Warm Rolled Temperature Effect on Microstructure and Mechanical Properties of 18Mn/40Si2CrMo Multilayer Composite Steel

Abstract

:1. Introduction

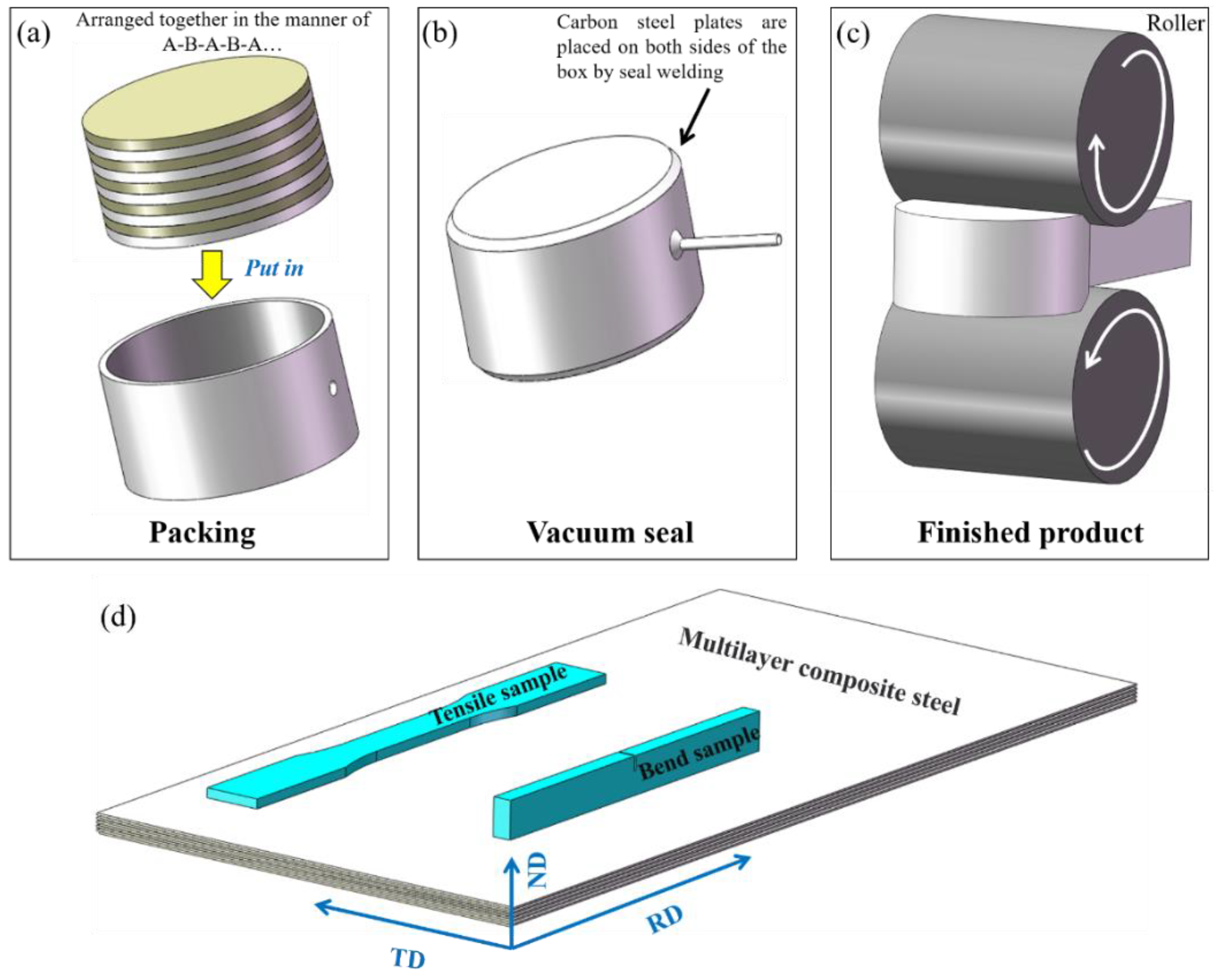

2. Materials and Methods

3. Results

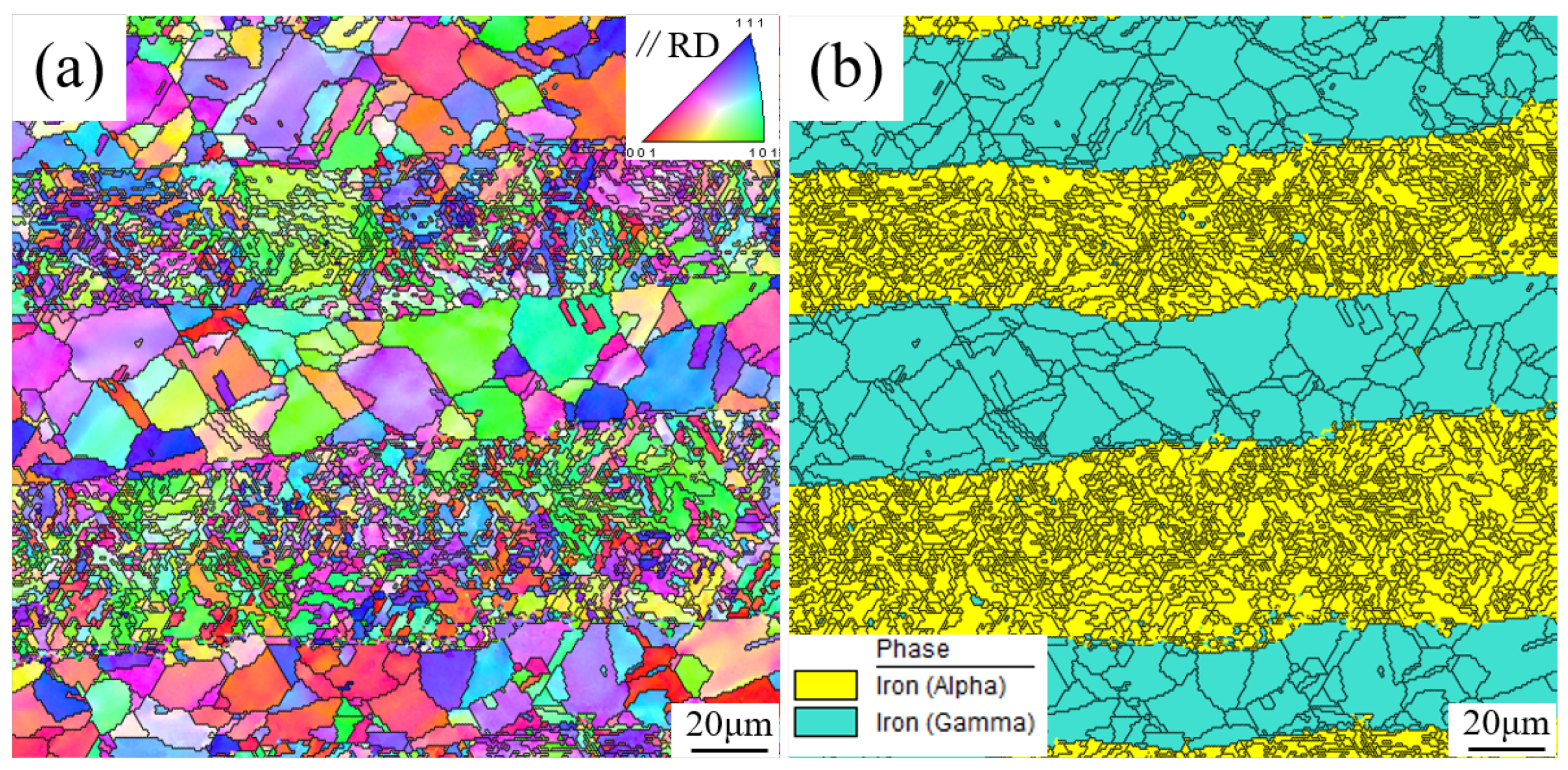

