Experimental Study on the Mechanical Properties and Disintegration Resistance of Microbially Solidified Granite Residual Soil

Abstract

:1. Introduction

2. Materials and Methods

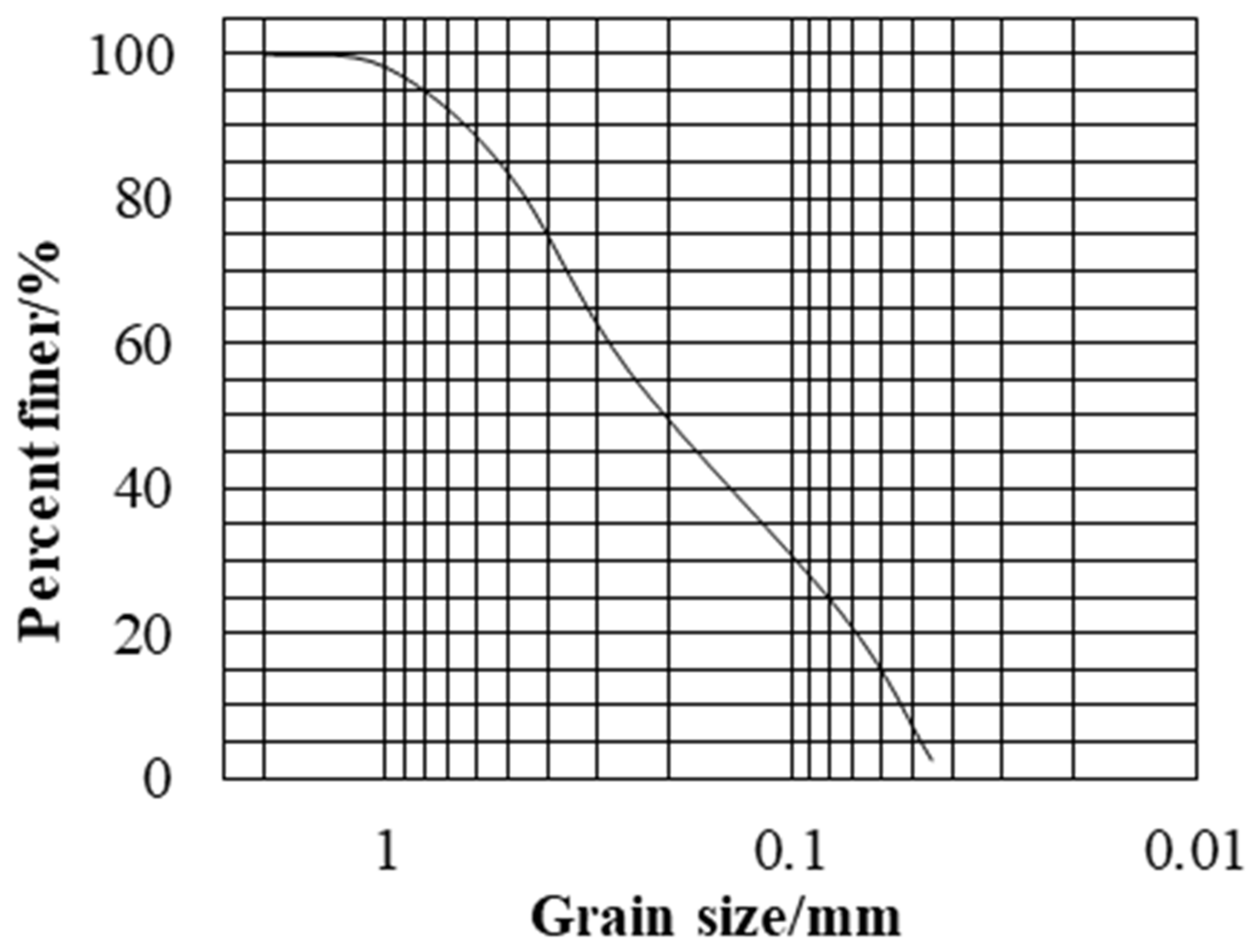

2.1. Soil

2.2. Bacterial and Nutrient Solutions

2.3. Sample Preparation

- m—the mass of wet soil required to prepare the specimen (g);

- —the dry density required to prepare the specimen (g/cm3);

- V—the volume of the specimen (cm3);

- —water content (%).

