Study on Mechanism of Glass Molding Process for Fingerprint Lock Glass Plates

Abstract

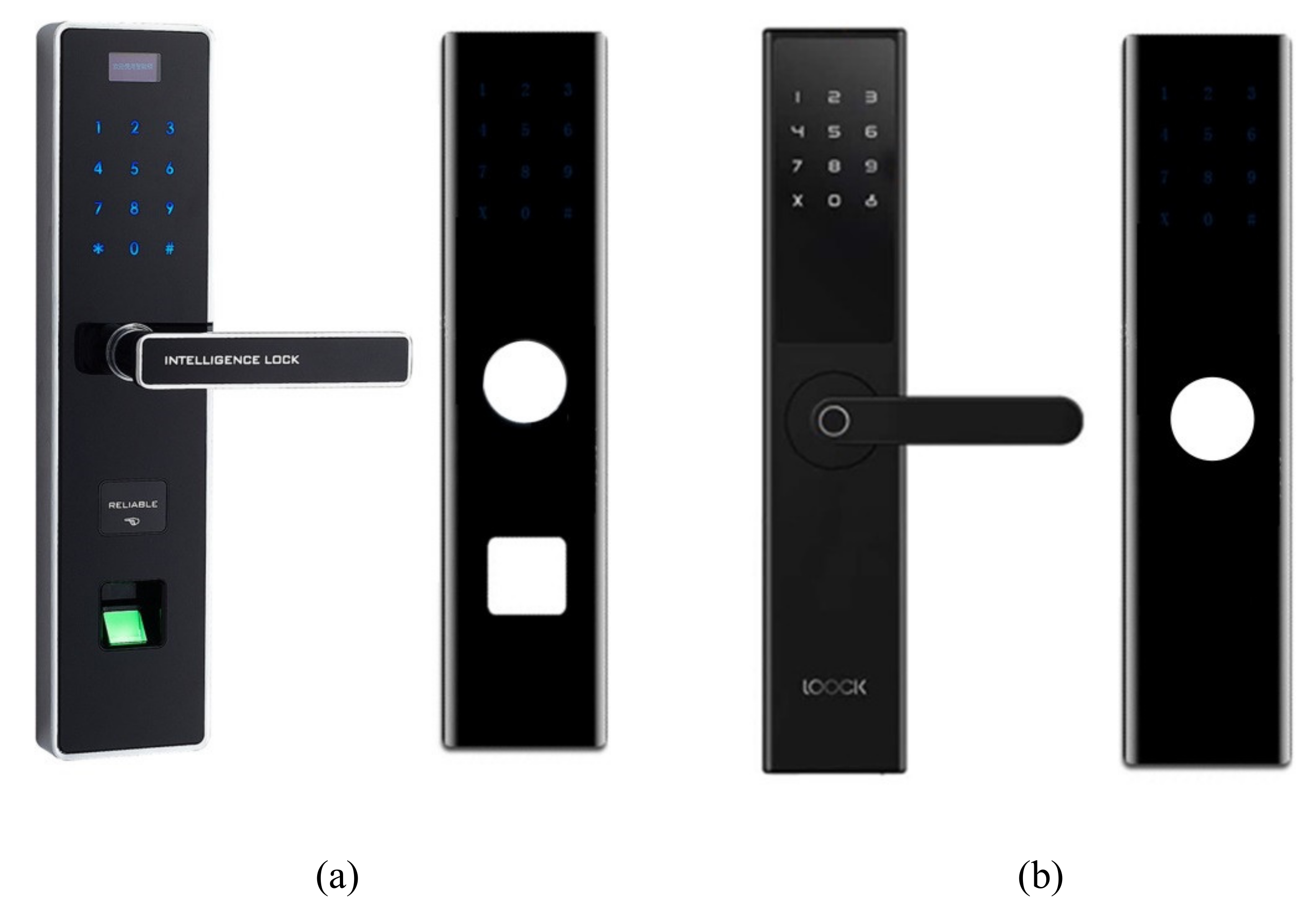

1. Introduction

2. Basic Theory of Optical Glass Molding

2.1. Creep and Viscoelastic Properties of Glass Materials

2.1.1. Viscoelastic Model and Stress Relaxation of Optical Glass

2.1.2. Heat Flow Characteristics

2.2. Structural Relaxation

2.3. Heat Transfer Model

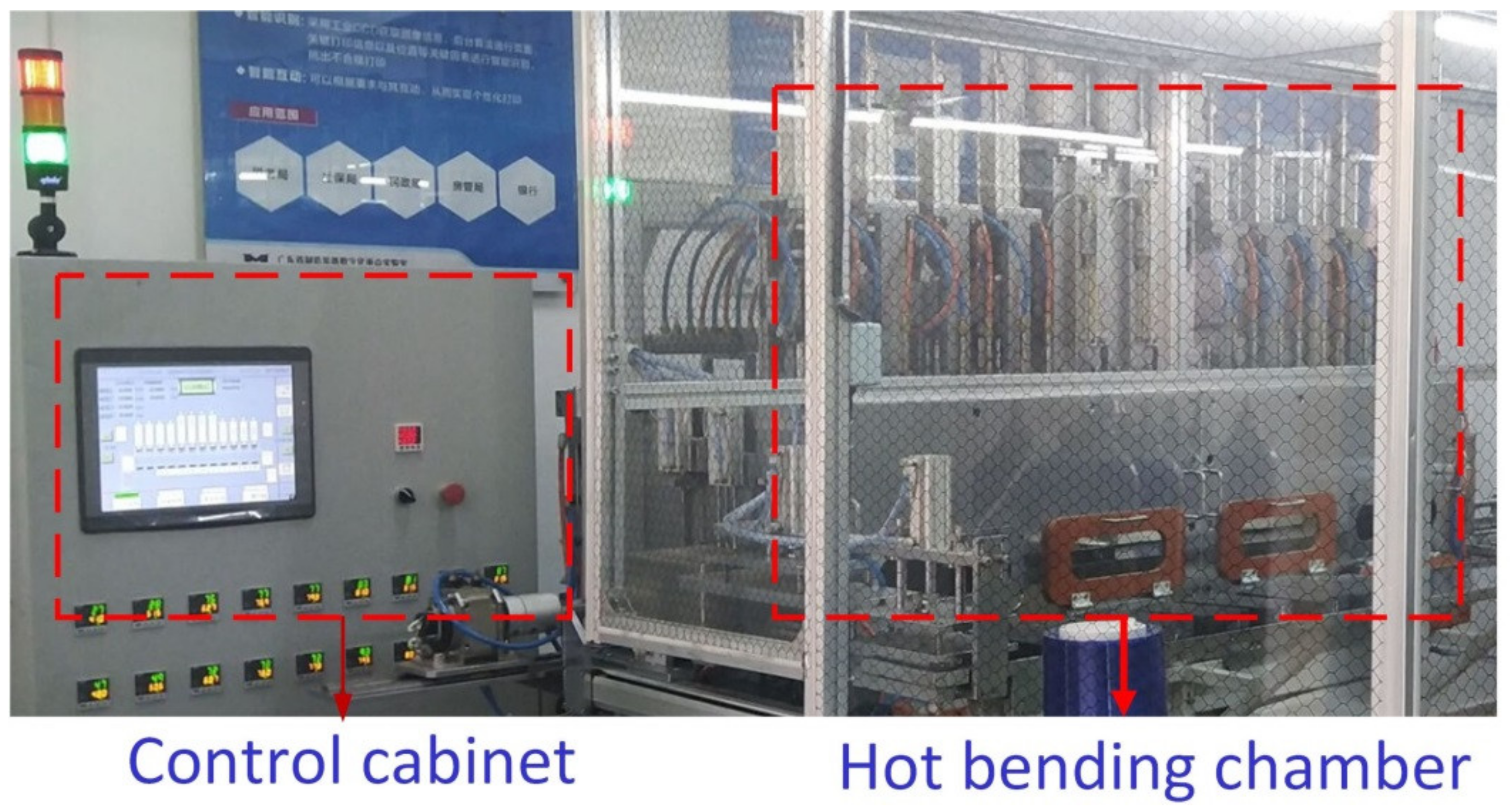

3. Experimental Setup

4. Simulation Modeling of GMP

4.1. Material Selection for Mold and Glass Preform

4.2. Boundary Conditions

5. Results and Discussion

5.1. Effect of Molding Temperature on Forming Quality

5.2. Effect of Heating Rate on Forming Quality

5.3. Effect of Cooling Rate on Forming Quality

5.4. Verification Experiment

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J. On the New challenges of fingerprint identification technology. J. Liaoning Police Acad. 2012, 1, 76–79. [Google Scholar]

- Xin, Q. Manufacturing Technology of Optical Plastic Aspheric Surface; National Defence Industrial Press: Beijing, China, 2005; pp. 25–33. [Google Scholar]

- Wang, Y. Development and application of optical glass. J. Appl. Opt. 2005, 26, 61–66. [Google Scholar]

