The Effect of Nickel Contents on the Microstructure Evolution and Toughness of 800 MPa Grade Low Carbon Bainite Deposited Metal

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Preparation

2.2. Mechanical Testing

2.3. Microstructure Characterization

3. Results and Discussion

3.1. The Effect of Ni on the Microstructure Evolution

3.2. The Effect of Ni on the Toughness of Deposited Metal

3.3. The Fracture Mechanism of Different Deposited Metals

3.3.1. The Analysis of Crack Propagation Feature from the Perspective of Microstructure

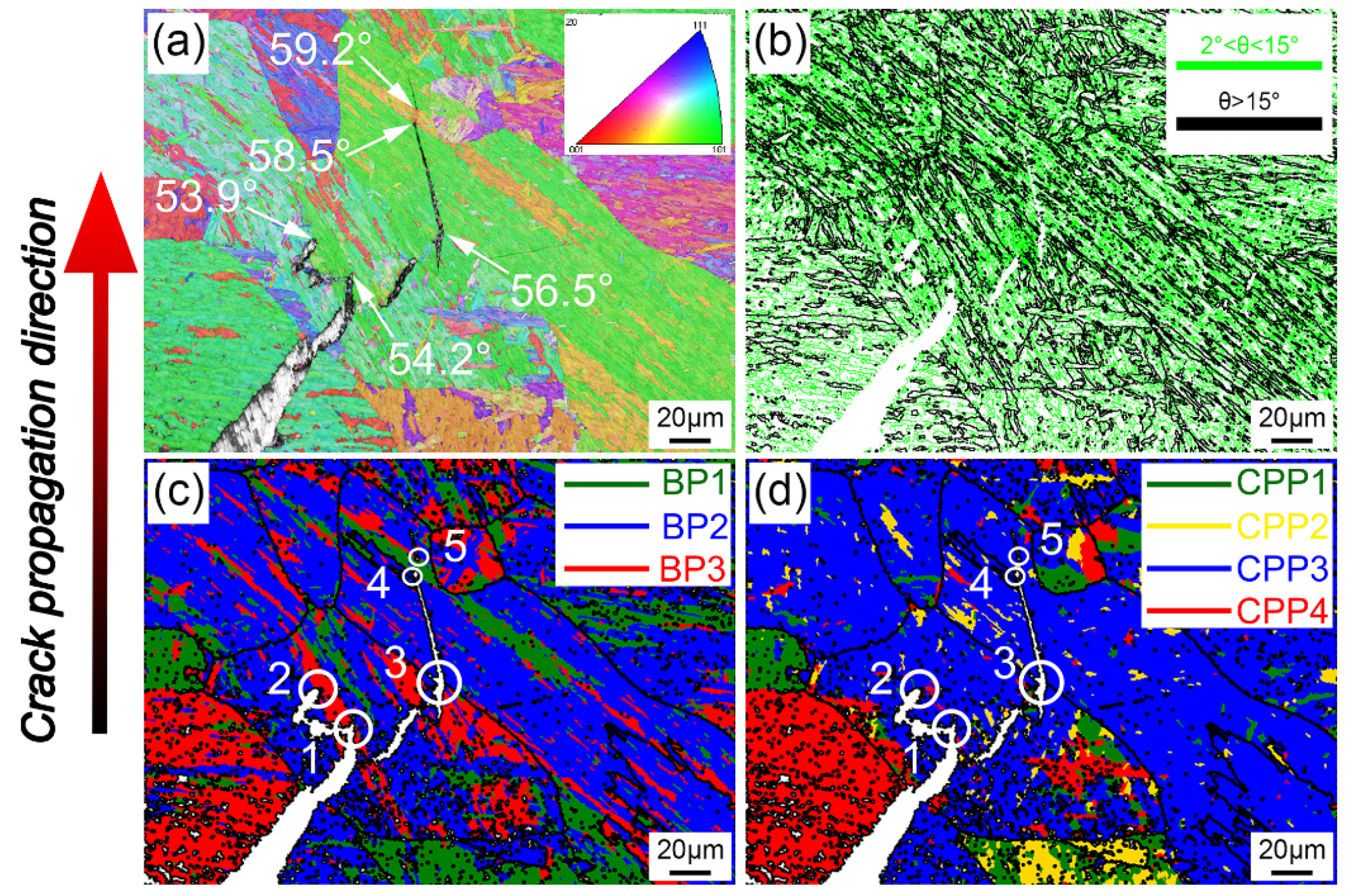

3.3.2. The Analysis of Crack Propagation Features from the Perspective of Crystallographic Characteristics

4. Conclusions

- The formation of CB in 800 MPa grade low carbon bainite deposited metal mainly depended on the nucleation methods of bainite ferrite laths. Autocatalytic nucleation weakens with the increase of Ni content, and those bainite ferrite laths with close orientation will coalesce when promoted by the large driving force of bainite transformation. The fraction of CB increased from 6.9% to 8.3% and 11.4% with the increase of Ni content, while the content of RA did not continue to increase once the Ni content exceeded 6.5% due to the C in deposited metal being controlled at a very low level.

