Effects of Polarity Inversion Layer on Performances of Lateral-Field-Excitation Piezoelectric Sensors Based on Lithium Niobate Single Crystal

Abstract

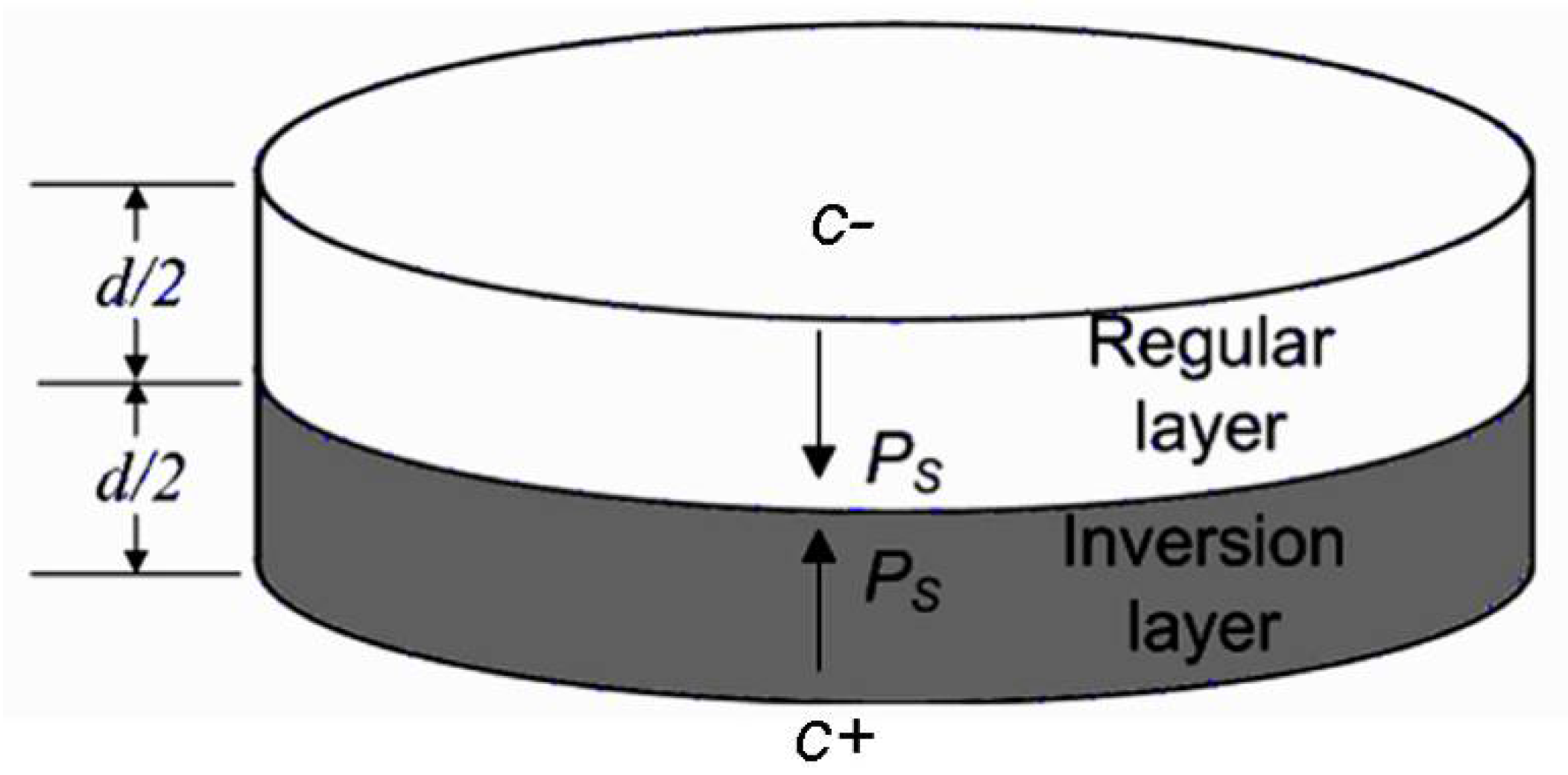

:1. Introduction

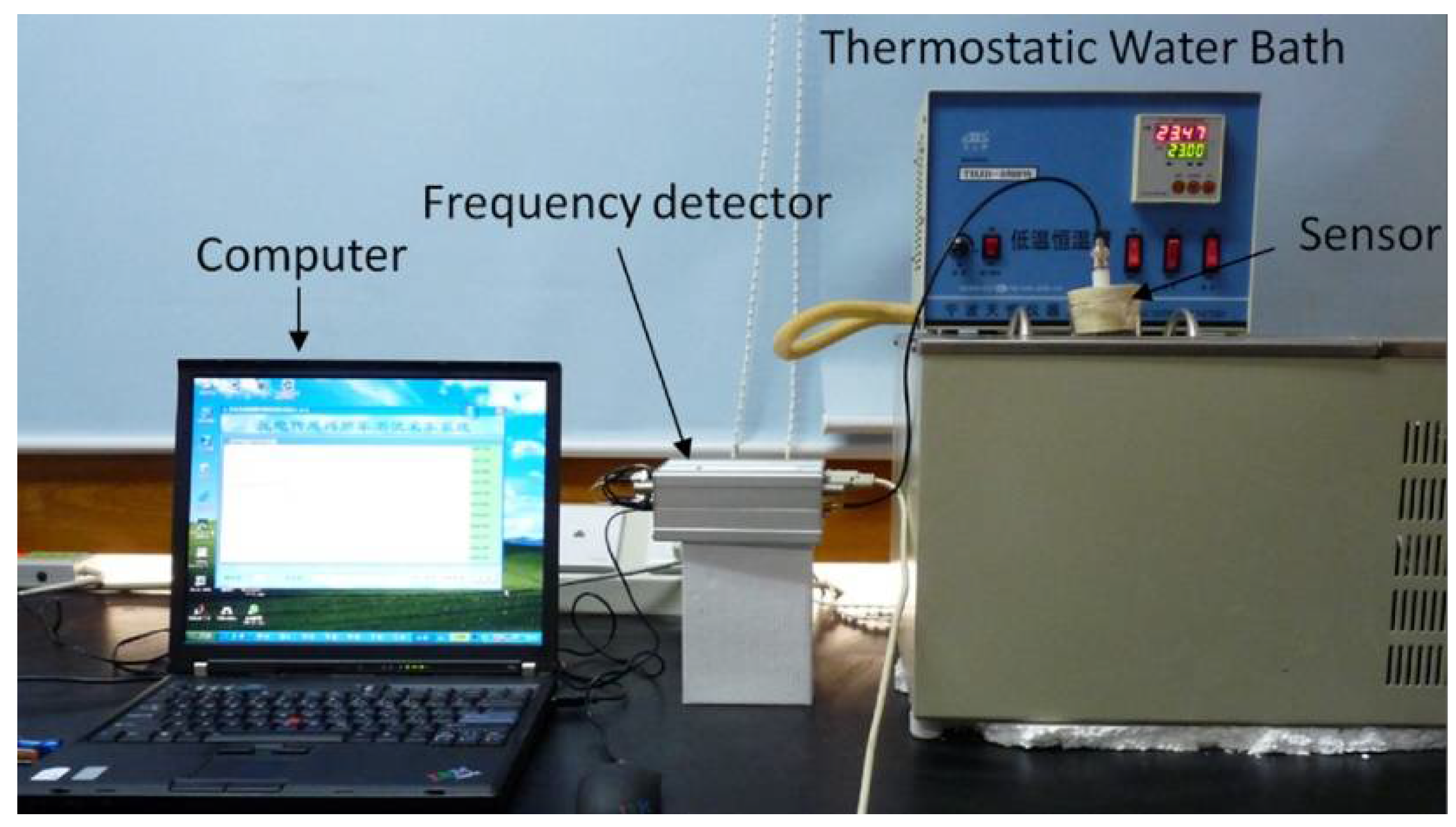

2. Experiments and Test Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stevens, D.S.; Tiersten, H.F. An analysis of doubly rotated quartz resonators utilizing essentially thickness modes with transverse variation. J. Acoust. Soc. Am. 1986, 79, 1811–1826. [Google Scholar] [CrossRef]

