, L.Y. Mechanical properties of non-uniformly corroded steel bars based on length characterization. J. Build. Mater. 2016, 19, 566–570. [Google Scholar]

- Kiesse, T.S.; Bonnet, S.; Amiri, Q.; Ventura, A. Analysis of corrosion risk due to chloride diffusion for concrete structures in marine environment. Mar. Struct. 2020, 73, 102804. [Google Scholar] [CrossRef]

- Wolfram, M.; Robin, E.; Beddoe, D.H. Sulfate attack expansion mechanisms. Cem. Concr. Res. 2013, 52, 208–215. [Google Scholar]

- Gao, R.D.; Zhao, S.B.; Li, Q.B.; Chen, J.H. Experimental study of the deterioration mechanism of concrete under sulfate attack in wet-dry cycles. China Civ. Eng. J. 2010, 43, 48–54. [Google Scholar]

- Wang, D.Z.; Zhou, X.M.; Meng, Y.F.; Chen, Z. Durability of concrete containing fly ash and silica fume against combined freezing-thawing and sulfate attack. Constr. Build. Mater. 2017, 147, 398–406. [Google Scholar] [CrossRef]

- Li, Y.; Zhai, Y.; Liang, W.B.; Li, Y.B.; Dong, Q.; Meng, F.D. Dynamic mechanical properties and visco-elastic damage constitutive model of freeze–thawed concrete. Materials 2020, 13, 4056. [Google Scholar] [CrossRef] [PubMed]

- Adorján, B. Long term durability performance and mechanical properties of highperformance concretes with combined use of supplementary cementing materials. Constr. Build. Mater. 2016, 112, 307–324. [Google Scholar]

- Duan, P.; Shui, Z.H.; Chen, W.; Shen, C.H. Efficiency of mineral admixtures in concrete: Microstructure, compressive strength and stability of hydrate phases. Appl. Clay Sci. 2013, 83–84, 115–121. [Google Scholar] [CrossRef]

- Nehdi, M.L.; Sumner, J. Optimization of ternary cementitious mortar blends using factorial experimental plans. Mater. Struct. 2002, 35, 495–503. [Google Scholar] [CrossRef]

- Elahi, A.; Basheer, P.A.M.; Nanukuttan, S.V.; Khan, Q.U.Z. Mechanical and durability properties of high performance concretes containing supplementary cementitious materials. Constr. Build. Mater. 2010, 24, 292–299. [Google Scholar] [CrossRef]

- KojiKinomura, T. Enhanced hydration model of fly ash in blended cement and application of extensive modeling for continuous hydration to pozzolanic micro-pore structures. Cem. Concr. Compos. 2020, 114, 103733. [Google Scholar] [CrossRef]

- Yan, P.Y. Mechanism of fly ash in hydration of composite cementitious materials. J. China Ceram. Soc. 2007, 35(s1), 167–171. [Google Scholar]

- Watcharapong, W.; Pailyn, T.; Athipong, N.; Arnon, C. Compressive strength and chloride resistance of self-compacting concrete containing high level fly ash and silica fume. Mater. Des. 2014, 64, 261–269. [Google Scholar]

- Al-Dulaijan, S.U.; Maslehuddin, M.; Al-Zahrani, M.M.; Sharif, A.M.; Shameem, M.; Ibrahim, M. Sulfate resistance of plain and blended cements exposed tovarying concentrations of sodium sulfate. Cem. Concr. Compos. 2003, 25, 429–437. [Google Scholar] [CrossRef]

- Erhan, G.; Mehmet, G.; Erdoğan, Ö. Strength and drying shrinkage properties of self-compacting concretes incorporating multi-system blended mineral admixtures. Constr. Build. Mater. 2010, 24, 1878–1887. [Google Scholar]

- Mohammed, S.M.; Mohamed, A.I.; El-Gamal, S.; Fitriani, H. Performances evaluation of binary concrete designed with silica fumeand metakaolin. Constr. Build. Mater. 2018, 166, 400–412. [Google Scholar]

- Liu, R.G.; Ding, S.D.; Yan, P.Y. Influence of hydration environment on the characteristics of ground granulated blast furnace slag hydration products. B. China Ceram. Soc. 2015, 34, 1594–1599. [Google Scholar]

- Wu, M.Y.; Wang, Q.C.; Zhang, K.; Dong, Y.T.; Wang, X.L. Influence of mineral admixtures on impermeability and frost resistance of high performance concrete. Highway 2016, 61, 239–242. [Google Scholar]

- Yan, X.L.; Gong, T.Z.; Chang, J.F.; Zheng, Y. Experimental research about sulfate resistance performance of high performance concrete. J. Electr. Power 2017, 32, 257–264. [Google Scholar]