- From the perspective of the crystallography characteristics, BP was the smallest control unit for toughness in 800 MPa grade low carbon bainite deposited metals.

- With the increase of Ni content, the impact energy of deposited metal first increased and then decreased, mainly due to the comprehensive influence of CB and RA. With the increase of Ni content, the fraction of CB continued to increase, but the content of RA stabilized at 5.4% when the Ni content exceeded 6.5%. RA in deposited metal could improve the toughness, while the CB would deteriorate the toughness of deposited metal.

- In low carbon bainite deposited metal, the toughness could be effectively improved effectively by increasing the content of RA while suppressing the formation of CB. This work provided the reference for the chemical composition design of 800 MPa grade steel welding consumables.

Author Contributions

Funding

Conflicts of Interest

References

- Barrick, E.J.; DuPont, J.N. Microstructural characterization and toughness evaluation of 10 wt% Ni steel weld metal gas tungsten arc and gas metal arc weld fusion zones. Mater. Sci. Eng. A 2020, 796, 140043. [Google Scholar] [CrossRef]

- Lan, H.F.; Du, L.X.; Misra, R.D.K. Effect of microstructural constituents on strength–toughness combination in a low carbon bainitic steel. Mater. Sci. Eng. A 2014, 611, 194–200. [Google Scholar] [CrossRef]

- Tian, Y.; Zhou, J.; Shen, Y.; Qu, Z.; Xue, W.; Wang, Z. Improved Toughness of a High-Strength Low-Alloy Steel for Arctic Ship by Ni and Mo Addition. Adv. Eng. Mater. 2020, 22. [Google Scholar] [CrossRef]

- Gaojun, M.; Rui, C.; Cyril, C.; Roland, L.; Xili, G.; Yong, J.; Jianhong, C. Microstructural evolution and mechanical property development with nickel addition in low-carbon weld butt joints. J. Mater. Process. Technol. 2018, 262, 638–649. [Google Scholar]

- Sun, J.; Wei, S.; Lu, S. Influence of vanadium content on the precipitation evolution and mechanical properties of high-strength Fe–Cr–Ni–Mo weld metal. Mater. Sci. Eng. A 2019, 138739. [Google Scholar] [CrossRef]

- Kwon, H.; Kim, C.H. FRACTURE-BEHAVIOR IN MEDIUM-CARBON MARTENSITIC SI-STEEL AND NI-STEEL. Metall. Trans. a-Physical Metall. Mater. Sci. 1986, 17, 1173–1178. [Google Scholar] [CrossRef]

- Kang, B.Y.; Kim, H.J.; Hwang, S.K. Effect of Mn and Ni on the Variation of the Microstructure and Mechanical Properties of Low-carbon Weld Metals. ISIJ Int. 2000, 40, 1237–1245. [Google Scholar] [CrossRef] [Green Version]

- Keehan, E.; Karlsson, L.; Andren, H.O. Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals Part 1—Effect of nickel content. Sci. Technol. Weld. Join. 2006, 11, 1–8. [Google Scholar] [CrossRef]

- Khodir, S.; Shibayanagi, T.; Takahashi, M.; Abdel-Aleem, H.; Ikeuchi, K. Microstructural evolution and mechanical properties of high strength 3–9% Ni-steel alloys weld metals produced by electron beam welding. Mater. Des. 2014, 60, 391–400. [Google Scholar] [CrossRef]

- Gao, G.; Zhang, H.; Gui, X.; Luo, P.; Tan, Z.; Bai, B. Enhanced ductility and toughness in an ultrahigh-strength Mn–Si–Cr–C steel: The great potential of ultrafine filmy retained austenite. Acta Mater. 2014, 76, 425–433. [Google Scholar] [CrossRef]

