Trends in Aluminium Matrix Composite Development

Abstract

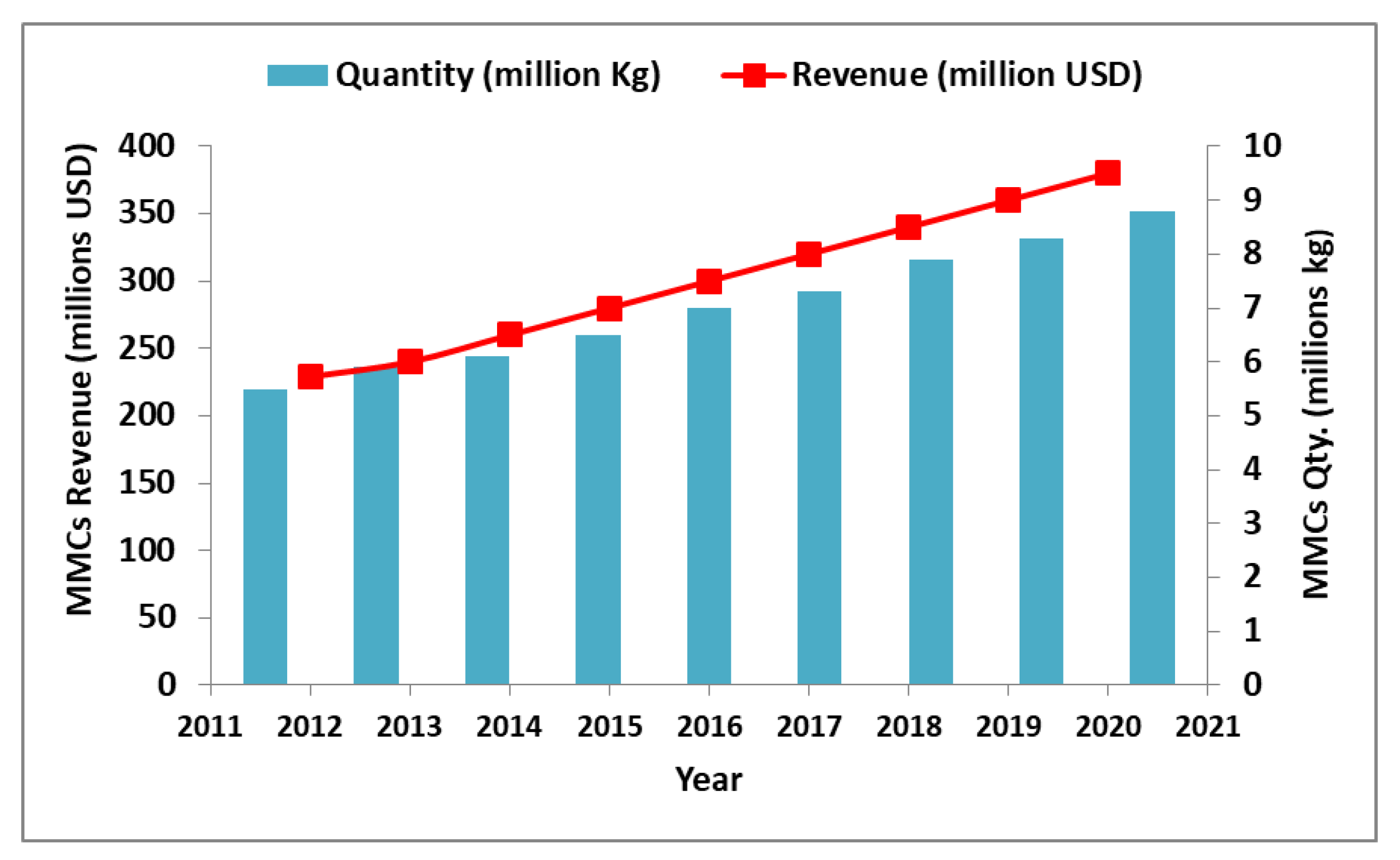

:1. Introduction

2. Types of Aluminium Matrix Composites

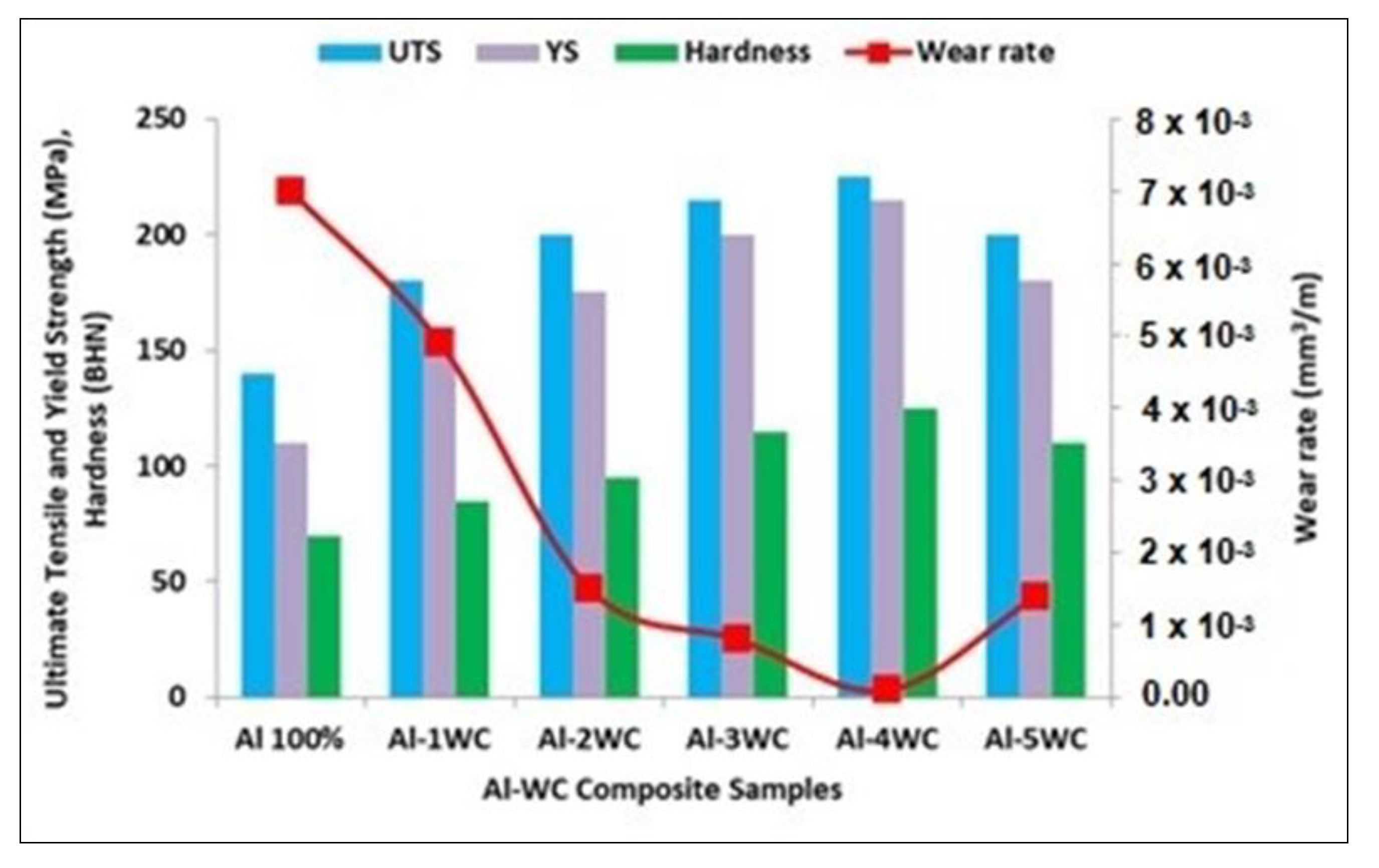

2.1. Aluminium Binary Composites

2.2. Aluminium Hybrid Composite System

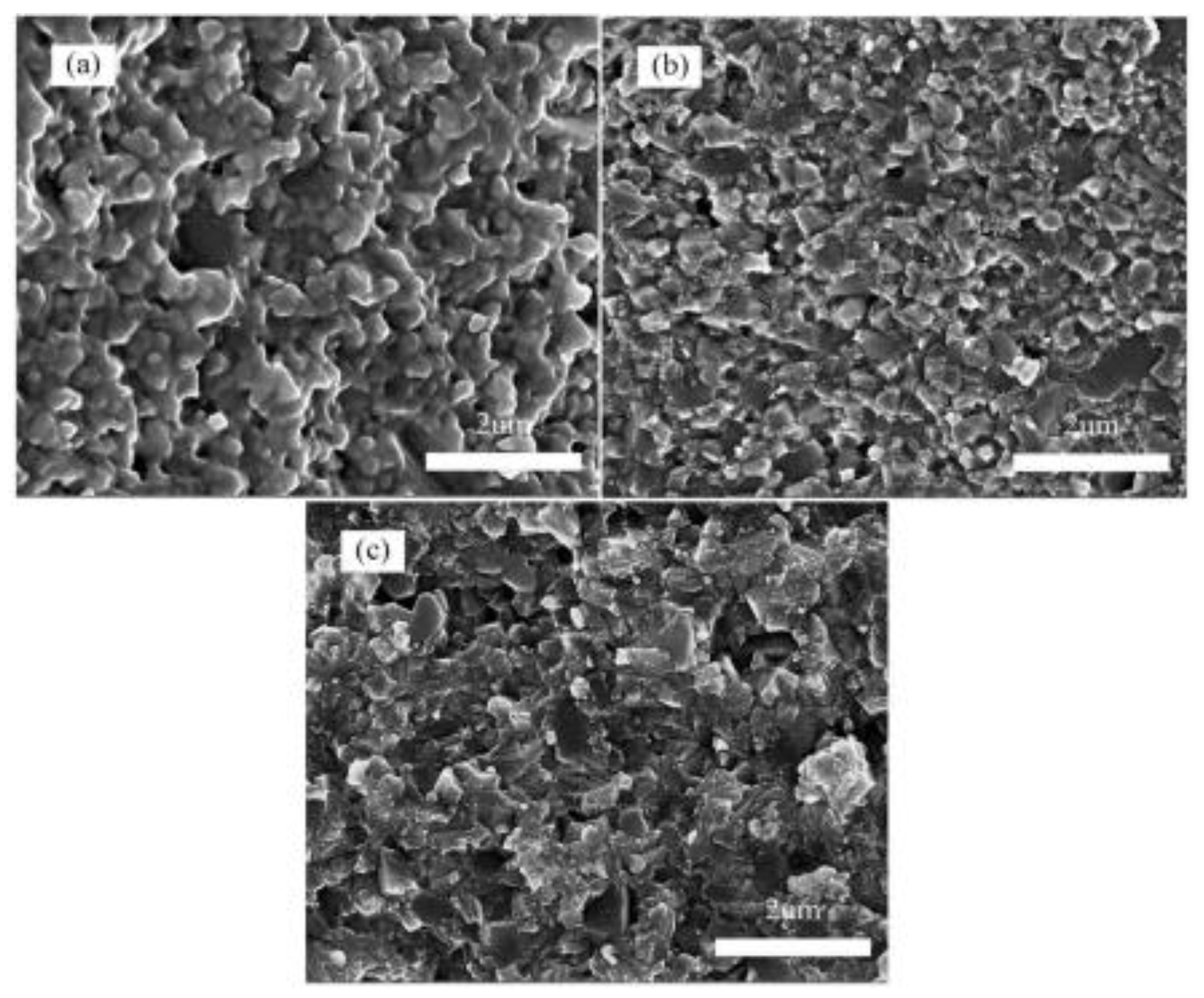

2.3. Aluminium Matrix Reinforced with Nano-Sized Reinforcements

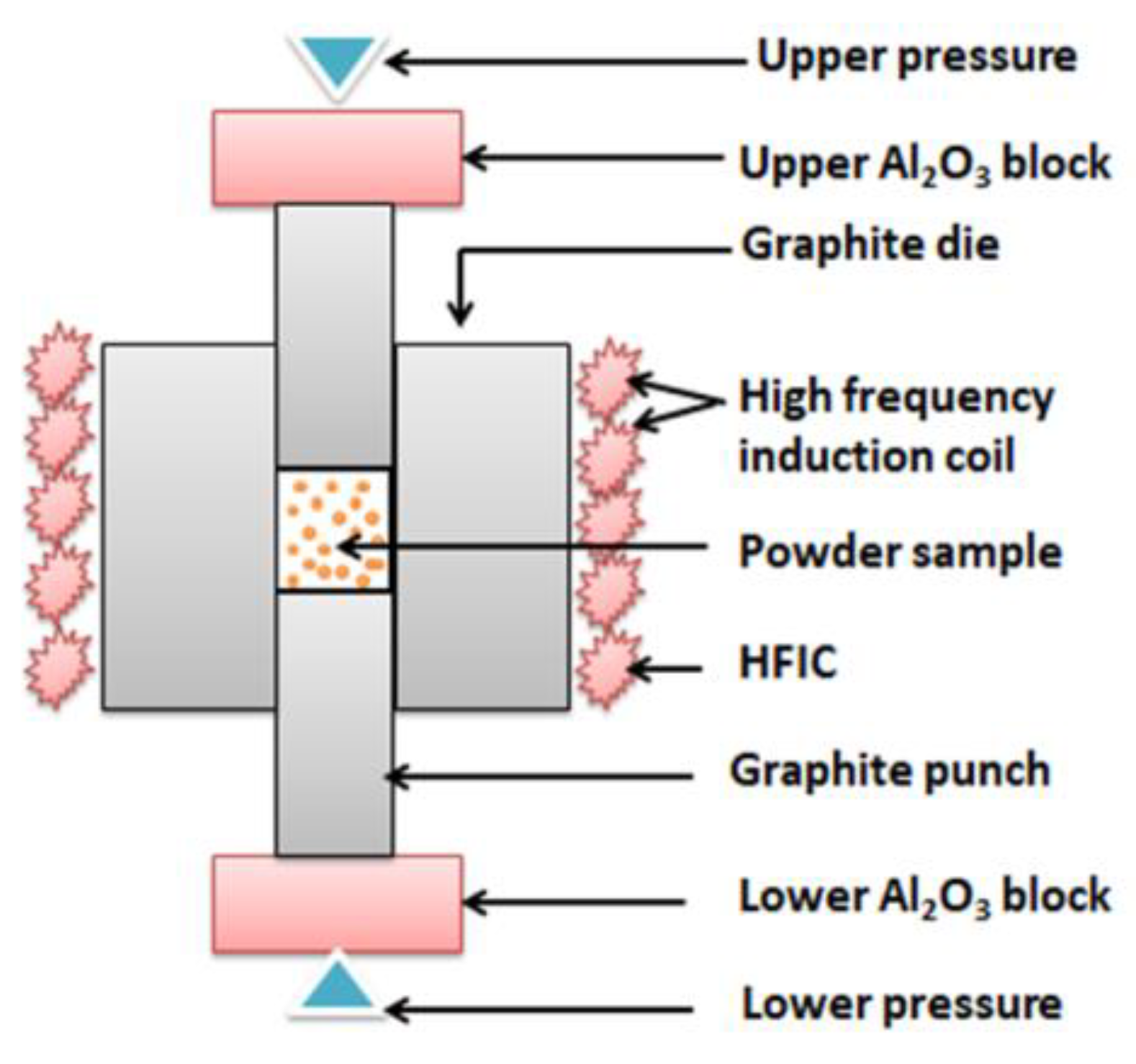

3. Techniques for the Development of AMCs

4. Applications and Challenges of Aluminium Matrix Composites

4.1. Applications of Aluminium Matrix Composites

4.2. Challenges in the Development of Aluminium Matrix Composites

5. Conclusions and Recommendations

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shyha, I.; Huo, D. Advances in Machining of Composite Materials; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Nagavally, R.R. Composite materials-history, types, fabrication techniques, advantages, and applications. Int. J. Mech. Prod. Eng. 2017, 5, 82–87. [Google Scholar]

- Kabir, R.B.; Ferdous, N. Kevlar—The super tough fiber. Int. J. Text. Sci. 2012, 1, 78–83. [Google Scholar] [CrossRef]

- Research. History of Composites. 2018. Available online: https://www.thoughtco.com/history-of-composites-820404#:~:text=He%20also%20writes%20about%20the%20industry.&text=When%20two%20or%20more%20different,create%20strong%20and%20durable%20buildings (accessed on 25 July 2022).

- Callister, W. Composites, chapter 16. In Material Science and Engineering an Introduction; John Wiley and Sons, Inc: Hoboken, NJ, USA, 2003; p. 527. [Google Scholar]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. Part B Eng. 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Ananth, C.; Chandra, N. Elevated temperature interfacial behaviour of MMCs: A computational study. Compos. Part A Appl. Sci. Manuf. 1996, 27, 805–811. [Google Scholar] [CrossRef]

- Kaczmar, J.; Pietrzak, K.; Włosiński, W. The production and application of metal matrix composite materials. J. Mater. Processing Technol. 2000, 106, 58–67. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.; Sun, W.; McCartney, D. A review of friction stir welding of aluminium matrix composites. Mater. Des. 2015, 86, 61–71. [Google Scholar] [CrossRef]

- Torralba, J.D.; Da Costa, C.; Velasco, F. P/M aluminum matrix composites: An overview. J. Mater. Processing Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Lloyd, D. Particle reinforced aluminium and magnesium matrix composites. Int. mater. Rev. 1994, 39, pp.1–23. [Google Scholar] [CrossRef]