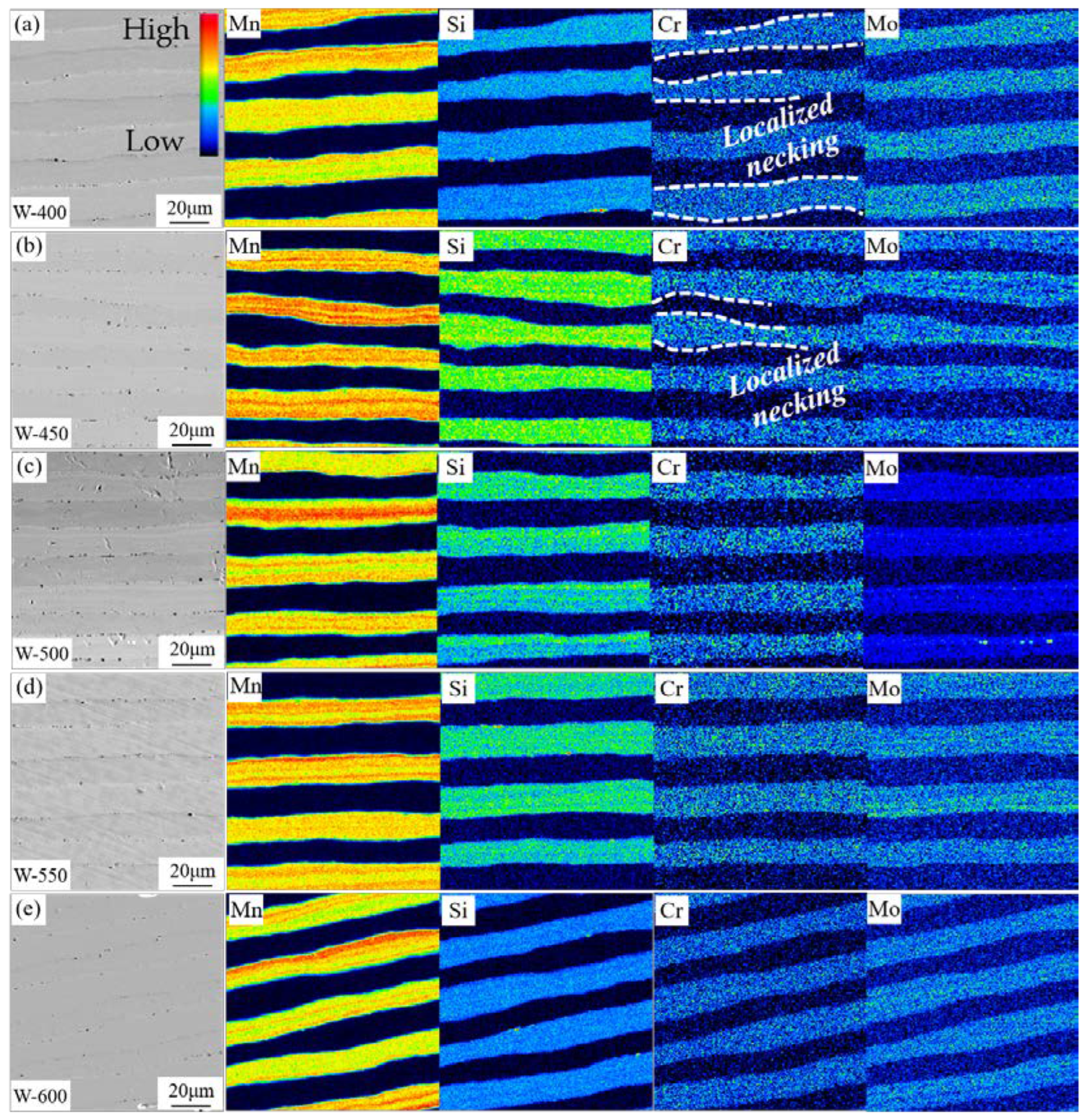

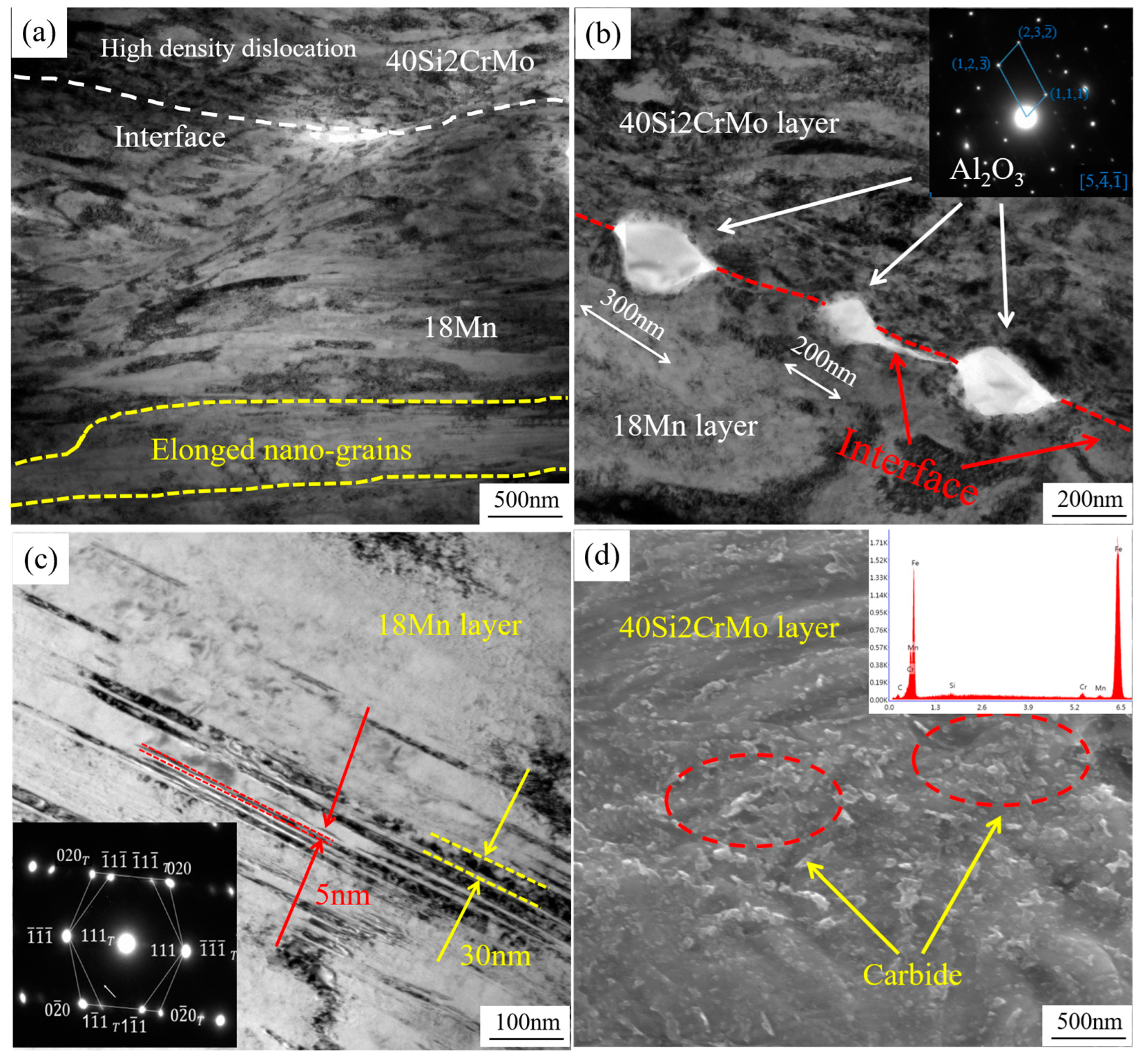

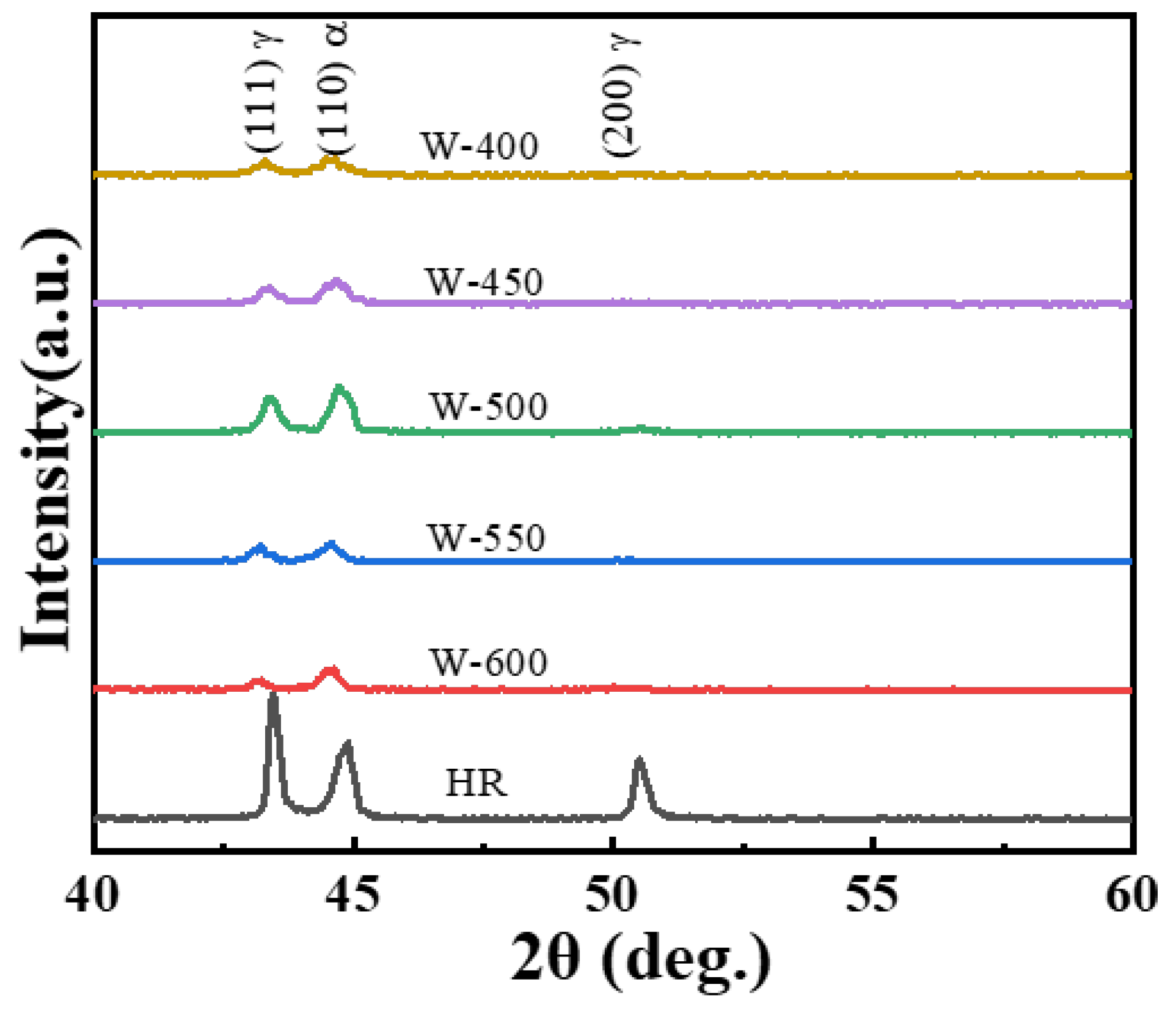

3.1. Microstructure

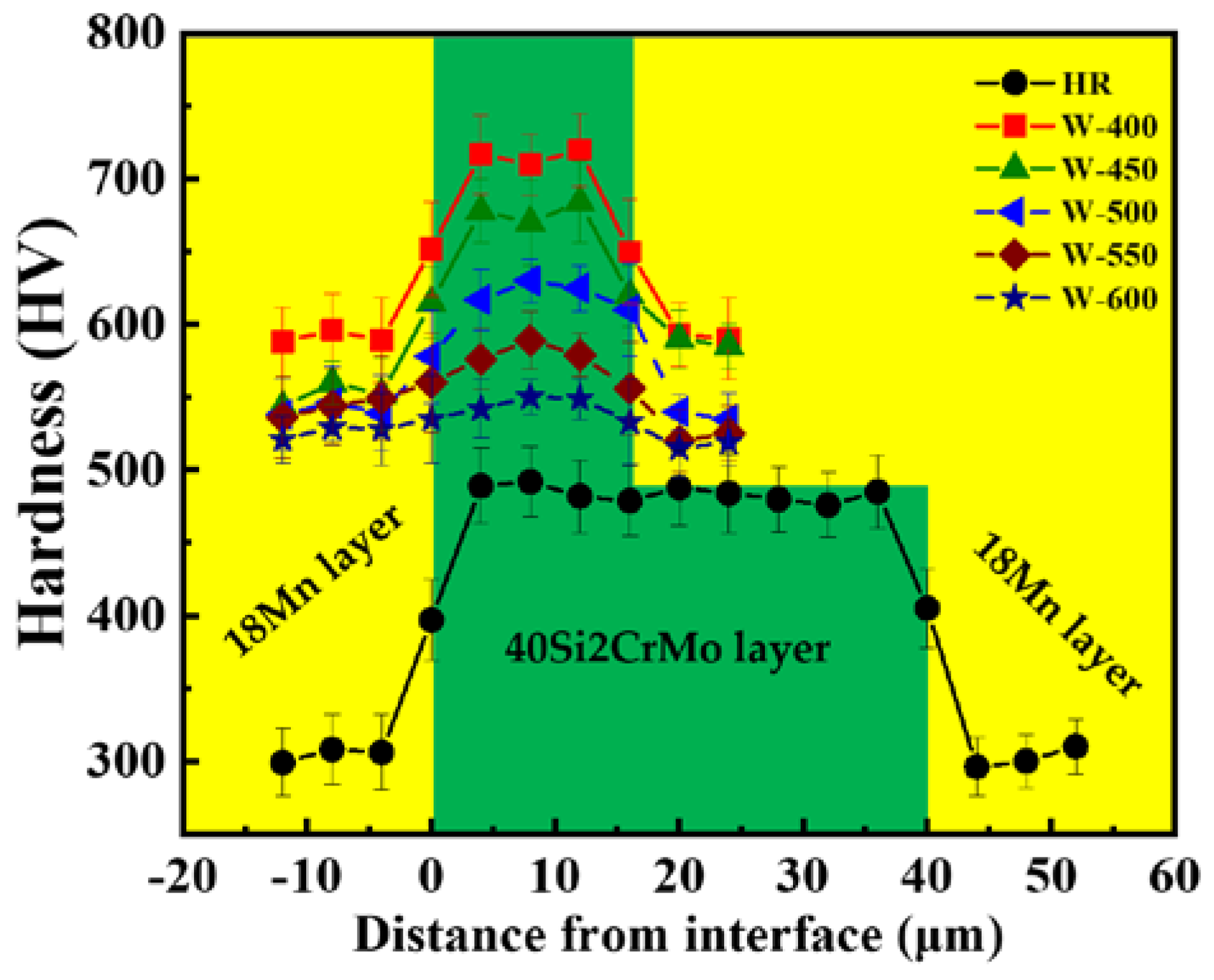

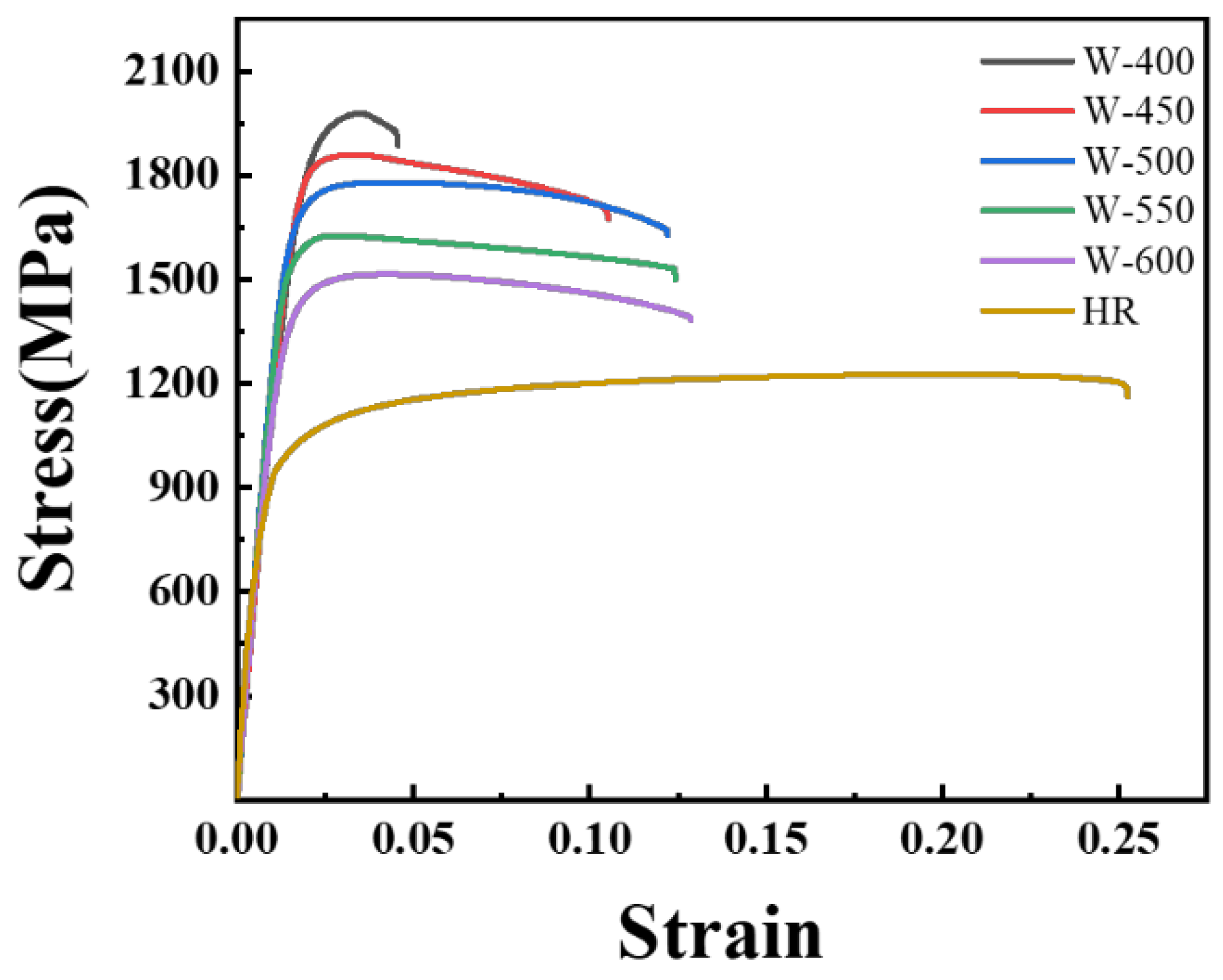

3.2. Tensile Properties and Hardness

4. Discussion

5. Conclusions

- The multilayer composite steel in the hot rolled state has good deformation coordination and the interface transitions to wavy as the warm rolling proceeds. Local necking occurs to varying degrees between both layers, which is due to the difference in hardening rates and flow stresses between 18Mn and 40Si2CrMo, resulting in shear stresses at the interface;

- The diffusion distance of Mn, Si, Cr, and Mo at the interface all increase with the increase of warm rolling temperature, which is mainly due to the increase of diffusion coefficient caused by the increase of temperature;

- As the warm rolling temperature decreases, the YS and UTS increase, TEL decreases. When the warm rolling temperature is 500 °C, the YS of the sample reaches 1670 MPa, YS reaches 1780 MPa, and the TEL is 12.2%, which is an excellent strength-plasticity combination;

