Research on Microstructure and Cracking Behavior of Al-6.2Zn-2Mg-xSc-xZr Alloy Fabricated by Selective Laser Melting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Composition

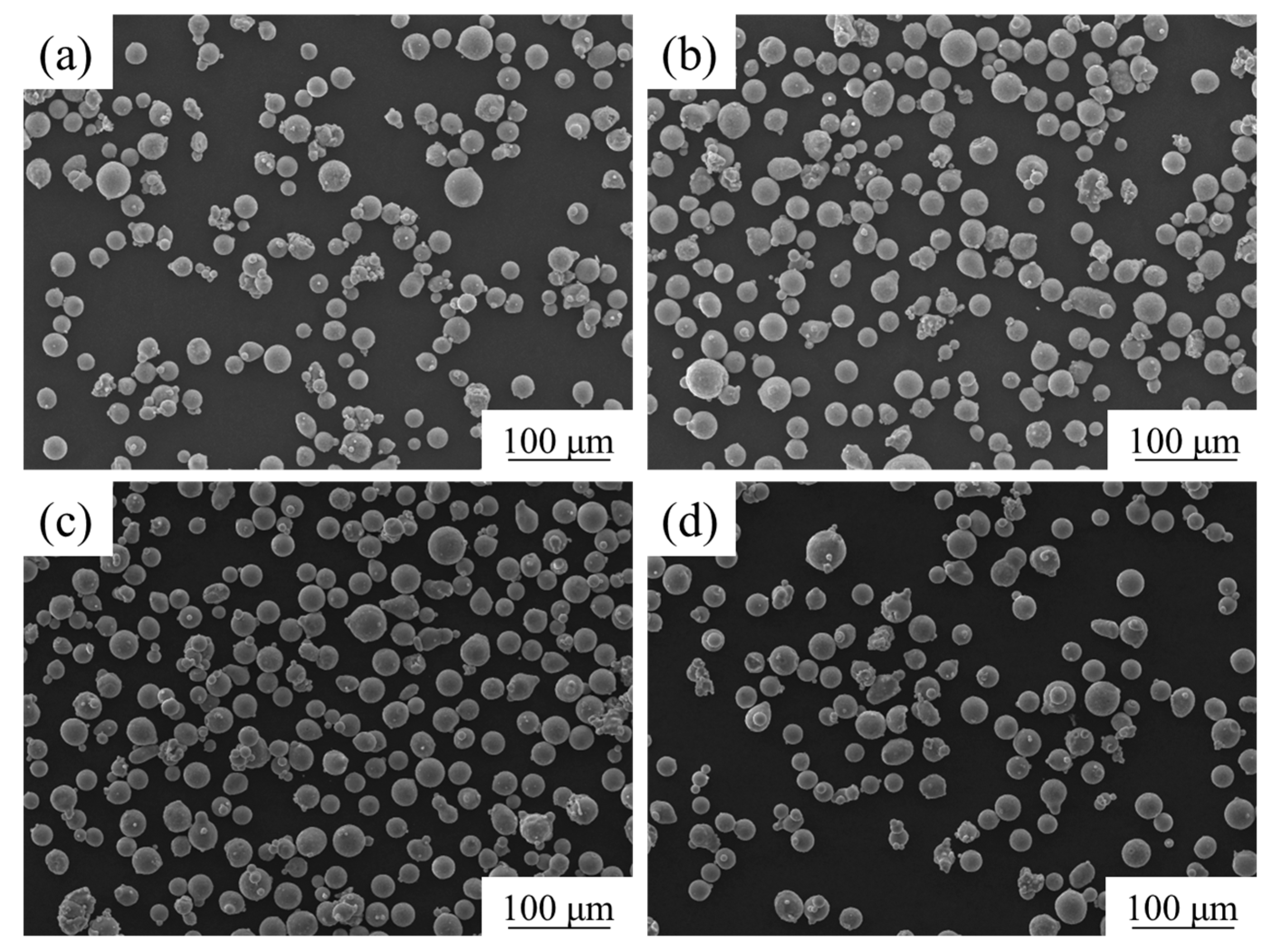

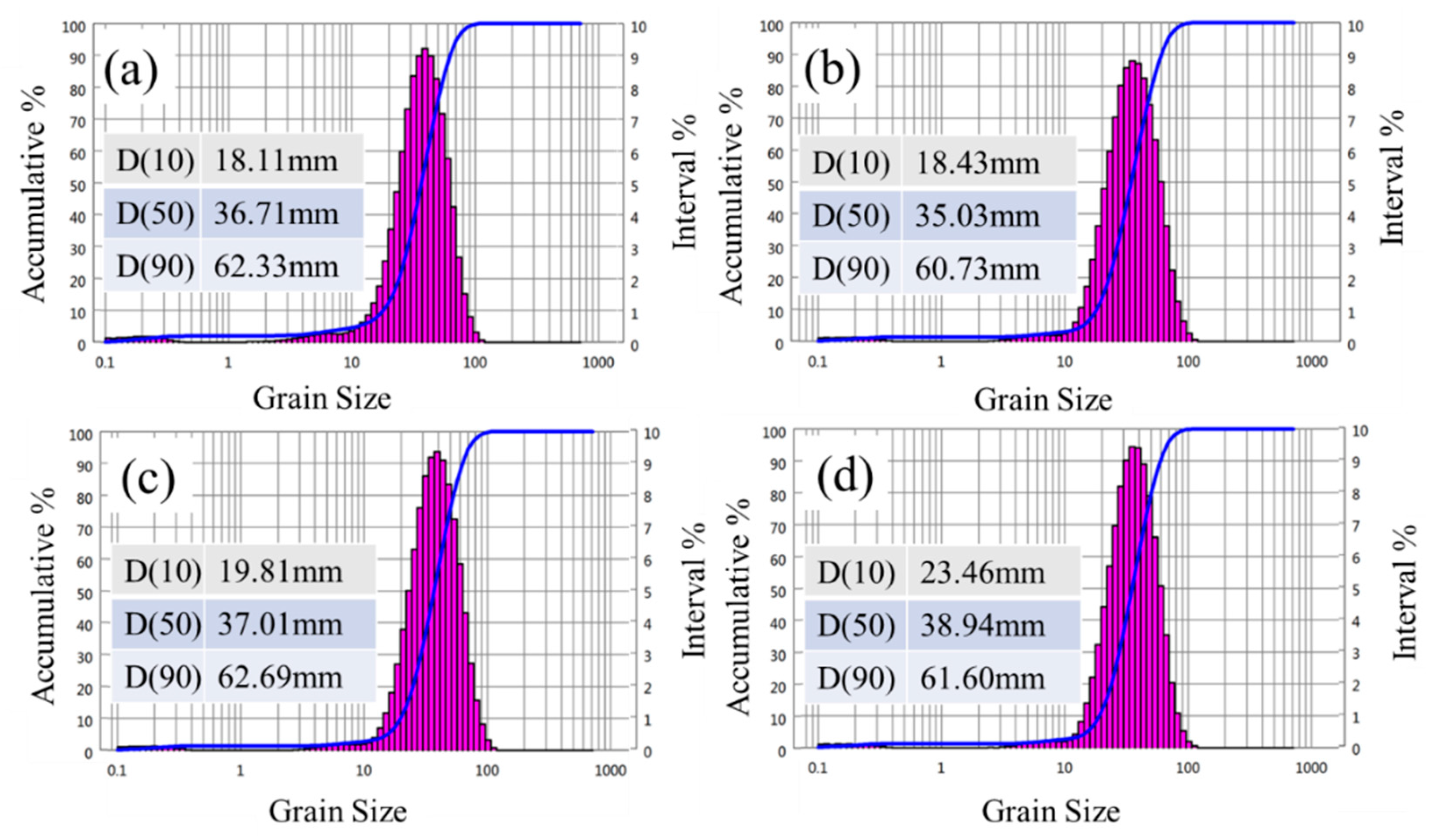

2.2. Al-6.2Zn-2Mg-xSc-xZr Alloys Powder

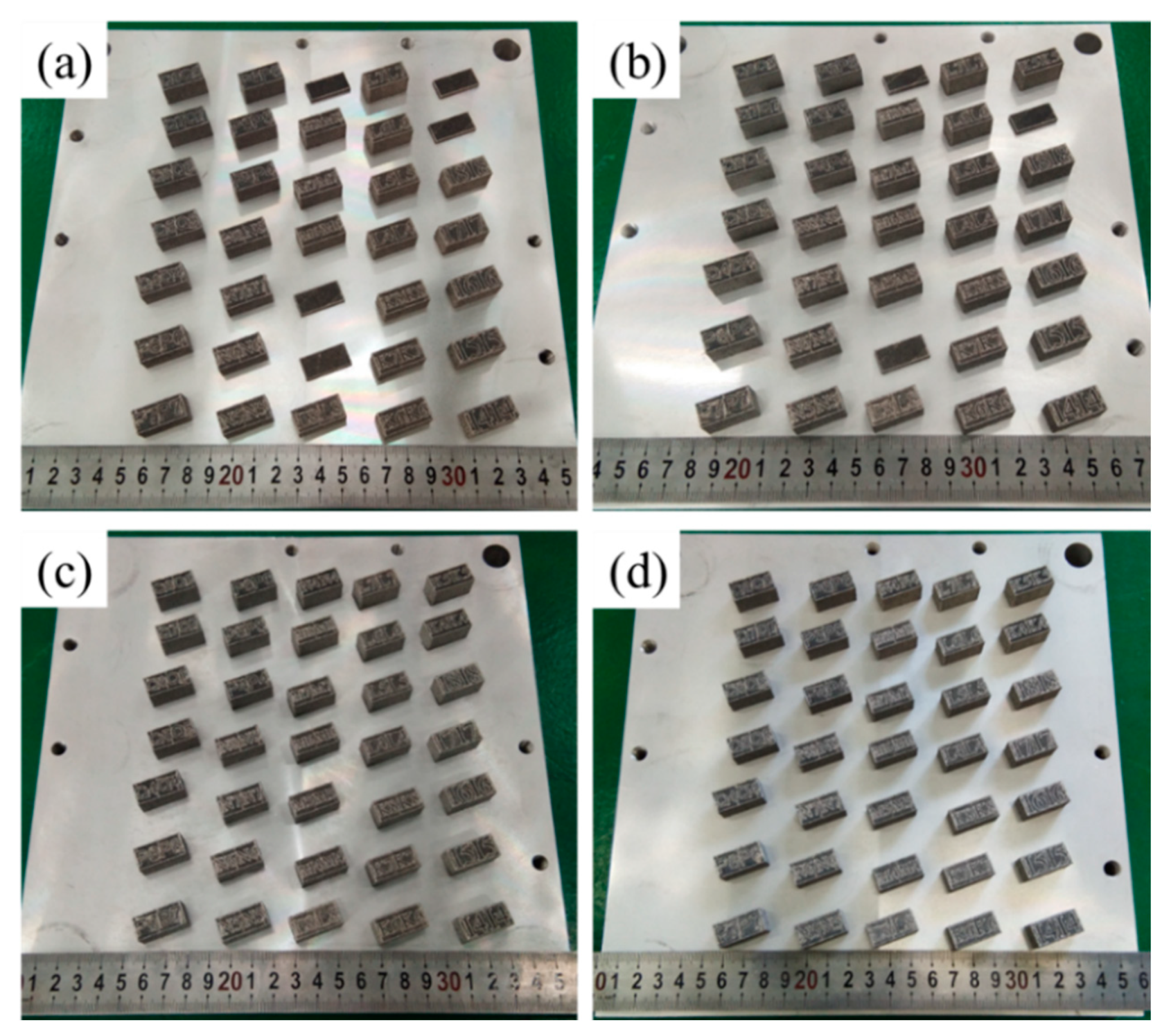

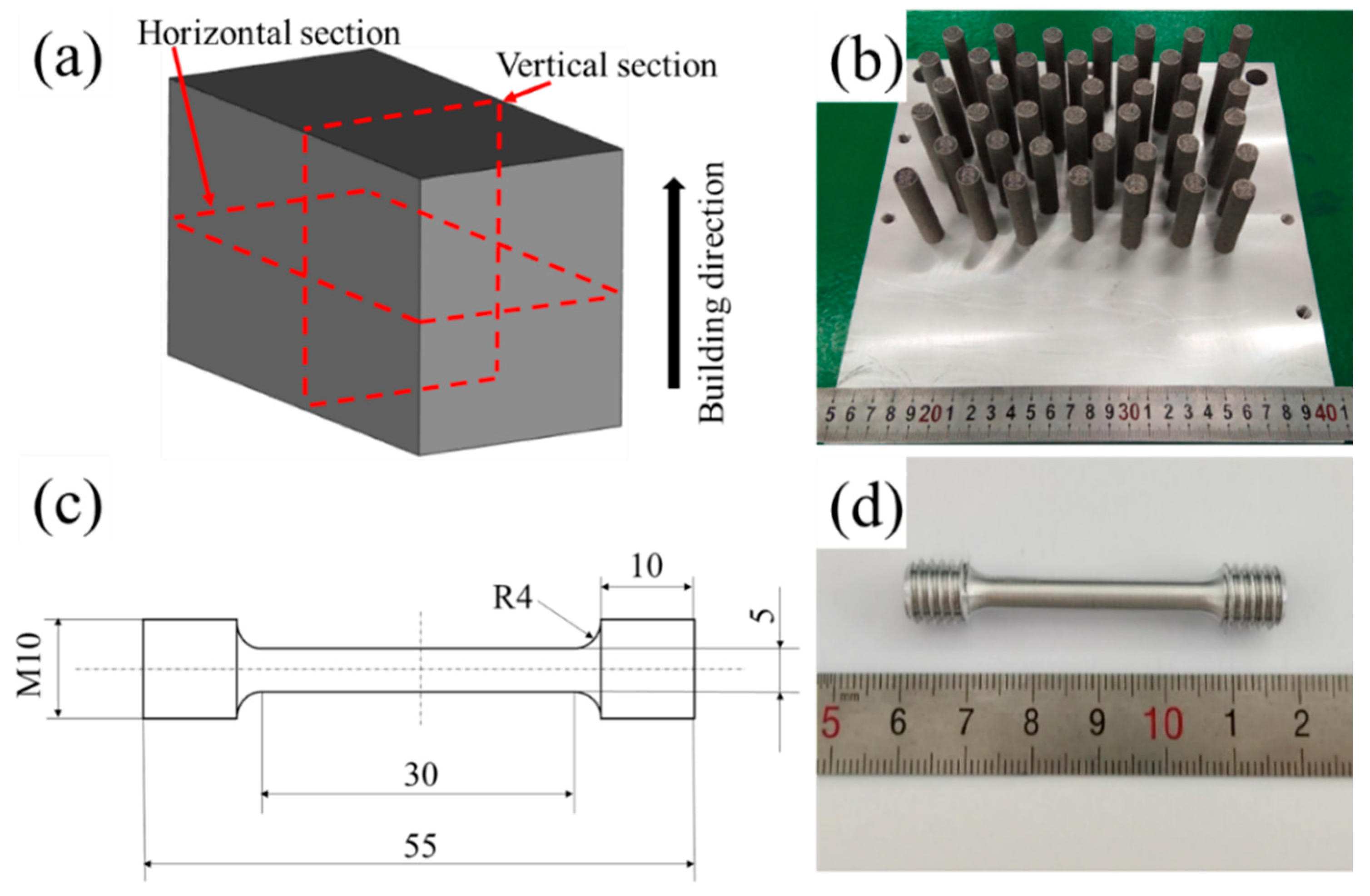

