Microstructure Evaluation Study of Al5083 Alloy Using EBSD Technique after Processing with Different ECAP Processes and Temperatures

Abstract

1. Introduction

2. Materials and Methods

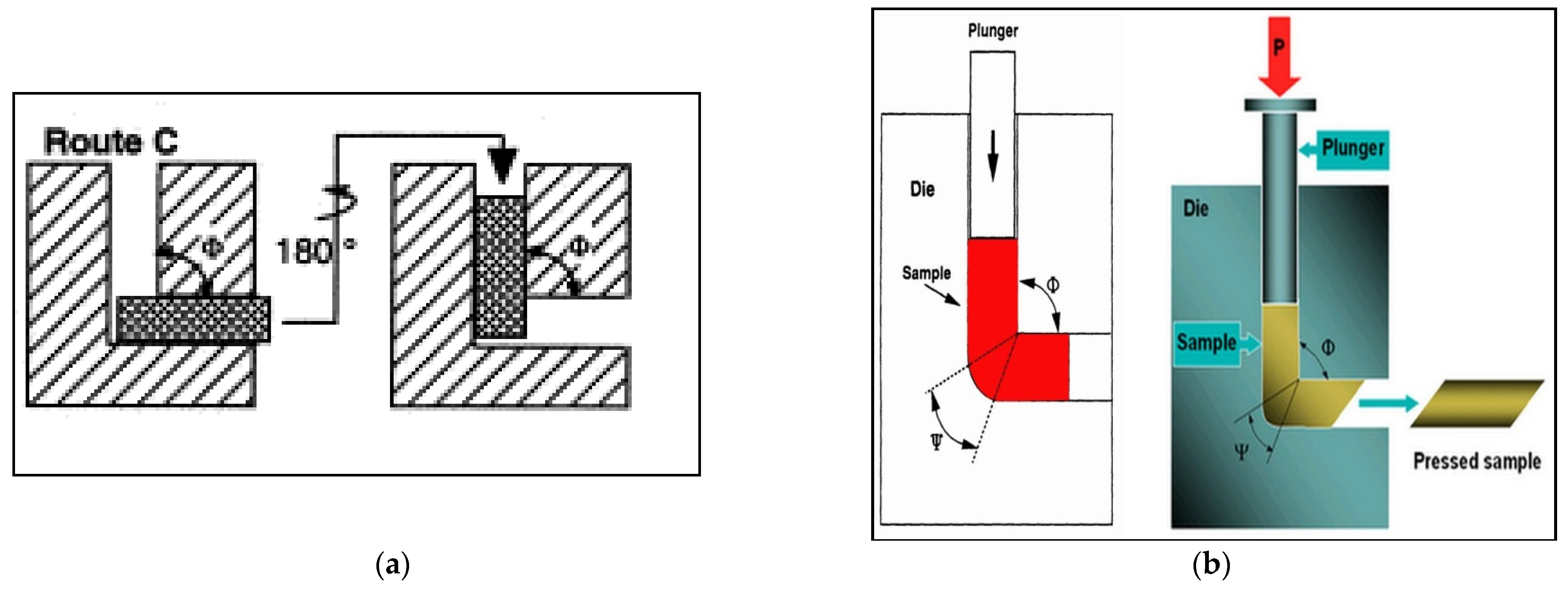

2.1. ECAP Process of Al-5083 Alloy

2.2. EBSD Process

3. Results and Discussions

3.1. EBSD Micrograph

3.2. Kernel Average Misorientation (KAM)

3.3. Texture

4. Conclusions

- Microstructural advancement in an entire volume of the Al alloy, which has undergone the ECAP process, is scarcely impacted by the pressing temperature in the first and second pass, while the arrangement of the new fine-grained structure is altogether influenced by the temperature from the third pass.

- The normal GND thickness was expanded from 3.2 × 1012 m−2 in the underlying state to 7.4 × 1012 m−2 for the example distorted in the third passes.

- Misorientation created a higher temperature after the third passes. The small portion of HABs with misorientations above 15° reductions and that of LABs alternately increased even with expansion in temperature.

- It can be seen from both surrounding temperature and high temperature that the second pass and third pass have not caused to recrystallize the material fully. Still, the separation content has stayed in the material. The fine grains which are formed after 3rd pass were combined effect of static recovery and recrystallization.

