Promoting Light Extraction Efficiency of Ultraviolet Light Emitting Diodes by Nanostructure Optimization

Abstract

:1. Introduction

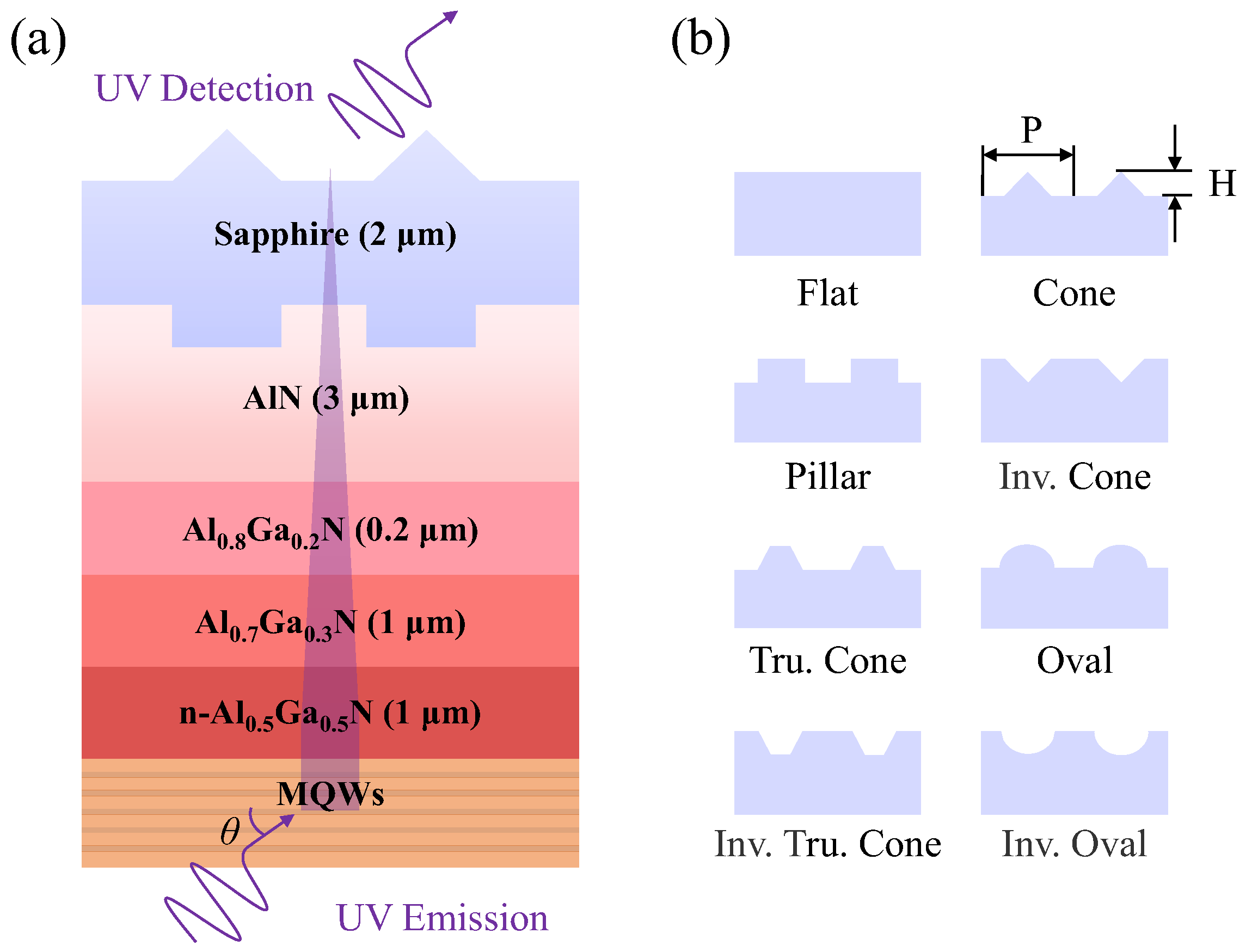

2. Model and Simulation Methods

3. Results and Discussion

3.1. Light Extraction of PC Patterns

3.2. Light Extraction of NPSS Patterns

3.3. Light Extraction of PC and NPSS Patterns

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khan, A.; Balakrishnan, K.; Katona, T. Ultraviolet light-emitting diodes based on group three nitrides. Nat. Photonics 2008, 2, 77–84. [Google Scholar] [CrossRef]