- Koli, D.K.; Agnihotri, G.; Purohit, R. Advanced aluminium matrix composites: The critical need of automotive and aerospace engineering fields. Mater. Today Proc. 2015, 2, 3032–3041. [Google Scholar] [CrossRef]

- Singh, J.; Chauhan, A. A review on sliding wear behaviour of aluminium matrix composites with hybrid reinforcements for automotive applications. Tribol. Online 2014, 9, 121–134. [Google Scholar] [CrossRef]

- Purohit, R.; Qureshi, M.; Jain, A. Forming behaviour of aluminium matrix nano Al2O3 composites for automotive applications. Adv. Mater. Processing Technol. 2020, 6, 272–283. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, P.; Popoola, O.; Aigbodion, V. Enhanced mechanical, electrical and corrosion characteristics of Al-CNTs-Nb composite processed via spark plasma sintering for conductor core. J. Compos. Mater. 2019, 53, 0021998319848055. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, A.; Popoola, O. Thermal conductivity improvement of Al alloy with Nb nanopowder using SPS for transmission conductor. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Boston, MA, USA, 12–14 October 2019; p. 012004. [Google Scholar]

- Ujah, C.; Popoola, A.; Popoola, O.; Aigbodion, V.S. Influence of CNTs addition on the mechanical, microstructural, and corrosion properties of Al alloy using spark plasma sintering technique. Int. J. Adv. Manuf. Technol. 2020, 106, 2961–2969. [Google Scholar] [CrossRef]

- Kumar, N.; Das, A. Ecofriendly energy efficient welding of aluminium matrix composites for aerospace applications: A state of art review. Mater. Today Proc. 2020, 26, 1666–1675. [Google Scholar] [CrossRef]

- Suryanarayanan, K.; Praveen, R.; Raghuraman, S. Silicon carbide reinforced aluminium metal matrix composites for aerospace applications: A literature review. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 6336–6344. [Google Scholar]

- Shibli, S.; Archana, S.; Ashraf, P.M. Development of nano cerium oxide incorporated aluminium alloy sacrificial anode for marine applications. Corros. Sci. 2008, 50, 2232–2238. [Google Scholar] [CrossRef]

- Vinod, B.; Ramanathan, S.; Ananthi, V.; Selvakumar, N. Fabrication and characterization of organic and in-organic reinforced A356 aluminium matrix hybrid composite by improved double-stir casting. Silicon 2019, 11, 817–829. [Google Scholar] [CrossRef]

- Hynes, N.; Sankaranarayanan, R.; Tharmaraj, R.; Pruncu, C.I.; Dispinar, D. A comparative study of the mechanical and tribological behaviours of different aluminium matrix–ceramic composites. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 330. [Google Scholar] [CrossRef]