- Yang, B.J. Experimental Study on the Sulfate Corrosion-Resistance Admixturefor Concrete. Master’s Thesis, Qingdao Technological University, Qingdao, China, 2011. [Google Scholar]

- Xu, Y.L.; Zhang, P.Y. Effect and mechanism of sulfate corrosion-resistance admixture on concrete performance. B. China Ceram. Soc. 2016, 35, 2304–2308. [Google Scholar]

- Chang, H.L.; Mu, S.; Liu, J.Z. Influence of anticorrosion agent and curing regimes on pore structure feature and moisture loss of concrete. J. Southeast U Nat. Sci. Ed. 2015, 45, 1155–1162. [Google Scholar]

- Liang, R. Compounding of High Durability Concrete and Application in Strong Corrosive Environment. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2018. [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete; GB 50082-2009; China Building Industry Press: Beijing, China, 2009. [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Inspection and Assessment of Concrete Durability; JGJ/T 193-2009; China Building Industry Press: Beijing, China, 2009. [Google Scholar]

- Gao, R.D.; Li, Q.B.; Zhao, S.B.; Yang, X.M. Deterioration mechanisms of sulfate attack on concrete under alternate action. J. Wuhan Univ. Technol. Sci. Ed. 2010, 25, 355–359. [Google Scholar] [CrossRef]

- Sossa, V.; Pérez-Gracia, V.; González-Drigo, R.; Rasol, M.A. Lab non-destructive test to analyze the effect of corrosion on ground penetrating radar scans. Remote Sens. 2019, 11, 2814. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Common Portland Cement; GB 175-2007; China Standard Press: Beijing, China, 2007. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Fly Ash Used for Cement and Concrete; GB/T 1596-2017; China Standard Press: Beijing, China, 2017. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Silica Fume Cement Mortar and Concrete; GB/T 27690-2011; China Standard Press: Beijing, China, 2011. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Ground Granlated Blast Furnace Slag Used for Cement, Mortar and Concrete; GB/T 18046-2017; China Standard Press: Beijing, China, 2008. [Google Scholar]

- National Development and Reform Commission of the People’s Republic of China. Sulfate Corrosion-resistance Admixtures for Concrete; JC/T 1011-2006; China Building Materials Industry Press: Beijing, China, 2006. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Sand for Construction; GB/T 14684-2011; China Standard Press: Beijing, China, 2011. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Pebble and Crushed Stone for Construction; GB/T 14685-2011; China Standard Press: Beijing, China, 2011. [Google Scholar]

- Ministry of Housing and Urban Rural Development of the People’s Republic of China. Specification for Mix Proportion Design of Ordinary Concrete; JGJ 55-2011; China Building Industry Press: Beijing, China, 2011. [Google Scholar]

- Ministry of Construction of the People’s Republic of China. Standard for Test Methods on Mechanical Properties of Ordinary Concrete; GB/T 50081-2002; China Building Industry Press: Beijing, China, 2002. [Google Scholar]

- American Society for Testing and Materials. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; ASTM C1202-19; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Zhao, M.L.; Ding, X.X.; Li, J.; Law, D. Numerical analysis of mix proportion of self-compacting concrete compared to ordinary concrete. Key Eng. Mater. 2018, 789, 69–75. [Google Scholar] [CrossRef]

- Ding, X.X.; Zhao, M.L.; Zhou, S.Y.; Fu, Y.; Li, C.Y. Statistical analysis and preliminary study on the mix proportion design of self-compacting steel fiber reinforced concrete. Materials 2019, 12, 637. [Google Scholar] [CrossRef] [PubMed]

- Li, C.Y.; Shang, P.R.; Li, F.L.; Feng, M.; Zhao, S.B. Shrinkage and mechanical properties of self-compacting SFRC with calcium sulfoaluminate expansive agent. Materials 2020, 13, 588. [Google Scholar] [CrossRef]

- Uysal, M.; Akyuncu, V. Durability performance of concrete incorporating Class F and Class C fly ashes. Constr. Build. Mater. 2012, 34, 170–178. [Google Scholar] [CrossRef]

- Zhao, S.B.; Li, C.Y.; Zhao, M.S.; Zhang, X.Y. Experimental study on autogenous and drying shrinkage of lightweight-aggregate concrete reinforced by steel fibers. Adv. Mater. Sci. Eng. 2016, 2016, 2589383. [Google Scholar] [CrossRef]

- Ding, X.X.; Li, C.Y.; Xu, Y.Y.; Li, F.L.; Zhao, S.B. Experimental study on long-term compressive strength of concrete with manufactured sand. Constr. Build. Mater. 2016, 108, 67–73. [Google Scholar] [CrossRef]