- Chen, M. Research on ultra-precision aspheric grinding technology; Harbin Inst: Harbin, China, 2011. [Google Scholar]

- Liu, W.; Shen, P.; Jin, N. Viscoelastic properties of chalcogenide glasses and the simulation of their molding processes. Phys. Procedia 2011, 19, 422–425. [Google Scholar] [CrossRef]

- Zhao, Y.; Yi, H. Glass Technology; Chemical IndustryPress: Beijing, China, 2006; pp. 95–116. [Google Scholar]

- Wang, Y. Numerical Simulation of Ultra-Precision Molding of Aspheric Optical Glass Lens; Hunan University: Hunan, China, 2011. [Google Scholar]

- Huo, J. Numerical Simulation and Simulation of Stress State and Molding Shape of Aspheric Glass Lens; Hunan University: Hunan, China, 2011. [Google Scholar]

- Xie, W. Numerical Simulation Analysis of Die Forming Of Microstructure Optical Element; Hunan University: Hunan, China, 2016. [Google Scholar]

- Yin, S.; Huo, J.; Zhou, T. Simulation of Heating and Pressure Parameters in Molding of Small Aperture Aspheric Lens; Hunan University: Hunan, China, 2011; Volume 38, pp. 35–39. [Google Scholar]

- Jain, A.; Yi, A.; Xie, X. Finite element modelling of stress relaxation in glass lens moulding using measured, temperature-dependent elastic modulus and viscosity data of glass. Model. Simul. Mater. Sci. Eng. 2006, 14, 465. [Google Scholar] [CrossRef]