- Reddy, A.P.; Krishna, P.V.; Rao, R.N.; Murthy, N. Silicon carbide reinforced aluminium metal matrix nano composites—A review. Mater. Today Proc. 2017, 4, 3959–3971. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ravichandran, M.; Kumar, S.S. Tribological and mechanical properties of Zirconium Di-boride (ZrB2) particles reinforced aluminium matrix composites. Mater. Today Proc. 2020, 21, 862–864. [Google Scholar] [CrossRef]

- Ferreira, L.; Bayraktar, E.; Robert, M. Magnetic and electrical properties of aluminium matrix composite reinforced with magnetic nano iron oxide (Fe3O4). Adv. Mater. Processing Technol. 2016, 2, 165–173. [Google Scholar] [CrossRef]

- Ravi, B.; Balu, N.; Uday, P. Fabrication and mechanical characterization of boron carbide reinforced aluminium matrix composites. Discovery 2016, 52, 1389–1395. [Google Scholar]

- Nagaral, M.; Auradi, V.; Ravishankar, M. Mechanical behaviour of aluminium 6061 alloy reinforced with Al2O3 & graphite particulate hybrid metal matrix composites. Int. J. Res. Eng. Technol. 2013, 1, 193–198. [Google Scholar]

- Khan, M.; Zulfaqar, M.; Ali, F.; Subhani, T. Hybrid aluminium matrix composites containing boron carbide and quasicrystals: Manufacturing and characterisation. Mater. Sci. Technol. 2017, 33, 1955–1963. [Google Scholar] [CrossRef]

- Talla, G.; Sahoo, D.K.; Gangopadhyay, S.; Biswas, C. Modeling and multi-objective optimization of powder mixed electric discharge machining process of aluminum/alumina metal matrix composite. Eng. Sci. Technol. Int. J. 2015, 18, 369–373. [Google Scholar] [CrossRef]

- Singh, N.; Belokar, R. Tribological behavior of aluminum and magnesium-based hybrid metal matrix composites: A state-of-art review. Mater. Today Proc. 2021, 44, 460–466. [Google Scholar] [CrossRef]

- Mavhungu, S.; Akinlabi, E.; Onitiri, M.; Varachia, F. Aluminum matrix composites for industrial use: Advances and trends. Procedia Manuf. 2017, 7, 178–182. [Google Scholar] [CrossRef]

- Macke, A.; Schultz, B.; Rohatgi, P. Metal matrix composites. Adv. Mater. Processes 2012, 170, 19–23. [Google Scholar]

- Stojanović, B.; Ivanović, L. Application of aluminium hybrid composites in automotive industry. Tehnički Vjesnik 2005, 22, 247–251. [Google Scholar] [CrossRef]

- Chawla, K.K.; Chawla, N. Metal matrix composites: Automotive applications. Encycl. Automot. Eng. 2014, 1–6. [Google Scholar] [CrossRef]

- Nturanabo, F.; Masu, L.; Kirabira, J.B. Novel Applications of Aluminium Metal Matrix Composites; University of Bradford: Bradford, UK, 2019; pp. 1–25. [Google Scholar] [CrossRef]

- Kar, K.K. Composite Materials: Processing, Applications, Characterizations; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Dokšanović, T.; Džeba, I.; Markulak, D. Applications of aluminium alloys in civil engineering. Tehnički Vjesnik 2017, 24, 1609–1618. [Google Scholar]

- Hihara, L. Corrosion of metal matrix composites. Reference module in materials science and materials engineering. Shreir’s Corros. 2010, 3, 2250–2269. [Google Scholar]

- Alves, F.L.; Baptista, A.; Marques, A. Metal and ceramic matrix composites in aerospace engineering. In Advanced Composite Materials for Aerospace Engineering; Elsevier: Duxford, UK, 2016; pp. 59–99. [Google Scholar]

- Miracle, D.B. Opportunities and approaches for doubling the structural efficiency of metallic materials. In Metallic Materials with High Structural Efficiency; Springer: Berlin/Heidelberg, Germany, 2004; pp. 3–20. [Google Scholar]

- Mouritz, A.P.; Gellert, E.; Burchill, P.; Challis, K. Review of advanced composite structures for naval ships and submarines. Compos. Struct. 2001, 53, 21–42. [Google Scholar] [CrossRef]

- Babalola, P.; Bolu, C.; Inegbenebor, A.; Odunfa, K. Development of aluminium matrix composites: A review. Online Int. J. Eng. Technol. Res. 2014, 2, 1–11. [Google Scholar]

- Surappa, M. Aluminium matrix composites: Challenges and opportunities. Sadhana 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Garg, P.; Jamwal, A.; Kumar, D.; Sadasivuni, K.K.; Hussain, C.M.; Gupta, P. Advance research progresses in aluminium matrix composites: Manufacturing & applications. J. Mater. Res. Technol. 2019, 8, 4924–4939. [Google Scholar]

- Karvanis, K.; Fasnakis, D.; Maropoulos, A.; Papanikolaou, S. Production and mechanical properties of Al-SiC metal matrix composites. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kozani, Greece, 23–25 September 2016; p. 012070. [Google Scholar]

- Shaikh, M.B.N.; Aziz, T.; Arif, S.; Ansari, A.H.; Karagiannidis, P.G.; Uddin, M. Effect of sintering techniques on microstructural, mechanical and tribological properties of Al-SiC composites. Surf. Interfaces 2020, 20, 100598. [Google Scholar] [CrossRef]

- Xiao, C.; Chen, L.; Tang, Y.; Zhang, X.; Zheng, K.; Tian, X. Three dimensional porous alumina network for polymer composites with enhanced thermal conductivity. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105511. [Google Scholar] [CrossRef]

- Ben-Nissan, B.; Choi, A.; Cordingley, R. Alumina ceramics. In Bioceramics and Their Clinical Applications; Elsevier: Cambridge, UK, 2008; pp. 223–242. [Google Scholar]

- Rahimian, M.; Ehsani, N.; Parvin, N.; reza Baharvandi, H. The effect of particle size, sintering temperature and sintering time on the properties of Al–Al2O3 composites, made by powder metallurgy. J. Mater. Processing Technol. 2009, 209, 5387–5393. [Google Scholar] [CrossRef]

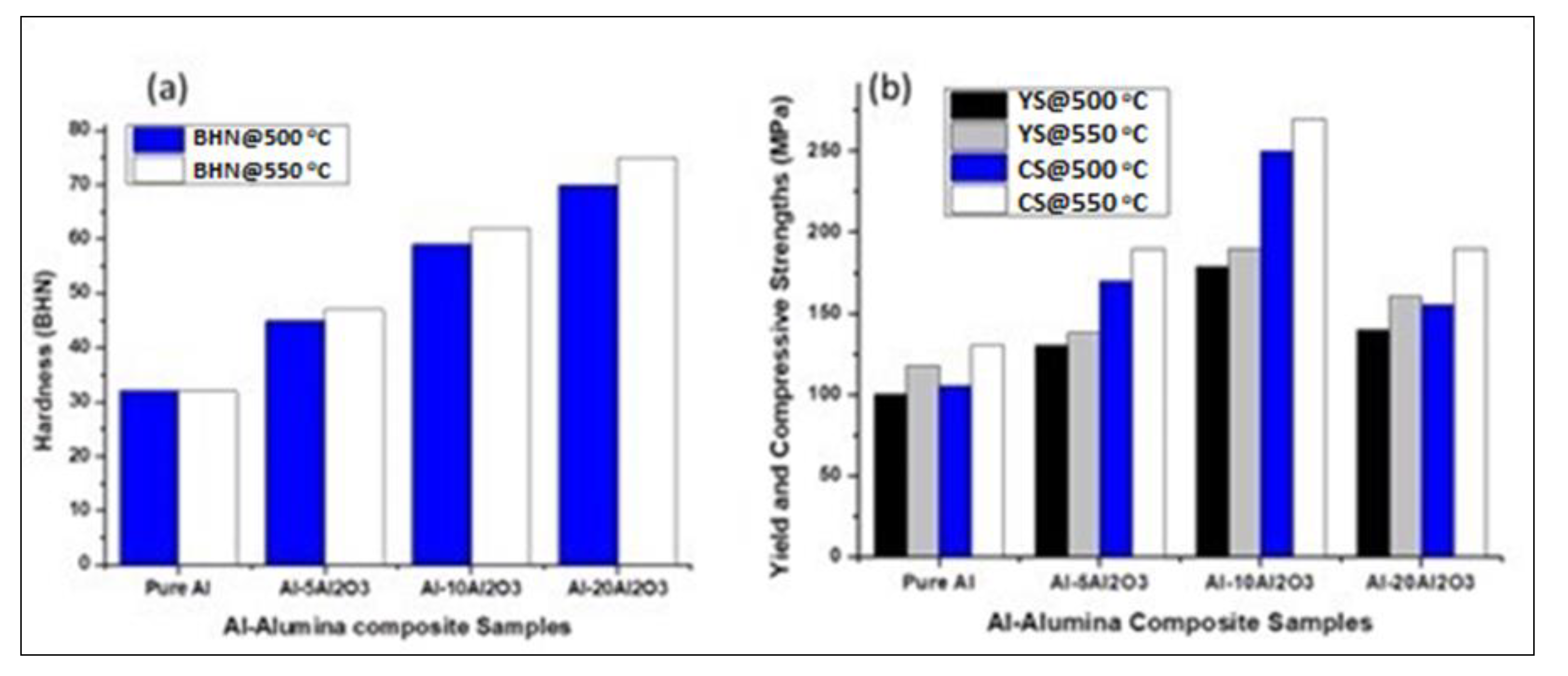

- Gudlur, P.; Forness, A.; Lentz, J.; Radovic, M.; Muliana, A. Thermal and mechanical properties of Al/Al2O3 composites at elevated temperatures. Mater. Sci. Eng. A 2012, 531, 18–27. [Google Scholar] [CrossRef]

- Rahimian, M.; Ehsani, N.; Parvin, N.; Baharvandi, H. The effect of sintering temperature and the amount of reinforcement on the properties of Al–Al2O3 composite. Mater. Des. 2009, 30, 3333–3337. [Google Scholar] [CrossRef]

- Garbiec, D.; Jurczyk, M.; Levintant-Zayonts, N.; Mościcki, T. Properties of Al–Al2O3 composites synthesized by spark plasma sintering method. Arch. Civ. Mech. Eng. 2015, 15, 933–939. [Google Scholar] [CrossRef]

