Recent Progress on Preparation Strategies of Liquid Crystal Smart Windows

Abstract

:1. Introduction

2. Single-Responsive Liquid Crystal Smart Windows

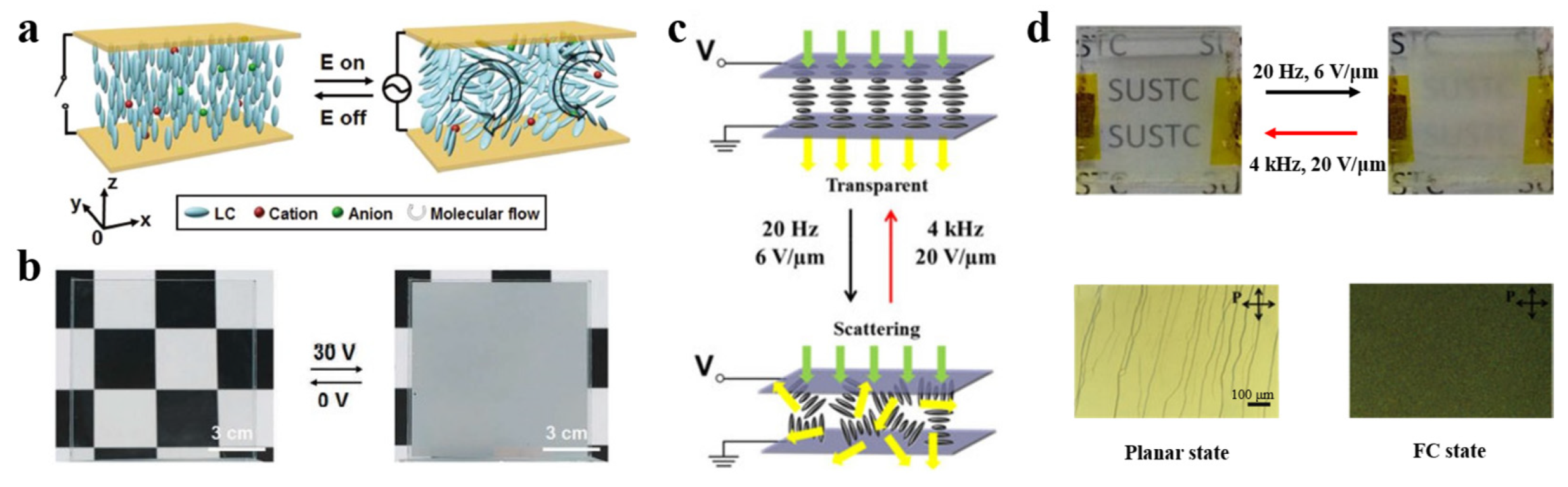

2.1. Electrical-Responsive Liquid Crystal Smart Windows

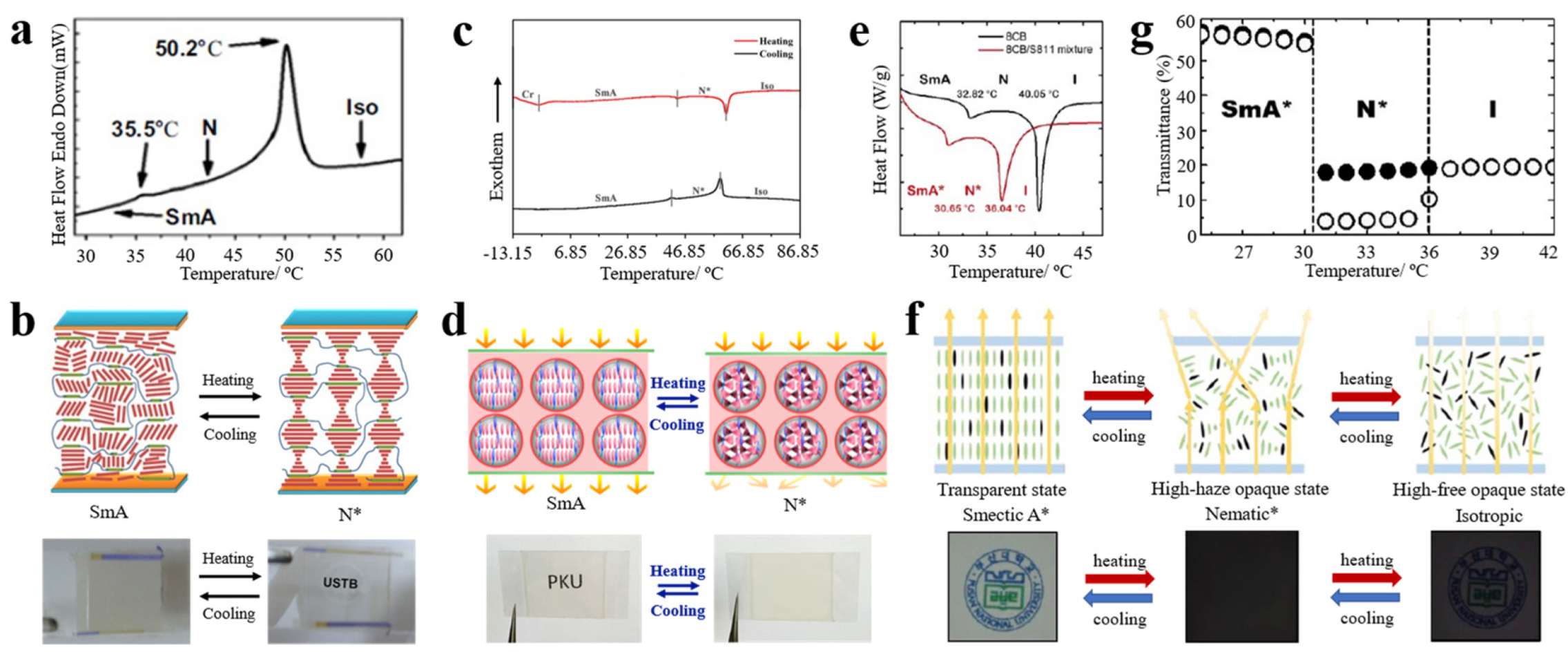

2.2. Thermal-Responsive Liquid Crystal Smart Windows

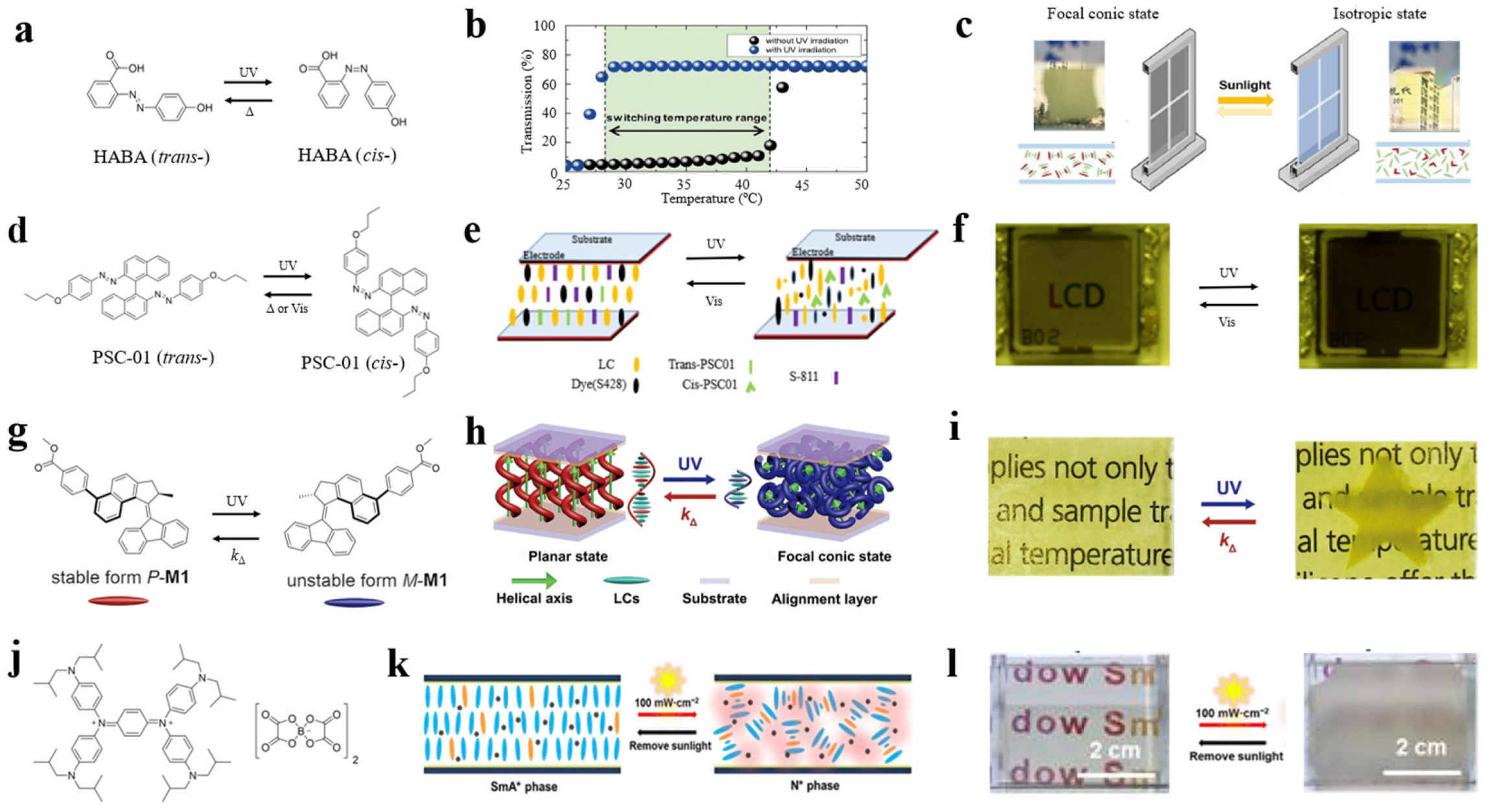

2.3. Photo-Responsive Liquid Crystal Smart Windows

2.4. Chapter Summary

3. Dual-Responsive Liquid Crystal Smart Windows

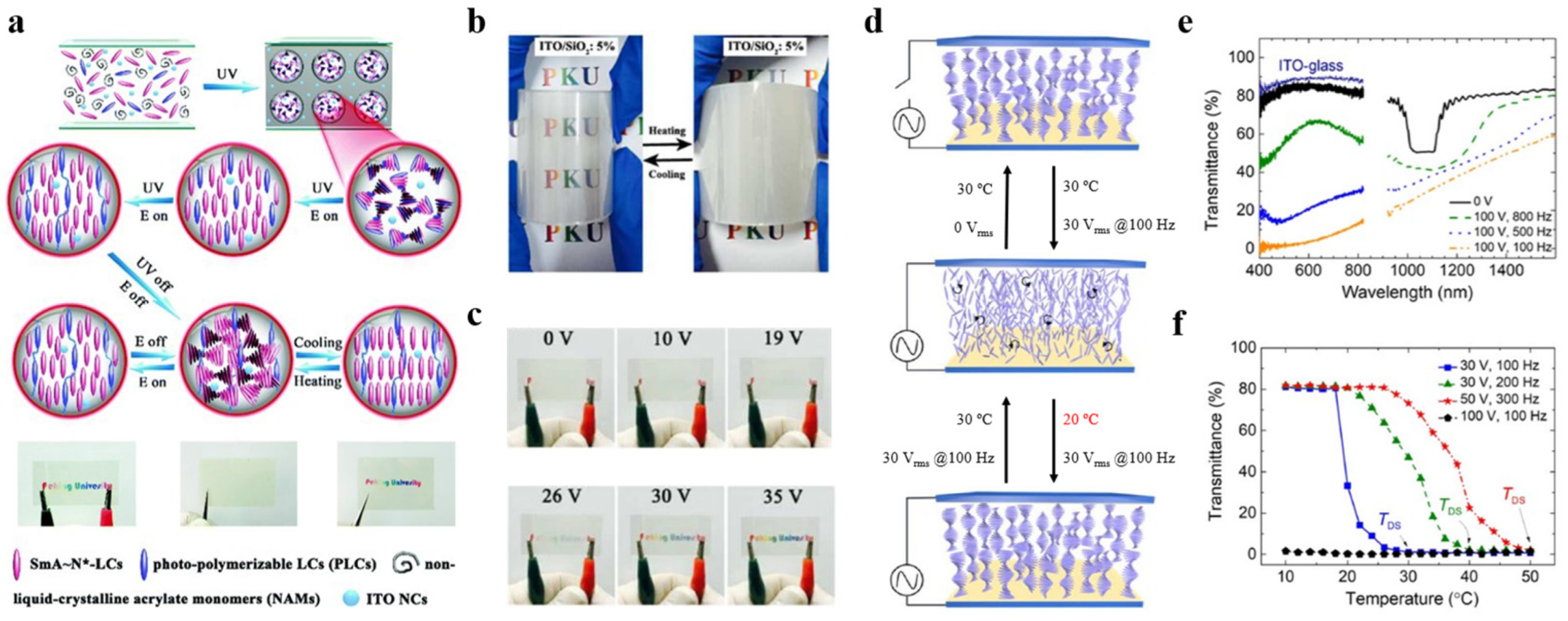

3.1. Thermal-/Electrical-Responsive Liquid Crystal Smart Windows