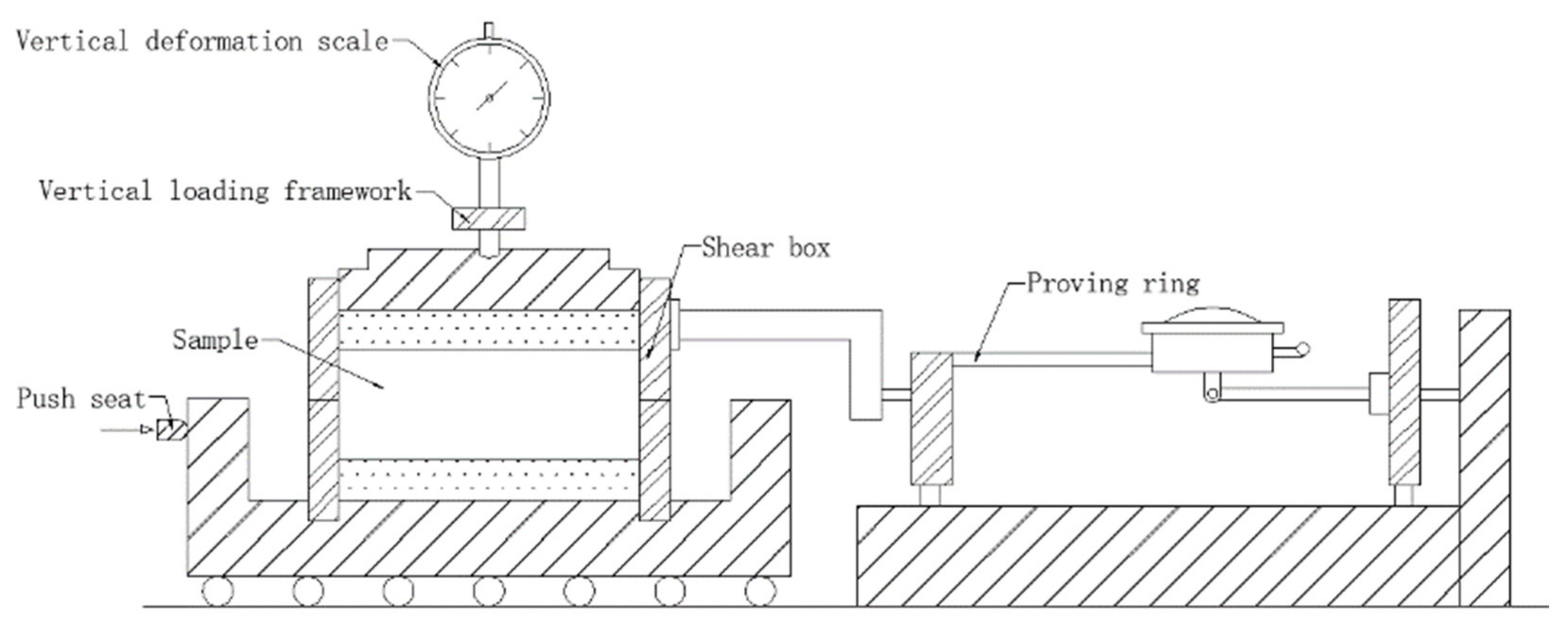

2.4. Direct Shear Test

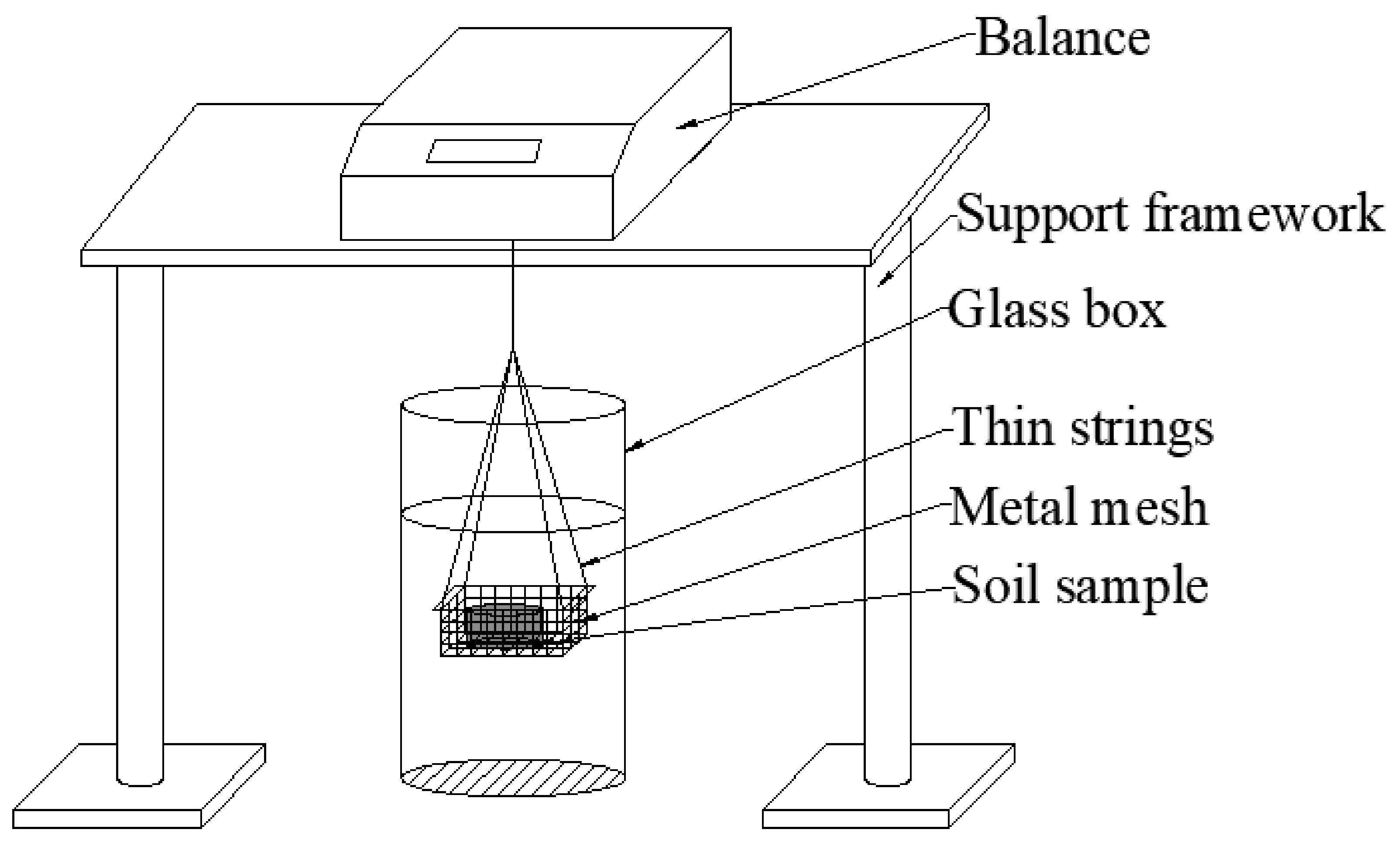

2.5. Disintegration Test

- —the cumulative amount of disintegration of a specimen at moment t (%);

- —the initial reading of the balance (i.e., the balance reading when the empty wire mesh is immersed into water) (g);

- —the balance reading in the beginning of the test (g);

- —the balance reading at moment t (g).