- Nourouzi, S.; Damavandi, E.; Rabiee, S.M. Microstructural and mechanical properties of Al-Al2O3 composites focus on experimental techniques. Int. J. Microstruct. Mater. Prop. 2016, 11, 383–398. [Google Scholar]

- Park, B.; Crosky, A.; Hellier, A. Fracture toughness of microsphere Al2O3–Al particulate metal matrix composites. Compos. Part B Eng. 2008, 39, 1270–1279. [Google Scholar] [CrossRef]

- Kok, M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J. Mater. Processing Technol. 2005, 161, 381–387. [Google Scholar] [CrossRef]

- Kumar, A.; Lal, S.; Kumar, S. Fabrication and characterization of A359/Al2O3 metal matrix composite using electromagnetic stir casting method. J. Mater. Res. Technol. 2013, 2, 250–254. [Google Scholar] [CrossRef]

- Qiu, J.Y.; Watari, K.; Hotta, Y.; Mitsuishi, K. Influence of powder characteristics on sintering of AlN ceramics. Key Eng. Mater. 2007, 280, 1409–1412. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, J.; Chen, X.; Yu, F.; He, J. Thermoplastic polypropylene/aluminum nitride nanocomposites with enhanced thermal conductivity and low dielectric loss. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2768–2776. [Google Scholar] [CrossRef]

- Abdoli, H.; Saebnouri, E.; Sadrnezhaad, S.K.; Ghanbari, M.; Shahrabi, T. Processing and surface properties of Al–AlN composites produced from nanostructured milled powders. J. Alloys Compd. 2010, 490, 624–630. [Google Scholar] [CrossRef]

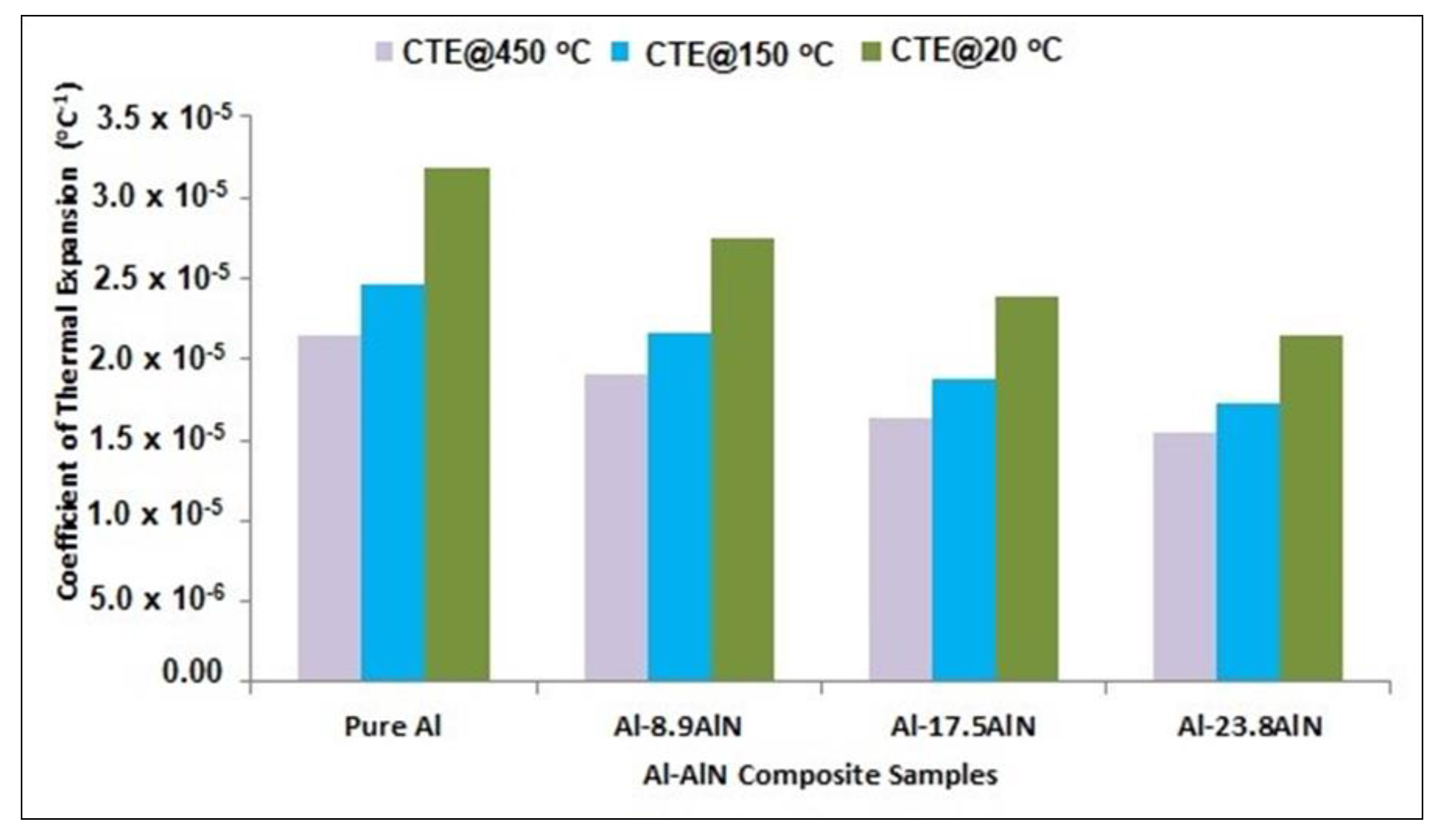

- Mizuuchi, K.; Inoue, K.; Agari, Y.; Nagaoka, T.; Sugioka, M.; Tanaka, M.; Takeuchi, T.; Tani, J.-i.; Kawahara, M.; Makino, Y. Processing and thermal properties of Al/AlN composites in continuous solid–liquid co-existent state by spark plasma sintering. Compos. Part B Eng. 2012, 43, 1557–1563. [Google Scholar] [CrossRef]

- Yu, P.; Balog, M.; Yan, M.; Schaffer, G.; Qian, M. In situ fabrication and mechanical properties of Al–AlN composite by hot extrusion of partially nitrided AA6061 powder. J. Mater. Res. 2011, 26, 1719–1725. [Google Scholar] [CrossRef]

- Pradhan, S.; Jena, S.; Patnaik, S.; Swain, P.; Majhi, J. Wear characteristics of Al-AlN composites produced in-situ by nitrogenation. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Rourkela, India, 5–6 December 2014; p. 012034. [Google Scholar]

- Balog, M.; Krizik, P.; Dvorak, J.; Bajana, O.; Krajcovic, J.; Drienovsky, M. Industrially fabricated in-situ Al-AlN metal matrix composites (part B): The mechanical, creep, and thermal properties. J. Alloys Compd. 2022, 909, 164720. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ravichandran, M. Experimental investigation on mechanical properties of AA7075-AlN composites. Mater. Test. 2019, 61, 554–558. [Google Scholar] [CrossRef]

- Grech, J.; Antunes, E. Zirconia in dental prosthetics: A literature review. J. Mater. Res. Technol. 2019, 8, 4956–4964. [Google Scholar] [CrossRef]

- Turon-Vinas, M.; Anglada, M. Strength and fracture toughness of zirconia dental ceramics. Dent. Mater. 2018, 34, 365–375. [Google Scholar] [CrossRef]

- Haddadi, S.; Mahdavian, M.; Karimi, E. Evaluation of the corrosion protection properties of an epoxy coating containing sol–gel surface modified nano-zirconia on mild steel. RSC Adv. 2015, 5, 28769–28777. [Google Scholar] [CrossRef]

- Volpato, C.Â.M.; Garbelotto, L.; Fredel, M.C.; Bondioli, F. Application of zirconia in dentistry: Biological, mechanical and optical considerations. Adv. Ceram.-Electr. Magn. Ceram. Bioceram. Ceram. Environ. 2011, 25, 397–420. [Google Scholar]

- Walker, R.C.; Potochniak, A.E.; Hyer, A.P.; Ferri, J.K. Zirconia aerogels for thermal management: Review of synthesis, processing, and properties information architecture. Adv. Colloid Interface Sci. 2021, 295, 102464. [Google Scholar] [CrossRef]