- Ming, W.; Jia, H.; Zhang, H. A comprehensive review of electric discharge machining of advanced ceramics. Ceram. Int. 2020, 46, 21813–21838. [Google Scholar] [CrossRef]

- Yan, J.; Zhou, T.; Masuda, J. Modeling high-temperature glass molding process by coupling heat transfer and viscous deformation analysis. Precis. Eng. 2009, 33, 150–159. [Google Scholar] [CrossRef]

- Curan, A.; Gocalinska, A.; Pescaglini, A. Structural and Electronic Properties of Polycrystalline InAs Thin Films Deposited on Silicon Dioxide and Glass at Temperatures below 500 °C. Crystals 2021, 11, 160. [Google Scholar] [CrossRef]

- Tao, B.; Yuan, Y. FEM simulation of the effect of coefficient of thermal expansion and heat capacity on prediction of residual stresses of compression molded glass lenses. In Proceedings of the 2017 4th International Conference on Advanced Materials, Mechanics and Structural Engineering (4th AMMSE 2017), Tianjin, China, 22–24 September 2017. [Google Scholar]

- Kim, J.H.; Kong, J.; Chung, K. Analysis of annealing processes of glass sheets based on structural relaxation model. Int. J. Mech. Sci. 2013, 66, 249–259. [Google Scholar] [CrossRef]

- Blair, G.; Clarence, C. Method for Molding Glass Lens. U.S. Patent 3833347, 3 September 1974. [Google Scholar]