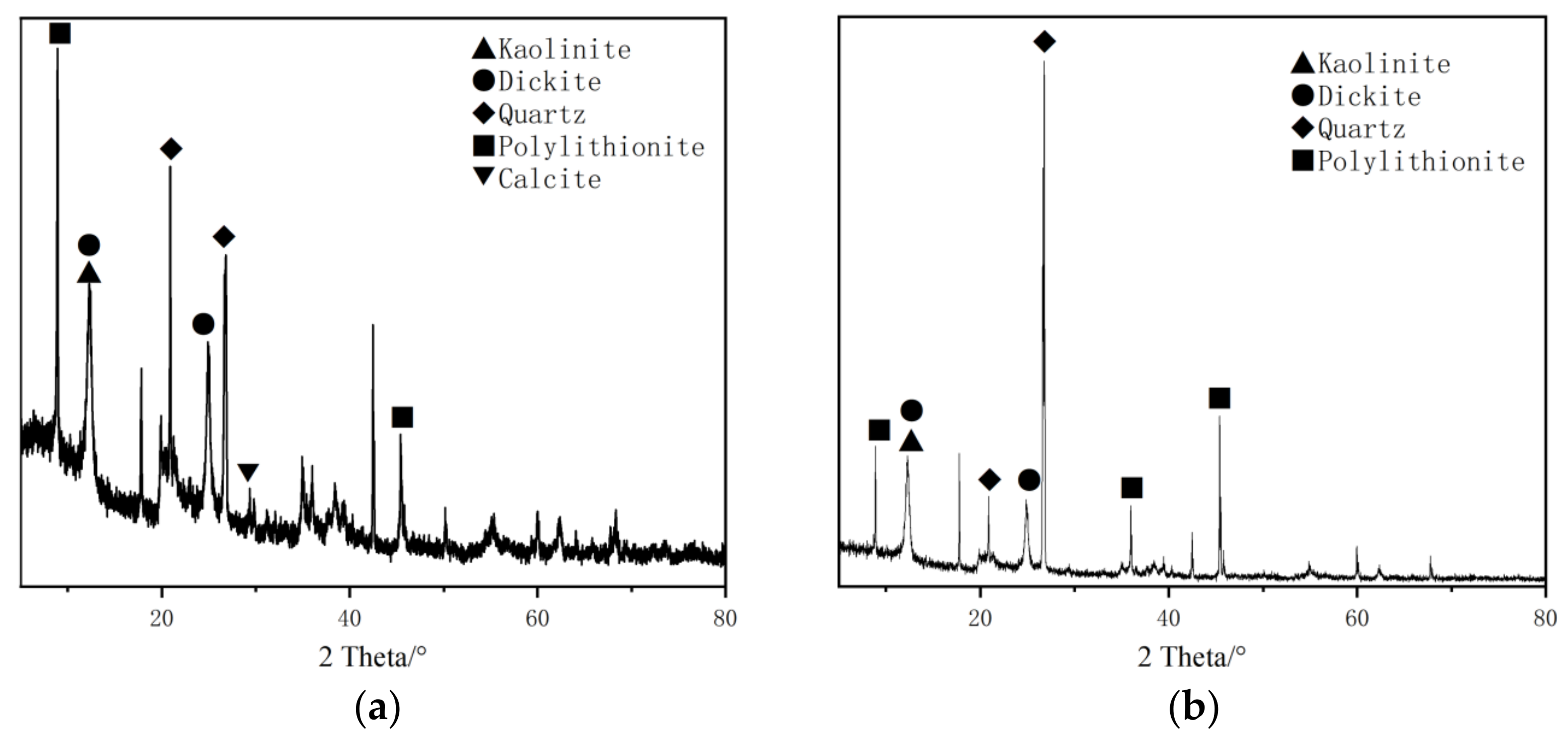

2.6. SEM and XRD Experiment

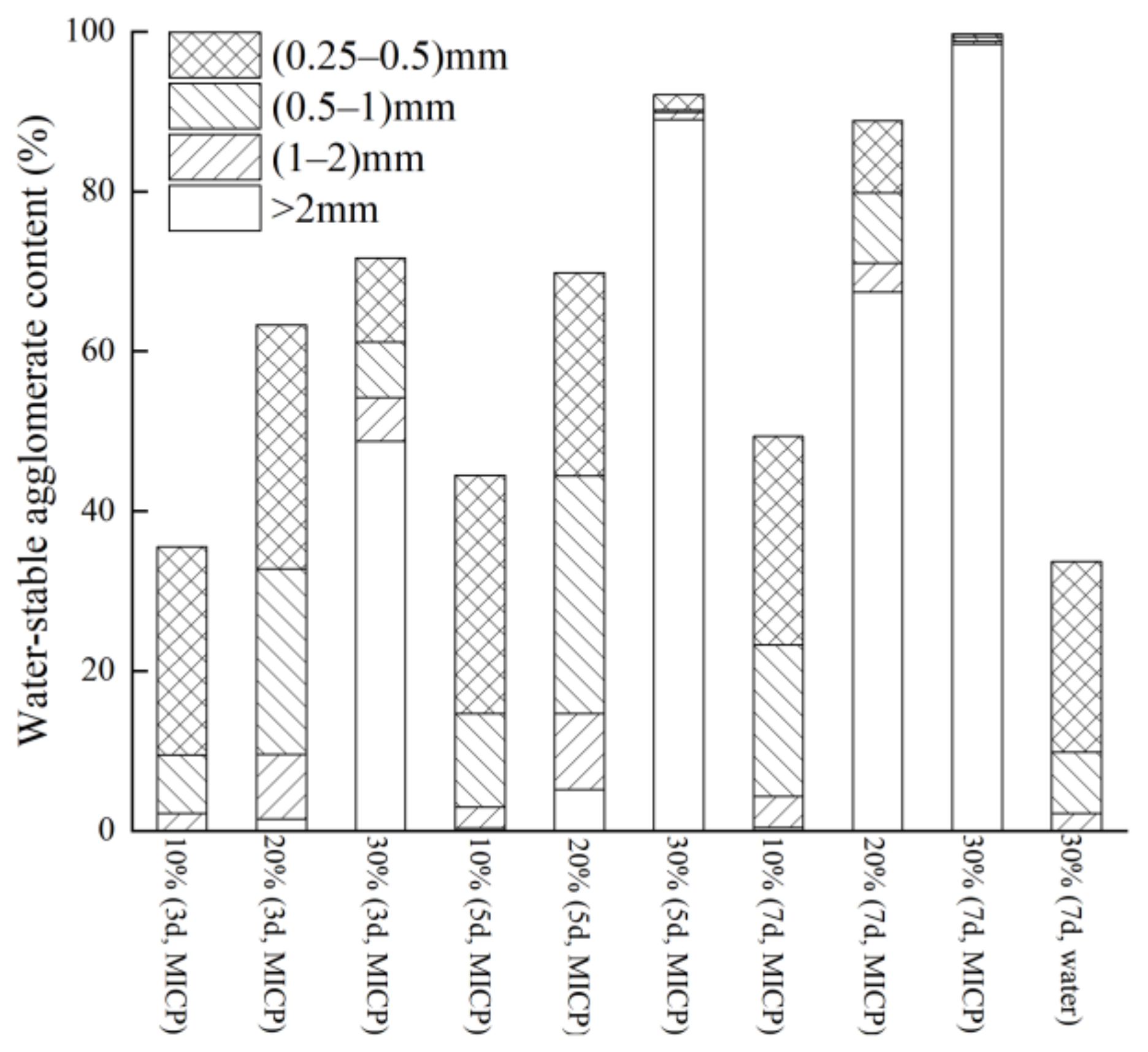

2.7. Determination of Water-Stable Agglomerate Content

3. Results

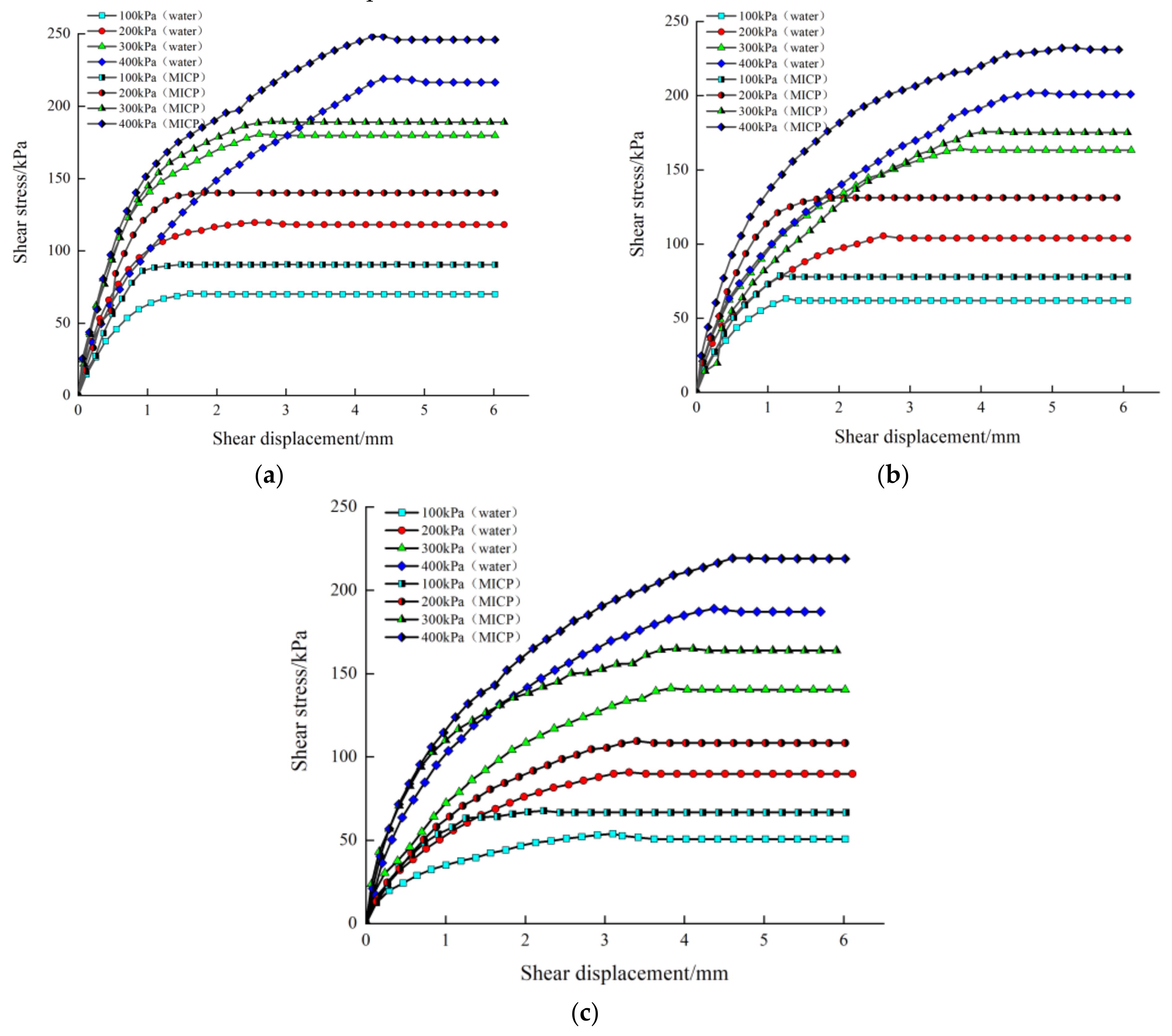

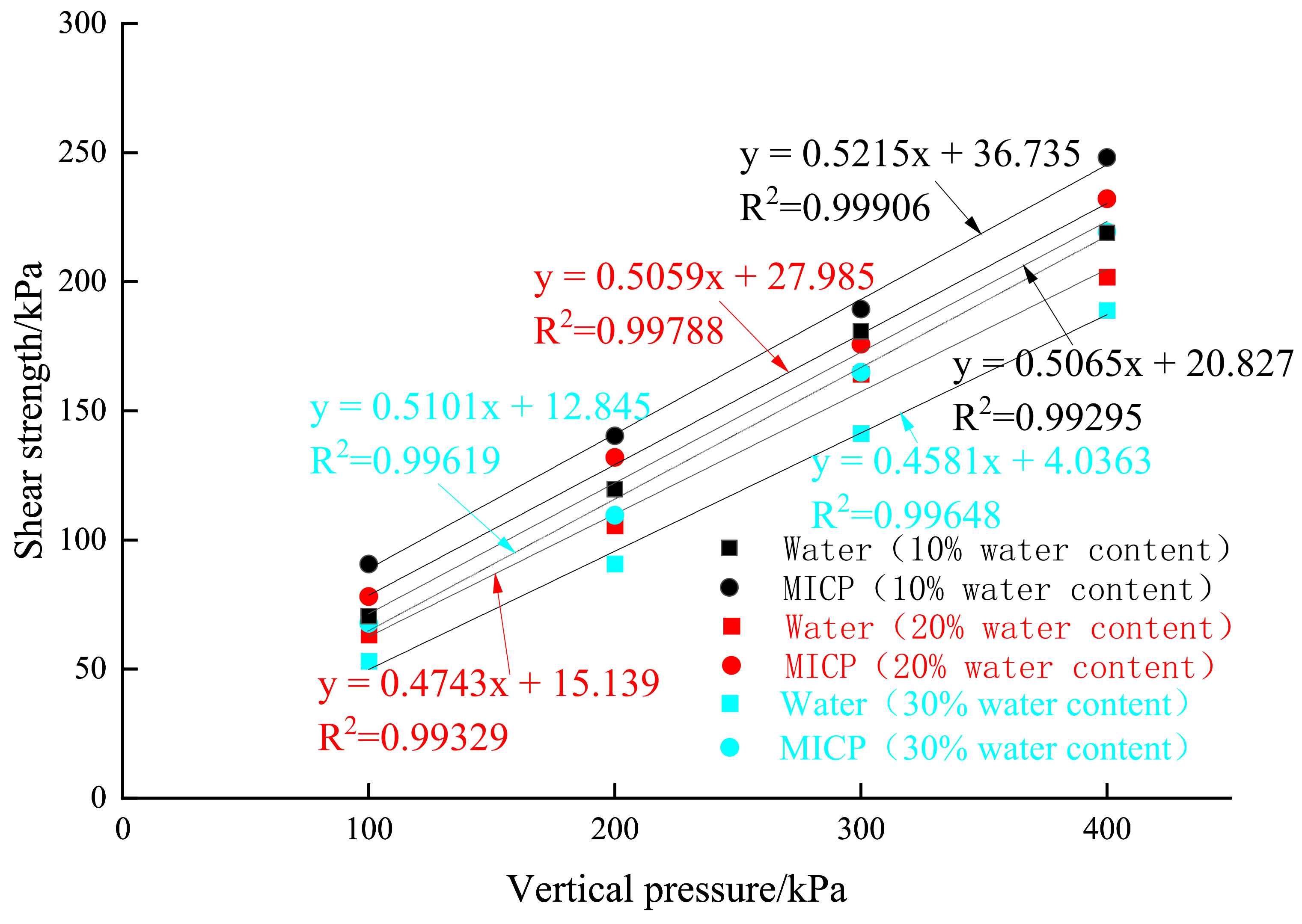

3.1. Analysis of the Shear Strength of Granite Residual Soil before and after MICP Curing

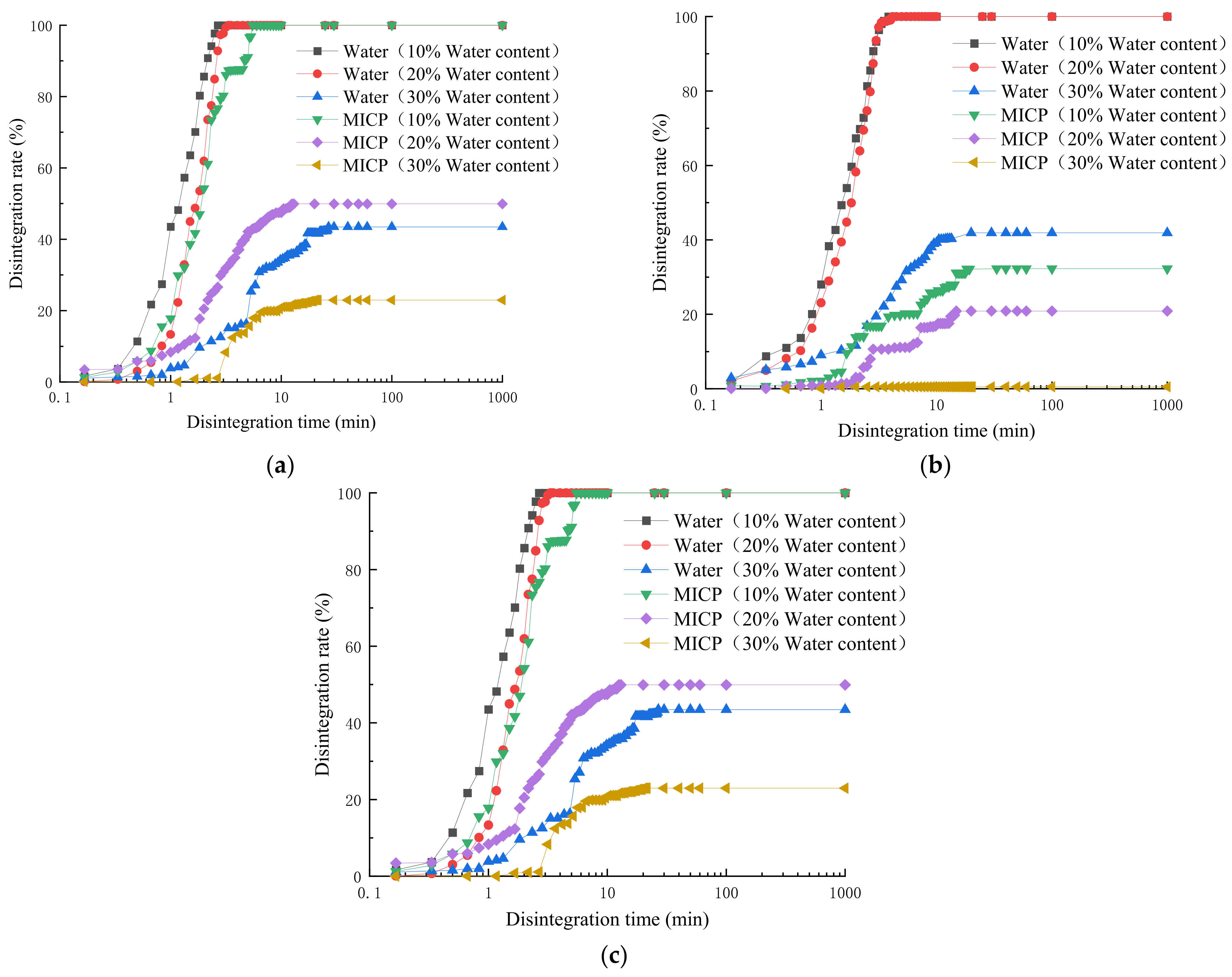

3.2. Disintegration Test

3.3. SEM and XRD

3.4. Water-Stable Agglomerate Content

4. Conclusions

- (1)

- The shear strength of granite residual soil decreases with an increase in water content. The cohesion and internal friction angle of its shear strength index