- In both ambient and higher temperature, the mixed deformation mode occurred due to the fan-shaped deformation zone and ECAP die geometry and constituted the reason for the gradual texture component rotation. The strain is restricted in one pass, and might very well be insufficient for the surface segments to be recovered close to the ideal surface parts. This can be one reason for the slants of the surface parts in the further number of passes concerning their optimal positions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Xu, C.; Langdon, T.G. Influence of a round corner die on flow homogeneity in ECA pressing. Scr. Mater. 2003, 48, 1–4. [Google Scholar] [CrossRef]

- Kim, K.H.; Chun, Y.B.; Hwang, S.K. Deformation heterogeneity of Ti under cryogenic channel-die compression. Prog. Nat. Sci. Mater. Int. 2011, 21, 277–285. [Google Scholar] [CrossRef][Green Version]

- Ebrahimi, M.; Djavanroodi, F. Experimental and numerical analyses of pure copper during ECFE process as a novel severe plastic deformation method. Prog. Nat. Sci. Mater. Int. 2014, 24, 68–74. [Google Scholar] [CrossRef]

- Djavanroodi, F.; Omranpour, B.; Ebrahimi, M.; Sedighi, M. Designing of ECAP parameters based on strain distribution uniformity. Prog. Nat. Sci. Mater. Int. 2012, 22, 452–460. [Google Scholar] [CrossRef]

- Korchef, A.; Champion, Y.; Njah, N. X-ray diffraction analysis of aluminium containing Al8Fe2Si processed by equal channel angular pressing. J. Alloys Compd. 2007, 427, 176–182. [Google Scholar] [CrossRef]

- Djavanroodi, F.; Ebrahimi, M. Effect of die parameters and material properties in ECAP with parallel channels. Mater. Sci. Eng. A 2010, 527, 7593–7599. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Shaeri, M.; Salehi, M.T.; Seyyedein, S.H.; Abutalebi, M.R. Effect of equal channel angular pressing on aging treatment of Al-7075 alloy. Prog. Nat. Sci. Mater. Int. 2015, 25, 159–168. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, L. Improving Corrosion Resistance of Friction Stir Welding Joint of 7075 Aluminum Alloy by Micro-Arc Oxidation. J. Mater. Sci. Technol. 2014, 30, 1251–1254. [Google Scholar] [CrossRef]

- Dehghani, K.; Nekahi, A.; Mohammad Mirzai, M.A. Optimizing the bake hardening behavior of Al7075 using response surface methodology. J. Mater. Des. 2010, 31, 1768–1775. [Google Scholar] [CrossRef]

- Ghosh, K.S.; Gao, N.; Starink, M.J. Characterisation of high pressure torsion processed 7150 Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2012, 552, 164–171. [Google Scholar] [CrossRef]

- Song, D.; Ma, A.B.; Jiang, J.H.; Lin, P.H.; Zhang, L.Y. Improvement of pitting corrosion resistance for Al-Cu alloy in sodium chloride solution through equal-channel angular pressing. Prog. Nat. Sci. Mater. Int. 2011, 21, 307–313. [Google Scholar] [CrossRef]

- Vaseghi, M.; Karimi Taheri, A.; Hong, S.I.; Kim, H.S. Dynamic ageing and the mechanical response of Al–Mg–Si alloy through equal channel angular pressing. J. Mater. Des. 2010, 31, 4076–4082. [Google Scholar] [CrossRef]

- Roven, H.J.; Liu, M.; Werenskiold, J.C. Dynamic precipitation during severe plastic deformation of an Al–Mg–Si aluminium alloy. Mater. Sci. Eng. A 2008, 483, 54–58. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Salehi, M.T.; Seyyedein, S.H.; Abutalebi, M.R.; Park, J.K. Microstructure and mechanical properties of Al-7075 alloy processed by equal channel angular pressing combined with aging treatment. J. Mater. Des. 2015, 57, 250–257. [Google Scholar] [CrossRef]

- Roshan, M.R.; Jenabali Jahromi, S.A.; Ebrahimi, R. Predicting the critical pre-aging time in ECAP processing of age-hardenable aluminum alloys. J. Alloys Compd. 2011, 509, 7833–7839. [Google Scholar] [CrossRef]

- Cepeda-Jimenez, C.M.; Garcia-Infanta, J.M.; Ruano, O.A.; Carreno, F. High strain rate superplasticity at intermediate temperatures of the Al 7075 alloy severely processed by equal channel angular pressing. J. Alloys Compd. 2011, 509, 9589–9597. [Google Scholar] [CrossRef]

- Cepeda-Jimenez, C.M.; Garcia-Infanta, J.M.; Ruano, O.A.; Carreno, F. Mechanical properties at room temperature of an Al–Zn–Mg–Cu alloy processed by equal channel angular pressing. J. Alloys Compd. 2011, 509, 8649–8656. [Google Scholar] [CrossRef]