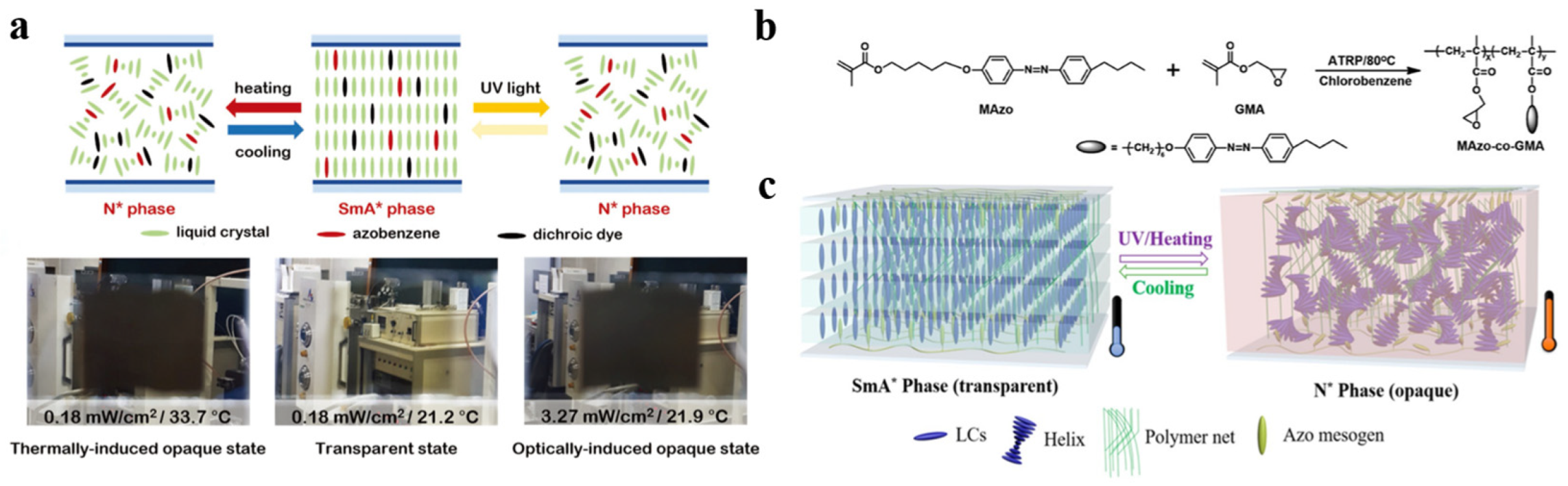

3.2. Thermal-/Photo-Responsive Liquid Crystal Smart Windows

3.3. Chapter Summary

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kammen, D.M.; Sunter, D.A. City-integrated renewable energy for urban sustainability. Science 2016, 352, 922–928. [Google Scholar] [CrossRef] [Green Version]

- Rezaei, S.D.; Shannigrahi, S.; Ramakrishna, S. A review of conventional, advanced, and smart glazing technologies and materials for improving indoor environment. Sol. Energy Mater. Sol. Cells 2017, 159, 26–51. [Google Scholar] [CrossRef]

- Tarantini, M.; Loprieno, A.D.; Porta, P.L. A life cycle approach to Green Public Procurement of building materials and elements: A case study on windows. Energy 2011, 36, 2473–2482. [Google Scholar] [CrossRef]

- De Gastines, M.; Pattini, A.E. Window energy efficiency in Argentina-Determining factors and energy savings strategies. J. Clean. Prod. 2020, 247, 119104. [Google Scholar] [CrossRef]

- Al-Ashwal, N.T.; Budaiwi, I.M.; Hassan, A. An approach to select ideal window area in office buildings: Modeling and simulation. Am. Trans. Eng. Appl. Sci. 2014, 3, 101–114. [Google Scholar]