also decrease with an increase in water content, and the effect of water content on internal friction angle is smaller compared with that of cohesion;

- (2)

- The shear strength of MICP-cured granite residual soil under three moisture contents (10%, 20%, and 30%) and vertical pressures of 100, 200, 300, and 400 kPa. The effect of MICP curing on cohesion was more significant than that on internal friction angle;

- (3)

- By combining the two shear strength indicators of internal friction angle and cohesion, the MICP curing of granite residual soil is relatively optimal when the water content of granite residual soil is 30%;

- (4)

- MICP technology can effectively improve the poor engineering characteristics of granite residual soil, which is prone to disintegration by water. The disintegration rate of MICP-cured granite residual soil decreases with increasing maintenance time and stabilizes after 5 days;

- (5)

- The improvement in shear strength and disintegration resistance of granite residual soil after treatment with MICP may be attributed to CaCO3 precipitation and surface coating.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhai, Q.; Rahardjo, H.; Satyanaga, A. Variability in unsaturated hydraulic properties of residual soil in Singapore. Eng. Geol. 2016, 209, 21–29. [Google Scholar] [CrossRef]

- Pan, Y.-L.; Jian, W.-X.; Li, L.-J.; Lin, Y.-Q.; Tian, P.-F. A study on the rainfall infiltration of granite residual soil slope with an improved Green-Ampt model. Rock Soil Mech. 2020, 41, 2685–2692. [Google Scholar]

- Li, C.S.; Kong, L.W.; Shu, R.J.; An, R.; Zhang, X.W. Disintegration characteristics in granite residual soil and their relationship with the collapsing gully in South China. Open Geosci. 2020, 12, 1116–1126. [Google Scholar] [CrossRef]

- Sun, Y.L.; Tang, L.S.; Wang, Y.X.; Xie, Z.X. Assessment of strength development in granite residual soil admixed coastal sludge. Fresenius Environ. Bull. 2021, 30, 758–770. [Google Scholar]