- DeLo, D.P.; Semiatin, S.L. Hot Working of Ti-6Al-4V via Equal Channel Angular Extrusion. Metall. Mater. Trans. A 1999, 30, 2473–2481. [Google Scholar] [CrossRef]

- Chen, Y.C.; Huang, Y.Y.; Chang, C.P.; Kao, P.W. The effect of extrusion temperature on the development of deformation microstructures in 5052 aluminium alloy processed by equal channel angular extrusion. Acta Mater. 2003, 51, 2005–2015. [Google Scholar] [CrossRef]

- Sitdikov, O.; Sakai, T.; Avtokratova, E.; Kaibyshev, R.; Kimura, Y.; Tsuzaki, K. Grain refinement in a commercial Al–Mg–Sc alloy under hot ECAP conditions. Mater. Sci. Eng. A 2007, 444, 18–30. [Google Scholar] [CrossRef]

- Murayama, M.; Horita, Z.; Hono, K. Microstructure of two-phase Al–1.7 at% Cu alloy deformed by equal-channel angular pressing. Acta Mater. 2001, 49, 21–29. [Google Scholar] [CrossRef]

- Gao, N.; Starink, M.J.; Furukawa, M.; Horita, Z.; Xu, C.; Langdon, T.G. Evolution of microstructure and precipitation in heat-treatable aluminium alloys during ECA pressing and subsequent heat treatment. Mater. Sci. Forum 2006, 503–504, 275–280. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Yamashita, A.; Yamaguchi, D.; Horita, Z.; Langdon, T.G. Influence of pressing temperature on microstructural development in equal-channel angular pressing. Mater. Sci. Eng. A 2000, 287, 100–106. [Google Scholar] [CrossRef]

- Chang, J.Y.; Yoon, J.S.; Kim, G.H. Development of submicron sized grain during cyclic equal channel angular pressing. Scr. Mater. 2001, 45, 347–354. [Google Scholar] [CrossRef]

- Sitdikov, O.; Kaibyshev, R.; Safarov, I.; Mazurina, I. Evolution of the Microstructure and Mechanisms of Formation of New Grains upon SeverePlastic Deformation of the 2219 Aluminum Alloy. Phys. Met. Metallogr. 2001, 92, 270–280. [Google Scholar]

- Mishin, O.V.; Jensen, D.J.; Hansen, N. Microstructures and boundary populations in materials produced by equal channel angular extrusion. Mater. Sci. Eng. A 2003, 342, 320–328. [Google Scholar] [CrossRef]

- Goloborodko, A.; Sitdikov, O.; Kaibyshev, R.; Miura, H.; Sakai, T. Effect of pressing temperature on fine-grained structure formation in 7475 aluminum alloy during ECAP. Mater. Sci. Eng. A 2004, 381, 121–128. [Google Scholar] [CrossRef]

- McQueen, H.J. Development of dynamic recrystallization theory. Mat. Sci. Eng. A 2004, 387–389, 203–208. [Google Scholar] [CrossRef]

- Apps, P.J.; Berta, M.; Prangnell, P.B. The effect of dispersoids on the grain refinement mechanisms during deformation of aluminium alloys to ultra-high strains. Acta Mater. 2005, 53, 499–511. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Swisher, D.L.; Oh-ishi, K.; Langdon, T.G.; McNelley, T.R. Microtexture and microstructure evolution during processing of pure aluminum by repetitive ECAP. Mater. Sci. Eng. A 2006, 429, 137–148. [Google Scholar] [CrossRef]

- Sakai, T.; Zhu, Y.T.; Langdon, T.G.; Horita, Z.; Zehetbauer, M.J.; Semiatin, S.L.; Lowe, T.C. Ultrafine Grained Materials IV. TMS Annu. Meet. 2006, 237, 73. [Google Scholar]

- Mazurina, I.; Sakai, T.; Miura, H.; Sitdikov, O.; Kaibyshev, R. Effect of deformation temperature on microstructure evolution in aluminum alloy 2219 during hot ECAP. Mater. Sci. Eng. A 2007, 4, 112. [Google Scholar] [CrossRef]

- Sitdikov, O.; Sakai, T.; Avtokratova, E.; Kaibyshev, R.; Tsuzaki, K.; Watanabe, Y. Grain. Refinement in a Commercial Al-Mg-Sc under hot ECAP conditions. Mater. Sci. Forum 2007, 558–559, 569–574. [Google Scholar] [CrossRef]

- Gourdet, S.; Montheillet, F. An Experimental Study of the Recrystallization Mechanism during Hot Deformation of Alumium. Mater. Sci. Eng. A 2000, 283, 274–288. [Google Scholar] [CrossRef]