2.3. Experimental Details

3. Results

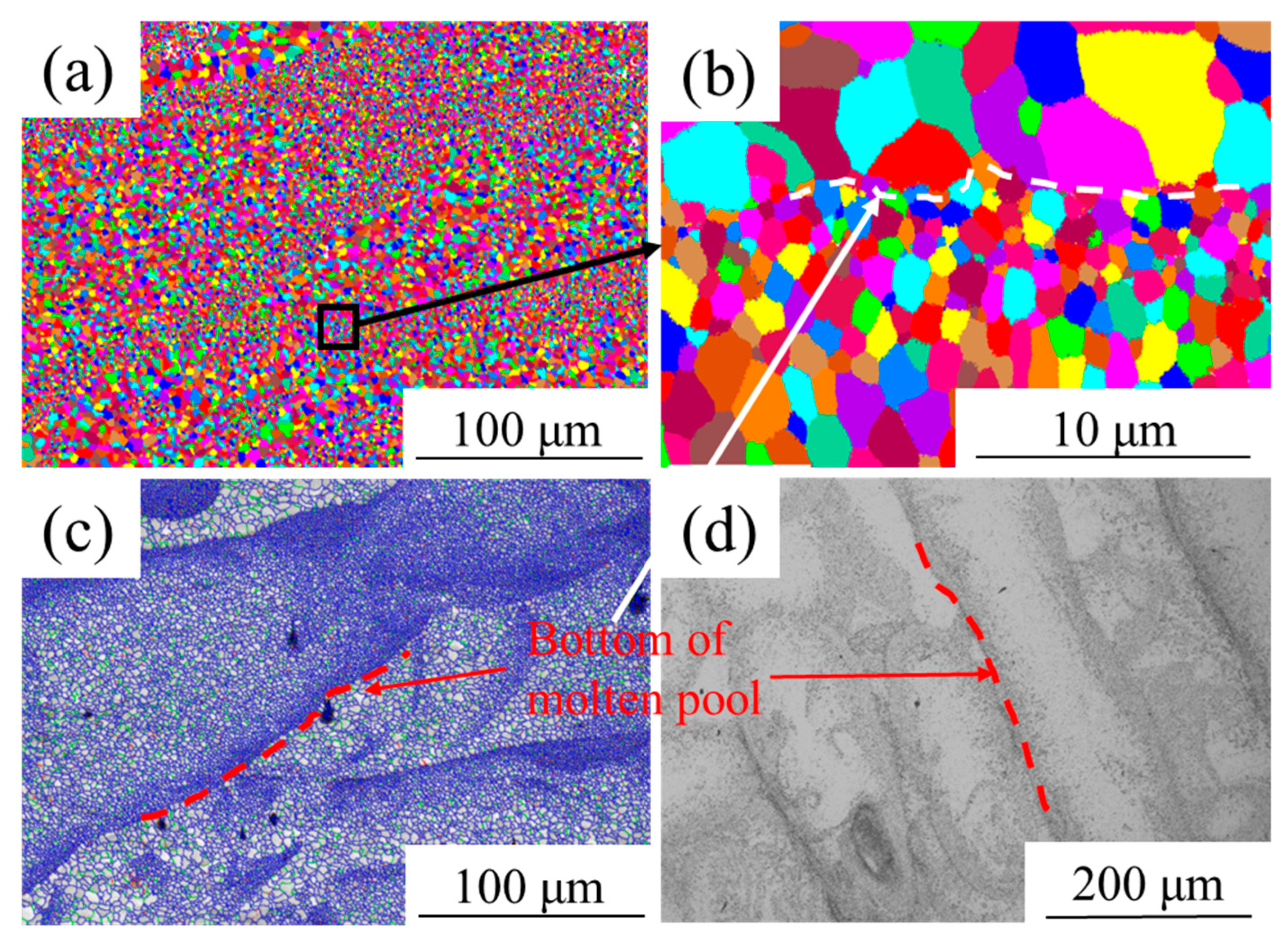

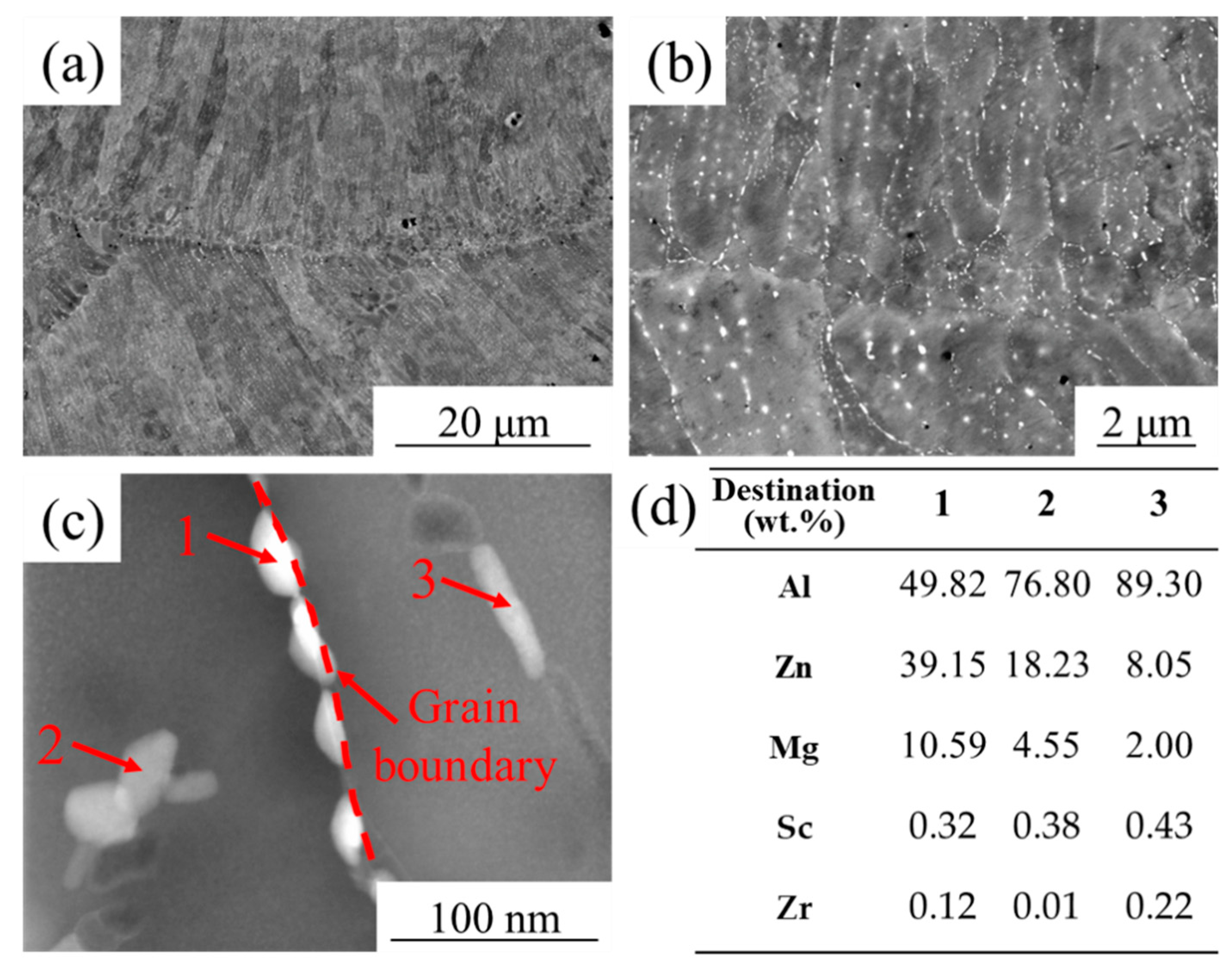

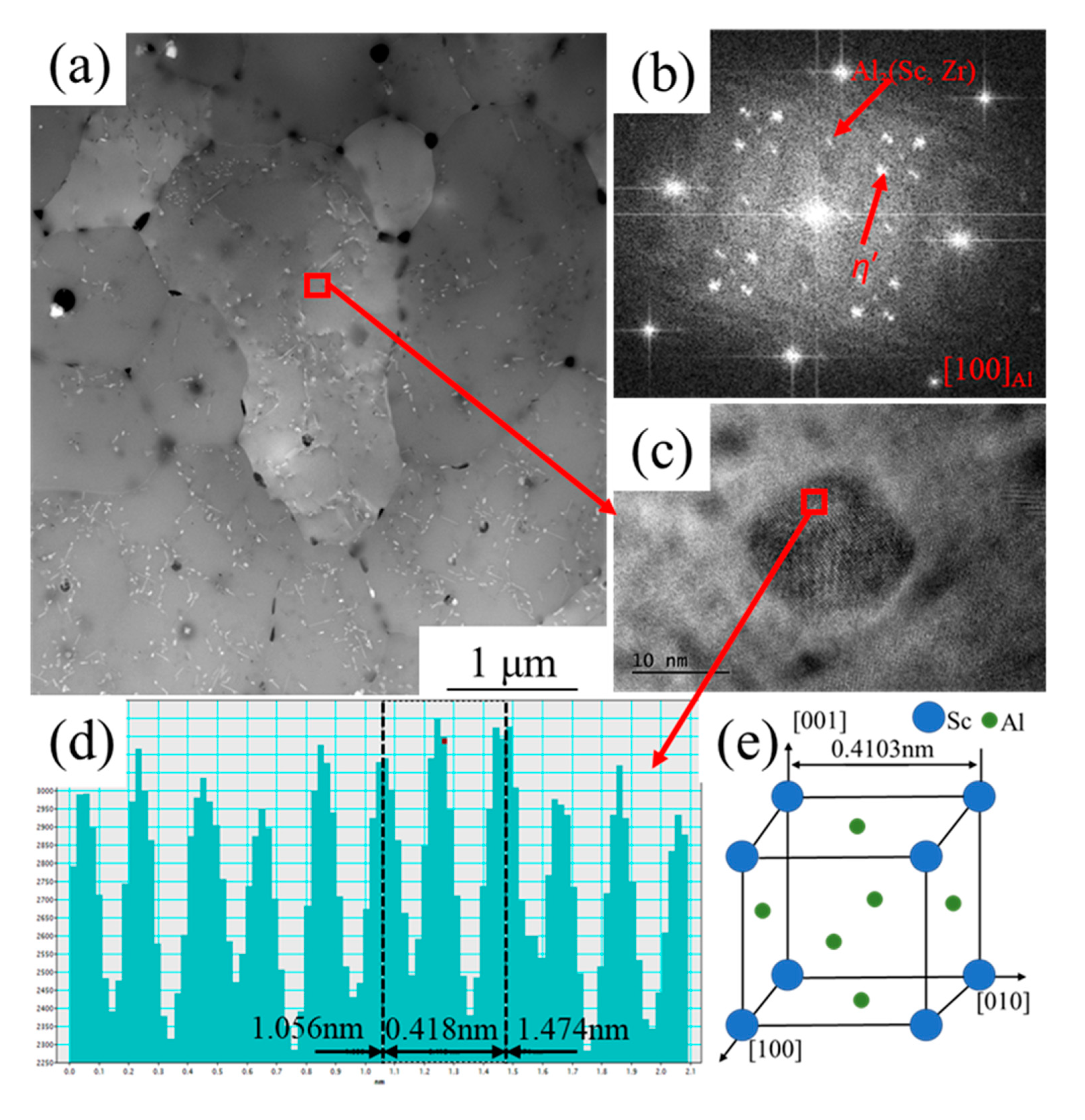

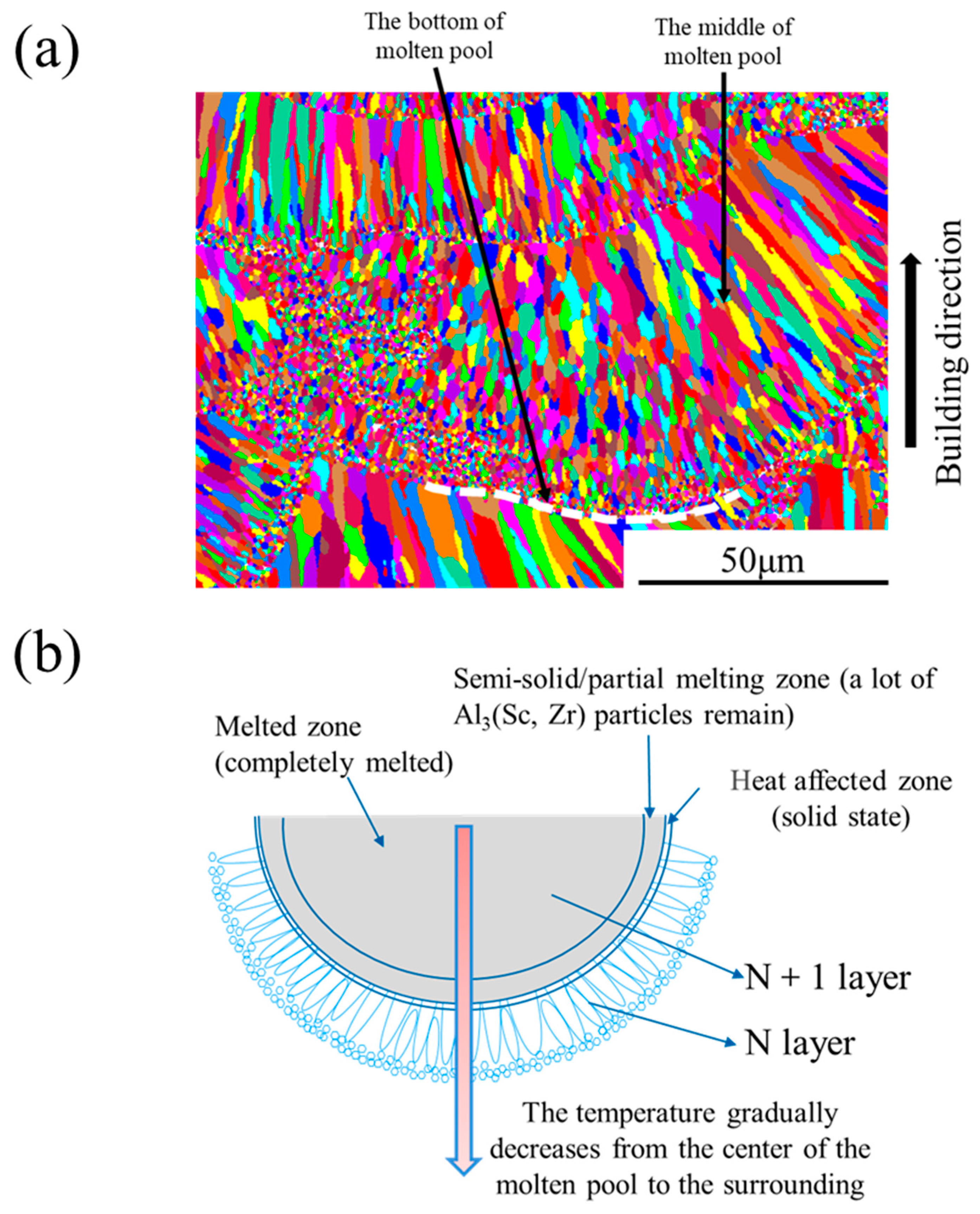

3.1. Microstructure of Al-6.2Zn-2Mg-0.6Sc-0.36Zr Alloy

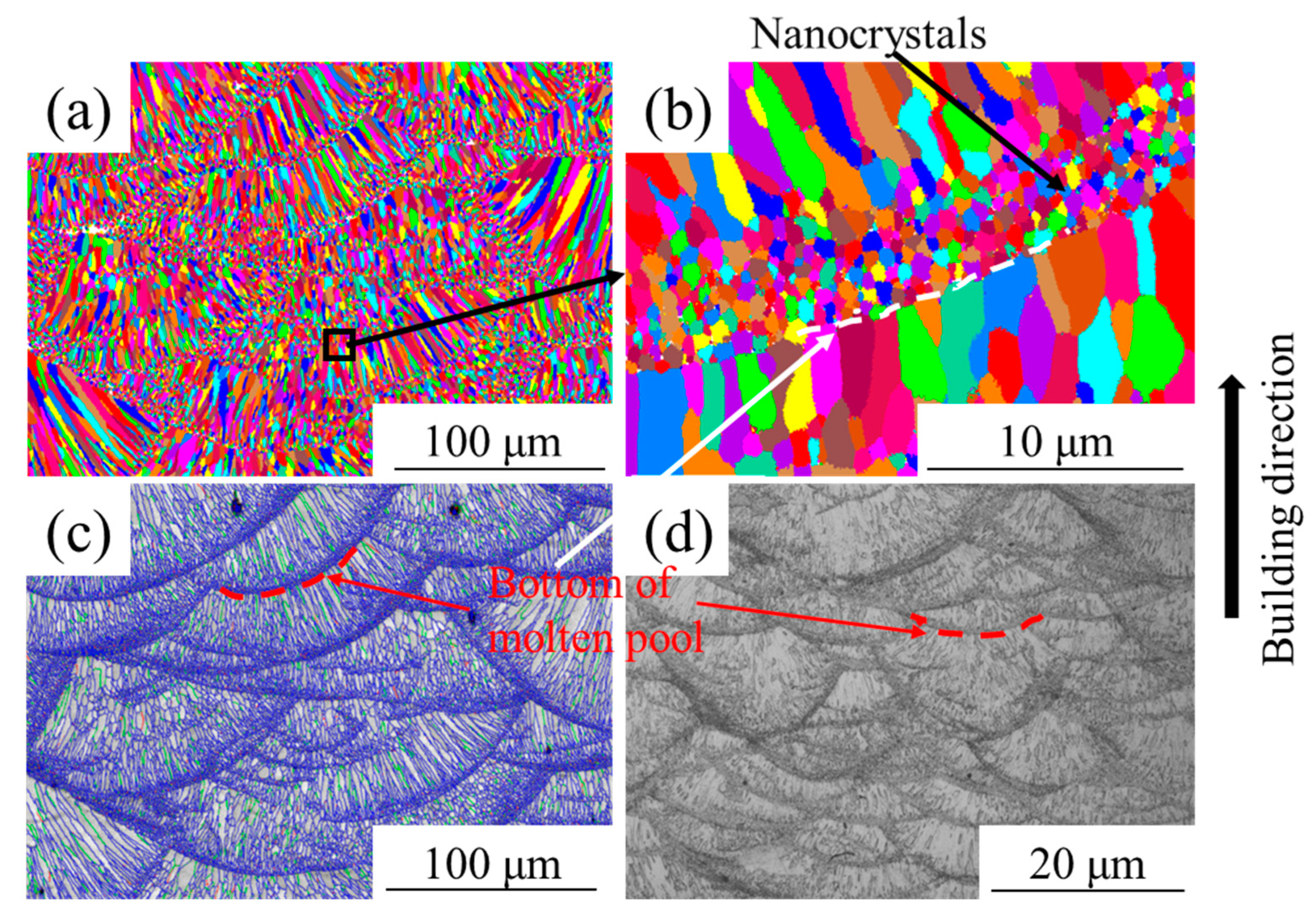

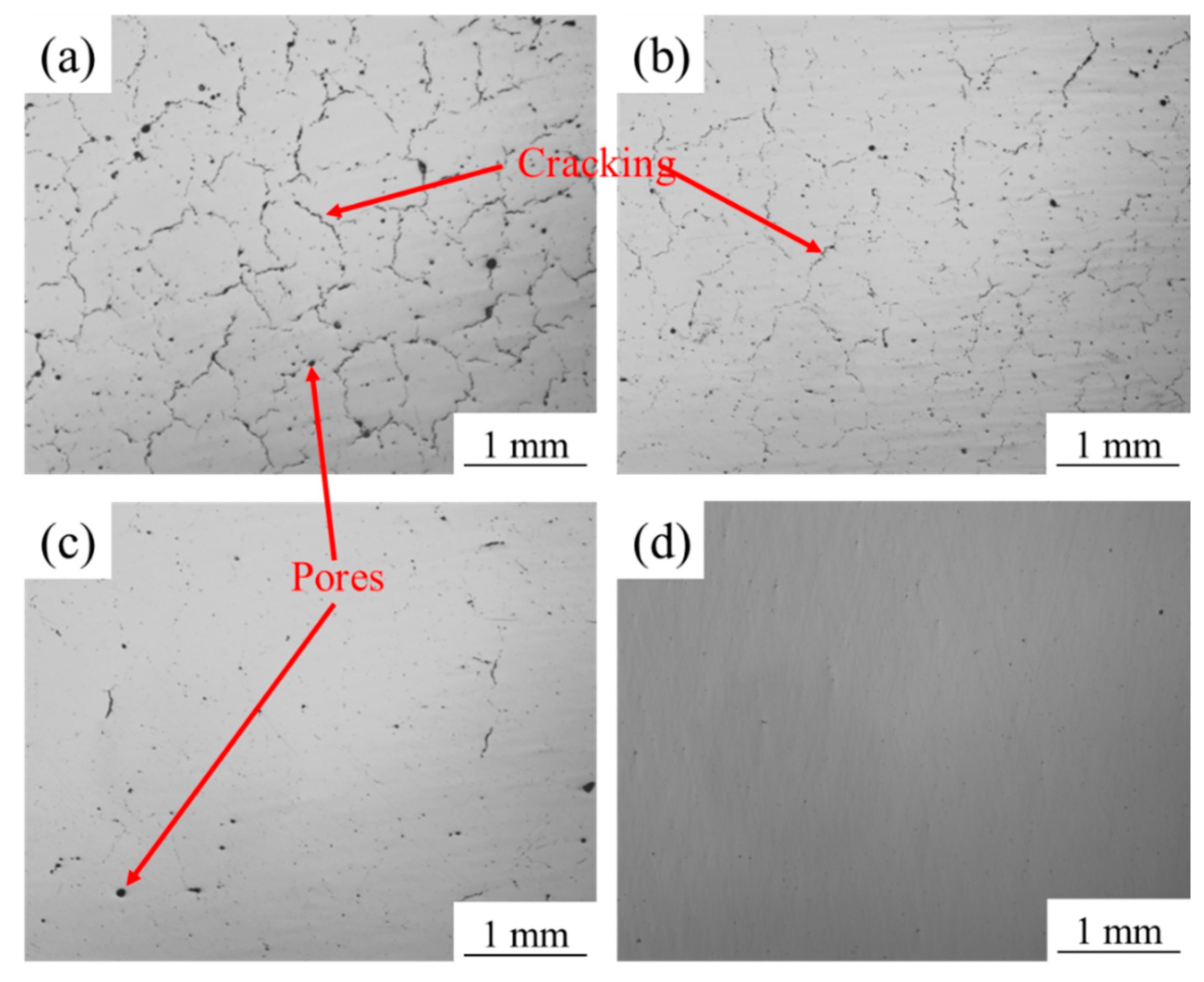

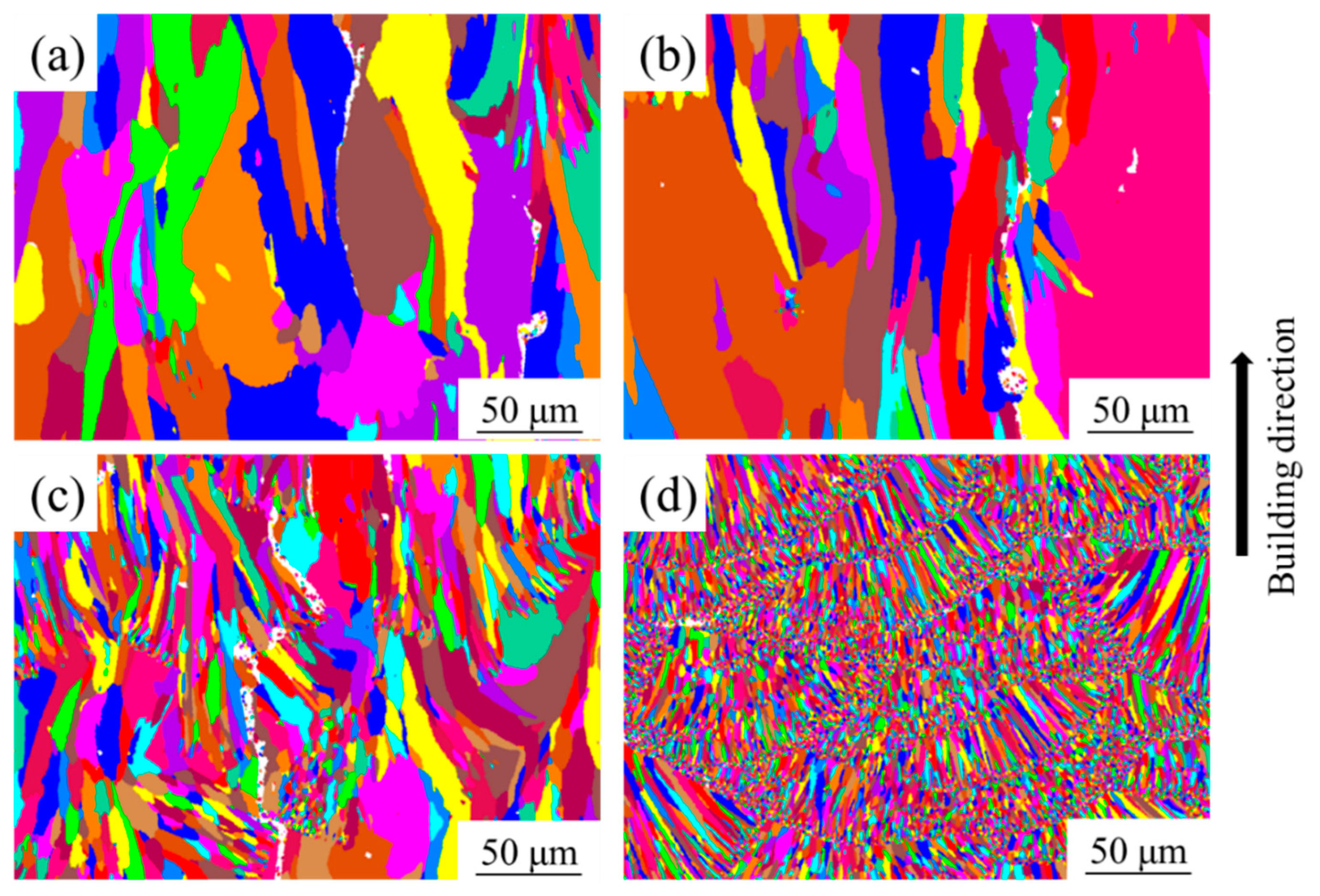

