1. Introduction

Bulk ZnO ceramics possessing excellent nonlinear voltage-sensitive characteristics can be applied in some typical uses, such as power electronics, varistors, and electronic self-protection devices [

1]. Nonlinear macroscopic electrical characteristics in bulk materials can be ultimately determined by the Schottky barrier at the inner grain boundary interface [

2,

3]. In fact, they can be also essentially attributed to the integrated electrical conductivity effects of multiple nonlinear and irregular grain boundary structures [

4].

At present, most studies on bulk electrical property measurements can lead to the lack of electrical conductivity property expressions of grain boundaries in bulk ceramics [

5,

6]. Moreover, it is usual to assume that the isometric structure in bulk materials can be utilized to divide the grain boundary. This cannot produce the effect of differentiation on a single grain boundary. Thus, electrical property measurements of inner grain boundaries can be developed under optical microscope to accomplish micrometer characterization [

7,

8,

9,

10]. The author’s team has also developed in scanning electron microscope (SEM) to conduct nanometer morphology measurement of the grain boundary [

11,

12]. However, existing electrical measurements may lack the three-dimensional topography data of a single grain boundary. Although the author has also developed a structure characterization of inner invisible grain boundary using nanorobot in SEM [

13], it is still short of nonlinear quantitative topographies. Thus, it is significant to pursue an attempt to address a difficulty regarding to how to characterize three-dimensional grain boundary length.

Due to lack of data on the nonlinear morphology to divide uneven grain boundary in bulk ceramics, an approach of three-dimensional length characterization of nonlinear single grain boundary can be proposed under SEM using nanorobot, to accomplish local nonlinear structure characterization of micro-area grain boundaries morphology in bulk polycrystalline ZnO. Furthermore, it can provide a feasible way for the characterization of the three-dimensional structure of an irregular grain boundary. With respect to potential applications, it can try to provide a better way to enhance the positive effect on polycrystalline materials synthesis and structure characterization.

2. Experiments

A polished bulk polycrystalline ZnO sample was mounted onto a nanorobot embedded into SEM (SU3500, Hitachi, Tokyo, Japan). The nanorobot, consisting of a macro piezoelectric motor and micro positioning table, can be utilized to conduct Z-directional heights probing of different positions in plane X-Y. Nanorobots with end probe tip 500 nm can accomplish 10 mm macro motion with resolution of 20 μm and 20 μm micro motion with a resolution of 1 nm, respectively.