- Cristelo, N.; Glendinning, S.; Miranda, T.; Oliveira, D.; Silva, R. Soil stabilisation using alkaline activation of fly ash for self compacting rammed earth construction. Constr. Build. Mater. 2012, 36, 727–735. [Google Scholar] [CrossRef] [Green Version]

- Chew, S.H.; Kamruzzaman, A.H.M.; Lee, F.H. Physicochemical and engineering behavior of cement treated clays. J. Geotech. Geoenviron. Eng. 2004, 130, 696–706. [Google Scholar] [CrossRef]

- Sun, X.H.; Miao, L.C.; Chen, R.F. Effects of Different Clay’s Percentages on Improvement of Sand-Clay Mixtures with Microbially Induced Calcite Precipitation. Geomicrobiol. J. 2019, 36, 810–818. [Google Scholar] [CrossRef]

- Arpajirakul, S.; Pungrasmi, W.; Likitlersuang, S. Efficiency of microbially-induced calcite precipitation in natural clays for ground improvement. Constr. Build. Mater. 2021, 282, 11. [Google Scholar] [CrossRef]

- Han, L.; Li, J.; Xue, Q.; Che, Z.; Zhou, Y.; Poon, C.S. Bacterial-induced mineralization (BIM) for soil solidification and heavy metal stabilization: A critical review. Sci. Total Environ. 2020, 746, 140967. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hora, R.N.; Ahenkorah, I.; Beecham, S.; Karim, M.R.; Iqbal, A. State-of-the-Art Review of Microbial-Induced Calcite Precipitation and Its Sustainability in Engineering Applications. Sustainability 2020, 12, 41. [Google Scholar] [CrossRef]

- Gebru, K.A.; Kidanemariam, T.G.; Gebretinsae, H.K. Bio-cement production using microbially induced calcite precipitation (MICP) method: A review. Chem. Eng. Sci. 2021, 238, 11. [Google Scholar] [CrossRef]

- Almajed, A.; Tirkolaei, H.K.; Kavazanjian, E., Jr.; Hamdan, N. Enzyme Induced Biocementated Sand with High Strength at Low Carbonate Content. Sci. Rep. 2019, 9, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Mwandira, W.; Nakashima, K.; Kawasaki, S. Bioremediation of lead-contaminated mine waste by Pararhodobacter sp based on the microbially induced calcium carbonate precipitation technique and its effects on strength of coarse and fine grained sand. Ecol. Eng. 2017, 109, 57–64. [Google Scholar] [CrossRef]

- Dilrukshi, R.A.N.; Nakashima, K.; Kawasaki, S. Soil improvement using plant-derived urease-induced calcium carbonate precipitation. Soils Found. 2018, 58, 894–910. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Sharma, M. Micro-mechanical performance evaluation of expansive soil biotreated with indigenous bacteria using MICP method. Sci. Rep. 2021, 11, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.Z.; Wei, Y.Q.; Cai, H.; Wang, Z.W.; Yang, T.; Wang, Q.H.; Wu, S.F. Microbial-Induced Carbonate Precipitation for Strengthening Soft Clay. Adv. Mater. Sci. Eng. 2020, 2020, 11. [Google Scholar] [CrossRef] [Green Version]

- Ou, X.D.; Peng, Y.S.; Hou, K.W.; Su, J.; Jiang, J. Experimental research on biochemical consolidation of bauxite tailings clay. Arab. J. Geosci. 2019, 12, 10. [Google Scholar] [CrossRef]

- Vail, M.; Zhu, C.; Tang, C.S.; Anderson, L.; Moroski, M.; Montalbo-Lomboy, M.T. Desiccation Cracking Behavior of MICP-Treated Bentonite. Geosciences 2019, 9, 16. [Google Scholar] [CrossRef] [Green Version]

- Osinubi, K.J.; Eberemu, A.O.; Ijimdiya, T.S.; Yakubu, S.E.; Gadzama, E.W.; Sani, J.E.; Yohanna, P. Review of the use of microorganisms in geotechnical engineering applications. SN Appl. Sci. 2020, 2, 207. [Google Scholar] [CrossRef] [Green Version]

- De Muynck, W.; Verbeken, K.; de Belie, N.; Verstraete, W. Influence of temperature on the effectiveness of a biogenic carbonate surface treatment for limestone conservation. Appl. Microbiol. Biotechnol. 2013, 97, 1335–1347. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Shahin, M.A.; Chu, J. Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech. 2019, 14, 615–626. [Google Scholar] [CrossRef] [Green Version]

- Gowthaman, S.; Yamamoto, M.; Nakashima, K.; Ivanov, V.; Kawasaki, S. Calcium phosphate biocement using bone meal and acid urease: An eco-friendly approach for soil improvement. J. Clean. Prod. 2021, 319, 128782. [Google Scholar] [CrossRef]

- Gowthaman, S.; Mohsenzadeh, A.; Nakashima, K.; Kawasaki, S. Removal of ammonium by-products from the effluent of bio-cementation system through struvite precipitation. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Yu, X.; Zhan, Q.; Qian, C.; Ma, J.; Liang, Y. The optimal formulation of bio-carbonate and bio-magnesium phosphate cement to reduce ammonia emission. J. Clean. Prod. 2019, 240, 118156. [Google Scholar] [CrossRef]

- Chen, L.; Song, Y.; Huang, J.; Lai, C.; Jiao, H.; Fang, H.; Zhu, J.; Song, X. Critical Review of Solidification of Sandy Soil by Microbially Induced Carbonate Precipitation (MICP). Crystals 2021, 11, 1439. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, G.; Zhang, Q.; Zheng, F.; Zhang, X.; Liu, P.; Zhang, J.; Hu, F.; Elbasit, M.A.M.A. Quantifying contributions of slaking and mechanical breakdown of soil aggregates to splash erosion for different soils from the Loess plateau of China. Soil Tillage Res. 2018, 178, 150–158. [Google Scholar] [CrossRef]