- Li, C.Y.; Wang, F.; Deng, X.S.; Li, Y.Z.; Zhao, S.B. Testing and prediction of the strength development of recycled-aggregate concrete with large particle natural aggregate. Materials 2019, 12, 1891. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.D.; Li, Q.B.; Zhao, S.B. Concrete deterioration mechanisms under combined sulfate attack and flexural loading. J. Mater. Civ. Eng. 2013, 25, 39–44. [Google Scholar] [CrossRef]

- Gao, R.D.; Zhao, S.B.; Li, Q.B. Deterioration mechanisms of sulfate attack on concrete under the action of compound factors. J. Build. Mater. 2009, 12, 41–46. [Google Scholar]

- Mu, R. Durability and Service Life Prediction of Concrete Subjected to the Combined Action of Freezing-Thawing, Sustained External Flexural Stress and Salt Solution. Master’s Thesis, Southeast University, Nanjing, China, 2000. [Google Scholar]

- Zhao, M.S.; Zhang, X.Y.; Song, W.H.; Li, C.Y.; Zhao, S.B. Development of steel fiber-reinforced expanded-shale lightweight concrete with high freeze-thaw resistance. Adv. Mater. Sci. Eng. 2018, 2018, 9573849. [Google Scholar] [CrossRef]

| Materials | Chemical Compositions (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Fe2O3 | Al2O3 | CaO | MgO | SO3 | f-CaO | K2O | K2O | LOI | |

| cement | 21.6 | 3.3 | 4.9 | 56.4 | 3.4 | 2.2 | 0.9 | 0.1 | 0.1 | 5.3 |

| FA | 55.9 | 5.9 | 17.3 | 6.6 | 3.8 | 1.9 | 0.3 | 1.9 | 1.9 | 2.6 |

| SF | 88.3 | 0.7 | 0.9 | 1.2 | 0.2 | 0.9 | 0.3 | 0.7 | 0.7 | 0.8 |

| GGBS | 25.9 | 2.6 | 8.4 | 41.4 | 4.5 | 0.1 | 0.1 | 0.5 | 0.5 | 4.0 |

| AS | 48.0 | 2.4 | 8.6 | 20.3 | 1.9 | 7.4 | 3.7 | 0.6 | 0.6 | 1.9 |

| Density (kg/m3) | Fineness (m2/kg) | Setting Time (min) | Flexural Strength (MPa) | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Initial | Final | 3d | 28d | 3d | 28d | ||

| 3133 | 324 | 236 | 308 | 5.1 | 7.8 | 24.9 | 47.2 |

| Materials | Density (kg/m3) | Fineness (m2/kg) | Water Demands Ratio(%) | Active Index (%) | |

|---|---|---|---|---|---|

| 7d | 28d | ||||

| FA | 2342 | 406 | 84 | — | 73.3 |

| SF | 2149 | — | 101.7 | 97.8 | — |

| GGBS | 2998 | 438.8 | — | 76 | 97.6 |

| AS | 2703 | 380 | — | 95 | 102 |

| Identifier of Mixture | w/b | Dosage of Raw Materials (kg/m3) | PS (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cement | FA | SF | GGBS | AS | Sand | Gravel | |||