- Zou, Y.; Xiang, K.; Zhan, Q.; Li, Z. A simulation-based method to predict the life cycle energy performance of residential buildings in different climate zones of China. Build. Environ. 2021, 193, 107663. [Google Scholar] [CrossRef]

- Aburas, M.; Soebarto, V.; Williamson, T.; Liang, R.; Ebendorff-Heidepriem, H.; Wu, Y. Thermochromic smart window technologies for building application: A review. Appl. Energy 2019, 255, 113522. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, S.; Peng, J.; Tan, Y.; Li, C.; Boey, F.Y.C.; Long, Y. Liquid thermo-responsive smart window derived from hydrogel. Joule 2020, 4, 2458–2474. [Google Scholar] [CrossRef]

- Sun, Z.; Xie, X.; Xu, W.; Chen, K.; Liu, Y.; Chu, X.; Niu, Y.; Zhang, S.; Ren, C. Chameleon-inspired energy-saving smart window responding to natural weather. ACS Sustain. Chem. Eng. 2021, 9, 12949–12959. [Google Scholar] [CrossRef]

- Liang, X.; Chen, M.; Wang, Q.; Guo, S.; Zhang, L.; Yang, H. Active and passive modulation of solar light transmittance in a hybrid thermochromic soft-matter system for energy-saving smart window applications. J. Mater. Chem. C 2018, 6, 7054–7062. [Google Scholar] [CrossRef]

- Cui, Y.; Ke, Y.; Liu, C.; Chen, Z.; Wang, N.; Zhang, L.; Zhou, Y.; Wang, S.; Gao, Y.; Long, Y. Thermochromic VO2 for energy-efficient smart windows. Joule 2018, 2, 1707–1746. [Google Scholar] [CrossRef]

- Strand, M.T.; Hernandez, T.S.; Danner, M.G.; Yeang, A.L.; Jarvey, N.; Barile, C.J.; McGehee, M.D. Polymer inhibitors enable >900 cm2 dynamic windows based on reversible metal electrodeposition with high solar modulation. Nat. Energy 2021, 6, 546–554. [Google Scholar] [CrossRef]

- Chowdhary, A.K.; Sikdar, D. Nanophotonic all-weather windows for energy-efficient smart buildings. In CLEO: Applications and Technology; Optica Publishing Group: Washington, DC, USA, 2021; p. JW1A-75. [Google Scholar]

- Insights on the Smart Window Global Market to 2027—By Technology, Type, Application and Region. Available online: https://www.globenewswire.com/en/news-release/2022/04/08/2419186/28124/en/Insights-on-the-Smart-Window-Global-Market-to-2027-by-Technology-Type-Application-and-Region.html (accessed on 15 September 2022).

- Kang, S.K.; Ho, D.H.; Lee, C.H.; Lim, H.S.; Cho, J.H. Actively operable thermoresponsive smart windows for reducing energy consumption. ACS Appl. Mater. Interfaces 2020, 12, 33838–33845. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, T.; Meng, Y.; Yang, R.; Tan, G.; Long, Y. Scalable thermochromic smart windows with passive radiative cooling regulation. Science 2021, 374, 1501–1504. [Google Scholar] [CrossRef]

- Li, C.C.; Tseng, H.Y.; Chen, C.W.; Wang, C.T.; Jau, H.C.; Wu, Y.C.; Hsu, W.H.; Lin, T.H. Versatile energy-saving smart glass based on tristable cholesteric liquid crystals. ACS Appl. Energy Mater. 2020, 3, 7601–7609. [Google Scholar] [CrossRef]

- Ruggiero, S.; De Masi, R.F.; Assimakopoulos, M.N.; Vanoli, G.P. Energy saving through building automation systems: Experimental and numerical study of a smart glass with liquid crystal and its control logics in summertime. Energy Build. 2022, 273, 112403. [Google Scholar] [CrossRef]

- Park, D.Y.; Chang, S. Effects of combined central air conditioning diffusers and window-integrated ventilation system on indoor air quality and thermal comfort in an office. Sustain. Cities Soc. 2020, 61, 102292. [Google Scholar] [CrossRef]

- Wang, K.; Meng, Q.; Wang, Q.; Zhang, W.; Guo, J.; Cao, S.; Elezzabi, A.Y.; Yu, W.W.; Liu, L.; Li, H. Advances in Energy-Efficient Plasmonic Electrochromic Smart Windows Based on Metal Oxide Nanocrystals. Adv. Energy Sustain. Res. 2021, 2, 2100117. [Google Scholar] [CrossRef]

- Zhang, S.; Cao, S.; Zhang, T.; Lee, J.Y. Plasmonic oxygen-deficient TiO2-x nanocrystals for dual-band electrochromic smart windows with efficient energy recycling. Adv. Mater. 2020, 32, 2004686. [Google Scholar] [CrossRef]

- Shen, N.; Chen, S.; Huang, R.; Huang, J.; Li, J.; Shi, R.; Niu, S.; Amini, A.; Cheng, C. Vanadium dioxide for thermochromic smart windows in ambient conditions. Mater. Today Energy 2021, 21, 100827. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, Y.; Jiang, T.; Yang, R.; Tan, G.; Long, Y. Thermochromic smart windows with highly regulated radiative cooling and solar transmission. Nano Energy 2021, 89, 106440. [Google Scholar] [CrossRef]

- Ji, C.; Wu, Z.; Wu, X.; Wang, J.; Gou, J.; Huang, Z.; Zhou, H.; Yao, W.; Jiang, Y. Al-doped VO2 films as smart window coatings: Reduced phase transition temperature and improved thermochromic performance. Sol. Energy Mater. Sol. Cells 2018, 176, 174–180. [Google Scholar] [CrossRef]