- Qian, Z.H.; Kishimoto, K.; Yang, J.S. Propagation of thickness-twist wave in a piezoelectric ceramic plate in contact with viscous fluids. Acta Mech. 2010, 212, 263–270. [Google Scholar] [CrossRef]

- Shi, H.; Yan, L.; Zheng, Y.; Ma, T.; Wang, M.; Huang, B.; Yuan, L.; Wang, J.; Du, J.; Zhang, H. Piezoelectric resonators excited by lateral electric fields based on a LiTaO3 single crystal. Crystals 2020, 10, 525. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, Y. Acoustic vortex beam generation by a piezoelectric transducer using spiral electrode. Chin. Phys. Lett. 2019, 36, 114302. [Google Scholar] [CrossRef]

- Bi, H.Z.; Zhang, H.; Wang, M.G. Study on thickness mode of piezoelectric ceramic disk with discrete series electrode structure. In Proceedings of the 13th Symposium on Piezoelectrcity, Acoustic Waves and Device Application, Harbin, China, 11–14 January 2019; pp. 1–5. [Google Scholar]

- Hu, Y.T.; Yang, J.S.; Zeng, Y.; Jiang, Q.A. High-sensitivity, dual-plate, thickness-shear mode pressure sensor. IEEE Trans. Ultrason. Ferroelectr. Freq. Contr. 2006, 53, 2193–2197. [Google Scholar] [CrossRef]

- Latif, U.; Rohrer, A.; Lieberzeit, P.A.; Dickert, F.L. QCM gas phase detection with ceramic materials-VOCs and oil vapors. Anal. Bioanal. Chem. 2011, 400, 2457–2462. [Google Scholar] [CrossRef] [PubMed]

- Shen, D.Z.; Zhang, H.T.; Kang, Q.; Zhang, H.J.; Yuan, D.R. Oscillating frequency response of a langasite crystal microbalance in liquid phases. Sens. Actuators B 2006, 119, 99–104. [Google Scholar] [CrossRef]

- Yang, J.S. The Mechanics of Piezoelectric Structures; World Scientific: Singapore, 2006. [Google Scholar]

- Liu, B.; Jiang, Q.; Hu, Y.T.; Yang, J.S. High-frequency vibrations of piezoelectric plates driven by lateral electric fields. Int. J. Eng. Sci. 2011, 49, 1435–1442. [Google Scholar] [CrossRef]

- Hu, Y.H.; French, L.A.; Radecsky, K.; Da Cunha, M.P.; Millard, P.; Vetelino, J.F. A lateral field excited liquid acoustic wave sensor. IEEE Trans. Ultrason. Ferroelectr. Freq. Contr. 2004, 51, 1373–1380. [Google Scholar] [CrossRef] [PubMed]

- Hempel, U.; Lucklum, R.; Hauptmann, P.; EerNisse, E.P.; Puccio, D.; Diaz, R.F.; Vives, A.A. Lateral field excited quartz crystal resonator sensors for determination of acoustic and electrical properties of liquids. In Proceedings of the 2008 IEEE International Frequency Control Symposium, Honolulu, HI, USA, 19–21 May 2008; pp. 705–710. [Google Scholar]

- Hu, Y.; Pinkham, W.; French, L.A.J.; Frankel, D.; Vetelino, J.F. Pesticide detection using a lateral field excited acoustic wave sensor. Sens. Actuators B 2005, 108, 910–916. [Google Scholar] [CrossRef]