3.2. Microstructure and Mechanical Property of Al-6.2Zn-2Mg-xSc-xZr Alloys

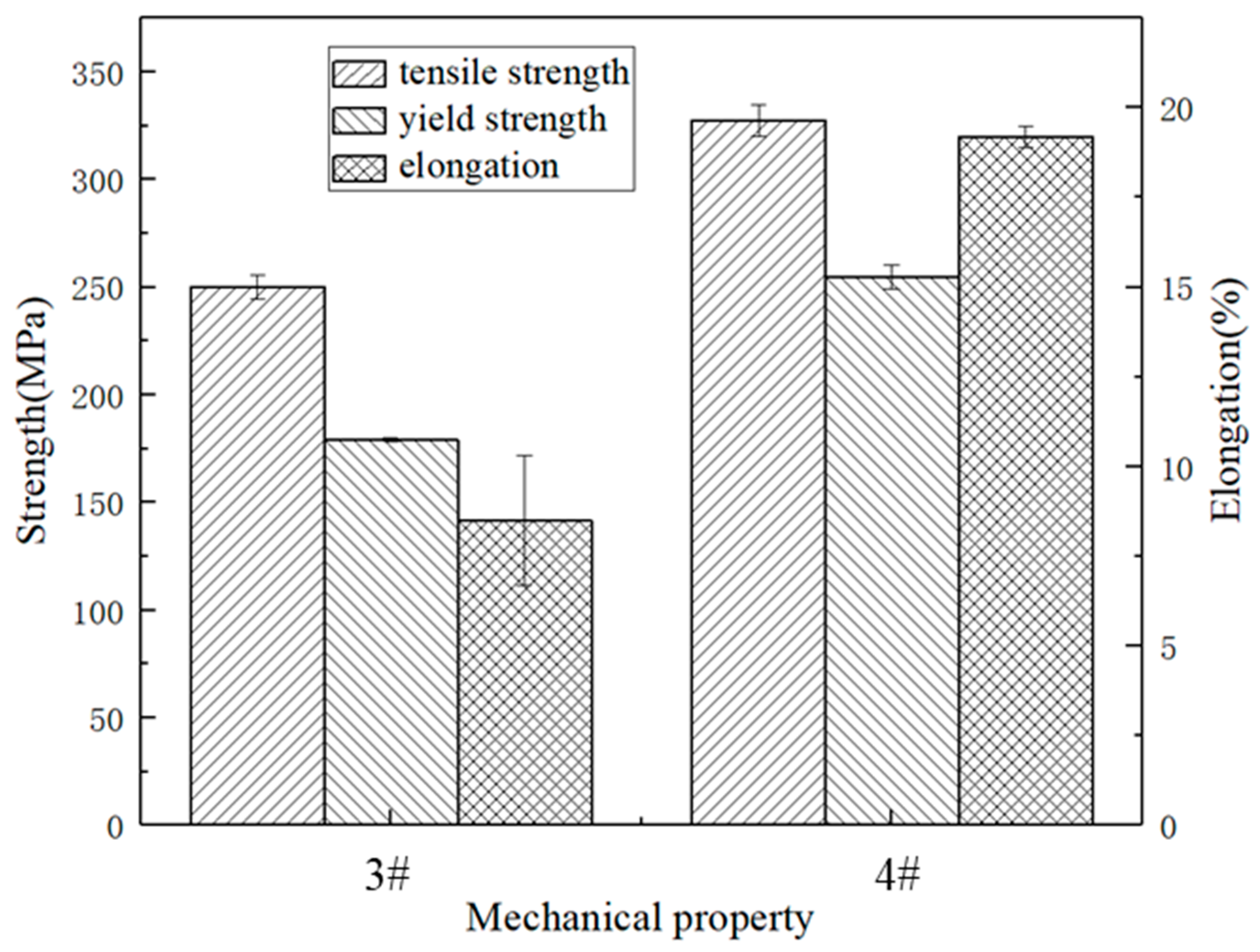

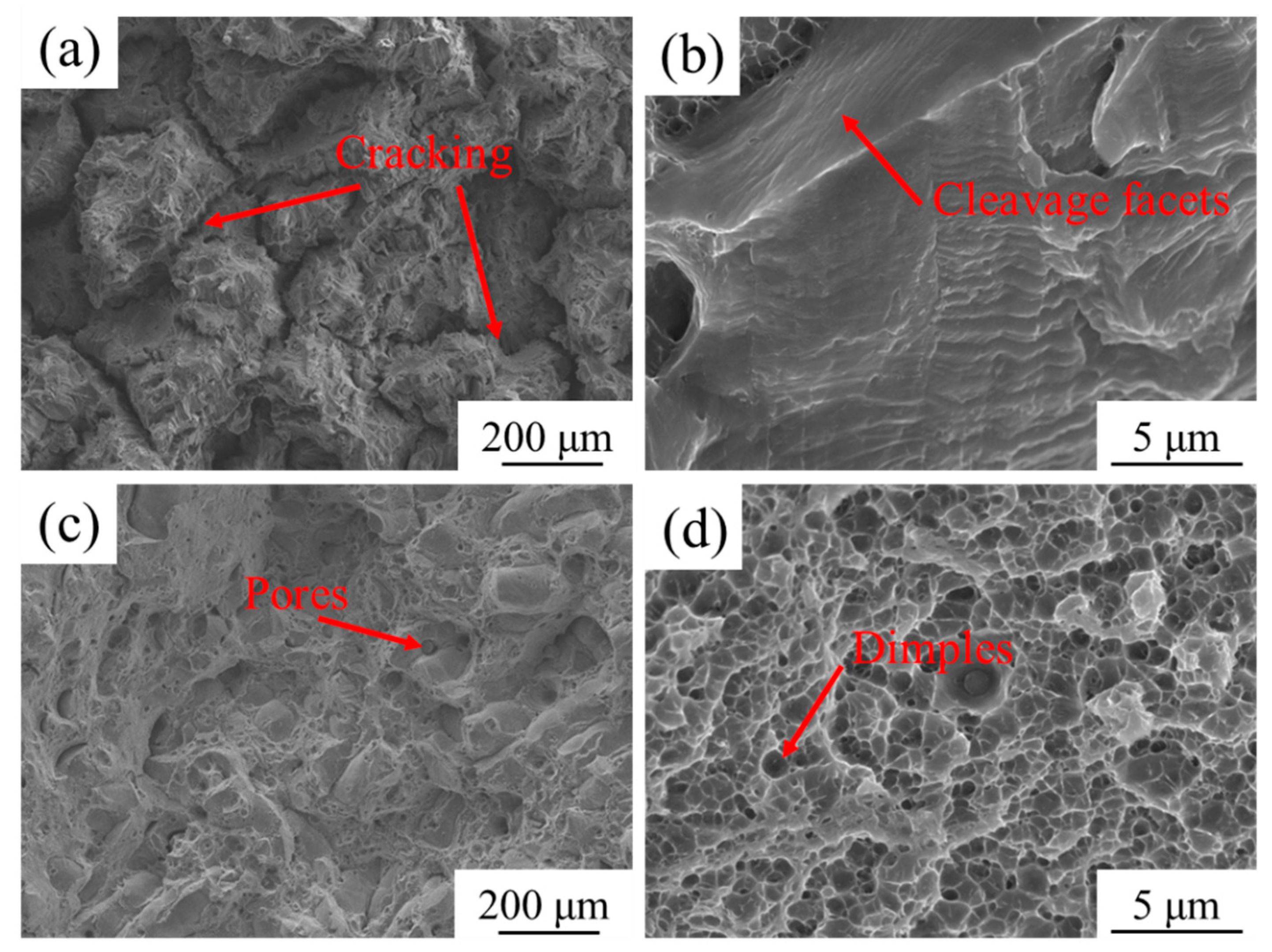

3.3. Mechanical Properties of Al-6.2Zn-2Mg-xSc-xZr Alloys

4. Discussion

4.1. Microstructure Analysis of Al-6.2Zn-2Mg-0.6Sc-0.36Zr Alloy

4.2. Effect of Sc and Zr on Al-6.2Zn-2Mg-xSc-xZr Alloys

4.3. Cracking Behavior Analysis of Al-6.2Zn-2Mg-xSc-xZr Alloys

5. Conclusions

- For the Al-6.2Zn-2Mg-xSc-xZr alloy, with the increase of Sc and Zr content from 0 and 0 to 0.6% and 0.36% respectively, the microstructure changes from coarse epitaxial growth columnar grains to fine equiaxed and columnar grains. And the cracking tendency gradually decreases until there is no crack at all. The addition of Sc and Zr can significantly refine the grains and reduce the cracking tendency.

- The precipitated phase of Al-6.2Zn-2Mg-0.6Sc-0.36Zr alloy in the as-printed status is mainly Mg/Zn phase. Sc and Zr are mainly dissolved in aluminum matrix. A small part of Sc and Zr exists in the form of fine Al3(Sc, Zr) phase, and there is no coarse Al3(Sc, Zr) phase. The primary Al3(Sc, Zr) phase can not only serve as the heterogeneous nucleation sites of the current layer to refine the grains, but also act as the nucleation particle in the subsequent layer to induce the formation of fine equiaxed grains. But when the content of Sc and Zr is 0.2% and 0.12% respectively, Sc and Zr cannot be effectively precipitated in the form of Al3(Sc, Zr) phase as heterogeneous nucleation sites to refine grains due to the high cooling rate of SLM.