- Vu, T.D.; Chen, Z.; Zeng, X.; Jiang, M.; Liu, S.; Gao, Y.; Long, Y. Physical vapour deposition of vanadium dioxide for thermochromic smart window applications. J. Mater. Chem. C 2019, 7, 2121–2145. [Google Scholar] [CrossRef]

- Nundy, S.; Ghosh, A. Thermal and visual comfort analysis of adaptive vacuum integrated switchable suspended particle device window for temperate climate. Renew. Energy 2020, 156, 1361–1372. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, Q.; Li, P.; Ren, F.; Yurtsever, A.; Ma, D. High-performance suspended particle devices based on copper-reduced graphene oxide core–shell nanowire electrodes. Adv. Energy Mater. 2018, 8, 1703658. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Shi, F.; Li, T.; Zhang, H.; Yang, D.; Li, Y.; Tian, Z.; Zhou, N. A novel bidirectional fast self-responsive PVA-PNIPAM/LimCsnWO3 composite hydrogel for smart window applications. Chem. Eng. J. 2022, 431, 133353. [Google Scholar] [CrossRef]

- Liu, S.; Du, Y.W.; Tso, C.Y.; Lee, H.H.; Cheng, R.; Feng, S.P.; Yu, K.M. Organic hybrid perovskite (MAPbI3-xClx) for thermochromic smart window with strong optical regulation ability, low transition temperature, and narrow hysteresis width. Adv. Funct. Mater. 2021, 31, 2010426. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Wang, Y.; Yu, K.M.; Huang, B.; Tso, C.Y. Near-infrared-activated thermochromic perovskite smart windows. Adv. Sci. 2022, 9, 2106090. [Google Scholar] [CrossRef]

- Nundy, S.; Mesloub, A.; Alsolami, B.M.; Ghosh, A. Electrically actuated visible and near-infrared regulating switchable smart window for energy positive building: A review. J. Clean. Prod. 2021, 301, 126854. [Google Scholar] [CrossRef]

- Wang, J.; Meng, C.; Wang, C.T.; Liu, C.H.; Chang, Y.H.; Li, C.C.; Tseng, H.Y.; Kwok, H.S.; Zi, Y. A fully self-powered, ultra-stable cholesteric smart window triggered by instantaneous mechanical stimuli. Nano Energy 2021, 85, 105976. [Google Scholar] [CrossRef]

- Hemaida, A.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Simulation study for a switchable adaptive polymer dispersed liquid crystal smart window for two climate zones (Riyadh and London). Energy Build. 2021, 251, 111381. [Google Scholar] [CrossRef]

- Kim, D.-J.; Hwang, D.Y.; Park, J.-Y.; Kim, H.-K. Liquid crystal–based flexible smart windows on roll-to-roll slot die–coated Ag nanowire network films. J. Alloy. Compd. 2018, 765, 1090–1098. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, J.; Hu, X.; Zhao, W.; Broer, D.; Zhou, G. Reverse mode polymer dispersed liquid crystal-based smart windows: A progress report. Recent Prog. Mater. 2021, 3, 1. [Google Scholar] [CrossRef]

- Meng, C.; Tseng, M.C.; Tang, S.T.; Zhao, C.X.; Yeung, S.Y.; Kwok, H.S. Normally transparent smart window with haze enhancement via inhomogeneous alignment surface. Liq. Cryst. 2019, 46, 484–491. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, C.; Zhao, W.; Li, M.; Wang, X.; Yang, X.; Hu, X.; Yuan, D.; Yang, W.; Zhang, Y. Polymer stabilized liquid crystal smart window with flexible substrates based on low-temperature treatment of polyamide acid technology. Polymers 2019, 11, 1869. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, S.; Li, Y.; Zhou, P.; Chen, Q.; Su, Y. Reverse-mode PSLC multi-plane optical see-through display for AR applications. Opt. Express 2018, 26, 3394–3403. [Google Scholar] [CrossRef] [PubMed]

- Timmermans, G.H.; Hemming, S.; Baeza, E.; Van Thoor, E.A.; Schenning, A.P.; Debije, M.G. Advanced optical materials for sunlight control in greenhouses. Adv. Opt. Mater. 2020, 8, 2000738. [Google Scholar]

- White, T.J.; McConney, M.E.; Bunning, T.J. Dynamic color in stimuli-responsive cholesteric liquid crystals. J. Mater. Chem. 2010, 20, 9832–9847. [Google Scholar] [CrossRef]

- Mrinalini, M.; Prasanthkumar, S. Recent advances on stimuli-responsive smart materials and their applications. ChemPlusChem 2019, 84, 1103–1121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bisoyi, H.K.; Li, Q. Liquid crystals: Versatile self-organized smart soft materials. Chem. Rev. 2021, 122, 4887–4926. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Ota, F.; San Jose, B.A.; Akagi, K. Chiroptical resolution and thermal switching of chirality in conjugated polymer luminescence via selective reflection using a double-layered cell of chiral nematic liquid crystal. Adv. Funct. Mater. 2017, 27, 1604529. [Google Scholar] [CrossRef]

- Liu, Q.; Smalyukh, I.I. Liquid crystalline cellulose-based nematogels. Sci. Adv. 2017, 3, e1700981. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Guo, Z.H.; Xu, F.; Jia, L.; Pan, C.; Wang, Z.L.; Pu, X. Triboelectric-optical responsive cholesteric liquid crystals for self-powered smart window, E-paper display and optical switch. Sci. Bull. 2021, 66, 1986–1993. [Google Scholar] [CrossRef]

- Cupelli, D.; Nicoletta, F.P.; Manfredi, S.; Vivacqua, M.; Formoso, P.; De Filpo, G.; Chidichimo, G. Self-adjusting smart windows based on polymer-dispersed liquid crystals. Sol. Energy Mater. Sol. Cells 2009, 93, 2008–2012. [Google Scholar] [CrossRef]

