Magnetic Characterization of the Nugget Microstructure at Resistance Spot Welding

Abstract

:1. Introduction

2. Brief Fundamentals of Measuring Magnetic Material Properties

- Residual magnetic flux density : Magnetic flux density that remains in the material when no external magnetic field is applied after previous magnetization;

- Coercivity : magnetic field strength necessary to obtain a magnetic flux of (with previous magnetization);

- Magnetic saturation , : point beyond which a change in magnetic field strength causes only a small change in flux density.

3. Preliminary Studies

4. Materials and Methods

4.1. Investigated Materials

4.2. Selected Methods for Measuring the Magnetic Material Properties, Sample Preparation and Geometries

4.3. Experimental Setup

5. Results and Discussions

5.1. Preliminary Studies

5.2. Hysteresis Loops of the Toroidal Ring Measurements

5.3. Results of the Vibrating Sample Magnetometer

5.4. Measurements of the Residual Magnetic Flux Density

5.4.1. Results of the Sample Preparation and Test Setup Configurations

5.4.2. Evaluation of the RMFD-Measurements

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

- The following abbreviations are used in this manuscript:

| CCM | chromatic-confocal microscope | |

| EDM | electrical discharge machining | |

| RSW | Resistance spot welding | |

| HAZ | heat-affected zone | |

| NDT | non-destructive testing | |

| pMFT | passive magnetic flux density testing | |

| RMFD | residual magnetic flux density | |

| ROI | region of interest | |

| VSM | vibrating sample magnetometer | |

| Nomenclature | ||

| cross-sectional area () | ||

| B | flux density () | |

| residual magnetic flux density () | ||

| flux density at saturation () | ||

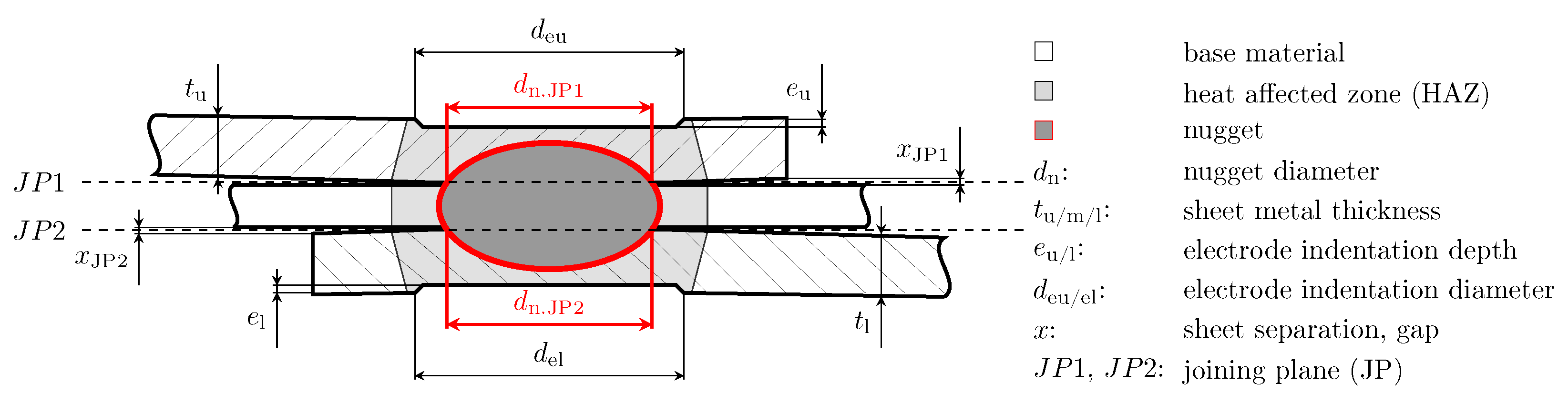

| d | diameter () | |

| indentation diameter () | ||

| nugget diameter () | ||

| inner diameter () | ||

| outer diameter () | ||

| weld diameter () | ||

| electrode indentation () | ||

| limit of electrode indentation () | ||

| f | frequency () | |

| electrode force () | ||

| H | magnetic field strength () | |

| magnetic coercivity () | ||

| magnetic field strength at saturation () | ||

| h | height () | |

| magnetization current () | ||

| welding current () | ||

| average length () | ||

| number of coil windings | ||

| r | radius () | |

| t | sheet thickness () | |

| weld time () | ||

| induced voltage () | ||

| magnetization voltage () | ||

| Rayleigh-constant | ||

| permeability | ||

| vacuum permeability | ||

| relative permeability |

References

- DVS 2916-5:2017-5; Prüfen von Widerstandspressschweißverbindungen: Zerstörungsfreie Prüfung. DVS Media GmbH: Düsseldorf, Germany, 2017.