- Kneissl, M.; Seong, T.-Y.; Han, J.; Amano, H. The emergence and prospects of deep-ultraviolet light-emitting diode technologies. Nat. Photonics 2019, 13, 233–244. [Google Scholar] [CrossRef]

- Sharma, V.K.; Demir, H.V. Bright Future of Deep-Ultraviolet Photonics: Emerging UVC Chip-Scale Light-Source Technology Platforms, Benchmarking, Challenges, and Outlook for UV Disinfection. ACS Photonics 2022, 9, 1513–1521. [Google Scholar] [CrossRef]

- Muramoto, Y.; Kimura, M.; Nouda, S. Development and future of ultraviolet light-emitting diodes: UV-LED will replace the UV lamp. Semicond. Sci. Technol. 2014, 29, 084004. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Gao, N.; Cai, D.; Lin, W.; Huang, K.; Li, S.; Kang, J. Multiple fields manipulation on nitride material structures in ultraviolet light-emitting diodes. Light Sci. Appl. 2021, 10, 129. [Google Scholar] [CrossRef]

- Peng, X.; Guo, W.; Xu, H.; Chen, L.; Yang, Z.; Xu, L.; Liu, J.; Tang, K.; Guo, C.; Yan, L.; et al. Significantly boosted external quantum efficiency of AlGaN-based DUV-LED utilizing thermal annealed Ni/Al reflective electrodes. Appl. Phys. Express 2021, 14, 072005. [Google Scholar] [CrossRef]

- Ahmad, S.; Raushan, M.A.; Gupta, H.; Kattayat, S.; Kumar, S.; Dalela, S.; Alvi, P.A.; Siddiqui, M.J. Performance enhancement of UV quantum well light emitting diode through structure optimization. Opt. Quantum Electron. 2019, 51, 243. [Google Scholar] [CrossRef]

- SaifAddin, B.K.; Almogbel, A.S.; Zollner, C.J.; Wu, F.; Bonef, B.; Iza, M.; Nakamura, S.; DenBaars, S.P.; Speck, J.S. AlGaN Deep-Ultraviolet Light-Emitting Diodes Grown on SiC Substrates. ACS Photonics 2020, 7, 554–561. [Google Scholar] [CrossRef]

- Liu, T.-Y.; Huang, S.-M.; Lai, M.-J.; Liu, R.-S.; Zhang, X.; Chang, Y.-T.; Zhang, L.-J.; Lin, R.-M. Narrow-Band AlGaN-Based UVB Light-Emitting Diodes. ACS Appl. Electron. Mater. 2021, 3, 4121–4125. [Google Scholar] [CrossRef]

- Inoue, S.-I.; Tamari, N.; Taniguchi, M. 150 mW deep-ultraviolet light-emitting diodes with large-area AlN nanophotonic light-extraction structure emitting at 265 nm. Appl. Phys. Lett. 2017, 110, 141106. [Google Scholar] [CrossRef]

- Zheng, Z.; Chen, Q.; Dai, J.; Wang, A.; Liang, R.; Zhang, Y.; Shan, M.; Wu, F.; Zhang, W.; Chen, C.; et al. Enhanced light extraction efficiency via double nano-pattern arrays for high-efficiency deep UV LEDs. Opt. Laser Technol. 2021, 143, 107360. [Google Scholar] [CrossRef]

- Guttmann, M.; Susilo, A.; Sulmoni, L.; Susilo, N.; Ziffer, E.; Wernicke, T.; Kneissl, M. Light extraction efficiency and internal quantum efficiency of fully UVC-transparent AlGaN based LEDs. J. Phys. D Appl. Phys. 2021, 54, 335101. [Google Scholar] [CrossRef]