- Hempel, U.; Lucklum, R.; Hauptmann, P.R. Lateral field excited acoustic wave devices: A new approach to bio-Interface sensing. In Proceedings of the 2007 IEEE Frequency Control Symposium, Geneva, Switzerland, 29 May–1 June 2007; pp. 426–430. [Google Scholar]

- Baron, C.; Cheng, H.; Mool, C.G. Domain inversion in LiTaO3 and LiNbO3 by electric field application on chemically patterned crystals. App. Phys. Lett. 1996, 68, 481–483. [Google Scholar] [CrossRef]

- Zhou, Q.F.; Cannata, J.M.; Shung, K.K. Design and modeling of inversion layer ultrasonic transducers using LiNbO3 single crystal. Ultrasonics 2006, 44, e607–e611. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, K.; Fukazawa, K.; Yamada, K. Broadband ultrasonic transducers using a LiNbO3 plate with a ferroelectric inversion layer. IEEE Trans. Ultrason. Ferroelectr. Freq. Contr. 2003, 50, 1558–1562. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.F.; Wang, J.; Du, J.K.; Yuan, L.L.; Zhang, Z.T.; Zhang, C. Effect of the ferroelectric inversion layer on resonance modes of LiNbO3 thickness-shear mode resonators. Appl. Phys. Express 2012, 5, 116501. [Google Scholar] [CrossRef]

- Ma, T.F.; Wang, J.; Du, J.K.; Yang, J.S. Lateral-Field-Excited electromechanical resonances in a LiNbO3 crystal plate with a ferroelectric inversion layer. Ferroelectrics 2015, 486, 184–192. [Google Scholar] [CrossRef]

- Zhang, C.; Vetelino, J.F. Bulk acoustic wave sensors for sensing measurand induced electrical property changes in solutions. IEEE Trans. Ultrason. Ferroelectr. Freq. Contr. 2001, 48, 773–778. [Google Scholar] [CrossRef] [PubMed]

- French, L.A.; McCann, D.F.; Wark, M.; Winters, S.; Vetelino, J.F. A Lateral Field Excited Acoustic Wave Sensor. In Proceedings of the International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 1287–1290. [Google Scholar]

| Device Type | Frequency Variation Range (Hz) | Allan Variance |

|---|---|---|

| With no inversion layer | ±9 | 4.47 |

| With an inversion layer | ±6 | 3.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Chen, D.; Sun, F.; Xu, K.; Ma, T.; Yuan, L.; Wu, R. Effects of Polarity Inversion Layer on Performances of Lateral-Field-Excitation Piezoelectric Sensors Based on Lithium Niobate Single Crystal. Crystals 2021, 11, 407. https://doi.org/10.3390/cryst11040407

Zheng Y, Chen D, Sun F, Xu K, Ma T, Yuan L, Wu R. Effects of Polarity Inversion Layer on Performances of Lateral-Field-Excitation Piezoelectric Sensors Based on Lithium Niobate Single Crystal. Crystals. 2021; 11(4):407. https://doi.org/10.3390/cryst11040407

Chicago/Turabian StyleZheng, Yuanzhen, Dudu Chen, Fei Sun, Kuanxiang Xu, Tingfeng Ma, Lili Yuan, and Rongxing Wu. 2021. "Effects of Polarity Inversion Layer on Performances of Lateral-Field-Excitation Piezoelectric Sensors Based on Lithium Niobate Single Crystal" Crystals 11, no. 4: 407. https://doi.org/10.3390/cryst11040407

APA StyleZheng, Y., Chen, D., Sun, F., Xu, K., Ma, T., Yuan, L., & Wu, R. (2021). Effects of Polarity Inversion Layer on Performances of Lateral-Field-Excitation Piezoelectric Sensors Based on Lithium Niobate Single Crystal. Crystals, 11(4), 407. https://doi.org/10.3390/cryst11040407