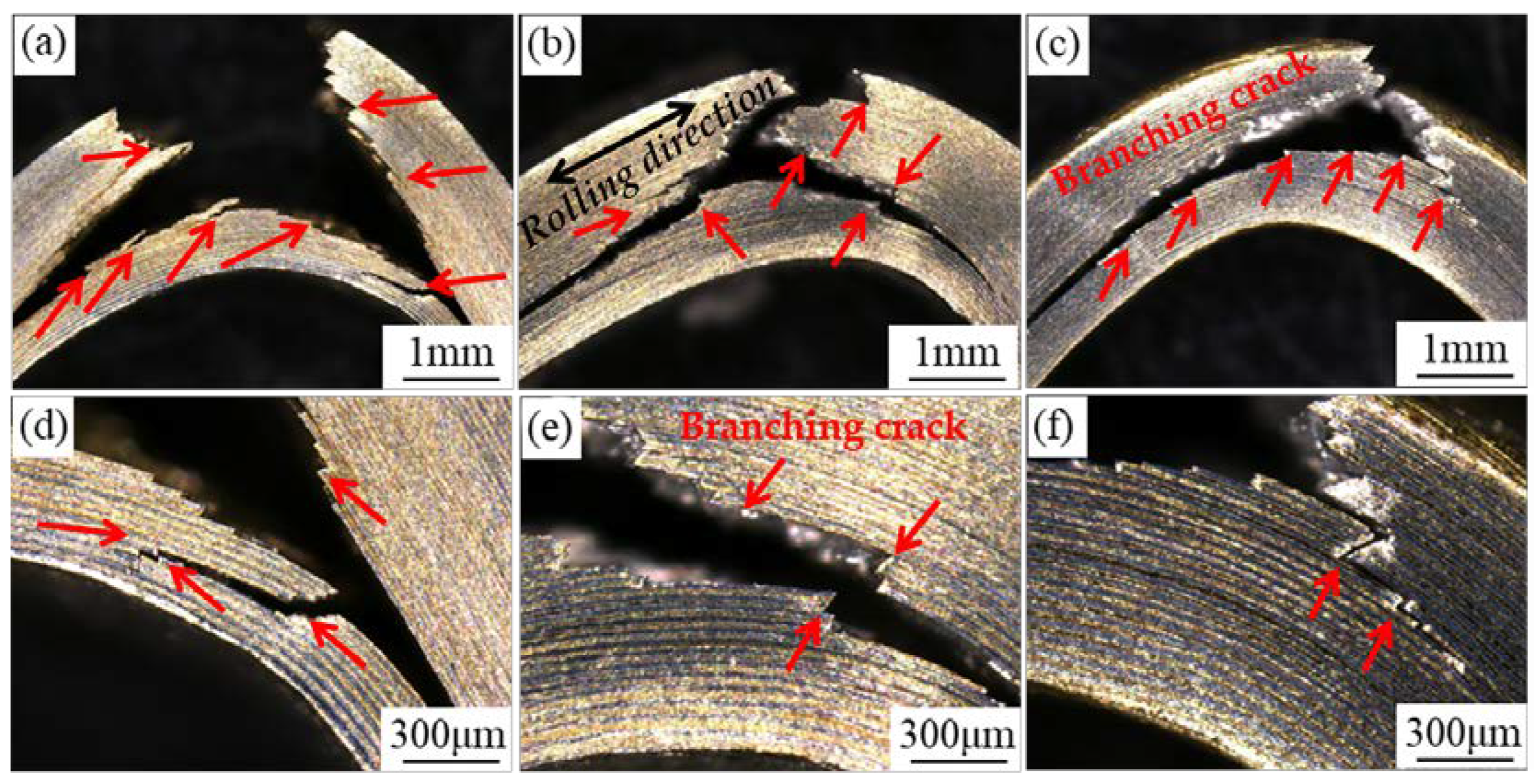

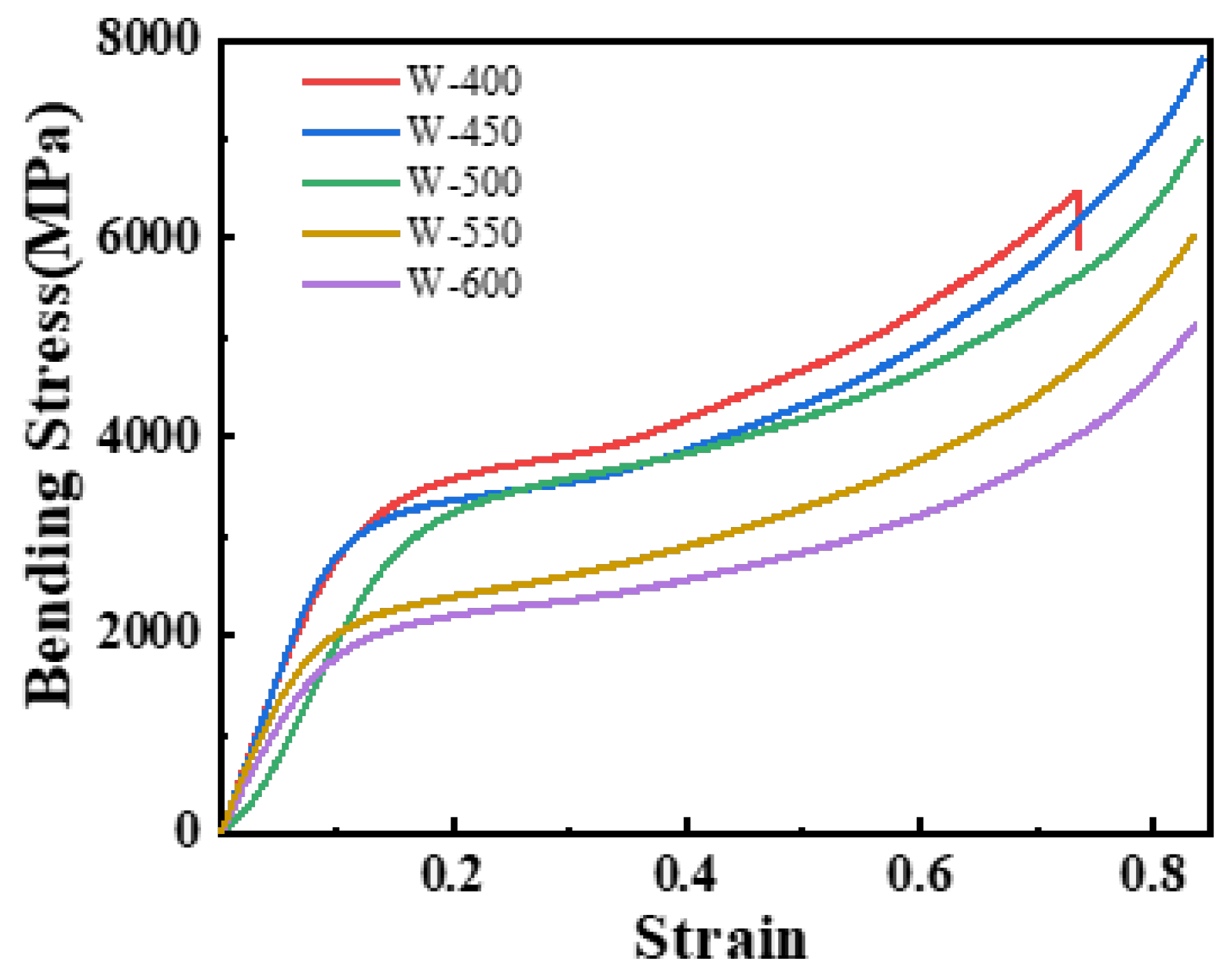

- In the bending process, lower warm rolling temperature leads to premature failure with a low number of deflection cracks, while with a higher warm rolling temperature due to good interfacial bonding, multiple cracks are passivated; there are numerous deflection cracks formed, and continuous crack deflection and delamination can absorb a large amount of energy, thus enhancing the bending resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, Z.; He, Y.; Zhang, X.; Liu, H.; Li, X. Effect of interface oxides on shear properties of hot-rolled stainless steel clad plate. Mater. Sci. Eng. A 2016, 669, 344–349. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Z.; Jha, B.; Xia, G.; Stevenson, J.W. Clad metals, roll bonding and their applications for SOFC interconnects. J. Power Sources 2005, 152, 40–45. [Google Scholar] [CrossRef]

- Gholami, M.D.; Davoodi, B.; Hashemi, R. Study of forming limit curves and mechanical properties of three-layered brass (CuZn10)/ low carbon steel (St14) /brass (CuZn10) composite considering the effect of annealing temperature. J. Mater. Res. Technol. 2022, 18, 4672–4682. [Google Scholar] [CrossRef]

- Foadian, F.; Soltanieh, M.; Adeli, M.; Etminanbakhsh, M. The Kinetics of TiAl3 Formation in Explosively Welded Ti-Al Multilayers During Heat Treatment. Metall. Mater. Trans. B 2016, 47, 2931–2937. [Google Scholar] [CrossRef]