- Füssel, U.; Mathiszik, C.; Zschetzsche, J.; Großmann, C.; Heide, M. Zerstörungsfreie Bewertung des Linsendurchmessers Beim Widerstandspunktschweißen Mit Magnetischen Prüfverfahren; Technische Universität Dresden, Professur für Fügetechnik und Montage: Dresden, Germany, 2015. [Google Scholar] [CrossRef]

- Mathiszik, C.; Füssel, U.; Zschetzsche, J. Zerstörungsfreie Bewertung des Linsendurchmessers beim Widerstandspunktschweißen durch bildgebende Analyse der Remanenzflussdichte; DVS Berichte: Sondertagung Widerstandsschweißen 2016 in Duisburg; DVS Media GmbH: Düsseldorf, Germany, 2016. [Google Scholar]

- Mathiszik, C.; Zschetzsche, J.; Großmann, C.; Füssel, U. Remanent Magnetization for Non-Destructive Testing of Spot Welds. In Proceedings of the 19th WCNDT 2016—World Conference on Non-Destructive Testing, Munich, Germany, 13–17 June 2016. [Google Scholar] [CrossRef]

- Füssel, U.; Mathiszik, C.; Zschetzsche, J. Zerstörungsfreie Charakterisierung der Anbindungsfläche beim Widerstandspressschweißen Durch Bildgebende Analyse der Remanenzflussdichte; Technische Universität Dresden, Professur für Fügetechnik und Montage: Dresden, Germany, 2019. [Google Scholar]

- Mathiszik, C.; Zschetzsche, J.; Füssel, U. Automated non-destructive evaluation of spot welds using the imaging analyses of the residual magnetic flux density. In Proceedings of the ASNT Research Symposium 2019, Stanford, CA, USA, 10–12 September 2019. [Google Scholar]

- Mathiszik, C.; Reinhardt, T.; Zschetzsche, J.; Füssel, U. NDT of spot welds by imaging analysis of the residual magnetic flux density—Investigation on the influence of electrode indentation on the measurement results. Mater. Test. 2018, 60, 1179–1183. [Google Scholar] [CrossRef]

- ISO 14373:2015-06; Widerstandsschweißen—Verfahren zum Punktschweißen von Niedriglegierten Stählen Mit oder Ohne Metallischem Überzug. DIN Deutsches Institut für Normung e.V. Beuth Verlag GmbH: Berlin, Germany, 2015. [CrossRef]

- Mathiszik, C.; Reinhardt, T.; Zschetzsche, J.; Füssel, U. NDT of austenitic steels—Evaluation of spot weld nugget diameters by imaging analyses of the residual flux density. In Proceedings of the 12th ECNDT, ECNDT and European Federation for Non-Destructive Testing and European Conference on Non-Destructive Testing, Sweden MEETX AB, Gothenburg, Sweden, 11–15 June 2018; Volume ECNDT2018. [Google Scholar]

- Holleman, A.F.; Wiberg, E.; Wiberg, N. Lehrbuch der Anorganischen Chemie, 101st ed.; de Gruyter: Berlin, Germany, 1995. [Google Scholar]

- Bramerdorfer, G.; Kitzberger, M.; Wöckinger, D.; Koprivica, B.; Zurek, S. State-of-the-art and future trends in soft magnetic materials characterization with focus on electric machine design—Part 2. Tech. Mess. 2019, 86, 553–565. [Google Scholar] [CrossRef]