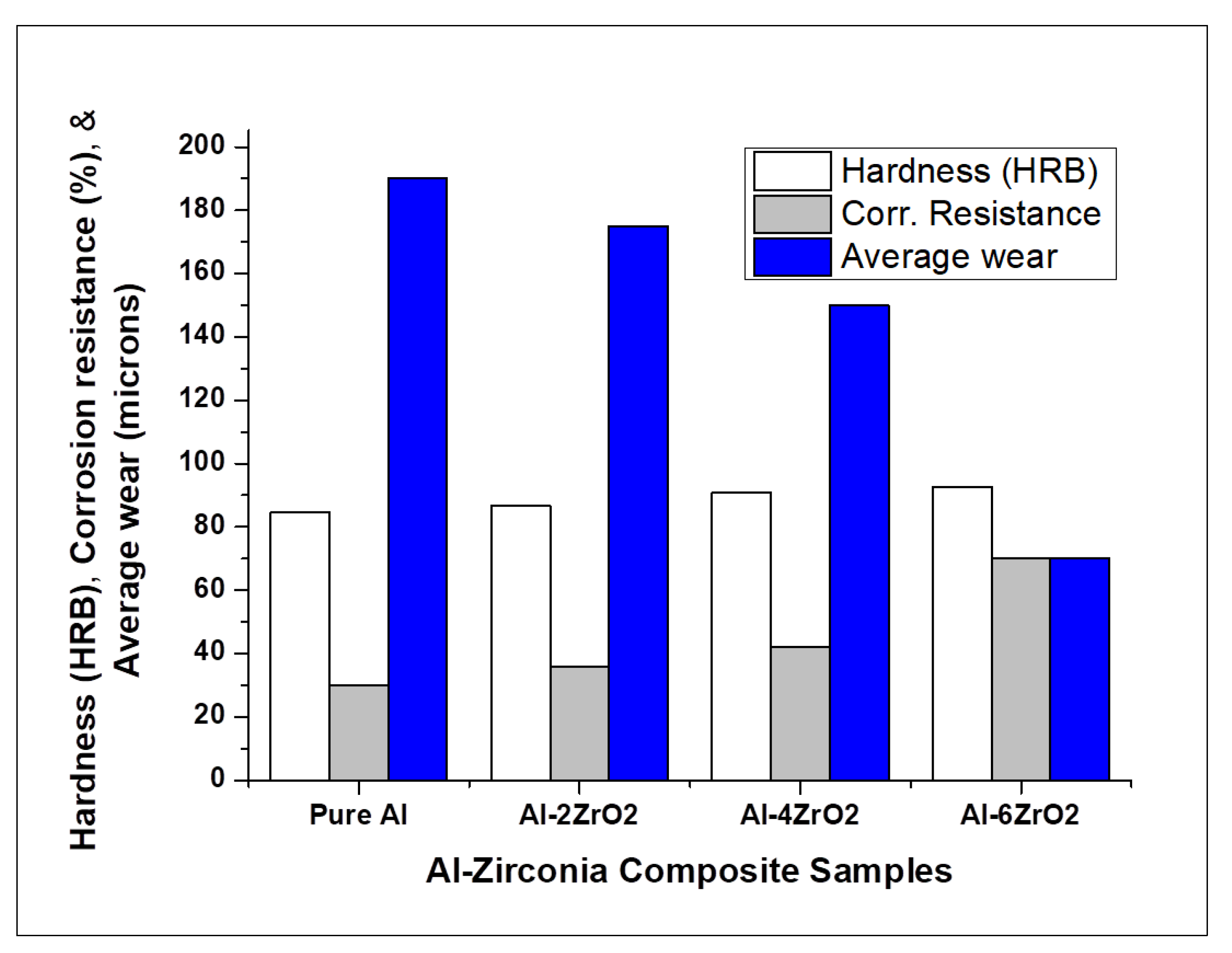

- Pal, K.; Navin, K.; Kurchania, R. Study of structural and mechanical behaviour of Al-ZrO2 metal matrix nanocomposites prepared by powder metallurgy method. Mater. Today: Proc. 2020, 26, 2714–2719. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Jalilvand, M.M.; Heidarpour, A.; Jahani, A.R. Tribological behavior of AZ31/ZrO2 surface nanocomposites developed by friction stir processing. Tribol. Int. 2020, 143, 106062. [Google Scholar] [CrossRef]

- Kumar, G.V.; Pramod, R.; Sekhar, C.G.; Kumar, G.P.; Bhanumurthy, T. Investigation of physical, mechanical and tribological properties of Al6061–ZrO2 nano-composites. Heliyon 2019, 5, e02858. [Google Scholar] [CrossRef] [PubMed]

- Baghchesara, M.; Baharvandi, H.; Abdizadeh, H. Investigation on mechanical properties and surfaces fracture of Al/ZrO2 composite. In Proceedings of the International Conference on Smart Materials and Nanotechnology in Engineering, Harbin, China, 1–4 July 2007; pp. 1554–1559. [Google Scholar]

- James, S.J.; Ganesan, M.; Santhamoorthy, P.; Kuppan, P. Development of hybrid aluminium metal matrix composite and study of property. Mater. Today Proc. 2018, 5, 13048–13054. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Baghchesara, M.A. Investigation on mechanical properties and fracture behavior of A356 aluminum alloy based ZrO2 particle reinforced metal-matrix composites. Ceram. Int. 2013, 39, 2045–2050. [Google Scholar] [CrossRef]

- Rajabi, M.; Khodai, M.; Askari, N. Microwave-assisted sintering of Al–ZrO2 nano-composites. J. Mater. Sci. Mater. Electron. 2014, 25, 4577–4584. [Google Scholar] [CrossRef]

- Yadav, M.; Kumaraswamidhas, L.; Singh, S.K. Investigation of solid particle erosion behavior of Al-Al2O3 and Al-ZrO2 metal matrix composites fabricated through powder metallurgy technique. Tribol. Int. 2022, 172, 107636. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. Microstructural and abrasive wear properties of SiC reinforced aluminum-based composite produced by compocasting. Trans. Nonferrous Met. Soc. China 2013, 23, 1905–1914. [Google Scholar] [CrossRef]

- Zhou, K.; Xiao, G.; Xu, J.; Huang, Y. Material removal behavior of Cf/SiC ceramic matrix composites as a function of abrasive wear during diamond abrasive belt grinding. Wear 2021, 486, 204101. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, H.; Wang, Z.; Li, Q.; Wu, J. Mechanical properties and corrosion behavior of Al/SiC composites. J. Alloys Compd. 2016, 678, 23–30. [Google Scholar] [CrossRef]

- Patel, M.; Sahu, S.K.; Singh, M.K. Abrasive wear behavior of SiC particulate reinforced AA5052 metal matrix composite. Mater. Today Proc. 2020, 33, 5586–5591. [Google Scholar] [CrossRef]

- Kumar, M.S.; Begum, S.R.; Pruncu, C.; Asl, M.S. Role of homogeneous distribution of SiC reinforcement on the characteristics of stir casted Al–SiC composites. J. Alloys Compd. 2021, 869, 159250. [Google Scholar] [CrossRef]

- Soltani, S.; Azari Khosroshahi, R.; Taherzadeh Mousavian, R.; Jiang, Z.-Y.; Fadavi Boostani, A.; Brabazon, D. Stir casting process for manufacture of Al–SiC composites. Rare Met. 2017, 36, 581–590. [Google Scholar] [CrossRef]

- Moses, J.J.; Dinaharan, I.; Sekhar, S.J. Characterization of silicon carbide particulate reinforced AA6061 aluminum alloy composites produced via stir casting. Procedia Mater. Sci. 2014, 5, 106–112. [Google Scholar] [CrossRef]

- Nirala, A.; Soren, S.; Kumar, N.; Dwivedi, V.; Kaushal, D. A comprehensive review on stir cast Al-SiC composite. Mater. Today Proc. 2020, 21, 1610–1614. [Google Scholar] [CrossRef]

- Zakaria, H. Microstructural and corrosion behavior of Al/SiC metal matrix composites. Ain Shams Eng. J. 2014, 5, 831–838. [Google Scholar] [CrossRef]

- Mosleh-Shirazi, S.; Akhlaghi, F.; Li, D.-Y. Effect of SiC content on dry sliding wear, corrosion and corrosive wear of Al/SiC nanocomposites. Trans. Nonferrous Met. Soc. China 2016, 26, 1801–1808. [Google Scholar] [CrossRef]

- Kitayama, M.; Hirao, K.; Toriyama, M.; Kanzaki, S. High hardness α-Si3N4 ceramics reinforced by rod-like β-Si3N4 seed particles. J. Ceram. Soc. Jpn. 2000, 108, 646–649. [Google Scholar] [CrossRef]

- Okada, A. Automotive and industrial applications of structural ceramics in Japan. J. Eur. Ceram. Soc. 2008, 28, 1097–1104. [Google Scholar] [CrossRef]

- Hoffmann, M. High-temperature properties of Si3N4 ceramics. MRS Bull. 1995, 20, 28–32. [Google Scholar] [CrossRef]

- Ul Haq, M.I.; Anand, A. Dry sliding friction and wear behavior of AA7075-Si3N4 composite. Silicon 2018, 10, 1819–1829. [Google Scholar] [CrossRef]

- Mattli, M.R.; Matli, P.R.; Shakoor, A.; Amer Mohamed, A.M. Structural and mechanical properties of amorphous Si3N4 nanoparticles reinforced Al matrix composites prepared by microwave sintering. Ceramics 2019, 2, 126–134. [Google Scholar] [CrossRef] [Green Version]

- Mohanavel, V.; Ali, K.A.; Prasath, S.; Sathish, T.; Ravichandran, M. Microstructural and tribological characteristics of AA6351/Si3N4 composites manufactured by stir casting. J. Mater. Res. Technol. 2020, 9, 14662–14672. [Google Scholar] [CrossRef]

- Ertug, B. Sintering Applications; BoD–Books on Demand: Norderstedt, Germany, 2013. [Google Scholar]

- Firestein, K.L.; Steinman, A.E.; Golovin, I.S.; Cifre, J.; Obraztsova, E.A.; Matveev, A.T.; Kovalskii, A.M.; Lebedev, O.I.; Shtansky, D.V.; Golberg, D. Fabrication, characterization, and mechanical properties of spark plasma sintered Al–BN nanoparticle composites. Mater. Sci. Eng. A 2015, 642, 104–112. [Google Scholar] [CrossRef]

- Gostariani, R.; Ebrahimi, R.; Asadabad, M.A.; Paydar, M.H. Mechanical properties of Al/BN nanocomposites fabricated by planetary ball milling and conventional hot extrusion. Acta Metall. Sin. Engl. Lett. 2018, 31, 245–253. [Google Scholar] [CrossRef]

- Xue, Y.; Jiang, B.; Bourgeois, L.; Dai, P.; Mitome, M.; Zhang, C.; Yamaguchi, M.; Matveev, A.; Tang, C.; Bando, Y. Aluminum matrix composites reinforced with multi-walled boron nitride nanotubes fabricated by a high-pressure torsion technique. Mater. Des. 2015, 88, 451–460. [Google Scholar] [CrossRef]

- Firestein, K.; Corthay, S.; Steinman, A.; Matveev, A.; Kovalskii, A.; Sukhorukova, I.; Golberg, D.; Shtansky, D. High-strength aluminum-based composites reinforced with BN, AlB2 and AlN particles fabricated via reactive spark plasma sintering of Al-BN powder mixtures. Mater. Sci. Eng. A 2017, 681, 1–9. [Google Scholar] [CrossRef]

- Reddy, M.P.; Manakari, V.; Parande, G.; Ubaid, F.; Shakoor, R.; Mohamed, A.; Gupta, M. Enhancing compressive, tensile, thermal and damping response of pure Al using BN nanoparticles. J. Alloys Compd. 2018, 762, 398–408. [Google Scholar] [CrossRef]

- Arlic, U.; Drozd, Z.; Trojanová, Z.; Molnárová, O.; Kasakewitsch, A. Characterisation of an Al-BN nanocomposite prepared by ball milling and hot extrusion. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Risø, Denmark, 4–8 September 2017; p. 012011. [Google Scholar]

- Domnich, V.; Reynaud, S.; Haber, R.A.; Chhowalla, M. Boron carbide: Structure, properties, and stability under stress. J. Am. Ceram. Soc. 2011, 94, 3605–3628. [Google Scholar] [CrossRef]