- Basak, S.; Mondal, M.; Gao, K.; Hong, S.-T.; Anaman, S.Y.; Cho, H.-H. Friction stir butt-welding of roll cladded aluminum thin sheets: Effect of microstructural and texture changes on mechanical properties. Mater. Sci. Eng. A 2022, 832, 142490. [Google Scholar] [CrossRef]

- Hosseini, M.; Pardis, N.; Manesh, H.D.; Abbasi, M.; Kim, D.-I. Structural characteristics of Cu/Ti bimetal composite produced by accumulative roll-bonding (ARB). Mater. Des. 2017, 113, 128–136. [Google Scholar] [CrossRef]

- Tan, H.F.; Zhang, B.; Luo, X.M.; Sun, X.D.; Zhang, G.P. Strain rate dependent tensile plasticity of ultrafine-grained Cu/Ni laminated composites. Mater. Sci. Eng. A 2014, 609, 318–322. [Google Scholar] [CrossRef]

- Kim, H.Y.; Chung, D.S.; Hong, S.H. Reaction synthesis and microstructures of NiAl/Ni micro-laminated composites. Mater. Sci. Eng. A 2005, 396, 376–384. [Google Scholar] [CrossRef]

- Romero, A.; Rodríguez, G.P.; Marjaliza, E. Processing of intermetallic laminates by Self-Propagating High–Temperature Synthesis initiated with concentrated solar energy. J. Alloys Compd. 2021, 891, 161876. [Google Scholar] [CrossRef]

- Ding, H.; Cui, X.; Wang, Z.; Zhao, T.; Wang, Y.; Zhang, Y.; Chen, H.; Huang, L.; Geng, L.; Chen, J. A new strategy for fabrication of unique heterostructured titanium laminates and visually tracking their synchronous evolution of strain partitions versus microstructure. J. Mater. Sci. Technol. 2022, 107, 70–81. [Google Scholar] [CrossRef]

- Inoue, J.; Nambu, S.; Ishimoto, Y.; Koseki, T. Fracture elongation of brittle/ductile multilayered steel composites with a strong interface. Scripta Mater. 2008, 59, 1055–1058. [Google Scholar] [CrossRef]

- Nambu, S.; Michiuchi, M.; Inoue, J.; Koseki, T. Effect of interfacial bonding strength on tensile ductility of multilayered steel composites. Compos. Sci. Technol. 2009, 69, 1936–1941. [Google Scholar] [CrossRef]

- Cao, W.; Zhang, M.; Huang, C.; Xiao, S.; Dong, H.; Weng, Y. Ultrahigh Charpy impact toughness (~450J) achieved in high strength ferrite/martensite laminated steels. Sci. Rep. 2017, 7, 41459. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sherby, O.D.; Wadsworth, J. Ancient blacksmiths, the Iron Age, Damascus steels, and modern metallurgy. J. Mater. Process. Technol. 2001, 117, 347–353. [Google Scholar] [CrossRef] [Green Version]

- Bruschi, S.; Cao, J.; Merklein, M.; Yanagimoto, J. Forming of metal-based composite parts. CIRP Ann. 2021, 70, 567–588. [Google Scholar] [CrossRef]

- Liu, B.X.; An, Q.; Ge, Y.F.; Yin, F.X.; Zhang, B.Y.; Yu, W.X.; Ji, P.G.; Zhang, X.; Chen, C.X. Deformation Behavior and Strengthening Mechanisms of Multilayer SUS304/Cr17 Steels with Laminate/Network Interface. Metall. Mater. Trans. A 2020, 51, 3658–3673. [Google Scholar] [CrossRef]

- Koseki, T.; Inoue, J.; Nambu, S. Development of Multilayer Steels for Improved Combinations of High Strength and High Ductility. Mater. Trans. 2014, 55, 227–237. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Liu, B.X.; Chen, C.X.; Feng, J.H.; Yin, F.X. Microstructure, mechanical properties and interface bonding mechanism of hot-rolled stainless steel clad plates at different rolling reduction ratios. J. Alloys Compd. 2018, 766, 517–526. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Liu, B.X.; He, J.N.; Ji, P.G.; Zhang, X.; Fang, W.; Feng, J.H.; Hu, X.L.; Yin, F.X. A new route to fabricate multilayer steel with multiscale hierarchical structure. Mater. Charact. 2020, 169, 110606. [Google Scholar] [CrossRef]

- He, H.; Liu, Y.; Yin, J.; Wang, X.; Lin, X.; Zhang, S. Introducing effective temperature into Arrhenius equation with Meyer-Neldel rule for describing both Arrhenius and non-Arrhenius dependent drain current of amorphous InGaZnO TFTs. Solid State Electron. 2021, 181–182, 108011. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, X.; Yan, C.; Li, H.; Zhu, Y.; Li, X.; Yu, L. Interfacial Microstructure and Properties of Carbon Fiber Composites Modified with Graphene Oxide. ACS. Appl. Mater. Inter. 2012, 4, 1543–1552. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Jiang, F.; Li, Y.; Zhang, M.; Chen, C.; Yang, Z.; Zhang, F. Effect of warm-rolling on the strength and ductility of multilayered composite steel. Mater. Sci. Eng. A. 2022, 841, 143043. [Google Scholar] [CrossRef]

- Busby, J.T.; Hash, M.C.; Was, G.S. The relationship between hardness and yield stress in irradiated austenitic and ferritic steels. J. Nucl. Mater. 2005, 336, 267–278. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T.; Yin, F.; Tsuzaki, K. Inverse temperature dependence of toughness in an ultrafine grain-structure steel. Science 2008, 320, 1057–1060. [Google Scholar] [CrossRef] [PubMed]

- Kimura, Y.; Inoue, T. Mechanical Property of Ultrafine Elongated Grain Structure Steel Processed by Warm Tempforming and Its Application to Ultra-High-Strength Bolt. ISIJ Int. 2020, 60, 1108–1126. [Google Scholar] [CrossRef] [Green Version]

- Inoue, T.; Kimura, Y. Effect of Delamination and Grain Refinement on Fracture Energy of Ultrafine-Grained Steel Determined Using an Instrumented Charpy Impact Test. Materials 2022, 15, 837. [Google Scholar] [CrossRef] [PubMed]