- The immediate reason for the absence of cracks is that the microstructure changes from coarse columnar grains to fine equiaxed-columnar grains when the content of Sc and Zr increases. The refined grain size may have the following beneficial effects: It helps with reducing the thickness of the liquid films. This will increase the tear sensitivity of the liquid film and the cracking tendency and therefore lowers the hot cracking tendency; And a refined grain size improves fracture roughness, leading to an enhanced cracking resistance. At the same time, the refinement of the grains will make the feeding channel of the grain boundary shorter and easy to feed, and the fine equiaxed grains can coordinate stress-strain during solidification more effectively than coarse columnar grains, which will decrease the cracking tendency.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Herzoga, D.; Seydab, V.; Wyciskb, E.; Emmelmannab, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Wang, X.J.; Zhang, L.C.; Fang, M.H.; Sercombe, T.B. The effect of atmosphere on the structure and properties of a selective laser melted Al-12Si alloy. Mater. Sci. Eng. A 2014, 597, 370–375. [Google Scholar] [CrossRef] [Green Version]

- Hooper, P. Melt pool temperature and cooling rates in laser powder bed fusion. Acta Mater. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–124. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Professora, A.; Gibbonsa, G.; Dasb, A.; Howes, P.D. A review of Laser Powder Bed Fusion Additive Manufacturing of aluminium alloys: Microstructure and properties. Addit. Manuf. 2021, 46, 102155. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Additive manufacturing of cardiovascular CoCr stents by selective laser melting. Mater. Des. 2017, 119, 338–350. [Google Scholar] [CrossRef] [Green Version]

- Christian, C.R.; Thomas, T.-D.; Dirk, M. Plasticity and fracture of cast and SLM AlSi10Mg: High-throughput testing and modeling. Addit. Manuf. 2021, 43, 101998. [Google Scholar] [CrossRef]

- Geng, Y.X.; Wang, Q.; Wang, Y.M.; Zang, Q.H.; Mi, S.B.; Xu, J.H.; Xiao, Y.K.; Wu, Y.; Luan, J.H. Microstructural evolution and strengthening mechanism of high-strength AlSi8.1Mg1.4 alloy produced by selective laser melting. Mater. Des. 2022, 218, 110674. [Google Scholar] [CrossRef]

- Hoffmann, K.G.; Haag, K.; Müssig, J. Biomimetic approaches towards lightweight composite structures for car interior parts. Mater. Des. 2021, 212, 110281. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Hu, K.H.; Liu, B.; Liu, M.; Huang, Z.R. Stereolithography-based additive manufacturing of lightweight and high-strength Cf/SiC ceramics. Addit. Manuf. 2020, 34, 101119. [Google Scholar] [CrossRef]

- Wang, P.; Song, J.; Nai, M.L.S.; Wei, J. Experimental analysis of additively manufactured component and design guidelines for lightweight structures: A case study using electron beam melting. Addit. Manuf. 2020, 33, 101088. [Google Scholar] [CrossRef]

- Hirsch, J.; Al-Samman, T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

- She, H.; Shu, D.; Dong, A.; Wang, J.; Sun, B.; Lai, H. Relationship of particle stimulated nucleation, recrystallization and mechanical properties responding to Fe and Si contents in hot-extruded 7055 aluminum alloys. J. Mater. Sci. Technol. 2019, 35, 2570–2581. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z.; Li, X.; Wang, Q.; Zhang, Y. The effects of grain size on the hot deformation and processing map for 7075 aluminum alloy. Mater. Des. 2013, 51, 592–597. [Google Scholar] [CrossRef]

- Yuan, L.L.; Guo, M.X.; Habraken, A.M.; Duchene, L.; Zhuang, L.Z. Extremely improved formability of Al–Zn–Mg–Cu alloys via micro-domain heterogeneous structure. Mater. Sci. Eng. A 2022, 873, 142737. [Google Scholar] [CrossRef]

- Wang, Z.P.; Wang, M.L.; Li, Y.G.; Xiao, H.Y.; Chen, H.; Geng, J.W.; Li, X.F.; Chen, D.; Wang, H.W. Effect of pretreatment on microstructural stability and mechanical property in a spray formed Al-Zn-Mg-Cu alloy. Mater. Des. 2021, 203, 109618. [Google Scholar] [CrossRef]

- Azarniya, A.; Taheri, A.K.; Taheri, K.K. Recent advances in ageing of 7xxx series aluminum alloys: A physical metallurgy perspective. J. Alloys Compd. 2019, 781, 945–983. [Google Scholar] [CrossRef]

- Fang, Y.J.; Kim, M.; Zhang, Y.L.; Duan, Z.Y.; Yuan, Q.; Suhr, J. Particulate-reinforced iron-based metal matrix composites fabricated by selective laser melting: A systematic review. J. Manuf. Process. 2022, 74, 592–639. [Google Scholar] [CrossRef]

- Cacace, S.; Semeraro, Q. Influence of the atomization medium on the properties of stainless steel SLM parts. Addit. Manuf. 2020, 36, 101509. [Google Scholar] [CrossRef]

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloys Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Sitek, R.; Molak, R.; Zdunek, J.; Bazarnik, P.; Wiśniewski, P.; Kubiak, K.; Mizera, J. Influence of an aluminizing process on the microstructure and tensile strength of the nickel superalloy IN 718 produced by the Selective Laser Melting. Vacuum 2021, 186, 110041. [Google Scholar] [CrossRef]

- Gu, D.D.; Hagedorn, Y.; Meiners, W.; Wissenbach, K.; Poprawe, R. Nanocrystalline TiC reinforced Ti matrix bulk-form nanocomposites by Selective Laser Melting (SLM): Densification, growth mechanism and wear behavior. Composit. Sci. Technol. 2011, 71, 1620–1621. [Google Scholar] [CrossRef]

- Han, C.; Babicheva, R.; Chua, J.D.Q.; Ramamurty, U.; Tor, S.B.; Sun, C.; Zhou, K. Microstructure and mechanical properties of (TiB+TiC)/Ti composites fabricated in situ via selective laser melting of Ti and B4C powders. Addit. Manuf. 2020, 36, 101466. [Google Scholar] [CrossRef]

- Olakanmi, E.O. Selective laser sintering/melting (SLS/SLM) of pure Al, Al–Mg, and Al–Si powders: Effect of processing conditions and powder properties. J. Mater. Process. Technol. 2013, 213, 1387–1405. [Google Scholar] [CrossRef]

- Chen, H.; Chen, Y.X.; Liu, Y.; Wei, Q.S.; Shi, Y.S.; Yan, W.T. Packing quality of powder layer during counter-rolling-type powder spreading process in additive manufacturing. Int. J. Mach. Tools Manuf. 2020, 153, 103553. [Google Scholar] [CrossRef]

- Riener, K.; Oswald, S.; Winkler, M.; Leichtfried, G.J. Influence of storage conditions and reconditioning of AlSi10Mg powder on the quality of parts produced by laser powder bed fusion (LPBF). Addit. Manuf. 2021, 39, 101896. [Google Scholar] [CrossRef]

- Le, T.; Wang, X.G.; Davidson, K.P.; Fronda, J.E.; Seita, M. Experimental analysis of powder layer quality as a function of feedstock and recoating strategies. Addit. Manuf. 2021, 39, 101890. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminum alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Kaufmann, N.; Imran, M.; Wischeropp, T.M.; Emmelmann, C.; Siddique, S.; Walther, F. Influence of Process Parameters on the Quality of Aluminium Alloy EN AW 7075 Using Selective Laser Melting (SLM). Phys. Procedia 2016, 83, 918–926. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.H.; Zhang, H.; Yin, J.; Ke, L.D.; Zeng, X.Y. Selective laser melting of Al7050 powder: Melting mode transition and comparison of the characteristics between the keyhole and conduction mode. Mater. Des. 2017, 135, 257–266. [Google Scholar] [CrossRef]

- Otani, Y.; Kusaki, Y.; Itagaki, K.; Sasaki, S. Microstructure and mechanical properties of A7075 alloy with additional Si objects fabricated by selective laser melting. Mater. Trans. 2019, 60, 2143–2150. [Google Scholar] [CrossRef] [Green Version]

- Otani, Y.; Sasaki, S. Effects of the addition of silicon to 7075 aluminum alloy on microstructure, mechanical properties, and selective laser melting processability. Mater. Sci. Eng. A 2020, 777, 139079. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Su, Y.; Wang, H.; Enz, J.; Ebel, T.; Yan, M. Selective laser melting additive manufacturing of 7xxx series Al-Zn-Mg-Cu alloy: Cracking elimination by co-incorporation of Si and TiB2. Addit. Manuf. 2020, 36, 10145. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Zhou, L.; Pan, H.; Hyer, H.; Park, S.; Bai, Y.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure and tensile property of a novel AlZnMgScZr alloy additively manufactured by gas atomization and laser powder bed fusion. Scripta Mater. 2019, 158, 24–28. [Google Scholar] [CrossRef]

- Bi, J.; Lei, Z.L.; Chen, Y.B.; Chen, X.; Tian, Z.; Liang, J.W.; Zhang, X.R.; Qin, X.K. Microstructure and mechanical properties of a novel Sc and Zr modified 7075 aluminum alloy prepared by selective laser melting. Mater. Sci. Eng. A 2019, 768, 138478. [Google Scholar] [CrossRef]

- Lei, Z.L.; Bi, J.; Chen, Y.B.; Chen, X.; Qin, X.K.; Tian, Z. Effect of energy density on formability, microstructure and micro-hardness of selective laser melted Sc- and Zr-modified 7075 aluminum alloy. Powder. Technol. 2019, 356, 594–606. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Ng, F.L.; Seet, H.L.; Lu, W.J.; Liebscher, C.H.; Rao, Z.Y.; Raabe, D.; Nai, S.M.L. Superior mechanical properties of a selective-laser-melted AlZnMgCuScZr alloy enabled by a tunable hierarchical microstructure and dual-nanoprecipitation. Mater. Today 2022, 52, 90–101. [Google Scholar] [CrossRef]