- DIN EN 60404-1:2017-08; Magnetic Materials—Part 1: Classification. DIN Deutsches Institut für Normung e.V. Beuth Verlag GmbH: Berlin, Germany, 2017. [CrossRef]

- Tumanski, S. Handbook of Magnetic Measurements, 1st ed.; Series in Sensors; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Kneller, E.; Seeger, A.; Kronmüller, H. Ferromagnetismus; Springer: Berlin/Heidelberg, Germany, 1962. [Google Scholar] [CrossRef]

- Lord Rayleigh, S.S.R. XVII. On the maintenance of vibrations by forces of double frequency, and on the propagation of waves through a medium endowed with a periodic structure. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1887, 24, 145–159. [Google Scholar] [CrossRef] [Green Version]

- DIN EN 60404-4:2009-08; Magnetic Materials—Part 4: Methods of Measurement of d.c. Magnetic Properties of Magnetically Soft Materials. DIN Deutsches Institut für Normung e.V. Beuth Verlag GmbH: Berlin, Germany, 2009. [CrossRef]

- Mathis, W.; Reibiger, A. Küpfmüller Theoretische Elektrotechnik; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Chang, L.; Jahns, T.M.; Blissenbach, R. Characterization and Modeling of Soft Magnetic Materials for Improved Estimation of PWM-Induced Iron Loss. IEEE Trans. Ind. Appl. 2020, 56, 287–300. [Google Scholar] [CrossRef]

- DIN EN 60404-2:2009-01; Magnetic Materials—Part 2: Methods of Measurement of the Magnetic Properties of Electrical Steel Strip and Sheet by Means of an Epstein Frame. DIN Deutsches Institut für Normung e.V. Beuth Verlag GmbH: Berlin, Germany, 2009. [CrossRef]

- Takahashi, S.; Kobayashi, S.; Kikuchi, H.; Kamada, Y.; Ara, K. Analysis of Minor Hysteresis Loops of Cold Rolled Low Carbon Steel. IEEE Trans. Magn. 2006, 42, 3782–3784. [Google Scholar] [CrossRef]

- Mathiszik, C.; Köberlin, D.; Heilmann, S.; Zschetzsche, J.; Füssel, U. General Approach for Inline Electrode Wear Monitoring at Resistance Spot Welding. Processes 2021, 9, 685. [Google Scholar] [CrossRef]

- Duffy, R.M.; Netterfield, R.P. Design of Faraday rotators and modulators. Rev. Sci. Instrum. 1984, 55, 743–746. [Google Scholar] [CrossRef]

- Basharat, M.; Ding, M.; Cai, H.; Li, Y.; Fang, J.; Liu, P.; Tu, X. Design and Analysis of Multilayer Solenoid Coil for Faraday Modulator. Matec Web Conf. 2017, 114, 04004. [Google Scholar] [CrossRef] [Green Version]

- Hünicke, U.D.; Möller, S. Auswertung der statischen Magnetisierungskurve zur Kontrolle von Gefüge- und Behandlungszuständen bei Stählen. In Proceedings of the ZfP in Forschung, Entwicklung und Anwendung, [Elektronische Ressource]; DGZfP, Ed.; Jahrestagung Zerstörungsfreie Materialprüfung and Deutsche Gesellschaft für Zerstörungsfreie Prüfung, DGZfP: Mainz, Germany, 2003; Volume 83-CD. [Google Scholar]

- Vinz, J. Simulation der Remanenzflussdichte Mittels der Finiten-Elemente-Methode. Diploma Thesis, Technische Universität Dresden, Dresden, Germany, 2016. [Google Scholar]