| S1-1 | 0.33 | 425 | 0 | 14 | 0 | 0 | 721.0 | 1227.6 | 2.6 |

| G1-1 | 0.33 | 425 | 0 | 0 | 14 | 0 | 674.8 | 1253.2 | 1.6 |

| S1G2-1 | 0.33 | 385 | 0 | 14 | 40 | 0 | 715.1 | 1217.5 | 2.4 |

| F1S2-2 | 0.29 | 425 | 35 | 40 | 0 | 0 | 697.1 | 1187.0 | 2.2 |

| F1G2-2 | 0.29 | 425 | 35 | 0 | 40 | 0 | 652.5 | 1211.8 | 1.8 |

| F1S2G2-2 | 0.29 | 385 | 35 | 40 | 40 | 0 | 691.2 | 1177.0 | 2.2 |

| F2S3-3 | 0.25 | 425 | 55 | 100 | 0 | 0 | 668.3 | 1138.0 | 2.2 |

| F2G3-3 | 0.25 | 425 | 55 | 0 | 100 | 0 | 625.6 | 1161.8 | 1.8 |

| F2S3G2-3 | 0.25 | 385 | 55 | 100 | 40 | 0 | 662.4 | 1127.9 | 2.4 |

| F1S2A1-2 | 0.29 | 375 | 35 | 40 | 0 | 50 | 657.7 | 1221.5 | 3.0 |

| F1G2A1-2 | 0.29 | 375 | 35 | 0 | 40 | 50 | 650.1 | 1207.4 | 2.0 |

| F1S2G2A1-2 | 0.29 | 335 | 35 | 40 | 40 | 50 | 652.1 | 1211.1 | 2.8 |

| F1S2A2-2 | 0.29 | 365 | 35 | 40 | 0 | 60 | 657.2 | 1220.6 | 2.8 |

| F1G2A2-2 | 0.29 | 365 | 35 | 0 | 40 | 60 | 649.6 | 1206.5 | 2.2 |

| F1S2G2A2-2 | 0.29 | 325 | 35 | 40 | 40 | 60 | 651.6 | 1210.2 | 2.8 |

| Identifier of Mixtures | fcu (MPa) | Qs (C) | fcu at 120 Times Cycle (MPa) | Kf (%) | fcu at 150 Times Cycle (MPa) | Kf (%) | ||

|---|---|---|---|---|---|---|---|---|

| Sulfate Attack | Ref. | Sulfate Attack | Ref. | |||||

| S1-1 | 87.2 | 589.8 | 90.0 | 89.5 | 100.6 | 88.2 | 89.1 | 99.0 |

| G1-1 | 67.3 | 1756.3 | 76.4 | 81.5 | 93.7 | 77.7 | 86.0 | 90.3 |

| S1G2-1 | 79.0 | 499.9 | 84.9 | 81.5 | 104.2 | 86.7 | 83.7 | 103.6 |

| F1S2-2 | 89.4 | 41.8 | 92.4 | 85.7 | 107.8 | 89.1 | 82.5 | 108.0 |

| F1G2-2 | 72.7 | 1193.3 | 82.0 | 84.4 | 97.2 | 85.3 | 85.9 | 99.3 |

| F1S2G2-2 | 89.5 | 182.4 | 88.5 | 87.1 | 101.6 | 87.3 | 88.4 | 98.8 |

| F2S3-3 | 113.7 | 48.3 | 120.0 | 110.3 | 108.8 | 125.0 | 108.0 | 115.7 |

| F2G3-3 | 77.5 | 708.3 | 87.4 | 89.1 | 98.1 | 89.1 | 91.0 | 98.0 |

| F2S3G2-3 | 91.5 | 164.6 | 101.4 | 88.8 | 114.2 | 100.6 | 89.4 | 112.5 |

| F1S2A1-2 | 102.8 | 31.3 | 107.7 | 102.0 | 105.6 | 103.5 | 100.6 | 102.9 |

| F1G2A1-2 | 70.2 | 221.0 | 76.6 | 72.5 | 105.7 | 79.2 | 77.1 | 102.7 |

| F1S2G2A1-2 | 103.9 | 27.4 | 114.1 | 100.0 | 114.1 | 121.0 | 103.2 | 117.2 |

| F1S2A2-2 | 101.5 | 27.3 | 95.9 | 99.9 | 96.0 | 103.6 | 96.3 | 107.6 |

| F1G2A2-2 | 85.8 | 184.2 | 85.9 | 81.0 | 106.1 | 89.0 | 86.7 | 102.7 |

| F1S2G2A2-2 | 105.9 | 24.9 | 113.1 | 102.9 | 109.9 | 103.1 | 98.7 | 104.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Zhu, M.; Ding, X.; Ren, Z.; Zhao, S.; Zhao, M.; Dang, J. High-Durability Concrete with Supplementary Cementitious Admixtures Used in Corrosive Environments. Crystals 2021, 11, 196. https://doi.org/10.3390/cryst11020196

Liu S, Zhu M, Ding X, Ren Z, Zhao S, Zhao M, Dang J. High-Durability Concrete with Supplementary Cementitious Admixtures Used in Corrosive Environments. Crystals. 2021; 11(2):196. https://doi.org/10.3390/cryst11020196

Chicago/Turabian StyleLiu, Shiming, Miaomiao Zhu, Xinxin Ding, Zhiguo Ren, Shunbo Zhao, Mingshuang Zhao, and Juntao Dang. 2021. "High-Durability Concrete with Supplementary Cementitious Admixtures Used in Corrosive Environments" Crystals 11, no. 2: 196. https://doi.org/10.3390/cryst11020196

APA StyleLiu, S., Zhu, M., Ding, X., Ren, Z., Zhao, S., Zhao, M., & Dang, J. (2021). High-Durability Concrete with Supplementary Cementitious Admixtures Used in Corrosive Environments. Crystals, 11(2), 196. https://doi.org/10.3390/cryst11020196