- Khan, M.A.; Maeda, N.; Yun, J.; Jo, M.; Yamada, Y.; Hirayama, H. Achieving 9.6% efficiency in 304 nm p-AlGaN UVB LED via increasing the holes injection and light reflectance. Sci. Rep. 2022, 12, 2591. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Jiang, J.; Chen, L.; Hoo, J.; Yan, L.; Guo, S.; Shen, C.; Wei, Y.; Shao, H.; Zhang, Z.-H.; et al. Direct demonstration of carrier distribution and recombination within step-bunched UV-LEDs. Photonics Res. 2021, 9, 764–771. [Google Scholar] [CrossRef]

- Li, D.; Jiang, K.; Sun, X.; Guo, C. AlGaN photonics: Recent advances in materials and ultraviolet devices. Adv. Opt. Photon. 2018, 10, 43–110. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, X.; Lunev, A.; Deng, J.; Bilenko, Y.; Katona, T.M.; Shur, M.S.; Gaska, R.; Khan, M.A. AlGaN Deep-Ultraviolet Light-Emitting Diodes. Jpn. J. Appl. Phys. 2005, 44, 7250–7253. [Google Scholar] [CrossRef]

- Wang, T.Y.; Tasi, C.T.; Lin, C.F.; Wuu, D.S. 85% internal quantum efficiency of 280-nm AlGaN multiple quantum wells by defect engineering. Sci. Rep. 2017, 7, 14422. [Google Scholar] [CrossRef] [Green Version]

- Susilo, N.; Ziffer, E.; Hagedorn, S.; Cancellara, L.; Netzel, C.; Ploch, N.L.; Wu, S.; Rass, J.; Walde, S.; Sulmoni, L.; et al. Improved performance of UVC-LEDs by combination of high-temperature annealing and epitaxially laterally overgrown AlN/sapphire. Photonics Res. 2020, 8, 589–594. [Google Scholar] [CrossRef]

- Miyake, H.; Nishio, G.; Suzuki, S.; Hiramatsu, K.; Fukuyama, H.; Kaur, J.; Kuwano, N. Annealing of an AlN buffer layer in N2–CO for growth of a high-quality AlN film on sapphire. Appl. Phys. Express 2016, 9, 025501. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Mitra, S.; Subedi, R.C.; Zhang, Y.; Guo, W.; Ye, J.; Shakfa, M.K.; Ng, T.K.; Ooi, B.S.; Roqan, I.S.; et al. Unambiguously Enhanced Ultraviolet Luminescence of AlGaN Wavy Quantum Well Structures Grown on Large Misoriented Sapphire Substrate. Adv. Funct. Mater. 2019, 29, 1905445. [Google Scholar] [CrossRef]

- Son, J.H.; Kim, J.U.; Song, Y.H.; Kim, B.J.; Ryu, C.J.; Lee, J.L. Design rule of nanostructures in light-emitting diodes for complete elimination of total internal reflection. Adv. Mater. 2012, 24, 2259–2262. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Li, J.; Sheikhi, M.; Jiang, J.A.; Yang, Z.; Li, H.; Guo, S.; Sheng, J.; Sun, J.; Bo, B.; et al. Comparative study on luminescence extraction strategies of LED by large-scale fabrication of nanopillar and nanohole structures. J. Phys. D Appl. Phys. 2018, 51, 24LT01. [Google Scholar] [CrossRef]

- Djavid, M.; Mi, Z. Enhancing the light extraction efficiency of AlGaN deep ultraviolet light emitting diodes by using nanowire structures. Appl. Phys. Lett. 2016, 108, 051102. [Google Scholar] [CrossRef]