- Xiao, T. Rediscovery and Re-Expansion: Research on Glass Fusing and Slumping Process. Decorative 2015, 2, 81–83. [Google Scholar]

- Hong, J. Finite Element Analysis of Optical Glass (Micro) Hot Pressing(Ⅱ); National Chiao Tung University: Hsinchu, Taiwan, 2005. [Google Scholar]

- Zhou, S. Molding Simulation and Experimental Study of Small Aperture Aspheric Glass Lens; Hunan University: Hunan, China, 2016. [Google Scholar]

- Zhou, J.; Shi, T.; Hu, Y. Numerical simulation in compression molding of glass lens. In Proceedings of the 2013 IEEE International Conference on Automation Science and Engineering (CASE), Madison, WI, USA, 17–20 August 2013. [Google Scholar]

- Kordonsky, I.; Prokhorov, I.V.; Gieb, L.K. New high-precision magnetorheological instrument-based method of polishing optic. Osa T Workshop Dig. 1992, 24, 134–136. [Google Scholar]

- Xiaobing, Z.; Center, E.T. Review on manufacture and measurement method of aspheric surface optical part. Ordnance Mater. Sci. Eng. 2014, 37, 106–111. [Google Scholar]

- Yi, A.Y.; Jain, A. Compression Molding of Aspherical Glass Lenses–A Combined Experimental and Numerical Analysis. J. Am. Ceram. Soc. 2005, 88, 579–586. [Google Scholar] [CrossRef]

- Cha, D.H.; Park, H.S.; Hwang, Y. Experimental study of glass molding process and transcription characteristics of mold surface in molding of aspheric glass lense. Opt. Rev. 2011, 18, 241–246. [Google Scholar] [CrossRef]

- Zheng, C. Study on chalcogenide infrared glass for precision molding; Xi’an Technological University: Xi’an, China, 2009. [Google Scholar]

- Ma, T.; Yu, J.; Wang, S. Precision molding manufacturing of small aperture thin glass lens. Infrared and laser engineering. Infrared Laser Eng. 2011, 40, 87–90. [Google Scholar]

- Zhao, W.; Chen, Y.; Shen, L.; Allen, Y.Y. Investigation of the refractive index distribution in precision compression glass molding by use of 3D tomography. Meas. Sci. Technol. 2009, 20, 055109. [Google Scholar] [CrossRef]

- Masahiro, A.; Yuusuke, K. Characterization of the Thermo-Viscoelastic Property of Glass and Numerical Simulation of the Press Molding of Glass Lens. J. Therm. Stresses 2009, 32, 1235–1255. [Google Scholar]

- Zhu, K. Numerical Simulation and Experimental Study on Molding of Optical Glass Lens; Hunan University: Hunan, China, 2013. [Google Scholar]

- Zhao, W.; Chen, Y.; Shen, L.; Allen, Y.Y. Refractive index and dispersion variation in precision optical glass molding by computed tomography. Appl. Opt. 2009, 48, 3588–3595. [Google Scholar] [CrossRef] [PubMed]

- Aronen, A.; Karvinen, R. Effect of glass temperature before cooling and cooling rate on residual stresses in tempering. Glass Struct. Eng. 2018, 3, 3–15. [Google Scholar] [CrossRef]

- Jain, A.; Yi, A.Y. Numerical modeling of viscoelastic stress relaxation during glass lens forming process. J. Am. Ceram. Soc. 2010, 88, 530–535. [Google Scholar] [CrossRef]

- Ohmori, H. Electrolytic In-process Dressing (ELID) grinding method for ultra-precision mirror surface grinding. Int. J. Jpn. Soc. Precis. Eng. 1993, 59, 1451–1454. [Google Scholar] [CrossRef][Green Version]

- Tain, Y.; Kawata, K. Development of High-Efficiency Fine Finishing Process Using Magnetic Fluid. Ann. Cirp 1984, 33, 217–220. [Google Scholar] [CrossRef]

- Nieto, D.; Flores-Arias, M.T.; O’ Connor, G.; Gomez-Reino, C. Laser direct-write technique for fabricating microlens arrays on soda-lime glass with a Nd: YVO4 laser. Appl. Opt. 2010, 49, 4979–4983. [Google Scholar] [CrossRef]