- Liu, C. Structure and properties of boron carbide with aluminum incorporation. Mater. Sci. Eng. B 2000, 72, 23–26. [Google Scholar] [CrossRef]

- Jianxin, D. Erosion wear of boron carbide ceramic nozzles by abrasive air-jets. Mater. Sci. Eng. A 2005, 408, 227–233. [Google Scholar] [CrossRef]

- Ibrahim, M.; Ammar, H.; Samuel, A.; Soliman, M.; Almajid, A.; Samuel, F. Mechanical properties and fracture of Al–15 vol.-% B4C based metal matrix composites. Int. J. Cast Met. Res. 2014, 27, 7–14. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Haseeb, A.; Celis, J.P. Tribo-surface characteristics of Al–B4C and Al–SiC composites worn under different contact pressures. Wear 2006, 261, 634–641. [Google Scholar] [CrossRef]

- Wu, C.; Fang, P.; Luo, G.; Chen, F.; Shen, Q.; Zhang, L.; Lavernia, E.J. Effect of plasma activated sintering parameters on microstructure and mechanical properties of Al-7075/B4C composites. J. Alloys Compd. 2014, 615, 276–282. [Google Scholar] [CrossRef]

- Auradi, V.; Rajesh, G.; Kori, S. Processing of B4C Particulate Reinforced 6061Aluminum Matrix Composites by melt stirring involving two-step addition. Procedia Mater. Sci. 2014, 6, 1068–1076. [Google Scholar] [CrossRef]

- Canakci, A.; Varol, T.; Özkaya, S.; Erdemir, F. Microstructure and properties of Al-B4C functionally graded materials produced by powder metallurgy method. Univers. J. Mater. Sci. 2014, 2, 90–95. [Google Scholar] [CrossRef]

- Isfahani, M.J.N.; Payami, F.; Asadabad, M.A.; Shokri, A.A. Investigation of the effect of boron carbide nanoparticles on the structural, electrical and mechanical properties of Al-B4C nanocomposites. J. Alloys Compd. 2019, 797, 1348–1358. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Iijima, S. Carbon nanotubes. MRS Bull. 1994, 19, 43–49. [Google Scholar] [CrossRef]

- Bethune, D.; Kiang, C.H.; De Vries, M.; Gorman, G.; Savoy, R.; Vazquez, J.; Beyers, R. Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls. Nature 1993, 363, 605–607. [Google Scholar] [CrossRef]

- Treacy, M.J.; Ebbesen, T.; Gibson, J. Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 1996, 381, 678–680. [Google Scholar] [CrossRef]

- Obitayo, W.; Liu, T. A review: Carbon nanotube-based piezoresistive strain sensors. J. Sens. 2012, 2012, 652438. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Lee, C.; Zhou, C.; Han, J. Carbon nanotube field-effect inverters. Appl. Phys. Lett. 2001, 79, 3329–3331. [Google Scholar] [CrossRef]

- Chu, L.L.; Que, L.; Gianchandani, Y.B. Measurements of material properties using differential capacitive strain sensors. J. Microelectromech. Syst. 2002, 11, 489–498. [Google Scholar] [CrossRef]

- Yildirim, M.; Özyürek, D.; Gürü, M. Investigation of microstructure and wear behaviors of al matrix composites reinforced by carbon nanotube. Fuller. Nanotub. Carbon Nanostruct. 2016, 24, 467–473. [Google Scholar] [CrossRef]

- Kumar, L.; Nasimul Alam, S.; Sahoo, S.K. Mechanical properties, wear behavior and crystallographic texture of Al–multiwalled carbon nanotube composites developed by powder metallurgy route. J. Compos. Mater. 2017, 51, 1099–1117. [Google Scholar] [CrossRef]

- Chen, B.; Li, S.; Imai, H.; Jia, L.; Umeda, J.; Takahashi, M.; Kondoh, K. Carbon nanotube induced microstructural characteristics in powder metallurgy Al matrix composites and their effects on mechanical and conductive properties. J. Alloys Compd. 2015, 651, 608–615. [Google Scholar] [CrossRef]

- Lu, Q.; Ni, S.; Guo, B.; Gu, J.; Adeli, M.; Song, M. Effects of the addition of CNTs and Al alloying on the microstructure and properties of Cu-(Al)/CNTs composites. Diam. Relat. Mater. 2021, 120, 108600. [Google Scholar] [CrossRef]

- Sahoo, B.; Joseph, J.; Sharma, A.; Paul, J. Particle size and shape effects on the surface mechanical properties of aluminium coated with carbonaceous materials. J. Compos. Mater. 2019, 53, 261–270. [Google Scholar] [CrossRef]

- Park, J.G.; Keum, D.H.; Lee, Y.H. Strengthening mechanisms in carbon nanotube-reinforced aluminum composites. Carbon 2015, 95, 690–698. [Google Scholar] [CrossRef]

- George, R.; Kashyap, K.; Rahul, R.; Yamdagni, S. Strengthening in carbon nanotube/aluminium (CNT/Al) composites. Scr. Mater. 2005, 53, 1159–1163. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [Green Version]

- Esteve, J.; Zambrano, G.; Rincon, C.; Martinez, E.; Galindo, H.; Prieto, P. Mechanical and tribological properties of tungsten carbide sputtered coatings. Thin Solid Film. 2000, 373, 282–286. [Google Scholar] [CrossRef]

- Krishna, A.R.; Arun, A.; Unnikrishnan, D.; Shankar, K.V. An investigation on the mechanical and tribological properties of alloy A356 on the addition of WC. Mater. Today Proc. 2018, 5, 12349–12355. [Google Scholar] [CrossRef]

- Megahed, A.; Mohamed, M.A.; Abdel Hamid, M.; Zoalfakar, S.H. Microstructure, hardness, and wear properties of AA6061/WC nanocomposite fabricated by friction stir processing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 09544062221091904. [Google Scholar] [CrossRef]

- Raviraj, M.; Sharanprabhu, C.; Mohankumar, G. Experimental analysis on processing and properties of Al-TiC metal matrix composites. Procedia Mater. Sci. 2014, 5, 2032–2038. [Google Scholar] [CrossRef]

- Bauri, R.; Yadav, D.; Suhas, G. Effect of friction stir processing (FSP) on microstructure and properties of Al–TiC in situ composite. Mater. Sci. Eng. A 2011, 528, 4732–4739. [Google Scholar] [CrossRef]

- Agrawal, E.; Tungikar, V. Study on tribological properties of Al-TiC composites by Taguchi method. Mater. Today Proc. 2020, 26, 2242–2247. [Google Scholar] [CrossRef]

- Wang, Z.; Qiu, Z.; Sun, H.; Liu, W. Effect of TiC content on the microstructure, texture and mechanical properties of 1060/Al–TiC/1060 laminated composites. J. Alloys Compd. 2019, 806, 788–797. [Google Scholar] [CrossRef]

- Parswajinan, C.; Ramnath, B.V.; Abishek, S.; Niharishsagar, B.; Sridhar, G. Hardness and impact behaviour of aluminium metal matrix composite. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tamilnadu, India, 8–9 March 2018; p. 012075. [Google Scholar]

- Chamis, C.; Lark, R. Hybrid composites-State-of-the-art review: Analysis, design, application and fabrication. In Proceedings of the 18th Structural Dynamics and Materials Conference, San Diego, CA, USA, 21–23 March 1977; p. 415. [Google Scholar]

- Banerjee, S.; Sankar, B.V. Mechanical properties of hybrid composites using finite element method based micromechanics. Compos. Part B Eng. 2014, 58, 318–327. [Google Scholar] [CrossRef]

- Akinwamide, S.O.; Akinribide, O.J.; Olubambi, P.A. Microstructural evolution, mechanical and nanoindentation studies of stir cast binary and ternary aluminium based composites. J. Alloys Compd. 2021, 850, 156586. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Vettivel, S.; Perumal, A.E.; Selvakumar, N.; Issac, R.F. Experimental investigation on mechanical behaviour, modelling and optimization of wear parameters of B4C and graphite reinforced aluminium hybrid composites. Mater. Des. 2014, 63, 620–632. [Google Scholar] [CrossRef]

- Radhika, N.; Subramanian, R. Effect of reinforcement on wear behaviour of aluminium hybrid composites. Tribol.-Mater. Surf. Interfaces 2013, 7, 36–41. [Google Scholar] [CrossRef]

- Kumar, N.S.; Ravindranath, V.; Shankar, G.S. Mechanical and wear behaviour of aluminium metal matrix hybrid composites. Procedia Mater. Sci. 2014, 5, 908–917. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Sharma, S.; Garg, H.; Singh, J.; Kumar, H.; Singh, G. Fabrication of aluminium carbon nano tube silicon carbide particles based hybrid nano-composite by spark plasma sintering. Mater. Today Proc. 2020, 21, 1637–1642. [Google Scholar] [CrossRef]

- Ghasali, E.; Pakseresht, A.; Rahbari, A.; Eslami-Shahed, H.; Alizadeh, M.; Ebadzadeh, T. Mechanical properties and microstructure characterization of spark plasma and conventional sintering of Al–SiC–TiC composites. J. Alloys Compd. 2016, 666, 366–371. [Google Scholar] [CrossRef]

- Oladijo, O.; Popoola, A.; Ujah, C.; Namoshe, M. Dataset of spark plasma sintering of AlZnSn alloy for soft solder application. Data Brief 2019, 24, 103948. [Google Scholar] [CrossRef] [PubMed]

- Venkatesh, V.; Deoghare, A.B. Effect of Sintering Mechanisms on the Mechanical Behaviour of SiC and Kaoline Reinforced Hybrid Aluminium Metal Matrix Composite Fabricated through Powder Metallurgy Technique. Silicon 2022, 14, 5481–5493. [Google Scholar] [CrossRef]

- Shaikh, M.B.N.; Arif, S.; Siddiqui, M.A. Fabrication and characterization of aluminium hybrid composites reinforced with fly ash and silicon carbide through powder metallurgy. Mater. Res. Express 2018, 5, 046506. [Google Scholar] [CrossRef]

- Tan, A.; Teng, J.; Zeng, X.; Fu, D.; Zhang, H. Fabrication of aluminium matrix hybrid composites reinforced with SiC microparticles and TiB2 nanoparticles by powder metallurgy. Powder Metall. 2017, 60, 66–72. [Google Scholar] [CrossRef]