- Ankener, W.; Böttger, D.; Smaga, M.; Gabi, Y.; Strass, B.; Wolter, B.; Beck, T. Micromagnetic and Microstructural Characterization of Ferromagnetic Steels in Different Heat Treatment Conditions. Sensors 2022, 22, 4428. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z.J.; Wang, Y.L.; Zhang, Z.J.; Zhang, Y.S. A Study on the Relationship between Hardness and Magnetic Properties of Ultra-High Strength Steel. Adv. Mater. Res. 2014, 1063, 78–81. [Google Scholar] [CrossRef]

| ID | Material | Microstructure Base Material | Magnetic Behavior |

|---|---|---|---|

| MAT1 | 22MnB5 (1.5528) | martensite | ferromagnetic |

| MAT2 | HX340LAD (1.0933) | ferrite | ferromagnetic |

| MAT3 | X5CrNi18-10 (1.4301) | austenite | non-ferromagnetic |

| MAT4 | S235 (1.0038) | ferrite | ferromagnetic |

| ID | Material | /mm | /mm | h/mm | /mm | /mm | /mm2 |

|---|---|---|---|---|---|---|---|

| MAT1 | 22MnB5 | 29.88 | 39.9 | 9.18 | 109.61 | 108.85 | 45.99 |

| MAT2 | HX340LAD | 29.93 | 39.85 | 9.7 | 109.61 | 108.86 | 48.11 |

| MAT3 | X5CrNi18-10 | 30 | 39.88 | 9.8 | 109.76 | 109.03 | 47.91 |

| MAT4 | S235 | 29.95 | 39.9 | 9.4 | 109.72 | 108.97 | 46.76 |

| Material | Sheet Thickness t | Welding Current | Welding Time | Electrode Force | Measuring Method |

|---|---|---|---|---|---|

| MAT1 1 | 2 × 1 | 360 | VSM | ||

| MAT2 1 | 2 × 1 | 300 | VSM | ||

| MAT1–MAT4 2 | 3 × 2 | 1000 | RMFD |

| Method | Measured Values | Sample Geometry | Sample Dimensions |

|---|---|---|---|

| VSM | H-loop: , , , | Cuboid | 2 × 6 |

| RMFD | Residual magnetic flux density | Disc |

| Material-ID | Temperature | Mass | Volume | Number of Samples |

|---|---|---|---|---|

| MAT1, base material | 25 | 6 | ||

| MAT1, weld | 25 | 8 | ||

| MAT2, base material | 25 | 5 | ||

| MAT2, weld | 25 | 8 |

| ID | Coil Configuration | Coil Core Material and Diameter |

|---|---|---|

| S1 | 1 coil D25, N180, one sided | steel 42CrMo4 (1.7225), |

| S2 | 2 coils D25, N180, both sided, same oriented | steel 42CrMo4 (1.7225), |

| A1 | 1 coil D25, N180, one sided | air, |

| A2 | 2 coils D25, N180, both sided, same oriented | air, |

| Material-ID | ||||

|---|---|---|---|---|

| MAT1 | 27,490 A m | |||

| MAT2 | 27,462 A m | |||

| MAT3 | 27,532 A m | – | ||

| MAT4 | 27,501 A m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mathiszik, C.; Zschetzsche, E.; Reinke, A.; Koal, J.; Zschetzsche, J.; Füssel, U. Magnetic Characterization of the Nugget Microstructure at Resistance Spot Welding. Crystals 2022, 12, 1512. https://doi.org/10.3390/cryst12111512

Mathiszik C, Zschetzsche E, Reinke A, Koal J, Zschetzsche J, Füssel U. Magnetic Characterization of the Nugget Microstructure at Resistance Spot Welding. Crystals. 2022; 12(11):1512. https://doi.org/10.3390/cryst12111512

Chicago/Turabian StyleMathiszik, Christian, Edwin Zschetzsche, André Reinke, Johannes Koal, Jörg Zschetzsche, and Uwe Füssel. 2022. "Magnetic Characterization of the Nugget Microstructure at Resistance Spot Welding" Crystals 12, no. 11: 1512. https://doi.org/10.3390/cryst12111512

APA StyleMathiszik, C., Zschetzsche, E., Reinke, A., Koal, J., Zschetzsche, J., & Füssel, U. (2022). Magnetic Characterization of the Nugget Microstructure at Resistance Spot Welding. Crystals, 12(11), 1512. https://doi.org/10.3390/cryst12111512