- Cui, H.B.; Lu, Y.; Xie, G.M.; Luo, Z.A.; Wang, C.X.; Kabwe, F.B.; Liu, Z.G.; Tang, X. The study on martensite morphology in the stir zone and its influence to impact toughness during friction stir welding medium–Mn ultrahigh strength steel. Mater. Sci. Eng. A 2020, 798, 140102. [Google Scholar] [CrossRef]

- Chang, L.C.; Bhadeshia, H.K.D.H. Microstructure of lower bainite formed at large undercoolings below bainite start temperature. Met. Sci. J. 1996, 12, 233–236. [Google Scholar] [CrossRef]

- Pak, J.; Suh, D.W.; Bhadeshia, H.K.D.H. Promoting the coalescence of bainite platelets. Scr. Mater. 2012, 66, 951–953. [Google Scholar] [CrossRef] [Green Version]

- Keehan, E.; Karlsson, L.; Andrén, H.-O.; Bhadeshia, H.K.D.H. Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals: Part 3—Increased strength resulting from carbon additions. Sci. Technol. Weld. Join. 2012, 11, 19–24. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Keehan, E.; Karlsson, L.; Andren, H.O. Coalesced bainite. Trans. Indian Inst. Met. 2006, 59, 689–694. [Google Scholar]

- Keehan, E.; Karlsson, L.; Bhadeshia, H.K.D.H.; Thuvander, M. Electron backscattering diffraction study of coalesced bainite in high strength steel weld metals. Met. Sci. J. 2008, 24, 1183–1188. [Google Scholar] [CrossRef]

- Lepera, F.S. IMPROVED ETCHING TECHNIQUE TO EMPHASIZE MARTENSITE AND BAINITE IN HIGH-STRENGTH DUAL-PHASE STEEL. J. Met. 1980, 32, 38–39. [Google Scholar] [CrossRef]

- Cayron, C. GenOVa: A computer program to generate orientational variants. J. Appl. Crystallogr. 2007, 40, 1179–1182. [Google Scholar] [CrossRef] [Green Version]

- Cayron, C.; Artaud, B.; Briottet, L. Reconstruction of parent grains from EBSD data. Mater. Charact. 2006, 57, 386–401. [Google Scholar] [CrossRef]

- Sun, J.; Lu, S. Influence of inter-dendritic segregation on the precipitation behaviour and mechanical properties in a vanadium-containing Fe–Cr–Ni–Mo weld metal. Scr. Mater. 2020, 186, 174–179. [Google Scholar] [CrossRef]

- Steven, W.; Haynes, A.G. Temperature of formation of martensite and bainite in low-allot steel. JISI 1956, 183, 349–359. Available online: www.researchgate.net/publication/303156093 (accessed on 19 May 2021).

- Bannykh, O.A.; Blinov, V.M.; Kostina, M.V.; Blinov, E. V Nickel saving in a 0Kh17N12M2-type (AISI 316) steel due to nitrogen alloying. Russ. Metall. 2006, 2006, 372–378. [Google Scholar] [CrossRef]

- Ravi, A.M.; Sietsma, J.; Santofimia, M.J. Exploring bainite formation kinetics distinguishing grain-boundary and autocatalytic nucleation in high and low-Si steels. Acta Mater. 2016, 105, 155–164. [Google Scholar] [CrossRef] [Green Version]

- Ravi, A.M.; Sietsma, J.; Santofimia, M.J. Bainite formation kinetics in steels and the dynamic nature of the autocatalytic nucleation process. Scr. Mater. 2017, 140, 82–86. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. A Perspective on Martensitic Nucleation. Annu. Rev. Mater. Sci. 1981, 11, 1–32. [Google Scholar] [CrossRef]

- Takayama, N.; Miyamoto, G.; Furuhara, T. Effects of transformation temperature on variant pairing of bainitic ferrite in low carbon steel. Acta Mater. 2012, 60, 2387–2396. [Google Scholar] [CrossRef]

- Lambert-Perlade, A.; Gourgues, A.F.; Pineau, A. Austenite to bainite phase transformation in the heat-affected zone of a high strength low alloy steel. Acta Mater. 2004, 52, 2337–2348. [Google Scholar] [CrossRef]

- Gong, W.; Tomota, Y.; Adachi, Y.; Paradowska, A.M.; Kelleher, J.F.; Zhang, S.Y. Effects of ausforming temperature on bainite transformation, microstructure and variant selection in nanobainite steel. Acta Mater. 2013, 61, 4142–4154. [Google Scholar] [CrossRef]