- Pugalenthi, P. Study of the microstructures and mechanical properties of aluminium hybrid composites with. Mater. Tehnol. 2019, 53, 49–55. [Google Scholar] [CrossRef]

- Mohanavel, V.; Rajan, K.; Senthil, P.; Arul, S. Mechanical behaviour of hybrid composite (AA6351+ Al2O3+ Gr) fabricated by stir casting method. Mater. Today Proc. 2017, 4, 3093–3101. [Google Scholar] [CrossRef]

- Arif, S.; Alam, M.T.; Ansari, A.H.; Siddiqui, M.A.; Mohsin, M. Study of mechanical and tribological behaviour of Al/SiC/ZrO2 hybrid composites fabricated through powder metallurgy technique. Mater. Res. Express 2017, 4, 076511. [Google Scholar] [CrossRef]

- Manikandan, R.; Arjunan, T. Mechanical and tribological behaviours of aluminium hybrid composites reinforced by CDA-B4C. Mater. Res. Express 2020, 7, 016584. [Google Scholar] [CrossRef]

- Venkatesh, L.; Arjunan, T.; Ravikumar, K. Microstructural characteristics and mechanical behaviour of aluminium hybrid composites reinforced with groundnut shell ash and B4C. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 295. [Google Scholar] [CrossRef]

- Kumar, R.A.; Devaraju, A.; Arunkumar, S. Experimental investigation on mechanical behaviour and wear parameters of tic and graphite reinforced aluminium hybrid composites. Mater. Today Proc. 2018, 5, 14244–14251. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, Y.; Yao, Z.; Liu, A.; Shi, G. Supercapacitors based on flexible graphene/polyaniline nanofiber composite films. ACS Nano 2010, 4, 1963–1970. [Google Scholar] [CrossRef] [PubMed]

- Raja, S.; Muhamad, M.R.; Jamaludin, M.F.; Yusof, F. A review on nanomaterials reinforcement in friction stir welding. J. Mater. Res. Technol. 2020, 9, 16459–16487. [Google Scholar] [CrossRef]

- Abdo, H.S.; Mohammed, M.L.; Khalil, K.A. Fiber-reinforced metal-matrix composites. In Fiber Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 649–667. [Google Scholar]

- Chen, L.; Qi, Y.; Fei, Y.; Du, Z. Enhanced mechanical properties and thermal conductivity for GNPs/Al2024 composites with in situ SiC nanorods. Met. Mater. Int. 2021, 27, 4263–4270. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Miracle, D. Metal matrix composites–from science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K.; Arumugam, S. Synthesis and characterization of sintered hybrid aluminium matrix composites reinforced with nanocopper oxide particles and microsilicon carbide particles. Compos. Part B Eng. 2014, 59, 43–49. [Google Scholar] [CrossRef]

- Saheb, N.; Iqbal, Z.; Khalil, A.; Hakeem, A.S.; Al Aqeeli, N.; Laoui, T.; Al-Qutub, A.; Kirchner, R. Spark plasma sintering of metals and metal matrix nanocomposites: A review. J. Nanomater. 2012, 2012, 983470. [Google Scholar] [CrossRef]

- Ruiz-Esparza-Rodríguez, M.; Garay-Reyes, C.; Mendoza-Duarte, J.; Estrada-Guel, I.; Hernández-Rivera, J.; Cruz-Rivera, J.; Gutiérrez-Castañeda, E.; González, S.; Garay-Tapia, A.; Martínez-Sánchez, R. Evaluation of high-frequency induction heat sintering and conventional sintering in AlxCoCrFeMnNi high-entropy alloys. J. Alloys Compd. 2022, 910, 164780. [Google Scholar] [CrossRef]

- Mendoza-Duarte, J.; Robles-Hernandez, F.; Estrada-Guel, I.; Martínez-Sánchez, R. Aluminum sintering in air atmosphere using high frequency induction heating. Microsc. Microanal. 2017, 23, 1950–1951. [Google Scholar] [CrossRef]

- Khalil, K.A.; Sherif, E.-S.M.; Nabawy, A.; Abdo, H.S.; Marzouk, W.W.; Alharbi, H.F. Titanium carbide nanofibers-reinforced aluminum compacts, a new strategy to enhance mechanical properties. Materials 2016, 9, 399. [Google Scholar] [CrossRef]

- Oliver, U.C.; Sunday, A.V.; Christain, E.I.-E.I.; Elizabeth, M.M. Spark plasma sintering of aluminium composites—A review. Int. J. Adv. Manuf. Technol. 2021, 112, 1819–1839. [Google Scholar] [CrossRef]

- Li, J.F.; Wang, K.; Zhang, B.P.; Zhang, L.M. Ferroelectric and piezoelectric properties of fine-grained Na0. 5K0. 5NbO3 lead-free piezoelectric ceramics prepared by spark plasma sintering. J. Am. Ceram. Soc. 2006, 89, 706–709. [Google Scholar] [CrossRef]

- Heng, W.; Jingfeng, L.; Cewen, N.; Min, Z.; Weishu, L.; Boping, Z.; Kita, T. High-performance Ag0.8 Pb18+x SbTe20 thermoelectric bulk materials fabricated by mechanical alloying and spark plasma sintering. Appl. Phys. Lett. 2006, 88, 092104. [Google Scholar]

- Ujah, C.; Popoola, A.; Popoola, O.; Aigbodion, V. Enhanced tribology, thermal and electrical properties of Al-CNT composite processed via spark plasma sintering for transmission conductor. J. Mater. Sci. 2019, 54, 14064–14073. [Google Scholar] [CrossRef]

- Beheshtipour, A.; Mahdizadeh, S.M.; Khademi, D.; Khodeir, E.; Emamiyan, H. Comparison of Mechanical Properties and Corrosion Behavior of Al-NanoAl2O3 with Al-MicroAl2O3 Composites Made by SPS Process. Met. Mater. Int. 2020, 26, 1697–1709. [Google Scholar] [CrossRef]

- Chai, J.; Zhu, Y.; Wang, Z.; Shen, T.; Liu, Y.; Niu, L.; Li, S.; Yao, C.; Cui, M.; Liu, C. Microstructure and mechanical properties of SPS sintered Al2O3–ZrO2 (3Y)–SiC ceramic composites. Mater. Sci. Eng. A 2020, 781, 139197. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, A.; Popoola, O.; Afolabi, A.; Uyor, U. Mechanical and Oxidation Characteristics of Ti20-Al16-V16-Fe16-Ni16-Cr16 High-Entropy Alloy Developed via Spark Plasma Sintering for High-Temperature/Strength Applications. J. Mater. Eng. Perform. 2022, 1–11. [Google Scholar] [CrossRef]

- Fattahi, M.; Mohammadzadeh, A.; Pazhouhanfar, Y.; Shaddel, S.; Asl, M.S.; Namini, A.S. Influence of SPS temperature on the properties of TiC–SiCw composites. Ceram. Int. 2020, 46, 11735–11742. [Google Scholar] [CrossRef]

- Moazzen, P.; Toroghinejad, M.R.; Karimzadeh, F.; Vleugels, J.; Ravash, H.; Cavaliere, P. Influence of zirconium addition on the microstructure, thermodynamic stability, thermal stability and mechanical properties of mechanical alloyed spark plasma sintered (MA-SPS) FeCoCrNi high entropy alloy. Powder Metall. 2018, 61, 405–416. [Google Scholar] [CrossRef]

- Thomson, K.; Jiang, D.; Yao, W.; Ritchie, R.; Mukherjee, A. Characterization and mechanical testing of alumina-based nanocomposites reinforced with niobium and/or carbon nanotubes fabricated by spark plasma sintering. Acta Mater. 2012, 60, 622–632. [Google Scholar] [CrossRef]

- Rohatgi, P. Cast aluminum-matrix composites for automotive applications. Jom 1991, 43, 10–15. [Google Scholar] [CrossRef]

- Ravi, K.; Sreekumar, V.; Pillai, R.; Mahato, C.; Amaranathan, K.; Pai, B. Optimization of mixing parameters through a water model for metal matrix composites synthesis. Mater. Des. 2007, 28, 871–881. [Google Scholar] [CrossRef]

- Singla, M.; Dwivedi, D.D.; Singh, L.; Chawla, V. Development of aluminium based silicon carbide particulate metal matrix composite. J. Miner. Mater. Charact. Eng. 2009, 8, 455–467. [Google Scholar] [CrossRef]

- Hashim, J. The production of cast metal matrix composite by a modified stir casting method. J. Teknol. 2001, 35, 9–20. [Google Scholar] [CrossRef]

- Rajan, T.; Pillai, R.; Pai, B. Reinforcement coatings and interfaces in aluminium metal matrix composites. J. Mater. Sci. 1998, 33, 3491–3503. [Google Scholar] [CrossRef]

- Kalaiselvan, K.; Murugan, N.; Parameswaran, S. Production and characterization of AA6061–B4C stir cast composite. Mater. Des. 2011, 32, 4004–4009. [Google Scholar] [CrossRef]

- Pai, B.; Ramani, G.; Pillai, R.; Satyanarayana, K. Role of magnesium in cast aluminium alloy matrix composites. J. Mater. Sci. 1995, 30, 1903–1911. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Laoui, T.; Haseeb, A.A.; Celis, J.-P.; Froyen, L. Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: A comparative study. J. Mater. Processing Technol. 2003, 142, 738–743. [Google Scholar] [CrossRef]

- Zulfia, A.; Atkinson, H.; Jones, H.; King, S. Effect of hot isostatic pressing on cast A357 aluminium alloy with and without SiC particle reinforcement. J. Mater. Sci. 1999, 34, 4305–4310. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Mahamood, R.; Akinlabi, S.; Ogunmuyiwa, E. Processing parameters influence on wear resistance behaviour of friction stir processed Al-TiC composites. Adv. Mater. Sci. Eng. 2014, 2014, 724590. [Google Scholar] [CrossRef]

- Prakrathi, S.; Ravikumar, M.; Udupa, K.; Udaya Bhat, K. Fabrication of hybrid surface composite through friction stir processing and its impression creep behaviour. Int. Sch. Res. Not. 2013, 2013, 541762. [Google Scholar] [CrossRef]