- Yoon, W.J.; Choi, Y.J.; Lim, S.I.; Koo, J.; Yang, S.; Jung, D.; Kang, S.W.; Jeong, K.U. A single-step dual stabilization of smart window by the formation of liquid crystal physical gels and the construction of liquid crystal chambers. Adv. Funct. Mater. 2020, 30, 1906780. [Google Scholar] [CrossRef]

- Miao, Z.; Jia, M.; Wang, D. Exploration of nanofibre/nanoparticle/PDLC composite system. Liq. Cryst. 2022, 17, 1–11. [Google Scholar] [CrossRef]

- Pagidi, S.; Manda, R.; Bhattacharyya, S.S.; Lee, S.G.; Song, S.M.; Lim, Y.J.; Lee, J.H.; Lee, S.H. Fast switchable micro-lenticular lens arrays using highly transparent nano-polymer dispersed liquid crystals. Adv. Mater. Interfaces 2019, 6, 1900841. [Google Scholar] [CrossRef]

- Williams, R. Domains in liquid crystals. J. Chem. Phys. 1963, 39, 384–388. [Google Scholar] [CrossRef]

- Zhan, Y.; Schenning, A.P.; Broer, D.J.; Zhou, G.; Liu, D. Light-driven electrohydrodynamic instabilities in liquid crystals. Adv. Funct. Mater. 2018, 28, 1707436. [Google Scholar] [CrossRef] [Green Version]

- Shaban, H.; Wu, P.C.; Lee, J.H.; Lee, W. Dielectric and electro-optical responses of a dielectrically negative nematic liquid crystal doped with cationic surfactant. Opt. Mater. Express 2021, 11, 3208–3222. [Google Scholar] [CrossRef]

- Zhan, Y.; Lu, H.; Jin, M.; Zhou, G. Electrohydrodynamic instabilities for smart window applications. Liq. Cryst. 2020, 47, 977–983. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Zhan, Y.; Zhang, Y.; He, J.; Lv, P.; Yuan, D.; Hu, X.; Liu, D.; Broer, D.J. Electroconvection in zwitterion-doped nematic liquid crystals and application as smart windows. Adv. Opt. Mater. 2021, 9, 2001465. [Google Scholar] [CrossRef]

- Chen, C.-W.; Brigeman, A.N.; Ho, T.-J.; Khoo, I.C. Normally transparent smart window based on electrically induced instability in dielectrically negative cholesteric liquid crystal. Opt. Mater. Express 2018, 8, 691–697. [Google Scholar] [CrossRef]

- Mrukiewicz, M.; Perkowski, P.; Urbańska, M.; Węgłowska, D.; Piecek, W. Electrical conductivity of ion-doped fluoro substituted liquid crystal compounds for application in the dynamic light scattering effect. J. Mol. Liq. 2020, 317, 113810. [Google Scholar] [CrossRef]

- Guo, S.; Liang, X.; Wang, M.; Zhang, C.; Zhang, L.; Yang, H. Periodic electro-optical characteristics of ion-doped smectic A phase liquid crystals driven by a low-frequency electric field. Liq. Cryst. 2019, 46, 905–912. [Google Scholar] [CrossRef]

- Lan, Z.; Li, Y.; Dai, H.; Luo, D. Bistable smart window based on ionic liquid doped cholesteric liquid crystal. IEEE Photonics J. 2017, 9, 1–7. [Google Scholar] [CrossRef]

- Mathew, V.; Kurian, C.P.; Augustine, N. Spectral, visual, thermal, energy and circadian assessment of PDLC glazing in warm and humid climate. Sol. Energy 2022, 241, 576–583. [Google Scholar] [CrossRef]

- Mesloub, A.; Ghosh, A.; Kolsi, L.; Alshenaifi, M. Polymer-Dispersed Liquid Crystal (PDLC) smart switchable windows for less-energy hungry buildings and visual comfort in hot desert climate. J. Build. Eng. 2022, 59, 105101. [Google Scholar] [CrossRef]

- Higgins, D.A. Probing the mesoscopic chemical and physical properties of polymer-dispersed liquid crystals. Adv. Mater. 2000, 12, 251–264. [Google Scholar] [CrossRef]

- Liao, C.C.; Su, C.W.; Chen, M.Y. Mitigation of image blurring for performance enhancement in transparent displays based on polymer-dispersed liquid crystal. Displays 2019, 56, 30–37. [Google Scholar] [CrossRef]

- Saeed, M.H.; Zhang, S.; Cao, Y.; Zhou, L.; Hu, J.; Muhammad, I.; Xiao, J.; Zhang, L.; Yang, H. Recent advances in the polymer dispersed liquid crystal composite and its applications. Molecules 2020, 25, 5510. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Zhang, X.; Yang, W.; Jiang, X.F.; Jiang, X.; de Haan, L.T.; Yuan, D.; Zhao, W.; Zheng, N.; Jin, M. Stable and scalable smart window based on polymer stabilized liquid crystals. J. Appl. Polym. Sci. 2020, 137, 48917. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, W.; Gu, M.; Wei, Q.; Lv, P.; Li, M.; Liu, D.; Zhao, W.; Broer, D.J.; Zhou, G. Versatile homeotropic liquid crystal alignment with tunable functionality prepared by one-step method. J. Colloid Interface Sci. 2022, 608, 2290–2297. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Chen, M.; Zhang, L.; Shen, W.; Liang, X.; Wang, X.; Yang, H. An electrically light-transmittance-switchable film with a low driving voltage based on liquid crystal/polymer composites. Liq. Cryst. 2020, 47, 106–113. [Google Scholar] [CrossRef]