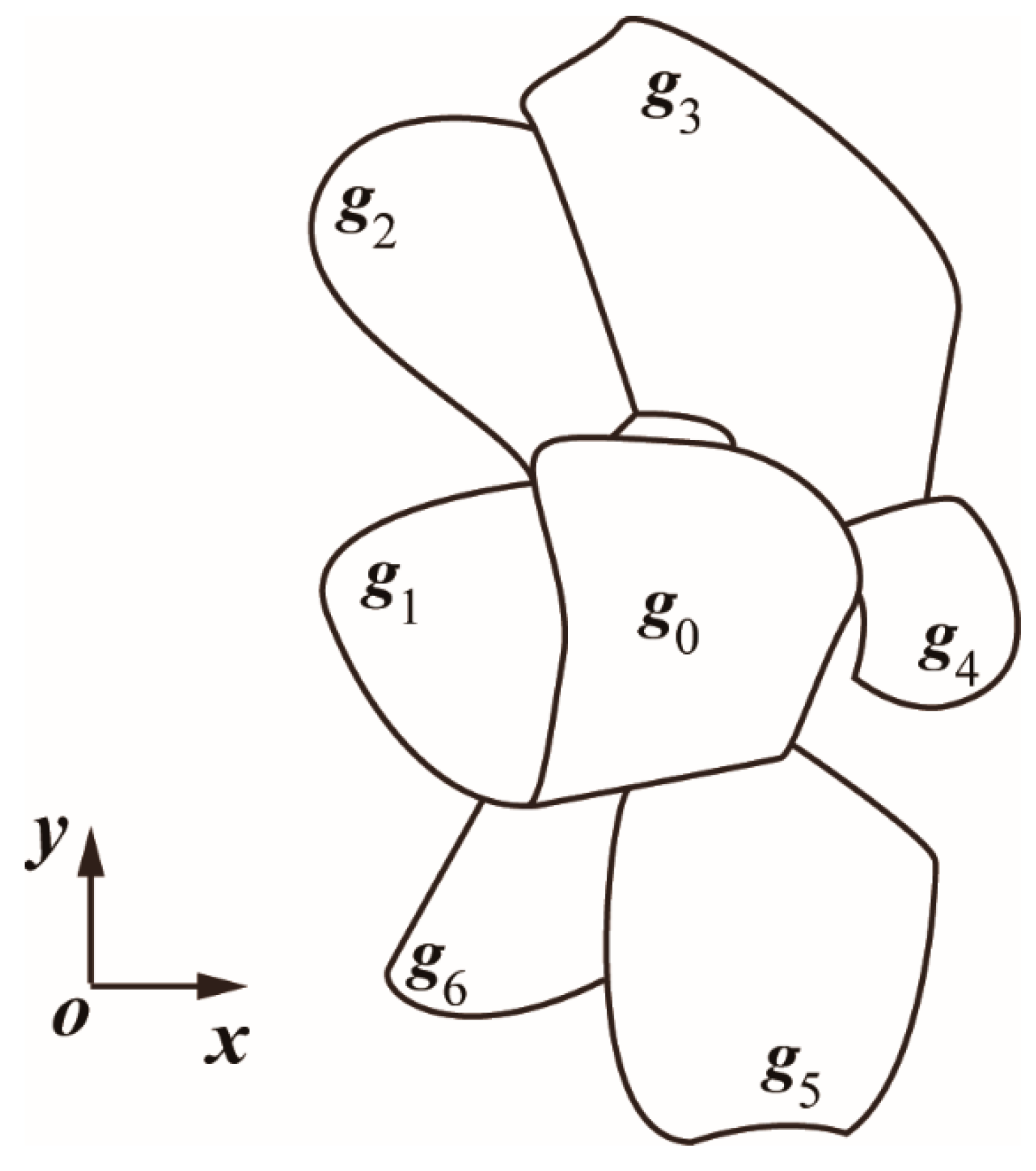

In order to accomplish the three-dimensional characterization of nonlinear grain boundary interface lengths in the micro-area of bulk ZnO, two-dimensional profile structure lengths of the targeted grain boundaries can be imaged in plane X-Y. Next, Z-directional heights in plane X-Z and plane Y-Z can be obtained by nanorobot probing at the equidistant positions. As illustrated in

Figure 1, it is a schematic diagram accounting for three-dimensional characterization of nonlinear structure lengths of micro-area grain boundary interfaces in bulk ZnO ceramics. After two-dimensional structures of the targeted grain boundary had been imaged to quantify the profile lengths in plane X-Y. When Z-directional relative differences had been vertically probed between different positions, the nanorobot end tip needed to be detected to accomplish the real contact to the upper surface in plane X-Y. At this point, taking Z-directional height as the initial reference occurred.

In order to verify the rationality of nanorobot-based probing of Z-dimensional heights, six positions at micro-area grain boundaries consisted of the targeted grains g1, g2, g3, g4, g5, and g6 were taken as the Z-directional height probing points. Here, the nanorobot-based Z-directional heights probing of grain boundary g1-g0-g4 in plane X-Z was regarded as an example, seen from the dashed box in details. The probing positions b1, b, b2 and position e1, e, and e2 were individually selected as the sample probing positions on the adjacent grain g1 and grain g4 along the X direction, with a horizontal equidistance of 1 μm. Assuming that the distance l1 = 1 μm, Z-directional relative vertical height difference h1 can be acquired by probing position b and b1 in sequence. As a result, it can be deduced to obtain the hypotenuse length as a part of grain boundary using the trigonometric geometric relation assumed by magnification. Similarly, after the position b2 has been probed by the nanorobot, partial nonlinear grain boundary length, which can be regarded as a projected length with oblique angle of grain boundary interfacial layer, can be drawn by Z-dimensional heights at position b1, b, and b2. It is then reasonable to demonstrate that the probing process of Z-directional heights probed at g2-g0-g6 and g3-g0-g5 in plane Y-Z are similar with that in plane X-Z.