- Izadi, H.; Nolting, A.; Munro, C.; Bishop, D.; Plucknett, K.; Gerlich, A. Friction stir processing of Al/SiC composites fabricated by powder metallurgy. J. Mater. Processing Technol. 2013, 213, 1900–1907. [Google Scholar] [CrossRef]

- Zahmatkesh, B.; Enayati, M. A novel approach for development of surface nanocomposite by friction stir processing. Mater. Sci. Eng. A 2010, 527, 6734–6740. [Google Scholar] [CrossRef]

- Ozturk, K.; Gecu, R.; Karaaslan, A. Microstructure, wear and corrosion characteristics of multiple-reinforced (SiC–B4C–Al2O3) Al matrix composites produced by liquid metal infiltration. Ceram. Int. 2021, 47, 18274–18285. [Google Scholar] [CrossRef]

- Kisasoz, A.; Guler, K.A.; Karaaslan, A. Infiltration of A6063 aluminium alloy into SiC–B4C hybrid preforms using vacuum assisted block mould investment casting technique. Trans. Nonferrous Met. Soc. China 2012, 22, 1563–1567. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V.; Aikhuele, D.O.; Aigbodion, V.S. Advanced Composite Materials: A Panacea for Improved Electricity Transmission. Appl. Sci. 2022, 12, 8291. [Google Scholar] [CrossRef]

- Caceres, C.H. Economical and environmental factors in light alloys automotive applications. Metall. Mater. Trans. A 2007, 38, 1649–1662. [Google Scholar] [CrossRef]

- Withers, G.; De Waas Tilakaratna, P. Performance evaluation of ULTALITE® low cost aluminium metal matrix composite based brake drums. SAE Trans. 2005, 114, 902–907. [Google Scholar] [CrossRef]

- Skillingberg, M.; Green, J. Aluminum applications in the rail industry. Light Met. Age 2007, 65, 8. [Google Scholar]

- Pedneault, J.; Desjardins, V.; Margni, M.; Conciatori, D.; Fafard, M.; Sorelli, L. Economic and environmental life cycle assessment of a short-span aluminium composite bridge deck in Canada. J. Clean. Prod. 2021, 310, 127405. [Google Scholar] [CrossRef]

- Kitzmantel, M.; Neubauer, E. Innovative hybrid heat sink materials with high thermal conductivities and tailored CTE. In Proceedings of the Components and Packaging for Laser Systems, San Francisco, CA, USA, 7–12 February 2015; pp. 51–61. [Google Scholar]

- Shu, S.; Yang, H.; Tong, C.; Qiu, F. Fabrication of TiCx-TiB2/Al composites for application as a heat sink. Materials 2016, 9, 642. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, A.; Popoola, O. Review on materials applied in electric transmission conductors. J. Mater. Sci. 2022, 57, 1581–1598. [Google Scholar] [CrossRef]

- Berg, J.S. Composite material advances in the golf industry. Europe 2000, 1, 7. [Google Scholar]

- Sun, Y.; Zhao, Y.; Wu, J.; Kai, X.; Zhang, Z.; Fang, Z.; Xia, C. Effects of particulate agglomerated degree on deformation behaviors and mechanical properties of in-situ ZrB2 nanoparticles reinforced AA6016 matrix composites by finite element modeling. Mater. Res. Express 2020, 7, 036507. [Google Scholar] [CrossRef]

- Rubel, R.I.; Ali, M.H.; Jafor, M.A.; Alam, M.M. Carbon nanotubes agglomeration in reinforced composites: A review. AIMS Mater. Sci. 2019, 6, 756–780. [Google Scholar] [CrossRef]

- Lengauer, W.; Dreyer, K. Tailoring hardness and toughness gradients in functional gradient hardmetals (FGHMs). Int. J. Refract. Met. Hard Mater. 2006, 24, 155–161. [Google Scholar] [CrossRef]

- Farajollahi, R.; Aval, H.J.; Jamaati, R. Effects of Ni on the microstructure, mechanical and tribological properties of AA2024-Al3NiCu composite fabricated by stir casting process. J. Alloys Compd. 2021, 887, 161433. [Google Scholar] [CrossRef]

| Industry | Products | Properties | Ref |

|---|---|---|---|

| Automotive | Piston and connecting rod, brake and chassis, engine block | Light weight, high thermal conductivity, high strength, wear resistance | [33,34] |

| Defence | Fins of a directed gun | Precision and strong rigidity | [35] |

| Sports | Golf, baseball, skiing equipment | Low cost and light weight | [36] |

| Building construction | Roofing sheet, door and window panels, shelves, | Strength and light weight | [37] |

| Electrical and electronic | Conductor, capacitor, inductor | Low CTE, high thermal conductivity | [38] |

| Aerospace | Wings, rudders, flaps, fuselage, fan outlet guide vanes, hydraulic pipes | Good specific stiffness, light-weight and low CTE | [39,40] |

| Rail and marine | Rail car body, marine ship body parts | Lightweight, high corrosion resistance, high fire hazard control | [41] |

| Composite | Technique | Properties (Percent Improvement) | Remarks | Ref. |

|---|---|---|---|---|

| a. A7075-10B4C-5Gr b. A6061-10B4C-5Gr | i. liquid casting ii. liquid casting | a. Hv: 120 Hb (9%) b. Hv: 108 Hb (8%) a. WR: 0.018 mg/m (233%) b. WR: 0.02mg/m (300%) a. TS: 230 MPa (10%) b. TS: 180 MPa (13%) | The elongation to failure was lower in A7075 than A6061. The improvements were attributed to the resistance to indentation and stress of the reinforcements, especially B4C. | [136] |

| Al-9Al2O3-3Gr | Stir casting | Hv: 94 Hb (20%) TS: 201 MPa (32%) Shear:142.3 Nmm−2 (25%) | Hard alumina and soft graphite particles influenced property improvement. The formation of mechanically mixed layer (MML) improved the wear properties of the composite | [137] |

| Al-3B4C-5MoS4 | Stir casting | Hv: 101 Hb (24%) Elongation: 2.95 (31%) TS and YS decreased by 38%. Wear rate decreased with increase in reinforcement | The ductility, tensile and yield strengths of the composite decreased as the reinforcement increased from 3 to 5% because of ineffective transfer of load by the reinforcements; and the formation of void at matrix reinforcement interface. | [138] |

| Al-5CNTs-10SiC | SPS | Hv: 158 HV (172%) | The authors predicted that the composite will possess high wear resistance. The dislocation defect was highly reduced in the composite. Further increase in CNTs concentration resulted in their agglomeration. | [139] |

| Al-15SiC-5TiC | SPS | Hv: 3060 MPa Bending: 312 MPa | When the authors compared SPS with conventional sintering, SPS gave better properties. Density generated by SPS and conventional sintering were 99.2 ± 0.4% and 90.4 ± 0.7%, respectively. | [140] |

| Al-10Zn-5Sn | SPS | Hv: 572.92 MPa TS: 188.08 MPa | The hardness/tensile data confirmed that the composite is good for replacing Pb solder. | [141] |

| Al-10SiC-4 Kaolin | SPS | TS: 263 MPa (13.3%) Compressive strength: 282 MPa (11.7%) Hv: 147 VHN (16.3%) | The authors compared SPS with conventional sintering (CS) and observed that the high sintering time in CS leads to the formation of detrimental Al2Cu intermetallic, which makes the composite brittle. | [142] |

| Al-10SiC-10FlyAsh | Conventional sintering | Hv: 62 HR (32%) Wear loss: 0.0017 g (65%) | The composite had improved hardness and wear resistance, which were attributed to restriction of dislocation and plastic deformation by the dispersed phases. | [143] |

| Al-10SiC-5TiB2 | Cold compaction and sintering | TS: 230 MPa (64%) YS: 125 MPa (23%) Elong: 2.5% (100%) | The low elongation recorded in the composite resulted in brittle fracture during tensile test, which was attributed to cracks and debonding effects of SiC particles. | [144] |

| Al-9SiC-2Al2O3 | Stir casting | TS: 325 MPa YS: 107 MPa Elong: 2.08% Hv: 119 VHN | The presence of SiC and Al2O3 induced brittle fracture in the composite. | [145] |

| Al-20Al2O3-3Gr | Stir casting | TS: 230 MPa (73%) Flexural: 427.43 MPa (72%) Hv: 95 HV (38%) | The increase in strength was attributed to the resistance to plastic deformation, particle strengthening and grain refinement effects of the reinforcements. | [146] |

| Al-5SiC-9ZrO2 | Green compact sintering | Hv: 59 RHN (43%) Wear loss: 0.004 g (100%) | The superior wear characteristics of this composite was attributed to the load-bearing capacity of ZrO2. | [147] |

| Al-7.5B4C-2.5Cow dung ash (CDA) | Double stir casting | Hv:145 BHN (32%) TS: 280 MPa (56%) Wear rate: 0.002 mm3/m (150%) | The impact strength decreased in the composite as compared to base metal because of reduced ductility of the composite. The presence of soft CDA in the composite improved its elongation to failure. | [148] |

| Al-2.5Groundnut shell ash-7.5B4C | Squeeze casting | Hv: 115 BHN (17%) TS: 348.45 MPa (18%) YS: 285 MPa (14.77%) | The addition of the GSA decreased the impact strength which resulted to cracks, brittle fracture and fractured particles in the composite. | [149] |

| Al-5Gr-4TiC | Stir casting | Hv: 142 HV TS: 225 MPa | The improvement in the mechanical properties was a result of increase in dislocation density around the matrix-reinforcement interface and grain refining of the composite. | [150] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ujah, C.O.; Kallon, D.V.V. Trends in Aluminium Matrix Composite Development. Crystals 2022, 12, 1357. https://doi.org/10.3390/cryst12101357

Ujah CO, Kallon DVV. Trends in Aluminium Matrix Composite Development. Crystals. 2022; 12(10):1357. https://doi.org/10.3390/cryst12101357

Chicago/Turabian StyleUjah, Chika Oliver, and Daramy Vandi Von Kallon. 2022. "Trends in Aluminium Matrix Composite Development" Crystals 12, no. 10: 1357. https://doi.org/10.3390/cryst12101357

APA StyleUjah, C. O., & Kallon, D. V. V. (2022). Trends in Aluminium Matrix Composite Development. Crystals, 12(10), 1357. https://doi.org/10.3390/cryst12101357