- Yin, S.; Wang, Y.; Zhu, K. Numerical simulation of ultra-precision molding of micro aspheric glass lens. Acta Photonica Sin. 2010, 39, 2020–2024. [Google Scholar]

- He, W.; Chen, Z.; Ming, W. Multi-objective optimization of glass multi-station bending machining. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 476. [Google Scholar] [CrossRef]

| Properties | Glass | Graphite |

|---|---|---|

| Young’s modulus E(GPa) | 72.6 | 10.2 |

| Poisson rate ν | 0.206 | 0.25 |

| Density ρ(g/cm3) | 2.51 | 1.78 |

| Thermal conductivity K(W/m °C) | 1.1 | 151 |

| Specific heat Cp(J/Kg °C) | 858 | 720 |

| Thermal expansion coefficient (°C) | Liquid 3.43 × 10−5 Solid 1.143 × 10−5 | 4.8 × 10−6 |

| Properties | Time(s) | Value |

|---|---|---|

| Stress relaxation (Shear modulus(MPa)) | 0.0689 | 12566 |

| 0.0065 | 12615 | |

| 0.0001 | 4582 | |

| Structural relaxation (Weights) | 3.0 | 0.108 |

| 0.671 | 0.443 | |

| 0.247 | 0.166 | |

| 0.091 | 0.161 | |

| 0.033 | 0.046 | |

| 0.008 | 0.077 |

| Number | Heating Rate A(s) | Holding Time B(°C) | Bending Temperature C(°C) | Bending Pressure D(MPa) | Cooling Rate E(°C/s) |

|---|---|---|---|---|---|

| 1 | 1 | 120 | 640 | 50 | 1.0 |

| 2 | 1.5 | 120 | 640 | 50 | 1.0 |

| 3 | 2.0 | 120 | 640 | 50 | 1.0 |

| Number | Cooling Rate A(°C/s) | Heating Rate B (s) | Holding Time C(°C) | Bending Temperature D(°C) | Bending Pressure E(MPa) |

|---|---|---|---|---|---|

| 1 | 0.5 | 1.5 | 120 | 640 | 50 |

| 2 | 0.75 | 1.5 | 120 | 640 | 50 |

| 3 | 1.0 | 1.5 | 120 | 640 | 50 |

| Region | Planeness(mm) | Region | Planeness(mm) | Region | Planeness(mm) |

|---|---|---|---|---|---|

| A1–3 | 0.02 | B1–3 | 0.03 | C1–3 | 0.035 |

| A4–6 | 0.033 | B4–6 | 0.034 | C4–6 | 0.045 |

| A7–9 | 0.01 | B7–9 | 0.023 | C7–9 | 0.015 |

| A | small | B | medium | C | large |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ming, W.; Jia, H.; Huang, H.; Zhang, G.; Liu, K.; Lu, Y.; Cao, C. Study on Mechanism of Glass Molding Process for Fingerprint Lock Glass Plates. Crystals 2021, 11, 394. https://doi.org/10.3390/cryst11040394

Ming W, Jia H, Huang H, Zhang G, Liu K, Lu Y, Cao C. Study on Mechanism of Glass Molding Process for Fingerprint Lock Glass Plates. Crystals. 2021; 11(4):394. https://doi.org/10.3390/cryst11040394

Chicago/Turabian StyleMing, Wuyi, Haojie Jia, Heyuan Huang, Guojun Zhang, Kun Liu, Ya Lu, and Chen Cao. 2021. "Study on Mechanism of Glass Molding Process for Fingerprint Lock Glass Plates" Crystals 11, no. 4: 394. https://doi.org/10.3390/cryst11040394

APA StyleMing, W., Jia, H., Huang, H., Zhang, G., Liu, K., Lu, Y., & Cao, C. (2021). Study on Mechanism of Glass Molding Process for Fingerprint Lock Glass Plates. Crystals, 11(4), 394. https://doi.org/10.3390/cryst11040394