- Wen, Y.; Yang, G.-H.; Tang, L.-S.; Xu, C.-B.; Huang, Z.-X.; Huang, Z.-M.; Zhang, Y.-C. Tests and parameters study of mechanical properties of granite residual soil in Guangzhou area. Rock Soil Mech. 2016, 37, 209–215. [Google Scholar]

- Tang, L.-S.; Zhao, Z.-L.; Chen, H.-K.; Wu, Y.-P.; Zeng, Y.-C. Dynamic stress accumulation model of granite residual soil under cyclic loading based on small-size creep tests. J. Cent. South Univ. 2019, 26, 728–742. [Google Scholar] [CrossRef]

- GB/T50123-2019. Specification of Soil Test; China Architecture and Building Press: Beijing, China, 2019. (In Chinese) [Google Scholar]

- Luo, X.; Gao, H.; He, P.; Liu, W. Experimental investigation of dry density, initial moisture content, and temperature for granite residual soil disintegration. Arab. J. Geosci. 2021, 14, 1060. [Google Scholar] [CrossRef]

- Li, X.-A.; Wang, L.; Yan, Y.-l.; Hong, B.; Li, L.-C. Experimental study on the disintegration of loess in the Loess Plateau of China. Bull. Eng. Geol. Environ. 2019, 78, 4907–4918. [Google Scholar] [CrossRef]

- Liu, W.P.; Song, X.Q.; Huang, F.M.; Hu, L.N. Experimental study on the disintegration of granite residual soil under the combined influence of wetting-drying cycles and acid rain. Geomat. Nat. Hazards Risk 2019, 10, 1912–1927. [Google Scholar] [CrossRef] [Green Version]

- Papadopoulos, A.; Bird, N.R.A.; Whitmore, A.P.; Mooney, S.J. Investigating the effects of organic and conventional management on soil aggregate stability using X-ray computed tomography. Eur. J. Soil Sci. 2009, 60, 360–368. [Google Scholar] [CrossRef]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. Freeze-thaw durability and shear responses of cemented slope soil treated by microbial induced carbonate precipitation. Soils Found. 2020, 60, 840–855. [Google Scholar] [CrossRef]

- Nafisi, A.; Montoya, B.M.; Evans, T.M. Shear Strength Envelopes of Biocemented Sands with Varying Particle Size and Cementation Level. J. Geotech. Geoenviron. Eng. 2020, 146, 04020002. [Google Scholar] [CrossRef]

- Cardoso, R.; Pires, I.; Duarte, S.O.D.; Monteiro, G.A. Effects of clay’s chemical interactions on biocementation. Appl. Clay Sci. 2018, 156, 96–103. [Google Scholar] [CrossRef]

| Curing Time (d) | Water Content (%) | |||||

|---|---|---|---|---|---|---|

| Water | Micp | |||||

| 10 | 20 | 30 | 10 | 20 | 30 | |

| 3 | 10.7 | 20.7 | 27.1 | 10.2 | 20.2 | 27 |

| 5 | 10.6 | 20.5 | 27.2 | 10.4 | 21 | 27.2 |

| 7 | 10.1 | 21.2 | 27.8 | 10.8 | 19.9 | 27.1 |

| Water Content (%) | Vertical Pressure (kPa) | ||||

|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | ||

| Water | 10 | 70.46 | 119.64 | 180.75 | 218.92 |

| 20 | 63.31 | 105.51 | 164.23 | 201.85 | |

| 30 | 53.12 | 90.83 | 141.30 | 189.01 | |

| MICP | 10 | 90.65 | 140.27 | 189.42 | 248.09 |

| 20 | 78.08 | 131.94 | 175.74 | 232.13 | |

| 30 | 67.71 | 109.55 | 164.97 | 219.28 | |

| Water Content (%) | Internal Friction Angle (°) | Cohesion (kPa) | ||

|---|---|---|---|---|

| Water | MICP | Water | MICP | |

| 10 | 26.9 | 27.5 | 20.8 | 36.7 |

| 20 | 25.4 | 26.8 | 15.1 | 27.9 |

| 30 | 24.6 | 27.0 | 4.0 | 12.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, S.; Xiao, X.; Fang, C.; Feng, D.; Wang, Y. Experimental Study on the Mechanical Properties and Disintegration Resistance of Microbially Solidified Granite Residual Soil. Crystals 2022, 12, 132. https://doi.org/10.3390/cryst12020132

Liang S, Xiao X, Fang C, Feng D, Wang Y. Experimental Study on the Mechanical Properties and Disintegration Resistance of Microbially Solidified Granite Residual Soil. Crystals. 2022; 12(2):132. https://doi.org/10.3390/cryst12020132

Chicago/Turabian StyleLiang, Shihua, Xueli Xiao, Caixing Fang, Deluan Feng, and Yuxin Wang. 2022. "Experimental Study on the Mechanical Properties and Disintegration Resistance of Microbially Solidified Granite Residual Soil" Crystals 12, no. 2: 132. https://doi.org/10.3390/cryst12020132

APA StyleLiang, S., Xiao, X., Fang, C., Feng, D., & Wang, Y. (2022). Experimental Study on the Mechanical Properties and Disintegration Resistance of Microbially Solidified Granite Residual Soil. Crystals, 12(2), 132. https://doi.org/10.3390/cryst12020132