- Liang, X.; Chen, M.; Guo, S.; Wang, X.; Zhang, S.; Zhang, L.; Yang, H. Programmable electro-optical performances in a dual-frequency liquid crystals/polymer composite system. Polymer 2018, 149, 164–168. [Google Scholar] [CrossRef]

- Guo, S.; Liang, X.; Zhang, H.; Shen, W.; Li, C.; Wang, X.; Zhang, C.; Zhang, L.; Yang, H. An electrically light-transmittance-controllable film with a low-driving voltage from a coexistent system of polymer-dispersed and polymer-stabilised cholesteric liquid crystals. Liq. Cryst. 2018, 45, 1854–1860. [Google Scholar] [CrossRef]

- Ranjkesh, A.; Yoon, T.H. Thermal and electrical wavelength tuning of Bragg reflection with ultraviolet light absorbers in polymer-stabilized cholesteric liquid crystals. J. Mater. Chem. C 2018, 6, 12377–12385. [Google Scholar] [CrossRef]

- Du, X.; Li, Y.; Liu, Y.; Wang, F.; Luo, D. Electrically switchable bistable dual frequency liquid crystal light shutter with hyper-reflection in near infrared. Liq. Cryst. 2019, 46, 1727–1733. [Google Scholar] [CrossRef]

- Zhang, D.; Cao, H.; Duan, M.; Wang, H.; Chen, Y.; Zong, C.; Gan, P.; Zhao, L.; Yang, Z.; Wang, D. Effect of monomer composition on the performance of polymer-stabilized liquid crystals with two-step photopolymerization. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 1126–1132. [Google Scholar] [CrossRef]

- Chen, G.; Hu, J.; Xu, J.; Sun, J.; Xiao, J.; Zhang, L.; Wang, X.; Hu, W.; Yang, H. Liquid crystalline composite stabilized by epoxy polymer with boscage-like morphology for energy-efficient smart windows with high stability. Macromol. Mater. Eng. 2022, 307, 2100991. [Google Scholar] [CrossRef]

- Shi, Z.; Shao, L.; Wang, F.; Deng, F.; Liu, Y.; Wang, Y. Fabrication of dye-doped polymer-dispersed liquid crystals with low driving voltage based on nucleophile-initiated thiol-ene click reaction. Liq. Cryst. 2018, 45, 579–585. [Google Scholar] [CrossRef]

- Jinqian, L.; Zhao, Y.; Gao, H.; Wang, D.; Miao, Z.; Cao, H.; Yang, Z.; He, W. Polymer dispersed liquid crystals doped with CeO2 nanoparticles for the smart window. Liq. Cryst. 2022, 49, 29–38. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, R.; Xu, L.; Li, J.; Yang, L.; Yang, Y.; Bolshakov, A.; Zhu, J. Visible and infrared optical modulation of PSLC smart films doped with ATO nanoparticles. Dalton Trans. 2021, 50, 10033–10040. [Google Scholar] [CrossRef]

- Ke, Y.; Zhou, C.; Zhou, Y.; Wang, S.; Chan, S.H.; Long, Y. Emerging thermal-responsive materials and integrated techniques targeting the energy-efficient smart window application. Adv. Funct. Mater. 2018, 28, 1800113. [Google Scholar] [CrossRef]

- Zhang, W.; Froyen, A.A.; Schenning, A.P.; Zhou, G.; Debije, M.G.; de Haan, L.T. Temperature-responsive photonic devices based on cholesteric liquid crystals. Adv. Photonics Res. 2021, 2, 2100016. [Google Scholar] [CrossRef]

- Sun, J.; Wang, H.; Wang, L.; Cao, H.; Xie, H.; Luo, X.; Xiao, J.; Ding, H.; Yang, Z.; Yang, H. Preparation and thermo-optical characteristics of a smart polymer-stabilized liquid crystal thin film based on smectic A–chiral nematic phase transition. Smart Mater. Struct. 2014, 23, 125038. [Google Scholar] [CrossRef]

- Guo, S.M.; Liang, X.; Zhang, C.H.; Chen, M.; Shen, C.; Zhang, L.Y.; Yuan, X.; He, B.F.; Yang, H. Preparation of a thermally light-transmittance-controllable film from a coexistent system of polymer-dispersed and polymer-stabilized liquid crystals. ACS Appl. Mater. Interfaces 2017, 9, 2942–2947. [Google Scholar] [CrossRef]

- Oh, S.W.; Kim, S.H.; Yoon, T.H. Thermal control of transmission property by phase transition in cholesteric liquid crystals. J. Mater. Chem. C 2018, 6, 6520–6525. [Google Scholar] [CrossRef]

- Talukder, J.R.; Lee, Y.H.; Wu, S.T. Photo-responsive dye-doped liquid crystals for smart windows. Opt. Express 2019, 27, 4480–4487. [Google Scholar] [CrossRef] [Green Version]

- Zou, X.; Ji, H.; Zhao, Y.; Lu, M.; Tao, J.; Tang, P.; Liu, B.; Yu, X.; Mao, Y. Research progress of photo-/electro-driven thermochromic smart windows. Nanomaterials 2021, 11, 3335. [Google Scholar] [CrossRef]

- Goda, K.; Omori, M.; Takatoh, K. Optical switching in guest–host liquid crystal devices driven by photo-and thermal isomerisation of azobenzene. Liq. Cryst. 2018, 45, 485–490. [Google Scholar] [CrossRef]

- Oh, S.W.; Nam, S.M.; Kim, S.H.; Yoon, T.H.; Kim, W.S. Self-regulation of infrared using a liquid crystal mixture doped with push–pull azobenzene for energy-saving smart windows. ACS Appl. Mater. Interfaces 2021, 13, 5028–5033. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.W.; Baek, J.M.; Kim, S.H.; Yoon, T.H. Optical and electrical switching of cholesteric liquid crystals containing azo dye. RSC Adv. 2017, 7, 19497–19501. [Google Scholar] [CrossRef] [Green Version]