After the grain boundary profile data in plane X-Y were obtained, a model of irregular length can be visually reconstructed by software to realize a virtual stereoscopic intuition expression for the nonlinear length of inner grain boundary.

3. Results and discussion

In order to establish three-dimensional structure morphologies of nonlinear grain boundaries, two-dimensional structures in plane X-Y need to be acquired first. After the targeted grain boundaries have been imaged by SEM, two-dimensional profile structure projections of multiple interface layers can be obtained in plane X-Y, as shown in

Figure 2. It can be easily observed that grain boundary length structures projections in plane X-Y can be constructed by the targeted six grains, i.e.,

g1,

g2,

g3,

g4,

g5, and

g6. Thus, relative positions away from the central grain

g0 were uniquely identified at the two-dimensional plane. It can be apparent to demonstrate that profile structures of grain boundaries in the two-dimensional plane present the characteristics of irregular shapes and unequal lengths. However, two-dimensional profile structures may be simplified to different shapes composed by straight lines and arc shapes.

It is worthy of note that it is an assumption to take the contour line of each grain to be considered as the relative uniform thickness of the grain boundary interface. In fact, the thickness of the grain boundary interface layer may vary in different orientations.

It can be further confirmed that grain boundary profile structures can be regarded as the nonlinear expression existing in a two-dimensional plane with irregular and unequal lengths. Furthermore, it can be envisioned that the grain boundary interface layer may exist nonlinearly in three dimensions.

In order to quantify the micromorphology of a grain boundary in plane X-Y, Z-directional height probing of the targeted grain positions along plane X-Z and plane Y-Z profiles can be performed using a nanorobot end probe.

As shown in

Figure 3, Z-directional relative heights of three positions on adjacent grains can be individually probed by a nanorobot along plane X-Z and plane Y-Z profiles at equal distances.

Figure 3a illustrates the projection drawing of Z-direction relative height differences of

g1 and

g4 relative to

g0 along the X direction. Probing positions on

g1 are individually represented as

b1,

b, and

b2, and

Lb1b =

Lbb2 = 1 μm along the X direction. Additionally, probing positions on

g4 are individually represented as

e1,

e, and

e2, and

Le1e =

Lee2 = 1 μm along the X direction. Correspondingly,

Figure 3b illustrates the projection drawing of Z-direction relative height differences of

g2 and

g6 relative to

g0 along the Y direction. Probing positions on

g2 are

c1,

c, and

c2, where

Lc1c =

Lcc2 = 1 μm along the Y direction. Additionally, probing positions on

g6 are

h1,

h, and

h2, and where

Lh1h =

Lhh2 = 1 μm along the Y direction.

Figure 3c illustrates the projection drawing of Z-direction relative height differences of

g3 and

g5 relative to

g0 along the Y direction. Probing positions on

g3 are

d1,

d, and

d2, where

Ld1d =

Ldd2 = 1 μm along the Y direction. Additionally, probing positions on

g5 are

f1,

f, and

f2, where

Lf1f =

Lff2 = 1 μm along the Y direction.