- Humphreys, F.J. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Djavanroodi, F.; Ebrahimi, M.; Rajabifar, B. Fatigue design factors for ECAPed materials. Mater. Sci. Eng. A 2010, 528, 745–750. [Google Scholar] [CrossRef]

- Gottstein, G. Physical Foundations of Materials Science, 1st ed.; Springer: Berlin, Germany, 2004. [Google Scholar]

- Humphreys, F.J. Review—Grain and subgrain characterisation by electron backscatter diffraction. J. Mater. Sci. 2001, 36, 3833–3854. [Google Scholar] [CrossRef]

- Xu, J.; Li, J.; Shan, D.; Guo, B. Microstructural evolution and micro/meso-deformation behavior in pure copper processed by equal-channel angular pressing. Mater. Sci. Eng. A 2016, 664, 114–125. [Google Scholar] [CrossRef]

- Gerber, P.H.; Tarasiuk, J.; Chiron, R.; Bacroix, B. Estimation of the recrystallized volume fraction from local misorientation calculations. Arch. Metall. Mater. 2005, 50, 747. [Google Scholar]

- Lu, H.; Sivaprasad, P.; Davies, C.H.J. Treatment of misorientation data to determine the fraction of recrystallized grains in a partially recrystallized metal. Mater. Charact. 2003, 51, 293–300. [Google Scholar] [CrossRef]

- Takayama, Y.; Szpunar, J.A.; Kato, H. Analysis of Intragranular Misorientation Related to Deformation in an Al-Mg-Mn Alloy. Mater. Sci. For 2005, 495–497, 1049–1054. [Google Scholar]

- Bunge, H.J. Mathematische Methoden der Textureanalyse; Akademie-Verlag: Berlin, Germany, 1969. [Google Scholar]

- Bunge, H.J. Texture Analysis in Material Science; Butterworths: London, UK, 1982. [Google Scholar]

- Cho, J.H.; Rollett, A.; Oh, K. Determination of volume fractions of texture components with standard distributions in euler space. Metall. Mater. Trans. 2004, 35, 1073–5623. [Google Scholar] [CrossRef]

- Schwartz, A.J.; Kumar, M.; Field, D.P.; Adams, B.L. (Eds.) Electron Backscatter Diffraction in Materials Science, 2nd ed.; Springer Science+Business Media: New York, NY, USA, 2009. [Google Scholar]

- Saiyi, L.I.; Beyerlein, J.; Alexander, D.J.; Vogel, S.C. Texture evolution during equal channel angular extrusion: Effect of initial texture from experiment and simulation. Scr. Mater. 2005, 52, 1099–1104. [Google Scholar]

- Vega, M.C.V.; Piva, B.H.; Bolmaro, R.E.; Ferrante, M.; Kliauga, A. The texture development of ECAP processed AA1050 aluminium before and after a final anneal: Effect of the initial texture. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012152. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Tóth, L.S. Texture Evolution in Equal-Channel Angular Extrusion. Prog. Mater. Sci. 2009, 54, 427–510. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baig, M.; Seikh, A.H.; Rehman, A.U.; Mohammed, J.A.; Hashmi, F.H.; Ragab, S.M. Microstructure Evaluation Study of Al5083 Alloy Using EBSD Technique after Processing with Different ECAP Processes and Temperatures. Crystals 2021, 11, 862. https://doi.org/10.3390/cryst11080862

Baig M, Seikh AH, Rehman AU, Mohammed JA, Hashmi FH, Ragab SM. Microstructure Evaluation Study of Al5083 Alloy Using EBSD Technique after Processing with Different ECAP Processes and Temperatures. Crystals. 2021; 11(8):862. https://doi.org/10.3390/cryst11080862

Chicago/Turabian StyleBaig, Muneer, Asiful H. Seikh, Ateekh Ur Rehman, Jabair A. Mohammed, Faraz Hussain Hashmi, and Sameh Mohamed Ragab. 2021. "Microstructure Evaluation Study of Al5083 Alloy Using EBSD Technique after Processing with Different ECAP Processes and Temperatures" Crystals 11, no. 8: 862. https://doi.org/10.3390/cryst11080862

APA StyleBaig, M., Seikh, A. H., Rehman, A. U., Mohammed, J. A., Hashmi, F. H., & Ragab, S. M. (2021). Microstructure Evaluation Study of Al5083 Alloy Using EBSD Technique after Processing with Different ECAP Processes and Temperatures. Crystals, 11(8), 862. https://doi.org/10.3390/cryst11080862