- Lin, R.; Galan, S.V.; Sun, H.; Hu, Y.; Alias, M.S.; Janjua, B.; Ng, T.K.; Ooi, B.S.; Li, X. Tapering-induced enhancement of light extraction efficiency of nanowire deep ultraviolet LED by theoretical simulations. Photonics Res. 2018, 6, 457–462. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Liu, X.; Pandey, A.; Zhou, P.; Dong, W.J.; Wang, P.; Min, J.; Deotare, P.; Kira, M.; Kioupakis, E.; et al. III-nitride nanostructures: Emerging applications for Micro-LEDs, ultraviolet photonics, quantum optoelectronics, and artificial photosynthesis. Prog. Quantum Electron. 2022, in press. [Google Scholar] [CrossRef]

- Dong, P.; Yan, J.; Wang, J.; Zhang, Y.; Geng, C.; Wei, T.; Cong, P.; Zhang, Y.; Zeng, J.; Tian, Y.; et al. 282-nm AlGaN-based deep ultraviolet light-emitting diodes with improved performance on nano-patterned sapphire substrates. Appl. Phys. Lett. 2013, 102, 241113. [Google Scholar] [CrossRef]

- Zhou, S.; Zhao, X.; Du, P.; Zhang, Z.; Liu, X.; Liu, S.; Guo, L.J. Application of patterned sapphire substrate for III-nitride light-emitting diodes. Nanoscale 2022, 14, 4887–4907. [Google Scholar] [CrossRef]

- Zhang, J.; Chang, L.; Zhao, Z.; Tian, K.; Chu, C.; Zheng, Q.; Zhang, Y.; Li, Q.; Zhang, Z.-H. Different scattering effect of nano-patterned sapphire substrate for TM- and TE-polarized light emitted from AlGaN-based deep ultraviolet light-emitting diodes. Opt. Mater. Express 2021, 11, 729–739. [Google Scholar] [CrossRef]

- Dong, P.; Yan, J.; Zhang, Y.; Wang, J.; Zeng, J.; Geng, C.; Cong, P.; Sun, L.; Wei, T.; Zhao, L.; et al. AlGaN-based deep ultraviolet light-emitting diodes grown on nano-patterned sapphire substrates with significant improvement in internal quantum efficiency. J. Cryst. Growth 2014, 395, 9–13. [Google Scholar] [CrossRef]

- Ren, Z.; Yu, H.; Liu, Z.; Wang, D.; Xing, C.; Zhang, H.; Huang, C.; Long, S.; Sun, H. Band Engineering of III-Nitride-Based Deep-Ultraviolet Light-Emitting Diodes: A Review. J. Phys. D Appl. Phys. 2020, 53, 073002. [Google Scholar] [CrossRef]

- Wang, H.; Dai, J.; Sun, H.; Mou, Y.; Cai, Y.; Liang, R.; Xu, L.; Gao, Y.; Peng, Y.; Li, J.; et al. Phosphor Glass-Coated Sapphire With Moth-Eye Microstructures for Ultraviolet-Excited White Light-Emitting Diodes. IEEE T. Electron. Dev. 2019, 66, 3007–3011. [Google Scholar] [CrossRef]

- Wang, S.; Dai, J.; Hu, J.; Zhang, S.; Xu, L.; Long, H.; Chen, J.; Wan, Q.; Kuo, H.-C.; Chen, C. Ultrahigh Degree of Optical Polarization above 80% in AlGaN-Based Deep-Ultraviolet LED with Moth-Eye Microstructure. ACS Photonics 2018, 5, 3534–3540. [Google Scholar] [CrossRef]

- Xie, N.; Xu, F.; Wang, J.; Sun, Y.; Liu, B.; Zhang, N.; Lang, J.; Fang, X.; Ge, W.; Qin, Z.; et al. Stress evolution in AlN growth on nano-patterned sapphire substrates. Appl. Phys. Express 2020, 13, 015504. [Google Scholar] [CrossRef]

- Ooi, Y.K.; Zhang, J. Light Extraction Efficiency Analysis of Flip-Chip Ultraviolet Light-Emitting Diodes With Patterned Sapphire Substrate. IEEE Photonics J. 2018, 10, 1–13. [Google Scholar] [CrossRef]

- Available online: https://refractiveindex.info (accessed on 10 October 2022).