After local micro-area Z-directional micromorphology of the targeted grains in plane X-Y have been probed by nanorobot, Z-dimensional relative height differences at different probing positions can be obtained by comparing with grain

g0. Specifically, viewed from

Figure 3a, Z-directional relative height differences of three equidistant probing positions

b1,

b,

b2 on

g1 and

e1,

e,

e2 on

g4 relative to

g0 are −2.3 μm, −2.1 μm, −2.0 μm, and −8.8 μm, −8.7 μm, −8.5 μm, respectively. Viewed from

Figure 3b, Z-directional relative height differences of three equidistant probing positions

c1,

c,

c2 on

g2 and

h1,

h,

h2 on

g6 relative to

g0 are −6.8 μm, −6.9 μm, −7.0 μm and −3.56 μm, −3.5 μm, −3.44 μm, respectively. Viewed from

Figure 3c, Z-directional relative height differences of three equidistant probing positions

d1,

d,

d2 on

g3 and

f1,

f,

f2 on

g5 relative to

g0 are −5.0 μm, −5.2 μm, −5.4 μm and −2.86 μm, −2.9 μm, and −2.93 μm, respectively. Consequently, Z-directional relative height differences at the local grain boundary interface in plane X-Y can be drawn by nanorobot probing at the same equidistant positions on each grain surface.

Viewed from height data obtained by nanorobot Z-directional probing of different positions in plane X-Y, grain boundary lengths can present irregular and non-flat conditions, possessing unequal expressions along three-dimensional directions. Grain boundary lengths in plane X-Y, constructed by grains g1, g4, and g6 away from the targeted grain g0, present a trend of relatively gradually increasing behavior. On the contrary, grain boundary lengths constructed by grains g2, g3, and g5 present a trend of relatively gradually decreasing behavior. By performing Z-directional nano-probing of adjacent grain surfaces, it is demonstrated that grain shapes can be regarded as irregular characteristics. As a result, three-dimensional nonlinear grain boundaries can also be verified. This method proves that it is effective to characterize three-dimensional length structures of nonlinear polycrystalline grain boundaries using a nanorobot in SEM. It can also make up for the nonlinear morphologies of three-dimensional grain boundaries in bulk ZnO.

Furthermore, SEM imaging combined with robotic Z-directional nano-probing can be utilized to exhibit different internal topographical features of three-dimensional grain boundaries in a micro area of bulk ZnO. Furthermore, it can be used to guide the improvement of composition proportion and synthesis process of bulk ZnO so as to achieve the purpose of improving the macroscopic properties of bulk ZnO by constructing three-dimensional grain boundary morphology.

Correspondingly, a map of local nonlinear lengths of different grain boundary interface layers can be virtually reconstructed, as illustrated in

Figure 4. Obviously, the grain boundary interface layer length of each grain possesses a different counter shape. Therefore, it can be deduced that the irregular nonlinear grain boundary length may play a key role in the expression of macro conductance characteristics, which can extend the influences of grain boundary thickness along the depth direction. It is further verified from a nonlinear virtual reconstruction map that an approach of SEM coupled with nanorobots for characterization of micro-area grain boundary lengths is feasible. A virtual reconstruction of the local micro-area of three-dimensional grain boundary length structures can be adopted to interpret the nonlinear electrical characteristics expression of macro bulk polycrystalline ZnO.

It is worth emphasizing that relative heights probed individually along plane X-Z and plane Y-Z can be further utilized to illustrate nonlinear height differences of grain boundary interface lengths. It is further envisioned that if all of the real relative heights of grain boundary interfaces could be quantitatively probed using a nanorobot in plane X-Y, nonlinear grain boundary lengths may be theoretically virtually reconstructed in details. Furthermore, the method can be advanced to accomplish three-dimensional lengths division of grain boundaries, which can potentially provide a unique way to realize the nonlinear mapping characterization of grain boundary length and electrical properties.

Additionally, this proposed method can be utilized to try to address the technological difficulties using isometric brick divisions of grain boundaries. Furthermore, the method can also obtain nonlinear quantitative topographies to divide grain boundaries to uneven structure in property analysis of bulk polycrystalline materials.

As for potential applications, this proposed characterization method can be further utilized to guide a technical improvement of polycrystalline materials synthesis, which can have positive effects on the material composition ratio and processing technology.