- Nakanishi, D.; Kawabata, T.; Aihara, S. Brittle crack propagation resistance inside grain and at high angle grain boundary in 3% Si-Fe alloy. Acta Mater. 2018, 144, 768–776. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, J.; Ye, Z.; Hong, X.; Huang, H.; Xu, W. Effect of grain size and misorientation angle on fatigue crack growth of nanocrystalline materials. Mater. Sci. Eng. A 2016, 663, 1–7. [Google Scholar] [CrossRef]

- Dai, Z.; Chen, H.; Ding, R.; Lu, Q.; Zhang, C.; Yang, Z.; van der Zwaag, S. Fundamentals and application of solid-state phase transformations for advanced high strength steels containing metastable retained austenite. Mater. Sci. Eng. R Rep. 2021, 143, 100590. [Google Scholar] [CrossRef]

- Luo, H.; Wang, X.; Liu, Z.; Yang, Z. Influence of refined hierarchical martensitic microstructures on yield strength and impact toughness of ultra-high strength stainless steel. J. Mater. Sci. Technol. 2020, 51, 130–136. [Google Scholar] [CrossRef]

- Wang, C.; Wang, M.; Shi, J.; Hui, W.; Dong, H. Effect of microstructural refinement on the toughness of low carbon martensitic steel. Scr. Mater. 2008, 58, 492–495. [Google Scholar] [CrossRef]

- Cayron, C. EBSD imaging of orientation relationships and variant groupings in different martensitic alloys and Widmanstätten iron meteorites. Mater. Charact. 2014, 94, 93–110. [Google Scholar] [CrossRef]

- Chabok, A.; van der Aa, E.; De Hosson, J.T.M.; Pei, Y.T. Mechanical behavior and failure mechanism of resistance spot welded DP1000 dual phase steel. Mater. Des. 2017, 124, 171–182. [Google Scholar] [CrossRef] [Green Version]

| Materials | C | Si | Mn | Cr | Ni | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|

| A517GrQ | 0.15 | 0.21 | 1.04 | 0.77 | 2.09 | 0.48 | < 0.01 | Bal. |

| Ni5.5-deposited metal | 0.045 | 0.39 | 1.03 | 0.99 | 5.45 | 0.71 | 0.053 | Bal. |

| Ni6.5-deposited metal | 0.042 | 0.35 | 1.00 | 0.97 | 6.11 | 0.66 | 0.050 | Bal. |

| Ni7.5-deposited metal | 0.044 | 0.36 | 1.00 | 1.01 | 7.43 | 0.70 | 0.054 | Bal. |

| Welding Process | Shielding Gas | Flow Rate (L/min) | Welding Current (A) | Welding Voltage (V) | Welding Speed (mm/min) | Preheating Temperature (°C) | Interpass Temperature (°C) |

|---|---|---|---|---|---|---|---|

| GMAW | 95%Ar + 5% CO2 | 20 | 230–250 | 28–30 | 300 | 70–90 | 80–110 |

| Misorientation (°) | Interface Type | |

|---|---|---|

| 1 | 54.2 | BP3/BP2 |

| 2 | 53.9 | BP3/BP2 |

| 3 | 56.5 | BP3/BP2 |

| 4 | 58.5 | BP2/BP1 |

| 5 | 59.2 | BP1/BP2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Sun, J.; Wei, S.; Lu, S. The Effect of Nickel Contents on the Microstructure Evolution and Toughness of 800 MPa Grade Low Carbon Bainite Deposited Metal. Crystals 2021, 11, 709. https://doi.org/10.3390/cryst11060709

Liu J, Sun J, Wei S, Lu S. The Effect of Nickel Contents on the Microstructure Evolution and Toughness of 800 MPa Grade Low Carbon Bainite Deposited Metal. Crystals. 2021; 11(6):709. https://doi.org/10.3390/cryst11060709

Chicago/Turabian StyleLiu, Jingwu, Jian Sun, Shitong Wei, and Shanping Lu. 2021. "The Effect of Nickel Contents on the Microstructure Evolution and Toughness of 800 MPa Grade Low Carbon Bainite Deposited Metal" Crystals 11, no. 6: 709. https://doi.org/10.3390/cryst11060709

APA StyleLiu, J., Sun, J., Wei, S., & Lu, S. (2021). The Effect of Nickel Contents on the Microstructure Evolution and Toughness of 800 MPa Grade Low Carbon Bainite Deposited Metal. Crystals, 11(6), 709. https://doi.org/10.3390/cryst11060709