- Engelbrecht, J.A.A.; Sephton, B.; Minnaar, E.; Wagener, M.C. An alternative method to determine the refractive index of AlxGa1−xN. Phys. B 2016, 480, 181–185. [Google Scholar] [CrossRef]

- Pan, J.-W.; Tsai, P.-J.; Chang, K.-D.; Chang, Y.-Y. Light extraction efficiency analysis of GaN-based light-emitting diodes with nanopatterned sapphire substrates. Appl. Opt. 2013, 52, 1358–1367. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, W.; Zeng, Y.; Shou, C.; Yan, B.; Chee, K.W.A.; Sheng, J.; Ye, J. Design and simulation of perovskite solar cells with Gaussian structured gradient-index optics. Opt. Lett. 2019, 44, 4865–4868. [Google Scholar] [CrossRef]

- Liang, R.; Hu, R.; Long, H.; Huang, X.; Dai, J.; Xu, L.; Ye, L.; Zhai, T.; Kuo, H.C.; Chen, C. Bio-Inspired Flexible Fluoropolymer Film for All-Mode Light Extraction Enhancement. ACS Appl. Mater. Interfaces 2019, 11, 19623–19630. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Tsai, C.-L.; Huang, C.-Y.; Yang, R.-Y.; Wu, Y.S.; Yen, H.-W.; Fu, Y.-K. Efficiency improvement analysis of nano-patterned sapphire substrates and semi-transparent superlattice contact layer in UVC light-emitting diodes. Appl. Phys. Lett. 2020, 117, 261102. [Google Scholar] [CrossRef]

- Lan, S.; Tang, B.; Hu, H.; Zhou, S. Strategically constructed patterned sapphire with silica array to boost substrate performance in GaN-based flip-chip visible light-emitting diodes. Opt. Express 2020, 28, 38444–38455. [Google Scholar] [CrossRef]

- Yu, H.; Jia, H.; Liu, Z.; Memon, M.H.; Tian, M.; Fang, S.; Wang, D.; Zhang, H.; Liu, J.; Xu, L.; et al. Development of highly efficient ultraviolet LEDs on hybrid patterned sapphire substrates. Opt. Lett. 2021, 46, 5356–5359. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Tang, B.; Wan, H.; Sun, H.; Zhou, S.; Dai, J.; Chen, C.; Liu, S.; Guo, L.J. Boosted ultraviolet electroluminescence of InGaN/AlGaN quantum structures grown on high-index contrast patterned sapphire with silica array. Nano Energy 2020, 69, 104427. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Xia, S.; Guo, W.; Yang, Z.; Zeng, Y.; Yuan, Z.; Ye, J. Promoting Light Extraction Efficiency of Ultraviolet Light Emitting Diodes by Nanostructure Optimization. Crystals 2022, 12, 1601. https://doi.org/10.3390/cryst12111601

Li B, Xia S, Guo W, Yang Z, Zeng Y, Yuan Z, Ye J. Promoting Light Extraction Efficiency of Ultraviolet Light Emitting Diodes by Nanostructure Optimization. Crystals. 2022; 12(11):1601. https://doi.org/10.3390/cryst12111601

Chicago/Turabian StyleLi, Biaomin, Shihong Xia, Wei Guo, Zhenhai Yang, Yuheng Zeng, Zhizhong Yuan, and Jichun Ye. 2022. "Promoting Light Extraction Efficiency of Ultraviolet Light Emitting Diodes by Nanostructure Optimization" Crystals 12, no. 11: 1601. https://doi.org/10.3390/cryst12111601

APA StyleLi, B., Xia, S., Guo, W., Yang, Z., Zeng, Y., Yuan, Z., & Ye, J. (2022). Promoting Light Extraction Efficiency of Ultraviolet Light Emitting Diodes by Nanostructure Optimization. Crystals, 12(11), 1601. https://doi.org/10.3390/cryst12111601