- Inoue, T.; Qiu, H.; Ueji, R.; Kimura, Y. Ductile-to-Brittle Transition and Brittle Fracture Stress of Ultrafine-Grained Low-Carbon Steel. Materials 2021, 14, 1634. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Bönisch, M.; Wu, Y.; Sehitoglu, H. Hardening by slip-twin and twin-twin interactions in FeMnNiCoCr. Acta Mater. 2018, 153, 391–403. [Google Scholar] [CrossRef]

- Shen, Y.F.; Lu, L.; Lu, Q.H.; Jin, Z.H.; Lu, K. Tensile properties of copper with nano-scale twins. Scripta Mater. 2005, 52, 989–994. [Google Scholar] [CrossRef]

- Kulkarni, Y.; Asaro, R.; Farkas, D. Are nanotwinned structures in fcc metals optimal for strength, ductility and grain stability? Scripta Mater. 2009, 60, 532–535. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, H.; Wu, Y.; Liu, X.; Chen, H.; Yao, M.; Gault, B.; Ponge, D.; Raabe, D.; Hirata, A.; et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 2017, 544, 460–464. [Google Scholar] [CrossRef]

- Pan, D.; Zhao, Y.; Xu, X.; Wang, Y.; Jiang, W.; Chong, X. A novel strengthening and toughening strategy for T250 maraging steel: Cluster-orientation governed higher strength-ductility combination induced by electropulsing. Mater. Design. 2019, 169, 107686. [Google Scholar] [CrossRef]

- Kamikawa, N.; Sato, K.; Miyamoto, G.; Murayama, M.; Sekido, N.; Tsuzaki, K.; Furuhara, T. Stress—strain behavior of ferrite and bainite with nano-precipitation in low carbon steels. Acta Mater. 2015, 83, 383–396. [Google Scholar] [CrossRef] [Green Version]

- Williamson, G.K.; Hall, W.H. X-ray Line Broadening from Filed Aluminum and Wolfram. Acta Mater. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Sauzay, M.; Fournier, B.; Mottot, M.; Pineau, A.; Monnet, I. Cyclic softening of martensitic steels at high temperature—Experiments and physically based modelling. Mater. Sci. Eng. A 2008, 483–484, 410–414. [Google Scholar] [CrossRef]

| Element | C | Mn | Al | Si | Cr | Mo | Fe |

|---|---|---|---|---|---|---|---|

| 18Mn | 0.62 | 17.48 | 1.46 | ≤0.1 | ≤0.1 | ≤0.05 | 80.19 |

| 40Si2CrMo | 0.4 | 0.2 | 0.022 | 2.0 | 1.0 | 1.01 | 95.368 |

| Distance (μm) | HR-92 | W-400 | W-450 | W-500 | W-550 | W-600 |

|---|---|---|---|---|---|---|

| Mn | 4.4 | 2.1 | 2.4 | 2.5 | 2.5 | 2.5 |

| Si | 2.8 | 2.2 | 1.9 | 2.1 | 1.8 | 2.6 |

| Cr | 4.4 | 2.4 | 2.6 | 2.6 | 2.6 | 3 |

| Mo | 3.2 | 1.6 | 2 | 1.8 | 2.2 | 2.4 |

| Sample | UTS (MPa) | YS (MPa) | TEL (%) |

|---|---|---|---|

| HR | 1028 | 1226 | 25.3 |

| W-400 | 1879 | 1978 | 4.6 |

| W-450 | 1760 | 1859 | 10.5 |

| W-500 | 1670 | 1780 | 12.2 |

| W-550 | 1496 | 1625 | 12.4 |

| W-600 | 1340 | 1515 | 12.8 |

| 18Mn/40Si2CrMo | The Full Half Maximum (B) | Dislocation Density (mm−2) | Dislocation Enhancement Value (MPa) | |

|---|---|---|---|---|

| Hot rolling | 18Mn | 0.209 | 9.953 × 106 | 324.8 |

| 40Si2CrMo | 0.325 | 1.492 × 107 | 397.7 | |

| W-400 | 18Mn | 0.366 | 3.051 × 107 | 566.8 |

| 40Si2CrMo | 0.468 | 4.781 × 107 | 712.3 | |

| W-450 | 18Mn | 0.359 | 2.934 × 107 | 557.6 |

| 40Si2CrMo | 0.430 | 4.035 × 107 | 654.0 | |

| W-500 | 18Mn | 0.351 | 2.808 × 107 | 545.5 |

| 40Si2CrMo | 0.396 | 3.425 × 107 | 602.5 | |

| W-550 | 18Mn | 0.311 | 2.203 × 107 | 483.2 |

| 40Si2CrMo | 0.382 | 3.190 × 107 | 581.5 | |

| W-600 | 18Mn | 0.277 | 1.746 × 107 | 430.2 |

| 40Si2CrMo | 0.358 | 2.797 × 107 | 544.5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Li, Z.; Fan, K.; Liu, B.; Yu, W.; Yin, F. Warm Rolled Temperature Effect on Microstructure and Mechanical Properties of 18Mn/40Si2CrMo Multilayer Composite Steel. Crystals 2022, 12, 1652. https://doi.org/10.3390/cryst12111652

Yang B, Li Z, Fan K, Liu B, Yu W, Yin F. Warm Rolled Temperature Effect on Microstructure and Mechanical Properties of 18Mn/40Si2CrMo Multilayer Composite Steel. Crystals. 2022; 12(11):1652. https://doi.org/10.3390/cryst12111652

Chicago/Turabian StyleYang, Bo, Zhuoyu Li, Kuanyuan Fan, Baoxi Liu, Wenxing Yu, and Fuxing Yin. 2022. "Warm Rolled Temperature Effect on Microstructure and Mechanical Properties of 18Mn/40Si2CrMo Multilayer Composite Steel" Crystals 12, no. 11: 1652. https://doi.org/10.3390/cryst12111652

APA StyleYang, B., Li, Z., Fan, K., Liu, B., Yu, W., & Yin, F. (2022). Warm Rolled Temperature Effect on Microstructure and Mechanical Properties of 18Mn/40Si2CrMo Multilayer Composite Steel. Crystals, 12(11), 1652. https://doi.org/10.3390/cryst12111652