- Huang, K.; Feng, Q.; Zhou, W.B.; Huang, L.; Xiang, J.; Luo, N.N.; Han, K.; Zhu, Y.T.; Wei, Y.Z. Effects of Sc addition on microstructure, mechanical and corrosion resistance properties of 7055 Al alloy. Mater. Res. Express 2021, 8, 046534. [Google Scholar] [CrossRef]

- Vlach, M.; Cizek, J.; Kodetova, V.; Leibner, M.; Cieslar, M.; Harcuba, P.; Bajtosova, L.; Kudrnova, H.; Vlasak, T.; Neubert, V.; et al. Phase transformations in novel hot-deformed Al–Zn–Mg–Cu–Si–Mn–Fe(–Sc–Zr) alloys. Mater. Des. 2020, 193, 108821. [Google Scholar] [CrossRef]

- Li, J.H.; Wiessner, M.; Albu, M.; Wurster, S.; Sartory, B.; Hofer, F.; Schumacher, P. Correlative characterization of primary Al3(Sc, Zr) phase in an Al–Zn–Mg based alloy. Mater. Char. 2015, 102, 62–70. [Google Scholar] [CrossRef]

- Deng, Y.; Yin, Z.M.; Pan, Q.L.; Xu, G.F.; Duan, Y.L.; Wang, Y.J. Nano-structure evolution of secondary Al3(Sc1−xZrx) particles during superplastic deformation and their effects on deformation mechanism in Al-Zn-Mg alloys. J. Alloys Compd. 2017, 695, 142–153. [Google Scholar] [CrossRef]

- Yang, Y.; Tan, P.; Sui, Y.D.; Jiang, Y.H.; Zhou, R.F. Influence of Zr content on microstructure and mechanical properties of As-cast Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2021, 867, 158920. [Google Scholar] [CrossRef]

- Samuel, A.M.; Alkahtani, S.A.; Doty, H.W.; Samuel, F.H. Role of Zr and Sc addition in controlling the microstructure and tensile properties of aluminum-copper based alloys. Mater. Des. 2015, 88, 1134–1144. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Ghayoumabadi, M.E.; Mochugovskiy, A.G. Superplasticity and mechanical properties of Al–Mg–Si alloy doped with eutectic-forming Ni and Fe, and dispersoid-forming Sc and Zr elements. Mater. Sci. Eng. A 2021, 817, 141319. [Google Scholar] [CrossRef]

- Mondol, S.; Kashyap, S.; Kumar, S.; Chattopadhyay, K. Improvement of high temperature strength of 2219 alloy by Sc and Zr addition through a novel three-stage heat treatment route. Mater. Sci. Eng. A 2018, 732, 157–166. [Google Scholar] [CrossRef]

- Wang, K.X.; Yin, D.F.; Zhao, Y.C.; Atrens, A.; Zhao, M.C. Microstructural evolution upon heat treatments and its effect on corrosion in Al-Zn-Mg alloys containing Sc and Zr. J. Mater. Res. Technol. 2020, 9, 5077–5089. [Google Scholar] [CrossRef]

- Pauly, S.; Wang, P.; Kühn, U.; Kosiba, K. Experimental determination of cooling rates in selectively laser-melted eutectic Al-33Cu. Addit. Manuf. 2018, 22, 753–757. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Guss, G.; Wu, S.; Matthews, M.J.; Schoenung, J.M. In-situ characterization of laser-powder interaction and cooling rates through high-speed imaging of powder bed fusion additive manufacturing. Mater. Des. 2017, 135, 385–396. [Google Scholar] [CrossRef]

- Bayoumy, D.; Schliephake, D.; Dietrich, S.; Wu, X.H.; Zhu, Y.M.; Huang, A.J. Intensive processing optimization for achieving strong and ductile Al-Mn-Mg-Sc-Zr alloy produced by selective laser melting. Mater. Des. 2021, 198, 109317. [Google Scholar] [CrossRef]

- Robson, J.D. A new model for prediction of dispersoid precipitation in aluminium alloys containing zirconium and scandium. Acta Mater. 2004, 52, 1409–1421. [Google Scholar] [CrossRef]

- Lee, Y.S.; Koh, D.H.; Kim, H.W.; Ahn, Y.S. Improved bake-hardening response of Al-Zn-Mg-Cu alloy through pre-aging treatment. Scripta Mater. 2018, 147, 45–49. [Google Scholar] [CrossRef]

- Buha, J.; Lumley, R.N.; Crosky, A.G. Secondary ageing in an aluminium alloy 7050. Mater. Sci. Eng. A 2008, 492, 1–10. [Google Scholar] [CrossRef]

- Berg, L.K.; Gjønnes, J.; Hansen, V.; Li, X.Z.; Knutson-Wedel, M.; Waterloo, G.; Schryvers, D.; Wallenberg, L.R. GP-zones in Al–Zn–Mg alloys and their role in artificial aging. Acta Mater. 2001, 49, 3443–3451. [Google Scholar] [CrossRef]

- Hunt, J.D. Steady State Columnar and Equiaxed Growth of Dendrites and Eutectic. Mater. Sci. Eng. 1984, 65, 75–83. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Heeling, T.; Uggowitzer, P.J.; Schäublin, R.; Palm, F.; Wegener, K. Microstructural features of Sc- and Zr-modified Al-Mg alloys processed by selective laser melting. Mater. Des. 2017, 115, 52–63. [Google Scholar] [CrossRef]

- Yang, K.V.; Shi, Y.; Palm, F.; Wu, X.; Rometsch, P. Columnar to equiaxed transition in Al-Mg(-Sc)-Zr alloys produced by selective laser melting. Scr. Mater. 2018, 145, 113–117. [Google Scholar] [CrossRef]

- Liu, J.; Kou, S. Crack susceptibility of binary aluminum alloys during solidification. Acta Mater. 2016, 110, 84–94. [Google Scholar] [CrossRef] [Green Version]

- Sigworth, G.K.; Kuhn, T.A. Grain refinement of aluminum of aluminum casting alloys. Int. Met. 2007, 1, 31–40. [Google Scholar] [CrossRef]

- Spittle, J.A. Grain refinement in shape casting of aluminum alloys. Int. J. Cast Met. Res. 2006, 19, 210–222. [Google Scholar] [CrossRef]

| Zn (wt.%) | Mg (wt.%) | Sc (wt.%) | Zr (wt.%) | Al (wt.%) | |

|---|---|---|---|---|---|

| sample 1 | 6.2 | 2 | 0 | 0 | Bal. |

| sample 2 | 6.2 | 2 | 0.2 | 0.12 | Bal. |

| sample 3 | 6.2 | 2 | 0.4 | 0.24 | Bal. |

| sample 4 | 6.2 | 2 | 0.6 | 0.36 | Bal. |

| No. | Ultimate Tensile Strength/MPa | Yield Strength/MPa | Elongation/% |

|---|---|---|---|

| Sample 3 | 250.0 ± 5.3 | 179.0 ± 1.0 | 8.5 ± 1.8 |

| Sample 4 | 327.3 ± 7.1 | 254.7 ± 5.5 | 19.2 ± 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, W.; Zhai, Z.; Liu, Y.; Liang, B.; Liang, Z.; Zhang, Y. Research on Microstructure and Cracking Behavior of Al-6.2Zn-2Mg-xSc-xZr Alloy Fabricated by Selective Laser Melting. Crystals 2022, 12, 1500. https://doi.org/10.3390/cryst12101500

Pan W, Zhai Z, Liu Y, Liang B, Liang Z, Zhang Y. Research on Microstructure and Cracking Behavior of Al-6.2Zn-2Mg-xSc-xZr Alloy Fabricated by Selective Laser Melting. Crystals. 2022; 12(10):1500. https://doi.org/10.3390/cryst12101500

Chicago/Turabian StylePan, Wei, Ziyu Zhai, Yantao Liu, Bo Liang, Zhuoheng Liang, and Yongzhong Zhang. 2022. "Research on Microstructure and Cracking Behavior of Al-6.2Zn-2Mg-xSc-xZr Alloy Fabricated by Selective Laser Melting" Crystals 12, no. 10: 1500. https://doi.org/10.3390/cryst12101500

APA StylePan, W., Zhai, Z., Liu, Y., Liang, B., Liang, Z., & Zhang, Y. (2022). Research on Microstructure and Cracking Behavior of Al-6.2Zn-2Mg-xSc-xZr Alloy Fabricated by Selective Laser Melting. Crystals, 12(10), 1500. https://doi.org/10.3390/cryst12101500