- Talukder, J.R.; Lin, H.-Y.; Wu, S.-T. Photo-and electrical-responsive liquid crystal smart dimmer for augmented reality displays. Opt. Express 2019, 27, 18169–18179. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Lan, R.; Gao, Y.; Wang, M.; Zhang, W.; Wang, L.; Zhang, L.; Yang, Z.; Yang, H. Stimuli-directed dynamic reconfiguration in self-organized helical superstructures enabled by chemical kinetics of chiral molecular motors. Adv. Sci. 2018, 5, 1700613. [Google Scholar] [CrossRef]

- Meng, W.; Gao, Y.; Hu, X.; Tan, L.; Li, L.; Zhou, G.; Yang, H.; Wang, J.; Jiang, L. Photothermal dual passively driven liquid crystal smart window. ACS Appl. Mater. Interfaces 2022, 14, 28301–28309. [Google Scholar] [CrossRef]

- Hwang, Y.J.; Pyun, S.B.; Choi, M.J.; Kim, J.H.; Cho, E.C. Multi-stimuli-responsive and multi-functional smart windows. ChemNanoMat 2022, 8, e202200005. [Google Scholar] [CrossRef]

- Liang, X.; Chen, M.; Guo, S.; Zhang, L.; Li, F.; Yang, H. Dual-band modulation of visible and near-infrared light transmittance in an all-solution-processed hybrid micro–nano composite film. ACS Appl. Mater. Interfaces 2017, 9, 40810–40819. [Google Scholar] [CrossRef]

- Liang, X.; Guo, S.; Chen, M.; Li, C.; Wang, Q.; Zou, C.; Zhang, C.; Zhang, L.; Guo, S.; Yang, H. A temperature and electric field-responsive flexible smart film with full broadband optical modulation. Mater. Horiz. 2017, 4, 878–884. [Google Scholar] [CrossRef]

- Sung, G.F.; Wu, P.C.; Zyryanov, V.Y.; Lee, W. Electrically active and thermally passive liquid-crystal device toward smart glass. Photonics Res. 2021, 9, 2288–2295. [Google Scholar] [CrossRef]

- Oh, S.W.; Kim, S.H.; Baek, J.M.; Yoon, T.H. Optical and thermal switching of liquid crystals for self-shading windows. Adv. Sustain. Syst. 2018, 2, 1700164. [Google Scholar] [CrossRef]

- Kuang, Z.Y.; Deng, Y.; Hu, J.; Tao, L.; Wang, P.; Chen, J.; Xie, H.L. Responsive smart windows enabled by the azobenzene copolymer brush with photothermal effect. ACS Appl. Mater. Interfaces 2019, 11, 37026–37034. [Google Scholar] [CrossRef] [PubMed]

| Categories | Actuation | Stimuli | Preparation Strategies | State Change 1 | Response Time 2 | Ref. | |

|---|---|---|---|---|---|---|---|

| Single-responsive liquid crystal smart windows | ERLC smart windows | Active | Electric field | EHDI | T (98.0%) → O (10.0%) | ton: 1 s toff: 200 ms | [53] |

| PDLC | O (1.0%) → T (79.0%) | ton: 58 ms toff: 10 ms | [48] | ||||

| PSLC | T (98.5%) → O (11.2%) | ton: 3 ms toff: 19 ms | [65] | ||||

| PD&SLC | O (2.0%) → T (80.0%) | _ | [68] | ||||

| TRLC smart windows | Passive | Temperature | PSLC | O (2.1%) → T (86.6%) | _ | [78] | |

| PD&SLC | T (80.0%) → O (2.0%) | _ | [79] | ||||

| LCs | T (59.8%) → O (4.3%) | _ | [80] | ||||

| PRLC smart windows | Passive | Light | Azobenzene | T (4.0%) → O (72.2%) | A few seconds | [85] | |

| O (70.0%) → T (23.0%) | _ | [86] | |||||

| Molecular motor | T (95.0%) → O (12.0%) | _ | [87] | ||||

| Photothermal materials | T (70.0%) → O (20.0%) | _ | [88] | ||||

| Dual-responsive liquid crystal smart windows | TR/ER LC smart windows | Passive/Active | Temperature/Electric field | PD&SLC | O (1.5%) → T (78.0%) | ton: ~100 ms @ V toff: 183 ms @ V | [91] |

| EHDI | T (95.1%) → O (0.3%) | _ | [92] | ||||

| TR/PR LC smart windows | Passive | Temperature/Light | LCs | T (64.0%) → O (17.1%) | _ | [93] | |

| Photothermal materials | T (80.0%) → O (3.0%) | _ | [94] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, L.; Liang, Y.; Feng, Y.; Mo, D.; Zhang, Y.; Chen, J. Recent Progress on Preparation Strategies of Liquid Crystal Smart Windows. Crystals 2022, 12, 1426. https://doi.org/10.3390/cryst12101426

Luo L, Liang Y, Feng Y, Mo D, Zhang Y, Chen J. Recent Progress on Preparation Strategies of Liquid Crystal Smart Windows. Crystals. 2022; 12(10):1426. https://doi.org/10.3390/cryst12101426

Chicago/Turabian StyleLuo, Linfeng, Yinghui Liang, Yuting Feng, Dan Mo, Yang Zhang, and Jiawen Chen. 2022. "Recent Progress on Preparation Strategies of Liquid Crystal Smart Windows" Crystals 12, no. 10: 1426. https://doi.org/10.3390/cryst12101426

APA StyleLuo, L., Liang, Y., Feng, Y., Mo, D., Zhang, Y., & Chen, J. (2022). Recent Progress on Preparation Strategies of Liquid Crystal Smart Windows. Crystals, 12(10), 1426. https://doi.org/10.3390/cryst12101426